By Tiffany Klaphake tiffany.k@dairystar.com

SLEEPY EYE, Minn. — A high school summer job at a dairy farm has impacted the career path of Lauren Stef. After choosing to work at a dairy farm more than an hour away from where she grew up in Prior Lake, Stef now is pursuing a college education in agriculture.

“I absolutely love the farm,” Stef said. “The rst time I milked a cow was May 11, 2019, and little did I know that would completely reroute my entire career and my entire life.”

Not only has Stef been working for John Rosenhammer of Sleepy Eye since 2019, but she has also changed her major in college from early childhood education to ag business and a minor in dairy science at South Dakota State University in Brookings, South Dakota.

While Stef is from Prior Lake, her dad, Tim, used to have a dairy farm near Sleepy Eye. He knew Rosenhammer and connected him with his daughter. The two worked out a way for Stef to be employed at the farm for a summer and then beyond.

“(Rosenhammer) was a little hesitant (to hire me) just because I didn’t have that ag background… but he gave it a try,” Stef said. “I still work for John today.”

Rosenhammer farms with his brother, Greg, and they milk 220 cows in a double-12 parallel parlor. Stef journeyed to Rosenhammer’s farm as often as she could when she lived in Prior Lake and continues now while going to college. When she is on the farm, her duties include milking, feeding calves, feeding heifers and now, in the summer, training new employees.

“When I rst started milking, I remember thinking, ‘Wow I’m milking cows and this is the milk that people will be drinking, how cool is that,’”

Stef said. “Ever since then, I wanted to just continue to do a deep dive in the industry and that’s how I got involved in so many things.”

As Stef’s responsibilities on the farm grew, so did her interest.

“I started out just having one role: milking,” Stef said. “I progressively got introduced to more things on the farm and eventually got introduced to everything on the farm, even assisting in breeding cows.”

Since Stef took a liking to the farm, Rosenhammer encouraged her to run for Brown County dairy princess. She was crowned Brown County dairy ambassador for one year and ever since 2021, Stef has been crowned a Brown County dairy princess.

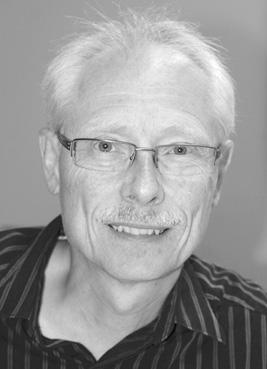

Dean Kammes

Darlington, Wisconsin

What year did you start farming, and what year did you retire? I started to help milk cows when I was 10 years old. I retired from milking in November 2023.

Tell us about your farm when you started, and describe what it looked like when you retired, including how many cows you milked when you retired. When we started, we had 48 cows milking. I was the third generation to farm, the second generation on our current farm to milk. We milked using the Surge buckets and carried them to a milk transfer station. When I retired, we had 40 cows and we were milking in tie stalls with a pipeline.

What were some of the big advancements you made during your career? We built three silos on our farm to help with feed. We put up a bred heifer barn in 1980 and a calf barn in 2016. We also installed the pipeline in 1977.

What did you love about milking cows? I loved the calmness that came with milking cows. That’s where I did most of my thinking.

What was the highlight of your dairy career? We had a herd of registered Holsteins, and I had a cow score Excellent 93 with a 94-point mammary in 2003.

What is the biggest challenge you faced in your career, and how did you overcome it? The biggest challenge I faced was the drought we had in 1988. We did the best we could with the crops that year and looked

forward to having a better harvest the next year.

If there is one thing you wish you could have done differently during your farming career, what would it be? I wish I had gotten certied organic sooner. We certied our milk in 2016; we had the land certied organic in 2008.

What piece of equipment or technology has been introduced that you wish you had for your dairy career? I liked the setup I used while I was milking. We had everything we needed for our farm.

What do you miss most about dairy farming? I miss the genetics part and

breeding cows. It was nice to see how they would turn out when they got to milking age.

What advice would you give to a young farmer today? Manage your debt as well as you can. You don’t have to have all the new stuff. It may be nice on the surface, but managing your debt is the most important part of keeping a dairy going.

What is your tie to the dairy industry today? I have a heifer and some steers yet. I’ll graze some heifers for an Amish herd nearby. I still crop my land, which is about 130 acres, and then I custom combine about 15 acres a year.

Within this feature the Dairy Star catches up to retired farmers and talks about the highlights and struggles they had when dairy farming.

The feature includes how each individual farm changed throughout the farmer’s career and what each has been doing since they hung the milkers up.

Was retiring an easy or hard decision/transition? It was easy for me.

About the third time I heard Cody Johnson’s song, “‘Til You Can’t,” I knew it was time to be done. I have 15 grandkids. I wanted to be around and spend more time with them. You can’t get back time, and I want to spend as much time with those kids as I can.

What have you been doing since you retired? I read quite a bit now and watch some “Court TV.” I go to a lot of football games as well. I also have more time to go to my grandkids’ events. The youngest is 6 weeks old now, and the oldest is 23. I liked to attend their games and plays or whatever event they might have going on. I am around them as much as I can be.

“That really got me stepping in the front door to all the opportunities the industry has to offer,” Stef said. “I really like to go to classroom visits. I like to make butter with the kids so they can see how easy it is to make butter with fresh milk and then they’re able to try it. That’s such a cool experience for them.”

From there, Stef got involved with her campus dairy club, which led her to being involved in dairy judging and dairy challenge.

“That’s where my passion for the industry really took off,” Stef said. “I was never in 4-H or FFA, so that was my rst time ever doing that and I really enjoyed it.”

Dairy challenge especially peaked Stef’s interest she said. Stef went on to compete at competitions in New York, Florida, California and across the Midwest.

“Ever since then, I’ve completely taken off with the dairy industry,” Stef said. “Now I am a dairy challenge teacher assistant and assistant coach for the team.”

Through her college dairy club events and trips, Stef has been able to see dairy farms across the country and abroad.

“I’ve been introduced to so many different dairy farms,” Stef said. “It’s so neat to see how farms differ from the Midwest. It was a cool opportunity to see how dairy farmers treat their cows and everything farmers do to care for their cattle.”

Last summer, in addition to helping Rosenhammer on the farm, Stef interned at Associated Milk Producers Inc. in New Ulm.

“I actually loved it there because I got to use both my ag business side and my dairy side and it was a full circle moment,” Stef said.

This summer, Stef will be interning with AMPI again and in the future intends to work full time for a dairy cooperative or another dairy business.

“May 11 completely changed my life and now I’m so involved in the industry,” Stef said. “I absolutely love the dairy industry.”

A lot of eyes are on dairy product demand right now as the spring ush begins. Exports are strong due to low U.S. prices, particularly on cheese and butter, but they are suspect due to the Trump tariff tit for tat and falling U.S. dollar.

We got a look back on February in the U.S. Department of Agriculture’s latest Dairy Supply and Utilization report, which showed overall cheese use at 1.1 billion pounds, down 0.8% from February 2024. HighGround Dairy blamed “tepid domestic consumption for both American and other-cheese as a volatile economic environment weighs on consumer purchasing.” The good news is, “Discounted U.S. product compared to the rest of the world continues to stimulate healthy export demand.”

Butter utilization, at 169.4 million pounds, was up 10.1% and “neared the monthly high set in 2021, missing it by just 500,000 pounds,” HGD said. “Exports and domestic disappearance were both robust, and international shipments hit their highest mark since March 2022. These were likely buoyed by the steep discount that U.S. product carries to international prices.”

Unfortunately, nonfat dry milk and skim milk powder continued to falter, coming in at 151.5 million pounds, down 13.8% from a year ago and down from the year before for the 17th time in the past 19 months. HGD said, “It was the lowest volume for the month since 2011, highlighting just how poor demand is presently.”

Dry whey utilization fell to 57.2 million pounds, down 11.3%, the smallest monthly volume since November 2022, primarily due to poor domestic demand. Exports were up 3.0%; however, HGD said, “Growth seems unlikely to continue given the tariff war with China, the top destination for U.S. whey.” With China’s tariff at 125%, a U.S. price of 47 cents per pound would put whey at over a dollar to China.

Speaking in the April 21 Dairy Radio Now broadcast, HGD’s Curtis Bosma pointed out that we export a signicant amount of the nonfat dry milk and whey we produce here, so there is a lot of concern about what lies ahead. Domestic demand is greatest for cheese and butter, he said, and cheese has faced some headwinds, while butter demand has been relatively steady.

“The thing that’s really going to move the price one way or the other,” said Bosma, “is going to be export demand, and right now, that’s quite questionable, given everything that’s going on.”

He adds that the new cheese plants which have come online were also built to tap into the whey supply chain, as demand for high-protein whey derivatives has seemingly been insatiable.

