By Dan Wacker dan.w@dairystar.com

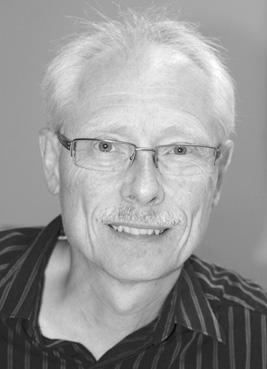

LA FARGE, Wis. — March 28 ushered in a new era at one of the nation’s leading organic farmer-owned cooperatives when Organic Valley announced Shawna Nelson as the cooperative’s CEO.

Nelson, a 20-year veteran of the company, is the fourth CEO in Organic Valley history, and the rst female to lead the cooperative. Nelson takes over for Jeff Frank, who became CEO of Monogram Foods earlier this year.

“This is something I have been working towards,” Nelson said. “I am really looking forward to the next year and the next decade.”

The Viola native began her career at Organic Valley as an intern with human resources and advanced to a fulltime position with the marketing, sales analysis and planning department. She jumped back to a role in HR before her career took on a new trajectory in 2016.

“That year we were looking for a role on the membership side and we couldn’t nd the right t,” Nelson said. “It was suggested that I take on that role, and with my limited background,

I took some time to develop within the cooperative and demonstrated myself as a leader.”

After a year in the new position, Nelson knew that working on the membership side was where her heart was. She ascended to the position of vice president of the dairy pool and served as the executive vice president of membership for the last 18 months. But it took a push from the leadership team before Nelson realized that the CEO position was within reach.

cooperative and how it t together.”

Those experiences from different departments helped provide a unique frame of reference for Organic Valley’s new leader. She gained a perspective that helps see the broader picture, while also understanding how each brush stroke can affect the next.

under her guidance.

“I left our annual meeting incredibly inspired,” Nelson said. “Having that opportunity to bring your membership and employee base together to talk about the future was tremendous.

“A few years ago, we had the conversations with my leaders, and we nally put CEO on my development plan,” Nelson said. “I wasn’t sure where I wanted my career to go. Sometimes life has these amazing moments where people see things in you that you don’t see, and I’m thankful for our leadership team for encouraging me to take on those challenges.”

Working across different departments throughout her career at Organic Valley shaped a unique perspective for Nelson. A former CEO who had a similar background across multiple departments with Organic Valley was George Siemon, the rst CEO in the company’s history.

“I always admired George and how he helped build this place from the ground up,” Nelson said. “He knew all those elements, so when it came to strategy and leadership, he knew the

“I’ve seen how we assemble milk routes, how we engage with farmers, how we work through supply chain issues,” Nelson said. “I’ve had the opportunity to be on many of our memberowner farms, and I know our employees because of my time in HR. When you can connect those, it’s a wellrounded approach.”

Growing up near Organic Valley’s headquarters, Nelson knows the impact that the company has on Wisconsin’s Driftless Region.

“As Organic Valley started to grow, you saw Main Street getting busier and busier,” Nelson said. “You were seeing a commitment to our rural communities. Our rural communities are so important not only to agriculture, but to all of us. Seeing how we can show up in our community — that’s always been a tenet for Organic Valley.”

Within the rst month of her new position, Organic Valley held its annual meeting, bringing more than 700 employees and farmers together as Nelson had the chance to discuss 2024 and look towards the company’s future

The mission of helping the family farm is Nelson’s primary reason for staying loyal to the company that provided her with an opportunity during college and committed to her development through her professional career.

“This company is in my backyard,” Nelson said. “I can look out my window and see my in-laws’ farm or drive 6 miles down the road and spend time with my family. I know the importance of this place to our communities, the people and member-owners that work with us.”

Those member owners are another driving force for Nelson. Spending greater than eight years on the membership side, Nelson had the unique position of visiting Organic Valley farms. Having those relationships with farmers and the people she represents personies what Organic Valley is working towards. Fighting for those farms is exactly what she plans on doing as CEO.

“I know that I get to ght each and every day to provide a vibrant future to family farms, where the next generation is excited about taking over,” Nelson said. “When you have those things — an opportunity for family farms and good food — it’s a winning combination.”

Central Plains Dairy Foundation awards scholarships exceeding $15,000

With an increased focus on investing in higher education, the Central Plains Dairy Foundation named four scholarship winners – up from one in previous years. Ashley Brandel, University of Wisconsin-Platteville, and Benjamin Styer and Rachel Visser, both studying at the University of Minnesota, each earned $5,000 CPDF scholarships. Paige Bunn, University of Nebraska-Lincoln, received the $500 Tonneson Scholarship. The CPDF scholarships go to students who have completed at least one semester of post-secondary education and are pursuing a degree in agriculture, with an emphasis in the dairy industry. Annually, the Tonneson scholarship goes to a student who has successfully completed at least one semester enrolled in a postsecondary college or university, pursuing a degree in agriculture with emphasis in ag communication and/or leadership. For these scholarships, preference is given to applicants in Iowa, Minnesota, Nebraska, North Dakota, South Dakota and Wisconsin.

2025 Gopher Dairy Camp registration opens

Registration is now open for the 2025 edition of Gopher Dairy Camp, which will be held June 12-14 at the University of Minnesota - Twin Cities. The camp is hosted by the Gopher Dairy Club in cooperation with the Minnesota 4-H Dairy Project Committee and the Minnesota Livestock Breeders’ Association. The goal of the camp is to provide dairy youth the opportunity to strengthen their dairy knowledge and skills, as well as to network with other dairy youth who share their interests.

Gopher Dairy Camp is open to all youth who have completed grades six through nine but have not yet started 10th grade. Held Thursday through Saturday, the camp’s agenda offers workshops which will allow attendees to excel in the show ring, improve their tting skills, and grow their knowledge of dairy judging and nutrition.

The primary focus areas of the camp are calf selection, showing preparation of dairy cattle and showmanship.

Because of generous support by camp sponsors, the 2025 Gopher Dairy Camp will continue to be offered at a registration fee of $100, which is all-inclusive

and covers the cost of housing, meals and camp materials. Registration information has been dispersed to local Extension ofces and is also available online at www.gopherdairyclub.com. Registration is due May 15.

With any questions, please contact co-chair Allison Foss at (612) 770-8720 or foss0387@umn.edu.

The Gopher Dairy Club is the largest and most active student organization on the Twin Cities campus of the University of Minnesota, and its members are students who desire to actively promote the dairy industry through youth education, dairy judging, scholarship, leadership, professional development and teamwork.

Minnesota dairy farmers are encouraged to apply for the Minnesota Department of Agriculture’s Dairy Business Planning Grants, a funding opportunity designed to support dairy operations in planning for the future.

Eligible projects include hiring a qualied, independent third party to help create a business plan for your dairy operation. This can include plans to:

—Evaluate the feasibility of expanding your operation.

—Plan for environmental upgrades.

—Develop a farm transition or succession strategy.

—Update feedlot permits.

—Address other business planning needs.

“Dairy farming comes with real challenges, and thoughtful planning is essential. We’re proud to offer Dairy Business Planning Grants to support Minnesota farmers as they look ahead to strengthen their operations. Their hard work brings fresh, high-quality dairy products to tables here in Minnesota and beyond,” said MDA Commissioner Thom Petersen.

The grant pays 50% of the cost to develop a business plan, up to $5,000. Producers are responsible for the remaining 50%. Applications will be funded on a rst come, rst served basis until June 1. The MDA has approximately $28,000 remaining to be used this scal year.

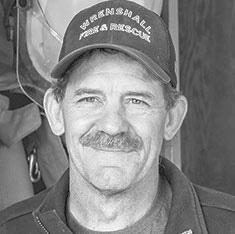

Greg Siegenthaler elected president of Dairy Business Association

The Dairy Business Association, Wisconsin’s leading advocacy group, elected a new president during the group’s annual business meeting at DBA’s Dairy Strong conference.

Greg Siegenthaler, vice president milk marketing, sustainability and sourcing for Grande Cheese in Fond Du Lac was elected president. Siegenthaler is a longstanding DBA member and previously served as the organization’s vice president.

Siegnethaler succeeds Lee Kinnard, dairy farmer from Casco who term-limited out as president but remains as a board member.

