Watch for our New podcast coming soon to Spotify and Apple Podcasts!

“All

dairy, all the time”™

Small farm, big dream Donnays work toward farm transition, processing

By Tiffany Klaphake tiffany.k@dairystar.com

KIMBALL, Minn. — Anna Donnay has had a single goal for some time that she has been continuously working towards.

“I have always wanted to come back to the farm,” Donnay said. “I have always dreamed of having a yogurt or ice cream business on the farm.”

Donnay graduated from South Dakota State University with a degree in dairy manufacturing and dairy production, and she is back home on the farm working in tandem with her parents, John and Chris Donnay, to transition the farm and eventually install a processing plant.

“I worked in the Davis Dairy Plant in Brookings and I made cheese and ice cream there, which was an eye-opening

experience,” Donnay said. “I just love the fact that you can take milk and make it into so many things and sell it directly to the consumer. I nd it just fascinating.”

Donnay and her parents milk 40 organic cows — a mix of Holstein, Jersey and Ayrshire — in a stanchion barn near Kimball. Since she graduated from college in December 2021, Donnay has been working on her family’s farm and on other farms across the country to learn more about dairy farming and onfarm processing.

“When I came back to the farm, I didn’t know anybody besides my dad and a few of his farming friends,” Donnay said. “I felt like I needed to get out and experience how other farms operate. While in college I was a distance runner on the Jackrabbits cross country

Turn to DONNAYS | Page 2

Award-winning gene cs

Henkes named Iowa Holstein Association Master Breeder

By Dan Wacker dan.w@dairystar.com

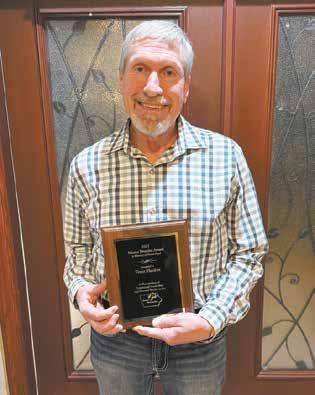

LUANA, Iowa — Being in charge of hosting the Iowa Holstein Association’s annual show means there must be trust involved with those you are working with. What show host Trent Henkes did not know was that the rest of the executive committee, and even his kids, were keeping a secret from him. During the awards ceremony, it was revealed that Henkes was winner of the 2025 Iowa Holstein Association Master Breeder award.

“It’s truly an honor to receive,” Henkes said. “Our family is good friends with Linda Pagel, and I’m very appreciative to receive the award she created in her husband’s mem-

ory. Russel bred a tremendous herd of high-producing cows. It’s a very impressive list of Iowa breeders that have already received the award, and I’m very grateful to be included in this elite group.”

Henkes, owner of Henkeseen Holsteins in Luana, currently milks 65 registered Holsteins and 10 registered Milking Shorthorns with a herd average of 28,726 milk and tests of 3.9% butterfat and 3.0% protein. The herd has a BAA of 110.6 with 24 cows currently scored Excellent. His herd is 96% homebred. Over the years, he has bred 184 Excellent cows.

A 1984 graduate of Iowa State University with a degree in dairy science, Henkes is the fth generation on his family farm. He has been active with

TIFFANY KLAPHAKE/DAIRY STAR

Anna Donnay takes a break in the hay shed March 31 at her family’s farm near Kimball, Minnesota. The Donnay family farm is cer ed organic.

PHOTO SUBMITTED

The Henkes family — Shane (front, from le ), Owen and Leigh Lange; (back, from le ) Ma , Leslie and Trent Henkes, and Marshall and Leah Lange — stand Feb. 22 in Gutenberg, Iowa. The Henkes family manages a 96% homebred herd that includes 24 Excellents.

DAIRY ST R

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Production Manager - Nancy Powell nancy.p@dairystar.com

Assistant Production Manager

Annika Gunderson • annika@star-pub.com

Karen Knoblach • karen.k@star-pub.com

Editorial Staff

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Dan Wacker - Staff Writer 608-487-3858 • dan.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Sarah Middendorf - Staff Writer sarah.m@star-pub.com

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413

laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Adam McClary (SW MN, NW Iowa, SD, Nebraska) 605-864-7917 • adam.m@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Hannah Ullom (Western Wisconsin) 715-933-4045 • hannah.u@dairystar.com

Keya Sleister (Eastern IA, Southwest WI, IL) 563-608-5988 • keya.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order.

Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

by

KLAPHAKE/DAIRY STAR

Anna Donnay cleans mangers March 31 at her family’s farm near Kimball, Minnesota. Donnay par cipated in the Dairy Grazing Appren ceship program and worked on a dairy farm in Vermont that has on-farm processing.

and track teams and because of that I couldn’t participate in a lot of the dairy clubs and trips.”

The summers of 2022 and 2023, Donnay spent working on an educational dairy farm in Pennsylvania that hosted summer camps. Then, she participated in the Dairy Grazing Apprenticeship program that led to her to spend 10 months working at a dairy farm in

Vermont that had an on-farm bottling facility.

“I heard about the Dairy Grazing Apprenticeship program and thought it would be a good t,” Donnay said. “I submitted my application on Friday and by Sunday I had 10 people reaching out to me asking to work for them.”

On her application, Donnay said she mentioned she would like to be on a farm that has on-farm processing since she would like to implement the practice on her own family farm. Donnay selected Miller Farm in Vermont because they bottled milk.

“I learned a lot while I was there,” Donnay said. “I helped them and they helped me. It was a win-win situation. It was an adjustment to be so far away from home but their family took me in as one of their own, which added to the whole experience.”

While there, Donnay helped on the farm where they milk 250 cows and

bottle a portion of their milk. She got experience with herd health, A.I. breeding, operations in the bottling facility, along with the business aspect of onfarm processing.

“The beautiful thing is that on the East Coast there are so many small dairy farms that are processing their own milk,” Donnay said. “It was a great vibe and it is slowly coming to the Midwest. So, it gives me a lot of hope that it is possible, what I want to do here.”

Then, in the summer of 2024, Donnay heard about a tour with the U.S. Ayrshire Breeders Association to visit 16 farms in Great Britain. More than 100 participants from 10 different countries traveled with the group.

“It was an amazing experience to see another country and to network with farmers,” Donnay said. “I am grateful for all these experiences, memories, and connections I have made. However, since I have returned home it feels like home, and (I) know the farm is where I should be.”

Today, Donnay takes care of the livestock on the farm and gets help from her mom with milking. Her dad and brother take care of the feeding and the crops. Donnay’s three siblings come to the farm and help when they can even though they are each married and have children of their own.

Turn to DONNAYS | Page 5

MAXIMUM PRODUCTIVITY AND PERFORMANCE

Get the right tools for this year’s hay season.

Sioux Falls, SD

Westgate, IA

Optimal hoofcare for dairy

System

• Automatic pump calculates the proper amount of water, cleanser, and disinfectant to fill the mat 24/7.

• High quality mat placed at the exit of the robot or parlor to deliver fresh treatment for each cow

• Cleans and conditions hooves to promote overall hoof health.

• Skin care for healthy claws

• Ensures good adhesion to the claw

• pH-neutral

• Contains natural extracts (propolis)

• Optimised for the MS AutoHoofClean System

• Environmentally friendly

TIFFANY KLAPHAKE/DAIRY STAR

John and Anna Donnay stand outside their barn March 31 at their farm near Kimball, Minnesota. Anna is working towards ownership of her family’s farm and intends to pursue on-farm processing.

“My family is all very supportive of me and the farm,” Donnay said. “Even though my siblings aren’t here all the time, I know they all have a passion for the farm and are supporting me. It’s a special place to be.”

When Donnay’s dad took over the farm from his dad, he was told to make it his own. That is when the farm went certied organic. Now, Donnay’s dad repeated the directive, telling Donnay to make the farm her own. And that is exactly what she plans on doing.

“I have always felt the call to feed our community,” Donnay said. “There are a lot of farmers markets and farm stands out there but there isn’t a lot of

dairy within that. I am passionate about giving back to my community and providing a food source to my community. That’s why I also feel passionate about coming back to the farm.”

Donnay said that she would like to start right away with on-farm processing, but she understands that it will take time to nd a system that works for their farm, family and community.

“I am just so grateful to have my parents’ support,” Donnay said. “It is a commitment and there are a lot of unknowns in the future, but I feel that I can get through them with God on my side, my parents and my community’s support.”

Foot Bath Automation

the Iowa Holstein Association and a member for 43 years.

