By Amy Kyllo amy.k@star-pub.com

DENNISON, Minn. — Dairy consumption in 2025 is doing well and is also outpacing alternatives in every product group.

“In a lot of the categories, we’ve got record highs,” said Scott Gilray, vice president, business unit operations–north with Midwest Dairy.

There is a lot of consumption of dairy. Cheese is at a new record high, butter is at its highest since 1965, and in yogurt, business is rebuilding.

Gilray said uid dairy milk sales are nine times higher than alternatives, dairy cheese is 174 times higher and dairy yogurt is 61 times higher.

Gilray presented this information and more alongside Shannon Watrin, farmer relations staff member for Midwest Dairy, Feb. 13 in Dennison at one of the Midwest Dairy regional meetings. The pair shared about 2024 checkoff work at the national, regional and local levels.

Locally, Minnesota had 68 Undeniably Dairy grants disburse over $200,000. Undeniably Dairy grants fund up to $5,000 per project for dairy promotion. Some projects include a milk cooler for a weight room, color changing cups for a malt stand and more.

“If there’s something you’re thinking about (doing) ask us,” Watrin said. “We’ll probably nd a way to write an application to fund it.”

In 2024, Undeniably Dairy grants did not fund on-farm events because of the H5N1 bird u. This year, with testing in place, they plan to again fund on-farm events, subject to change.

“All

the milk cows can go outside.

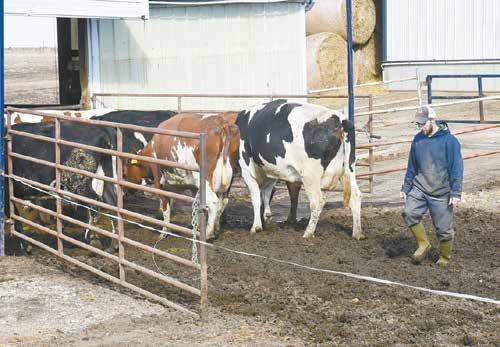

Minn. — Matt Rewitzer is living proof that dreams do come true. As of Oct. 1, 2024, Rewitzer is milking cows at his own dairy farm.

“I’ve tried many different ways to get here,” Rewitzer said. “Whenever I did anything, my thought process was, ‘How is this going to get me closer to dairy farming?’ That was always the goal — to dairy farm.”

Last year, Rewitzer purchased a dairy farm complete with 130 cows, a double-6 parlor and freestall barn from Kor Mulder near Bellingham. The farm features headlocks in the freestall barn and the heifer shed and a 10-acre pasture next to the freestall barn so

“I like how efcient this place is,” Rewitzer said. “There are lots of headlocks, so it is easy to catch the cows or heifers for pregnancy checking and breeding. I really like the pasture by the freestall barn. The cows will stay outside until I go get them for milking.”

The farm site is 35 acres and feed is purchased.

“Kor already had agreements with neighbors to get feed so we will continue doing that,” Rewitzer said. “This way I have more time for the cattle and the kids.”

Rewitzer grew up on his parents’ dairy farm near Eagle Bend. However, they sold their herd in 2007. After graduating from Ridgewater

Turn to REWITZERS | Page 5

By Stacey Smart stacey.s@dairystar.com

WEST BEND, Wis. — Last fall, Peter and Gina Muth received news no parent ever wants to hear: their son had cancer. Wade Muth was 18 months old when he was diagnosed with acute myeloid leukemia Oct. 21, 2024. AML is a cancer of the bone marrow and blood.

“I was shocked,” Peter said. “It was scary, but it was in God’s hands; it was out of our hands. All you can do is pray about it, and we had a lot of people praying for him.”

The Muths milk 200

and

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, SD, Nebraska) 605-864-7917 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Keya Sleister (Eastern IA, Southwest WI, IL) 563-608-5988 • keya.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

by

Peter went back and forth between the farm and Children’s Wisconsin in Milwaukee to help as much as he could while Gina stayed with Wade, who spent 4.5 months in the hospital undergoing four rounds of chemotherapy treatments.

“We still had everything going on here too,” Peter said. “With dairy farming, you can’t turn it on and turn it off. It’s 24 hours a day.”

Peter went down two nights a week to the hospital to give Gina a break, so she could return home to their 4-year-old daughter, Josie.

“We have a great group of employees,” Peter said. “A lot of neighbors stepped up this past fall as well to get eldwork done. They were all a phone call away if we needed an extra set of hands and were more than willing to help. The whole community came together for us.”

In between each round of treatments, Wade was able to come home for approximately one week.

“It was a long road, and the rst month was very rough,” Gina said. “He was in the pediatric intensive care unit and was intubated for a week. He got a cold, and he had a feeding tube for a while until he pulled it out.”

Wade also received three different chemotherapy drugs in his spine.

“Leukemia can hang out in all parts of the body, and a big area that it

The

hides in is the spine,” Peter said.

Cancer did not keep this toddler down, however. Peter said Wade was at that age where he wanted to explore everything and was always on the go.

“During the rst round of treatments, Wade slowed down, but after that, he never slowed down,” Peter said. “He was very active.”

On March 4, Wade returned home cancer-free. Although his cancer is in remission, he has to go back for checkups once a month for the next year to ensure the cancer has not returned and every other month for the second year.

Cancer screening visits will become less frequent the longer Wade remains in remission. Doctor visits drop to every three months during

the third year and every six months during the fourth. Following that, he would return yearly for 10 years. If the cancer were to come out of remission, a bone marrow transplant would be the next course of treatment.

Wade’s journey began last August, when his pediatrician noticed bruising on his chest, which Gina said can be a sign of cancer. A blood panel was run but did not reveal anything abnormal. By September, Gina noticed Wade looked paler, he was clingy, and he was waking up multiple times throughout the night. He had also exhibited signs of Bell’s palsy on one side of his face and had an ear infection that would not heal.

Turn to MUTHS | Page 6

water College, Rewitzer worked for other farmers in the area. He and his wife, Skyla, eventually bought his grandparents’ farm hoping to turn that into a dairy.

“My grandparents’ farm had an old barn, which could have been remodeled to a parlor, but we had a barn re that set us back,” Rewitzer said.

The farm site also had a machine shed that he said had housed all his grandpa’s machinery years ago, but would not come close to housing the machinery he needed.

“We would have to remodel that to even make it work for a heifer shed,” Rewitzer said. “The cost of building keeps going up between concrete, steel, lumber and labor.”

Rewitzer decided he would have to buy a different farm and started looking online while working for other dairy farmers. Most of the farms he found online were either too far away or too big and out of his budget.

After scouring the internet, Rewitzer saw a 130-cow dairy with a parlor for sale by Bellingham, but it had been posted more than 10 years ago. Rewitzer assumed it had been sold after all this time and was never taken off the website.

“Eventually, I called on this farm and sure enough it was still for sale,” Rewitzer said.

Early last year, Rewitzer looked at the farm and immediately liked what he saw. A little while later he came back a second time with his dad and a third time with his wife.

“When I came to look at it with my wife and she saw the house, she agreed,” Rewitzer said. “She knew it was my dream to have my own dairy farm.”

The Rewitzers decided to purchase the farm in the summer. In August, they looked at schools for their kids: Jazlyn, Maverick and Harvey. The school they chose started in August and wanted their kids to start

their new school at the beginning of the year so they gured out a way to live on the farm before the sale was nalized.

They borrowed a camper from Rewitzer’s parents so Skyla and the kids could live at the farm while they nalized the paperwork with Mulder and nished the moving process.

“We set (the camper) up the day before school started and Skyla stayed there with the kids while I went back and forth moving stuff,” Rewitzer said. “I came as much as I could, but I was still working.”

Mulder, originally from the Netherlands, immigrated to farm in the U.S. After more than 20 years of trying to obtain permanent residency, Mulder was not able to meet the criteria to stay, so decided to sell his farm.

The Rewitzers, Mulder and their loan ofcer all agreed that on Oct. 1, 2024, the farm would belong to the Rewitzers. For the week leading up to Oct. 1, Rewitzer milked evenings and Mulder milked mornings to make for a smooth transition.

“For me, (the transition) couldn’t have gone any better,” Rewitzer said. “We really appreciate how much Kor helped us out by letting us set up the camper and using his house to get running water. Even after we took over, he would still come by and help us out.”

Rewitzer said it feels good to have accomplished his dream.

“I like all of it, being with the cattle, mixing feed, breeding the cows, raising up the calves and seeing my kids out here with me,” Rewitzer said.

Tell the advertisers you saw their ad in the Dairy Star!

Wade Muth drives a car down the hallway March 4 as he is released from Children’s Wisconsin in Milwaukee, Wisconsin. Wade was diagnosed with acute myeloid leukemia Oct. 21, 2024, at 18 months of age and is now in remission a er having four rounds of chemotherapy treatments.