The association also elected two producer members and one corporate member to the board:

Duane Ducat, partner and manager of Deer Run Dairy in Kewaunee. Ducat has been a member of DBA since the association was founded and is actively involved in various other agricultural organizations, including his local farmer-led watershed conservation group Peninsula Pride Farms and Farmers for Sustainable Food.

Steve Schalla, Bomaz Farms in Hammond was reelected to the board. As a long-serving DBA member, Schalla has been a member of DBA’s government affairs committee and has participated in many events, including Dairy Day at the Capitol, advocating on behalf of dairy farmers accross the state. He will hold the position of secretary on the board.

Amy Penterman of Vine Vest Partners LLC, is an experienced crop insurance agent and farms in Thorp with her husband. Having previously served as a producer director, she is familiar with DBA and has been involved in the organization for many years.

Outgoing board members include Steve Bodart of AgriGrowth Solutions and Kevin Collins of Collins Dairy in Greenleaf.

Other DBA board members include: Travis Speirs

of Shiloh Dairy, vice president; Chris Schneider of Nicolet Bank, treasurer; Spencer Frost of Frost Farms; Jessse Dvorachek of Wayside Dairy and Lee Kinnard of Kinnard Farms.

opportunities to grow Minnesota ag product sales

Applications are now being accepted for two grant opportunities available through the Minnesota Department of Agriculture aimed at helping value-added businesses and livestock product processors seeking to start-up, modernize, or expand their operations and increase their sales of Minnesota agricultural products.

The Agricultural Growth, Research, and Innovation Value-Added Grant and Meat, Poultry, Egg, and Milk Processing Grant programs provide funding for businesses to invest in equipment and physical improvement projects that support expanding production capacity, market diversication and market access for their products.

Applicants must:

—Intend to or be engaged in the processing of Minnesota agricultural products; or intend to or be engaged with livestock slaughter or processing, including meat, poultry, eggs and/or milk.

—Be an individual (such as a farmer), business, agricultural cooperative, nonprot, educational institution, a local unit of government, or a Native American Tribal government.

—Be located or reside in Minnesota and be authorized to conduct business in Minnesota.

Grant applications will be accepted until 4 p.m. Aug. 7, through the MDA’s online application system. For more information and to apply, visit the AGRI Value-Added Grant and Meat, Poultry, Egg, and Milk Processing Grant webpages.

Dairy’s Foundation now accepting grant applications

Dairy’s Foundation is taking applications for the next round of grant requests to support new programs in the dairy industry. The application deadline is June 1. Grants of up to $10,000 will be awarded to programs that build the skills of students or dairy producers or increase public trust in the people and products of dairy are available for organizations across the country.

“Dairy’s Foundation is excited to support new programs that strengthen the industry, share our story and improve skills of dairy farmers,” said Brian Forrest, dairy producer from Stratford, Wisconsin, and chair of Dairy’s Foundation board of directors. “These initiatives are critical to the future of our industry, communities and food chain.”

As the only public-held national foundation supporting dairy education and initiatives across the entire dairy industry food chain, Dairy’s Foundation strives to identify emerging educational needs and help ll gaps in funding for new or innovative programs. Since 2010, Dairy’s Foundation has awarded more than $350,000 in grants to support vital programs that equip the dairy community with the latest tools and resources to be effective managers, leaders and ambassadors of dairy to their neighbors in rural and urban settings.

Applications will be reviewed by an independent grant-selection committee. Organizations with a tax status of 501(c)(3) or (5) may apply.

Please share the grant information with organizations that might benet. Complete grant information is available here. Inquiries about Dairy’s Foundation grants can be sent to info@dairyfoundation.org.

By Amy Kyllo amy.k@star-pub.com

NEW PRAGUE, Minn.

A good mood lled the air April 27 as kids and adults alike waited their turn to play with Saanen goat kids at Next Chapter Winery near New Prague.

The goats were from Four Seasons Farm near Jordan, which is owned by Chris and Laura Kieser. The Kiesers brought all 14 doe kids born this spring. Eight kids at a time hung out with attendees while the others were rotated into the group, giving each kid a rest time when they needed it.

“Goats are so personable, people can’t help but smile,” Laura Kieser said.

Jackie Brockway, one of the owners at Next Chapter Winery, agreed.

“The baby goats were such a hit,” she said. “They were so adorable. It was amazing to see children and the goat kids interacting.”

The winery estimated over 1,000 attendees came from noon to 5 p.m. Kieser said the line to see the goats was about 20 minutes long at times.

“Every once in a while, I would walk up and down the line … and I would thank them for coming,” Kieser said.

“They were just so happy to be there. They were so excited. Not one person was upset or anything (about the wait). It was so amazing.”

Attendees could also visit vendors with goat soaps and lotion, cheese, maple syrup, bread, crafts, caramels, books and more. They could also partake in meals from three food trucks.

The Kiesers’ friends from the goat community helped them with the ow and logistics of the day.

Brockway said all age levels of attendees were interacting with the goats and learning.

“(They were) being made

aware that these animals are part of our lives, without us even knowing about it,” Brockway said. “Farms in general are just such a big part of how we eat, how we live.”

Kieser takes a gentle approach to agriculture promotion.

“You can’t push a person to think beyond where they are in that day or moment,” Kieser said. “All you can do is provide the answers for the questions they’re asking.”

Kieser said it takes a lot of storytelling to show attendees how the goats affect their lives.

“We have these cute little animals that people relate to,” Kieser said. “If they’re really interested in their food source, then they continue to ask those questions, and we continue to provide those answers.”

However, she said some people are not ready for that.

“They nd a little bump in the story that they’re a little uncomfortable coming to terms with,” Kiesser said. “Some-

Turn to FOUR SEASONS FARM | Page 7

times reality is not necessarily what they think it is in a storybook.”

Kieser said they monitored the kids closely to give them a break when necessary. They noticed the kids were tired, though, for the next day and a half. She said normally, when they feed during chore time, the goats are bouncing off the wall. They did not do that for a couple of feedings, but she said they are back to their normal antics now.

The idea for the event, which rst happened last year, came by accident. The Kiesers had been going to the winery for several years and became friends with the owners. Last winter the Kiesers joined a book club put on by the winery. When kidding season came around, one of the book club meetings coincided with the feeding time for several goat kids. Instead of missing the book club, they brought the kids in a plastic tote and fed them there.

“We attracted a little bit of a crowd as you might imagine,” Kieser said.

After the book club was done, they stayed to let other guests at the winery interact with the goats.

After that experience, the Brockways reached out, wondering whether the Kiesers would be willing to do an ofcial event.

The rst year’s event in 2024 drew a crowd of 400-500.

“None of us estimated how popular it was going to be,” Kieser said.

When it comes to next year, Kieser said if the Brockways want to do it again, and they can nd a time that works, they will certainly entertain the idea.

They have decided that one of these events per year is enough, however. Their kids are only young for a certain amount of time. Plus all the interaction puts stress on their herd’s most vulnerable population.

The Kiesers’ main focus on their farm is developing quality genetics to sell. The Kiesers breed for longevity, production, structure and a rugged/ sturdy frame.

Kieser grew up with goats, but they were sold when she was in college.

“When (Chris and I) were planning our lives together, I said, ‘Well, not sure where we’ll end up, but I want land, because I would like to have goats again,’” Kieser said.

They started their herd in 2004 with Saanens and Nubians. In 2014, they sold the Nubians and concentrated their efforts on the Saanens.

The Kiesers both work full time off the farm and do not have outside help. They try to keep a herd of about a dozen does.

“It’s a continual challenge on a small herd scale, because you want to see those genetics come to fruition, but that takes three or four years,” Kieser said. “Sometimes you just don’t have the space to do that for as many as you’d like.”

Their herd is shown regionally and nationally, appraised with the linear system and tested through the Dairy Herd Improvement Association, which has been done for about 15 years.

Though sales of genetics are the focus of Four Seasons Farm, not goat events, Kieser said watching the interactions between attendees and the goats at the winery event encouraged her.

“They are a reminder, in some ways, of why we do this: to see the smiles on people’s faces, to see those kids’ faces who are just lit up by the interaction,” Kieser said.

The April federal order benchmark Class III milk price was announced by the U.S. Department of Agriculture at $17.48 per hundredweight, down $1.14 from March, but $1.98 above April 2024. It is the lowest Class III price since April 2024. The 4-month Class III average is at $19.16, up from $15.77 a year ago and $18.46 in 2023.