“I nd a great deal of pride in having a majority homebred herd,” Henkes said.

Henke has received the Progressive Breeders Registry award from the Holstein Association USA for 24 years. One of the qualications of the award is being at least 75% homebred.

The genetics at Henkeseen Holsteins started to take off when his dad purchased a cow from his neighbor’s herd sale in 1974. Henkes decided to breed her to a high Total Performance Index bulls to create the Henkeseen Chairman Mandy family, which includes Henkeseen Mark Marci. Mark Marci was classied Excellent 94 and produced over 170,000 pounds of milk in her lifetime.

With elite-level scores and high-production cows, Henkes felt his herd was trending in the right direction, but it was Marci’s daughter, Henkeseen M Hillary that garnered interest in Henkeseen Holsteins.

“Henkeseen M Hillary certainly put us on the map and brought worldwide interest in our herd,” Henkes said. “She scored high as a 2-year-old and was … (a high) protein-indexing cow. … This was in the 90s, when protein was rst becoming an important trait.”

Nellie, who was the District 1 Holstein Show grand champion.

Along with venturing into Red & White Holstein genetics, his son’s interest in Milking Shorthorns has created a new pool of genetics to work with and added another market for cattle, embryos and semen.

With interest in his cows, Henkes began to distribute genetics around the world. In all, 20 of Hillary’s descendants were sent to A.I., 13 daughters were Excellent and 19 were Very Good.

“We continue to use the best genetics available when breeding our cows and selecting a service sire,” Henkes said. “A great deal of time is spent Googling Holstein bull names. We do some ushing and (in vitro fertilization) work with our elite cows to hopefully produce more offspring from them. I also really enjoy working with the Red & Whites, which adds marketability to our cattle.”

One of those Red & White Holsteins that has continued Henkeseen’s tradition of high-scoring cows is Henkeseen Lad Nellie Red EX-92. She is currently milking and producing show heifers. Nellie Red traces back to his rst homebred Excellent, Henkeseen Wayne Noel

“We are enjoying success with showing and merchandising our Milking Shorthorns,” Henkes said. “We bred a Red & White great, great granddaughter of Hillary to a Milking Shorthorn that has developed into our top Milking Shorthorn cow family. We have bred several World Dairy Expo winners and have sold offspring from that family across the country.”

With the new venture into Milking Shorthorns, Henkes is co-chairing the National Milking Shorthorn Convention this summer, held at the Delaware County Fairgrounds in Manchester. Henkeseen Holsteins will be a featured farm tour. The event will be a family affair as his wife, Leslie, is the nancial chair and his son, Matt, the sixth generation at Henkeseen Holsteins, is the sale chairman.

PHOTO SUBMITTED

Trent Henkes stands with his Iowa Holstein Associa on Master Breeder award a er the annual mee ng Feb. 22 in Gu enberg, Iowa. Henkes milks 65 registered Holsteins and 10 registered Milking Shorthorns at Henkeseen Holsteins.

An environment for the people Employee management a focus at Driftwood Dairy

By Michelle Stangler Staff Writer

BALTIC, S.D. — At Driftwood Dairy, managing cows is only part of the job — managing people is equally as important. Just ask Oscar Rivera, the farm manager responsible for overseeing the day-to-day operations of the 5,500-head Jersey-cross dairy farm.

Rivera said he believes the key to success lies in keeping employees engaged and involved.

Since joining the team in 2021, Rivera has focused not only on herd performance but on creating a welcoming and positive environment. He stepped into the role as the farm was implementing a new rotary parlor and has since analyzed efciencies to nd ways to grow the farm.

“Using a parlor like this just helps a lot being able to bring more cows in and still be able to milk them in a 7-hour

shift,” Rivera said.

During a recent DeLaval tour, attendees got a rsthand look at the new facility showcasing the technology and processes being used on the farm. But even with modern equipment, Rivera said success still comes down to the people.

Rivera’s tasks include managing the people on the farm, planning the day-to-day schedule and placing feed orders. His role also includes nding ways to increase milk production, with the long-term goal of expanding the herd in the coming years.

Today, he is thinking about ways to help Driftwood Dairy improve their statistics. The herd is averaging 72 pounds of milk per cow, with a butterfat content of 4.98% and protein at 3.76%. Rivera’s long-term goal is to increase that average to 75 pounds per cow, primarily by improving herd health and transitioning to a more youthful herd.

“We’re planning to sell the older cows and get a younger and fresher herd,” Rivera said. “Hopefully, with (more) rst and second lactation (cows), the milk is going to go up to 75 (pounds per cow). That’s our goal for this and next year.”

That goal will not be met by herd changes alone. Rivera said employee engagement is just as important. One of Rivera’s tasks is sharing performance metrics of the herd with employees, including milk testing results and somatic cell counts, to help them understand how their work impacts the farm’s success.

“(I) try to get them involved in the everyday tasks and the results of it so they can tell (if) they’re doing a good or bad job,” Rivera said.

The culture of open communication, Rivera said has created a welcoming environment. This has led to some employees asking Rivera for updates on herd performance so they can improve as employees.

“We encourage a nice environment and try to keep our employees, so we don’t have to train guys every two weeks,”

Rivera said. “There are guys that have been with us since (the farm) started a (few years ago) so that helps a lot.”

Employee retention can be seen as a big task to some, but

Rivera has found that building relationships and showing appreciation goes a long way.

The Industry Leader In Agriculture Curtains

SARAH MIDDENDORF/DAIRY STAR Oscar Rivera sits in the office March 25 at Dri�wood Dairy near Bal�c, South Dakota. Rivera is the farm manager at Dri�wood Dairy.

With a staff of 34 employees, Rivera said he knows that building a team-like culture is imperative for the farm’s success.

One way he keeps building on the culture is by promoting continuous education. While milking cows in a parlor can become repetitive, Rivera said periodic training sessions and refreshers keep morale high and skills sharp.

Rivera’s dedication to growth is not limited to his staff; he too enjoys learning. His own journey in agriculture began through a veterinary medicine program in college in Mexico. It was there he found his calling working with dairy cows.

“I always worked with dairy cows in Mexico when I graduated, and that’s how I got involved in the dairy business,” Rivera said.

Now, with perspectives of different areas in North America and hands-on experiences on a few dairy farms, Rivera brings both technical knowledge and a people-rst philos-

ophy to his role at Driftwood Dairy. The focus is not just on producing more milk, but on building a workplace where people feel valued and connected to the results of their labor.

SARAH MIDDENDORF/DAIRY STAR

Cows ride the carousel parlor March 25 at Dri wood Dairy near Bal c, South Dakota. The farm is averaging 72 pounds of milk per cow, with a bu erfat content of 4.98% and protein content of 3.76%.

(Right) Visitors view the carousel parlor March 25 at Dri wood Dairy near Bal c, South Dakota. Dri wood Dairy milks 5,500 Jersey crosses.

Genetic progress leads to formula changes

Jorgensen discusses April proof differences

By Danielle Nauman danielle.n@dairystar.com

WAUPUN, Wis. — Driven by data, the dairy industry requires producers to constantly reevaluate information to make the best decisions for continued improvement.

Three times a year, new genetic information is provided by the Council on Dairy Cattle Breeding in the form of proofs. The most recent round of proofs came out April 1, with changes of note being made to the formulas for both Net Merit and Cheese Merit, as well as the 5-year base change.

Kevin Jorgensen, senior Holstein sire analyst for Select Sires Inc., said the 5-year base change is the measure of genetic progress made within each breed over ve years. To readjust genetic levels, Jorgensen said the 2020 cow population becomes the base of zero. Changes will be applied to production and type, as well as health and tness traits.

Jorgensen compared one of the more dramatic adjustments in the Holstein breed — 74 pounds of combined fat and protein — to the adjustment made two base changes ago in December 2014 of 29 pounds.

“It’s really telling how much genetic progress we’ve made, particularly in the production traits,” Jorgensen said. “We’ve made revolutionary changes, especially in (combined fat and protein). When you speak to producers, this astronomical increase in CFP is pretty

direct, most people see it in their bulk tank and components on their farm. It’s not entirely genetic — there have been amazing breakthroughs in how we’re feeding cows — but genetic selection has really intensied in the last generation or generation and a half.”

The base changes are applied equally to all bulls in the population, Jorgensen said, using the example of a bull previously at 174 pounds CFP would now be at 100 pounds. Despite the change in index, the bull will remain in the same percentile. Jorgensen said like every new proof run, additional daughter data will ultimately factor into the bull’s nal ranking.