The problem is, a good segment of that demand is international, and if we’re unable to export that product because of tariffs or other trade concerns, then that presents a challenge, according to Bosma.

Timing is essential, he said, because as these plants come online, they’re not initially manufacturing the higher value whey products but are starting with the baseline commodity grade dry whey. How-

ever, those prices have slumped the last few months. The product mix may change over time, he concluded, but “That may be a lot slower than we want it to be.”

Fluid milk sales may be returning to their old ways. The USDA’s February data reports packaged sales at 3.4 billion pounds, down 2.2% from February 2024, following a 0.5% slippage in January and a 2.6% increase in December 2024.

Conventional product sales totaled 3.1 billion pounds, down 2.5% from a year ago. Organic sales, at 241 million pounds, were up 2.8% from a year ago and represented 7.1% of total milk sales in the month.

Whole milk sales totaled 1.2 billion pounds, down 1.3% from a year ago but up 0.1% year to date. Whole milk represented 35.5% of total milk sales for the month. Skim milk sales totaled 143 million pounds, down 6.7% from a year ago.

Packaged uid sales in the 2-month period totaled 7.2 billion pounds, down 1.3% from 2024. Conventional product sales totaled 6.7 billion pounds, down 1.7% from a year ago. Organic products, at 517 million pounds, were up 4.8% and represented 7.2% of total milk sales in the two months. The gures represent consumption in Federal Milk Marketing Orders, which account for about 92% of total uid sales in the U.S.

Down on the farm, dairy margins weakened slightly over the rst half of April as increasing feed costs more than offset a small improvement in milk futures, according to the latest Margin Watch from Chicago-based Commodity and Ingredient Hedging LLC.

“Market participants continue to monitor the evolving trade war that the Trump administration is pursuing, with the reciprocal tariff scheduled that was revealed on ‘Liberation Day’ much more aggressive than most were anticipating,” the MW said. “While a 90-day reprieve was issued shortly after the announcement following stress in the U.S. Treasury market with yields spiking in response to a sharp selloff, punitive tariffs on China remain in place, and the country now faces an effective 145% duty on goods shipped to the U.S. An exemption was made for some consumer electronic products, including cell phones and computers that only face a 20% tariff, although China raised duties on U.S. exports to 125%, which effectively shuts down trade between the two countries.

“China is the largest buyer of U.S. dry whey, with shipments of 150 million pounds last year and representing a market share of around 40% of U.S. exports between 2022 and 2024. February U.S. dairy exports declined by 4.3% in volume to 463 million pounds but increased in value by 12.1% to $723.5 million. Nonfat dry milk exports fell 25.7% from last year to 106.9 million pounds, the weakest February volume since 2016. By contrast, February cheese exports of 99 million pounds were the strongest volume ever recorded for the month and up 7.3% from 2024. Butter exports rose 134.2% while exports of anhydrous milk fat were 10 times larger than in February last year,” the MW said.

Chicago Mercantile Exchange cheddar block

cheese closed the Good Friday holiday-shortened week at $1.8350 per pound, up 9 cents on the week, the highest since Feb. 27, 2025 and 15.50 cents above a year ago. It has gained 23.25 cents in the past four weeks.

The Cheddar barrels climbed to $1.90 per pound Tuesday, the highest CME price since Oct. 30, 2024, but closed Thursday at $1.84, up 3.50 cents on the week, 18 cents above a year ago and a half-cent atop the blocks. The barrels have gained 29 cents in four weeks. Sales this week totaled 14 cars of block and 14 of barrel.

Midwest cheesemakers told Dairy Market News that demand tones have improved the past two weeks. Retail customers are more aggressive in buying. Retail Cheddar and Italian-style cheesemakers relay similar notes. Barrel makers say demand has steadied somewhat, but they are also actively purchasing milk and increasing production. Milk has grown in availability, and spot milk prices mid-week were as low as $6 under Class III. Lower prices were expected later in the week and over the spring holiday weekend. Seasonal milk production continues to be more than ample for Western cheese manufacturers. Cheese production varies from lighter to steady. Availability of varietal cheeses is mixed. Buyers convey certain varieties are tight and present challenges securing loads. Stakeholders indicate strong export demand is playing a part in the tightness of certain types. Domestic demand is steady to moderate, with demand from frozen pizza makers strong, according to DMN.

Cash butter inched up to $2.35 per pound Tuesday but closed Thursday at $2.3425, a half-cent lower on the week, and 57.75 cents below a year ago. There were 38 sales put on the board for the short week. Butter churning remains busy in the Central region, and plants continue to add to inventories for future demand needs, focusing on expectations of late summer and fall upticks. Cream availability has been wide open for the entire year, though plant managers reported a slight tightening cream market this week, relative only to previous weeks, but it remains far from tight. Cream suppliers say they are unsure what to expect following the spring holiday weekend.

Cream availability continues to be steady for Western butter manufacturers. Some reported spot loads were being offered at somewhat lower multiples with the holiday weekend at hand. Plants were generally running heavy butter production before the weekend. Butter inventory growth is mixed, and a few manufacturers said that not much was making its way to the freezer. Sellers note that, despite 2025 trade policy changes, domestic prices remain competitive internationally and export demand continues to be strong overall. Domestic retail butter demand is mixed. For some butter sellers, food service demand is down compared to last year, said DMN.

Grade A nonfat dry milk closed Thursday a halfcent higher at $1.1725 per pound, 5.25 cents above a year ago, with only three sales for the week.

Hoard’s Dairyman article Jan 2025: Staph aureus is a subclinical threat. “Mastitis can be caused by many pathogens, but if you ask any dairy veterinarian or farmer which is the most damaging, the odds are good that their response will be Staphylococcus aureus.” “Staph. aureus is especially dangerous because it persistently infects cows.”

Dr. Justine Britten, Pres. Udder Health Systems, NMC board: “In my personal experience, every dairy is impacted to some degree by Staph. aureus,” and “If Staph. [aureus] was easier to see, farmers would be a lot less tolerant of it.” {Translation – you don’t pay attention to the problem so they will test your milk samples}

Cornell University in Journal of Dairy Science: CoPulsation™ prevents new Staph a. infections by 16:1

Dry whey saw its Thursday close at 48.25 cents per pound, up 1.75 cents on the week and 9 cents above a year ago, with eight sales reported for the four days.

The USDA’s weekly crop progress report showed U.S. corn was 4% planted as of the week ending April 13, 2% behind a year ago and 1% behind the 5-year average. Two percent of the soybeans were in the ground, 1% behind a year ago and dead even with the 5-year average.

The agriculture department’s monthly Livestock, Dairy and Poultry Outlook, issued April 16, mirrored milk price and production projections in the April 10 World Agricultural Supply and Demand Estimates report.

It also reported that the highly pathogenic avian inuenza impact remains. California is the state with the highest number of dairy herds from September through December 2024. Since then, the number of reported outbreaks has declined signicantly both in California and elsewhere.

The 2025 U.S. dairy herd size forecast was 9.405 million head, up 25,000 head from the previous month’s projection. An anticipated higher milk yield per cow throughout the year led to an increase of 10 pounds per cow, which is now forecast at 24,130 pounds per head, according to the Outlook.

Tuesday’s Global Dairy Trade saw its weighted average inch up 1.6%, following a 1.1% gain April

1. Volume continued to fall, totaling 36.9 million pounds, down from 38.9 million April 1 and the lowest since May 5, 2020. The average metric ton price crept up to $4,385 U.S., up from $4,250.

Results were mixed. Lactose led the gains, jumping 22% after dropping 2.6% April 1. GDT mozzarella was up 5.4% after dropping 4% last time, while Cheddar was down 1.8%, following a 1.7% rise. Whole milk powder was up 2.8%, following a 0.1% slip. Skim milk powder was down 2.3% after rising 5.9%. Anhydrous milkfat was up 2.1% after a 2.3% gain, while butter was up 1.5% after dropping 1.2% April 1.

StoneX says the GDT 80% butterfat butter price equates to $3.3980 per pound U.S., up 3.4 cents, after falling 2.9 cents last time, and it compares to CME butter, which closed Thursday at $2.3425. GDT Cheddar equated to $2.2330, down 4.3 cents, and compares to Thursday’s CME block Cheddar at $1.8350. GDT skim milk powder averaged $1.2677 per pound, down from $1.3044 last time. Whole milk powder averaged $1.8917 per pound, up from $1.8424. CME Grade A nonfat dry milk closed Thursday at $1.1725 per pound.

Analyst Dustin Winston said, “Regionally, North Asia, which includes China, purchases fell from the last event and last year. Skim milk powder purchases were a signicant factor in this decline. Southeast Asia and Oceania purchases and market share also

fell from both the last event and last year. This market share was picked up in the most part by Europe, where market share nearly tripled from last year’s levels. Middle Eastern market share stayed in line with last year and last event’s levels.”