“Wade went more downhill after that,” Gina said. “He had a respiratory infection and colds that didn’t go away. His symptoms lingered on. When we thought he was nally getting better, a whole new dose of something else would start. It took three medications to nally clear his ear infection. He would also puke randomly and was very pale. He was not himself.”

At an urgent care visit in Mequon, the doctor noticed Wade had an enlarged spleen. Wade’s 18-month appointment was moved up, and another blood panel was run. This time, the results were troublesome.

The Muths were already on their way to Children’s Wisconsin to check on Wade’s Bell’s palsy when their pediatrician called, and they were instructed to go to the emergency room. Another panel was run, and Wade was admitted to the hospital that night.

of distress they experienced kindness from many directions.

“The generosity from friends, family, and complete strangers was overwhelming,” Peter said. “It still is.”

The Muths said they are happy to be on the other side of this ght.

“We’re cautiously optimistic,” Peter said. “We’re really excited to be here, but it’s always in the back of your mind now — what if? Doctors told us if the cancer comes out of remission, more than likely it will be in the rst year. After the rst year, odds of it coming back drop greatly.”

The Muths’ neighbors are hosting a benet for Wade March 29 starting at 1 p.m. at Fillmore Turner Hall in Fredonia. The event, which was spearheaded by the farm community, will feature a tractor ride, food, drinks, rafes, a silent auction, kids’ activities and live music.

“Prior to this, I had said to Peter, ‘What if Wade has cancer?’” Gina said.

Her fears were conrmed that October day as the family entered what would be an intense battle to save their son’s life. Wade was immediately given blood and platelets, and his color came back.

Wade’s leukemia was caused when chromosome 16 ip-opped with another chromosome.

“What he has is very rare,” Peter said. “He has low-risk AML, and there are not many cases each year of this type of leukemia. AML is more prevalent in adults than children, but low-risk AML has a higher probability of being cured.”

Doctors told the Muths Wade’s age and sex were helpful factors in his recovery.

The Muths said during this time

The Muths said they have received tremendous love and support from their community.

“We’re really thankful for what they’re doing for us,” Peter said. “I’m on the Fillmore volunteer re department, and my re department family has done a lot too. The whole community has been amazing.”

Gina’s sisters and cousins also put on a benet for the Muths in Gina’s hometown.

Wade is a busy toddler who enjoys playing with tractors and other farm toys. On April 4, he will celebrate his second birthday.

“We’re grateful we’re home and grateful for this outcome,” Peter said. “Wade is in a really good place now, and hopefully the cancer stays in remission. If it comes back, we know what we have to do. But the outlook is very promising.”

In 2024 Midwest Dairy was working on science-focused education, including a seminar and webinar at the Minnesota Science Teachers Association conference.

“We’re giving them opportunities to hear … how does dairy work within the sciences, what kind of technology is working within the dairy,” Gilray said. “As they’re talking to their students … (they’ve) got a very positive view of dairy and how we do things.”

Through MSTA, Midwest Dairy shared a science agriculture curriculum that meets state and national standards.

As a parent, Watrin said she is excited about this collaboration.

“We’re (not) feeding them an agenda,” she said. “We’re empowering the teachers to teach the students how to think on their own.”

She said learning about food is interesting to students because of its universal common-ground factor.

“They want to know what they’re eating is good,” she said. “They want to know that the dairy farmers … that are making their food are doing good things for the environment.”

Gilray agreed, and said increasingly people, especially in the younger generation, view food as medicine.

Another science education focused initiative in 2024

was a panel Midwest Dairy was part of with an AI climate change team for a lunch and learn at the University of Minnesota.

On the panel, several dairy farmers shared about the dairy industry and its sustainability efforts. Gilray said the panel was well received by the leader of the AI climate group.

“(He basically said) ‘This was amazing, we learned more in this 1- or 2-hour session than we’ve learned in the last six months,’” Gilray said. “(He said,) ‘We have to have more of these conversations.’”

dairy markets. The projects are from six universities supported by 16 professors.

Shannon Watrin

Midwest Dairy’s investment in increasing dairy sales at the retail level had multiple activations in the Midwest. These activations helped grow incremental milk sales, which represent sales above and beyond the baseline of what would have been sold without the extra promotion.

Gilray said these partnerships only occur with organizations that are like minded.

Midwest Dairy was also involved with a conference for the Upper Midwest Association for Campus Sustainability. There, they shared a fact versus ction panel session on sustainable farming practices and other topics for over 300 students representing 49 universities.

“We have very open and honest conversations,” Gilray said. “That’s how we get our … information out to these college kids so they start understanding the truths about what … dairy farmers do.”

In research, the Midwest Dairy Foods Research Center helped fund six research projects that benet consumers and help create strong

“We want to work with those organizations that want to partner with farmers,” he said. “We don’t want to come in and bring our dollars and talk about the goodness of dairy and then the very next week, they’re advertising an alternative beverage. … We want somebody that really partners with us.”

Midwest Dairy worked with Kwik Trip to help promote three of their limited time ice cream avors. The campaign resulted in over 578,000 pounds of incremental milk.

Midwest Dairy helped Pizza Ranch develop and promote loaded cheesy ranch stix as well as helping promote a value meal deal. The campaigns resulted in over

900,000 pounds of incremental milk.

Coborn’s Inc. grocery store did four campaigns with Midwest Dairy. This included videos of Princess Kay of the Milky Way and Kerfeld Hillview Farm going on their website as well as an appearance on TV, a back-to-school cooking class, and more. The promotions resulted in over 620,000 pounds of incremental milk.

Midwest Dairy also collaborated with Freddy’s Frozen Custard & Steakburgers to develop and promote three menu items: a grilled cheese steakburger, a pumpkin pie concrete shake and a caramel apple pie concrete shake. The activations resulted in 5.8 million pounds of incremental milk.

Midwest Dairy also collaborated with thought leaders, working to connect to consumers through them.

“We explain to them about how good dairy is, the benets of dairy, from the nutritional value, to recipes, to sustainability,” Gilray said. “Then, they go and they talk to their consumers.”

This work with thought leaders included 39 TikTok videos aimed at GenerationZ consumers. The videos resulted in 5.26 million impressions and follow-up surveys showed an 11% increase in trust in the dairy industry’s animal care.

Online, Midwest Dairy utilized banner ads, dairy recipes ads with a “shop recipe” quick link button and more to encourage dairy sales. This initiative worked to capitalize on the fact that 60% of shoppers purchase their groceries online.

On the international scene, Dairy Management Inc. continued to encourage dairy exports, which account for 17% of the U.S. milk production.

“Exports are increasing as global demands of protein are increasing,” Watrin said. “We have a lot of developing countries that are looking to dairy to be an inexpensive, very effective source of protein for their growing nations.”

DMI has eight retail chain partnerships in ve countries and culinary partnerships in seven countries. One collaboration has been to get 30% more cheese on pizzas at Pizza Hut in Japan.

Recently, DMI collaborated to help General Mills develop a new, snackable, crispy yogurt-based product called YoBark.

Watrin said General Mills is looking to collaborate beyond product development as well.

“They’re very interested in the farmer story and how they can share that through their products and branding,” she said.

By Amy Kyllo amy.k@star-pub.com

OWATONNA, Minn. —

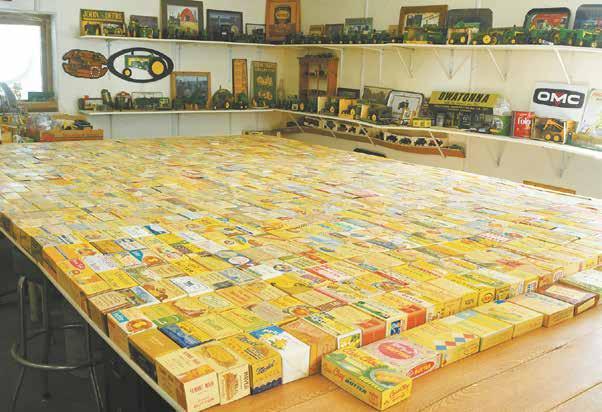

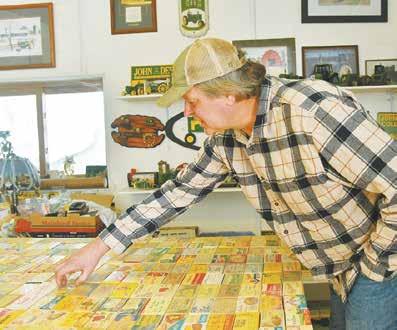

Ninety-six square feet of table-top real estate holds about two-thirds of Scott Krause’s butter box collection. The 8by 12- foot table space holds about 980 boxes.

And yes, these are butter boxes, the small, branded cardboard containers which hold four sticks of buttery deliciousness.