Jorgensen said changes to the Net Merit and Cheese Merit formulas are based on changes in economic values since the last formula revision. Fat will be factored into the index at 31.8%, with protein applied at 13% and milk at 3.2%. Health and tness traits will continue to comprise 21.2% of the formulation, while calving and fertility will account for 8.7%.

“Net Merit is geared for producers that want a commercially-friendly cow,” Jorgensen said. “There is more emphasis on pounds of fat, relative to protein; more emphasis on reduced body size and on the Feed Saved traits; less on productive life, but more on livability, which makes sense because cull cows are worth more at this stage of the game. There’s probably a little less emphasis on daughter fertility — they reduced a little bit on (Daughter Pregnancy Rate) and increased cow and heifer

conception rates, but not to the degree that DPR was moved down.”

Cheese Merit is calculated similarly, but with a nod to cheese yield; milk is factored in at -2%, focusing on fat and protein, which comprise 48% of the formulation, Jorgensen said.

Jorgensen said the base changes and formula changes are needed to keep pace with the advancing world of dairy cattle genetics, and the speed of those advancements are the reason for some of the dramatic adjustments made.

“The reason we have a base change every ve years is that used to be the span of a generation,” Jorgensen said. “With our accelerated genetic progress, our generation interval in this genomic selection era is about 21 months now. We’re accounting for 2.5 generations in that same period of time. It’s a credit to the genetic progress we’re making.”

Jorgensen said he speculates that the increased percentage in semen sales from genomic bulls over proven bulls has factored into the rapid increases and shrinking generation intervals.

Jorgensen said the volume of young bulls genomically tested is the cornerstone of that progress.

“Our selection pressure is so intense because of the critical mass of testing so many calves,” Jorgensen said. “That selection pressure is so deep that it is very rare anymore that a bull that is a huge minus on fat test would make it to a marketing lineup — he’d have to be so extreme in the other 70-some traits.”

Jorgensen said Select Sires tested 7,684 Holstein bulls in 2024, out of about 25,509 tested industry–wide. From that pool, Jorgensen said 275 bulls — just over 3% — entered the Se-

lect Sires lineup. Jorgensen said he encourages producers to look inside their operation when weighing the various indexes in their own breeding programs.

“It’s really important for a producer to know exactly what they want,” Jorgensen said. “With the reduced number of replacement heifers we have, every heifer counts, because you don’t have another to take the place of ones you don’t like. We’re at historical lows of female replacements. Our cows are going to have to live longer.”

Jorgensen does not see that trajectory changing.

“No one is going to stop making those little black calves,” Jorgensen said. “They are way too lucrative; they can’t take that revenue stream out of their operation. It’s a huge paradigm shift in our industry. Some people might be rethinking what the right amount of heifers is and making slight adjustments there. We’re seeing a slight increase in sexed semen sales because of that. They are trying to make enough heifers with the fewest uteruses possible, so they can devote more to making those black calves.”

With rapid advancements and constant changes, Jorgensen said he advises producers to use the tools and data provided in the proofs and indexes.

“If we believe in genetics, we believe in the next generation,” Jorgensen said. “It’s not always perfect, but I believe with the genetic progress we are making, this system is far more accurate than the measures we were using in the pre-genomic era.”

USED TRACTORS

CIH 8910, 1955 hrs., 2WD, like new$105,000

CIH 7120, 2WD, 5800 hrs. ................$55,000

CIH 7120, 2WD, 4,900 hrs. ...............$55,000

CIH 7120, 2WD, 6,100 hrs. ............Coming In

CIH 7110, 2WD, 4500 hrs..................$63,000

CIH 5250 2WD, 4,700 hrs. .............. $54,000

CIH MX120, 2WD, 3,800 hrs. ............$72,000

CIH MX120 w/loader ........................$75,000

CIH MX100, 2WD, open station w/ldr. ...$69,900

IH 1466, 6800 one-owner hrs ............$21,000

IH 1086, 7,500 hrs. .........................Coming In IH 686 . ..............................................$14,000

McCormick MC120 FWA, 2,600 hrs ..$57,000

TILLAGE

CIH Tigermate II, 26’..........................$28,000

CIH Tigermate II 26’ w/rolling basket $32,000

CIH Tigermate 200 w/basket, 34’ ..... $42,500

CIH Tigermate 200, 28’ w/rolling basket ...............................$40,000

CIH Tigermate 200 28’ w/basket ...... $37,000

CIH 3950 disc, 23’, non-cushion.....Coming In

CIH RMX340 25’, 3-bar harrow ......Coming In Tigermate 200 28’ w/rolling basket ....$31,000

DMI Tigermate II, 26.5’, 3-bar mulcher ..................................$14,000

DMI Tigermate 18’ w/harrow ...............$11,000

CIH RMX 340, 28’ w/mulcher ........... $35,000

CIH RMX 340, 25’...........................Coming In

box, red .................$20,500

644, tarp & fenders ..................$21,000

644,green .................................$17,500

557 gravity box, red .................$19,000

544 w/roll tarp & fenders ..........$14,500

President Donald Trump announced a new 10% across-the-board tariff on all countries. Individualized higher reciprocal duties are being imposed on countries in which the U.S. has the largest trade decits. “April 2nd, 2025, will forever be remembered as the day American industry was reborn, the day America’s destiny was reclaimed and the day that we began to make America wealthy again,” Trump said, also saying unfair trade practices have harmed U.S. agriculture. “Today’s actions [are] also standing up for our great farmers and ranchers who are brutalized by nations all over the world,” he said, pointing to high Canadian dairy tariffs and European Union restrictions on American poultry. Trump also criticized Australia for banning U.S. beef while beneting from $3 billion in beef exports to the U.S. last year. Canada and Mexico will be exempt from all the new tariffs. The preexisting 25% tariff on Canada and Mexico is still in effect, and goods that comply with the U.S.-Mexico-Canada Agreement will continue to receive preferential treatment and are exempt.

Level playing eld sought

“It’s just

to track everything for your herd.”

three main reports that I use are the lactation report, herd summary and heifer calf listing. Those give me most of the information that I’m looking for.

Which is your favorite and why? The rst one I go to is the somatic cell count report, both herd and individual. It helps me cull problem cows.

How do you use them within your dairy? We use the production and SCC reports for culling decisions and use the fat, protein, and MUN reports to evaluate feed ration changes.

How does testing with DHIA bene t your dairy operation? It gives me paperwork to track all the cattle and reports on which cows to breed. It’s just great information to track everything for your herd. You have a lifetime of information on them, where they came from, when they born, their sire and dam, and so much more.

Tell us about your farm. My wife Becky and I and our children milk 40 cows. We also farm 220 acres of corn, wheat and alfalfa. My dad comes out and helps as needed too.

Tariff uncertainty pressures dairy markets

Dairy markets are feeling the strain from the new trade tariffs. Mark Newman, a market analyst with Commodity & Ingredients Hedging, noted Class III milk prices have dropped signicantly in recent months. “You know, we were at $19.50, even $20. And now you’re seeing nearby Class III at $17 so it’s fallen to $2 from $3 just from these tariffs,” he said. In response to uctuating prices, dairy producers are taking steps to protect their margins, particularly on feed costs. “A lot of our clients have been booking their meal, whether that be canola or soybean meal,” Newman said, also emphasizing the importance of maintaining exibility in risk management strategies, particularly during the seasonal lull in demand.

Export challenges and cheese surplus weigh on dairy market

The National Milk Producers Federation and U.S. Dairy Export Council released a joint statement in reaction to President Trump’s tariff strategy. NMPF and USDEC said this plan can be positive if it is used as leverage to x trade barriers. “A rm hand and decisive approach to driving changes is most needed with the European Union and India to correct their distortive trade policies and mistreatment of American agriculture,” said Krysta Hardin, CEO, USDEC. Gregg Doud, president and CEO of the NMPF, agreed. “If Europe retaliates against the United States, we encourage the administration to respond strongly by raising tariffs on European cheeses and butter,” he said. “We also appreciate the president’s recognition of the sizable barriers facing U.S. dairy exports into the Canadian market.”

Trade uncertainty and rising cheese production are pressuring dairy prices. Sarina Sharp, a market analyst with The Daily Dairy Report, discussed the market during the Central Plains Dairy Expo in Sioux Falls. “Unfortunately, I think that lower is the more likely path, especially for producers in this Central Plains region who mostly get Class III milk revenue,” Sharp said. Uncertainty surrounding trade policies is also affecting international demand. Sharp noted that while buyers are still purchasing, they are cautious about future commitments.