Late Friday morning, Class III futures portended a May price at $18.37, June at $17.37 and July at $17.77, with a peak of $18.38 in October.

The Class IV price was $17.92 per cwt., down 29 cents from March, $2.19 below a year ago and the lowest since October 2021. Its average stands at $19.19, down from $19.86 a year ago, and it compares to $18.80 in 2023.

Another drop in the all-milk price and a rise in alfalfa hay pulled the milk feed price lower again. The USDA’s latest ag prices report shows the March ratio at 2.46, down from 2.68 in February, and it compares to 2.15 in March 2024.

The index is based on the current milk price in relationship to feed prices for a ration consisting of 51% corn, 8% soybeans and 41% alfalfa hay. One pound of milk would purchase 2.46 pounds of dairy feed of that blend.

The all-milk price averaged $22.00 per cwt. with a 4.36% butterfat test, down $1.60 from February, which had a 4.43% test, and it compares to $20.60 in March 2024 with a 4.27% test.

The national corn price averaged $4.57 per bushel, down a penny from February but 21 cents above a year ago. Soybeans averaged $10.20 per bushel, unchanged from February but $1.60 below a year ago. Alfalfa hay averaged $167 per ton, up $8 from February and $29 below a year ago.

Looking at the cow side of the ledger, the March average cull price for beef and dairy combined was at $140 per cwt., up $5 from February, $16 above March 2023 and $68.40 above the 2011 base average.

Quarterly milk cow replacements averaged $2,870 per head in April, up $210 from January and $750 above April 2024. Cows averaged $2,700 per head in California, up $100 from January and $800 above a year ago. Wisconsin’s average, at $3,130 per head, was up $270 from January and $750 above 2024.

“The all-milk price was lower for the second month in a row, while feed costs were higher for the fourth straight month to put the milk-feed ratio lower,” said dairy economist Bill Brooks of Stoneheart Consulting in Dearborn, Missouri.

“Milk production margins moved lower for the third time in the past four months but remained at historically high levels and were $1.76 per cwt. below February,” he said. “Income over feed costs in March was above the $8 per cwt. level needed for steady to higher milk production for the 17th month in a row. Input prices were mixed with two of the three input commodities inside of the top 10 for March all-time. Feed costs were the ninth highest ever for the month of March and increased 16 cents per cwt. from February. The all-milk price stayed in the top 10 for the month, at the third highest ever recorded for the month.”

“Milk income over feed costs for 2024 was $13.39 per cwt.,” Brooks said. “Income over feed in 2024 was above the level needed to maintain or grow milk pro-

duction and up $5.39/cwt. from 2023’s level.”

“Milk income over feed costs for 2025, using April 30 CME (Chicago Mercantile Exchange) settling futures prices for milk, corn and soybeans, plus the Stoneheart forecast for alfalfa hay, are expected to be $12.84 per cwt., a loss of 55 cents per cwt. versus 2024. Income over feed in 2025 would be above the level needed to maintain or grow milk production, and down 40 cents from last month’s estimate,” Brooks concluded.

This week’s crop progress report shows U.S. corn planting at 24% as of the week ending April 27, up from 12% the week before, 1% behind a year ago and 2% ahead of the 5-year average. Five percent was emerged, 1% behind a year ago.

Soybeans were at 15% planted, up from 11% the previous week, 1% ahead of a year ago and 1% ahead of the 5-year average.

The latest weekly slaughter report showed 45,400 dairy cows were sent to slaughter the week ending April 19, down 1,900 from the previous week and down 9,700 or 17.6% from a year ago. Year to date, 835,600 head had been culled, down 79,800 head or 8.7% from a year ago.

Cash dairy prices started May mostly higher as much of the dairy industry gathered this week in Chicago for the American Dairy Products Institute annual conference. Speaking in the May 5 Dairy Radio Now broadcast, HighGround Dairy’s Curtis Bosma said the eyes of attendees are on domestic demand, which for the past year or so has weakened, particularly in food service.

The “silver lining” is the discount that U.S. cheese and butter prices are to the world. Bosma said there was a lot of chatter at the conference about export opportunities, although there are some complications with respect to what types of cheese and butter the U.S. produces. In the end, however, the most important factor is price, he said. “If we’re cheap enough, those deals will always nd a way to come together.”

When asked how big an impact the tariff tit for tat was having, Bosma said, “As we stand here today, with countries that we do have tariffs with and where the tensions are, the only region or country that is somewhat problematic is China.”

He said there has been a lot of front loading going on in the rst quarter, and not just in dairy. Looking at the U.S. rst quarter gross domestic product data, it posted its rst negative year-to-year growth in a couple of years.

He added that a lot of that fall, considering how GDP is calculated, was due to “the net importer-export factor that’s in there. With all these looming tariff threats, it’s pretty safe to assume that most companies or businesses that rely on goods or materials from overseas are bringing in things or restocking things as quickly as possible to make sure they weather any storms that may arise later this year.”

Meanwhile, CoBank says, “U.S. food and agricultural exports to Mexico have surged 65% over the past four years, making it the fastest growing export market for a host of American agricultural commodities and products. Mexico’s growth as a destination for U.S. exports has been spurred by the country’s booming post-COVID-19 economy and a rapidly growing manufacturing sector.”

“The economic upswing has allowed Mexican consumers to expand their traditional diet, and U.S. food and agricultural producers are helping meet the country’s growing demand for meat, poultry, dairy, processed foods and feed grains. In 2024, U.S. food and ag exports to Mexico climbed to $31.4 billion, slightly below Canada, the top market at $32.4 billion,” according to CoBank.

A new research brief from CoBank’s Knowledge Exchange says, “Mexico will likely surpass Canada to claim the top spot for the rst time in 2025 despite some emerging headwinds.”

Checking prices in Chicago, after the cheese plunged 13.50 cents the previous week, the Cheddar blocks closed May 2 at $1.76 per pound, up 6 cents on the week but 3 cents below a year ago. The barrels saw their Friday nish at $1.7550, 5 cents higher over the week and 12.50 cents below a year ago. Sales totaled 28 loads of block on the week and 132 for the month of April, down from 138 in March. Barrel sales totaled 12 for the week and 66 for April, up from 56 in March.

Central region cheese demand has been strong in recent weeks, but contacts tell Dairy Market News that spot activity was somewhat muted this week. Spot loads were mixed, as cheesemakers said inventories are tight while others said they are becoming more available. Milk output is trending higher in the region and milk at mid-week was reported as low as $7-under class. Milk is plentiful, says DMN.

Milk output has passed spring peak in the West, but cheese manufacturers have enough available. Production varies from somewhat lighter to somewhat stronger. A few manufacturers note tight spot load availability regardless of what type of cheese is requested. Domestic demand varies from lighter to steady. Food service remains comparatively less robust than retail, while export demand is steady to strong. Sellers say U.S. prices remain competitive, according to DMN. Spot butter fell to $2.24 per pound Tuesday, the lowest CME price since Dec. 22, 2021, but it rallied and closed Friday at $2.33, up 5 cents on the week but still 74.50 cents below a year ago when it was trading at $3.0750. There were 20 CME sales on the week and 116 on the month, down from 164 in March.

Central butter makers are actively churning as cream remains plentiful, DMN said, but increasing seasonal demand from ice cream makers has drawn inventories down somewhat from early spring. Cream multiples have increased slightly at the bottom of the range, but most are at or near at market. Domestic butter sales are steady, meeting expectations. Spot loads are available, and some are freezing product for use later in the year.

Seasonally strong milk production is beginning to tick down from the peak of spring for some parts of the West. However, butterfat component levels continue to be more than sufcient, helping to keep cream widely available. Butter manufacturers were keeping their churns busy. Inventories are generally growing despite strong export demand. Domestic demand is steady, but retail demand remains comparatively more robust than food service. Domestic prices remain competitive internationally despite trade policy changes that have taken place this year, according to DMN.

Grade A nonfat dry milk saw its close at $1.1950 per pound Friday, up 0.75 cents on the week and 6.50 cents above a year ago. There were 22 sales on the week and 50 for the month, down three from March. The weak dollar has made U.S. exports more attractive. Dry whey closed Friday at 52 cents per pound, up 1.50 cents and 12.50 cents above a year ago. There were ve sales on the week and 33 for the month, up from 19 in March.