“It’s an addiction,” Krause said. “If I drank beer as much as I collect butter boxes, I’d be alcoholic.”

Though he has never counted his full collection, Krause believes it numbers around 1,500 boxes, of which about 1,000 are unique.

“It’s a rush when you nd one that you don’t have,” Krause said.

Krause and his dad, Loren, milked around 100-120 cows until 2021. Now, Krause raises beef and dairy animals.

His butter box collection spans about 100 years of butter boxes. His earliest boxes are from the 1920s, he said, and a few familiar boxes from the current decade also grace

his collection. Most boxes are from the 1950s and 1960s.

“That was a time when a lot of those creameries (were) a center point of most little communities,” Krause said.

Krause’s collection has boxes representing creameries largely from Minnesota, Wisconsin, Iowa, South Dakota and North Dakota and a few from Michigan, Pennsylvania, Nebraska and Wyoming. Many of his boxes are from creameries that once existed in southeast Minnesota.

“I like to get the ones that are more local,” Krause said. “It’s always fun just nding one that you never had or found.”

Several of his favorite butter boxes include Moose Lake Special Creamery, Lakeland Creamery and Mountain Lake Creamery, each of which has an outdoor scene with a lake depicted on the front of the box. Another favorite box is the Ewald Bros. butter box. This box features a Guernsey cow on the front. The Krause’s milked predominantly Guernseys until the 1980s when they began switching to Holsteins and some Jerseys.

Krause’s collection is not displayed yet. He hopes to eventually get the boxes un-

der glass in alphabetical order by county. Krause nds the butter

boxes at antique stores, swap meets, online auctions, Facebook Marketplace and more. Everywhere he goes he gives out his number to vendors, asking them to call him if they get a box.

“Every couple of months you nd a different one,” Krause said. “Sometimes, you go for a long time and do not nd any, but I’m always on the lookout.”

If he has time on the weekends, he goes hunting at antique stores.

“It’s fun to do,” Krause said. “When I go somewhere, I just get excited, like, am I going to nd one or not?”

Local towns’ history centers can also be helpful when it comes to knowing what creameries existed, Krause said. Krause also watches for old creamery buildings in the countryside when he and his dad go for drives.

While prices vary, Krause said the most he has ever spent on a box in his collection is about $70.

“I like to go to the swap meets because those guys you can work with,” Krause said. “If they want to get rid of it … you can give them an offer and they’ll usually take it.”

APRIL 1 THROUGH APRIL 30 AT

Krause said once he got caught up in an online auction bidding on boxes and the price went to $600. He decided he had to quit and did not get the boxes. A few months later, he found the same box designs for less.

If a box is selling cheaply, he will buy a duplicate that he can trade or sell with someone else if he wants to.

Krause said he has only been scammed once, and that was on Facebook Marketplace.

“They got my money and I didn’t get the boxes,” Krause said. “There’s a crook in every business, even butter boxes.”

Krause started collecting about 20 years ago. He was rst introduced to the hobby by a dairy eld representative who came to the farm. Krause said the eld representative would show him whenever he found a butter box.

“I never dreamed back in those days I’d be doing this,” Krause said.

Krause knows a few other people who collect butter boxes. He is part of a group with a Facebook page dedicated to butter box collecting. He said his parents’ generation had a different mentality when it came to saving things.

“Everyone else thinks it’s junk and they throw it out,”

Krause said. “There’s probably a lot of butter boxes that were in someone’s attic that just got tossed.”

Besides butter boxes, Krause has a small collection of cardboard containers from other dairy products. He also collects John Deere farm toys and has a collection of about 1,500 beer cans.

“It’s always fun, just the challenge to nd another one,” he said.

Looking to the future,

Krause hopes to collect for as long as he can.

“Maybe I’m too old fashioned, but … I like doing it,” he said.

Eventually, he said he is thinking about donating the collection to the Minnesota State Fair for permanent display. He would like to have them in the dairy building near the Princess Kay of the Milky Way butter sculpting booth.

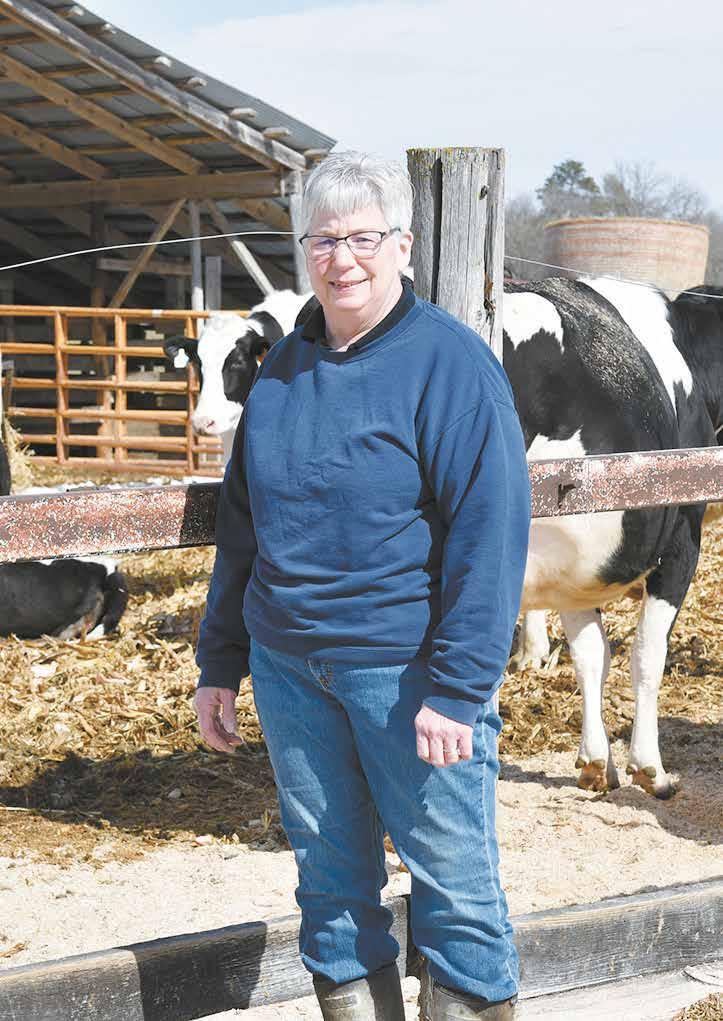

“The pregnancy report is very useful.”

What are some of the DHIA tests you use?

Other than the standard reports, we also receive pregnancy results.

Which is your favorite and why? The pregnancy report is very useful to keep our calving interval where we would like it.

How do you use them within your dairy? We use the production and SCC reports for culling decisions and use the fat, protein, and MUN reports to evaluate feed ration changes.

How long have you been using the DHIA pregnancy test? We have been using the milk pregnancy test for about two years.

What do you like about the DHIA Pregnancy Tests? It’s nice to be able to do the pregnancy test without any extra time or labor.

How does testing with DHIA bene t your dairy operation? We also use the individual somatic cell count scores. This helps us keep our SCC low so that we can receive quality premiums from our co-op.

Tell us about your farm. We milk 95 cows and raise all of our replacements. The cows are housed in sand bedded freestalls and milked in a double 5 parlor. We also have a 40-cow beef herd and raise chickens for Pilgrims Pride. Our farm was started by my father and grandfather in 1937. Two of our children and most of the grandkids work on the farm.

On March 6, President Trump announced a 30-day pause on all tariffs to Canada and Mexico. A day later, Trump made another change in the tariff policy. “Canada has been ripping us off for years on lumber and dairy products; 250% (tariff on dairy products), nobody ever talks about that, which is taking advantage of our farmers.” Trump promised to retaliate with new tariffs coming in a matter of days.

International Dairy Foods Association response

The International Dairy Foods Association released a statement in response to President Trump’s criticism of Canadian dairy tariffs. “It is accurate that Canada imposes a tariff of approximately 250% on U.S. exports of certain dairy products from Canada, and even more with Canada’s 25% retaliatory tariffs in place,” said Becky Rasdall Vargas, senior vice president, IDFA. However, that tariff would only apply if U.S. dairy exports exceed the parameters of the U.S.-Mexico-Canada Agreement. Due to protectionist policies in Canada, the U.S. has not gotten close to those quota levels. Rasdall Vargas said the U.S. dairy industry appreciates the Trump administration’s efforts. “At the same time, a prolonged tariff war with our top trading partners will continue to create uncertainly and additional costs for American dairy farmers, processors, and our rural communities. We urge Canada and the United States to negotiate a resolution to these issues.”

