“All

“All

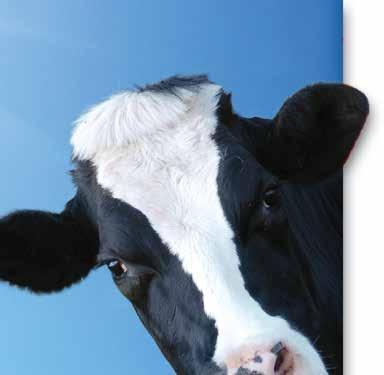

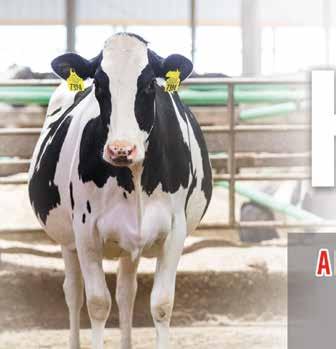

Testing of lactating dairy cows mandated prior to interstate movement

By Danielle Nauman danielle.n@dairystar.comOver six weeks have passed since the illness affecting dairy cattle in the southwestern United States was identied as highly pathogenic avian inuenza H5N1, or bovine inuenza A virus. In the days since, questions about H5N1 have been answered and many more have arisen.

To slow the spread of the virus, especially because cow-to-cow transmission is yet to be understood, effective April 29, the U.S. Department of Agriculture mandated that lactating dairy cattle receive a negative test

for the inuenza A virus from an approved National Animal Health Laboratory Network laboratory for interstate commerce.

As of May 6, lactating dairy cattle have tested positive for H5N1 in 36 herds in Colorado, Idaho, Kansas, Michigan, New Mexico, North Carolina, Ohio, South Dakota and Texas.

According to a USDA press release April 24, the federal order was spurred because cow-to-cow spread was identied within a herd. As well, the spread of the virus from cows to poultry and from dairy farm to dairy

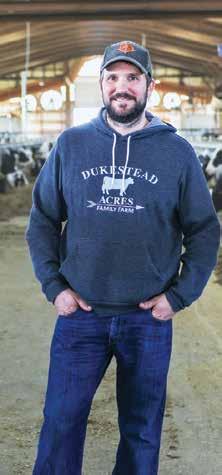

WAVERLY, Minn. — A group of Wayzata High School juniors and seniors saw something not every student their age sees.

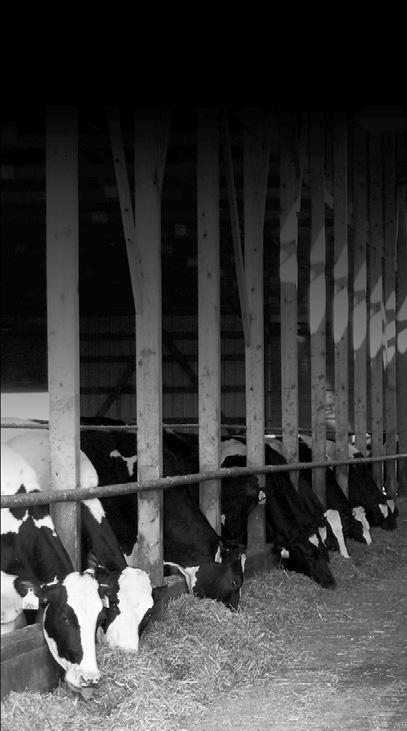

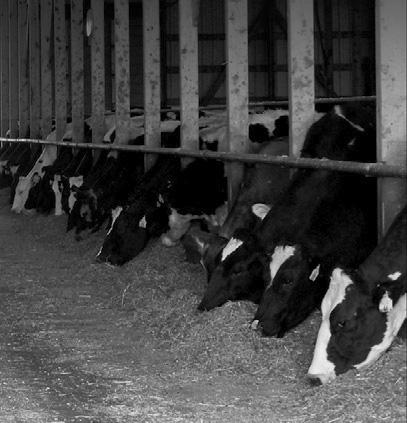

The cybersecurity and applied mathematics students from the school toured two dairy farms that use a robotic milking system May 6.

“It’s a way for these kids to see computer science in a different format, so they are seeing this in a whole different industry and in a practical application,” said Tika Kude, a teacher at Wayzata High School.