Checking the rearview mirror, U.S. milk production decreased 0.2% in 2024 to 226 billion pounds, according to the USDA’s Milk Production, Disposition, and Income Summary issued this week. The rate per cow, at 24,178 pounds, was up 61 pounds from 2023. The annual average number of milk cows on farms was 9.34 million head, down 42,000 from 2023.

Cash receipts from milk marketings totaled $50.7 billion, up 10.5% from 2023. Producer returns averaged $22.56 per cwt., up 10.7% from 2023. Marketings totaled 225 billion pounds, down 0.2% from 2023, and included whole milk sold to plants and dealers and milk sold directly to consumers. An estimated 985 million pounds was used on farms where produced, down 1.1% from 2023. Calves were fed 92% of this milk, with the remainder consumed in producer households, according to the report.

Meanwhile, the Dairy Products Summary reported total cheese production in 2024 at 14.2 billion pounds, up 0.7% from 2023. Wisconsin was the leading state, with 3.586 billion pounds of that total, or 25.2%, with 116 producing plants.

California produced 2.481 billion pounds in 47 plants.

Italian varieties totaled 6.03 billion pounds, up 2.9% from 2023 and accounting for 42.3% of total cheese in 2024. Mozzarella accounted for 79.5% of the Italian production, followed by Parmesan with 7.4% and Provolone with 6.4%. Wisconsin was the leading state with 28.3% of the total.

American output hit 5.58 billion pounds, down 3.0% from 2023 and accounting for 39.1% of total cheese in 2024. Wisconsin again was the leading state at 19.7%. Cheddar output came in at 3.785 billion pounds, down 5.2%.

Butter production totaled 2.24 billion pounds, up 5.9% from 2023. California was the No. 1 butter producer, accounting for 29.8% of that total.

Nonfat dry milk for human consumption totaled 1.67 billion pounds, down 10.7% from 2023. Skim milk powders, at 599 million pounds, were down 13.3%. Dry whey totaled 853 million pounds, down 9.0%. Lactose, at 1.11 billion, was up 0.3%, and whey protein concentrate totaled 495 million pounds, down 1.9%.

Good old-fashioned ice cream totaled 886 million gallons, up 2.7%. Low-fat ice cream amounted to 412 million gallons, down 6.6%. Sherbet totaled 26.4 million gallons, down 6.9%, and frozen yogurt totaled 37.8 million, down 5.6% from 2023.

In politics, the Consortium for Common Food

Names, National Milk Producers Federation and U.S. Dairy Export Council applauded the U.S. Trade Representative’s decision to spotlight protection of common food names in the agency’s 2025 Special 301 Report issued this week.

A joint press release stated, “The annual report outlines major global intellectual property concerns. It highlighted the European Union’s persistent campaign to monopolize common names such as “parmesan” and “feta” through protectionist geographical indication (GI) policies. These efforts restrict the use of widely recognized food and beverage terms to only specic European producers and effectively cut U.S. producers out of certain key markets.”

“The European Union’s approach to geographical indications is entirely unacceptable. It intentionally crowds out fair competition by restricting market access for U.S. and international producers,” said Jaime Castaneda, executive director of CCFN. “Too many trading partners have been coerced into imposing trade barriers for products using common food and beverage names. We appreciate USTR’s ongoing recognition of this issue but urge the U.S. government to stop trading partners to succumbing to European pressures and imposing trade barriers on U.S. products.”

Cows

Holstein cow fresh 30 days and milking well. Parlor adapted and will have individual test by sale day. Her heifer calf sells right behind. Justin Oberholtzer, Neillsville Fresh Brown Swiss cow. Fresh 2 weeks and milking heavy! Good hand milker.

9 Holstein tie stall cows. All fresh 38 to 91 days. 67 to 109 lbs. Reputation consignor!!

Heifers

Small group of open heifers approx. 500 to 700 lbs Bulls

(Offering an exceptional lineup of Registered Holsteins today!) Registered Holstein 14 Month old. Hooverdale A2P2 Fenton P. Vogue A2P2 x Windle way Undenied Fall VG87 + 10 more generations VG + 10 more generations of VG & EX back to Elegance. He’s polled and A2A2 . Joseph Hoover, Edgar. 5 bulls, all fully registered with papers in hand Brian Bradley, Denmark. #5077 8400032755147661 03/03/24. Combination 7HO16105 x Unix 23860M 4.5F x 3.2P in 305 day 1st lactation . Grand dam had 4 consecutive lactations over 35000M!

ET 5065 Parfect Pearce 7HO15793 x Pharo Jewel 840003275147649 01/28/24. 26370M 4.1F x 3.1P 1st lac and Grandam made 422110M 3.7F x 2.9P in 305 day.

ET 5066 Pazzle 250HO16115 x Select Tootsie roll 02/02/24 840003275147650 Dam made 27600M 4.7F x 3.1P in her 1st lactation and granddam made 38580M 4.1F x 3.5P in 305 days 2nd lactation.

ET 5056, 840003275147640 Revolution (250HO15664) x Battist Hancock Aslyn DOB 01/07/24 Milk records up to 40610 with 4.2 x 3.3. ET 5069, 840003275147653, Altakamara-Red (11HO16227) x Battist Reeve Pepper Red. Milk records up to 35,000 in 305 days. 17 month old Holstein. Elevation x Black Onyx with aAa code of 516! Consigned by James Weaver ,Colby. 2yr old Brown Swiss. Proven Breeder.ET 1290 Kickstart x Lamborini 5/8/22 A1A2 23194M 4.6F x 3.5P bred by Brandon Meier of Thorp and consigned by Ron Serocki. 14 month old Jersey bull. Polled, A2A2 and aAa 5614. Registered Polled Red Holstein (08/17/21) Rampage Red (94HO860) x Hercules VG88 with milk records 365 Day 21235M 4.7F x 3.2P Weighs approximately 1600lbs. Bred by Mike Christoph of Boyd.

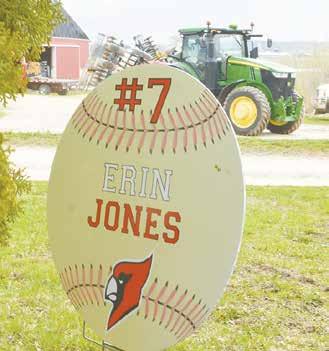

After taking a cow to the Equity Cooperative Livestock Sales Association in Sparta, Jones headed to his John Deere 7210R with a turbo tiller and drove down to a 12-acre eld 6 miles from the farm.

“We do a lot of no-till for our crops, but this eld, we’re planning on putting corn back in on what was a corn eld last year,” Jones said. “The soil quality in this eld is among our best, so we feel good about back-to-back corn years. We want to break up what’s on the surface here to just help with the planting when it’s time.”

With those 12 acres now ready for planting, a trip to the facility that houses his steers was in order. Down the road in West Salem, Jones houses his steers in a former tiestall milking barn. Using dry hay from big square bales and shell corn from a silo, Jones makes sure that his steers are well-fed.

With planting season on the horizon, Jones made a trip to the store for parts for his sprayer before adding a stop in town for lunch.

“There’s one piece we need for the sprayer, but we also keep some extra parts on hand,” Jones said. “It always seems that whenever something breaks down, it’s hard to get the part, so we want to try to be as proactive as possible.”

Threats of severe weather that evening meant that the rst pitch for that night’s softball contest was bumped to 4 p.m., and with that change in time, so came a change in Jones’ timeline on the farm.

“We normally try to start evening chores around 3:15 when there is a game,” Jones said. “But with the change, we’ll get started a little earlier so we can be out of here on time.”

That exibility is something afforded to him with the technology installed seven years ago.

Prior to beginning the evening feedings, Jones and his hired help, Chase Reding, a student at West Salem High School, xed a fence post in their dry cow pen. A railroad tie replaced a telephone pole, and some well-placed staples secured the fencing once again. Jones’ father, Ralph, spread fertilizer in

‘18 Bobcat S650, 3,600 hrs

‘17 Bobcat S650, SJC, 5,400 hrs

‘23 Bobcat T64, ONLY 13 HRS!

Bobcat T76, 882 hrs

‘21 Bobcat T76, 1,400 hrs

‘21

‘22 MF 4707, MFWD, MF

a 50-acre eld as the family prepares for planting this spring. Reding headed to the freestall barn to fetch the cows that had yet to be milked as Jones started mixing dinner for the milking herd and feeding the youngstock.