The letter was sent by Minnesota Sen. Amy Klobuchar, Wisconsin Sen. Tammy Baldwin, Kansas Sen. Roger Marshall and Iowa Sen. Joni Ernst

Policy experts seek better safety net for farmers

By Don Wick Columnist

At the National Farmers Union Convention, agricultural policy leaders addressed key farm policy challenges, including legislative uncertainty in Washington. “I think right now, the easiest way to describe Capitol Hill is a bit chaotic,” said Brad Weddelman, majority chief economist, Senate Agriculture Committee. “There’s a lot going on with a new administration, new chairman.” Despite the turbulence, Weddelman stressed that Chairman John Boozman remains focused on passing a 5-year farm bill with a stronger safety net. “He’s preached that over and over again. That is his goal for this year,” he said. The conversation also centered on improving disaster assistance programs for farmers. Harlea Hoelscher, a professional staffer for the House Ag Committee, outlined House farm bill provisions aimed at strengthening relief efforts. “Chairman (Glenn ‘GT’) Thompson followed the principle of how we can bolster the programs that we already have and make them work better for producers.”

Waters of the U.S. guidance updated

Lawmakers seek fairness in trade

A bipartisan group of senators is calling for fairness for dairy farmers in any trade talks with Canada. The lawmakers sent a letter to the agriculture secretary, commerce secretary and U.S. trade representative, saying Canada has hurt U.S. dairy prices by selling dairy products worldwide at articially low prices. The letter said, “Historically, Canada has failed to live up to its commitments to provide access to its market.” The lawmakers also contend Canada appears to be evading USMCA rules and is exporting protein at articially low prices.

The Waters of the United States rule is getting another revision. Environmental Protection Agency Administrator Lee Zeldin said this change will stand the test of time. “We are not looking for this to be ping pong anymore; what we’re looking for is to simply follow the guidance from Sackett (Supreme Court ruling),” Zeldin said. “It gave us a clear path in determining the waters of the United States. It found only those wetlands with a ‘continuous surface connection to a relatively permanent water’ are Waters of the United States. The court also struck down the long-utilized signicant nexus test, leaving only

those wetlands that abut or are adjacent to waters of the United States as jurisdictional.” Zeldin said his agency will work with the U.S. Army Corps of Engineers to cut permitting costs and reduce red tape. American Farm Bureau Federation President Zippy Duvall was part of the announcement and said WOTUS has been a pain in the side for farmers; “This is a rst big step in a very difcult farm economy that gives farmers and ranchers hope, hope that good things are going to happen in the future.”

Make America Healthy Again Commission meets

The Trump Administration’s Make America Healthy Again Commission met for the rst time. Health and Human Services Secretary Robert F. Kennedy Jr. and Agriculture

Secretary Brooke Rollins said they are committed to a holistic process to improve the federal dietary guidelines. Rollins said these guidelines will be based on sound science and released ahead of its Dec. 31 deadline.

Testing underway in Minnesota dairy herds

Minnesota is in the third week of testing its dairy herds for highly pathogenic avian inuenza. “We’ve tested over 400 farms and had no positive cases,” reports Agriculture Commissioner Thom Petersen. “We also haven’t had a positive case in poultry for a couple of weeks.” Petersen said another week of testing is needed before the next phase can begin. “We’re optimistic that will happen; we’re continuing to urge farmers to follow biosecurity measures and to keep their guard up.”

Bill introduced to support processing

State Senator Andrew Lang of Olivia has introduced a bill to appropriate funding to support Minnesota’s milk and meat processing sectors. “By investing in our processing facilities, we not only support our local farmers and producers but also ensure that Minnesotans have access to highquality, locally produced food products,” Lang said.

March supply and demand estimates released

According to the U.S. Department of Agriculture’s latest supply and demand report, 2025 milk production estimates were lowered to 226.2 billion pounds. Lower-than-expected milk output per cow was cited as the reason. The Class III price forecast was lowered with a drop expected in cheese and whey values in the year ahead.

Export assistance program gets a name change

The National Milk Producers Federation board of directors has voted to change the name of its voluntary dairy export assistance program. Cooperatives Working Together was created in 2003 with dairy co-ops and individual producers contributing to this program. The new name of this program will be NEXT, which stands for NMPF Exports and Trade. A new business plan for the successor organization will be up for nal approval in June.

Danish dairy co-op to partner with South Dakota rm

Arla Foods plans to produce whey protein for the food and beverage industry through a partnership with Milbank, South Dakota-based Valley Queen. Arla Foods is one of the largest dairy cooperatives worldwide and is based in Denmark.

Trivia challenge

Texas is the home state for Agriculture Secretary Brooke Rollins That answers our last trivia question. For this week’s trivia, what country consumes the most cheese on a percapita basis? We’ll have the answer in our next edition of the Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

We are sourcing

nd those hard to nd items including:

• Electric motors

• Fan parts (blades, bearings, belts and pulleys)

• Gearboxes

• Submersible pumps

• PPE - hoof trimming and maintenance

• Camlock fittings

• Hose & Tubing

• Push to connect fittings

• Air compressors

• Waterer parts

• Parlor items

Scan the QR codes to find our pages or follow us @dairy_star_newspaper

USED TRACTORS

Midsota wagons ON HAND!

CIH 8910, 1955 hrs., 2WD, like new$105,000

CIH 7120, 2WD, 5800 hrs. ................$55,000

CIH 7120, 2WD, 4,900 hrs. ...............$55,000

CIH 7120, 2WD, 6,100 hrs. ............Coming In

CIH 7110, 2WD, 4500 hrs..................$63,000

CIH 5250 2WD, 4,700 hrs. .............. $54,000

CIH MX120, 2WD, 3,800 hrs. ............$72,000

CIH MX120 w/loader ........................$75,000

CIH MX100, 2WD, open station w/ldr.Coming In

IH 1456, ........................................... $22,000

IH 1466, 6800 one-owner hrs ............$21,000

IH 1086, 7,500 hrs. .........................Coming In

IH 686 . ..............................................$14,000

‘98 JD 7610, 19 spd., PS, 5,500 hrs., 25 MPH, very sharp ....................... $75,000 McCormick MC120 FWA, 2,600 hrs ..$57,000

TILLAGE

CIH Tigermate II, 26’..........................$28,000

CIH Tigermate II 26’ w/rolling basket $32,000

CIH Tigermate 200 w/basket, 34’ ..... $42,500

CIH Tigermate 200, 28’ w/rolling basket ...............................$40,000

CIH Tigermate 200 28’ w/basket ...... $37,000

CIH 3950 disc, 23’, non-cushion.....Coming In

CIH RMX340 25’, 3-bar harrow ......Coming In

Tigermate 200 28’ w/rolling basket ....$31,000

DMI Tigermate II, 26.5’, 3-bar mulcher ..................................$14,000

CIH RMX 340, 28’ w/mulcher ........... $35,000

CIH RMX 340, 25’...........................Coming In

CIH 530C Ripper, nice ......................$31,000

By Stacey Smart stacey.s@dairystar.com

MARSHFIELD, Wis. — Ammonia is a major component of dairy manure susceptible to being lost to the atmosphere during spreading. Injecting manure in the soil versus applying it on top of the soil is proven effective for retaining ammonia and preventing its escape into the environment.

Using low disturbance injection to reduce ammonia losses in dairy manure has been a focus of research for the U.S. Department of Agriculture’s U.S. Dairy Forage Research Center. A key area of scientists’ work at the University of Wisconsin’s Marsheld Agricultural Research Station was to examine low disturbance manure application, especially in hay elds, versus the traditional approach of broadcasting manure on the surface without incorporating it into the soil.

Eric Young is a research soil scientist in the Environmentally Integrated Dairy Management Manure Management unit with the U.S. Dairy Forage Research Center. Before he came on board in 2018, his predecessors looked at shallow disc injection and using an aerator to poke holes in the soil with the idea of increasing inltration of the manure.

“This gives liquid manure a place to go and get under the surface,” Young said. “It showed quite a bit of promise, particularly shallow disc injection where a large disc creates a crease or slot in the

A shallow disk injec on tool injects manure into a hay eld at the Marsheld Agricultural Research Sta on in Stra ord, Wisconsin. This form of low disturbance manure applica on uses a large disc to create a crease or slot in the soil where manure is placed and then covered back up to increase inltra on.

soil where manure is placed and then covered back up. There are a whole bunch of companies that make these products now.”

Young said using low disturbance injection to reduce ammonia losses from liquid dairy manure reduces and minimizes tillage where possible, so the soil will not be disrupted or erosion increased.

“The ultimate in low disturbance is no till – using coulters or discs to open and close the soil,” Young said. “Low disturbance manure injection gets manure under the surface of the soil, which

reduces that ammonia loss. Ammonia is very volatile. We’re really limited in terms of trying to capture that ammonia unless we do some kind of physical disturbance to the soil.”

Approximately half of the total nitrogen found in liquid dairy manure is in the ammonia end form, Young said.