Bob and Mike Sawatzke, owners of Creekside Dairy near Waverly, were one of the two locations the students visited. Merryville Farm, also near Waverly, was the second farm visited.

The Sawatzke brothers have been dairy farming since 2014. In 2021, they installed three Lely A5 robots and are now milking 190 cows.

“It’s nice to let the kids, or anybody who doesn’t have a background or know what we are all about, know what’s going on here,” Bob said. “We like to let them know why we do it and how we do it.”

Mike and Bob said their favorite part of farm tours is showing others the robots. Mike said he enjoys showing the automatic calf feeder.

Midwest Dairy CEO Scott shares her background, goals

By Amy Kyllo amy.k@star-pub.comST. PAUL, Minn. — Midwest Dairy has a new CEO, Corey Scott, who joined Midwest Dairy March 13. Scott is taking over the reins from Molly Pelzer, who retired after a long career serving dairy farmers.

“I don’t think there’s any other profession that I could have found the absolutely incredible people to serve and represent as I did here,” Scott said.

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Maria Bichler - Assistant Editor maria.b@dairystar.com

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute

nal acceptance of the advertiser's order.

Letters

Mike Sawatzke (le ) and his brother, Bob (right), stand with a group of Wayzata High School

This was the second year Wayzata High School students toured a farm.

“I love seeing the kids’ reaction to it, by opening their eyes and letting them see there is more to computer science,” Kude said.

and

“It’s nice to see the look on their face when they have questions, and you give them the answer and it just clicks,” Bob said.

During the tour, the students asked questions to learn about all aspects of the dairy farm.

About half of the students and teachers said they had been on a farm before. For the rest, the experience was a rst.

“It’s pretty cool that times have

changed,” said Taf Rahman, a cybersecurity and applied mathematics student. “I imagined everything by hand, and seeing technology improve is pretty cool to see.”

The students said a dairy farm is

class toured the Sawatzkes’ farm May 6 near Waverly, Minnesota. This was the second year a class from Wayzata came to the farm. Turn to FARM TOURS | Page 5

Fluegge's Ag Mora, MN Burco Sales Independence, IA

IA

Implement Of Waukon Waukon, IA

Implement Company Dewitt, IA Rexco Equipment Farley, IA

Implement Company Ottumwa, IA Helmuth Repair Kalona, IA Beck Implement Elgin, MN

Woller Equipment Swanville, MN

Sellner Slayton Slayton, MN

more connected with technology than they anticipated.

“You wouldn’t think that we are using robots, recognition and data information on a dairy farm in the middle of rural Minnesota,” said Jake Paitrick-Witsoe, a cybersecurity and applied mathematics student.

The students also said they learned that farms use computer software and offer an abundant supply of jobs.

“I was pretty surprised on how much data and technology an average farm in Minnesota can use because they track everything: how much the calves eat, how much the cows eat

and how often the cows go to get milked,” Rahman said.

After the students were done with the tour and back in class, they had a group discussion to reect on the farm tour.

“They learn so much more physically coming out here seeing it, smelling it and touching it,” Kude said.

Throughout this class, Kude said she teaches empathy for people who differ from themselves. This experience allows the students to see a differing lifestyle and ways of using computer science.

“A lot of kids aren’t going to become farmers, but they want to be software develop-

GRACE JEURISSEN/DAIRY STAR

Bob Sawatzke shows students data the robo c milking system collects when a cow is milked May 6 on the Sawatzke family’s farm near Waverly, Minnesota. Sawatzke and his brother, Mike, milk 190 cows with three robots.

ers,” Kude said. “This is a way for them to come up with a unique way where they can help someone in a way they haven’t thought about.”

Mike said he enjoyed sharing cheese with the students at the end of the tour.

“They get a taste of our product,” he said.

Bob said opening their farm to students allows them to see the process of making milk and dairy products, from the beginning to tasting the nished product that is produced from their milk.

For some students, it was not only the cheese they enjoyed.

“The explanation of the logistics is interesting, seeing how they have gone from this farm being 70-80 years old, how all the milk goes through and where it goes is really interesting to think about,” Paitrick-Witsoe said.

The Sawatzkes said they spend time keeping the farm clean every day.

“We do the best we can to take care of our animals every single day,” Mike said.

It does not take a lot of work to prepare for a farm tour when they tend to cleanliness every day, Bob said.