Collin England, a student at Bangor High School, joins the fold as more hired help for evening chores.

Turn to JONES | Page 13

S64,

At Jones Dairy Farm that day, England fed 36 calves with a pasteurizer on the back of a John Deere Gator utility vehicle.

“It’s important to give these kids a chance to get their feet wet in agriculture,” Jones said. “Obviously their help is really important for me on the farm. But for those kids who want to see if a career in agriculture is right for them, there’s no better way than spending time on the farm.”

As evening chores were nishing up, Jones got word that his daughter’s game had

been canceled as inclement weather was forecast for that night. With work done early, Jones and his family got extra time together that night .

“That’s life sometimes,” Jones said. “You can make your plan for the week, but that’s going to change on a day-to-day basis. Thankfully, Erin will have more games this week, and when she does, we’ll be sure to adjust our schedule accordingly to make sure I can see her take the eld.”

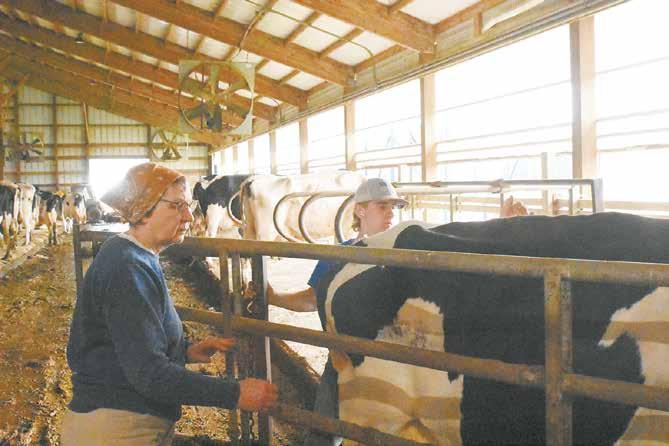

DAN WACKER/DAIRY STAR

John Jones stands next to his total mixed ra on mixer the morning of April 28 on his farm near Bangor, Wisconsin. Jones feeds his milking cows twice a day and u lizes two Harvestore silos for haylage and bags his corn silage.

DAN WACKER/DAIRY STAR

John Jones and Chase Reding reattach metal paneling to a newly installed fence post April 28 near Bangor, Wisconsin. Jones employs several high school students.

By Danielle Nauman danielle.n@dairystar.com

MADISON, Wis. — For over three-quarters of a century, Alice in Dairyland has been an iconic representative of everything agriculture in Wisconsin. Another chapter of the Alice history book will begin May 17 as Wisconsin’s 78th ambassador of agriculture will be named in Prairie du Chien.

“Alice is a unique position, a unique name that has endured for so many years because it does what it was designed to do,” said Lisa Behnke, who served as the 38th Alice in Dairyland, selected in 1985. “Alice gets attention and holds that attention. The role allows you to tell people a great story about where their food comes from. I hope we’re still naming Alices for another 78 years.”

The role has evolved over time, from a high school beauty queen to a professional communications and marketing specialist. But, the core remains the same: sharing the story of Wisconsin agriculture with new audiences.

Turn to ALICE IN DAIRYLAND | Page 16

Halei Heinzel is serving as the 77th Alice, a role she will continue until July 1, when the newly selected Alice will assume the title.

“The uniqueness of being Alice is getting to do so many different jobs, in one role in a single year,” Heinzel said.

Outside of traditional public appearances, media interviews and classroom visits, Heinzel said Alice has fully embraced social media, growing the presence to over 21,000 followers on Facebook and Instagram.

“Many of those 21,000 people are not located in Wisconsin,” Heinzel said. “We have people from around the world tuning in and learning about Wisconsin agriculture. We’re reaching a global audience without ever leaving the state.”

Debbie Crave, the 34th Alice in 1981, said the responsibility of communicating on social media is probably one of the biggest changes in Alice’s role over time.

“Serving as Alice is a lot of hard work, you are always on — always expected to be focused and relevant,” Crave said. “I believe the job would be even harder now with the advent of social media and cell phones. We’ve always had a great story to share using traditional media, now there are so many more avenues available to capture that audience.”

Behnke agreed.

“I look at what Alice is doing now, pushing out social media content,” Behnke said. “She is always in reporter mode. I admire the strength and endurance they have.”

Finding the right person to ll the role of Alice has changed over the decades. Initially, the selection of Alice began by narrowing the eld of contestants to 16 young women based on photos alone.

Today the application is rigorous, detailed and not based on pictures. Once the eld of applicants is narrowed to a group of as many as six top candidates, an intense 2-month job interview ensues. Candidates begin the task of immersing themselves in Wisconsin

Barbara Jo Ward-McCrory (le ) presents a “Something Special From Wisconsin” T-shirt to Willie Nelson in 1983 while serving as the 36th Alice in Dairyland. Ward-McCrory was from Fort Atkinson, Wisconsin.

agriculture while showcasing their communication talents.

“The core of the job hasn’t changed over the years; it’s always been a sophisticated position,” Behnke said. “You’re acting on behalf of the Wisconsin Department of Agriculture, Trade and Consumer Protection. That the state would allow Alice to speak on behalf of the department is a remarkable responsibility, and the training is phenomenal. It’s a shame everyone can’t walk in Alice’s shoes for a year, because you cannot imagine the wealth of knowledge and pride that is shared with you.”

The story Alice has shared has grown to include many more facets of Wisconsin’s agricultural industry.

Alice used to wear a rhinestone tiara that she kept after her reign. In 1984 the first tiara featuring eight gemstones native to Wisconsin, including the amethyst, which is given to Alice as a pendant at the conclusion of her year. In 2004, a brooch was made as a replica of the tiara for occasions when the tiara was not appropriate.

Turn to ALICE IN DAIRYLAND | Page 17

Initially, the selection of Alice began by narrowing the field of contestants to 16 women based on photos alone.

“It’s amazing all the different topics Alice might talk about, agriculturally, now,” Crave said. “We probably didn’t talk about nursery trees or some of those industries we hear promoted now. They’re all a great story for our state.”

The duty to learn that story is immense, Behnke said.

“It was such a learning experience, trying to be the best sponge you could be,” Behnke said. “(It was) not just soaking all that knowledge in, but guring out how to package it and put it back out so you retain the same enthusiasm and absolute love for the subject as the people who initially shared it with you.”

One piece of the Alice program that has not changed is the time put forth to communicate the value of Wisconsin’s agricultural industry.

“Alice used to be quite the globetrotter; she even had her own private jet,” Heinzel said. “In the early days, Alice spent most of her time outside of the state, in places like Hollywood and New York City, meeting famous people and presidents. Most people living in Wisconsin then were connected to the dairy industry — they didn’t need to be told how great Wisconsin cheese is. Today, most people are four generations removed from the farm.”

Alice still racks up the miles, Heinzel said, mostly zigzagging the highways and back roads of the state.

“I’ve driven 33,500 miles by the end of April,” Heinzel said. “I’m hoping to hit 50,000 by the time I’m done. I think I’ll have a pretty good chance, attending many of our great dairy breakfasts across the state in June.”

During her year as Alice, Crave still traveled around the country to several events representing Wisconsin agriculture, experiences she said opened her eyes to new things.

“At one event in New Orleans I was in a crawsh eating contest,” Crave said. “I never knew crawsh as anything but something in the lake, under the pier. I really didn’t know anything about Cajun food, but it was fun to experience that and get a little taste of

New Orleans.”

While Alice is a job, the woman holding that position becomes Alice, Behnke said.

“For one year, you commit that you are going to be Alice, you kind of drop your own identity and you become the spokesperson,” Behnke said. “As the job evolves, so do the people who hold it. They each put their own stamp on it.”

Heinzel said embracing the role and infusing her personality into it has been gratifying.

“The best part of Alice is that she is a different person every year,” Heinzel said. “There is no mold to the perfect Alice in Dairyland. Each one is different. It’s all about her sharing her unique story in agriculture.”

This year’s Alice, Halei Heinzel, had driven 33,500 miles by the end of April. Her hope is to reach 50,000 by the end of her tenure.

and support a healthier, more productive herd.

Animal-centered environments offer cross-path, natural, tunnel, forced-air, or hybrid ventilation to encourage natural behaviors & increased rest time.