Research at the Marsheld farm showed immediate incorporation of manure into the soil can create a reduction in ammonia losses of around 90-95% compared to broadcasting manure on the surface.

Stjernholm sand separator now available through Midwest dealerships

A new partnership is bringing high-quality sand separation to the doorsteps of U.S. dairy farmers. Originating in Denmark, Stjernholm technology can now be found close to home through a full-circle approach that includes dealerships in Wisconsin and Minnesota working alongside a local distributor, Dairy Nutrient Reclamation. Providing three layers of quality to ensure a seamless experience, farmers will enjoy quick service with local boots on the ground.

The Stjernholm sand separating system provides quality sand bedding for maximum cow comfort, recycling at levels exceeding 90% retention. The tailor-made systems have the smallest footprint on the market. Currently, 12 systems are installed in the U.S. with 10 more to come this year.

Through this new partnership, you will have the backing of a trifecta of knowledge, service and experience accentuated by farmer-to-farmer interaction. Trillium Hill Farm is working with Dairy Nutrient Reclamation in showcasing its own Stjernholm system. See the system in action on a farm reclaiming 98-99% of its sand.

“We are here for the farmers,” said Mike Jones of Trillium Hill Farm. “Through this unique setup, we are engaged with customers from day one.”

“This level would be achieved with plow tilling,” Young said. “For example, a farm could apply liquid manure in the spring when ready to plant corn and come back through with a disc or chisel plow to incorporate manure into the soil. You see a little less reduction in ammonia loss when using no-tillage tools.”

Young said a shallow disc produces decent results above 90% reduction in ammonia loss, whereas an aerator-band system would be less effective, reducing ammonia loss by two-thirds to threequarters. Both units can be used in hay elds or corn elds.

“A shallow disk injection unit more effectively reduces ammonia and other soluble nutrient losses in runoff than an aerator-band unit,” Young said. “The aerator doesn’t quite get it in the soil as effectively.”

In addition to ammonia capture, Young said another benet of these systems pertains to water quality and runoff.

“By mixing that manure into the soil, it’s less vulnerable to runoff during rain events and snowmelt losses,” he said. “If manure is broadcast on a corn eld or hay eld versus being incorporated into the soil, it sits on the surface and is much more vulnerable to being lost in surface runoff.”

At the Midwest Manure Summit Feb. 26 in Green Bay, Dr. Horacio AguirreVillegas, a scientist at the University of Wisconsin-Madison, shared results from a study on ammonia emissions from conventional, organic and grazing dairy farms. During his presentation, AguirreVillegas highlighted how the farms’ unique management practices impacted how much ammonia was emitted.

–Stjernholm technology, farm distributor and dealer –here

Thirteen dairy farms were modeled: ve conventional, ve organic and three grazing. Farms ranged in size from 501,000 lactating cows and maintenance animals. Aguirre-Villegas said diet composition determines the nutrients in excreted manure.

“Organic and grazing dairies feed more pasture and forages which have more crude protein and nitrogen in the diet,” he said. “Higher crude protein results in higher nitrogen excretion that has a potential to be emitted as ammonia throughout manure storage and land application. During the grazing season, manure is excreted on the pasture in small pockets, creating high concentrations of nitrogen, which might not all be utilized by growing pastures as opposed to a controlled application of manure on growing crops when manure is stored and land applied.”

The study revealed farm size does not signicantly affect results when expressed per excreted manure. Despite a reduced surface area exposed to wind because it is stacked, solid manure has higher ammonia levels than other forms of manure due to its higher pH, which is one of the main drivers of ammonia emissions, Aguirre-Villegas said. When looking at storage, the average pH was 7.4 for liquid manure, 7.8 for slurry, and 8.5 for solid manure.

Liquid manure or slurry, which has less total solids, has higher inltration rates into the soil, and therefore reduced ammonia emissions from land application. Barns have the lowest ammonia emissions when compared to stoarge and land application, except for two organic farms with bedded packs, as those create ideal conditions for ammonia to be emitted.

“Higher temperatures create more opportunity for ammonia to be lost,” Aguirre-Villegas said.

The study revealed that the top practices for reducing ammonia emissions

were solid liquid separation and injection, which reduced ammonia loss by about 40%. Injection alone lowered ammonia loss by 30%. Reducing crude protein in the diet reduced ammonia loss by more than 20% as did a combination of anaerobic digestion, solid liquid separation and injection. However, anaerobic digestion and solid liquid separation without injection could increase ammonia emissions Aguirre-Villegas found if proper management is not applied. Furthermore, he found compost increases ammonia emissions by 25% from high temperatures and aeration caused by turning the compost.

Research conducted at the UWMarsheld Agricultural Research Station is aligned with the Ruminant Farm Systems model for testing and validating best practices, such as manure incorporation and crop rotation on nutrient losses. This whole-farm simulation model is designed to simulate all major nutrient ows on a dairy farm, including manure generation and nutrients in manure, as well as milk production. Young’s role in its development includes soil and water module aspects.

“We’re honing in on crop production, fertilizer, manure, runoff and nutrient cycling in the eld,” he said. “A lot of our work up at the station is designed to help test that model by applying different types and rates of manure. The model will take this into account and provide recommendations.”

For example, if a farm has 100 acres and applied X amount of manure to a eld that has been in corn for three years in well-drained soil with a certain pH, the RuFaS model will calculate nitrogen recommendations based on those inputs.

“You can look at these cascading levels across the whole farm and change different variables and test different scenarios,” Young said.

The RuFaS model is still in development and will be free for all to access once available.

Joel

Groetsch Sauk Centre, Minnesota

Stearns County 120 cows

Tell us about a recent vacation you took. We are leaving in a couple weeks for Cabo, which is on the west side of Mexico. Usually, we go to the east of Mexico but decided to change it up this year.

What made you decide a vacation was in order? For my wife and I, it is a de-stressor. You go to relax and unwind so you can come back refreshed and ready to go. I farm with my brother; every January, he goes on a trip with his wife, and every February, I go on a trip with my wife.

What logistics did you work through in order to leave the farm? I farm with my brother, Josh, and between him, his kids and my kids, it is not too difcult since we have robots. We line it up so the kids get up with Josh in the morning; then, they can drive to school. It really helps that we have each other to balance out chores when ei-ther one of us wants to leave so we don’t have to hire anybody extra. The kids help out on the farm enough to understand what to do.

Tell us about your best vacation. Jamacia. It was a smaller, all-inclusive hotel that had a pool bar and a nice beach. It was small enough that we got to know the other people at the hotel. I liked it because we didn’t have to walk as far to get to the beach and got to know the other people. Also, there were a lot of farmers from the U.S. there.

What is the return on investment, for you personally, when you take a vacation? I think everybody needs to get away to have some downtime to appreciate what you have. You feel so much better when you get back. It gives you something to look for-ward to instead of the same routine every day.

If you could take a trip anywhere in the world, where would you go? It depends on how long I could get away. If I could, I would go all over Europe, and not the tourist places. I want to experience the rural areas to get to know the agriculture and the communities. I would also like to go to Japan someday; it is something different.

Tell us about your farm. I farm with my brother, Josh, and we milk 120 cows with two Lely milking robots. I have three boys, and he has two boys who help on the farm, too. We are the second generation on our farm. We farm 800 acres of corn, soybeans and alfalfa.

Josh Kraska

Pine Grove Dairy

Swanville, Minnesota

Morrison County

70 cows

Tell us about a recent vacation you took. Last fall, I went elk hunting in Colorado. I was there for a week with two of my brothers and a nephew. We rode horses seven miles out to a camp, then stayed at that camp for a week. It was really fun.

What made you decide a vacation was in order? My brothers and I do a hunting trip every fall. We go to Colorado, Wyoming or Montana every year. What logistics did you work through in order to leave the farm? I farm with my brother, Dan, and we are partners at the dairy. We take turns going on vacation so we can both get time off. It makes it so much easier to get away because one of us will always be here to take care of things.

Tell us about your best vacation. One winter, we took a 2-week family vacation to Florida. We drove and spent time in St. Lois, Fort Meyers and Orlando and swam in the ocean. We did Universal Studios in Orlando. My in-laws spend the winter in Fort Meyers, so, we spent some time with them. We went in the winter because it is easier to get away for an extended amount of time.

What is the return on investment, for you personally, when you take a vacation? Rest, recharge, refresh. It’s also good for the kids. We made a lot of memories on the Florida trip and had good family bonding.

If you could take a trip anywhere in the world, where would you go? I would take my wife to Europe. I don’t have a specic place in mind, but we have that in the back of our minds.

Tell us about your farm. I farm with my brother, Dan, and we milk 70 cows in a stanchion barn. We farm about 800 acres of corn, soybeans and alfalfa. We are the third generation on our farm. Our wives work off the farm, but my two sons help with chores now. We ship our milk to Bongards.