Common names bill resurfaces Legislation has been reintroduced in the House and Senate to dene a list of common names for ag commodities, food products and terms used in the marketing and packaging of products. The bill directs the U.S. Department of Agriculture and the U.S. Trade Representative’s Ofce to defend the right to use common names in foreign markets, like parmesan and asiago.

Glen Christen 40 cows • Sauk Centre, Minnesota Testing with DHIA since 1977

The

Con nued from AG INSIDER | Page 10

Glessing testies before Congress

Minnesota Farm Bureau President Dan Glessing testied before the House Subcommittee on Highways and Transit, emphasizing the need for a reliable transportation system to support American agriculture. “The products we grow and raise must travel far beyond our farm gates to reach markets, processors, and consumers,” he said. Glessing urged Congress to address supply chain challenges and reafrmed the Farm Bureau’s support for the Infrastructure Investment and Jobs Act, National Highway Trust Fund fees, and exemptions for agricultural haulers. Glessing is a dairy farmer from Waverly, Minnesota, and a member of the American Farm Bureau Federation board of directors.

Shipbuilding proposal has unintended consequences

The Ofce of the U.S. Trade Representative is hearing from agriculture groups regarding its investigation into China’s shipbuilding dominance. The Trump administration is considering fees of up to $1 million for Chinesemade or operated ships when in U.S. ports. The International Dairy Foods Association said the proposed penalties would lead to an 8% decline in dairy exports. Becky Rasdall Vargas, International Dairy Foods Association Senior Vice President of Trade and Workforce Policy, said the dairy industry sees the value of U.S.-owned and U.S.-agged ships when supply chains are tested. “USTR’s proposed actions, however, risk inicting unintended consequences on American exporters, producers and workers by raising shipping costs, rerouting global trade and weakening supply chains, especially for time-sensitive, perishable products like dairy,” she said.

Dairy exports dip in February

During February, U.S. dairy exports totaled 463 million pounds. That’s down 38 million pounds from the same period last year. Cheese exports increased, up 3.4 million pounds from a year ago. Exports of butter and whole milk powder also rose, up 6.4

million pounds and 813,00 pounds respectively. According to USDA, exports of nonfat dry milk and skim milk powder declined 42 million pounds from February 2024. Whey protein concentrate exports dropped 8.6 million pounds.

Public input sought for feedlot rules

The public comment period is open for the Minnesota Pollution Control Agency’s proposal to amend the state feedlot rules. The MPCA website says the purpose of this measure is to improve land application of manure to protect water quality and avoid sh kills. Public comments will be accepted until July 22. The last major revision of the feedlot rules in Minnesota was 25 years ago.

Success for Central Plains Dairy Expo

The Central Plains Dairy Expo in Sioux Falls drew dairy producers and industry professionals from across the country and beyond. “When we put this show on, we focus on these dairies in the Central Plains region, but we are nding more and more people coming from all over the nation and worldwide,” said Kristy Mach, Central Plains Dairy Association executive director. The dates for next year’s expo are March 17-19.

Trivia challenge

France consumes the most cheese on a per-capita basis at 58 pounds per year. That answers our last trivia question. For this week’s trivia, what is the term for the loose ap of skin on the underside of a dairy cow’s neck? We’ll have the answer in our next edition of the Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Your planting and tillage equipment require proper maintenance to perform at their most efficient levels. Your milking equipment requires the same amount of attention.

Place your trust in the experienced hands of Centre Dairy of Sauk Centre. As a respected dealer in Sauk Centre for over 33 years, Jon and his staff know the benefits of having properly tuned equipment that can perform at maximum efficiency.

What can you expect? • Check CFM of vacuum pump • Check vacuum controller condition • Check for vacuum loss across the system

• Graph pulsators and do any needed repairs.

A life story with a lesson

Roozeboom inspires through persistence, compassion

By Sarah Middendorf sarah.m@star-pub.com

SIOUX FALLS, S.D.

From a farming family to a pastoral calling, Rob Roozeboom has conquered and learned many things throughout his life.

Roozeboom spoke during the prayer breakfast March 26 at Central Plains Dairy Expo.

“I never had a dream of running a ministry; I had a dream of being a farmer,” said Roozeboom, founder of Rise Ministries and RiseFest.

At 5 years old, Roozeboom was diagnosed with muscular dystrophy. He was raised with the belief that the harder you try, the better you will become.

“What I didn’t understand is that I can’t (physically), because I can’t beat (muscular dystrophy),” Roozeboom said.

Until Roozeboom was 9 years old, he was raised on his family’s farm. At that time his dad felt a calling to become a pastor, so they moved into the city to start this chapter.

“What a weird transition

— from a farmer to a pastor,” Roozeboom said. “The journey began. I lost the farm, what I loved most in life, and all of a sudden, I started realizing that God will take what I love most.”

Through ministry, muscular dystrophy and the journey of life, Roozeboom shared with attendees ve lessons he has learned about joy, grief, brokenness, emotions and community. Joy and grief coexist. Everyone’s brokenness

is different, but grief and pain are the same. Grieving is okay. People all have emotions, just not everybody has access to them. And nally, individuals were never meant to walk this life alone.

“We all have a story,” Roozeboom said. “Every one of you is walking through something that’s been challenging. Grief and pain are the same. Whether it’s been the loss of a loved one, or it’s an expectation that hasn’t been met.

Things aren’t going as well on the dairy as you had hoped. Prices aren’t where they’re supposed to be. Wondering what’s around the next corner or how are we going to make it through, that’s real pain (and) that’s real grief.”

Like most people, Roozeboom has struggled throughout his life.

“I used to ask my mom why we never talk about muscular dystrophy in our house,” Roozeboom said. “She said,

‘Rob if we don’t talk about it, it doesn’t exist.’”

For Roozeboom, he had to live through muscular dystrophy whether it was talked about or not. All people have emotions, just not everybody has access to them, Roozeboom said.

“I’m here (speaking) with a lot of tough people, I understand that,” Roozeboom said.

FEED MILL SERVICES

With Several Quality Ingredients At Our Disposal, We Can Produce A Wide Variety Of Bulk Custom Mixes To Fit Any Nutritional Need At Our Glacial Plains Feed Mill In De Graff, MN.

SARAH MIDDENDORF/DAIRY STAR

Visitors listen to Rob Roozeboom during the Central Plains Dairy Expo Prayer Breakfast March 26 at the Denny Sanford Premier Center in Sioux Falls, South Dakota. At 5 years old, Roozeboom was diagnosed with muscular dystrophy.

“I know what you do for a living. … If you think you can’t grieve because it makes you weak, you are wrong.”

When things don’t go the way they are supposed to, Roozeboom said, it is OK to grieve.

“I wish someone would have told me that a long time ago,” Roozeboom said. “It doesn’t make you weak, it just makes you human.”

Four years ago, a mother and son walked into Roozeboom’s ofce. He was looking for help getting around, so the son was going to assist Roozeboom. This young man would end up helping Roozeboom for the next four years until he went to college. Little did Roozeboom know how impacted he would be by the young man.

“The biggest moment of joy and grief for me was last year,” Roozeboom said. “(The young man) was wrestling at the state tournament in Des Moines. I was sitting in the arena going, ‘God why do I have to sit up here (in the handicapped accessible area)?’ Yes, my wife’s next to me. Yes, my daughters (are too), but all the support is like 13 rows down. ‘God why do I have to be up here? Why can’t I be down there?’”

Roozeboom said he was ghting

SARAH MIDDENDORF/DAIRY STAR

Rob Roozeboom smiles on stage March 26 at the Denny Sanford Premier Center in Sioux Falls, South Dakota. Roozeboom spoke during the prayer breakfast March 26 at Central Plains Dairy Expo.

with God the whole time during the match, trying to gure this out.

“All of a sudden it hits me, ‘Rob if you weren’t broken, you wouldn’t be here. If you weren’t broken, you wouldn’t know that young man the way you do,’” Roozeboom said.

“I got to watch the state champion wrestle. Four years of his life he gave to me.”

Roozeboom said he realized there was a reason for the lessons he has learned throughout his life, such as a time when he was lming a Good Friday program in the desert in Arizona.

Roozeboom showed a video of him climbing a hill with his wheelchair. Evidently, the hill was a little too steep, and he fell backwards in the middle of the hill. His team came to the rescue to pick him up again.

