ISSN Print: 2834-619X • Online: 2834-6203

522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303

Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) • 320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Production Manager - Nancy Powell nancy.p@dairystar.com

Assistant Production Manager

Annika Gunderson • annika@star-pub.com

Karen Knoblach • karen.k@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer • amy.k@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, SD, Nebraska) 605-864-7917 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Keya Sleister (Eastern IA, Southwest WI, IL) 563-608-5988 • keya.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378.

Advertising

Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

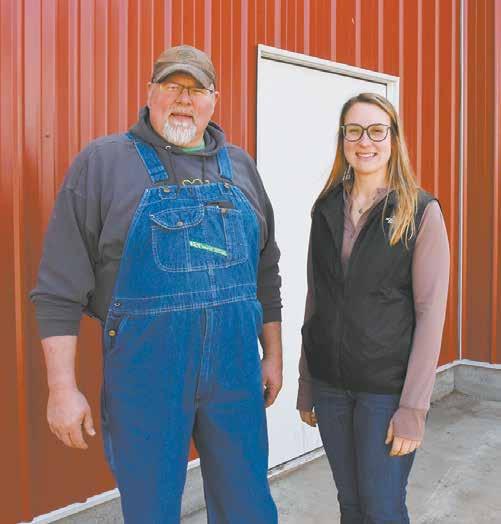

By Sarah Middendorf sarah.m@star-pub.com

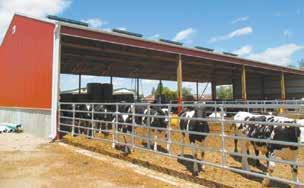

STEWART, Minn. — Keeping calves warm, dry and healthy may be a daunting task, but the Kurth Haven Farms’ new mono-slope calf barn has made the job easier.

Kurth Haven Farms is owned by Mike and Kacie Kurth, who milk 85 cows in a tiestall barn.

Before the new calf barn, calves were housed in a machine shed tted with hog panels.

“Over there (in the machine shed) we were kind of just making due with what we had and it worked,” said Sierra Swanson, niece and full-time employee at Kurth Haven Farms.

The building process started in October 2024 and the rst calf moved in Jan. 15. The barn is 34 feet by 84 feet with 12-foot sidewalls. There is also an attached 14-by-16 milk house with heating and plumbing.

The barn can hold 30 hutches — 20 on the north and 10 on the south — and has a group pen.

Swanson said they had raised some good calves before the new barn, but they had never been as healthy as now.

Though calf chores take the same amount of time, they are easier to do and the environment is a lot nicer, Mike Kurth said.

Two positive pressure air tubes push air in and an exhaust fan pulls air out, making ventilation continual. The calf barn has curtains on both the north and south walls of the barn.

The manual curtains have been a learning curve for employees because they do not have curtains anywhere else on the farm, Swanson said.

During the summer, Kurth anticipates having all the curtains open on the calf barn to maximize air ow.

hutches have a cover on the back that can be pulled off to improve airow.

At the beginning of the process, the Kurths toured another facility and talked to people to gure out the best plan for their barn. Kurth said their Vita Plus team also helped during the planning process.

Once the barn was nished, the Kurths did not waste time getting the barn occupied. No older calves were moved in, just newborns.

“Calf health is the most important,” Kurth said. “They are the foundation of the herd.”

When a calf is born, it makes its

way directly to the new calf barn. During the cold months, it may make a pit stop in the warmer. Otherwise, a freshly bedded hutch will be its home for the next 10 weeks. The rst eight weeks, calves are on whole milk; the last two weeks, they are transitioned to water before being moved into the group pen in the calf barn.

“(Weaning has) been super convenient to have them in the same barn,” Swanson said. “They just go to group housing, nothing else changes.”

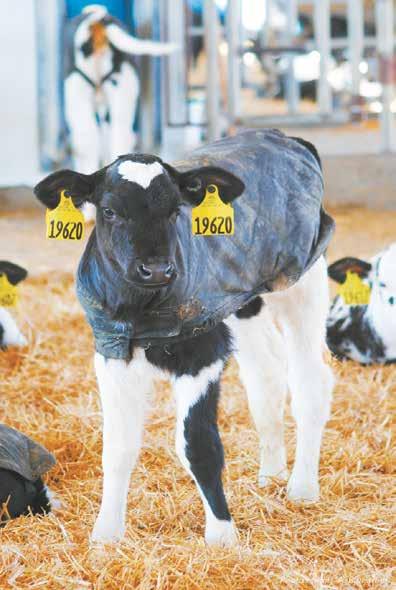

SARAH MIDDENDORF/DAIRY STAR

The curtains are closed on the newly built calf barn April 11 at Kurth Haven Farms near Stewart, Minnesota. The rst calf was moved into the barn Jan. 15.

Kurth said calves are easy to monitor for the rst few weeks after moving them to group housing.

After the calves move to the group pen, their hutches are picked up, pressure washed and sprayed with sanitizer. The Kurths aim to

let them sit for two weeks, if possible. They also clean out the bedding and pressure wash the oor.

The Kurths also added drains that run along the north and south walls.

“You will notice urine coming out of the stalls after

the calf’s been in there about three days,” Kurth said.

The oor is sloped so the middle of the barn is the highest point, allowing liquid to ow to either wall and nd a drain. The drain is connected to the calf barn milkhouse and the tiestall barn

milkhouse to drain into their mound system.

“The drains are super nice (because) we have to use less bedding and it’s so much cleaner,” Swanson said.

Kurth agreed.

“They are dry and the odor, the ammonia smell, is

way down just because the pens are dry,” Kurth said.

Being able to have a controlled barn to house calves is benecial for the Kurths.

“In the long run, our vet bill will be less, our bedding bill will be less, and the calves are just going to be way better,” Kurth said.