“The way you see it is pretty much how it is,” Bob said. “It’s nice to stay tidy.”

Bob said farm tours could impact the students’ future.

“I’d like to think that some of them might strike up an interest in it after touring,” Bob said.

Scott was previously the vice president of sales and marketing for Athian Inc. and also worked for Land O’Lakes Inc. in their sustainability division, Truterra LLC. Scott plans to focus on sustainability at Midwest Dairy.

“My responsibility is to tell the story for our farmers in such a way that it appeals to consumers, then appeal to food and beverage companies with sustainability goals to ensure the future of dairy as a solution in sustainability versus a problem,” Scott said.

Scott said this is about sharing the work that dairy farmers are already doing and innovating.

“My opportunity is to be the bridge, telling that story in an effective manner to where it builds trust,” Scott said.

Scott’s new role is her rst with the dairy checkoff.

“With any business, there are things where ... it’s done that way for many, many years,” Scott said. “Somebody coming in with a fresh perspective has the opportunity to understand more deeply the why behind (things).”

Scott said as she has learned more about the checkoff program, it has also been an opportunity for her staff to reect.

“Dairy farmers have been under signicant economic pressure in recent months,” Scott said. “It’s critically important that we’re being good stewards of how we use checkoff dollars. ... It’s always been, but even now, there’s a higher awareness of how we’re deploying those dollars.”

Scott respects the dairy farmers she serves.

“Farmers are some of the most hard-working, highest-integrity, saltof-the-earth people that you could nd,” Scott said. “They wake up every single day to do work to serve others. ... They do it in the hard times and in the good times equally well.”

Scott’s background in agriculture stretches to childhood. She grew up in Massachusetts. In the summers, her family visited South Dakota on vacation to help friends work cattle, doing tasks like ear tagging, vaccinations and castrations.

from the university’s Carlson School of Management.

Scott said Midwest Dairy’s strategic priorities for the next 2-3 years are focused on increasing consumption.

To do this, Scott said building trust is the rst pillar toward that goal.

“We recognize that consumers don’t consume dairy in the same way as generations before us did,” Scott said. “They love innovative products. They love cheese. So, dairy consumption doesn’t look the same. Also, what’s not the same is awareness of where food comes from.”

With that change comes alterations in how to reach these consumers to build awareness, Scott said.

“We will need to work to build trust, but we’ll be doing that through some different pathways that appeal to the generations coming behind us, meeting them where they are in their journey,” Scott said.

Scott said that a new initiative for Midwest Dairy is using 20 social media inuencers to share about how dairy farmers care for their animals and dairy’s impact on sustainability. If the test pilot is successful, they will expand the program.

“(We are) leveraging different thought leaders and inuencers than we have historically,” Scott said.

Scott said she wants to encourage dairy farmers to share what they are doing on their farms digitally through social media. Scott said that consumers want to hear directly from farmers and that this is a crucial element of building trust.

“Many population centers will never have the opportunity to see a cow in person, much less touch a cow or have the opportunity to talk to a farmer,” Scott said. “Farmers have this unique superpower. If they invite others into their world, ... their reach is enormous.”

Farmers looking for digital training or support can go to the Midwest Dairy website or speak with Midwest Dairy eld staff. Scott said Midwest Dairy is going to amplify farmers’ voices.

Then, when Scott was in high school, her family moved to South Dakota. In high school, she said she became interested in agriculture and worked at a sales barn. In college, she worked at an agronomy cooperative.

Scott earned her undergraduate degree from the University of MinnesotaCrookston and then a master’s degree

An activation that Scott appreciates that Midwest Dairy had completed before her arrival was late-night snack pairings that were done on several college campuses. She said this activation helps to build trust and excitement with college students who will soon be making their own grocery decisions.

“It was wildly popular,” Scott said. “Activations like that excite me for the future.”

farm coincided with the movement of cattle. The press release also said that cows not showing clinical signs of the virus were testing positive.

Dr. Diego Diel, director of the virology laboratory at Cornell University’s Animal Health Diagnostic Center, spoke April 30 during a webinar hosted by the National Milk Producers Federation.

Initially, producers dealing with infected cows were asked to submit a broad variety of samples for testing, including nasal swabs and samples of whole blood, serum, urine, feces and raw milk. Samples collected from euthanized cows included tissue from lungs, lymph nodes, small and large intestines, and the mammary gland.