“They come running when things happen,” Roozeboom said. “I wanted to navigate a mountain in my wheelchair to show people that sometimes, when we have help, we can keep going up the mountain, even when it’s steep, even when it’s rocky.”

People are going to have hills and valleys throughout their lives and when other people are let into their lives, individuals can navigate those, Roozeboom said. Even though Roozeboom was diagnosed with muscular dystrophy at a young age, he has not let that stop him from climbing hills.

“Our circumstances don’t determine how God feels about us,” Roozeboom said. “It is time to take back ground in our own hearts, whether you are a believer or you don’t know who Jesus is.”

from our side our side OF THE

Delbert Bechtold St. Joseph, Minnesota Stearns County 33 cows

What is the somatic cell count of your milk? 85,000.

Walk us through your milking procedure. I prep with an iodine-based udder wash and use individual rags for washing and drying. I then attach the unit and, when the cow is done milking, I use a post dip. I started using Fight Bac, which is an aerosol can. It’s a very sanitary option with less waste than a dip cup.

What three details do you attribute the low SCC to? We strive for the overall health of our herd and cleanliness of cows. I’m the one who does all the milking, so that keeps things consistent. We also bed every day with sawdust, and the cows go out every day when we scrape everything down.

How often do you review SCC, and in what ways do you monitor it? The processor has bulk tank results on the sample information system. I call in a couple of times a week, and we also monitor it through our monthly Dairy Herd Improvement Association testing. We have been testing with DHIA ever since I can remember. Our dad started when he farmed, and we have continued.

If a cow’s SCC rises, what is the protocol to correct it? A cow with mastitis will be treated with intravenous Banamine and followed with ve days of ampicillin. If she is persistent with high SCC, she will be culled.

Why is having a low SCC important? For many reasons, including better production and better milk quality. The premium from the processor makes it worthwhile.

Regarding SCC, what valuable advice have you received? Low somatic cell count is an indicator of udder health in your cows. We have always focused on having clean cows, and we often get compliments on that. We go around the barn many times to scrape manure.

Tell us about your farm and family. I farm in a partnership with my brother, Delroy. Along with the dairy, we also nish approximately 400 steers a year and farm 1,100 acres of land. We grow corn, alfalfa, small grains and soybeans.

Jason Barkeim Winona, Minnesota Winona County 320 cows

What is the somatic cell count of your milk? In 2024, our SCC averaged 76,000. Since 2017, it has been below 100,000.

Walk us through your milking procedure. We have a double-9 herringbone parlor. We start by going down one side of nine, wiping the sand off with a microber towel and pre dipping them with an iodine teat dip. Then, we go back to the beginning and clean the teats with a clean towel for each cow. Then, we attach the milkers and post dip them with 4XLA post dip when they are nished milking.

What three details do you attribute the low SCC to? I believe the biggest contributor to SCC is cow health. Feed quality, nutrition and stress all play a factor in their health.

How often do you review the SCC, and what ways do you monitor it? I look at the bulk tank average daily, and on an individual basis, I test every other month and receive a report I look at.

If a cow’s SCC rises, what is the protocol to correct it? I don’t really treat them if they are high. Usually, they are up one test and back to normal the next test. I only treat them when they have clinical signs and give them Banamine and 4-7 days of Spectramast LC.

Why is having a low SCC important? It is one of many benchmarks of the health of your cows. It helps you correct any issues in your herd and produce a healthy product for consumers.

Regarding SCC, what valuable advice have you received? Just keep the cows healthy and be consistent, and the cows will do the rest.

Tell us about your farm and family. We have 320 cows; about a quarter of the heifers are on the farm, and the rest are custom raised. We have around 400 tillable acres on which we raise corn, soybeans and alfalfa. My wife, Emily, works in realty; our daughter, Olivia, is in her second year at St. Cloud Technical & Community College and plays softball; and our daughter, Alaina, is a freshman in high school and plays softball and volleyball.

Stearns County

240 Cows

What is the somatic cell count of your milk? Our average for 2024 was 107,000.

Walk us through your milking procedure. Step one: We use a microber towel and dry wipe manure and sawdust off. Step two: We pre-dip and strip at least twice from each teat, watching for abnormalities. Step three: We use one side of a microber towel to wipe off barrels of teats, then ip the towel over to wipe off teat ends before attaching the unit. Step four: We post dip each teat completely. We milk a group of four cows at a time to achieve proper lag time.

What three details do you attribute the low SCC to? Consistency in milking procedure, cleanliness of stalls and culling cows with high SCC.

How often do you review the SCC, and in what ways do you monitor it? We get SCC updates via text message from our creamery every week and individual SCC reports monthly through DHIA.

If a cow’s SCC rises, what is the protocol to correct it? I will usually monitor the SCC and treat the affected quarter if the cow exhibits signs of illness. If there is a persistent high SCC, I will cull as necessary. Why is having a low SCC important? It’s an indicator of a healthier cow and is also a higher quality product for consumers.

Regarding SCC, what valuable advice have you received? Sometimes, it’s trial and error with what you read and are told. Cleanliness of stalls and alleyways helps achieve clean, dry udders for milking.

Tell us about your farm and family. We have 240 cows and milk in a double-12 herringbone parlor. We use mattresses with sawdust bedding. We raise our own replacements and steers. We farm 800 acres. I am in a partnership with three of my siblings: Perry, Becky and Brenda. We have eight wonderful parttime employees, and our parents help as well.

Rhonda Kuechle (second from right), pictured with siblings Perry, Brenda and Becky

Eden Valley, Minnesota

Page 16

Dairy Star • Saturday, April 12, 2025

Con nued from OUR SIDE | Page 15

Darin Grimsgard (pictured with his wife, Brierly)

Grove City, Minnesota

Meeker County 100 cows

What is the somatic cell count of your milk? We average around 70,000.

Walk us through your milking procedure. I predip and use paper towels to clean the teats. I do not do any pre-stripping. Then, after they are milked, I post dip each teat on every cow.

What three details do you attribute the low SCC to? Mainly consistency. It’s a lot of little things, doing my procedure right each milking and ensuring clean stalls and cleanliness of the teat ends. It’s just doing the little things right every time. It’s not an overnight success procedure, but every year, my SCC is lower and lower.

How often do you review the SCC, and what ways do you monitor it? I get a text message from my milk cooperative after every pickup, and I look at that every time. I also test through the Dairy Herd Improvement Association

Dave Hall and Connor VonHaden. Tomah, Wisconsin Monroe County 235 cows

What is the somatic cell count of your milk? Our SCC is 75,000.

Walk us through your milking procedure. We fore-strip to look for any abnormal milk and then spray a peroxide-based pre-dip and make sure we cover the entire teat with spray. We leave the spray on the teat for about 30 seconds, wipe it off with a paper towel and then apply the milking unit to the cow. We have automatic takeoffs, but we check them to make sure they are done and then post-dip with Blockade.

What three details do you attribute the low SCC to? The most important step is the fore-stripping. If you bypass this step, it could be several milkings before

once a month. If it ever spikes, I then refer to my DHIA results to see where the problem is coming from.

If a cow’s SCC rises, what is the protocol to correct it? After pinpointing where the problem is from my DHIA papers, I dump that cow’s milk for a while until it clears up. Usually, it clears up on its own. I feed dump milk to the calves. If the cow does not get better in a couple of days, I treat her with a Today tube. It’s been a while since I have had to treat a cow.

Why is having a low SCC important? I never set out to have a low SCC. It is kind of a byproduct of doing the best job I can to put out a quality product. By doing everything I can to make the cows happy and healthy, having a low SCC just happens.

Regarding SCC, what valuable advice have you received? I read a lot of articles on healthy cows and mastitis prevention. I look for articles from other farmers who are doing well and learn about what works for them. I have never gotten one specic tip or trick that ipped the switch to having low SCC.

Tell us about your farm and family. I milk 100 cows in a swing-11 parlor. I am the fourth generation on this farm, so we are a century farm. I have a wife who does bookwork and helps as needed along with our two kids: one in college, Ellie, and one in high school, Brinley. I grow most of our feed and buy a little hay. We raise all our own replacements and graze our heifers. Two-thirds of my freestall barn is bedded with sand, and the last third is bedded with sawdust. My cousin, Blake, helps me when he can.

you realize a cow has a high cell count. We primarily have family members doing the milking who care about quality milk. We never put milk in the tank that we wouldn’t be willing to drink ourselves. It is important to use the data from the Dairy Herd Improvement Association to pinpoint any cows with high cell counts. We use a California Mastitis Test paddle to test all fresh cows before their milk enters the tank and use the paddle to check any cows that are questionable. The cow is then treated if needed, and we also use Udder Comfort. We use ground oat hulls for our bedding on top of the waterbeds. We bed them every four days and clean stalls off every milking and re-bed the area where their udders would be.

