By Stacey Smart stacey.s@dairystar.com

BRILLION, Wis. — In March, Shiloh Dairy achieved a hard-earned goal many years in the making. After redirecting their focus back on milk quality, the dairy received an award from Grande Cheese Company for achieving a somatic cell count under 100,000.

Getting to this point was not happenstance. The turnaround resulted from a strategic effort led by Shiloh Dairy’s parlor manager, Danielle Ware-Dreier. It took a restructuring of the team and a commitment to ensuring protocols were followed faithfully.

“We worked hard to get here,” WareDreier said. “It’s taken a lot of sweat and tears. It has not been easy.”

Shiloh Dairy was established in 2003 by Gordon and Cathy Speirs, who emigrated from Alberta, Canada.

“We wanted to get out of the dairy quota system and provide more of a freemarket business opportunity,” Gordon said.

Their son, Travis, is the fourth generation and an owner and manager alongside his father. His mother, who managed calves and genetics, retired ve years ago.

A series of expansions brought the Speirs family to their current herd size, milking 2,900 cows. Cows are milked three times a day in a double-36 parallel parlor. Currently, the SCC is at 59,000, and cows are averaging 112 pounds of

energy-corrected milk per day.

“We always paid attention to milk quality, but as we grew and roles shifted and changed, instead of our focus being narrower, our focus got wider,” Travis said.

Throughout the growth, milk quality experienced setbacks. Changes in bedding posed part of the challenge.

“We changed how we managed recycled sand and got into dry ber recycled bedding, which was a huge learning curve for everyone,” Travis said. “Managing the parlor on that bedding is a whole different game. That’s where Danielle came in.”

Returning the focus to milk quality and to doing the right thing when no one was looking were Ware-Dreier’s primary goals.

“My passion is milk quality,” she said. “I love the parlor. If I could sleep in there, I probably would.”

Getting rid of problematic cows was not the answer to lowering SCC. Rather, correcting cows was the mission.

“It’s easy to go in and say, ‘We’re going to ship the highest somatic cell cows,” Ware-Dreier said. “We didn’t do that. We didn’t cull to get here; we earned it.”

Building the right team was imperative.

“It took a solid six months to one year to get the right employees in the parlor as well as the right vendors,” Ware-Dreier said. “We had to get everyone doing the same things 24 hours a day, 365 days a year and weed out the people who aren’t going to listen.”

Numerous teaching moments took place as the managers at Shiloh Dairy continually demonstrated the correct way to do things in the parlor.

“Even the declaration of saying that we’re returning to those polices takes a

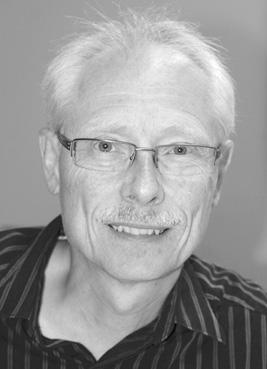

Ware-Dreier (from le ), Gordon

parlor April 29 at Shiloh Dairy near Brillion,

cows and recently received an award from

ing a soma c cell count under 100,000.

Danielle to be in the parlor at every minute of the day to check and correct and check and correct until it is beaten into the routine that this is how we do it,” Gordon said.

Increasing the morale of her team and building them up as people was equally important as learning the work itself, Ware-Dreier said.

“I put just as much emphasis on them learning the routine as them being a good person,” she said. “We feel if

they’re good people, they’re going to be good team members, and then in return, they’re going to treat the cows good.”

Shiloh Dairy has 53 employees, with 27 on the milking crew. There are six people per shift, including four milkers, a cow mover and a supervisor.

Turn

Parlor manager Danielle Ware-Dreier inspects a teat end for cleanliness April 29 at Shiloh Dairy near Brillion, Wisconsin. From the number of cows prepped to how cows are prepped, the dairy made many changes protocol-wise in the parlor to help reach its current soma c cell count of 59,000.

From the number of cows prepped to how cows are prepped, Danielle said they made many changes protocol-wise in the parlor. For example, they removed brushes in lieu of foaming and wiping with towels and added supervisors to each shift.

“It’s the little details,” she said. “I was trying to be in the parlor as much as I could and watch the camera, but it’s physically impossible. One person cannot be there 24 hours a day.”

Shiloh Dairy’s milking procedure is to pre-foam each teat, strip three squirts from each quarter, wipe each teat with a clean towel, ip the towel and clean each teat end, then attach the unit. After milking, a post dip is applied, providing complete coverage of each teat.

“The thing I keep reminding my team is to put the unit on a clean, dry, well-stimulated teat, but do you know how hard that is to accomplish?” Gordon said. “It’s every cow, every day, every time — the same way.”

Ware-Dreier believes in eliminating distractions in the parlor, therefore, there is no radio or cell phones allowed.

“Your focus is milking,” she said. “If you have earbuds in, how are you going to hear the cows squeaking, etc. We have high expectations (for our employees) and hold them accountable.”

High SCC cows are identied in the parlor. Cows exhibiting mastitis receive a California Mastitis Test, get banded, and moved to the hospital pen.

banded cows is a fraction of what it once was. The dairy has also done a complete revamp of its dry cow protocol.

“It was all-hands-on-deck before,” Ware-Dreier said. “Now, there are only six of us who dry cows. It’s focused; there’s no talking.”

The dairy is using the same medicines to treat dry cows but has gone back to treating every cow versus certain cows. Also, the treatment protocol is followed to a T.

“There was a lot of drift on that before Danielle straightened it out,” Gordon said. “We’ve stopped making new (mastitis) cows over the dry period.”

In addition to ne-tuning the milking routine, the equipment function needed correcting as well.

“We went through the challenge of trying to nd the right ination for our cows,” Gordon said. “Danielle does a tremendous job on equipment maintenance and holds the dealership to account to get those jobs done.”

Deciding which teat dip to use, how much and how often, was another factor.

“We’re doing it differently than we did two years ago,” Gordon said. “Now, we use straight iodine but seem to have better results.”

“We push hard on that, and our employees have done an amazing job on it,” Ware-Dreier said.

The dairy does on-farm culturing and treats based on those results. Within a lactation, cows can be treated up to three times for mastitis. If they are not better after three treatments, they are culled.

All chronic mastitis and high SCC cows are milked last and dipped with different cups. Repeat offenders wear an orange band, but the number of orange-

Ware-Dreier is the herd, parlor, employee, maternity, calf and heifer manager, and her approach was holistic. Once the parlor was working as desired, she looked beyond it to address issues in other areas, such as how cows were getting milked in maternity.

“She systematically worked through the different departments of the farm and got each one ironed out,” Travis said.

Continuous tweaking has churned out the kind of results the managers at Shiloh Dairy were striving for.

“We are big on doing what’s right for the cow,” Ware-Dreier said. “We’re not perfect, and every day is a challenge. We do a lot of things good, but we’re always looking to improve.”

Farm-Rite

By Tiffany Klaphake tiffany.k@dairystar.com

When brothers and business partners Louis and Cyril Keller were asked by a customer to build a compact machine to clean a barn, they could not have predicted the invention would lead to a multi-billion-dollar business.

Joe Keller has been collecting and preserving this history since 1997.

His dad, Louis, and uncle, Cyril, hold the original patent for what became the Bobcat skid loader.

“How many people have the honor to have something in their family’s history so well known that everybody else knows what it is?” Keller said. “Not many people have that opportunity. It’s signicant enough that it needs to be preserved.”

Louis and Cyril grew up on a farm near Tintah, Minnesota.

“Instead of bringing machinery to town to get xed, their dad and grandpa would x it at home,” Keller said. “They learned the basic mechanics from them, and when they couldn’t buy what they needed to get the job done, they could make something.”