In politics, Agriculture Secretary Brooke Rollins announced the cancellation this week of the Partnerships for Climate-Smart Commodities. “Following a thorough line-by-line review of each of these Biden era partnerships,” Rollins said, “It became clear that the majority of these projects had sky-high administration fees which in many instances provided less than half of the federal funding directly to farmers. … Select projects may continue if it is demonstrated that a signicant amount of the federal funds awarded will go to farmers. We continue to support farmers and encourage partners to ensure their projects are farmer focused or reapply to continue work that is aligned with the priorities of this administration. With this action, USDA is cutting bureaucratic red tape, streamlining reporting, lowering the paperwork burden on producers and putting farmers rst.”

“USDA will review existing grant agreements based on three farmer-rst policy priorities: a minimum of 65% of federal funds must go to producers; grant recipients must have enrolled at least one producer as of Dec. 31, 2024; and grant recipients must have made a payment to at least one producer as of Dec. 31, 2024.”

CIH 7240 FWA 3,400 hrs. $95,000

USED TRACTORS

IH 1466 w/cab, 3854 orig. hrs $28,000

CIH 8910, 1955 hrs., 2WD, like new$105,000

CIH 7120, 2WD, 5800 hrs. ................$55,000

CIH 7120, 2WD, 4,900 hrs. ...............$55,000

CIH 7120, 2WD, 6,100 hrs. ............Coming In

CIH 7110, 2WD, 4500 hrs..................$63,000

CIH 5250 2WD, 4,700 hrs. .............. $54,000

CIH MX120, 2WD, 3,800 hrs. ............$72,000

CIH MX120 w/loader ........................$75,000

CIH MX100, 2WD, open station w/ldr. ...$69,900

IH 1466, 6800 one-owner hrs ............$21,000

IH 1086, 7,500 hrs. .........................Coming In

IH 686 . ..............................................$14,000

McCormick MC120 FWA, 2,600 hrs ..$57,000 JD 4630 .............................................$25,000

TILLAGE

CIH Tigermate II, 26’..........................$28,000

CIH Tigermate II 26’ w/rolling basket $32,000

CIH Tigermate 200 w/basket, 34’ ..... $42,500

CIH Tigermate 200, 28’ w/rolling basket...............................$40,000

CIH Tigermate 200 28’ w/basket ...... $37,000

CIH RMX340 25’, 3-bar harrow ......Coming In Tigermate 200 28’ w/rolling basket ....$31,000

DMI Tigermate II, 26.5’, 3-bar mulcher ..................................$14,000

DMI Tigermate 18’ w/harrow...............$11,000

CIH RMX 340, 28’ w/mulcher ........... $35,000

CIH RMX 340, 25’...........................Coming In

CIH 530C Ripper, nice ......................$31,000

DMI 2500, 5-shank ............................$12,000

By Danielle Nauman danielle.n@dairystar.com

DEERBROOK, Wis. — With a lifetime of organic farming principles, it was an easy decision for the Keller family to make the commitment to organic dairy farming over 20 years ago.

Jim and Sharon Keller, along with their sons, Ben and Daniel, and daughter, Emily, operate Keller Organic Dairy Farm near Deerbrook, where they milk 120 cows and crop 1,100 acres of loamy and silt-loam ground. The farm has been in the Keller family since 1917, when Jim’s grandparents purchased it.

“I basically farmed organically anyhow; I didn’t like using chemicals or anything,” Jim said. “There was a little more money in organic milk and they were looking for it, so it just made sense.”

The Kellers began with certied organic crop production in 2002 and certied their 35-cow herd a year later when an organic milk market opened up for them.

“There are a lot of advantages to organic production,” Ben said. “We are able to get a pretty consistent pay price in the organic milk market with Organic Valley without the volatile swings you see happen with conventional markets.”

The Kellers joined the Organic Valley cooperative in 2008 and began expanding to their current size when they built a new parlor in 2012. This was followed by a freestall barn a couple years later.

The herd consists primarily of crossbreds, particularly Fleckvieh crosses, with a few older Holsteins re-

maining. The herd is bull-bred. They sell springers, depending on their own replacement needs. The family started using Fleckvieh bulls a few years ago.

“We were hoping to get more meat and better calves, along with more longevity and fewer health issues,” Ben said. “We were looking for more efcient, hardy cows. You can’t beat the Fleckviehs for disposition, either.”

The Kellers calve their herd yearround, taking advantage of the additional premium placed on fall and winter milk to create a more consistent revenue stream. Emily oversees the cows and this year began experi-

menting with the practice of letting cows raise their calves for several weeks.

In addition to grazing, the cows are fed a total mixed ration. The Kellers have around 100 acres dedicated to pasture, which they rotationally graze during the growing season.

“We rotate pastures daily, with a 21–25-day rotation on average, depending on rainfall,” Ben said. “If we’re getting a lot of rain, we can be down to a 15-day rotation — last year, pasture was the only thing that grew, we couldn’t keep up.”

The balance of the Keller’s land is used to raise hay, corn and soybeans

for the herd, as well as a diversied cash cropping enterprise: growing certied organic specialty forages and crops, including raising triticale for seed companies. They also market organic corn and soybeans, foodgrade oats and food-grade clear hilum soybeans which are exported to Asia if they meet quality standards.

“We have a lot of stuff in our rotation,” Ben said. “You have to gure out how to generate as much revenue per acre as possible to continue to stay viable.”

Jim agreed.

“If someone wants to buy it, we’ll grow it,” he said. “We try to do different things, things not everyone is doing.”

This year the Kellers plan to add a new crop to the rotation, growing a grain called Kernza, which is a perennial alternative to traditional wheat crops.

“Kernza has been a buzzword at organic conferences for some time; it’s at the point now that I could nd a market for it,” Ben said. “We’ll plant it with a grain drill in mid-August. It’s a perennial, so the next year and the years after it will produce seed (and be) ready to harvest in late July and early August, similar to wheat. We can take the straw off for bedding, too.”

A downfall of organic production comes in the form of weed control, Jim said. Ben agreed.

“Everything takes a lot more labor,” he said. “There’s more money spent on equipment to control weeds.”

Those needs often mean labor is a concern for the family.

“We shouldn’t have to work seven days a week just to survive,” Ben said. “You should be able to go on a vacation once in a while, to be able to afford to hire someone

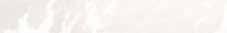

Heifers eat total mixed ra on April 16 at Keller Organic Dairy Farm near Deerbrook, Wisconsin. The Kellers sell

as an addi onal revenue stream, depending on their own replacement needs.

so you can take some time off. We’re fortunate to have enough family members involved with the farm that we can leave once in a while, but

a lot of people don’t have that option.”

The Kellers are concerned for the future of the dairy industry, particularly for small

family farms like their own. “It’s getting harder to compete with the larger guys, and it’s not necessarily small guys versus big guys,” Ben said. “Everyone keeps saying they want to keep the farmers going, but nobody is willing to pay the extra it would take to make it viable.”

By Danielle Nauman danielle.n@dairystar.com

WISCONSIN DELLS, Wis. — When it comes to optimizing the performance of forages in dairy rations, alfalfa and corn silage have a symbiotic relationship according to Dr. Luiz Ferraretto, a ruminant nutrition specialist with the University of Wisconsin-Madison.

“Alfalfa is such a good match to corn silage and so important to dairy diets,” Ferraretto said.

Ferraretto presentated on the importance of highquality forages in dairy diets at the Midwest Forage Association Symposium Feb. 19 in Wisconsin Dells.

Ferraretto said he rst learned to formulate dairy diets using corn silage as the only forage source. He said adding alfalfa into the mix was a difference-maker.

“There are a lot of other nutrients we have to consider, things we can use to formulate diets, but there is nothing we can do if we don’t have very good forage digestibility,” Ferraretto said. “Whether you are talking about alfalfa or corn silage, at the end of the day, our goal is to make sure we have very good forage neutral detergent ber digestibility. That is what actually drives performance in dairy cows.”

Ferraretto said forage quality and efcient feeding behavior go hand-in-hand.

“We care a lot about intake and production numbers, but feeding behavior is something we overlook,” Ferraretto said.

Ferraretto discussed a study of diets low in digestible ber and high in digestible ber, comparing sorghum-based diets with conventional corn silage-based diets. Cows consuming the lower digestibility diet had an intake of 85%-95% of those fed the diet that was more easily digested.

“What was really shocking was that those cows took between 6%-20% more time to eat 5%-15% less feed,” Ferraretto said. “That cow is very likely sorting. It is a major issue. As a nutritionist, if that cow is sorting my diet, (that diet) doesn’t mean anything. She is eating something else, or she is probably taking longer to masticate, because it has lower digestibility.”

Ferraretto said sorting behavior impacts more than milk production.