Supports the immune system, gastrointestinal health and rumen development

• For use from the first day of life through weaning

• Liquid product mixes easily with milk replacer

• For best results use in conjunction with First Care

For more information contact your local IBA Dealer / Technician

Balzer IBA Owatonna, MN • 507-456-1617

Dairyland Equipment Menahga, MN • 218-564-4958

Pettit IBA Farm Supply Lewiston, MN • 507-269-5714

Zumbro Ag Solutions Zumbrota, MN • 651-380-2856

River Divide IBA Epworth, IA • 563-543-7710

Valley Dairy Supply Corona, SD • 605-432-5224

Bill’s Dairy Supply, Inc. Spring Valley, WI • 715-505-2607 IBA Fahrney, Inc. Monroe, WI • 608-325-4248 Innovative IBA Oconomowoc, WI • 608-347-4948

Johnson Dairy Supply Viroqua, WI • 608-606-2388 LakeView IBA Malone, WI • 920-378-2924 Manitowoc IBA Whitelaw, WI • 920-732-4680

By Stacey Smart stacey.s@dairystar.com

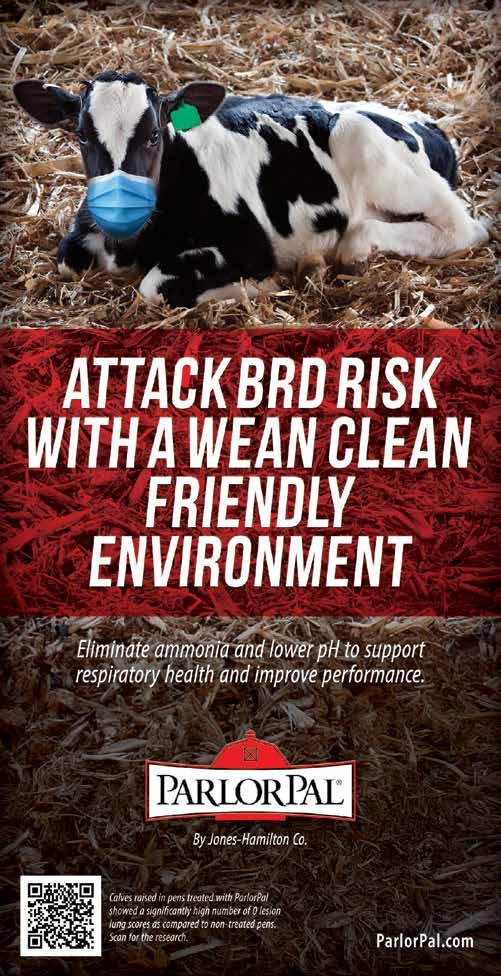

MANITOWOC, Wis. — Transporting animals for any length of time can be stressful, especially when the animal in transit is a newborn calf. Calves of this age have underdeveloped immune systems, making them more susceptible to the effects of stress. Postponing transport and getting calves off to a good start before they leave can help ensure calves are equipped to make the journey.

formed Thriving Agricultural Leader conference hosted by the UW-Madison Extension at Farm Wisconsin Discovery Center near Manitowoc.

Calves should be at least 3 days old at time of transport, and picking the right person to haul calves is critical, Bjurstrom said.

“Transport is very complex, and our transporters play an important role in that,” she said.

“The best thing you can do for your calf is make sure it is in the best shape possible before you put it on a trailer,” said Aerica Bjurstrom, regional dairy educator, University of Wisconsin–Madison Division of Extension. “Setting calves up for success before they get on the trailer is the most important thing.”

“Once calves are on the trailer, you don’t have much control over them, but you do have control over who picks them up.”

Bjurstrom shared tips on how to provide the best transport experience for young calves during her presentation, “Ready, Set, Go: Are Your Calves Fit for Transport?”

March 7 at the Valuably In-

Bjurstrom said trailers should be washed and disinfected and contain clean, dry bedding. They should be stocked at a low density that allows 1.7 square feet per 100 pounds of calf. In addition, the trailer should feature a solid front to protect from wind and openings to provide ventilation while minimizing draft in winter and protection from sun and excessive heat in summer.

Transporting calves can involve numerous stressors, such as loading and unloading, facing unfamiliar environments,

A Holstein heifer calf stands on golden straw in a group pen with about 25 other calves at a Kewaunee County dairy farm. Postponing transport and ge�ng calves off to a good start before they leave can help ensure calves are equipped to make the journey.

social disruption, isolation, uctuations in temperature, and feed and water withholding, among others.

Stress overtaxes the system, causing disease, which causes a lack of performance. The impacts of stress include dehydration, weight loss, episodes of bovine respiratory disease and mortality.

When average daily gain in the preweaning period suffers due to sickness, future milk production is impacted.

Bjurstrom said for every pound of preweaned ADG, rst lactation milk yield increases by 1,200 pounds.

“That is a loss of $255 or more from disease in the rst 60 days (of lactation), based on $19 milk,” she said.

Calfhood disease and poor growth are associated with additional diseases in the future, as well as an older age at rst calving and higher treatment and labor costs.

“If they’re sick and sluggish as a calf, they’re not going to be a thrifty cow,” Bjurstrom said.

Bjurstrom shared results of a survey conducted by Colorado State University in 2023–2024 that included answers from haulers, homesite farms and calf raisers. The survey was distributed to dairies

-

Mitchell Feed - Bloomer, WI, Bloomer Hardware - Bloomer, WI, Seeds & Stuff Farm Market - Colfax, WI, Boyd Feed & Seed - Boyd, WI, Beguhn’s Feed & Seed - Menomonie, WI, Valley Feed - Menomonie, WI, Tony Lumber - Tony, WI, Merton Feed - Merton, WI, Synergy - Chetek, WI, Maple Hill Feed - Maple, WI, Darlington Feed - Darlington, WI, Ed’s Feed - Bloomer, WI

in the Midwest and western states, but the majority of respondents were from Wisconsin and Colorado.