Flags a ached to loaders — S250 (from le ), M610, M371, the rst Melroe skid loader, serial number 1001 and the Keller loader which was displayed at the 1958 Minnesota State Fair — wave in the wind Sept. 26, 2021, near Gwinner, North Dakota. The rst skid loader was sold in 1957.

The brothers worked on the farm until World War II. Cyril joined the Navy, and Louis joined the Army. After returning home, they had intentions to farm but did not have the capital to start such a venture.

In 1947, Louis opened a welding and repair shop in Rothsay, Minnesota. By 1953, Louis had more business than he could handle, so he asked Cyril to work with him as an equal partner.

In the summer of 1956, a turkey farmer came to the Keller brothers and asked if they could build a small, light-weight machine that could turn in tight spaces and be used to clean his barns.

“Summers are the busy time for farmers and for farm mechanics, so they said they would think about it but wouldn’t have time until later in the fall to experiment with new ideas,” Keller said. “Anyone who invents stuff knows that once they get an idea in their head, they can’t get it out until they x the problem.”

That fall, the brothers began sketching ideas. They came up with the idea of a three-wheeled machine — two drive wheels and a caster wheel — with control levers and a 6-horsepower engine. Six weeks later, the brothers had a prototype to test. After a few tweaks, the farmer purchased the machine in February 1957 for $1,360. The rst Keller self-propelled loader was established.

“That $1,360 check turned into what the skid loader industry is today,” Keller said.

Interest in the loader took off during the fair, and Melroe Manufacturing and the Kellers formed a contract shortly after. The brothers received a royalty from each loader sold, and they became employees of the company to develop more loaders.

Melroe Manufacturing Company already had a manufacturing plant in Gwinner, North Dakota. So, the brothers moved to North Dakota. After the rst several loaders were built, Louis worked in the shop, helping build and create new loaders while Cyril worked in sales.

“In 1958 and 1959, trying to sell a machine without a steering wheel was a pretty difcult task,” Keller said.

Business was booming for the loaders until 1960, when the poultry industry declined.

“Sales got to the point where there were 200 M200 three-wheeled loaders on hand,” Keller said. “There was talk about stopping production of the loaders. Instead, another axle was added in the back of an M200, creating the rst 4-wheel-drive skid steer, the M400.”

In 1962, the M440 was introduced. This became the rst true skid loader with double-acting cylinders, 70/30 weight balance and chains running on oil. This also became the rst machine to carry the Bobcat name.

Keller said, according to early employees, a box was placed in the lunchroom at Melroe Manufacturing Company for employees to offer name suggestions for the machine.

Cyril was in the Navy.

After building more machines and selling them, the brothers could not keep up with running the repair shop and building their loader machines.

In 1958, Les Melroe, of Melroe Manufacturing Company, heard of the Kellers’ invention and invited the brothers to bring their machine to the 1958 Minnesota State Fair.

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

“When the marketing team drew the name Bobcat out of the box, they looked it up in the dictionary, and it said a tough, quick, agile animal,” Keller said. “That is what the machine was, so that became the name.”

The clutch drive system the Kellers invented was used from 1958 until 1981. After that, the machines tran-

PHOTO SUBMITTED

A replica of Louis Keller’s rst shop displays the seventh Keller Loader made as well as other items May 11 at the Sargent County Museum in Forman, North Dakota. The tools and equipment in the display are originally from Louis Keller’s shop.

By Lee Mielke

The tariff tit-for-tat took on another new look this week. Talks last weekend between the U.S. and China in Switzerland produced a temporary de-escalation.

Beginning May 14, they have agreed to a 90-day pause, reports HighGround Dairy. “The U.S. will reduce tariffs on Chinese goods from a peak of 145% to 30%, while China will lower tariffs on U.S. imports from 125% to 10%. China has also halted and scrapped other non-tariff countermeasures, such as the export of critical minerals to the U.S., put in place in response to the initial escalation.”

“The 30% levy that the U.S. is now imposing on Chinese goods includes an existing 20% tariff intended to pressure China into doing more to prevent the synthetic opioid fentanyl from entering the U.S. It also includes the same 10% ‘baseline’ tariff Trump slapped on imports from most of the world’s countries. The 30% tax comes on top of other levies on China, including some left over from Trump’s rst term and kept by former President Joe Biden (such as solar panels and electric vehicles). On the Chinese side, retaliatory tariffs imposed in March on specic U.S. dairy exports remain in effect. These measures highlight that deeper trade frictions persist,” HGD said. Walmart announced it will raise its prices when tariff-affected merchandise arrives at its stores.

Meanwhile, the April Consumer Price Index was better than expected, according to StoneX. “Ination increased 0.2% versus 0.3% expected month over month and appears to not be inuenced by tariffs yet. However, if we look at the major categories of the CPI, we see that services did not cool, and energy is helping to keep commodities even on average. If rates are cut and the economy expands (instead of the expected recession), we would expect energy prices to come back, leaving commodities to inate higher,” StoneX said.

The U.S. Department of Agriculture raised its 2025 milk production forecast from last month in its latest World Agricultural Supply and Demand Estimates report, citing expectations of an increased cow herd and a faster growth rate in output per cow. The report also gave us our rst preview of 2026 and looks for an expanding milk cow herd and slightly higher milk per cow.

2025 production and marketings were projected at 227.3 and 226.3 billion pounds respectively, up 400 million on both from a month ago. If realized, both would be up 1.4 billion pounds or 0.6% from 2024. 2026 production and marketings were projected at 227.9 and 226.9 billion pounds, respectively. If realized, both would be up 600 million pounds or 0.3% from 2025.

Butter, cheese, nonfat dry milk and whey price forecasts for 2025 were raised from last month, based on recent prices and increased export demand for the second half of the year. The Class III and Class IV price forecasts were also raised.

The Class III average was projected at $18.70 per hundredweight, up $1.10 from last month’s estimate, and it compares to $18.89 in 2024 and $17.02 in 2023. The 2026 average was projected at $17.50.

The 2025 Class IV is expected to average $18.45, up 25 cents from last month’s estimate, and it com-

pares to $20.75 in 2024 and $19.12 in 2023. The 2026 average was estimated at $18.10.

Commercial exports for 2026 were forecast to be lower than in 2025 on a fat basis but higher on a skimsolids basis due to additional exports of whey products. Commercial imports were forecast to increase on a fat basis due primarily to increases in imports of butter. Imports on a skim-solids basis were forecast to increase slightly. Domestic use in 2026 is expected to increase on both a fat basis and skim-solids basis, according to the WASDE.

Dairy product prices in 2026 were forecast to be lower for butter, nonfat dry milk, cheese and whey compared with 2025, primarily due to increased milk supplies. As a result, Class III and Class IV milk prices were also forecast lower.

This month’s corn outlook included record supplies and total use and higher ending stocks. The corn crop was projected at a whopping 15.8 billion bushels, up 6% from a year ago on increases to both area and yield. Planted area of 95.3 million acres, if realized, would be the highest in over a decade, says USDA. The yield projection of 181.0 bushels per acre is based on a weather-adjusted trend assuming normal planting progress and summer growing season weather. With smaller beginning stocks partially offsetting the increase in production, total corn supplies were forecast at 17.3 billion bushels. Total U.S. corn use was forecast to rise over 1% from a year ago on higher domestic use and exports. Food, seed and industrial use was forecast at 6.9 billion bushels. Corn used for ethanol was unchanged from a year ago at 5.5 billion bushels.

The soybean outlook showed slightly lower supplies, higher crush, reduced exports and lower ending stocks from a year ago. The soybean crop was projected lower, at 4.34 billion bushels, with trend yield and lower area. With higher beginning stocks but lower imports and production, soybean supplies are down less than 1% from 2024-2025. The U.S. crush was projected at 2.49 billion bushels, up 70 million from the 2024-2025 forecast, with higher soybean meal disappearance and exports. Domestic disappearance was forecast to increase 2%. Soybean meal exports were forecast at 18.0 million short tons, a 20% global trade share, compared to the prior 5-year average of 19%.