How often do you review the SCC, and what ways do you monitor it? We have SCC results after each pickup for the entire tank that we monitor and once a month we check results from DHIA. If one comes back with a high cell count, we will CMT each quarter to see where the problem is. We will treat the cow if necessary.

If a cow’s SCC rises, what is the protocol to correct it? We CMT all four quarters and nd out which quarter has the issue. We will treat with antibiotics if necessary. If she is a low-end cow, she will be culled.

Why is having a low SCC important? There are added premiums for keeping our cell count low, and we want to sell a high-quality product that consumers will enjoy.

Regarding SCC, what valuable advice have you received? Make sure that you utilize the SCC reports from DHIA to pinpoint problem cows.

Tell us about your farm and family. Our farm was established in 1868 and has changed and grown over the years. Dave and Don are the current owners of the dairy, and Don’s sons — Jake, Cody and Brady — assist them. We have one fulltime employee, Connor VonHaden.

Hall Dairy Farms LLC

Don (from left), Jacob, Cody and

•

•

•

How many times a day do you milk, and what is your current herd average, butterfat and protein? Our herd is 730 cows; we milk 650 cows three times a day. Our current herd average is 33,197 pounds of milk (103 pounds per day), with tests of 4.7% butterfat and 3.3% protein.

Describe your housing and milking facility. We have a four-row barn for our rst and primarily second- and thirdlactation cows. We have a 6-row barn for our aged cows. The barns are both tunnel ventilated with pasture mats and sawdust bedding. Our parlor is a double-12 parallel.

Who is part of your farm team, and what are their roles? Jason manages the nutrition for the herd with a fulltime feeder. He also manages the crop operation and oversees nances with his wife, who does the books. Derek manages the calf barn, schedules employees, takes care of herd manager duties and helps in the eld as needed. Justin does all the A.I., cattle sorting between barns, herd health checks and vaccinations with the vet, along with eldwork as needed. Derek’s son, Devin, is primarily in charge

TOP PERFORMERS

Jason (from le ) and his wife, Sharon, Derek and his wife, Lori, Amber and Jus

March 25 at the farm near Westgate, Iowa. Jason, Derek and Jus n Decker milk 650 cows with a herd average of 33,197 pounds of milk and tests of 4.7% bu erfat and 3.3% protein.

of maintenance of equipment and facilities along with the bulk of the eldwork, including planting and combining. We have a full-time feed man who also helps with eldwork and another full-time man who works closely doing herd management with Derek. We also have two shifts of fulltime milkers. Besides our full-

time milkers, we have help from high schoolers who milk after school until 8:30 p.m. We have one employee who feeds calves, working a 3-hour morning shift and a 3-hour afternoon shift.

What is your herd health program? We have a herd health check every Tuesday

with the Winthrop vet clinic. We pregnancy check the milking herd weekly and do heifer pregnancy rechecks on the herd twice a month. Our vaccination program is as follows: At birth, we give Inforce 3, followed by Bovishield Gold and Vision 7 at 4-5 months and 10-11 months; at the rst pregnancy check,

we give salmonella and Vision 7; at the 6-month pregnancy check, it’s Guardian and JVac, and we’ll do that again at six weeks from calving and two and a half weeks prior to calving; at the fresh check, we’ll do Bovishield Gold and J-Vac followed by another JVac at the pregnancy recheck; nally, at dry check, we’ll do salmonella and Vision 7 and dry off is dosages of Guardian and J-Vac.

What does your dry cow and transition program consist of? Cows are dried up every Wednesday between 48-56 days. Some are dried off earlier if they are low producers or due with twins. Far-off dry cows are housed in free stalls. They are moved to a bedded pack area at three weeks before due date. Cows calve in a group setting on a bed pack.

What is the composition of your ration, and how has that changed in recent years? Our ration consists of low-lignin haylage, protein mix, cottonseed, dry ground corn, roasted soybeans and brown midrib corn silage and some liquid molasses. We

Thanks to unique bolus technology and precise

Jason Decker of Top-Deck Holsteins Westgate, Iowa | Fayette County

PHOTO SUBMITTED

n Decker gather

“We have used Udder Comfort™ for 15 years. We use it on any type of swelling or edema. Everyone milking knows if a cow comes through with any swelling in the udder, it’s just automatic. You don’t need told or asked, you apply Udder Comfort, and the vast majority of the time you see results afterwards,” says John Burket, Burket Falls Holsteins, East Freedom, Pennsylvania.

“We use Udder Comfort on our fresh cows, particularly on first-calf heifers. It’s a must. We haven’t tried other products because Udder Comfort has been so successful for us. It’s a natural fit for our herd. Everyone milking here realizes this, uses it, and the results are positive.”

As HAUSA president, John says: “Every day on the dairy farm presents an opportunity. It’s all about the amazing Holstein cow and the people who own and care for her; Best of both worlds.”

have moved to a higher concentration of BMR in the diet over the past few years as we have focused on increasing digestibility for dry matter intake.

Tell us about the forages you plant and detail your harvest strategies. We plant roughly 1,000 acres of corn each year with 450 acres of BMR corn silage. We shoot for a half milk line on the kernel to optimize starch when harvested. We plant around 500 acres of beans every year, with the bulk of them going into higholeic beans this year so we can feed even more and offset some more of the purchased fat costs. We have around 350 acres of low-lignin alfalfa, harvested as 100% haylage every year.

What is your average somatic cell count and how does that affect your production? We average about 130,000 on our SCC and feel this a good number, considering we are not looking to bed with any sand.

What change has created the biggest improvement in your herd average? We have had multiple changes over the years, but we feel adding tunnel ventilation in 2020 to both milking barns was huge for us. Before that, we struggled every summer with falling production that usually wouldn’t

be recovered until late fall. Now, production may dip a few pounds in extreme heat and humidity, but it usually recovers quite fast once the heat subsides. A new calf barn in 2016 also helped propel our heifer performance signicantly. A more recent addition of a new barn nished in December 2023 to house 4-11-month-old heifers has allowed us to introduce total mixed ration at a younger age, and we hope to see the benets of that already this sum-

mer. Sexed semen, along with an aggressive double ovsynch program, has kept pregnancy rates much higher than we have ever seen.

What technology do you use to monitor your herd? We use SCR collars for heat detection and rumination. Our dairy data is entered into PCDart. We also use EZfeed technology in our mixer tractor for more precise management of feeding data. That has been quite benecial.

sq. ft.

• Best strapping system in the industry

• 70% shade on mesh tarp

DAN WACKER/DAIRY STAR

Calves eat total mixed ra on March 25 on the newly constructed calf barn at Top-Deck Holsteins near Westgate, Iowa. The Deckers moved calves into the new barn in January.

resistance and fertility. Using this strategy provides us with the best ability to maximize production when all other management factors are well executed.

List three management strategies that have helped you attain your production and component level. First, focusing on reducing cull rates to keep older cows around longer has been something we have honed in on the last few years. That is really where you put it in the tank. Second, we have a very sound breeding and heifer rearing program with the goal to have as high a conception rate as possible. Third, we have highly digestible feed put up at the proper moisture.

What is your breeding program, and what role does genetics play in your production level? Our breeding program is a double ovsynch program. Genetics plays a huge role. Our goal is for our cows to produce a lot of milk with high pounds of fat and protein. We also want trouble-free cows that last multiple lactations. We use elite genetics through Select Sires and our main genetic selection criteria are milk, pounds of fat and protein, mastitis

“Cleaning

Tell us about your farm and your plans for the dairy in the next year. At the moment, there are no plans for expanding the milking herd. We have general improvements we need to make every year to maintain the facilities. We are focused primarily on maximizing income over feed costs with what we have. My brothers and I are fth generation, with a nephew being sixth generation. Our goal is to be good stewards of the land that has been passed down to us so future generations can enjoy this way of life.