According to Diel, a few positive results were detected in samples of whole blood, serum and nasal swabs, but the vast majority of positive polymerase chain reaction results were found in samples of raw milk and mammary gland tissue.

“It seems like the virus is actively replicating in the mammary gland tissue based on the results we have,” Diel said. “Is there an infectious virus being shed in milk from those affected animals? The answer to that is, yes. The milk samples contain high viral loads in clinically affected animals and can serve as a source of spread to other animals.”

In an April 26 webinar hosted by the University of Minnesota Extension and the Minnesota Board of Animal Health, Dr. Joe Armstrong, UMN Extension, said that while the major-

ity of affected dairy cows tend to be multiparous cows in mid-to-late lactation, the virus has been seen in other populations in affected herds.

“It is important to look at all animals in the herd and monitor them for symptoms,” Armstrong said. “Symptoms in individual cows are lasting about 3-5 days. Herds appear to be impacted for 14-21 days before returning to near normal feed intake and milk production.”

In addition to the rst-reported symptoms that included decreased feed intake, rumination and milk production, and abnormal milk appearance, Armstrong said that some cows present with diarrhea while others present with dry, tacky feces as a result of dehydration. Fever, clear nasal discharge and lethargy have also been reported among affected cows.

Armstrong said on average, about 5% of the cows in affected herds present with clinical symptoms. The only treatment for infected cows is supportive care.

According to a USDA press release, on April 16, Animal and Plant Health Inspection Service microbiologists identied a shift in an H5N1 sample from a cow in Kansas that could indicate that the virus has an adaptation to mammals. Based on their analysis of that specimen sequence, the Centers for Disease Control and Prevention has not changed its overall risk assessment for the general public, because the substitution has been seen previously in other mammalian infections.

In the UMN Extension webinar, Dr. Stacy Holzbauer, the CDC’s epidemiology eld ofcer for the Minnesota Department of Health, detailed concern surrounding the control of H5N1, which prompted the issue of the federal order.

“This particular virus is an inuenza A virus, which is circulating in wild birds,” Holzbauer said. “They are constantly changing. Inuenza A virus widely circulates in humans, wild birds, domestic birds, swine and equine. But all of these viruses, including the seasonal inuenza viruses we get vaccinated for every year, have an origin in wild birds at some point in time.”

Holzbauer said these viruses have epidemic potential because they are constantly changing and exchanging genes with other viruses. The virus can mutate and infect other species.

“The concern is that we have more mammal-to-mammal spread, that this virus may mutate to where it can then spread to people more easily and then spread person to person,” Holzbauer said. “That is why we are very interested in what is happening in both our poultry and dairy industries. We have people and animals in the same environment working together. The fear is we will have a person who is infected with a human seasonal inuenza virus and then also happens to get infected with the avian H5N1 virus and those two viruses essentially swap their genes. Then, we have this new human virus that could circulate person to person.”

According to Holzbauer, avian inuenza viruses are typically spread to people through direct contact with infected birds or their environment.

“Person-to-person spread of these viruses is rare and limited,” Holzbauer said. “We expect there to be occasional spillover for the people who have direct contact, especially with poultry, but we don’t see person-toperson spread. So, it’s not a risk to the public, and it’s not a food safety risk either.”

Based on what they have learned through avian inuenza infections in domestic poultry ocks, Holzbauer said the response to monitor people having direct contact with infected dairy cattle would be to initiate active surveillance for 10 days after the cows on the affected dairy farm have recovered from clinical signs.

Holzbauer said the use of personal protective equipment by people working with infected animals is their best defense to avoid infection from the H5N1 virus.

“Our PPE recommendations for people working on dairy farms in direct contact with ill cattle are gloves, goggles, N95 masks, coveralls and boots,” Holzbauer said. “We know these PPE recommendations are difcult in operations where these are not normal types of PPE.”

The key message is to protect mucus membranes — eyes, nose and mouth — to prevent uids that may be carrying the virus from entering the body through these access points as much as possible.

Advocacy did not deter new USDA rules

By Jan Lefebvre jan.l@star-pub.comWASHINGTON — In November 2022, the U.S. Department of Agriculture revealed proposed rule changes to the Supplemental Nutrition Program for Women, Infants, and Children. Many in the dairy industry were surprised and alarmed because the rule changes included a reduction in the amount of milk program participants would be allotted.