U.S. soybean exports were forecast at 1.815 billion bushels, down 35 million from 2024-2025. Ending stocks were projected at 295 million bushels, down 55 million from the revised 2024-2025 forecast. The U.S. season-average soybean price was forecast at $10.25 per bushel, compared with $9.95 per bushel in 2024-2025. The soybean meal price was forecast at $310 per short ton, up $10, the WASDE said.

The U.S. corn crop was 62% planted as of the week ending May 11, up from 40% the week before, 15% ahead of a year ago and 6% ahead of the 5-year average. Twenty-eight percent was emerged, up from 11% the previous week, 7% ahead of a year ago and 7% ahead of the average. Soybeans were 48% planted, up from 30%, 14% ahead of a year ago and 11% ahead of the 5-year average.

The Chicago Mercantile Exchange Cheddar blocks closed Friday at $1.93 per pound, 11.25 cents higher on the week, the highest since Jan. 30 but 1.25

cents below a year ago. The barrels nished at $1.88, up 11 cents on the week, highest since April 15 and 24.50 cents below a year ago. There were 24 sales of block on the week and seven barrel.

Retail cheese sales remain strong in the Central region, according to Dairy Market News, but contacts report food service sales continue to soften. Export demand is strengthening. Milk output is at or near its seasonal peak; however, some cheesemakers noted it was more difcult to obtain in some parts of the region. Class III milk was available as low as $7 under class. Cheese production is active and inventories are somewhat tight, according to DMN.

Milk production is seasonally ticking down for some parts of the West, but cheese manufacturers indicate supplies are meeting needs. Cheese output is generally steady. Demand from domestic and international buyers is somewhat stronger as domestic prices continue to retain competitiveness against international levels.

Cash butter saw its Friday close at $2.3425 per pound, up 1.25 cents on the week but 72.75 cents below a year ago when it gained 8 cents on the week and closed at $3.07 per pound. There were 16 CME sales this week.

Cream is plentiful throughout the Midwest, though contacts in the southern part say increasing temperatures are having a negative impact on milk components. Ice cream makers are purchasing a greater volume of cream, but butter makers say cream remains sufcient to run busy schedules. Some are at capacity and unable to purchase additional cream even at favorable pricing. Butter makers continue to freeze butter for the fall and winter months. Domestic butter prices remain competitive internationally and are contributing to increased export interest, according to DMN.

Milk output is ticking down seasonally for some parts of the West, but cream remains widely available. Bottom-end cream multiples moved up to at market at mid-week for the rst time this year in the West.

Churns are heavily active for the most part, and manufacturers continue to seasonally build inventories. Domestic demand is steady to strong. Export demand is strong, says DMN.

Grade A nonfat dry milk climbed to $1.2275 per pound Thursday, the highest since Feb. 21, but it closed Friday at 1.2250, 1.75 cents higher on the week and 6 cents above a year ago. There were 35 sales on the week, the highest total this year.

Dry whey nished Friday at 55 cents per pound, 0.75 cents higher on the week and 13.50 cents above a year ago, with eight CME sales for the week.

The latest Dairy Supply and Utilization report gave us a good look at demand. HighGround Dairy’s Alyssa Badger reported in the May 19 Dairy Radio Now broadcast that March cheese utilization was down 0.9% from a year ago and down for the second month in a row. She blamed weaker domestic demand, which was off 0.8% and smallest for the month since 2021. Exports were down 1.5%, but that’s compared to a record month in March 2024. Totaling 108.7 million pounds, it was the third highest March on record, according to Badger.

Disappointing domestic demand is an ongoing concern, she said, as store sales slump and pizza sales struggle. “Consumers are really weary about where their dollar is going right now, and unfortunately, dining out will be taking a bigger hit because of that, and that’s where a lot of cheese consumption happens.”

On a brighter note, “Butter demand was ‘red hot’ and followed the seasonal increase from February to March. It was the third consecutive month of year-onyear gains, up 6.8% throughout the rst quarter compared to a year ago, Badger said.

Domestic disappearance topped 200 million pounds for the rst time ever, and that’s important because domestic use makes up 94% of total sales. Butter exports saw the highest monthly volume on a 30-day adjusted basis since April 2014, she said, as U.S. butter is priced over $1 per pound lower than global levels.

Nonfat and skim milk powder utilization totaled 191.7 million pounds, up 0.9%, nally exceeding prior-year levels for the rst time since February 2024. Domestic use narrowly missed March 2024 levels, according to Badger, and was the smallest for the month on record. Typically, consumption rises from February to March, but unfortunately, it declined this year, and that may have been the result of higher domestic demand in February as buyers locked in product early and backed off in March. Exports were up to Mexico and the Philippines, according to Badger.

Dry whey utilization was down 2.7% and down for the 10th month in a row; however, that was the smallest decline in the period. Demand has dropped in the U.S., with March numbers the lowest value for the month since 2014, HGD said.

Dairy margins continued to improve over the rst half of May on a combination of higher milk prices and lower feed costs, according to the latest Margin Watch from Chicago-based Commodity and Ingredient Hedging LLC. “Nearby Class 3 milk futures posted a dramatic rally to new life-of-contract highs, completely reversing the steep selloff through Q1 while deferred contracts posted more modest gains,” the MW said.

“The corn market continues to decline on favorable planting weather across the Midwest, despite the USDA May WASDE report, which revealed lower projected corn ending stocks than expected. The strong recovery in margins has led to increased milk and dairy product production. American-style cheese production of more than 1.4 billion pounds in Q1 was up 3.3% from 2024, with cheddar production of 984 million pounds pacing the gain with a 2.8% increase from 2024. U.S. dairy producers have also increased butterfat by 82 million pounds in Q1, up 3.4% from 2024, with most of the increase going to butter production, which, at nearly 650 million pounds, is up 5% from Q1 last year,” the MW said.

“Big discounts of U.S. cheese and butter in the global market compared to the EU and Oceania, due to the weaker dollar, have helped boost exports. According to the latest data from USDA’s Global Agricultural Trade System, March cheese exports were down just 1.5% from the record set last year, while shipments to Japan were an all-time high. After adjusting for leap year, Q1 cheese exports were at a record high, up 8.3% from last year. Q1 butter and milkfat exports were also the strongest since 2014. The export market will be increasingly important to clear inventory as production expands, particularly for cheese,” the MW concluded.

Agriculture Secretary Brooke Rollins announced the suspension of live cattle, horse and bison imports through U.S. ports of entry along the southern border this week due to “the continued and rapid northward spread of New World Screwworm in Mexico, effective immediately. NWS has been recently detected in remote farms with minimal cattle movement as far north as Oaxaca and Veracruz, about 700 miles away from the U.S. border.”

“The U.S. and Mexico continue efforts to interdict and eradicate NWS in Mexico and work in good faith,” a USDA press release said. “However, despite these efforts and the economic impact on both countries due to this action, there has been unacceptable northward advancement of NWS and additional action must be taken to slow the northern progression of this deadly parasitic y.”

The May 13 Daily Dairy Report said, “New World screwworm ies lay eggs on mammals, especially in wounds, eyes, noses and udders. When the eggs hatch, the larvae burrow or ‘screw’ deep into the host’s esh. For nearly a century, the U.S. and Mexico have worked together to reduce the spread of the devastating pest by seeding Central America with sterile ies to ensure that female screwworms lay nonviable eggs. USDA estimates that the return of screwworm could cost the beef industry billions of dollars every year.”

Dairy Sale is June 5th. Monday and Wednesday Sale as usual.