6R 175 2023, 292 hrs.,

84” Bucket, #577143 ....................$77,500

JD 333G 2023, 343 hrs., Wide Rubber Tracks, #579849 ..............................$84,900

DRAWN PLANTERS

JD DB60 2015, 39666 Est. Acres, 24 Row, 30” spacing, #566673............. $145,900

JD DB60 2013, 31093 Est. Acres, 24 Row, 30” spacing, #578708............. $119,900

JD DB66 2022, 9060 Est. Acres, 36 Row, 22” spacing, #576258............... $459,900

JD DB66 2019, 29422 Est. Acres, 36 Row, 22” spacing, #584389............. $385,500

JD DB88 2012, 60000 Est. Acres, 48 Row, 22” spacing, #589832............. $139,900

ROW CROP TRACTORS

JD 6R 155 2024, 63 hrs., Cab, MFWD w/ Suspension, #572329

JD 6R 155 2024, 147 hrs., Cab, MFWD, #591533 ....................................

JD 6R 155 2024, 156 hrs., Cab, MFWD, #591538 ....................................

6R 215 2024, 203 hrs., Cab, MFWD w/ Suspension, #561234 ............

7R 230 2023, 415 hrs., Cab, MFWD, #586953

JD 7R 310 2023, 790 hrs., Cab, MFWD w/ Suspension, #583432

JD 8R 410 2024, 110 hrs., Cab, MFWD w/ Suspension, #593977 ............

JD 8R 250 2024, 248 hrs., Cab, MFWD w/ Suspension, #591742 ............

JD 8R 410 2024, 250 hrs., Cab, MFWD w/ Suspension, #593988

JD 8R 370 2024, 720 hrs., Cab, MFWD w/ Suspension, #590773 ............ $439,900

JD 8R 370 2024, 835 hrs., Cab, MFWD w/ Suspension, #590828 ............ $437,900

JD 8R 370 2024, 950 hrs., Cab, MFWD w/ Suspension, #591035 ............

JD 8R 310 2023, 159 hrs., Cab, MFWD w/ Suspension, #582309 ............

JD 8R 230 2023, 400 hrs., Cab, MFWD, #579785 .................................... $279,900

JD 8R 280 2023, 400 hrs., Cab, MFWD w/ Suspension, #579792 ............ $349,900

JD 8R 310 2023, 528 hrs., Cab, MFWD w/ Suspension, #592709 ............

JD 8R 370 2023, 620 hrs., Cab, MFWD w/ Suspension, #585436 ............

JD 8R 230 2023, 641 hrs., Cab, MFWD w/ Suspension, #579474 ............

JD 8R 370 2023, 672 hrs., Cab, MFWD w/ Suspension, #577931 ............

JD 8R 410 2023, 1050 hrs., Cab, MFWD w/ Suspension, #587664 .......... $419,000

JD 8R 310 2023, 1318 hrs., Cab, MFWD w/ Suspension, #584308 ..........

JD 8R 370 2022, 821 hrs., Cab, MFWD w/ Suspension, #585317

8R 280 2022,

SKID STEER LOADERS

Dairy Mora, MN 320-679-1029 Pierz, MN 320-468-2494 St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

UPCOMING EVENTS:

April 1-3; 8-10; 15-17; 22-24; 29-30

The Dairy Signal ® Online, noon - 1 p.m.

Visit www.pdpw.org to participate in live-streamed event. Audio/video recordings also available free.

April 1, 8, 15

Dairy’s Visible Voice ®

April 1: Pagel’s Ponderosa, Kewaunee, Wis.

April 8: Weiss Family Farms, Durand, Wis.

April 15: Miltrim Farm, Athens, Wis.

Visit www.pdpw.org for details.

April 5 - 17

PDP International Tour of Italy

Visit www.pdpw.org for details.

May 1, 6-8, 13-15, 20-22, 27-29

The Dairy Signal ® Online, noon - 1 p.m.

Visit www.pdpw.org to participate in live-streamed event. Audio/video recordings also available free.

PDP mission: to share ideas, solutions, resources and experiences that help dairy producers succeed.

BOTTOM LINE DAIRY’S Focus, planning key to conservation efforts

Caring for our land and animals is a top priority on our farm, just as it is on everyone’s. However, the practices and management strategies we each adopt are different based on our operation’s geography and soils, needs for livestock feed, nancial situation, equipment and labor availability, among other factors.

We farm about 2,000 acres near Pittsville, Wisconsin. It isn’t the best-quality farmland around; in fact, cranberry marshes dot the landscape nearby. We’ve carefully managed our rotations over the years based on our needs for corn silage and haylage. We’re not able to grow straight alfalfa on many of our acres, so we grow an alfalfa/ grass mix or a red clover/grass mix.

principles that guide us as we think about adding and expanding our changing conservation practices, including those listed below.

Find a network

By Paul Lippert

As we’ve been able to add acres over the years, we’ve also gained exibility to be more creative with our rotation to get the production we need, while not pushing our best land too hard with continuous corn. Double cropping triticale with either soybeans or corn has allowed us to grow more feed on our better acres that is truly digestible. Adding wheat and summer annuals to the rotation, along with adopting no-till practices and cover crops, has increased quality and yields in our rotation.

We also primarily work with custom operators, so every pass of tillage equipment means added cost to the operation. When windows for planting are already short, the possibility of being able to plant in no-tilled or minimum-tilled ground more quickly is really a benet.

It has been a big transition for us to move from chisel plowing every time we planted corn to no-till. I won’t say we have it all gured out. In fact, we are still learning something new each year. We have found a few

As farmers, we’re fortunate to have a wealth of resources for advice and information. For conservation practices, a good starting point is to nd farmers who’ve already been using the practices you’re interested in. We have a neighbor who has been notill farming with cover crops for a number of years. To be honest, the things he did 10 years ago — practices we thought were nuts — don’t seem so crazy anymore, and I appreciate the opportunity to learn from him.

In Wisconsin, local watershed groups and the Discovery Farms program through the University of WisconsinMadison Division of Extension offer a wealth of knowledge and experience, and attending Professional Dairy Producers conferences and training programs are as valuable for the content as well as the networking with other farmers. And we all know, when a group of farmers is gathered in one location, there’s always an opportunity to “talk farming” and learn about what others are doing.

Start small

When trying something new, start on 40 acres, not 1,000. Starting small gives you the chance to experiment with new crops or timing and compare results, then build a foundation to expand on the next growing season.

Ask questions

We can avoid a lot of headaches by asking questions. Don’t be afraid to ask someone to explain new terms or walk through

the nuances of different equipment options. If a custom operator or vendor isn’t willing to try something new, nd out whether they are simply stuck in their ways or if there is a technical, nancial or other reason why it isn’t possible.

Whether it is understanding nitrogen cycling or the variations in dribble bars and injection rates for manure application, the learning curve can be steep. Taking every opportunity you can to ask questions for shortening that curve will pay dividends.

Be exible

What works one year may be a terrible idea the next, depending on weather, growing conditions and many other things. For example, planting into green cover crops works great until the rye gets away from you. Knowing when to terminate your cover can be the difference between success and frustration. For our part, we’ve learned to shift gears to summer annuals sooner when spring gets away from us. Those summer annuals can deliver real soil health benets, allow for exible manure application and provide winter cover.

We all want to grow the best feed possible in the most efcient manner and do what is best for our land and water resources. Sharing ideas, learning from each other and being open-minded and exible will benet everyone.

Paul Lippert of Pittsville, Wisconsin, owns Grass Ridge Farm LLC with his father, Matt, and brother, Carl. The dairy is home to 700 registered Holsteins and Jerseys as well as 600 youngstock. Paul is the herdsman and human resources manager. He graduated from UW-River Falls with a dairy science degree. Paul serves on the PDP board of directors.

Networking, learning,

MICHELLE STANGLER/DAIRY STAR

(Above) Marlen Schmitz, a regional sales manager with Papillon Agricultural Company, visits with a�endees March 26 at Central Plains Dairy Expo in Sioux Falls, South Dakota. Schmitz has extensive dairy industry experience and resides in Minnesota.

(Le�) Mitch Schulte with Midwest Dairy engages with kids March 26 at the checkoff ’s booth at Central Plains Dairy Expo in Sioux Falls, South Dakota. The booth was one of many interac�ve exhibits at CPDE, with others offering free ice cream, pens, bags and more.

endees stop at

the

Air King industrial air cleaners are a valuable tool for capturing most airborne nuisance particulate. Our self-contained filtration units continuously pull contaminated air through multiple stages of highly efficient micro-glass filters. The filtered air is then recirculated back into the working environment without the need for duct work. This results in a cleaner, healthier atmosphere for employees, while saving you money by keeping heated or air-conditioned air inside your facility.