“There wasn’t a good explanation for why USDA was working to reduce milk,” said Matt Herrick, senior vice president of public affairs and communications for the International Dairy Foods Association. “There wasn’t really any forewarning. We were surprised, confused and frustrated, and the more we talked to WIC agencies and moms who are in the program, the less we understood the proposal. It just didn’t make a lot of sense.”

nicant and aggressive advocacy program on this that lasted more than a year. We really felt like we were making headway — the arguments we had were factual, relevant and supported by people in the (WIC) program — but at the end of the day, the USDA still decided to reduce (the allotted amount of) milk.”

On April 9, USDA issued a nal rule, making the changes ofcial. For milk, the allotted amount per month through WIC will be reduced from 16 quarts to 12 quarts for children 12-23 months of age, from 16 quarts to 14 quarts for children ages 2-4, and from 22 quarts to 16 quarts for pregnant and breastfeeding women.

and the dairy industry itself.

“The reduction is as much as 3 gallons per mother per month, which would be for a mother who has at least one other child and is pregnant,” Herrick said. “We estimate that’s about 150 million gallons per year, or about 0.5% of all U.S. production by volume.”

The 0.5% estimate is for the reduction in milk due specically to the new rules, Herrick said, but that is just part of the equation.

anything you want in terms of food and beverages.”

WIC enrollees are limited to a specic list of about 25 items that they are allotted through the program.

“For a lot of people, (WIC’s limitations are) generally frustrating anyhow, and with reduced milk, we believe there will be reduced participation, unfortunately,” Herrick said.

The new rules, therefore, seem counterproductive to USDA’s efforts to increase the number of eligible families who enroll. According to USDA statistics, only half of those eligible for WIC apply for the program.

“That’s only if all the people who are in the program stay in the program,” Herrick said. “It doesn’t account for people leaving WIC if they are dissatised with this rule.”

USDA’s website states what it aims to achieve through the changes to WIC.

IDFA and other groups in the dairy industry worked to deter the proposed changes.

“We felt that if we advocated enough, we could change their minds,” Herrick said. “We had a sig-

“The changes will provide WIC participants with a wider variety of nutritious foods to support healthy dietary patterns and accommodate special dietary needs and personal and cultural food preferences,” USDA said. “The revisions provide foods in amounts that are more consistent with the supplemental nature of the program, encourages fruit and vegetable consumption, and strengthens support for breastfeeding.”

Many in the dairy industry see the changes as negative for both nutrition

When IDFA was advocating to deter the new rules, it interviewed moms in the WIC program and sent videos of those moms talking about their experiences with WIC to the USDA and Congress. IDFA found that many moms were enrolled in WIC specically for access to milk and were not happy about the new rule.

“What we learned is that there are a lot of women in the program who may just leave it because they are in it for milk,” Herrick said. “If the amount of milk they are used to receiving is no longer there, why participate, why give all your information to the government, because it’s a very prescriptive program as it is. It’s not like (the Supplemental Nutrition Assistance Program) where you can go to the grocery store and buy almost

For making changes to WIC rules, the USDA said on its website that it relied on research from the National Academies of Science, Engineering and Medicine. It also used research from the National Institute of Medicine which suggested increasing access to fruits and vegetables within the program, leading to a reduction in access to milk.

“This seemed more like a shell game … like they were looking for some food item in (WIC) that they could reduce, whether it was fruit juices or milk, and then nd the resources to increase fruits and vegetables without needing to ask for additional funding from Congress for the program,” Herrick said. “Milk was simply the victim of looking for other alternatives to increase in the program.”

The rules come at a time when research is showing the benets of dairy consumption while also showing that most Americans do not get enough dairy in their diets.

In an April 9 press release issued by the National Milk Producers Federation, Gregg Doud, president and chief executive ofcer, addressed the nutrition aspect of USDA’s decision.

“NMPF is disturbed by (USDA’s) decision to reduce access to the essential nutrients dairy adds to the diet,” Doud said. “Nutrition science demonstrates that dairy products like milk, yogurt and cheese are especially important for women, infants and children. Meanwhile, nearly 90% of Americans don’t meet the number of dairy servings recommended by the 2020-25 Dietary Guidelines for Americans.”

Doud also said the change is counterproductive.