45 Holstein cows and 22 bred heifers. Approximately a third of cows and most of heifers due June thru August! A very nice group of 11 dry cows with this herd! 2 Brown Swiss cows. Tank average is 68 in winter and 80+ lbs in summer with 4.4F x 3.5P 120SCC. Several outstanding fresh cows. Priced at $3000/head. 715-626-0002 for more details. Photos available. Located in Northern WI. Motivated seller! Price drops effective 5/10/25 to $2,900. Reasonable offers will be seriously considered. Can sort off 12 cows if desired.

After 50 yrs of successfully dairy farming, owners have decided to offer their herd in its entirety. Cows and heifers are all AI bred, with cows being let out daily for exercise. Heifers and dry cows are in loose housing with a deep straw bedded pack. Current herd production is 77 lbs with 4.2F x 3.15P 105SCC. 48 milking and 17 dry cows and springing heifers. 4 Short serviced heifers and 9 calves babies to 3 month old. Owners specify priority will be given to those who can keep herd as one unit. Quote: ( We have built this herd and the farm itself from nothing and would love to see another aspiring young farmer take it from here!) $210,000 for entire package. Call Irvin for showing appointments @ 715-626-0002

enough to make a difference, small enough to care

Con nued from SKID LOADER | Page 6 sitioned to hydro-stat. Today, the Bobcat Company continues to make skid loaders and sell them around the world.

Keller has artifacts, memorabilia and original loaders on display at the Sargent County Museum in Forman, North Dakota.

Les Melroe of Melroe Manufacturing Company heard of Louis and Cyril Keller’s invention and invited the brothers to bring their machine to the 1958 Minnesota State Fair. After the fair, interest in the loaders grew and Melroe and the Kellers agreed to work together at the Melroe Manufacturing plant in Gwinner, North Dakota.

Louis and Cyril Keller were inducted into the Association of Equipment Manufacturers Hall of Fame in 1999, the Minnesota Inventors Hall of Fame in 2004 and the National Inventors Hall of Fame in 2023.

“It’s been 27 years since I started collecting and trying to nd a place to put the display, and now, we nally have a place,” Keller said.

Even though Louis and Cyril and the Melroe family members have died, their legacy lives on at the Sargent County Museum. The museum showcases Keller loaders, Melroe loaders, Bobcats and other projects the families invented.

“There is a replica of Louis’ rst shop, a single-car garage, and within that is the third Keller loader made,” Keller said. “The shop is set up so it looks like they are still working the Keller loader. There are several tools, like the anvil and turning lathe that actually were in Louis’ shop in 1947.”

Keller said the highlights of the museum include Melroe family and Keller family products. The Bobcat display starts with the serial No. 1 Melroe loader. Early models, several successful prototypes and a couple of models that did not see production are also on display.

Louis and Cyril were inducted into the Association of Equipment Manufacturers Hall of Fame in 1999, the Minnesota Inventors Hall of Fame in 2004 and the National Inventors Hall of Fame in 2023. The Melroe family was inducted into the Association of Equipment Manufacturers Hall of Fame in 2014.

Louis Keller drives a skid loader in fall of 1961 at Cyril Keller’s house near Gwinner, North Dakota. Louis and Cyril worked together at a welding and repair shop in Rothsay, Minnesota, when they invented the machine known today as the skid loader.

By Mark Klaphake mark.k@dairystar.com

ALBANY, Minn. — Father and son, Tom and Austin Dobmeier, completed another yearly milestone May 13 on their farm south of Albany. They nished planting corn on that Tuesday, now having all their seed in the ground for what they hope will be a productive crop year.

“It is a relief, because it is our cropping season, and after you get the seed in the ground, you hope for rain so you have feed for the cows,” Tom said.

The Dobmeiers planted 180 acres of corn and alfalfa that is undersown with barley and peas.

Tom and Austin milk 110 cows alongside their family.

“There is no other person I would want to work with than my son and my family,” Tom said.

Turn to DOBMEIERS | Page 12

“That’s valuable time that we can spend together as a family.”

Austin and his wife, Kiley, are raising their children, Harper and Emerson, on the farm with the help of Austin’s mom, Anita.

“Whether it is over lunch or out in the yard, it makes my day better to see those little kids,” Tom said. “We did it with our kids this way, and now, we are doing it with his kids.”

Austin returned to the farm in 2017 and has been earning a portion of the milk proceeds.

Before Tom and Austin could begin work in the eld, they did morning chores. They woke up shortly after 4 a.m. and by 5, they were milking 110 cows in a swing-9 parlor.

In September 2024, they converted a pack barn that housed heifers into a freestall barn.

The Dobmeiers raise calves until 5 months of age. Then, they are sent to Jeremy Holthaus. Heifers return when they are 7 to 8 months pregnant.

By adding 40 stalls, the Dobmeiers increased their herd. Earlier this year, they nished renovating the tiestall barn into a parlor. They have been in their new setup since Feb. 17.

“The original barn was built in 1880 and has been taken care of over

the years, and now, we put a parlor in it and are still milking cows in the same exact barn,” Austin said.

Austin said the parlor cuts milking time in half and has been benecial.

“We were switching the cows, and it took around three and half hours to milk,” Austin said. “It’s been phenomenal seeing the cows and how much they enjoy not having to stand

Turn to DOBMEIERS | Page 13

Tom Dobmeier lls the planter with fer lizer May 13 at his farm near Albany, Minnesota. The Dobmeiers planted 180 acres of corn and alfalfa that is undersown with barley and peas.

around waiting to be milked. We have been able to spend more time with our family.”

Once out of the barn, the main focus for the Dobmeiers, on what turned out to be a warm and windy day, was to nish planting. Shortly before 9 a.m., the duo headed in separate ways. Austin had to pick up milk replacer and run errands while Tom fed calves and got their 6-row planter ready.

After a quick lunch, Tom’s brother, Dan, who helps with eldwork and mechanical jobs, arrived and immedi-

ately worked the remaining 30 acres while Tom started planting. Austin mixed feed for the cows, worked on taking a hood off a tractor in preparation for doing radiator work and then weed trimmed around the yard.

By 4 p.m., Austin fed calves and prepared for night milking. Working with the cows has been a passion of his for a long time and cow longevity has been a focus. He recently had a

Turn to DOBMEIERS | Page 14

Cows make their way from the freestall barn to the milking parlor May 13 at Lakeshore Dairy near Albany, Minnesota. Cow longevity is a focus for the Dobmeiers.

May

TIFFANY KLAPHAKE/DAIRY

cow reach eight lactations.

“I am making a difference in the cows’ lives, from when they are born to when they are milking,” Austin said. “I really like a good, long-lasting cow. Nothing makes me happier than to see a cow that has ve or six lactations. Some cows are coming in next to their daughters, and I like watching their progression.”

Around 7 p.m., Austin nished chores and spent time with his family, and Tom planted until 9 p.m. when

he ran one bag short of seed; he nished off the eld the following morning. Their planting season that started May 9 was complete.

“Every year, we sit down and make a goal for ourselves, whether it’s production, components, conception rates or a certain quality feed,” Austin said. “Both of us are cow-minded people. We always decide rst and foremost what we can do for the cows and reect that on our eldwork.”

810 Mayhew Lake Rd. NE • St. Cloud, MN 320-240-2085 • 844-262-2281 19612 US-71 • Long Prairie, MN 320-732-3715 • 866-514-0982

Pronschinskes

By Amy Kyllo amy.k@star-pub.com

ROLLINGSTONE, Minn. — For the Pronschinskes, being organic has given their farm the nancial ability to continue. From 2009-2018, the family was embroiled in a court battle that went all the way to the Minnesota Supreme Court over the succession of their farms.

Kim and Kim Pronschinske are the owners of Do Over Dairy near Rollingstone. The Pronschinskes farm with the help of their children, Annabelle, Clayton, Adreanna, Gage, Autumn and Alaina. They milk 85-100 organic cows on 315 acres split between several farms, including a wooded acreage in Wisconsin.