The survey found 43% of replacement calves were raised off-site and transported at about 3 days of age. Fifteen percent of the operations transport calves more than 50 miles. Some replacements have depot stops as well, adding another new environment to a calf’s young life.

“That’s a lot to put on a dairy replacement heifer,” Bjurstrom said. “It’s a lot of movement, and cattle don’t like to be put in new situations and have to gure out what’s going on. That’s a lot of stress, and it’s hard on them. It’s important to set those calves up for a good future.”

The survey concluded that nearly half the calves being shipped ranged in age from less than 24 hours to 3 days old and had at least one health abnormality. Abnormal conditions included diarrhea, navel inammation, dehydration, difculty breathing, respiratory disease and lameness.

•

“The younger they are, the more likely they are to be compromised,” Bjurstrom said. “Some people are shipping calves they know are going to be compromised.”

Transporting compromised calves puts them at greater risk, Bjurstrom said, as travel can exacerbate an existing health issue. For example, when a calf has a navel infection at the source dairy, it is 2.8 times more likely to be treated for diarrhea at the calf raiser. A dull or depressed calf at the source

dairy is 2.5 times more likely to die at the calf raiser.

Bjurstrom said producers should focus on preconditioning of calves before transport. This includes navel disinfection and feeding quality colostrum.

“Navel dipping is a simple task that sets the calf up for a lot of success,” Bjurstrom said. “The navel is a direct conduit to the liver and the bladder. If you’re putting infection into that lter, it’s going to really slow that calf’s immune system.”

Infection can then spread to other parts of the body, causing arthritis, septicemia and other diseases.

“Navel infections reduce the chances of a calf surviving to its rst lactation, impacting the long-term productivity of the herd,” Bjurstrom said.

The Colorado State survey revealed that calves greater than 7 days old had better average daily gains and a reduced incidence of abnormal respiratory score compared to calves 2-6 days old. Calves 1-3 days old had lower odds of being dehydrated prior to transport compared to calves less than 24 hours old. Finally, calves 2-19 days old were less likely to suffer from navel inammation.

“Just one more day at the dairy reduced the odds of dehydration by ve times,” Bjurstrom said.

To minimize stress, Bjurstrom said to wait until calves are older before transporting. She also recommended reducing the amount of time traveling and incidences of travel for calves.

By Stacey Smart stacey.s@dairystar.com

MANITOWOC,

Wis. — It is no secret that rst-milking colostrum is essential for newborn calf health and well-being. The part that might be less clear, however, is how much colostrum should be fed.

The current industry recommendation is to feed a calf four quarts of colostrum or 8.5%–10% of its body weight for the rst feeding. This is a recommendation Dr. Donald Sockett, DVM, does not believe in after seeing the effects rsthand of feeding what he said is too large a volume of colostrum.

“Feeding four quarts of colostrum for the rst feeding is too much for most calves,” Sockett said. “The pathologists I work with are appalled at current colostrum feeding recommendations. Feeding these large volumes is not natural or normal.”

Sockett is a veterinary microbiologist/epidemiologist at the Wisconsin Veterinary Diagnostic Laboratory at the University of Wisconsin–Madison, focusing on dairy calves.

Sockett discussed issues from overfeeding colostrum during his presentation, “New Concepts in Colostrum Feeding for Dairy Calves,” March 7 at the Valuably Informed Thriving Agricultural Leader conference hosted by the UW-Madison Extension at the Farm Wisconsin Discovery Center near Manitowoc.

One of the dangers of feeding too much colostrum is the formation of a large colostrum curd within the abomasum that causes abdominal distention and colic. Sockett said this serious complication is usually seen after the second colostrum feeding. Feeding large volumes of colostrum with an esophageal tube feeder can cause aspiration pneumonia, pharyngeal and/or esopha-

geal trauma, rumenitis, reticulitis, omasitis, abomasitis and even death in some cases.

Sockett said there is always a risk when tube feeding a calf.

“Colostrum goes from the reticular-rumen and then ows into the abomasum, leaving a small reservoir of colostrum in the rumen that never gets to the abomasum,” he said. “We see rumenitis all the time. About 40% of calves will form an abomasum curd, and up to 5% will form a curd that’s well organized, which can cause colic.”

When a calf feeder at a dairy in Wisconsin tried to get more immunoglobulins into the calves, he decided to add a third feeding of colostrum. A Guernsey calf weighing 75 pounds was given four quarts within two hours of birth. Eight hours later, it was tubed two more quarts, and eight hours later, it was given another two quarts. Within 20 hours, the calf received two gallons of colostrum, and it died.

“When the calf came into our lab, we opened it up and the abomasum looked like

a big, water-lled balloon,” Sockett said. “All this colostrum spewed out on the table. The cause of death was that it couldn’t handle this large volume of colostrum. The calf regurgitated the colostrum from the abomasum and then aspirated the colostrum into its lungs post-feeding. Therefore, the aspiration pneumonia it died from was not caused by improper tube feeding technique.”

The attending veterinarian was not condent of the cause and treated the calf with intravenous uids and banamine. After 23 hours, the calf was humanely euthanized due to no response to medical therapy and sent to the WVDL.

“This was the fourth or fth calf affected on this farm,” Sockett said. “The vet had seen this on other farms

“Colostrum is called liquid gold, so why don’t we treat it like it’s liquid gold?”

Dr. Donald Sockett, DVM

Sockett also shared a story about an 88-pound Holstein calf that was fed four liters of colostrum 30 minutes after birth and given two more liters six hours after the rst feeding. An hour-and-ahalf after the second feeding, the calf was found lying on its side with all four legs extended.