Troy Colsrud Finlayson, Minnesota Pine County 70 cows

Tell us about a recent vacation you took. My wife and I went to New Mexico to visit her parents. We visited family and took a hot air balloon ride.

What made you decide a vacation was in order? My wife and kids wanted to see their parents and grandparents. Winter is a nice time to get away to feel some warmer weather.

What logistics did you work through in order to leave the farm? I had my oldest son come home to take care of the feeding, and my other two boys, a junior and senior in high school, took care of the milkings.

Tell us about your best vacation. Alaska. We went salmon shing and did the Alaska Grand Circle. That was a scenic highway drive from Tok to Fairbanks, Gateway and back again. It is more than 1,000 miles but is very scenic and shows the diversity of Alaska. Totally worth it.

What is the return on investment, for you personally, when you take a vacation? Coming back relaxed and refreshed. I can’t sleep in while on vacation, but it is still a good time to recharge and relax.

If you could take a trip anywhere in the world, where would you go? Australia. Just to see what the country, culture, agriculture and people are like. It sounds so different than here. I’m curious what their setups are like.

Tell us about your farm. I farm with my wife, Vicki, and kids, Jake, Justin, Loren and Joe. We milk 70 cows in a step-up parlor. I am the second generation on this farm. We raise all our own crops of corn and alfalfa and our own replacements. We plan to put up a new shop this year on our farm.

Tom Gregory Mill Creek Dairy Kimball, Minnesota Stearns County 650 cows

Tell us about a recent vacation you took. In recent years, my vacations have been conventions through the Soil and Water Conservation District. They usually last three days. This consists of a type of in-service where a facilitator picks your brain. I am a Stearns County supervisor, and there are many issues we contend with. These conventions give us a lot of opportunities to network with other SWCDs and discuss various issues.

What made you decide a vacation was in order? This happens every year in early December. It’s the time of the year when the real farm workload is over, and it’s a nice time to get away.

What logistics did you work through in order to leave the farm? I come and go often. I am 70 years old. We have lots of help; I can do most things ahead of time, and my son or brother can cover my regular duties for me.

Tell us about your best vacation. My best vacation occurred when my daughter was completing college. We were nishing work on a new barn, and she called me to see if I wanted to go to Australia. She had gotten a good deal for tickets. I said yes, and we quickly harvested the fourth crop of alfalfa. When we left, we ew to California, then to Fiji for a couple of days, and then, nally, Australia.

Rick Balzer

Balzer Family Dairy LLC

Owatonna, Minnesota

Steele County

140 cows total herd

Tell us about a recent vacation you took. We went to Aruba this winter. This is the 10th year we have been going there. We go to the same resort — we always rent somebody else’s timeshare. We relax in the sun, but not too much because the sun is pretty intense, so we nd a palapa to sit under and we both usually read a book. For me, it’s the only time I truly read a whole book. We also wade through the pool and meet new people. This year we met a man from Toronto, Canada. We sang karaoke to “Friends in Low Places” by Garth Brooks. (I did not know that I could sing so well — not.) We also hang out with old friends and play bingo and dance.

What made you decide a vacation was in order? In the beginning, it was a nice reset to life. Now, we look forward to going.

What logistics did you work through in order to leave the farm? In the beginning, our sons were still at home, and we went when they had winter college break. My dad was still helping with chores so we could get away. If not for our sons and my dad, it might not have been possible to go.

Fiji was like taking a 40-year step back in time. We hired a tour guide who took us all over. He dropped us in a village, and we mingled with the village people. Fiji was so far behind our time they harvested sugarcane by hand with machetes. The people were very kind, and they had very little.

Then, we were off to Australia. Every night, we came back to the hostel and talked to the people there. They had traveled from all over the world and were from different backgrounds, but we could easily share stories and humor. At night, we would also plan our trip for the next day. Snorkeling the Great Barrier Reef was incredible, and we did twice. White water rafting was also great and so was crossing the Great Divide. We traveled to the Outback. We toured a dairy farm, it was very interesting; he had 300 cows and did all grazing. He had a little dingy building where he milked his cows. We saw 20 kangaroos in a group, and we stopped and took a ton of pictures. We were really excited

What is the return on investment, for you personally, when you take a vacation? It’s a change in perspective. You think of your operation differently, and you think about how you can make your business more productive.

If you could take a trip anywhere in the world, where would you go? New Zealand. The people I’ve talked with and the reading I’ve done makes it sound like a very interesting place to visit.

Tell us about your farm. Mill Creek Dairy was built in 1997 and started with 250 cows milked in a double-8 parlor. When we grew to 300, we expanded to a double-12 parlor. In 2012, we increased our cattle numbers again, up to 550. Now we have around 650 cows. We milk all the cows on one site, but we do have four sites where we have young stock and cattle. We have around 15 employees, full time and part time. We crop around 1,200 acres, which is a combination of rented and owned land. Our crops are corn and alfalfa.

Tell us about your best vacation. One of many was going to national peddle pull in Omaha, Nebraska. Our oldest son won state and so we could take him to nationals. We all went: my wife, the four boys and me. From Omaha, we went up to the Black Hills, South Dakota. The Black Hills are special because that’s where my wife and I spent our honeymoon.

What is the return on investment, for you personally, when you take a vacation? It’s just a good reset and chance to visit with old and new friends. It is an opportunity to see how other parts of the country are doing. As I mentioned, we have met people from Canada, Philadelphia, Connecticut, North Carolina, Miami and upper New York.

If you could take a trip anywhere in the world, where would you go? If we could go anywhere in the world, we would maybe go to Germany. Medford School has had foreign exchange students, and there was a young lady in our son’s class we got to know pretty well and she had been out to our farm. She had been learning how to drive, so I was teaching her how to drive our Ford Ranger stick shift. It was quite a challenge, but she got it eventually. Over the years, she has come back to visit, so it would be nice to go visit her.

Tell us about your farm. We farm 500 acres of corn, soybeans, alfalfa and oats. The 120 milking cows are milked in two robotic milking units. We raise all of our heifers and nish out our steers.

Five ladies (from left) April Klaphake, the daughter of Mark and Jennifer of Sauk Centre, Haddie Walter, the daughter of David and Cathy of Sauk Centre, Jaiden Smith, the daughter of Jeremy and Emily of Melrose, Bella Schiffler, the daughter of John and Kristie of Albany, and Daisy Zimmermann, the daughter of Mike and Lori Zimmermann of Sauk Centre were crowned Stearns County dairy princesses March 15 at the Freeport Community Center in Freeport, Minnesota. Klaphake and Walter won the Stearns County ADA scholarships and Ava Smith, the daughter of Jeremy and Emily Smith, was named miss congeniality. Ambassadors are Chloe Hoppe, the daughter of Travis Hoppe and Amy Hoppe of Albany, Megan Frieler, the daughter of Duane and Amy Frieler of Greenwald and Ava Smith.

With DeLaval VMS V300, it all revolves around you, which is why we have developed the V300 to be the world’s most exible milking robot–so that it works for you and not the other way around. Whether your operation is small or large, the VMS V300 can help you farm your way.

How many times a day do you milk, and what is your current herd average, butterfat and protein? We milk twice per day. Our rolling herd average is 30,214 pounds of milk, 1,313 pounds of butterfat and 992 pounds of protein, with component tests of 4.5% butterfat and 3.3% protein.

Describe your housing and milking facility. Fresh cows and cows that need extra attention are housed in deep-bedded sand stalls in a barn with the dry cows. The rest of the milk cows, which is the majority of the herd, are housed in a freestall barn with waterbeds and bedded with chopped straw. Cows are milked in a double-8 parallel parlor in the old tie stall barn.

Who is part of your farm team, and what are their roles? Our farm team consists of three owners who manage and run the day-to-day operations. There are two full-time and two part-time employees who help cover the milking shifts. There are six other parttime people who help, mostly family members who help with feeding calves and other jobs where needed.

What is your herd health program? Pregnancy checks are done every two weeks

by our vet using ultrasound. Typically, we meet every two weeks with our nutritionist to go over animal performance and any adjustments that need to be made on any diets. We discuss any concerns and ideas with both our veterinarian and nutritionist to best position our cattle to perform their best. Vaccination protocol on heif-

ers includes giving Alpha-7/ MB-1 and Bovi-Shield Gold FP 5 L5 before breeding, along with a de-wormer. Vaccination protocol on cows includes giving Bovi-Shield Gold FP 5 L5 at 30 days in milk and a Vaxxon SRP Salmonella vaccine and Alpha-7/MB-1 at dry off. Cows also receive a de-wormer twice per year. All cows are

dried off using Quartermaster and a teat sealant.

What does your dry cow and transition program consist of? Dry period is 60 days for rst lactation and 50 days for all older cows. We have a group of dry cows that is housed on a bedded pack, using either corn stalks or straw.