“This rule works against the WIC program’s goal of ensuring all Americans have consistent and equitable access to healthy, safe and affordable foods,” he said.

Herrick said the rule change will make budgeting and shopping for food more difcult for moms in the WIC program.

“If you think about WIC moms, they are low income, and they’re likely also on the SNAP program, so they have these two supplemental programs for grocery shopping,” Herrick said. “If you’re going to use your SNAP benets for the majority of your grocery shopping, you’re going to look for items that are available through WIC that you don’t need to use your SNAP benets for.”

For many of those moms, one of those main items is milk, Herrick said.

“Now they no longer have as many benets available for that milk,” Herrick said. “For moms in particular, that’s deeply disappointing.”

The new WIC rules were not all negative for dairy.

“(USDA) did make some changes that were helpful,” Herrick said. “You no longer have to buy a big 32-ounce tub of yogurt. You can buy smaller, individualized containers that equal 32 ounces, which is how people mainly eat yogurt, or you can swap your milk for yogurt or cheese, which is helpful to the overall dairy category.”

State WIC agencies have two years to implement the changes. In the meantime, the only remaining avenue for changing the rules is through Congressional action. Herrick said some industry organizations are already contemplating legislative recourse.

“The WIC rule demonstrates that when the government issues rules that impact our industry in some way, it’s an opportunity for us to come together and advocate, and it requires us to have our eyes and ears open to pay particular attention to the rules that impact our industry,” Herrick said.

This, he said, includes federal nutrition programs because they are vital to the industry.

“For those with low income and for kids at school, nutrition programs are often their introduction or connection to dairy products,” Herrick said. “We’ve got 30 million kids in schools getting meals every day, 6-7 million women and kids in the WIC program and 40 million people in the SNAP program. Those are all very important to our industry, to the vitality and growth of our industry, and to creating generations of dairy consumers and milk drinkers.”

Herrick said it takes work and collaboration to protect dairy.

“Anytime there’s a rule proposal out there, I encourage people to work with their associations and with their networks to advocate for whatever is in the best interest of themselves as farmers or processors or as our industry in general,” Herrick said. “It’s an important lesson that we shouldn’t take anything for granted, and we need to work hard to protect our interests.”

NELSON’S AGRI STRUCTURES

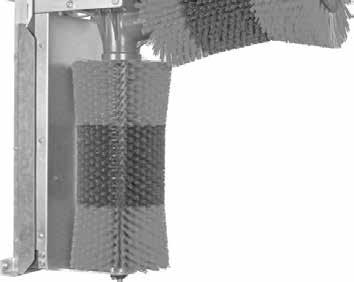

The FutureCow® Prep System features a mechanical brush unit that gently washes, disinfects, stimulates and dries all in one visit to the cow.

Dairy producers can potentially reduce labor costs and can certainly reduce operating costs by eliminating towels and laundry.

Streamlined and consistent cow prep — allows for a more efficient parlor and greater parlor labor productivity — even increasing the number of cows milked per hour.

Superior udder stimulation — can increase milk flow rates and decrease milking times, further improving parlor throughput.

Improved teat health and milk quality — the durable, yet soft, multi-layered brushes accommodate all teat lengths and ensure teat-ends are properly cleaned before the milking unit is applied.

FutureCow Blending Devices

Fixed cost for pre-milking prep — flat rate per cow pricing provides consistent and easily managed cost.

A system for all herd sizes — whether you milk 50, 500, or 5,000 cows or more, there is a FutureCow® Prep System to accommodate any herd size.

Installed and supported by GEA dealers — a professional network with unsurpassed dairy equipment experience available 24/7.

GEA now offers three different automated blending systems to blend cleansing solution ingredients with water to create a ready-to-use (RTU) product that cleans and disinfects the teats.

FutureCow Air-Operated Pump

The pump delivers product from the blending system to the FutureCow Control and Brush Unit.

FutureCow Control and Brush Unit

Controls the dispensing and use of the solution.