“I saw a video of the affected calf, and it had a large, extended abdomen and was grunting in agony,” Sockett said. “It was the worst colic I’ve ever seen.”

as well. Everyone thought the colic and abdominal distension was from a tubing injury. You can’t predict when you’re feeding (newborn calves) such large volumes of colostrum which one is going to develop this complication.”

Current guidelines for colostrum feeding are based on an immunoglobulin concentration of greater than or equal to 50 grams per liter.

However, Holstein rst-milking colostrum has a mean IgG concentration of 75-85 grams per liter, Sockett said.

“Why is 50 grams per liter considered good quality?” he said. “That’s not good quality; it’s fair-quality colostrum.”

Sockett said bovine colostrum containing 7599.9 grams per liter of IgG is good quality, while colostrum containing at least 100 grams per liter is considered excellent.

“We need to get more calves in the excellent category, but there’s a nite supply of colostrum,” Sockett said. “How do I manage this nite supply, which is one of the most important things affecting the life and well-being of our calves?”

Feeding smaller but more concentrated volumes of colostrum helps increase the farm’s supply, potentially by as much as 25%–35%, Sockett said.

“Colostrum is called liquid gold, so why don’t we treat it like it’s liquid gold?” he said.

Extra colostrum can be used to fortify a calf’s liquid feed diet for the rst 3–14 days of life. This can improve gut health and average daily gain while reducing the incidence of neonatal diarrhea and pneumonia.

Sockett said the IgG concentration is more important than the timing of when colostrum is fed to calves in the rst 2-6 hours of life. He referenced a study done in 1983 in which either one or two liters of colostrum was fed to calves. The mass of immunoglobulin fed to the calves was the same, but the one-liter volume was twice as concentrated as the two-liter volume.

Results showed that the more concentrated the colostrum is, the more efciently it is absorbed. The serum IgG levels when measured at 24 hours of age were roughly 20% higher in calves that were fed the smaller volume of colostrum.

“You will have a more rapid and efcient absorption of immunoglobulin if you feed 200 grams of IgG in three quarts versus 200 grams in four quarts,” Sockett said.

Sockett said farmers should consider feeding smaller volumes of colostrum to newborn calves while still delivering an adequate mass of IgG to ensure successful transfer of passive immunity.

“We

Dr. Bethany Dado-Senn stands at a calf raising facility. Dado-Senn, who works as a calf and heifer technical specialist for Vita Plus, is passionate about ensuring the health of dairy calves.

By Danielle Nauman danielle.n@dairystar.com

AMERY, Wis. — The future of a dairy farm is built upon its smallest members, the calves that will grow to take their place in the farm’s milking herd. As the national replacement heifer population continues to dwindle, each calf becomes more valuable.

Raising calves, the most vulnerable population on the farm, is challenging, especially during the weather uctuations that come with spring in the upper Midwest. According to Dr. Bethany Dado-Senn, a calf and heifer technical specialist with Vita Plus, with dedication and due diligence, rearing healthy, well-grown calves is an achievable goal.

“Spring is one of the worst periods of time for risk for things like respiratory disease in calves,” Dado-Senn said. “Calves don’t handle temperature swings or elevated moisture levels well. Everything we can do to minimize the management risks of respiratory disease is going to be helpful.”

Dado-Senn said increased moisture allows pathogens to collect within the water particles that make up the damp, springtime air, creating issues for vulnerable, young calves.

For calves housed in a calf barn, Dado-Senn advocates for aggressive curtain management.

“Crack those curtains open, even when it’s colder than you think you should,” Dado-Senn said. “Even if it feels chilly to you, anything above freezing, let’s get started opening those curtains up.”

Dado-Senn said those with positive-pressure tubes should take action early to ensure their tubes are fully

functional for springtime ventilation needs, to ensure 4-8 air changes per hour.

If keeping calves warm is a concern, Dado-Senn recommends addressing warmth through other avenues, such as ensuring plenty of clean, dry bedding for calves to nest in, enhanced nutrition and use of calf jackets, particularly for calves 3 weeks of age and under.

“If the minimum and maximum temperatures of the day combined are less than 90 degrees, then jackets should stay on, both in hutches and in barns,” Dado-Senn said. “A lot of barns tend to not be thermostatically controlled. They might be a little warmer than outside, but not drastically so, especially if you’re following guidelines about getting curtains open.”

Preparing for the rst drastic spike in temperatures that can occur in late spring months pays off, Dado-Senn said.

“Be proactive, watching for when that rst heatwave is coming,” Dado-Senn said. “Calves can really struggle during that rst heat spell they experience.”

Dado-Senn said she recommends preparing summer ventilation with curtains and tubes and propping up the rears of calf hutches up and opening side panels. Ensuring proper hydration is also essential.

“I recommend still giving warm water to calves, which helps encourage intake and keeps them hydrated,” Dado-Senn said. “Feeding a prophylactic electrolyte can help get calves through a heatwave when they are sweating or panting, causing their blood gases to get a little out of whack.”

Nutrition is a vital tool in supporting calf health, particularly during weather challenges, Dado-Senn said.

“In the winter we focus on increasing total volume of milk fed or adding a little bit of fat to the milk,” Dado-Senn said. “The extra calories from more milk volume can really help ght those temperature drops and swings, espe-

cially for our younger calves. In spring conditions, it’s important to continue that strategy until we get into consistently warmer weather.”

When feeding milk, Dado-Senn suggests a step-up and step-down approach, starting calves on around six quarts of milk per day, moving up to at least eight quarts; maintaining at that level before implementing a 1-2 week step-down weaning. If calves are fed more than eight quarts per day, she recommends extending the weaning period by an additional week to encourage adequate starter intake.

Dado-Senn said offering calf starter to calves from day one builds towards weaning-time consumption goals.