The dry cow ration is made up of corn silage, grass hay and a mineral/protein mix. Cows that calve are put into the fresh cow pen on day one.

Hoard’s Dairyman article Jan 2025: Staph aureus is a subclinical threat. “Mastitis can be caused by many pathogens, but if you ask any dairy veterinarian or farmer which is the most damaging, the odds are good that their response will be Staphylococcus aureus.” “Staph. aureus is especially dangerous because it persistently infects cows.”

Dr. Justine Britten, Pres. Udder Health Systems, NMC board: “In my personal experience, every dairy is impacted to some degree by Staph. aureus,” and “If Staph. [aureus] was easier to see, farmers would be a lot less tolerant of it.” {Translation – you don’t pay attention to the problem so they will test your milk samples}

Cornell University in Journal of Dairy Science: CoPulsation™ prevents new Staph a. infections by 16:1 YOUR MILKING SYSTEM IS RESPONSIBLE FOR THE PROBLEM! TridentPulsation™ System

607-849-3880 • 607-352-0053 Trident@TridentPulsation.com

Cow comfort is more important than ever in today’s times of tight milk margins and reduced numbers of dairy replacement cattle. Protect your cattle investments and capitalize on them. Help your herd reach its genetic potential with fresh starts that pay back dividends. Nothing impacts cash flow like problem-free lactations and smooth heifer transitions. Got fresh cows? Get Comfort... with Udder Comfort!TM

“Soft, comfortable udders that milk out quickly and completely have a big impact on milk quality and performance,” says Erik Hagedoorn, managing one of two Bos Dairies locations near Lovington, N.M., milking 5400 Jersey cross cattle, calving over 30 a day.

“We rely on Udder Comfort for routine use in our hospital groups and for our fresh cows at the start of lactation.

“When outdoor conditions decline, we increase our preventive use. It works like a charm,” Erik adds. At Beer Cattle Co., Berne, Ind., 250 heifers calve-in monthly.

“We use Udder Comfort after each milking for 5 to 7 days after calving to remove swelling. This gets udders softer, faster, for more milk,” says Keith Beer. “We saw better first-lactation performance in our 2-year-olds with a 3 to 4 pound production increase at 14 DIM, and a reduced SCC for the group. We love how easy it is to do this in the parlor,” he adds.

time, money,

What is the composition of your ration, and how has that changed in recent years? Our milk cow diet consists of corn silage, haylage, ground corn and a protein mix. The ration is usually between 58%-60% forage. This has been a very similar diet we have been using for many years, aside from recently removing cottonseed. Over the past couple of years, we have been and currently are experimenting with a cocktail mix consisting of grasses and clovers and how it might t into our cow diets. There are multiple reasons behind looking into this, with a main focus on improving cow health and soil health.

Tell us about the forages you plant and detail your harvest strategies. We grow all of our own forages and grain corn. Corn silage varieties are picked with a focus on digestibility. Alfalfa is harvested four times, sometimes ve times per year, with 28-32 days between cuttings. On alfalfa, our goal is to have a relative feed quality of 150-190. All forages are harvested by a custom chopping crew.

What is your average somatic cell count and how does that affect your production?

Average SCC is 120,000. We installed waterbeds one year ago and have seen how much more comfortable the cows are compared to the old mats we used. We have just installed a Lely Discovery Collector, and we hope this will help lower

farm near Winona, Minnesota. The Prigges said they hope this will lower soma c cell among other things.

SCC as well as result in fewer cases of mastitis and ultimately lead to healthier cows.

What change has created the biggest improvement in your herd average? The biggest change was putting more focus on putting up higher quality forages and working with our nutritionist to feed for higher levels of production. Although this is what we believe to be the biggest contributing factor to a higher herd average, it still all starts with teamwork and

communication between everyone on the farm.

What technology do you use to monitor your herd? We don’t have any technology directly tied to the cows. We use Dairy Herd Improvement Association testing to help make management decisions on cows along with DairyComp for cattle records. We have a robotic feed pusher and, recently, a robotic manure collector. We have looked into different monitoring systems

for the cows but haven’t committed to anything at this time.

What is your breeding program, and what role does genetics play in your production level? We start breeding heifers at 13 months. All cows are on a double ovsynch program for their rst breeding, with average days in milk at rst breeding being 80 days. We breed with sexed dairy semen and beef semen. We started genomic testing heifers in 2020 and use sexed dairy

semen on our highest genomic testing heifers and cows and the rest get beef. We focus on health traits and components when picking bulls. We have had fewer health-related issues and have continued seeing higher components in rst lactation heifers since we started genomic testing.

List three management strategies that have helped you attain your production and component level. One: communication between everyone involved with the day-to-day chores to outside labor, like the vet and nutritionist. Two: being able to adapt our thinking when facing challenges and having the willingness to embrace change. Three: being open-minded to new ideas, being open to thinking outsidethe-box and always having the desire to learn something new.

Tell us about your farm and your plans for the dairy in the next year. We are the second and third generations on our dairy and have been milking cows at our current location since 1972. We raise all of our own heifers and feed out all beef crosses to nish. We grow all of our own crops. We have no major plans for the coming year other than the robotic manure collector which was just recently installed. It all starts and ends with giving all the glory to God and having the opportunity to do what we love in caring for the land and cattle.

JD S780 2023, 490 hrs., 358 Sep hrs.,PRWD, Duals, #572927

S780 2023, 605 hrs., 318 Sep hrs., PRWD, Duals, #573365

S780 2021, 1233 hrs., 925 Sep hrs., PRWD, Duals, #588551 .............. $329,900

JD S790 2023, 691 hrs., 390 Sep hrs., PRWD, Duals, #573286 ................ $519,900

JD 2680H 2021, 35 ft.,

JD DB60 2017, 13900 Est. Acres, 24 row, 30” spacing ,

JD DB60 2015, 39666 Est. Acres, 24 row, 30” spacing, #566673

JD DB60 2013, 31093 Est. Acres, 24 row, 30” spacing, #578708

JD DB60 2010, 24 row, 30” spacing, #569759.........................................

JD DB66 2022, 15600 Est. Acres, 36 row, 22” spacing, #584419

JD DB66 2022, 3260 Est. Acres, 36 row, 22” spacing, #584423

JD DB66 2022, 9060 Est. Acres, 36 row, 22” spacing, #576258

JD DB66 2019, 33000 Est. Acres, 36 row, 22” spacing, #584411

JD DB66 2019, 29422 Est. Acres, 36 row, 22” spacing, #584389

JD DB80 2006, 32 row, 30” spacing , #586764 ........................................

JD DB88 2016, 40000 Est. Acres, 48 row, 22” spacing, #584456

JD DB88 2012, 60000 Est. Acres, 48 row, 22” spacing, #589832

JD 1770NT CCS 2011, 25000 Est. Acres, 24 row, 30” spacing, #590808......

JD 1770NT CCS 2007, 16 row, 30” spacing, #589399 .................................

JD 1770NT CCS 2005, 25500 Est. Acres, 16 row, 30” spacing, #592309......

JD 1775 2019, 3500 Est. Acres, 12 row, 30” spacing, #578706 ...................

JD 1775NT 2023, 1500 Est. Acres, 16 row, 30” spacing, #579850 ...........

JD 1790 2013, 18500 Est. Acres, 24 row, 20” spacing, #591922

MF 9200 2017,

Prairie Land Ag Supply Inc.

Rock Valley, IA 712-476-9290

United Dairy Systems, Inc.

West Union, IA 563-422-5355 Monticello, IA 319-465-5931 WISCONSIN Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI 715-654-5252

Ederer Dairy Supply Plain, WI 608-546-3713 DeLaval Dairy Service Kaukauna, WI 866-335-2825

Refrigeration Inc. Withee, WI 715-229-2321 Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Dairy Services Arlington, WI 608-635-0268 Redeker Dairy Equipment Brandon, WI 920-346-5579

MN 218-632-5416

Tell us about your family and farm. My husband, Ray, and I bought our farm from his parents. We raised our four kids — Roger, Amber, Joshua and Allyson — here. Allyson is farming with us now. We started with tie stalls in the barn and transformed this into a swing-8 parlor with a bedded pack barn for the cows. We raise our own replacements and calve mid-March to midNovember. We don’t have facilities for cold-weather calving.

What is a typical day like for you on the dairy? We start milking around 5 a.m. Ally and I do the milking while Ray feeds the cows. After breakfast, I clean the parlor and holding area. I do all the cooking, especially when we have eld work or harvesting help. We start milking again around 5 p.m. Afternoons are meant for lawn mowing, gardening or baking.

Tell us about your most memorable experience working on the farm. My most memorable experience has been watching our kids grow into the adults they are now. Our kids have worked and learned from grandparents who help us farm.