Inlet Fans

Circulating Fans

Exhaust Fans

Rolled Curtains

5 years ago

In 2020, Branden Sauer had been milking his own cows since 2010 at his parents’ farm near Pierz, Minnesota. Sauer rented the farm and was planning on building a freestall barn and manure pit when he was approached by a neighbor who was going to sell their farm across the road. The neighbor’s farm came with a farm site and 160 acres, so he purchased that instead. Sauer still housed his youngstock at his parents’ farm, but planned to update the facilities at the new site and have everything in one place in the future.

When Bruce Richter had triple bypass surgery in late April, his family and friends stepped up to help with spring work. Bruce and his wife, Karyl, farmed with their son, Chris, and their daughter, Mandy. The family milked 80 cows near Wadena, Minnesota. Bruce had come home from the hospital April 26, 2020, and three days later, seven Ford tractors, each with a plow behind, arrived to get to work. In that one day, the crew worked 180 acres of land.

Rosy-Lane Holsteins which had 955 milk cows near Watertown, Wisconsin, was owned by Lloyd and Daphne Holterman, Tim Strobel and Jordan Matthews. The farm received the national Outstanding Dairy Farm Sustainability award from The Innovation Center for U.S. Dairy. The dairy placed a strong focus on genetics, people, animal housing, nutrition, herd health, milk harvest, technology and calf care. The team at Rosy-Lane said they credited their breeding efforts to making each cow as efcient and as sustainable as possible.

Sassy Cow Creamery was a dairy farm run by James Baerwolf and his brother, Robert, and their families. They made ice cream and bottled their own milk at their farm near Columbus, Wisconsin. James’ daughters, Taylor, Faith and Anika, came up with the idea for a Kindness Cooler as a way to help those in need during the coronavirus pandemic. The cooler was open 24/7 and free to those who lost their jobs due to the pandemic. The family went through an average of 150-200 gallons of milk per day with the Kindness Cooler, which was located by their on-farm store.

After renting a dairy farm near Sturgeon Lake, Minnesota, from Adam Klosowski for 22 years, John Kliniski purchased the 232-acre farm from Klosowski. Kliniski had grown his herd to 70 cows while renting the farm. Since Kliniski was renting the farm, he did not make any upgrades to the facilities, but now that he owned the farm, he had xed the leaky roof of the barn and put in a plate cooler. Kliniski had worked at the Klosowski farm since he was a teenager, all while helping his parents at their dairy farm. When the opportunity came to rent Klosowski’s farm, he knew that this was what he wanted to do, Kliniski said.

Ever since Morgan Krause attended Minnesota’s State Greenhand Leadership Camp as a freshman, she knew she wanted to become a state FFA ofcer. During the 86th Minnesota FFA State Convention, Krause was named state vice president for 2015-2016. Krause grew up on a 200-cow dairy farm operated by her par-

ents, Charles and Robyn, near Buffalo, Minnesota. Krause was active with her high school FFA chapter at the local and regional levels, both of which she served as president. She also participated in career development events, leadership camps and other local, regional and state FFA events.

20 years ago

Grazing grows green for Abrahamsons

When Al and Sue Abrahamson converted their hay shed into a sand-bedded freestall barn, they knew it had poor ventilation, so they decided to graze their milking herd. The Abrahamsons transitioned their 45-cow stanchion barn into a swing-10 parlor. The Abrahamsons milked 100 cows at their farm near Lindstrom, Minnesota. The Abrahamsons had been grazing their herd for more than 10 years and planned to continue because they were maintaining a herd with a rolling herd average of 23,000-26,000-pounds of milk and good overall health.

New farm means new role for Roers

At 18 years old, Mike Roers had his hands full attending college at Alexandria Technical & Community College for welding and milking a herd of 55 cows. Mike grew up helping his parents, Kevin and Ellen, on their 43-cow dairy farm and working on a neighboring dairy farm as well. When a dairy farm nearby came up for sale, Kevin and Ellen purchased it to help Mike get started on his dairy career. While Mike continued his schooling, his parents and seven siblings stepped up to do the chores at not only the home farm, but also at the second farm. With the second farm site, the family had the option to expand and incorporate more family members if they chose to do so in the future, Kevin said.

Trial lawyers are using an outlier report from a World Health Organization subagency to attack farmers and a safe weed fighting tool they’ve depended on for over fifty years.

Without crop protection tools like glyphosate, food inflation in the U.S. could double. Think grocery prices are high now?

Act now to support American farmers and keep foreign interests out of America’s farms and food supply. We can’t afford to wait.

We would like to take a moment to thank the people and area business that have made our spring consignment sale another huge success.

Sauk Centre Tire

Voller Farms

Sauk Centre Truck Stop Dairyland Supply

Sauk Centre Police Department

For allowing people to drive or park on or near their business/property and putting up with all the traffic over this past month. We would also like to thank all the people who came out and helped work at the consignment sale whether it be, help park cars to take bids or working in the office. Without your help this auction would not be possible.

Also, a big thank you to all the sellers & buyers who came out to support the spring consignment sale and having your trust in our company to do a good job for you. We truly appreciate it.

By Michelle Stangler michelle.s@dairystar.com

SIOUX FALLS, S.D. — Over the last decade, dairy farming has evolved beyond producing milk. Producers are nding new income opportunities to supplement their milk check. As farms specialize, not losing sight of the core business of making milk is important for long-term sustainability.

Kevin Dhuyvetter and Sara Kvidera, both with Elanco Animal Health, look at ways farmers can tap into sustainability initiatives. They shared tips during their presentation, “Credit for Good: Producer Pathways to Prot for Sustainable Practices,” March 27 at the Central Plains Dairy Expo in Sioux Falls.

Many Fortune 500 companies and consumer packaged goods brands are actively seeking ways to reduce their environmental impact, often through partnerships with the agriculture sector.

“About two-thirds of all Fortune 500 companies have set signicant climate reduction goals, and when you’re a publicly traded company and you make a commitment to do something, you’re under a legal obligation to fulll that commitment,” Kvidera said.

This is where dairy farmers can come into play.

Kvidera, dairy sustainability technical lead at Elanco, said the dairy industry has reduced the emission intensity of milk production by about 40% since 1990.

“This decrease in intensity is mostly due to our ability to be more produc-

tive and produce more milk,” Kvidera said. “If I only said emissions, not emissions per unit of milk, emissions would be going up because we are growing, we’re making more milk, we’re producing more.”

From an economic perspective, the dairy income landscape has shifted over the last decade.

“Milk is still the primary source of revenue on most dairies, but we know that milk as a share of the income generated on dairy (farms) is going lower and lower,” Dhuyvetter said.

When looking at income sources on dairy farms — especially in recent years — beef calf sales have made up a growing percentage, driven by current market prices. There are also income opportunities tied to sustainability initiatives, such as installing a digester.

However, Dhuyvetter said that digesters are sometimes not included in a dairy farm’s accounting records if they are treated as a separate business, making it difcult to quantify their magnitude on dairy income.

He said that while diversication is valuable for additional income, it should not compete with the core focus of the farm’s primary business.

“Your core business is making milk,” Dhuyvetter said. “If you diversify and it competes with that, (be) a little nervous of that… What we really want to (do) is to diversify so that it really complements (the farm).”

In the past, dairy farms often included various livestock species, but today, many are specialized with opportunities related to the dairy farm. That is why sustainable practices should be approached strategically, he said.

Manure management is one area where farmers can reduce environmental impact. Others include feed manage-

ment, energy use and enteric methane emissions.

Elanco, among various other agriculture commodities and related groups, hopes to be the connection point from farmers to companies in today’s sustainability-driven environment.

“You sell milk to a processor,” Kvidera said. “A processor sells it to a food company and the money goes back to the producer. What we’re trying to do is open a whole new revenue stream that’s independent of milk markets for you.”

Verication, she said, is important to ensure transparency and accuracy of what is being done.

“A producer will send their data to get veried…the third parties in the world verify that what you did on your farm adheres to the right standards, and then they sell those reductions to food companies,” Kvidera said.

More than 1 million cows, or over 11% of the U.S. dairy herd, are now enrolled in Elanco’s UpLook database — the company’s digital solution for quantifying greenhouse gas emission reductions and the rst step in enabling farmers to monetize their on-farm interventions, Kvidera said.

“Know what opportunities exist in your area,” she said. “This can be very milk dependent. It can be state dependent. Talk to your supplier, your nutritionists, your advisors on what opportunities exist in your area today.”