“There is a health component, too,” Ferraretto said. “Every minute that this cow is spending extra at the feed bunk, she is not resting or, more importantly, ruminating while resting, which I think is a metric we should be using more.”

Corn silage and alfalfa are a perfect match in dairy rations, Ferraretto said.

“Alfalfa has much higher numbers for crude protein compared to corn silage, while corn silage has more starch,” Ferraretto said. “Those match quite well in the rumen of a dairy cow. We need both. The synchronization of those makes sure the cow digests them together to create microbial proteins in the rumen. That helps a lot with milk production, milk protein production and so on.”

Amounts of alfalfa used in rations have decreased over the years, Ferraretto said.

“The number of acres of alfalfa harvested over the years has been declining in the U.S.,” Ferraretto said. “Herd sizes continue to increase, but not necessarily land availability for forage production. Whenever we don’t have enough land, we plant something that produces more, or you buy forage. That is part of the reason why corn silage continues to increase in diets, while alfalfa decreases. It’s not that people don’t want to use alfalfa, it’s just that it’s getting harder.”

Another downside to alfalfa is the lack of consistency that comes from having multiple cuts per year, creating variability in the nutrient value of the feed stuff.

“We need the combination of (quickly) degradable carbohydrates and slowly degradable carbohydrates,” Ferraretto said. “The combination of alfalfa and corn silage helps with that.”

A study that evaluated rations ranging from 90% alfalfa and 10% corn silage to the converse of 90% corn silage and 10% alfalfa showed the ratio of corn silage to alfalfa does not signicantly affect the general outcome, Ferraretto said.

“Milk production was the same; efciency was the same,” Ferraretto said. “However, it was found that when we have between 30%-50% of the forage being al-

falfa, those cows produced more protein and more of the fatty acids, which are the fat truly produced by the mammary gland.”

Particle size is another reason to include alfalfa in dairy rations, Ferraretto said, as the generally larger particle size of corn silage leads to lower intake and decreased production because cows spend more time eating less.

“Alfalfa is typically much more difcult for cows to sort, with the exception of very dry, very long particle-size hay,” Ferraretto said. “Alfalfa allows you to have shorter-size corn silage and still have good, effective ber.”

Ferraretto said producers should be vigi-

lant in watching for signs of clostridia when storing and using alfalfa haylage.

Dr. Luiz Ferraretto University of Wisconsin-Madison

“Clostridia is a nightmare; corn silage has no clostridia, but with haylage, it isn’t so hard to happen,” Ferraretto said. “It’s wet, has less sugar and a lot of protein, which buffers fermentation. It also has more soil contamination. I think we should pay more attention to soil contamination than fermentation with alfalfa.”

Overall, Ferraretto said he believes using alfalfa in tandem with corn silage is a positive venture.

“Alfalfa has a lot of economic benets,” Ferraretto said. “Feeding alfalfa makes corn silage better. We want to keep increasing forages in the diet to the extent we are able to.”

By Amy Kyllo amy.k@star-pub.com

Editor’s note: Information for this article was gathered from Ron Eustice’s book, “Gentlemen Farmers, Farms & Ranches of the Rich & Famous,” interviews with Carol (Heins) Pyfferoen and Rick Pagel, as well as news articles, a Heins family scrapbook and website material.

ROCHESTER, Minn. — In 2024, the Mayo Clinic cared for patients from every state in the U.S. as well as 135 countries. Yet what is sometimes not covered is the Mayo Clinic’s historic connections to the dairy industry.

“Urban people, they al-

ways look at me (with) a little bit of shock when you point out to them that the Mayo Clinic … was founded by a bunch of farmers,” said Rick Pagel, who grew up on a dairy farm in Olmsted County. This agriculture connection Pagel refers to was best delineated by Ron Eustice in his book, “Gentlemen Farmers, Farms & Ranches of the Rich & Famous.” Eustice writes about ve medical doctors who owned dairy farms: Dr. Charles Mayo, Dr. Frank Mann, Dr. Christopher Graham, Dr. Donald Balfour and Dr. Hiram Essex. Dr. Graham, brother-in-law of Dr. Charlie Mayo, donated the land for the

Turn to DAIRY HISTORY | Page 12

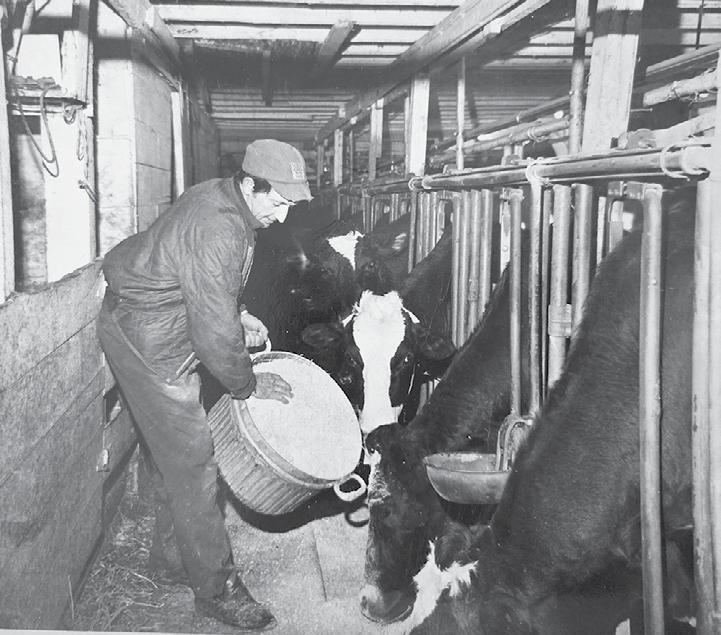

The dispersal sale of Esmur Downs in 1979 brought in what would equal $1.1 million today.

Olmsted County Fairgrounds in 1919. Each farm had premium genetics and impacted the dairy community.

Dr. Essex is one of the most recent of these doctors and is still remembered within the Olmsted County dairy community. According to Eustice’s book, Dr. Essex worked at the Mayo Clinic from 1928–1958, specializing in cardiac physiology, parasites, venom and poison. His Esmur Downs herd was elite, with genetics sold across the world and a herd dispersal that broke Minnesota records.

Dr. Essex and his wife, Marian, established the 52-cow capacity dairy in 1942 in a 50/50 lease with the Leon Heins family.

Carol (Heins) Pyfferoen, Leon’s granddaughter, grew up at Esmur Downs while her parents, Howard and Marian Heins, were working with the Essexes.

“Mom always talked about how the Mayo brothers encouraged the young doctors to invest in property, in farms,” Pyfferoen said. “A lot of people couldn’t afford to buy a farm. … That was very popular back then to have tenant farmers.”

According to Eustice’s book, Dr. Essex became interested in being involved in agriculture through his friend, Dr. Mann, who owned Mandan Farm near Stewartville.

Pyfferoen has the original lease agreement her grandfather signed. It goes over everything from the number of horses and chickens allowed to be fed on the shared feed, to the killing of Canadian thistles, the daily hauling of manure, silage costs and more.

The income and bills were split and the Heins family provided labor while Dr. Essex provided for upkeep and owned the farm. They farmed with horses originally, purchasing an Allis Chalmers tractor in 1946 but continuing to use horses.

Initially the herd was grade Holsteins, but by 1954, the herd had transitioned to 100% registered Holsteins.

Dr. Essex and the Heins were both involved in breeding choices.

“(My parents) made good decisions, they worked hard, they took care of things,” Pyfferoen said. “The more successful Mom and Dad were with

Dr. Hiram Essex worked at Mayo Clinic from 19281958, specializing in cardiac physiology, parasites, poison and venom.

that, the more successful (the Essexes) were.”

Genetics from Esmur Downs were sold across the U.S. and abroad, including the countries of Japan, Italy, France and Mexico. They also sent bulls to stud.

“The success was the genetics,” Pyfferoen said.

According to a Holstein News article from April 1977, the Esmur Downs current herd had a BAA of 106.3 with 10 cows classied as Excellent. Pyfferoen said Eustice worked with their farm to extend their showing efforts beyond the local area. This helped give them exposure, which assisted in selling their genetics.

By April 1980, a Minnesota Regional Holstein News article said the Heins family — and by extension, the Essexes — had bred the 1979 AllAmerican aged bull, Esmur Downs Elevation Bell, who had a score of EX–95. They also had bred 30 Excellent cows.

According to Eustice’s book, in total, the Esmur Downs herd by 1979 had 46 cows that surpassed 100,000 pounds of milk. According to an Agri News newspaper article from 2003, Esmur Downs had three of the four 1970 AllAmerican get-of-sire honorable mention animals.

A Post Bulletin article from approximately 1968 published during the Olmsted County Fair chronicles a taste of what success looked like locally for Esmur Downs. The Heins siblings had the 4-H grand champion cow, the 4-H reserve champion cow, the 4-H grand champion dairy herd, rst and second place in the 4-H junior herd cow division, the 4-H rst-place junior yearling and the 4-H rst-place junior heifer calf. Open class had not happened yet.