The legal challenges the Pronschinske family went through were difcult to endure.

“It was like you were walking around in quicksand with a silo stave on your back,” Mrs. Pronschinske said. “You just didn’t feel like you could get ahead, but we really couldn’t get out, because then we would have lost everything. If we walked, we wouldn’t have been able to ght for anything that we had invested.”

The farms have been in Mrs. Pronschiske’s family for four generations. In 2008, after her dad passed, the future of the farms came into question with two non-farming siblings involved in the will and some parties desiring the farms to be sold for cash versus continuing as a dairy.

“A trust came in and owned the farms, and we all became tenants,” Mrs. Pronschinske said. “It was a nightmare.”

During the battle, the Pronschinske family was transitioning to organic. About a decade and $300,000 in legal fees later, the Pronschinskes owned their farms.

“If we weren’t organic, we’d have never survived,” Mrs. Pronschinske said. “It’s a good way for the future to survive, if they can get into it.”

Annabelle, 22, and Clayton, 20, are both interested in being the next generation to farm. Through

their growing-up years, they also experienced the hardship incurred by the legal challenges.

“They’d come home from that (legal) stuff and they’d ask us, ‘How bad do you guys still want to farm,’” Annabelle said. “(Mom) would be crying. … Seeing her in tears every day made it harder for Dad. … We kept ghting for it. There were denitely times where we thought, well, maybe this is it.”

Currently, the dairy cannot support all four adults, so Annabelle is part time. She is nishing up school at Ridgewater College and working for a cooperative.

“It’s tough because you know what you want to end up doing, but you can’t do it quite yet,” Annabelle said.

Annabelle helps with the genetics. The dairy has predominantly Holstein cows with some crossbreds and Red & White Holsteins. They are breeding for A2A2 as well as using almost exclusively polled bulls.

Clayton does eld work and most of the feed mixing. Adreanna works off the dairy but helps as she is able, and Gage, Autumn and Alaina lend a hand with chores every night, helping with milking, fencing, pitching pens and more.

For Annabelle and Clayton, exibility is a big draw to farming.

“The wages (for an off-farm job) are awfully tempting and everything, but I don’t get my own schedule,” Clayton said. “The biggest thing is my own freedom and schedule.”

For their parents, they said seeing the dairy continue would help make the struggle they have had worth it.

“If nobody’s going to do the work that we did, was it really worth it for us to do that?” Mr. Pronschinske said. His wife agreed.

“You don’t want to see all your work go to waste,” she said. “On the ip side, Kim said it was our dream, it doesn’t mean it’s their dream. And that’s something harder for me to swallow.”

Over the years, the Pronschinskes have made updates to the farms. In 2018, they retrotted the parlor, poured a cement feed alley, built a lean-to and took down two silos. With everything they do, cost is forefront.

“You got to know the numbers,” Mrs. Pronschinske said. “You can’t just be a ‘yes’ person and anything goes, because that doesn’t work.”

Their milk is sold to Organic Valley. The dairy has been a patron of Elba Cooperative Creamery, which handles their milk, since 1957.

They have looked into putting in robotic milking units to make it easier for the next generation, but the costs have made them pause, especially after working hard to pay off the farm early.

“We’re not really wanting to jump back into debt, because it’s the rst time we’ve been out of debt,” Mrs. Pronschinske said. “(My husband) is pretty much if we can’t cash ow it, or we can’t pay for it, he doesn’t get it.”

They have considered adding another grain bin to the dairy if they can nd a good deal, so they could buy all their grain for the year at once at the best prices. The Pronschinskes grow their own forages but buy organic grain. They have found that if organic grain comes up for sale, they have to move quickly to secure it. They collaborate with the other farmer to nd a good deal for both of them. The Pronschinskes prioritize maintaining their relationships with the farmers around them.

“You don’t want to burn bridges, because you usually have to cross them again,” Mrs. Pronschinske said. “Organic maybe teaches you more to be humble in that way, because you’re in a smaller pool. … We help each other to survive and thrive, remembering everything we have is a gift of God. We’re all just trying to be successful with our faith, our families and our farms.”

The Pronschinskes have tried to instill in their family the motto, “Keep God in rst place and everything else will fall into place,” which was shared with them by their IBA Dairy Supplies dealer.

After their succession battle, one of Mrs. Pronschinske’s goals is to make sure other farmers understand the importance of having a working, legal succession plan.

“I wish that people could hear the horror stories of family farms who have had to go through this,” Mrs. Pronschinske said. “Do not sit on your thumbs and think this is all going to work out, or the kids can deal with it. … You got to have some sort of a plan.”

Now, the family is trying to nd the right plan for their own next generation. The Pronschinskes said they want their kids to work and invest in the farms outside their parents’ leadership.

“The biggest thing is, is there going to be enough prot there in the future, even with organic (to be) worth their time?” Mr. Pronschinske said.

Mrs. Pronschinske agreed.

“If this is something they want to take on … we will support them, but they will have to put the work in to make it happen,” she said.

Frenskos look back at ve decades of dairying

Within this feature the Dairy Star catches up to retired farmers and talk about the highlights and struggles they had when dairy farming. The feature includes how each individual farm changed throughout the farmer’s career and what each has been doing since they hung the milkers up.

Tom and Cindy Frensko Ivanhoe, Minnesota

What year did you start farming and what year did you retire? Tom was born and raised on the dairy farm that his dad owned along with his grandfather. They also milked cows on the farm, and we milked the Holsteins. Tom was one of ve boys along with his ve sisters who helped on the dairy. Tom was milking cows in the fall of 1968 as an eighth grader because his dad, Cecil, hurt his leg. Tom and his younger brother, John, were responsible for milking cows. Tom was also raising pigs as his brother, who had the pigs, went into service. In 2012, we sold 15 cows to a local dairy farmer, and another big group of 50 went to Wisconsin. We had 15 we milked until we culled them in 2013. Tom kept one cow to milk for fresh milk until 2014.

Tell us about your farm when you started and describe what it looked like when you retired, including how many cows did you milk when you retired? Tom and I were married in 1974, and we lived in the old house on the dairy farm until 1976, when we bought Uncle Danny’s farm, which was a half mile from the dairy. On the dairy were Tom’s dad and his brothers, Dennis, John, Greg and Tom. On our farm, we had pigs and stock cows. In 1987, when Tom’s dad passed away and two brothers wanted out, Tom and I started to milk morning and night. We had a 3-unit high line system. The parlor was built in 1957 with three cows on each side. We added cement to the barns so the feeding system was under a roof.

We usually milked about 60 cows. The Holstein heifer calves were replacement heifers, and the Holstein bull calves were raised as steers that we fed out. They t well with our stock cow calves.

What were some of the big advancements you made during your career? We upgraded the parlor to a 6-unit low line and added rubber mats on the cement for walking.

What did you love about milking cows? The best part of milking was in the spring, summer and fall, as we could leave the door open where the cows exit. I took pictures of the calves and gave them names, so those cows had their own personality. Tom liked to spend quality time with his family during milking.

What was the highlight of your dairy career? It was getting low cell count and quality award for our milk.

What is the biggest challenge you faced in your career and how did you overcome it? We were going to build a parlor and barn on our place for 120 cows in 1990. It would have cost us $300,000 to build, so we did not improve where we were milking the cows.

If there is one thing you wished you could have done differently during your farming career, what would it be? Why? We wished we would have

built a new milking and freestall barn because we had a new well dug, a lagoon, dirt work moved and had plans for the set up. We didn’t follow through but we should have.

What piece of equipment or technology has been introduced that you wish you had for your dairy career? The robotic milker would have been something to explore.