Chairwoman of the Senate Committee on Agriculture, Nutrition & Forestry Sen. Debbie Stabenow said it must be a bipartisan bill to get a farm bill done. When unveiling her farm bill plan, the Michigan senator said she had three major goals: keeping farmers farming, families fed and rural communities strong. The bill enhances crop insurance “for small farmers, for specialty crops as well as large farmers.” The commodity title includes a minimum of a 5% reference price increase for all crops. Traditionally, dairy policy is in the crosshairs during a farm bill debate. Stabenow took steps to strengthen the dairy titles. “The Dairy Margin Coverage program seems to have worked really well,” Stabenow said. “The biggest concerns we heard about was with smaller farms; they go to tier 1 basically.”

emphasized there is no evidence of a live virus in pasteurized milk. Cooking ground beef to the proper temperature is also recommended.

By Don Wick Columnist Ag Insider

New traceability rule announced USDA’s new standard for traceability in cattle is electronic ID tags. This replaces the 2013 rule that called for visual ID tags. In a statement, USDA said the decision was being made to respond quickly to foreign animal diseases. This rule applies to sexually intact cattle 18 months of age or older, rodeo and exhibition cattle, and dairy cattle moving interstate.

Ag industry responds to USDA announcement

Hesston 565A Round Baler

‘20 MF 3983 Hicap Rake, 12 wheel

‘19 Kuhn GA7501 Rotary Rake

‘22 MF 1393, 13’ Disc/Mow Cond. ‘16 Pottinger NovaCat Triple Mower w/rolls

‘17 JD 835 9’ MoCo, center pivot

‘14 CIH DC112 Disc Mow/Cond. Gehl 2450, 15’ hydro swing

JD MX7 3PT Brush Mower Patz Bale Chopper

‘21 Rhino 3150-15’ Batwing Mower

‘20 Rhino TS12 flex wing mower

‘23 NH 313 plus 13’ disc mower cond

‘22 MF 4707, MFWD, MF ldr., Only 520 hrs. ‘21 MF 2850, CAH, hydro, loader, ONLY 139 HOURS!

IH 966, 9,000 hrs. MF GC2400, 60” deck, 600 hrs. ‘21 MF GC1723, ldr., mower, 180 hrs. JD 2640 w/146 loader JD 2940, WF MF 285 w/246 loader

Farm bill on the way to the House Ag Committee House Committee on Agriculture Chairman Glenn “GT” Thompson will mark up the farm bill May 23. After the release of Thompson’s bill Wednesday, ranking member David Scott rejected the proposal saying it includes poison pill policies with “an untenable funding scheme.” In a brieng with farm broadcasters, Thompson said that complaint is disingenuous. In a brieng with farm broadcasters, the Pennsylvania lawmaker said he is willing to pass the farm bill out of his committee with just Republican votes. “I’ve got a number of different options of getting to the House oor,” Thompson said. “The process through the House has yet to be determined, but I’m condent that I will nd a successful pathway.”

Senate bill holds ag coalition together Stabenow emphasized bipartisanship when she released her new farm bill. Minnesota Sen. Tina Smith said the Stabenow bill can hold the big agriculture coalition together. There are a lot of similarities between the House and Senate farm bill proposals. The exception would be the approach to nutrition spending in the House bill. “Which they know the Democrats aren’t going to do, and I think they have to get through that and just appreciate that they can’t pass a bill that has those kinds of cuts,” Smith said. “I don’t think they have the Republican votes in the House to pass their proposal even without Democratic support. We have to get serious and understand what we’re dealing with here and come to an agreement.”

Congressional calendar complicates farm bill timeline

National Council of Farmer Cooperatives President and CEO Chuck Conner has seen his share of farm bills and said this is the most partisan farm bill he has ever seen. Conner, who was the U.S. Department of Agriculture deputy secretary during the George W. Bush presidency, said this farm bill process needs to start. “Even if it’s a partisan process, get a bill that people can begin to look at, start marking it up in committee, and get us started,” Conner said. “You can’t nish something that never starts, so we’ve got to start.” Timing is critical for this important piece of legislation. “Congress is in session so few days between now and the end of the year; it’s a presidential election year, you’ve got party conventions, and they’re never in session during any of those kinds of periods,” Conner said. “It’s just going to be hard to get done with the farm bill.”

A statement released by National Milk Producers Federation President and CEO Gregg Doud said USDA’s action on testing and interstate movement of dairy cattle is appropriate. Doud also stressed milk is safe and pasteurization leaves all viruses inactive. Meat Institute President and CEO Julie Anna Potts also released a statement, saying properly prepared beef remains safe to eat. The Meat Institute also called on the USDA and the Centers for Disease Control and Prevention to ensure the movement of healthy animals to slaughter.