What have you enjoyed most about dairy farming or your tie to the dairy industry? I have enjoyed working with my husband and now working with our daughter. The other kids have helped

Cheryl Seibert Sebeka, Minnesota Wadena County 65 cows

while they lived at home. Our other daughter lives nearby and helps when we need her.

What is your biggest accomplishment in your dairy career? Raising four kids with a passion for agriculture.

What are things you do to promote your farm or the dairy industry? Since nieces and nephews all grew up coming to the farm, they now bring their families to watch milking and learn how to milk.

What advice would you give another woman in the dairy industry? Dairy cows are a 24/7 job. Take time off whenever possible, even day trips help.

What is a challenge in the dairy industry you have faced, and how did you overcome it? Milk price has been a challenge. We have put projects on hold because of low prices. As prices got better, we took on those projects. We live and farm in sand, so water retention for crops is an issue. We installed center pivots.

When you get a spare moment, what do you do? I like to read in my spare time. I grow a vegetable garden and keep our yard mowed. I like to bake. We live close to the Crow Wing River and like to canoe.

SEEDDAYSSPECIAL

Expires03/29/25 PulaskiWarehouse $5OFF

Each50lb.bagof Magna-Red RedClover (Abovevarietyonly)

MagnaRed,50lbs.....................................$149.95

MediumRed,50lbs...................................$139.95 MammothRed,(Annual)50lbs.................$129.95

AlsikeClover,50lbs...................................$149.95 YellowBlossomSweet,50lbs...................$159.95 CrimsonClover,(Annual)50lbs..................$67.95 BerseemClover,(Annual)50lbs...............$114.95 LadinoClover,50lbs..................................$229.95 WhiteDutchClover,50lbs.........................$249.95 BalansaWhiteClover50lbs......................$134.95

MISCELLANEOUS

HybridSorghum-Sudangrass,50lbs..........$43.95

BMRSorghum-Sudangrass,50lbs.............$65.95 WildGameFoodSorghum,50lbs...............$54.95 RapeSeed,50lbs........................................$59.95 JapaneseMillet,50lbs................................$49.95 PearlMillet,50lbs.......................................$94.95 SunflowerBlackOil,1lb...............................$3.95 Sunflower,GreyStripe,1lb.........................$11.99 AustrianWinterPeas,50lbs.......................$39.95 DiakonRadishes-Tillage,50lbs..................$85.95

HairyVetch,50lbs.....................................$114.95

Flax,50lbs...................................................$59.95

Buckwheat,50lbs.......................................$36.95

SEEDDAYSSPECIAL

Expires03/29/25 PulaskiWarehouse $5OFF

Each50lb.bagof Mor-Leaf Timothy (Abovevarietyonly)

Mor-LeafTimothy,50lbs...........................$105.95 ClimaxTimothy,50lbs.................................$95.95

OrchardGrass(late),50lbs.......................$139.95 OrchardGrass,50lbs................................$129.95 SmoothBromegrass,50lbs......................$159.95

ItalianRyegrass(Annual),50lbs................$59.95

TetraploidAnnualRyegrass,50lbs.............$49.95

TetraploidPerennialRyegrass,50lbs........$99.95

FestuloliumPerennialRyegrass,50lbs....$109.95 MeadowFescue50lbs..............................$129.95

TallFescue,50lbs........................................$99.95

SwitchgrassCave-In-Rock,1lb.pls...........$14.99

ReedsCanarygrass(lowalkaloid)50lbs.....$309.95

SEEDDAYSSPECIAL

Expires03/29/25 PulaskiWarehouse $10OFF

Each50lb.bagof Hay&PastureMix or$5OFF each25lb.bag

AlfalfaForageMix,50lbs..........................$179.95 AlfalfaBaseMix,50lbs.............................$169.95 CloverBaseMix,50lbs.............................$144.95 HorsePastureMix,25lbs............................$74.95 MaxForageExtenderMix,25lbs................$59.95 WildLifeCloverMix,50lbs.......................$219.95 AlloftheabovemixesaremadewithDura-LeafPlusAlfalfa, Magna-RedRedCloverandMor-LeafTimothy

Kewaunee,50lbs.........................................$20.95 Uncert.Robust,50lbs..................................$17.95

Triticale,Spring,50lbs................................$19.95

Alfalfa-Clover,Treats50lbs..........................................$8.95 Trefoil,Treats50lbs........................................................$9.95 SoybeanTerraMaxDry,Treats500lbs.-10unit.........$18.95 SoybeanTerraMaxDry,Treats2000lbs.-40unit.......$48.95 Cell-TechLiq.Soybean,Treats50units........................$93.95 ExceedDeerPlotInoculant,Treats100lbs..................$10.95 (Treatsmorethen96varietiesofseed) INOCULANTS

SEEDDAYSSPECIAL Expires03/29/25

Each50lb.bagof Athletic,Sunnyor ShadyLawnSeed

AthleticLawnMix,50lbs..........................$119.95 SunnyLawnMix,50lbs.............................$129.95

ShadyLawnMix,50lbs.............................$119.95

AnnualRyegrass,50lbs..............................$49.95 PerennialRyegrass,50lbs........................$104.95 CreepingRedFescue,50lbs.....................$119.95

KentuckyBluegrass,50lbs.......................$119.95

TurfTypeTallFescue,50lbs........................$99.95 WhiteDutchClover,50lbs.........................$249.95

Weed&Feed(Trimec)22-0-5Formula $27.99/50lb.bag.Covers12,500sq.ft. CrabgrassPreventer(Dimension)19-0-6Formula $25.99/50lb.bag.Covers12,500sq.ft

Lawn&GardenLime,50lbs..........................$3.59 PelletizedLawn&GardenLime,40lbs.........$6.99 PelletizedGypsum,40lbs..............................$9.99

Cert.Antigo,bu.-early.................................$13.50

Cert.Badger,bu.-early................................$13.50

Cert.Rushmore,bu.-mid............................$13.50

Cert.Esker2020,bu.-mid...........................$13.50 Cert.Goliath,bu-late...................................$13.50 ForagePlus,bu.-Late..................................$13.75 Uncert.Ogle,bu.-mid..................................$12.50 Uncert.Jerry,bu.-mid.................................$11.50

ForageFieldPeas,40-10,50lbs.................$22.95 50%Pea-50%OatMix,50lbs...................$22.95 50%Pea-50%BarleyMix,50lbs..............$22.95 50%Pea-50%Tritcale,50lbs....................$22.95

Krug,90Day,56lbs.....................................$96.95 ReidsType,100Day,56lbs.........................$96.95 HenryMoore,110Day,56lbs......................$96.95 BooneCountyWhite120Day,56lbs...........$96.95

SugarAnn,56day,50lbs..........................$119.95 LittleMarvel,63Day,50lbs......................$119.95

SugarSnap,64day,50lbs........................$109.95 GreenArrow,68Day,50lbs.......................$109.95 OregonGiant,69Day,50lbs......................$109.95 Wando,70Day,50lbs................................$119.95 GARDENPEAS

BoltXR,bi-color,66day.............................3,000Kernel/$42.95 CatalystXR,bi-color,66day......................3,000Kernel/$42.95 NorthernXtra-Sweet,67day.....................3,000Kernel/$32.95 Signature,bi-color,73day.........................3,000kernel/$43.95 AnthemXR,bi-color,73day.......................3,000Kernel/$42.95 X-traTenderXTH2475,bi-color,75day....3,000Kernel/$40.95 Honey’NPearl,bi-color,76day.................3,000Kernel/$32.95 IlliniX-traSweet,85day...........................3,000Kernel/$31.95 KandyKorn,89Day...................................3,000Kernels$29.95

MANYOTHERBULKGARDENSEEDSTOCHOOSEFROM: Peas,Beans,Carrots,Cantaloupe,Beets,Squash,Pumpkins, Watermelon,Radishes,Gourds,OrnamentalCorn,Etc.

WildlifeCloverMix,50lbs.........................$219.95

ImpactForageCollards,3lb.......................$13.99

HunterBrassica,3lb...................................$16.99

WinfredBrassica,3lb..................................$16.99

GrazaRadish,3lb........................................$19.99

SmallBurnett,3lb.......................................$17.99

Chicory,1lb...................................................$7.95

SugarBeets,1lb...........................................$5.95 Plantain,1lb.................................................$6.99

Rutabaga,3lb..............................................$14.99

BarKantTurnips,3lb..................................$12.99

Kale,1lb.........................................................$4.99

RapeSeed,50lbs........................................$59.95

Turnips-PurpleTop,50lbs...........................$89.95

WidowMakerBrassicaMix,25lbs...........$124.95

BrassicaBrunchMix,25lbs......................$124.95

WildGameFoodSorghum,50lbs...............$54.95

BuckBuffet,25lbs......................................$18.95