What do you miss most about dairy farming? What we missed most is talking with our dairy people. Milking with the kids was time well spent. We have ve kids, and while the boys would milk, they were more into eld work and haying with Dad. The girls milked cows with Mom when the hay needed to be cut and made.

What advice would you give to a young farmer today? For young farmers to get into farming; there are too many regulations, and the cost of everything is so high.

What is your tie to the dairy industry today? We have no ties to dairy today.

Was retiring an easy or hard decision/transition? When the buyer called to see if we could milk the cows early and load on a semi-truck, I said, “Sure can.” We milked them and loaded them up to take into town, where there was a loading ramp. The last cow was loaded and the lights on the semi headed down the highway Dec. 3, 2012. The next morning, the buyer called to say all the cows made the trip just ne. That was so good to hear. Tom really didn’t want to quit, but milk and cattle prices were low. We got about $1,450 to $1,500 each. The last cow we sold was the one Tom milked for his fresh glass of milk. We got $1,800 as a cull cow because the market went up.

What have you been doing since you retired? We have 125 stock cows we calve out, and we raise feeder calves and fats with our son, Bill.

•

•

•

•

•

By Stacey Smart stacey.s@dairystar.com

FREDONIA, Wis. — Steps from the barn at Sandy Loam Dairy is a thriving ower business where seven greenhouses lled with owers of all kinds stand on a former heifer pasture. Diane Hamm grows and sells annuals, perennials, herbs and vegetables at Hamm’s Farmstead Greenhouse, which is now in its fth season.

“I do this because I enjoy it,” Diane said. “I’m addicted to owers. It’s a hobby I love, and I happen to make some money too.”

Diane runs the greenhouse with help from her husband, Don, their daughter, Heather, and Diane’s four sisters: Mary, Joanne, Sue and Paula.

“This is like a family operation, and we all bring a special gift to the table,” Diane said. “Heather is my right-hand man and wants to take over the greenhouse someday, and I can’t tell you how happy I am to have my sisters helping. We are all close and get along really well.”

Heather said she enjoys the greenhouse’s connection to agriculture and the agritourism aspect the business provides.

“I like that people can come out to the farm and experience farm life,” Heather said.

The Hamms milk 320 cows and farm 400 acres near Fredonia. Don’s brothers, Rick and Randy, and Mary also work on the farm. After milking cows, Mary helps in the greenhouse all day. Joanne works in the greenhouse

full time, and Sue and Paula help as often as they can.

The greenhouses are lled to the brim with over 300,000 owering plants in every color of the rainbow and beyond, as well as another 100,000 plug

plants. Hamm’s business has doubled in size every year since opening in 2021. “I could ll another three houses if I had them,” Diane said. “I am burstingTurn to HAMMS | Page 23

Crop and weather conditions in Dairy Star country

Sponsored

by:

All the corn is in. We finished in the middle of May. We just have to pick rocks, dig and plant 100 acres of soybeans and we are done. We plant DeKalb soybeans. I would say most people are done with planting except for some small fields that will get seeded with soybeans. I checked the alfalfa and it’s 16 to 17 inches tall. I hope we are cutting next week (May 25-31). The pastures are really starting to pop after the hot spell. There is a little water standing in the low spots in the fields.

We finished planting the soybeans and the alfalfa on May 14. We have 1,170 acres of soybeans and 50 acres of new seeding alfalfa. Everyone was scrambling to get done May 12-14 before the rain. I would say 75% of our soybeans are up. The oats are looking really good. Everything was consistent coming out of the ground this year, since our conditions were really good and the seed was going into moisture. The day after Memorial Day we plan to start cutting alfalfa. It is knee high now.

We finished corn and soybeans May 9 and they are all poking out of the ground. I would say our corn is in the V1 stage. Nearly all the corn is done in the area and a few farms have to finish soybeans. The neighbor’s alfalfa looks phenomenal. I think most guys should be cutting next week (May 25-31). We cut our rye May 10 and the yields were disappointing due to the dry fall. The quality was excellent though. We have a neighbor pumping our lagoon on those acres. We have 70% of the lagoon done and plan to do the rest when it dries. We plan to plant a cocktail mix on those 70 acres.

We finished our manure May 14. We finished our small grain two weeks ago. We planted corn May 16-18 and have one 23-acre field left. I am digging up a 40-acre alfalfa field that we lost to winter kill. The new seeding is coming back really well and the other alfalfa fields have just a little loss. The corn is starting to poke out. We are discing today (May 20). The pastures are greening up pretty good. It is 38 degrees today (May 20) and it is supposed to get down to 35 tonight. We have had strong northeast winds with gusts as high as 40 mph.

it in action Visit our website and go to the Videos tab and watch the product in action to see cows milk as you have never seen before. These videos are from customer dairies. The third video shows how the liner fully closes during the rest phase – try this with your liner to see the obvious difference. Yours will never stop sucking air, therefore no rest and no effective braking to the milking action. Other videos show fast milking, very high peak flow rates and of course groups of happy cows just calmly milking – compare it all to what you see in your parlor. Stop the teat swelling, liner slip and damaged teat ends to get more milk with higher quality.

Over the last two weeks we got 1.4 inched of rain. We finished spreading our manure in the field and have been planting. We planted our corn and soybeans, which we finished up Monday (May 19). We have been busy getting our hay equipment ready for the season. We are planning on doing our first-crop hay and rye next week, but that is weather permitting.

It is raining some this morning (May 20), but the last two weeks the rain has been spotty, we have had about 0.4 inches. Thursday afternoon (May 15) I was planting beans, got in the shed as it started raining and was back out with the soil finisher about a half hour later. Before the rain this morning, our heavy ground was in about perfect condition. We started planting corn May 10. We have 155 acres of corn in, about 75 acres to go. We finished planting beans yesterday. The cool weather has slowed our hay down substantially, but that is alright since I’m still planting. We poured what is hopefully our last silage bag pad Friday.

The corn is all in around here and the planters are in the shed. Most every crop is in a row. The alfalfa is knee high. We wanted to cut this week, but have to wait until it dries. We plan to start post spraying the corn and soybeans next week (May 25-31).. We have had a lot of strong winds in our area. Yesterday (May 19) numerous buildings had damage and some corn was broke off. We had a storm cell that had 60 to 70 mile per hour winds in the morning and more that night. It also tangled up the alfalfa. We have had some people do their first crop hay.

The lack of rain allowed us to get our planting done. In total, with a custom job included, we planted 1,100 acres of corn, with probably 800 of that in the last week and a half. We have chopped first-crop alfalfa for silage. We feel it was pretty good quality with good tonnage also. We do have some grassy alfalfa mix to bale yet when the weather allows. In our area, 75% to 80% of planting is done with a few others that have made some first-crop alfalfa. With some moisture in the ground and some good heat our corn has been emerging as good as I have ever seen.

• Silo Relining

• Barn Walls and Basement Resurfacing

• Bunker Silo Wall and Deteriorating Barn Walls Restoration

Approximately 1” of steel reinforced material added to bunker walls

6 gauge heavy duty wire mesh installed

SERVING IA, MN, WI, IL AND SD

CONTACT: 800-866-7327 • 563-586-2425 AND CELL 563-419-4279

Over the last two weeks we have gotten about a quarter inch of rain. During that time, we chopped rye and finished chopping first crop. We baled the last 20 acres, but we had a nice crop of hay and we got some spraying done. We got our beans planted into the rye and then sprayed it off with Roundup. The beans we planted before Mother’s Day weekend are starting to come out of the ground, but the ones we planted in drier ground haven’t popped yet. We’re ready to get some rain and the first couple days of this week look good for that.

We finished planting corn and seeding alfalfa May 13. We planted every acre we have for corn for the first time in a long time. We didn’t have to drive around any wet holes; everything dried up pretty good. Next on the list, we do a side business planting some deer food plots for guys in their woods for hunting. We are also getting everything ready to start cutting hay on Memorial Day and are cleaning things up for the Marquette County Dairy Breakfast that we are hosting June 8.