“Starter intake at a young age will help get that rumen development started,” Dado-Senn said. “We want to get that calf off to a good start so it doesn’t miss a beat at weaning.”

Calves lack depth perception, which can impact early starter consumption, Dado-Senn said.

“A good way to encourage starter intake early on is to only offer a little bit, so they can still see the bottom of the bowl,” Dado-Senn said. “The goal is to get them interested in the rst two or three weeks, then gradually increase that volume.”

Dado-Senn said produc-

ers should make sure calves are consuming no less than two pounds of starter per day as they begin the weaning process.

“The minimum you’d want to see is four pounds of calf starter per day, by the end of weaning,” Dado-Senn said.

“We’d really like to see it closer to 6-10 pounds per day.”

Use of probiotics to support gut health can prove benecial to young calves, Dado-Senn said.

“We nd that direct-fed microbials reduce a lot of noise,” Dado-Senn said. “Probiotics improve the microora of the calf’s gut. The calf is then better able to ght off pathogens, digest their food

with a healthier gut, and use those nutrients to avoid inammation and grow.”

The roller coaster forecasts that come with spring are a source of stress facing calves throughout the springtime. Dado-Senn said caregivers should take volatile weather into consideration when implementing management protocols.

“This time of year, watch how you’re stacking those stressors and avoid adding concurrent stressors during temperature swings,” Dado-Senn said. “Don’t wean a whole group of calves or give vaccinations on the day we go from 70 degrees to 20 — wait for more consistent temperatures.”

Fight Bac for calf navels: Fight Bac’s antibacterial formula with chlorhexidine has been proven to be just as effective as 7% tincture of iodine, plus it’s more available and costs a lot less at only $0.08 per navel compared to $1.10 or more for navel dip. Fight Bac also is more convenient and less messy than using iodine in a dip cup (or paper cup). No gloves are needed, and there is no chance to spread infection.

Dairy producers have benefited for decades from using Fight Bac on teats post milking. Now they also can benefit from using it on calf navels, cuts, wounds, injection sites, udder rot and to cleanse a teat prior to intramammary infusion. Put a can in every corner of your dairy.

DANIELLE NAUMAN/DAIRY STAR

Calves wait for their milk April 10, 2024, at a St. Croix County dairy farm near Woodville, Wisconsin. Mi ga ng temperature and weather swings can make raising calves challenging.

PHOTO SUBMITTED

Dr. Bethany Dado-Senn measures a heifer’s skin temperature using an infrared thermometer during a heat stress study conducted in Florida. The study was part of Dado-Senn’s research on environmental stressors in dairy ca le.

See us at Booths 82-83

By Dan Wacker dan.w@dairystar.com

Using a total mixed ration has become commonplace for feeding older dairy cattle. The balanced mouthful with every bite has helped improve energy, protein and minerals in the ration while lowering cost and boosting milk production. Jordan Hunt with GPS Dairy Consulting LLC recommends using a TMR strategy for calves and heifers as young as 3 1/2 months.

about a 50/50 mix. By the second week, we switch it to 60%–70% TMR.”

Easing the calves onto this new feed is important, especially considering the changes the calf is experiencing at the time of transitioning to a new housing situation.

“We all know how nicky weaned calves can be when you’re changing their diets and environments,” Hunt said. “All that can be a cascade of stressful events that can lead to health challenges. We try our best at really making it as seamless as possible for the calves.”

By deploying a ration that is a balanced TMR, Hunt said his clients have seen how the mix changed the development of their youngstock.

Hunt works with farms milking anywhere from 200 to 2,500 cows in northeast Iowa, southeast Minnesota and southwest Wisconsin.

“Our clients who have made this switch early have talked about how their youngstock have more bloom,” Hunt said. “They take off on intake quicker and the manure is more con-

“W’lld

“We’ve really started making this push to get TMR in front of those younger animals over the last four years,” Hunt said. “It started with our clients who were challenging the normal paradigm of what we could start the calves on, going through the process, learning about what works and what does not.”

“We’ve really started making this push to get TMR in front of those younger animals over the last four years.”

Jordan Hunt, GPS Dairy Consulting LLC

sistent. Those are big factors in why I continue to recommend this.”

When taking a macro-viewpoint on the TMR diet for the younger animals, the ration bears a resemblance to a typical diet for milk cows. One difference, however, is the dry matter content.

“It’s a very nutrient-dense ration, made up of milk-cow-quality haylage and corn silage.” Hunt said, “We add some grass or alfalfa for additional ber and to control the DM of the ration.”

What sets the ration apart is making sure DM content is closely monitored so it does not drop below 48%. Too little DM results in too wet of a mix. This means the younger animals are not going to consume enough for the consistent growth this practice is designed to promote.

Hunt has also witnessed more consistency in the growth of groups that have been on the TMR mix earlier. On newly freshened 2-year-olds, the cows have hit the barn running, seeing anywhere from 96- to 100-pound peaks.

One of the biggest factors in developing a new ration for this age group is the size of the mixer Hunt said. Mixer size is the biggest potential threat to the ration’s efcacy.

“I want there to be 11–13 pounds of dry matter intake of this ration at minimum,” Hunt said. “That’s where the diet balances best, so having accurate intake data is important to validate this. With wetter forages, I will supplement with alfalfa or grass hay to dry the diet out and bring more structure to it, but the high-quality forages are what I am wanting to leverage. There is zero tolerance for moldy, sub-par feedstuffs in this ration. I also pay close attention to nutrient density, so I am hitting my targets for protein, energy, ber, minerals and monensin.”

The timing of the change in diet coincides with the calves’ transition to group living and when the calves are no longer relying on milk for their primary nutrients.

“If you’re trying to mix a 1,000-pound batch of feed in a mixer that can hold 20,000 pounds, it can create some inconsistencies,” Hunt said. “We recommend trying to verify consistency with shaker boxes, or sending TMR samples to see the variation along the bunk if you are in question. Feed pushups also help and are very important in making sure the feed is accessible.”