MICHELLE STANGLER/DAIRY STAR

A�

one of

booths March 26 at Central Plains Dairy Expo in Sioux Falls, South Dakota. A�endees represented 38 states and 20 countries.

AMY KYLLO/DAIRY STAR

Wya� and Gwen Dickes wear paper hats March 27 at Central Plains Dairy Expo in Sioux Falls, South Dakota. The hats were made using the Dairy Star newspaper.

MICHELLE STANGLER/DAIRY STAR

Tina Hoff (from le�) with her kids, Thomas and Samuel, joined her father, Paul Re�mann, March 26 at Central Plains Dairy Expo in Sioux Falls, South Dakota. Re�man, a herdsman at LAX-Pie�g Dairy, was visited by his grandkids who now reside in El Paso, Texas, during the farm show.

AMY KYLLO/DAIRY STAR

RaeLynn performs March 25 at Central Plains Dairy Expo in Sioux Falls, South Dakota. RaeLynn’s performance kicked off Central Plains Dairy Expo.

Surviving a bull chase

Willie Dux stands outside his barn March 21 on his former dairy farm near Stewartville, Minnesota. Dux was a acked by a beef bull Sept. 7, 2024, pushing him to re re from dairy farming.

Injuries give Dux the push to retire

By Amy Kyllo amy.k@star-pub.com

STEWARTVILLE, Minn. —

On Sept. 7, 2024, dairy farmer Willie Dux went out to his beef cow pasture by himself to sort out the bull. The day would prove pivotal, pushing him to sell the cows and partially retire one week later.

The bull, which had been underperforming, also had recently been tangled in some barbed wire, leaving the animal with a missing toe.

Willie, who has dairy farmed his entire life near Stewartville, said he did not think twice about being out with the animal.

The bull had tested him a few weeks before, but a matador-like hand movement had veered the bull off. That Saturday, Dux was not so lucky.

“I tried to sort him out,” Dux said. “Pretty soon, it was just me and him.”

He said he and the bull were playing “Ring around the Rosie” with a gooseberry bush before the bull attacked.

“He pushed me down and started beating on my arm with his head,” Willie said. “I could feel his brisket on my hip, but then he left.”

Willie had been pushed into the gooseberry bush, and he said he theorizes that the bull’s injured hoof and possibly his eye came into contact with the prickly bush which made him back off.

“He left, and I had my glasses yet, had my cell phone yet, so I called my wife and called the owner of the bull,” Willie said. “I felt pretty good by that time.”

The Duxes paused long enough for Kathy to get a quick change of clothes for the chilly hospital setting and headed to the emergency room.

“On the way to the hospital, he said, ‘I don’t even feel like I’m in shock,’” Kathy said. “I didn’t argue

PHOTO SUBMITTED

Remote Monitoring Made Easy

Paul Mueller Company’s MAXXimizer™ L-40 package chiller, designed to ease the daily burdens of dairy farmers, has plug-and-play design and cloud connectivity, so you benefit from remote, real-time access to your refrigeration system data.

MAXXimizer™ L-40 Package Chiller

Central Ag Supply Juneau, WI; Baraboo, WI

Advanced Dairy Spring Valley, WI; Mondovi, WI; West Salem, WI; Mora, MN; Pierz, MN; Wadena, MN; St Charles, MN

Ederer’s Dairy Supply Plain, WI; Blanchardville, WI; Dodgeville, WI

Central Ag Supply Juneau, WI; Baraboo, WI

J. Gile Dairy Equipment, Inc. Cuba City, WI

Eastern Iowa Dairy Systems Epworth, IA

Monroe Westfalia Surge Monroe, WI

Ederer Dairy Supply Plain, WI

Professional Dairy Services Arlington, WI

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Redeker Dairy Equipment Brandon, WI

Seehafer Refrigeration, Inc. Marshfield, WI; Sparta, WI

Gorter’s Clay & Dairy Equipment Pipestone, MN

Stanley Schmitz Inc. Chilton, WI

J. Gile Dairy Equipment, Inc. Cuba City, WI

Leedstone

Total Dairy Services Kewaunee, WI

Tri-County Dairy Supply Janesville, WI

Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI; Sparta, WI

Fuller’s Milker Center Lancaster, WI; Richland Center, WI

Lely Center Monroe Monroe, WI

Eastern Iowa Dairy Systems Epworth, IA

Midwest Livestock Systems Zumbrota, MN; Renner, SD; Menomonie, WI; Kaukauna, WI; Weston, WI

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Monroe Westfalia Surge Monroe, WI

United Dairy Systems West Union, IA

Professional Dairy Services Arlington, WI

Gorter’s Clay & Dairy Equipment Pipestone, MN

Redeker Dairy Equipment Brandon, WI

Leedstone

Sioux Dairy Equipment Rock Valley, IA; Colton, SD

Melrose, MN; Glencoe, MN; Plainview, MN; Menomonie, WI

Stanley Schmitz Inc. Chilton, WI

Midwest Livestock Systems Zumbrota, MN; Menomonie, WI; Renner, SD

Total Dairy Service Kewaunee, WI

S&S Dairy Systems St. Charles, MN

Tri-County Dairy Supply Janesville, WI

Glencoe Co-Op Assn. Glencoe, MN

United Dairy Systems West Union, IA; Monticello, IA

with him. (I thought) ‘You can believe what you want. We’ll just see what the ER (emergency room) doctor says.’”

At the emergency room they estimated he had broken about 20 ribs. The doctor documented three broken on each side. None of the ribs were dislocated, however, and the lungs and heart were OK.

When it came time to tell his story to the doctors, Willie said reading the doctor’s notes afterwards brought some levity.

“The rst line states he is a farmer,” Willie said. “She didn’t know what a gooseberry was, so I said a thorn bush.”

The doctor misunderstood thorn bush and the nished narrative said Willie had been pushed into a phone booth. Willie said it made him think of Doctor Who.

Willie was admitted to the hospital to begin recovery, where he stayed until the following Friday. Meanwhile, back on the farm, the Dux family rallied to get the work done. The Duxes’ son, Kenny, took a week off work to help milk cows and x the fence. Their daughter, Clara, came from Montana for a few weeks to help, and their other daughters helped as they were able on the farm and with doctor visits around their jobs.

The Duxes, who are retirement age, had been planning on selling their cows in the next several years and had already begun talking with their neighbors, Jeff and Tim Pagel, about buying their herd as Willie had wanted the cows to go to a small farm.

The summer of 2024 had been hard on her and Willie, Kathy said, as they struggled to keep up physically with the work on their farm.

“I tried pressing him with making plans, but it seemed like there was never any time for that,” Kathy said. “It was morning till night, and it was just consuming our lives. We just didn’t really get a chance to plan.”

The injury brought the need to sell the cows to the forefront. Several other dairy farmers helped with the negotiations, and the cows and the milk quota they held were sold.

“It is hard to face up to our limitations as we get older,” Kathy said. “That’s a very real thing. But not that we need to be inactive, but we do

Cows stand in the stanchion barn Sept. 14, 2024, at the Dux farm near Stewartville, Minnesota. The Duxes sold their en re 40-cow herd and the milk quota that went with them last fall.

need to give our body a break.”

They waited until Willie was home for the 40 cows to leave.

“Our oldest daughter, she said, ‘I think Dad should be here when the cows go,’” Kathy said. “I think that was good.”

On loading day, one week after the bull attack, Willie was outside in his hospital pants being part of things.

“There was sadness,” Willie said. “You realize that (will) be the last time you see them.”

Kathy agreed.

“It’s always been a dairy farm since the Duxes came in 1919,” she said. “This is the last time that this farm will have dairy.”

The Duxes plan to raise up their remaining dairy heifers and sell them as springers. They will continue their beef herd, which has nine brood cows and 28 animals for nishing. They also will farm their 200 acres of tillable cropland and 120 acres of pasture.

Willie had taken over the farm from his parents in the 1980s. He al-

ways enjoyed farming, sneaking out of school to help his dad with farm work.

After college, he designed a new stanchion barn and his dad built and paid for it.

“(I was) always amazed by that,” Kathy said. “He must have known that you were passionate enough about it that you were going to stick with it.”

The barn was used up until Willie retired. Willie was indeed passionate, with some years not taking even one

milking off.

“(Now) ve o’clock rolls around … what do I do now?” Willie said.

Looking to the future, the Duxes said they want to do more retirement planning.