“We were very successful showing cattle,” Pyfferoen said. “Dad always said, ‘You don’t need to tell everybody else how good you are, because if you’re that good, they’re going to know it.’”

In 1972, Esmur Downs received the Henry S. Bartel Memorial Trophy for the best three females at the Minnesota State Fair.

Turn to DAIRY HISTORY | Page 13

Esmur Down sold genetics to countries around the world, including Japan, Mexico, Italy and France.

Dr. Essex was

said.

“He liked to be involved,” she said. “Especially when he was younger, when we would show cattle, he’d be at the fairs and the black and white show.”

Dr. Essex was also part of the community. According to Eustice’s book, he served as the president of the Olmsted County Holstein Association in 1950. An article in a 1977 issue of the Minnesota Holstein News indicates he also served on the Minnesota Holstein Association board for nine years and was the president for two.

According to Eustice’s book, Dr. Essex, as well as Dr. Mann and Rick Pagel’s grandfather, George Pagel, would travel to southeast Minnesota to help nd animals for the Rochester Area Holstein Sale. Pagel said his grandpa told him that when the doctors came, they often would be riding in Dr. Charlie Mayo’s blue Buick.

Pyfferoen said the Essexes would come out to Esmur Downs often and that they had a good relationship with them.

Esmur Downs was situated on 320 acres. The barn at Esmur Downs had a haymow in the middle of the barn with four rows of cows surrounding it, three rows with their heads facing the mow and one with their heads faced away.

“It was the most unhandy (setup) ever because nothing was level,”

Pyfferoen said.

In 1979, the year after Dr. Essex’s death, the herd was dispersed. At the time it was the highest-averaging dispersal for a Minnesota Holstein herd at an average of $4,356 per lot according to a Post Bulletin article dated April 16, 1979. There were 58 lots that sold for a total of $252,700. Adjusted for ination, that would equal over $1.1 million today. One of the animals, Esmur Downs Astro Elevation, sold for $12,100, which, adjusted for ination, would be more than $54,800.

After the herd dispersal, a portion of the farmland was donated to the city of Rochester and became Essex Park, and the remainder was sold later. The Heins family continued the Esmur Downs prex on a farm near Oronoco.

•

•

Roadways, Buildings, and Natural Features

• Little to No Disturbance to Wetlands or Other Sensitives Areas

• Many Unique Installation Capabilities vs. Open Cutting/Digging (Entering under Buildings or Tanks)

• Minimal Site Restoration

Land Improvements

DRAIN

Changing weather and higher inputs got you down?

Using Drain Tile to manage excess moisture in the soil pro le is the foundation for increasing pro tability per acre.

- Less compaction

- Better soil Structure

- Allows more days per year for eld operations

- More Yields with same or less inputs

By Michelle Stangler michelle.s@dairystar.com

RIVER FALLS, Wis. — As the agriculture industry changes and evolves, University of Wisconsin-River Falls college students are stepping up to grow alongside the industry, as they aim to develop their skills, grow their networks and contribute to a community they call home.

One opportunity for students to connect, learn and advocate was the University of Wisconsin-River Falls’ 13th annual student-led Ag Day on Campus. The event, hosted by the UW-River Falls Farm Bureau Collegiate Chapter, brought students to hear from agriculture leaders and promote agriculture to a broad audience, including local daycare groups and community members.

The theme this year, “Raising the Bar in Agriculture,” centered around building deeper connections and encouraging continuous learning within the industry.

“This theme encompasses not only the hard work we put into the industry, but how we continue to grow and develop each and every day,” said Brooke Beardsley, one of the chairs of the event. “It’s the purpose we all share and provide for the next generation.”

With many of the attendees being students, the event emphasized the value of engaging young adults in the agriculture industry. Throughout the day, interactive booths, panels of agriculture industry leaders and activities combined education and entertainment.

One of the booths was hosted by the college’s dairy club, where attendees could test their bovine anatomy knowledge by matching cow parts to a diagram.

“We’ve already had a couple people come through and they labeled a part correct and just seeing their eyes, they’re like, ‘Oh my gosh, (I) actually got it right,’” said Ainsley Noble, president of the club. “They don’t understand like we do. They didn’t grow up around the industry that we did, and it’s super cool to see all the sparks and the people learn more about dairy – something that all of us are super passionate about.”

As the semester winds down, this event is a highlight many students look forward to each year.

“It’s very important that a school like this — that’s especially involved in the agriculture industry — keeps that spirit alive,” Noble said. “Seeing all these agriculture clubs is super cool.”

Noble helped design the booth to connect with visitors from all backgrounds, no matter their connection to the agriculture community.

“One of the most important parts

(from the theme) ‘Raising the Bar in Agriculture’ is seeing all these college aged students put on something so special to a lot of them,” Noble said. “(I like) seeing all these clubs come together and take time out of their busy schedules … to spread awareness about agriculture because they truly care.”

The event also sparked conversations about the future of the industry and how it can grow. Katie Cink, one of the three main student organizers, said providing opportunities for everyone involved in agriculture is valuable.

highlighted the power of community within the industry.

“In agriculture, one of the biggest things right now that we’re all having to do is being able to do more with less,” Sankey said. “To do that, we need to really raise the bar. We’re getting more and more urban sprawl.”

Gerhke agreed.

“It means stepping up and improving and building on the past,” she said.

This event highlighted the different journeys into a career in agriculture. Sankey said the industry offers a wide range of opportunities to learn and grow no matter the initial connection to the industry.

“Events like this really just do enhance the experience of other college kids (bringing in) city folks to little daycare kids running around,” Kink said. “It just brings an environment that is unmatched. You see everybody celebrating what they have done in agriculture.”

Fellow organizer JoHannah Gehrke said connections made through the agriculture industry boosted her condence, leading her to pursue a career in meat science.

The importance of investing in people and fostering growth was also discussed during a panel highlighting the professional opportunities in agriculture.

Mike Sankey, a Wisconsin sales agronomist with Legacy Seeds was one of the panelists.

“We need people in this industry because without people, agriculture doesn’t thrive,” Sankey said.

He encouraged students to take advantage of networking opportunities and

Sankey grew up in a city, yet saw himself one day somehow being involved in agriculture.

“Growing up working on farms in my hometown I saw the need like, ‘Hey, we denitely need more people in this industry,’” Sankey said. “When I came to college here at UW-River Falls, I denitely saw that need arise again. There’s a lot more people like me that didn’t grow up on family farms that are here.”

Noble said the event brought togetherness.

“It’s a great opportunity for members, especially our ofcers, to really get the opportunity to share who they are,” Noble said. “They can share how passionate they are about the dairy industry and then get to network with all these other agricultural clubs and the community and the other students on campus that come.”

Jeremy (le ) and Fred Arceneau load their drill

(Right) Fred Arceneau seeds a eld of oats for his son, Jeremy, April 21 near Elrosa, Minnesota. Jeremy hauled manure while his dad planted.

By Sarah Middendorf sarah.m@star-pub.com

SIOUX FALLS, S.D. — What happens in utero affects the health and longevity of the next generation.

Billy Brown, an assistant professor at Kansas State University, spoke about using dam nutrition to set calves up for success during the Central Plains Dairy Expo March 26 in Sioux Falls.

Brown presented on the effects of prenatal exposure to choline and methionine, how dam heat abatement can play a role in the life of their offspring and the effects of parent body conditioning on calves.

mune response.

“Maybe these animals … are able to ght off infection, maybe a little better than their counterparts that did not receive exposure to choline,” Brown said.

During their study, the researchers found choline affected body weight and marbling. Brown said there were areas it did not affect, such as feed efciency, slaughter weight or carcass weight.

“This should be really exciting to the beef industry and the dairy industry,” Brown said. “We don’t really know of any way to nutritionally increase marbling other than just giving more energy to feedlot animals.”

When there is a female in utero, her eggs are present by the time she is born. Those cells are prepped for the environment they think they are going into, Brown said. If a dam is starved and her offspring is being starved at the same time, this tells the calf to prepare for a lifetime of potential starvation, Brown said. When they have nutrients later, the animal stores them for potential future scarcity.

“We could be altering what happens to that animal later in its life as an adult by what’s happening to the dam or even the sire at conception,” Brown said.

Brown said if the mother is obese, the offspring could be obese as well into the third generation. Knowing these affects can play a role in improving cow nutrition on the farm.

Brown started his postdoctoral research at the University of Wisconsin-Madison in January 2021. At that time, he and other researchers were doing a transition cow study looking at rumen-protected choline, a dietary supplement. They were also following the calves for a certain period of time to see its effect.