Though it may not be the industry norm yet, Hunt and his clients have found success with this strategy, and the willingness of other farmers to try it has helped Hunt and GPS Dairy Consulting gain traction. By implementing early TMR feeding, farms can purchase less calf grain mix, lowering the cost of inputs.

“Every farm is different, but in most cases, we allow a 2-week transitional phase for feed,” Hunt said. “We use the same grain they would have been getting prior to the TMR, along with the TMR for that rst week for

“In a day and age where it is extremely expensive to raise replacements, it becomes critical to do it economically without sacricing growth and future milk potential,” Hunt said. “These heifers are the future of our herds, and I want quality heifers that stay around a long time and are profitable.”

By Sarah Middendorf sarah.m@star-pub.com

SIOUX FALLS, S.D. — Kickstarting gut health can set calves up for success, especially when it comes to ghting off scours.

Dr. Michael Nagorske spoke during the Central Plains Dairy Expo March 26 about calf scours and a new treatment strategy using colostrum to ght scours. Nagorske owns and operates ProGen Cattle Solutions as well as Nagorske Brothers Angus.

“The biggest inuence on a calf’s ability to establish its microora is colostrum,” Nagorske said. “This is the jet fuel that drives everything.”

In calves, the gastrointestinal tract is the last group of organs to develop, meaning it is more vulnerable to pathogens at birth. Nagorske said the micro barrier of the gastrointestinal tract is compromised at birth. Calves need to ingest colostrum to kick-start microora, microorganisms and bacteria in the gastrointestinal tract.

Nagorske shared some of the ways producers attempt to treat scours — anti-inammatories, antibiotics, electrolytes, prebiotics, probiotics and nutrition, charcoal and resting the gut.

“When you’ve tried these things, do you actually see an impact in terms of scours?” Nagorske said. “There are a lot of good products out on the market, but is our expectation of them maybe a little too much?”

Nagorske talked about three feeding options he likes to use for scouring calves, each of which utilize colostrum. The rst is using maternal colostrum and electrolytes fed separately; second, using a whole bovine colostrum replacer and electrolytes fed separately; or third, using a whole bovine colostrum replacer and electrolytes fed together. Within his practice and farm operation, he has used each of these methods.

“Clhbli

“Calves are a humbling process as far as raising them, keeping them alive, and getting good gains out of them.”

Dr. Michael Nagorske

When feeding colostrum and electrolytes, Nagorske said the colostrum should be free of pathogens and have minimal bacterial load, and the electrolyte used should have an alkalizing agent.

“If you nd these (scouring) calves, you have to get on top of them early; the sooner the better,” Nagorske said.

Even though the gut is closed after the rst 24 hours, Nagorske said, colostrum can still be fed to calves. This will bathe the gut with antibodies to help protect it. Nagorske has been working on implementing colostrum into calves’ diets until day 7 to help get the gut going and to protect it.

“There’s just a lot to colostrum, and that’s the big thing,” Nagorske said. “When we break down everything that’s in colostrum, we get to appreciate that.”

There are more things than just immunoglobulins, antibodies, passed from dam to offspring to absorb, Nagorske said.

“If IgG was the only gift to us with colostrum, why is it so effective in terms of increasing gastrointestinal tract protection and development and immunity in other species?” Nagorske said.

Colostral fat is one of these benets.

“Colostral fat is very unique,” Nagorske said.

“It’s not just a crude fat. … Colostral fat has these projections called sialic acid. They’re antiviral and antibacterial.”

When calves get sick within the rst 2-3 days of life, it is likely from E. coli, he said.

“Research shows for every calf that scours, they are about 1.5-2 times more likely to get respiratory disease,” Nagorske said.

For example, when calves contract rotavirus, it targets all the villi, which are nger-like projections in the gastrointestinal tract, and cuts them off, Nagorske said. This prevents the intestine from absorbing nutrients from the food.

“All that food, instead of going into the calf, goes out the other end,” Nagorske said.

In addition to extended feeding of colostrum,

Nagorske said it is important to prevent calves from being exposed to bad bacteria.

Nagorske said he uses antibiotics to treat septicemia, not bugs, which is what calves are ghting with scours.

“In my practice … calves that have blood in their feces or a temperature, they need antibiotics,” Nagorske said.

Knowing how to identify, treat and manage scours in calves can be daunting. There are many factors contributing to scours, and Nagorske said he has found his treatments and methods work on his operation.

“Calves are a humbling process as far as raising them, keeping them alive, and getting good gains out of them,” Nagorske said.

Real-time alerts ensure each calf gets the attention it needs, leading to timely interventions, lower treatment intensity, reduced reliance on antibiotics, and improved labor efficiency. Powered by Artificial Intelligence and continuously evolving algorithms, the system adapts to your specific farm and the unique behavior of each calf.

With CowManager's Lifetime Monitoring system, you can support the full lifecycle of your herd - from calf to cow - ensuring optimal health, growth and performance at every stage.

Implement the technology designed to optimize calf rearing and maximize future herd health and productivity. Youngstock Monitor uses lightweight ear sensors to track crucial development stages, helping you improve calf health and welfare now for a strong, productive herd later.

By Nesli Akdeniz and Jackie McCarville University of Wisconsin-Madison Extension

Proper housing is essential for the health and growth of dairy and beef calves. It provides a clean, dry and comfortable environment to support healthy development and minimize disease risks.

Calf hutches

Calf hutches are typically constructed from polyethylene or berglass, providing shelter from environmental conditions. By minimizing direct contact between calves, hutches reduce the risk of disease transmission. They allow close monitoring of each calf, facilitating early disease detection and personalized feeding strategies when needed. Proper placement of hutches facing away from prevailing winds and adequate spacing to prevent contamination between calves are important. Dur-ing colder months, deep bedding, often straw, is utilized, allowing calves to nest comfortably and maintain body heat.