Likewise, Dhuyvetter said to consider whatever idea the revenue stream may bring and understand if it com-

petes with or complements your core business.

“Know what’s generating the income, and what costs it’s generating,” Dhuyvetter said. “Is the decision reversible if conditions change? Does it allow a lot of capital investment? Is this part of the dairy, or is this completely separate?”

As farmers look ahead in 2025, Kvidera said they should look for opportunities while remaining in control of their practices.

We started planting corn on May 4 and have 100 acres done. We have been fertilizing, digging and picking rock. We finished pumping our pit May 4. The alfalfa is coming good. We have a couple places on top of the hills that dried out, and we didn’t get the regrowth we wanted. A lot of farmers in our area are wrapping up on corn and starting on soybeans. We might seed alfalfa today (May 6) and finish picking rock and plant corn on that tomorrow. The pastures are greening up pretty good. We have 45 cow-calf pairs on pasture and have 15 yet to calve.

We have 750 acres of corn and 770 acres of soybeans in as of today (May 6). The field conditions are fantastic. We are planting everywhere. We are seeing a little winter kill on the northern ridges of hills, but, for the most part, the alfalfa came through pretty nice. I would say everybody in this area is half done or nearing the halfway point. We plan to keep going on corn and then do soybeans and 70 acres of new seeding alfalfa. Our first soybeans just starting cracking out of the ground.

Today (May 6) we started planting corn and, if everything goes well, we should be done by Thursday. We plant 99 and 108-day Redtail corn, all for silage. We do two maturities to work around our custom chopper. We plan to plant Plenish soybeans, which are a high oleic variety of soybeans. This will be our first year trying it. We are working with Daniel Olson of Forage Innovation and we plan to plant our population at 26,000. We are hoping for equal yields and better quality. The neighbors alfalfa stands look great, so does the winter rye. We should be chopping that next week. Everybody in our area is out planting corn and soybeans.

I am hauling liquid manure today (May 6) and are about half done. Overall, we have around 600,000 gallons in a manure slurry storage and then 100,000 under a slatted floor. We are half done with the manure slurry storage. Before this week, we were going around wet spots, but now we are full go. We plowed up some alfalfa and have worked most of the fields. By the end of the week, we will be planting corn. We planted 45 acres of oats and have 25 acres of small grain left. Everybody is running around here now. The tractor lights are on half the night.

We just started planting corn today (May 6) and we are still spreading manure. We had to take a break for a while from spreading manure with all the rain we have been getting the last several weeks. In the next two weeks our goals are to keep planting, keep spreading manure and start getting haying equipment ready. We hope to get to planting soybeans in the next two weeks as well. Planters are running hard in our neighborhood. A lot of fertilizer and spraying are going on too.

We had a tornado touch down with some damage about three miles from us on Apr. 28, but we barely even got any wind. There are some corn planters in our area rolling, but the first corn we will put in the ground will be some notill. We have heavier soil, so we are not quite ready to go yet. The hay looks good from the road, I have not been out in the fields yet. There is maybe a few spots with some winterkill, but not too bad at all.

We really have not had anything to stop us from getting field work done. My last piece of corn is going in right now (May 6). By the end of the week everything will be in. Even the later guys will be done. Quite a bit of the corn and soybeans have popped out of the ground; you can row the corn from the road. People are spraying and putting pre-emerge down on corn and soybeans. The alfalfa looks fantastic. Usually, it is around Memorial Day when we do first-crop alfalfa. We are a little dry and could use some moisture.

We got a good amount of planting done last week, only getting rained out Thursday (May 1). We’ve had a couple pretty good soakers in the last two weeks. We have about 150 acres of corn and 100 acres worth of beans planted over the last two weeks. We’re finishing up emptying our manure pit and with good weather for the next three or four days we should stay on schedule. Once we get the pit empty, we’ll get done planting beans pretty quickly. Our neighbors with rye will probably cut at the end of the week (week of May 5).

We had some really good weather the last two weeks, with four little rain showers. It was perfect rain for soaking the ground. We got our animals out on pasture this past week. It’s great to see them out there and grazing. We finished planting corn and have a couple hundred acres of beans planted. All the fields that didn’t have a cover crop were planted. We’re finishing the 80 acres of rye now, and we have first-crop hay right around the corner, maybe by the end of the week (week of May 5), depending on the help we will have around.

We finished spreading manure and started planting corn April 30. Then it rained for four days, we went back in on May 5. We had 352 acres in the ground as of May 6. We plant Pioneer seed, with 60% BMR and 40% conventional. Everybody in the area is going pretty heavy with corn now. Many got started May 5. We have 100 acres of alfalfa seeding left to do that we are hoping to finish by May 8.

We have not had much rain, everything has gone north or south of us. We are in the fields full-tilt right now and were able to get all of our manure out. We got 16 acres of corn planted yesterday (May 5) and are going back at it today (May 6). The hay is greening up, it is up about inches tall already. We had some freeze-outs in some hollows, but not as bad as I expected. We are waiting for a field to dry out to put new seeding on.

We started planting soybeans again April 23 after the rain and had about 300 acres in as of May 6. We started planting corn May 5, and soil conditions are really good. We plant a variety of seed, including Pioneer, Golden Harvest, and Dairyland. We completed all our burndown of first-pass herbicide on corn and soybean acres May 6. We also did second pass nitrogen on our wheat acres May 1. Everybody in the area is getting going with corn.

“Thank you for helping when I was gone from the farm.”

- Leon Peplinski

With over 40 years experience, Wisconsin Silos is the most complete builder of concrete silos in the United States. From pouring the footing, to fixing the accessories, unloaders, feeders, conveyors, silo pipes, silo distributors & silo chutes.

WE DO IT ALL!

3700 Post Rd., Plover, WI 1-800-472-9202 • 715-570-0069 • wisilos@gmail.com www.wisconsinsilos.com

www.mndhia.org

The Minnesota DHIA rolling herd average production yields in 2024 reached a new all-time high of 25,895 milk, 1,123 fat, and 853 protein pounds. Especially noteworthy is the record solids percentages, which were 4.34% for butterfat and 3.29% for protein. The SCC ended the year at an average of 195,000. The dollar value is weighted by the pay prices for these four components and was also a new record of $5,653. For 2024, the dollar value formula saw a major increase in the value of butterfat relative to protein.

The 2024 Dollar Value formula is: (0.0150 x milk pounds) + (3.38 x fat pounds) + (1.68 x protein pounds) + [(350SCC/1000) x 0.00090 x (milk pounds/100)]

Below are the highest-ranking herds within each county afliate, alphabetically by county and herd owner. Congratulations to all!

Wabasha DHIA Technicians Don Heise Lake City, MN 19 years 612-618-6333

Leon Sexton Zumbro Falls, MN 8 years 507-696-4712

Within this feature the Dairy Star catches up to retired farmers and talk about the highlights and struggles they had when dairy farming. The feature includes how each individual farm changed throughout the farmer’s career and what each has been doing since they hung the milkers up.

Stephen Nigon Rochester, Minnesota

What year did you start farming and what year did you retire? I started in 1961 at 10 years old with milking cows. My brothers and I took turns milking for our dad because he hurt his back. I played football for two years at a junior college, and had a scholarship to play at Northern Iowa, but my back went out so I returned home. In 1971, I started dairy farming with my dad. I sold the dairy cows in June 1996. In 1995, I started expanding my beef herd. For the next 20 years, I fed out beef cattle. In 2015, I partially stepped back but continued to raise beef animals and crop farm until 2020.

Tell us about your farm when you started and describe what it looked like when you retired, including how many cows you milked when you retired. When I started, my dad, Ralph, had about 20 dairy cows, 30 beef cows, pigs and chickens. In 1973, my dad and I went into partnership. We had the home farm with 180 acres and rented another 200 acres. In 1973, I also went to school to learn articial insemination and worked part time for Midwest Breeders on

the weekends. We expanded the dairy barn in 1976 with a 40-stall tiestall barn with a manure pit. Dad and I farmed together until 1985 when he retired, and I bought his part of the cattle and machinery. I farmed on my own from 1985 until 2020. In 1988, part of the barn burnt down. We rebuilt and continued to milk cows until we sold the herd to Scott and Michelle Herber. They bought 50 milking cows as well as the youngstock we had raised.