The calves that had prenatal choline exposure had reduced stress levels, more ideal respiration rates, better rectal temperatures and tumor necrosis factor, which is produced by immune cells during an im-

Brown presented another study conducted at the University of Florida. This study watched calves that were exposed to rumen-protected choline prenatally.

The death loss in the control group of calves which were not exposed to choline prenatally through their dam was 23%, whereas the calves that were exposed to choline the death loss was 9%, Brown said.

Brown also presented data from studies that researched rumen-protected methionine prenatally. The studies showed it increased calf weaning weight.

There may be environmental events that are affecting cows as well. Things like heat stress and cold stress can potentially affect the offspring, Brown said.

UW researchers have been doing studies regarding heat abatement and its effect on offspring.

Based on the study Brown presented, during heat stress, calves that were cooled prenatally live longer in the herd and averaged 300 more days of life than the calves that were not cooled in utero.

“You get another lactation out of those cows,” Brown said.

A calf that is heat stressed in utero has decreased birth weight and weaning weight, Brown said.

Prenatal choline and methionine can promote early growth, potentially enhance carcass characteristics and maybe enhance milk production, Brown said. Prenatal cooling has benets for the cow and an increase in offspring milk production, Brown said.

“Anything we do on a dairy farm, whether it’s your dairy farm or somebody you work for, we need to be considering our return on investment,” Brown said.

Crop and weather conditions in Dairy Star country

We do not have anything seeded yet. They are starting to plant corn in the neighborhood. The guys digging are leaving a lot of dust. The hay fields are starting to green up. We have been hauling pack manure and plan to finish this week. After that we will work on getting the planting and digging equipment ready and start planting corn. We have been busy with our beef cows. We are half done calving; we have 32 calves on the ground and 32 left. We have been taking out a fence line as well.

We have 100 acres of oats planted. We did that April 12-13. We started planting soybeans yesterday (April 22) and have 30 acres in. We grow Pioneer or Stine. We started planting on our sandy, irrigated land. We are not far from being able to plant on everything. Our soybeans will be planted before our corn. The past week we’ve been fertilizing the ground for soybeans and doing a little tillage. We also drag lined our 2.5-milliongallon lagoon. We have some pack manure to haul and then we are done with manure. We will need some rain when we finish planting.

We are not seeding yet. We have been hauling pack manure on the corn fields. Our neighbors have their small grain in, but we do not have any small grain seed to plant. We had 180 acres of winter triticale and winter rye. The triticale did not make the winter because it was too dry or it froze out. The rye looks good though. The fields are spongy, but we have a neighbor five miles away that has been corn planting. The moisture has been spotty, but we hope to start planting corn in the next week.

We had two inches of snow and two tenths of rain yesterday morning (April 21). We had all four seasons in the day. We had snow in the morning and then hit 57 degrees in the afternoon. On April 19, we hauled liquid manure on a couple hay fields. We also cultivated a couple dirt fields, so they dry. The alfalfa is starting to green up. I plan to put wood ash and lime on the fields that I plan to do oats on. There is no one in the area that is planting because it is too wet. Hopefully, by this weekend we are hitting it hard.

We are working on spreading manure. We have planted 70 acres of oats and are done with that. In the next couple of weeks, we are hoping to continue spreading manure. Our pit is about half empty, and we have another 200,000 gallons to haul. In the next couple weeks, we also hope to get corn in the ground. Our neighbors got a lot of corn in and some soybeans as well the third week of April.

We just started planting corn today (April 22). We plant Masters Choice corn that gets used for silage and high moisture corn. A lot of guys around here started planting a week ago. Most of the farmers around here have their soybeans in. We are dry around here. The fall tillage fields are dry, but the spring tillage fields have some nice moisture. I was in one of our alfalfa fields and it had a lot of shoots and looks good. As long as it stays dry here, farmers will be planting their corn.

We have had 3 inches of rain in the past week. We are still waiting for the weather to get started with field work, outside of our daily manure hauling. There have been a few of the Amish in the area plowing a little bit and one neighbor doing some chisel plowing, but not much activity going on around here. The lawns are starting to green up, as are the alfalfa fields. I was doing some work in the dozer Sunday (April 20) in the swampy areas and there was still ice under some of the tall grass.

Since the start of April we’ve gotten about three inches of rain, most of that came last weekend. We got an inch Friday (April 18) and another three-quarters Sunday. We started planting beans, and got about 75 acres planted. We got our alfalfa seeding in, and another farmer south of me got some corn in the ground last week. It’s calling for more rain this week, so we’ll see how much comes when we can get back in the field. We got some hail the third week of April, around here we got quarter-sized hail. In Platteville they got some bigger stuff, up to about golf ball or even baseball sized.

Two largest models will process whole round bales

Twin augers and nearly vertical sidewalls eliminate dead spots

All Stainless Steel mixing chamber for extremely long life Input power options include electric motor or 540 PTO

Over the last two weeks, we’ve gotten about 1.6 inches of rain, most of that came through on Easter Sunday. We had reports of up to two inches, but before then we were dry. Last week I finished up our pre-plant spraying for both corn and soybeans. We started planting corn last Thursday (April 17). We’re 85% done. Wind slowed us down a bit when we were trying to get our spraying done. Winter rye has come on strong and it’s about 16 inches tall, so we will have some decisions to make when it dries out which comes first.

We seeded 200 acres of alfalfa April 17-18 and have 135 acres to go. We plant American 423T alfalfa seed. We’ve been doing a lot of tilling after spreading manure. We continue to spread manure and are hoping to be 80%-90% done by April 28. We are deep tilling some lower fields that we spread manure on so they will dry out. We also did some spraying of winter rye that we planted as a cover crop last fall.

The weather has not been cooperating and now in the forecast there looks to be only two days without rain in the next ten. The ground is not warming up, I talked to someone the other day who had taken a sample and the soil temp was 35 degrees. We hauled manure Saturday (April 19) and have about half of it out, but now we are at a standstill. We chiseled all day Easter Sunday just to get it worked in so it didn’t wash away. The machinery is pretty much all ready to go, but a bearing went bad in the cooling fan on the tractor. We tore it apart yesterday (Apr. 21) and will put that back together today. We are hosting grade school tours next week.

We did 25 acres of new alfalfa seeding April 15. We use lowlignin HarvXtra seed. We planted 20 acres of soybeans April 16. We are in a holding pattern now, but everything is ready as soon as the weather breaks. We didn’t have warm enough weather to put down herbicide application, but that will be the first thing we start on once it clears up. We also did a growth regulator application on wheat via drone April 20-21. This compound is applied at the boot stage and goes on regardless of soil conditions as long as it’s not raining.

Small Squares

Grass

2nd crop

3rd crop

4th crop

1st crop

2nd crop

3rd crop

4th crop

Grass

Rye straw

New Seeding

$135/ton 1 load

Large Squares

$105-130/ton 3 loads

$120-165/ton 5 loads

$195/ton

Rounds

$20-90/ton 13 loads

$40-120/ton 13 loads

$80-95/ton 3 loads

$75-120/ton 2 loads

$40-105/ton 5 loads

$40-105/ton 5 loads

$40/ton 1 load

Hay 10:00 a.m. • Cattle 11:00 a.m.

Dairy Cows

COMPLETE DISPERSAL: (20) Cows and 10 heifers, Herd consists of mostly Jersey and Jersey cross with one Fleckvieh and several holsteins. Cows are out e3very day , fed home grown feed, and not pushed for production. Current tank average 4.3F and 3.4P 265SCC. Fully vaccinated and dewormed. Cows with huge upside potential! Coming from Chetek WI

(3) Holstein tie stall cows fresh 28 to 61 days milking 86 to 97 lbs. Reputation consigner! Jeryl Martin, Ashland Heifers ET 1030 Parfect daughter due 5-12-25 to Haze-P ET 1034 Luster P, due 8/12/25 to Saga. Raised in free stalls, fully vaccinated and fancy! Norman Hoover, Owen (4) Holstein Springers. Bull bred. Nice, due May and June. (6) Holstein Springers, Freestall and headlock adapted. Bred 6 to 7 month. Nice!

(6) Organic Springing heifers due May 20th to July 1st. aAa mated and Triple Hill and Select Sires . All sires and service sires will be available. Very nice group of heifers coming out of an overstacked herd! Craig Sosalla, Whitehall WI

1st and 3rd Mondays of the month at Thorp SELLING 300 TO 600 HEAD EVERY TIME

OBERHOLTZER AUCTIONS - THORP Formerly Turenne Livestock

SALE EVERY MONDAY AND WEDNESDAY 5:00 PM Selling Baby Calves, Hogs, Sheep, Goats, Feeder Cattle, Fat Cattle, Market Cows and Bulls VERY COMPETITIVE MARKET PRICES Call 712-432-5500 for daily market report

MARKET REPORT:

Big enough to make a difference, small enough to care

By Stacey Smart stacey.s@dairystar.com

WISCONSIN DELLS, Wis. — From grasses to legumes, deciding what to plant in a pasture can be intimidating. Sometimes the rst thing to determine is not what to plant, but rather, whether planting is necessary. Starting from scratch may not be required if renovating an existing pasture is possible.