Indoor pens

Indoor pens are individual enclosures within a barn or shed, offering protection from weather extremes. While offering a controlled environment, these pens require proper ventilation systems to prevent respiratory health issues caused by inadequate air circulation.

Group hutches or pens

Group hutches or pens accommodate multiple calves in a shared space, promoting social interac-tion and natural behaviors. Transition housing is employed from the post-weaning period until calves reach approximately 6 months of age, assisting them in adapting to larger group dynamics and supporting continued growth.

Providing consistent care, such as feeding and bedding, can be more challenging in outdoor set-tings, particularly during severe weather conditions. Calves housed outdoors are directly exposed to environmental conditions, such as extreme temperatures, precipitation and wind, increasing the risk of cold stress during win-

ter. When temperatures fall below a calf’s thermoneutral zone, 50 degrees, the upper vents of hutches are sometimes closed to minimize heat loss, inadvertently reducing air quality.

Indoor housing settings protect from harsh weather for both calves and caregivers. However, poorly designed indoor facilities may have inadequate ventilation, resulting in decreased air quality and the buildup of airborne pathogens, therefore increasing the risk of respiratory diseases. Addi-tionally, placing calf hutches directly on soil can result in moisture buildup and muddy conditions, fostering pathogen growth and further elevating disease risks.

One of the primary air quality concerns in calf housing is ammonia. Ammonia is a pungent, wa-ter-soluble gas that irritates the mucous membranes of the respiratory tract, making calves more vul-nerable to viruses and bacteria that can lead to infections. It is strongly associated with Bovine Res-piratory Disease, the leading cause of morbidity and mortality in pre-weaned calves.

The recommended exposure limits for ammonia for workers are an 8-hour time-weighted aver-age of 25 ppm and a short-term exposure limit of 35 ppm for a 15-minute exposure. However, am-monia can begin affecting calf health at much lower concentrations because calves experience con-tinuous exposure. Studies showed that calves exposed to ammonia levels above 4 ppm were associat-ed with a higher prevalence of lung lesions. It was reported that in general, ammonia levels are de-sired to be below 10 ppm and, when possible, below 5 ppm.

Our site visits indicated that ammonia levels in calf hutches or pens typically remain at a few ppm when bedding is well-managed and airow is adequate. However, it can increase to the 10-20 ppm range in localized pockets or under poor ventilation. If there are concerns about ventilation design, low airow zones, or ammonia levels, an easy way to measure ammonia concentrations is by using

Con nued from HOUSING | Page 17

colorimetric detection tubes, which consist of glass tubes containing chemical reagents that change color upon exposure to NH3. Air is manually drawn through the tube using a calibrated hand pump. The length of the color change within the tube indicates the concentration, which can be read direct-ly from the printed scale. These tubes are easy to use, provide immediate results, and are convenient for quick on-site assessments. Several brands are available for purchase.

been widely adopted in calf buildings to continuously deliver fresh air at the calf level.

Bedding management

Do you have what you need to keep your youngest calves & lambs healthy and growing? Find everything for calves & lambs at Leedstone, including:

The odor detection threshold for ammonia is around 5 ppm, meaning we can often smell ammo-nia well before it reaches its recommended exposure limits. Although the human nose is sensitive enough to detect ammonia at low concentrations, prolonged exposure can cause individuals to become nose-blind, reducing their ability to notice its presence over time.

Mitigation strategies for improved air quality

Good ventilation

Adequate air exchange is essential for preventing the buildup of ammonia and other airborne contaminants. Outdoor hutches usually provide good ventilation unless the front opening is closed to protect calves from cold weather. Indoor calf barns need to be designed to ensure sufcient ventila-tion and air exchange. Recommendations suggest a minimum of four air exchanges per hour during cold weather. This can be achieved through natural or mechanical ventilation. The goal is to remove ammonia without creating drafts on the calves. In recent years, positive-pressure ventilation tubes have

The importance of keeping bedding material dry cannot be overstated. Dry bedding not only provides comfort and insulation for calves but also helps minimize ammonia emissions, as urea in urine must be hydrolyzed to release NH3, and this process is limited when the bedding remains dry. Many farms use a “deep bedding” or “pack system” for calves, where straw is continuously added on top. The frequency of bedding changes varies by farm. If bedding is not changed often enough, urine and feces accumulate, leading to increased ammonia emissions, while changing it too frequent-ly can be labor-intensive. A common approach is to remove and replace all bedding between batches of calves. But if calves remain in the same pen for more than eight weeks, periodic cleanouts are necessary.

Maintaining good air quality in calf housing is essential for calf health, especially when it comes to ammonia exposure. Although the human nose can detect ammonia around 5 ppm, studies show that calf health may already be affected at this level. When possible, ammonia concentrations should be kept below 5 ppm through proper ventilation and bedding management.

If you are concerned about ammonia levels in your calf housing, please reach out to Nesli at nesli@wisc.edu to schedule a site visit.

By Tiffany Klaphake tiffany.k@dairystar.com

LEOTA, Minn. — Many things have changed in the dairy industry in the last 20 years. But one thing has remained constant at M&M Livestock: raising heifers to reach their full potential.

Myron Hulstein started M&M Livestock in 2004 after some dairies he hauled cattle for asked if he would raise their heifers. More than 20 years later, Hulstein is still at M&M Livestock. But as of Dec. 1, 2024, Rob Van Hill and his wife, Kendra, have taken over ownership of the farm to transition it to Van Hill Farms LLC.

heifer business raises 11,000 heifers.