The storms, Thursday (May 15), all missed us for the most part. We had some damage in a rented field — a half dozen trees pulled up by the roots, but nothing at the home farm. We are short on moisture, the hay looks poor on the knolls. There is a possibility we will start making hay next week because it is running out of water. It’s going to take a lot of water to make second crop. We have had a busy week, we wrapped up with planting yesterday (May 19), the corn and alfalfa seeding are all in. Thank God for GPS, it was so dusty I could not hardly tell where I was in the field.

We finished planting all our soybeans and corn May 16. It was perfect planting conditions for the 10 days that most of the acres went in. We probably have not had that kind of a solid dry stretch since 2021, where a huge percentage of our crop went in during one window. I would say over 80% of corn and soybeans are in for the immediate area. As soon as the rain clears now, we will do firstcrop hay.

at-the-seams full.”

The Hamms promote the business through newspaper ads and social media, such as Facebook.

“I keep prices reasonable,” Diane said. “There are other greenhouses in the area, and there is room for everybody. I think what I bring special to the table is the knowledge I provide, and that you come right here to get the owers. The farm is a draw for people, too. Everybody loves to see the animals.”

Visitors to the greenhouse can pet calves and horses and watch cows get milked through the windows in the front of the barn. Some people even take home kittens that Diane is giving away.

“I’m so grateful for my customers,” she said. “I have a lot of faithful customers. I wouldn’t be able to do this without them.”

Diane’s love for owers started young. Born and raised on a farm, she grew up planting owers with her mom and grandma.

“It really blossomed when I had my own house,” Diane said. “I have more ower beds than you can shake a stick at. It’s hard work but very satisfying to grow stuff.”

One year, Diane bought nearly $800 worth of owers, and Don said, ‘Well, you better get a job to pay for those.’ Thus, she started working at Appleland Farm Market, where she continues to work from late August to February.

Before she placed her rst ower order in 2020, Diane had been saving empty owerpots and trays and doing research. This ower guru knew what she was doing when she called a broker and bought $15,000 worth of plants.

“You can’t go directly through a greenhouse; you have to have a broker,” Diane said. “Once I got the plants ordered, I had to gure out where to put them.”

Diane purchased her rst greenhouse from Nifty Hoops in Ann Arbor, Michigan.

“It costs $3,000 less if you help build it, so I called my family to come help,” she said. “We built it within a day. The rst year, I had no drip lines for watering, and I watered everything by hand with a watering can. It took 12 hours a day. It was crazy.”

Diane is at home in the greenhouse surrounded by owers. She knows the nuances of plant behavior and growth and understands owers’ tempera-

ments. Deadheading is a constant task in the greenhouse as Diane and her crew remove dead ower heads to ensure owers constantly bloom.

“You don’t walk around here without a pair of scissors in your hand,” she said. “A good pair of scissors is all I need.”

Diane began partnering with a wholesaler this year, and now three greenhouses are dedicated to wholesale orders. Opening day this year at Hamm’s Farmstead Greenhouse was April 25. By the end of May, all the wholesale plants will be gone.

“By the 4th of July, I want everything sold,” Diane said. “I make all my money in 6-8 weeks. It’s a short season. Then I spend all summer cleaning.”

The greenhouse is open seven days a week: Monday through Friday, 8 a.m.–7 p.m., Saturday, 8 a.m.–5 p.m., and Sunday 11 a.m.–3 p.m.

“The Saturday before Mother’s Day last year was the best day I ever had,” Diane said. “We were swamped.”

Diane hosts potting workshops in April and grows mums to sell in the fall. By Oct. 15, she places her ower order for the following year. By the third week of January, the plants start arriving. Diane nurtures most of her plants from a one-inch plug that she plants in containers. Plants that she does not sell many of, she will seed by hand.

The Hamms started planting in February, giving 3,000 petunias a new pot in one day. Diane sells many kinds of petunias in over 50 colors, such as purple polka, moonstruck and tea amingo. She also sells a lot of begonias, marigolds, moss roses and gazanias.

“We do a lot of custom baskets too,” Diane said.

Having worked at a couple of greenhouses, Diane had ample experience before starting her own business. An expert in plant care, she enjoys sharing her passion for owers with others.

“I want to educate people about owers and about planting,” she said.

Diane would like to tear down their old chicken coop and build a storefront in its place for selling décor, planters and other items, including plant-related products from other vendors. With help from her family, Diane’s ower farm is continually expanding.

“I can’t say enough nice things about this business,” Diane said. “I absolutely love it, love it, love it.”

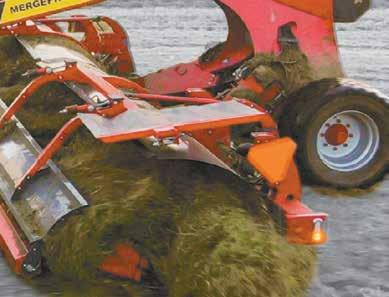

• Adaptive True Ground Speed Technology - This truly unique feature to the MERGE PRO allows the pickup and belt to be constantly monitoring the ground speed and adjusting themselves to deliver constant and equal crop on the belt as you go insuring consistent swath.

• Camless Pickup - Simple rotation, no additional moving parts, no additional wear.

• Fastest Working Speed - Maximum working speed from 0 to 18 mph

• Deflector above pickup and belt - Insures constant and smooth flow of the crop from the field ground to the belt conveyor without damaging the leaves or letting them flying off the swath.

• Multiple crop delivery options - Left, Right, Left and Right, Left Left with center delivery, Right right with center delivery, All center.

• Narrow and simple transport

By Danielle Nauman danielle.n@dairystar.com

MARSHFIELD, Wis. — Helping farmers learn to address and care for their own mental health is a crusade Carissa Weber has dedicated her career to. Ensuring that therapists and counselors are properly equipped to meet the needs of the farming population goes hand-inhand wit h that.

“I’m seeing a lot of farmers that are struggling,” Weber said. “(I see) everything from weather to markets, decreasing margins and growing input costs, increasing regulatory pressures — all those stressors, the little grievances that happen day to day. It’s enough to make us feel like the world is working against us and the negativity can start to suck us in.”

Weber, a licensed professional counselor, offers virtual counseling through her practice, The Joyful Mind Counseling. With her diversied background in agriculture, helping farmers weather the storms they frequently face is a priority for her.

“It seems like farmers are shifting back to putting their mental health and self-care on hold,” Weber said. “They’re busy trying to gure out how to do the things they need to do, and how to pay for them. They are compartmentalizing things that are associated with the chaos and the expectations they are facing. They’re not getting the help they need.”

Farmers bring a unique set of circumstances to therapy sessions, Weber said.

“As therapists, if we have a client involved in a profession we’re not familiar with, we ask a lot of questions,” Weber said. “For the farmer, that turns very frustrating, very quickly. They don’t feel they have time to educate the therapist about their issues.”

Therapists with an agricultural background comprise a minuscule percentage of the profession, making that cultural disconnect striking. Weber wants to help give those therapists lacking an agricultural background training to better aid farmers seeking a listening ear.

Weber was the rst American therapist to undergo training with the National Farmers Mental Health Alliance, a Canadian-based program that is focused on helping farmers receive the mental health services they need. The training focuses on helping counselors understand how to best reach and connect with their agricultural clientele. Finding value in the pro-

gram, Weber is leading the charge, trying to bring the group’s training to more American counselors.

“In Wisconsin we have a lot of therapists who practice in more urban settings that want to be able to help, to take the vouchers from the (Wisconsin) Farm Center,” Weber said. “They understand there is a need, but often, if the therapist isn’t well-versed in ag issues, the farmer is going to go in and not feel heard. It will be a one-and-done session.”

and therapists unaccustomed to the life a farmer lives.