Jason Cavadini, grazing outreach specialist at the University of Wisconsin-Madison Division of Extension, addressed this topic in his presentation: “What should I plant in my pastures?” at the GrassWorks Grazing Conference in January in Wisconsin Dells.

“The most important component of a successful grazing system is the forage base,” Cavadini said. “Planting is a step in the development of a forage base, but it is not the most important step. It should not always be the rst step, and it is not always a necessary step.”

Before doing any planting, Cavadini said the following questions must be answered: What are my grazing goals? What are my farm’s existing resources? Can I work with what I’ve got?

A farm’s grazing goals should consider the type and class of livestock being grazed. The producer should also have a clear understanding of that livestock’s nutritional needs and grazing habits. Grazing management intensity is another key factor.

“Will you move your livestock every day or will it be every four days?” Cavadini said. “It’s good to know that from the start and then plan for that. Management is what helps us achieve the quality we need more than the species does.”

Cavadini said top-notch pasture management should abide by the three Rs: rotational, residual and rest.

Paddocks should be rotated at least every three days, leaving a minimum of 4 inches of post-grazed residual behind, followed by a rest period greater or equal to 30 days. The three Rs are based on the physiology of coolseason perennial grasses.

When looking at a farm’s existing resources, Cavadini said it is important to know what species are present on the pastureland and hay elds. From there, a farmer must determine whether existing species are desirable and compatible with their farm’s goals.

“The species are often a result of management, and some species are only there because of overgrazing,” Cavadini said. “Management can be used to improve the species present, but rst, you need to know what’s growing on your land.”

Species prevalent in the seed bank oftentimes show up whether wanted or unwanted and may appear as pastures mature.

“Work with these species to your advantage, and select seed of species that complement them,” Cavadini said. “You don’t want to put in a mix that’s going to compete with each other.”

An example of uncomplimentary species is meadow fescue and orchard grass. Cavadini said their vast difference in palatability will result in repeated, selective overgrazing and elimination of desirable species from pasture.

“Meadow fescue is one of the best grasses available

to us,” he said. “There are some situations where (meadow fescue and orchard grass) can work well together, but it needs intense management. It can be addressed with trampling at high density for short duration or by clipping seedheads.”

Soil types also play a part as the forage species must be compatible with the soil in which it is planted. The three classes of soils are droughty, well-drained and poorly drained. Soil texture and drainage may have the most signicant inuence on species and seed selection, Cavadini said.

If a farm has existing pastureland and hayelds compatible with the operation’s grazing goals, then Cavadini recommends planting fence posts instead of seed. The elds can then be opened to graze.

“This is the most economical approach to getting a pasture started and should always be the rst consideration,” he said. “It buys you time and allows you to gure out management rst rather than starting out with an expensive seed mix. Applying seed before management often results in wasted money. Management makes a huge difference.”

If the farm does not have existing pastureland and hayelds compatible with grazing goals or enough acres of pasture to support those goals, then it is time to plant new pasture. Settings primed well for new seeding include fall seeding on a small-grain eld and spring seeding in a corn silage eld. Cavadini said a soybean eld has a tighter window but can still work for fall/spring seeding. A cover crop can be used to set up a site for either fall or spring seeding. Outwintering on cropland is another option.

“There are different levels of competition with different species, and most seed mixes don’t establish equally under high competition,” Cavadini said. “You need a low-competition setting in order for a seed mix to thrive. It’s also tougher to establish a mix where other vegetation is present. New seeding or a clean seedbed provides the greatest chance of successful establishment and allows for the greatest selection of seed and species.”

Common cool-season perennials for the Upper Midwest include grasses such as festulolium, Kentucky bluegrass, meadow fescue, meadow/creeping foxtail, orchard grass, perennial ryegrass, quack grass, reed canary grass, smooth brome, tall fescue and timothy as well as legumes such as alfalfa, Alsike clover, birdsfoot trefoil, Kura clover, Ladino clover, red clover and white clover. Sod formers such as Kentucky bluegrass, quack grass, reed canary grass and smooth brome can all be great for grazing but are aggressive in new seedings. If they currently exist in the seed bank, Cavadini recommends not including them in a new seeding mix.

“Sods do not allow legumes to establish well and will make future renovation difcult,” he said.

For dairy cattle, Cavadini recommends a mix of meadow fescue, festulolium, perennial ryegrass, red clover and Ladino clover.

An initial seeding mix should contain 50%-60% grass and 40%-50% legumes. The result will be 15%30% legumes after the rst established year. Cavadini said to study varietal differences, especially maturity, when deciding which seed to use.

“Pre-mixes can be good, but some suppliers will mix custom blends for you,” he said. “Always use named varieties and try to avoid (variety not stated) seed. With VNS, you don’t know for sure what you’re getting, and sometimes they don’t perform like named varieties.”

A great run of cows today with dairy cows continuing their strong market. Top 12 cows $3,800-4,300. Average cows $2,600-3,700. Common or 3- quarter cows sold $1,8002,400. Great quality Holstein and Swiss springers $2,900-3,400. Average $2,200-2,600. Common and light weight $1,800-2,200. Open heifers $1,200-1,975. 300 to 500 lb. Jerseys $800-925. Holstein heifer calves $550-700. (5) Jersey heifer calves 385/ head. Beef Cows $1,625-2,825. Black calves sold in a fairly tight range of $1,000-1,100/ head with 1 black heifer at $1,500. Holstein bull calves $600-810. Bulls mostly $1,900-3,125. Market bulls $1.52-1.72. Market cows $1.21-1.49 with only 7 head under $1.20. Thank you! We really appreciate your business!! 4/14/25 (Thorp)

Beef cross calves $1,000-1,220. Hol bull calves mostly $730-820. Light or blemished calves discounted. Holstein heifer calves $450-600. Kid goats $30-35 per head. Lambs $2.10-2.67/lb. Cull ewes $1.20-1.30. Choice beef strs & hfrs $2.00-2.07. Choice Holsteins $1.84-1.87. Butcher cows mostly sold $1.24-1.36. Feeding type cows $1.40-1.50. Low yielding cows $1.15 and down. Thank you for your business! Check out our new website features! Get a detailed market report for every

Sale Location: W1461 State Hwy 98, Loyal, WI 54446

From Spencer, WI take Hwy 98 west 5 miles. From Loyal, 5 miles east on 98 4/17/25

SALE CONDUCTED BY: Oberholtzer Dairy Cattle & Auction Co.

Auctioneer: Mark Oberholtzer, WI license #2882-052 Mark Oberholtzer 715-773-2240 Irvin Martin 715-626-0002 • Office 715-255-9600 www.oberholtzerauctions.com

www.mndhia.org

The Minnesota DHIA rolling herd average production yields in 2024 reached a new all-time high of 25,895 milk, 1,123 fat, and 853 protein pounds. Especially noteworthy is the record solids percentages, which were 4.34% for butterfat and 3.29% for protein. The SCC ended the year at an average of 195,000. The dollar value is weighted by the pay prices for these four components and was also a new record of $5,653. For 2024, the dollar value formula saw a major increase in the value of butterfat relative to protein.

The 2024 Dollar Value formula is: (0.0150 x milk pounds) + (3.38 x fat pounds) + (1.68 x protein pounds) + [(350SCC/1000) x 0.00090 x (milk pounds/100)]

Below are the highest-ranking herds within each county afliate, alphabetically by county and herd owner. Congratulations to all.

Redwood DHIA Technician

Renville DHIA Technician

Rice DHIA Technician

Tiffany Lesmeister-Knott Redwood Falls, MN 22 years

507-430-1705

Tiffany Lesmeister-Knott Redwood Falls, MN 22 years

507-430-1705

Tracie Vikla

507-215-1827 Keith Korkowski Mayer, MN 35 years 952-994-1660

1 pound hamburger

1 tablespoon ketchup

1 teaspoon mustard

1 teaspoon hot sauce

1 teaspoon garlic powder

1 teaspoon onion powder

1/2 teaspoon seasoned salt

1/2 teaspoon pepper

2 cups noodles

3 1/2 cups beef broth

1/2 cup sour cream

2 cups shredded cheddar cheese

Brown hamburger; add all ingredients except sour cream and cheese. Stir well, cover and simmer until pasta is done. Turn off heat and then stir in sour cream and cheese.