What were some of the big advancements you made during your career? It was always a small farm. When we rst started out, we had buckets. Then, we went to a step saver. When we remodeled in 1976, we installed the pipeline. The change in equipment was also something big I saw over the years. I saw one-row corn pickers all the way up to computerized combines and sprayers, and changes in horse power from 50-horse tractors to 150-horse tractors.

What did you love about milking cows? For a number of years, I got to work with my parents every day. As my kids, Wes and Amanda, were growing up, they were really good help. Also, my brother, Kevin, was a great vet for us. From grade school on, I wanted to be outside and to be a farmer. I also really enjoyed the different farm organizations. I was on the Dairy Herd Improvement Association board and got to know all those people. I was the DHIA board chair for two years. I was on the soil and water board for 12 years. I was on the Olmsted County breakfast on the farm board for about 20 years. There was also an informal young farmers club in our area who would get together.

What was the highlight of your dairy career? In 1989, we hosted the second Olmsted County

breakfast on the farm. There were about 1,300 attendees. What is the biggest challenge you faced in your career, and how did you overcome it? One of the hardest moments I had was telling my dad he had to stop driving equipment when health issues were impairing his abilities. Crop-wise, in 1988, we had a big drought. Then, on Sept. 5, 1988, part of our barn burned. I found a hay source south of town. I had enough silage to feed the cows but no crops to sell. In June 1991, our crops froze on us. We were able to replant for silage but again didn’t have any crops to sell. In 2012, I started having heart issues. After being on heart medication, I was going to sell the beef cows. I went into partnership with Tony Rossman 50/50 on the beef cattle. I had heart surgeries in 2015, and after that, I had the cows during the grazing months and the herd went to Rossman over the winter.

If there is one thing you wished you could have done differently during your farming career, what would it be? Not really anything. We were small but made a good living. We saw different farms getting bigger, but I enjoyed what I was doing on the small scale.

What piece of equipment or technology has been introduced that you wish you had for your dairy career? Nothing. I was happy with what I had. When I had my auction, most of my equipment was about 30 years old. Over the years, I could see when I had had a good year based off the equipment I had purchased.

What do you miss most about dairy farming? The calves. When I got rid of the dairy cows, I still had the beef cows and

could watch those calves. Now, there are no calves around here. I also miss fully living in the country. It has gotten worse because many of the acres I once rented are houses.

What advice would you give to a young farmer today? Decisions you make when times are tight don’t hurt you. It’s the decisions you make when times are good that can cause issues. You want to be careful.

What is your tie to the dairy industry today? I’m still involved with the Olmsted County breakfast on the farm board. I also still get together with the Herbers a couple of times a year.

Was retiring an easy or hard decision/transition? It was easy. I sold the cows in 1996 in part because we were small and I was not interested in getting larger. Also, Rochester city limits borders our farm. Already in 1996, we were seeing increased

trafc on our roads, and I did not have a next generation for the dairy. My wife, Sharon, was working for the Mayo Clinic which gave us income.

What have you been doing since you retired? I continued to farm until 2020 after I quit dairying. I would volunteer in the winters. I worked as a custom chopper for 25 years as well. A golf course was being developed next door to my farm and I worked there a few years. I helped seed down the fairways. I also took up golf, playing in a league from 1996-2014. Now, after fully retiring, I volunteer for my daughter with the Village Agricultural Cooperative. I wake up in the morning with nothing to do, and when I go to bed at night, I only have it half done. The worst part about dairying is all the getting up early — I still can’t help but wake up. I still have dreams I’m farming and my dad is involved.

School will be out for summer by the end of the month, and I’m sure you’re already starting to think of different ways to keep your kids entertained and engaged. I found a bunch of old recipes I used when my children were much younger. Some were things for them to create, some were things for them to eat, but all of them were something to do together, lled with giggles and gooness. What memories. Someone once said, “While we try to teach our children all about life, our children teach us what life is all about.” Enjoy.

Children’s playdough (not edible)

1 cup our

1 cup water

1/2 cup salt

2 teaspoon cream of tarter

1 tablespoon vegetable oil food coloring

Combine ingredients. Cook over medium heat, stirring until a paste forms. Best to knead on counter until well blended, like dough and not sticky, and it will be ready to play with. Store in a tightly covered container.

Homemade nger paint (not edible)

1 cup our 1/2 cup water clear liquid detergent food coloring

Mix our and water until creamy. Mix equal parts paste and detergent; add food coloring. Best paper to paint on is freezer paper or shelf paper.

Treats to eat

Fudgesicles

1 package instant chocolate pudding

2 cups milk 1/2 cup cream 1/2 cup sugar

Mix all together and ll ice cube trays. Freeze. Enjoy.

Knox blocks/ nger gelatin

4 cups boiling water

4 package Knox gelatin

3 package gelatin, any avor

Mix gelatins together. Add boiling water; stir three minutes until completely dissolved. Pour into 9-by-13 pan. Refrigerate two hours until set. Cut into blocks or use cookie cutters to make different shapes.

Seasoned pretzels: Susan Block, Royalton Church Cookbook

1 bottle butter avored popcorn oil

1 package Hidden Valley Ranch dressing mix

3 teaspoons garlic powder

1 teaspoon onion powder

1 teaspoon dill weed

3 pounds pretzels

Mix rst ve ingredients and pour over pretzels. Spread on a rimmed baking sheet. Bake at 200 degrees for 30 minutes, stirring several times to continue to coat pretzels. Cool and store in zipper storage freezer bags. Susan says her family loves these pretzels; she will

even freeze them after they have cooled to make them last longer.

Dirt

1 large package instant chocolate pudding

2 cups milk

1 container (8 ounces) whipped topping

1 package chocolate crème sandwich cookies, crushed

Gummy worms

In a big bowl mix pudding and milk according to directions. Fold in whipped topping. Mix three-quarters of crushed cookies into pudding mixture. Stir in gummy worms. Sprinkle remaining cookies on top and serve.

Two kid ice cream: Jenene Schaubhut, Royalton Church Cookbook

1 cup milk

3 tablespoons sugar

1 teaspoon vanilla or 1 tablespoon chocolate or strawberry syrup

1 small zipper storage bag

1 large zipper storage bag

In the small zipper storage bag, add all the ingredients. Place this bag in the large zipper storage bag half lled with ice and 6 tablespoons salt. Shake until thick and frozen. This is enough for two children to do together.

As their four children pursue dairy careers off the family farm, Natalie and Mark Schmitt started an adventure of milking registered Holsteins just because they like good cows on their farm north of Rice, Minnesota.

3 cups graham crackers, crushed

2 cups powdered sugar

1 cup peanut butter

Combine graham crackers and powdered sugar, mix well. Add peanut butter to melted butter, stir until smooth. Add butter to mixture of crackers and stir until mixed. Pat into a buttered 9-by-13 pan and cover with melted chocolate chips. Cool until bars are rm enough to cut. Makes 24 bars.

9 slices of bacon

1 medium onion

2 cups cooked wild rice

1 cup celery

1 small onion, diced

2 tablespoons cooked chicken

1 can cream of chicken soup

4 cups milk or heavy cream

2 cans cream of potato soup

2 cups

1 cup butter, melted 1 1/2 cup chocolate chips, melted 2/3 cup milk 1 1/2 cup grated American cheese 1 tube refrigerator biscuits

Fry bacon in frying pan, remove once cooked and let cool on paper towels, reserve grease. In bacon grease cook onion until tender. Add wild rice, milk, soup and cheese. Stir well. Simmer until cheese is melted.

In large saucepan, melt butter, then saute onion and celery until tender. Add chicken, soup, milk and cheese. Stir until combined and heat through. Pour into a greased casserole dish and top with refrigerator biscuits. Bake at 350 degrees for 13-16 minutes or until golden brown.

“The Hanson Silo Bunker empowers us to control shrink loss. With our piles, we used to see lots of spoilage. But now we see very little, if any at all.”

Sako Vandermeer - White, South Dakota

• Engineered for strength and long-term durability

• DRY CAST formulation creates low porosity and slump

• Computerized batching for uniformity

• Robotic mold system provides consistency

• Quality nished for smooth edges and sure footing

• Manufactured in a controlled environment (Steam Beds) for faster curing

• Delivered, professionally leveled and installed

• Strength Compression Tests to exceed quality standards

• Modular design for easy installation