Weber refers to creating cultural competency for the therapists, helping them understand the culture behind farming and how farmers view mental health, allowing for a better connection between therapist and client.

“In continuing education, we’re great at looking at cultural competency as nationalities, but not when it comes to the subcultures within that,” Weber said. “I would treat a farmer very differently than I would a client that lives in downtown Milwaukee — their needs, upbringings and life experiences are all very different.”

Creating that competency means providing the therapist with the tools they need to understand the pressures farmers face on a daily basis, the long-term ramications and the history that is entwined in everything they do.

“The training helps therapists learn about issues that are facing farmers, teaching them the familiar terms used in agriculture, so they don’t need to spend that time asking about it,” Weber said. “They understand when the farmer walks in, how things like the weather, equipment failures and prices all create challenges and stress.”

Many nuances of life resonate differently in the agricultural community, Weber said.

“Every human is exposed to grief on some level, but when we talk about farming, we see grief on a consistent basis,” Weber said. “(This might be) the death of a calf; crops under water or frosted; futures nose-diving; that one part that you desperately need but they don’t make it any more or is on backorder for six months — all things out of our control, but all things we might struggle to cope with.”

Weber said farmers do not typically display their mental health needs in the same way as those in other walks of life.

“Farmers don’t talk directly about their mental health,” Weber said. “They talk about tension headaches, or that they can’t sleep — they talk about the symptoms. They don’t label it, and sometimes it’s just hard for them to verbalize what they’re feeling.”

Understanding the need for exibility is another disconnect between farmers

“We’re taught in school to keep rm boundaries on attendance that shows dedication to yourself and your therapy,” Weber said. “But in farming, we have to compartmentalize that sometimes. Other tasks are just bigger than us.”

Having exibility by putting aside no-show fees for particular cancellations is huge, Weber said.

“It shows the farmer you understand there are many things in their lives that are just completely outside of their control, and it goes a long way in building trust and camaraderie,” she

said. “It allows them to feel safe enough to come back.”

With everything farmers face, navigating the complexities of modern-day agriculture, having that outlet and support system can help make the burdens they shoulder feel less oppressive, Weber said.

“A lot of farmers are wondering how they are supposed to continue to do everything, on top of all the expectations placed on them of demonstrating the proud culture of agriculture,” Weber said. “We need to help farmers start talking about the pressures they face, and as long as they know we understand, they’ll keep coming back and their mental health with continue to be better.”

2 1/2 pounds hamburger

1 small onion

1/2 cup spaghetti noodles

1 pint pizza sauce

1 cup sour cream

3 1/2 tablespoons salad dressing

3 cups grated cheese

Biscuit dough of your choice

Fry hamburger with onion. Cook spaghetti. Put hamburger in casserole dish; add pizza sauce and spaghetti. Mix sour cream, salad dressing and grated cheese and add to casserole dish. Top with your favorite biscuit dough. Bake until lightly brown.

4 cups sugar

4 cups oleo, softened

4 cups peanut butter

8 eggs

4 cups quick oats

2 teaspoons salt

2 2/3 cups brown sugar

4 teaspoons vanilla 8 cups our 8 teaspoons baking soda 1 24-ounce package chocolate chips

Cream together sugar, oleo and peanut butter. Add eggs. Add the dry ingredients and vanilla. Stir in choclolate chips. Bake at 350 degrees for 8-10 minutes or until golden brown. Yields a large batch, enough to share.

2 cups our

1 1/2 tablespoons paprika

2 cups cracker crumbs

1 1/2 tablespoons salt

1/2 teaspoon onion powder

1 tablespoon vegetable oil 1/2 teaspoon garlic powder

Soak chicken in salt water overnight. Roll chicken pieces in melted butter or cream, then in Sallyʼs mixture. Bake for one hour. Can use bread crumbs instead of crackers.

The best quality feed needs the best quality mix. Penta TMR Mixers are designed, tested and farm proven to deliver the best mix on the market. Our Hurricane Auger allows forage to circulate faster through the mix for quicker processing and mixing times.

888-844-7788 www.pentaequipment.com

‘22 Gehl RT165, T-Bar, Dsl, 15” All Season Tracks, 2100 Lift Cap, C/H/A, 2 Spd, 1,884 hrs ......$37,800 ‘17 Gehl RT250, ISO/Dual H-Ctrls, Dsl, Camso Tracks HXD 450x86x58, Both Standard and Hi-Flow Hyd, 2 Spd, Hydra Glide, 295 hrs, Warranty till 6-30-26 or 1000 hrs ................................$48,500

‘18 Gehl R220, JS Ctrls, Dsl, 2200 Lift Cap, SS, 4,854 hrs ...............................................$17,500 Gehl V400, T-Bar Ctrls, Dsl, 4000 Lift Cap, C/H/A, 2 Spd, 2,570 hrs ..............................$37,750 ‘19 Gehl V270, JS Ctrls, 73HP Dsl, 2700 Lift Cap, C&H, 2 Spd, 250 hrs ...........................$57,500

‘19 Gehl R260, T-Bar Ctrls, Dsl, 2600 Lift Cap, C/H, 2 Spd, 1,400 hrs .........................$39,500

Gehl RT135, ISO Ctrls, 46HP Dsl, 1350 Lift Cap, C/H/A, SS, 107 hrs. .....................................$46,500

‘21 Gehl RT165, T-Bar Ctrls, Dsl, 15” All Season Tracks, 2150 Lift Cap, C/H/A, 2 Spd, 2,015 hrs......................................................$36,000

‘21 Gehl R190, T-Bar Ctrls,Dsl, 2100 Lift Cap, C/H/A, 2 Spd, 800 hrs .............................................$44,250

‘21 Gehl R190, T-Bar Ctrls, 69HP Dsl, 2000

Lift Cap, C&H, 2 Spd, 1,184 hrs. .................$41,500

‘23 Manitou 3200VT, ISO Hyd Pilot Ctrls, 3.6L Dsl, 114HP, 4572 LBS At 50%, 3200 LBS At 35%, Machine Weight 11,800, Standard and Hi-Flow (38GPM) Hydraulics, C/H/A, 2 Spd, Fold Up Door, Camera, All Season Tracks, Warranty Until 8-232025.............................................................$77,900

‘23 Manitou 1900R, H/F JS Ctrls, Dsl, 2100 Lift Cap, C/H/A, 2 Spd, 185 hrs .................................$48,500

‘22 Manitou 1650RT, H/Ft Ctrls, Dsl, 12” Tracks, 1650 Lift Cap, C/H/A, 2 Spd, 169 hrs .........$56,500

‘21 Mustang 1650R, H/F Ctrls, Dsl, C/H/A, SS, 3,640 hrs ...............................................$29,900

‘18 Mustang 1650RT, H/F Ctrls, Dsl, 2350 Lift Cap, C/H/A, 2 Spd, 975 hrs ..................$47,500

‘19 Mustang 2700V, ISO Ctrls, 72HP Dsl, 2700 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 14 Pin, Back Up Camera, 261 hrs. ..........................$58,900

‘16 Mustang 2200R, ISO/Hyd JS Ctrls, 72HP Dsl, 2200 Lift Cap, C/H/A, 2 Spd, 3,375 hrs ......$35,500 Bobcat 7753, H/Ft Ctrls, Dsl, 1700 Lift Cap, SS, 6,300 hrs......................................................$12,500 ‘21 PENTA 4930, 460 Cu Ft, 3’ LH Flip-Up Conveyor, Minimum 95HP - $31,500

‘14 ARTEX SB600, 600 Bu, Guillotine Endgate, Vert Beater, 2 Ft Rock Guard, New Apron Chains, New Tube Slats, 88C Chain .................................$44,900