“We were a sub grower until the last few years, then we started to help more with the management decisions,” Rob said. “My dream has always been to farm, but I never had that opportunity until this job came around.”

Van Hill Farms LLC manages 11,000 heifers — from 5 months in age to 7 months pregnant. The heifers are spread across several sites and they work with sub growers to raise all of them.

“We have to be constantly changing with the industry,” Kendra said. “We have to keep growing because our customers keep growing.”

The two main facilities, which Van Hills and Hulstein oversee, have on average 6,500 heifers and are located near Leota and Edgerton.

“Our goal is to produce the absolute best heifer we can; not the cheapest, but the best,” Rob said.

The operation has enough acreage to produce silage to feed the animals, but they purchase hay and straw. Van Hill Farms LLC works with seven dairies across the Midwest, ranging from 10 miles to 900 miles away.

Besides growing in size, Hulstein has seen several changes to the farm since he started.

“When I rst started, it was all conventional breeding with a clean-up bull,” Hulstein said. “Now, it is sexed semen, using embryos and breeding some heifers to beef semen.”

A majority of animals are genotyped prior to coming to Van Hill Farms.

work with.

“Our motto is to produce the heifer to her genomic potential,” Hulstein said. “If she has the genomic potential to produce X amount of pounds, we want to provide that to the dairy. That’s our goal.”

Another industry change is that dairies want more uniformity in calving ages.

“It used to be an average daily gain of 1.8; dairies were satised with that,” Rob said. “Now, to get them to calve at 22 months, you really need to be at a 2 or 2.1 average daily gain. That’s the biggest thing we have noticed in the last ve years.”

To maintain their level of quality, Van Hills and Hulstein are in constant contact with their dairies and utilize DairyComp for record keeping. Van Hill Farms uses electronic identication tags to track the animals. They also have an in-house breeder who breeds according to each dairy’s guidelines.

“We communicate with our dairies weekly, and once a month we send out information to our dairies,” Rob said.

We track everything, from inventory, reproduction rates and so on, he said.

“It helps the dairy and us to know where we are at,” Rob said. “It helps create a good relationship between us and the customer.”

Hulstein and the Van Hills

said they are in this business for the long haul and want to maintain a strong working relationship with their dairies.

“Communication is the key to any good relationship,” Hulstein said. “If something comes up, we call the dairy and tell them and share how we are trying to resolve it.”

Each month, Van Hill Farms LLC receives about 1,000 heifers and each month they adapt their ration for each group of heifers.

“We watch ration changes and conditioning as much as possible,” Hulstein said. Rob agreed.

“I spend a day every oth-

to their success in the custom heifer business.

“It’s a combination of our phenomenal customers and outstanding employees that allows us to accomplish what we can,” Kendra said. “Myron has been a very good mentor to us.”

Kendra did not grow up on a farm, but Rob did and worked as a dairy nutritionist for more than 20 years prior to working at M&M Livestock. Now, one of their children has graduated from college and is working alongside them.

“Neither of us started farm until we were later in career and we are very driven to succeed because of that,” Rob said. “We are a business that gets to farm, not a farm that has a business.”

For Van Hill Farms LLC, their dedication and communication with employees, sub growers, customers and each other allows them to deliver quality.

er week just looking at cattle for body condition, Rob said.

“How has it changed, what should we change? It’s amazing how fast it can change. We aren’t afraid to try new things.”

The Van Hills and Hulstein also credit their team of employees and sub growers

“It looks like a strong dairy industry here in the Midwest,” Hulstein said. “Every industry has its ups and downs, but the Midwest is a pretty good place to be. There is a lot of dairy and creamery expansion, which will only encourage more dairy. We are quite fortunate to be where we are.”

Be

Your future is now. And it starts with her. Help her maintain normal digestive health and support a functioning immune system with First Arrival® total eubiotics. This easy-to-feed product is available in powder or paste. Kickstart tomorrow’s production today.

Fiberglass freestalls offer a heightened level of comfort which can lead to an increase in milk production!

New additive in our paint now prevents & protects against the growth of mold & mildew.

• All Solid Rail Fencing that has a 20 year UV coating to prevent slivers, colors available

• Show Fencing & Pasture fencing

• Cattle Panels & Continuous Fencing

• 1" & 1-1/4" Electric Fence Post UV Protected

•13% Chrome Post for Head Locks & Feed Rail

• Guard Rail and Fiberglass posts.

• Lifetime warranty on our fiberglass products from rusting and rotting

“We installed freestalls from TJ’s Fencing in our new expansion freestall barn. I really enjoyed the durability and longevity of the freestals and gates in my old barn. I will never install a steel post again after using their posts since they will never rust. They are also reasonably priced compared to other options.”

KG4 Farms, Ridgeway, IA

They are a great company to work with and have top notch customer service. We like how our new free stalls are hardy and sturdy but are also flexible”

- Adam and Drew Martins, Luana, IA

“I have fiberglass freestalls and my milk production has gone up since we installed them. We love the fiberglass freestalls! I have cows standing in the morning because all the fiberglass stalls are full.”

Steve Kaiser Little Falls, MN

“Very easy to install, the fencing should last a lifetime and is very high quality. I would recommend it. My dad has had fencing from TJ’s in for over 16 years and it is still holding up like the day we installed it.”

- Jeff Novak, Highland, WI

“I have used fiberglass rods from TJ’s Fencing for my pasture fencing for five years. I like how they are durable and nice and solid. I can also tie the high tensile wire right to the posts.”

Jordan Meyer, Caledonia, MN

“We have been supplying Glasfiber boxes for 10 years. Every customer is satisfied with this product and will definitely choose the glass fiber freestall again in the future. It is also a good fit for renovation projects. In addition, we also offer glass fiber fencing. The glass fiber is an excellent alternative to the iron barn equipment.”

Bertha Swaving, Holland, Netherlands