1 cup butter

2 cups sugar

3 eggs

2 yolks

1 tablespoon vanilla

2 2/3 cups our

1 cup buttermilk (or 1 cup milk mixed with 1 tablespoon lemon juice or vinegar)

4 cups rhubarb

2 1/2 teaspoons baking powder

1 teaspoon salt

1/4 cup butter

1/2 cup chopped onion

2 garlic cloves, minced

1 cup sugar

1 pint heavy whipping cream

Cream butter and sugar. Add eggs and vanilla. Add dry ingredients alternately with buttermilk. Put in a 9-by-13 pan. Gently put diced rhubarb on uncooked cake batter. Sprinkle the 1 cup of sugar on the rhubarb. Slowly drizzle the whole pint of cream on the sugar. Bake for 50-55 minutes at 350 degrees. You will be able to tell when it ʼs done when the top is golden brown and the sides of the cake are slightly detached from the cake pan.

1/2 teaspoon salt

4 cups fresh broccoli orets (about 8 ounces)

1 large carrot, nely chopped

3 cups chicken stock

2 cups half-and-half cream

2 bay leaves

1/4 teaspoon pepper

1/4 cup cornstarch

1/4 cup water or additional chicken stock

2 1/2 cups shredded cheddar cheese

Optional toppings: crumbled cooked bacon, additional shredded cheddar cheese, ground nutmeg and pepper

In a 6-quart stockpot, heat butter over medium heat; sauté onion, carrot and garlic until tender, 6-8 minutes. Stir in stock and seasonings; bring to a boil. Simmer another 10-12 minutes. Add 3/4 cup cream and bring to a boil. Cook broccoli until tender crisp in separate pan. Mix remaining cream and cornstarch until smooth; stir into soup. Bring to a boil, stirring occasionally. Cook and stir until thickened, about 1-2 minutes. Remove bay leaves. Stir in broccoli and let cool just a bit and then stir in cheese until melted. If desired, serve soup with toppings.

full Genex MAP breeding program. Cows will sell on test. Very young herd with approximately 50% being 2 & 3 year-old’s. Kitzhaber Dairy ~ Greenwood, WI

QUALITY CONSIGNMENTS CONSIGNMENTS 10 Holstein Dairy Cows, 2-3 year olds. Load has all fresh and bred back cows. Cows milking well, with low scc. Tie stall milked, outside daily, freestall/headlock adapted, vaccinations. Reputation consignor. Mara Clark Dairy

Weekly Highlights at Premier 3,095 head sold at Premier Livestock & Auctions. We had strong sales and a solid market. Tuesday’s special feeder auction saw 570 head, with top beef feeders bringing $2.60–$4.25 per lb and lightweights up to $5.60. Most Holstein steers sold from $2.10–$3.00, with 300–400 lb lightweights at the higher end. bred beef cows were a light test this week, but last week’s topquality cows brought $2,500–$4,350. A herd of 70 beef cows averaged over $3,500.

‘22 Gehl RT165, T-Bar, Dsl, 15” All Season Tracks, 2100 Lift Cap, C/H/A, 2 Spd, 1,884 hrs ......$37,800 ‘17 Gehl RT250, ISO/Dual H-Ctrls, Dsl, Camso Tracks HXD 450x86x58, Both Standard and Hi-Flow Hyd, 2 Spd, Hydra Glide, 295 hrs, Warranty till 6-30-26 or 1000 hrs ................................$48,500

‘18 Gehl R220, JS Ctrls, Dsl, 2200 Lift Cap, SS, 4,854 hrs ...............................................$17,500

Gehl V400, T-Bar Ctrls, Dsl, 4000 Lift Cap, C/H/A, 2 Spd, 2,570 hrs ..............................$37,750

‘21 Gehl V330, JS Ctrls, Dsl, 3300 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 1224 hrs ..........$53,900

‘19 Gehl V270, JS Ctrls, 73HP Dsl, 2700 Lift Cap, C&H, 2 Spd, 250 hrs ...........................$57,500

‘19 Gehl R260, T-Bar Ctrls, Dsl, 2600 Lift Cap, C/H, 2 Spd, 1,400 hrs .........................$39,500 Gehl RT135, ISO Ctrls, 46HP Dsl, 1350 Lift Cap, C/H/A, SS, 107 hrs. .....................................$46,500

‘21 Gehl RT165, T-Bar Ctrls, Dsl, 15” All Season Tracks, 2150 Lift Cap, C/H/A, 2 Spd, 2,015 hrs......................................................$36,000

‘21 Gehl R190, T-Bar Ctrls,Dsl, 2100 Lift Cap, C/H/A, 2 Spd, 800 hrs .............................................$44,250

‘21 Gehl R190, T-Bar Ctrls, 69HP Dsl, 2000 Lift Cap, C&H, 2 Spd, 1,184 hrs. .................$41,500 Gehl 4835, T-Bar Ctrls, Deutz, C & H, SS, 4,600 hrs..................................................... $15,500

‘23 Manitou 3200VT, ISO Hyd Pilot Ctrls, 3.6L Dsl, 114HP, 4572 LBS At 50%, 3200 LBS At 35%, Machine Weight 11,800, Standard and Hi-Flow (38GPM) Hydraulics, C/H/A, 2 Spd, Fold Up Door, Camera, All Season Tracks, Warranty Until 8-232025.............................................................$77,900

‘23 Manitou 1900R, H/F JS Ctrls, Dsl, 2100 Lift Cap, C/H/A, 2 Spd, 185 hrs .................................$48,500

‘22 Manitou 1650RT, H/Ft Ctrls, Dsl, 12” Tracks, 1650 Lift Cap, C/H/A, 2 Spd, 169 hrs .........$56,500 ‘21 Mustang 1650R, H/F Ctrls, Dsl, C/H/A, SS, 3,640 hrs ...............................................$29,900

‘18 Mustang 1650RT, H/F Ctrls, Dsl, 2350 Lift Cap, C/H/A, 2 Spd, 975 hrs ..................$47,500

‘20 Mustang 1650RT, H/F Ctrls, 68HP Dsl, 2350 Lift Cap, C/H/A, 2 Spd, 1,517 hrs ......$38,700

‘19 Mustang 2700V, ISO Ctrls, 72HP Dsl, 2700 Lift Cap, C/H/A, 2 Spd, Hydra Glide, 14 Pin, Back Up Camera, 261 hrs. ..........................$58,900

‘19 Mustang 2150RT, Hyd Pilot- H Ctrls, 72HP Dsl, 18” All Season Tracks, 3000 LBS At 50% Tip Load, C/H/A, 2 Spd, 660 hrs .................................$44,900 ‘16 Mustang 2200R, ISO/Hyd JS Ctrls, 72HP Dsl, 2200 Lift Cap, C/H/A, 2 Spd, 3,375 hrs ......$35,500 Bobcat 7753, H/Ft Ctrls, Dsl, 1700 Lift Cap, SS, 6,300 hrs......................................................$12,500

‘15 NEW HOLLAND L220, Ft Ctrls, Dsl, 2000 Lift Cap, C/H/A, 2 Spd, Set of Steel Tracks, New Engine At 3191 Hours, 903 Hours On New Engine .$24,500

‘21 PENTA 4930, 460 Cu Ft, 3’ LH Flip-Up Conveyor, Minimum 95HP - $31,500

‘13 Penta 5020SD, 540 PTO, 486 Cu Ft, 3’ LH Discharge ...........................................$17,400 ‘08 Penta 4120HD, 540 PTO, 400 Cu Ft, 3’ RH Discharge...........................................$12,900 ‘06 Penta 3010, 350 Cu Ft, 4’ RH Conveyor ....$12,900 PATZ 1100 Series 420, 450 Cu Ft, Flip-Up Conveyor ........................................$12,900 Kuhn Knight 4142, 460 Cu Ft, 3’ LH Chain & Slat Discharge, 9” Rubber Ext, EZ2400 Digistar Scale Head ............................................................$18,500

‘17 Kuhn Knight 8124, 19L X 16.1 Flotation Tires, 2400 Gals, 500 Bu, Frt & Rear Splash Guards, Low Usage ...................................................$34,500 ‘21 Kuhn Knight PS270,

HD Flighting, Vert Beater, New Ploy Floor, Sequence Valve, Flow Control Apron ..............................................$46,000 ‘11 Kuhn Knight 1150, 500 Cubic Feet ......$19,000 ‘09 Meyers VB750, 482 Cu Ft Struck..........$29,000

Upper Beater, Hyd Drive Apron, Twin Apron, 80”x36”x204” Box Dimensions ..........................................$18,500 ‘19 Doda AFI-35, 1 3/8 1000 PTO,6” .............$7,500 ‘22 Artex SBX800, 800 Bu, Clevis Hitch.......$58,800 ‘20 Artex SBX800, 800 Cu Ft, Guillotine Endgate, 88C Apron Chain, Hyd Apron Pressure Relief Kit, Heavy Duty Vert Beaters, Teeth & Rippers Updated ......................................................$57,500