The Minnesota Milk Producers Association has led a request to the Minnesota Supreme Court to participate in the Clay View Dairy case as an amicus curiae. The goal is to clarify the statute of limitations for stray voltage claims led in the state. MMPA is advocating for a six-year statute of limitations rather than the current two-year statute of limitations used by most courts.

A record-breaker

Minnesota FFA Association Executive Director Dr. Lavyne Rada said this year’s convention was one for the books. “The convention is denitely record-breaking as our membership continues to grow,” Rada said. “Currently, we’re sitting at over 15,000 FFA members, which is more than doubled in the last ve years and continues to grow as we continue to grow new programs.” Minnesota FFA added 35 school districts with FFA chapters in the last handful of years. “We could have another ve FFA chapters joining us just in the next year if they’re able to nd teachers,” Rada said.

New ofcer team installed

The Minnesota FFA 2024-25 state ofcer team was named during the nal general session of the state convention. Lauren Stoel of Murray County Central is the state president. There are three state ofcers from the Grand Rapids chapter: Emma Braford, vice president; Kaiya Grossman, secretary and Victoria Gunderson, sentinel. Cole Sundeen from the Rockford FFA Chapter is treasurer, and Natalie Clemenson of Zumbrota-Mazeppa is the reporter.

McConkey honored

700 hrs.

‘23 Bobcat T770, high flow, 114 hrs., LOADED!

‘22 Bobcat T770, 200 hrs.

‘20 Bobcat T770, 240 hrs.

‘21 Bobcat T770, highflow, 958 hrs.

‘19 Bobcat T770, SJC, 500 hrs.

‘20 Bobcat T770, CAH, highflow, SJC, 765 hrs.

‘20 Bobcat T770, SJC, 300 hrs.

‘18 Bobcat T770, SJC, 2,400 hrs.

‘18 Bobcat T770, A91, highflow, SJC, 2,000 hrs.

‘21 Bobcat T770, 165 hrs ‘07 Bobcat T300, CAH, SJC, 1,900 hrs.

‘18 Bobcat E50 long arm, 700 hrs.

‘14 Bobcat S770, 3,200 hrs.

S300, 4,200 hrs.

S650, 9,000 hrs.

Bobcat S590, 3,900 hrs.

Bobcat S570,

H5N1 in beef?

The H5N1 virus has been identied in dairy cattle in nine states. USDA limited the interstate movement of dairy cattle and implemented mandatory testing. In a meeting with farm broadcasters, USDA Under Secretary for Marketing and Regulatory Programs Jennifer Lester Moftt was asked if it was safe to assume the virus is also in the beef herd. “The information and data that Animal and Plant Health Inspection Service has at this point is only positive in dairy cows,” Lester Moftt said. “As we do more mandatory testing and gather more information, hopefully, we will be able to get a better understanding of what’s happening across the landscape in other states and across livestock.” Lester Moftt

Monica McConkey was named by the Minnesota Rural Behavioral Health Provider of the Year by the Minnesota State University-Mankato’s The Blue Cross and Blue Shield of Minnesota Center for Rural Behavioral Health. She is a mental health specialist for the Minnesota Department of Agriculture. McConkey also has her own mental health consulting business called Eyes on the Horizon Consulting.

Trivia challenge

The Ayrshire breed originated in Scotland. That answers our last trivia question. For this week’s trivia, what has been the best-selling pickup truck in the U.S. for nearly 50 straight years? We will have the answer in our next edition of Dairy Star. Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

We have been testing with DHIA since the early 70’s when my grandpa, Fred, started testing with DHIA.

What tests do you use and what do you like about those tests? We just do the milk analysis test and like to look at butterfat, protein, and somatic cell count. Our nutritionist likes to look at the sheets to see if he needs to make changes to our ration to boost protein or butterfat.

How does testing with DHIA bene t your dairy operation? DHIA bene ts our operation because of the accurate records and tells us which cows are more pro table and which cows it doesn’t pay to have in the herd. DHIA also helps with choosing which bulls to use on certain cows to improve components of the next generation of cows. I really enjoy the simplicity of getting the information. I can download the results of the tests through dairy comp to my computer to see the last test results.

Tell us about your farm. I farm with my mom, Nancy, and dad, Pat, we have 550 acres of corn and alfalfa and nish out our Holstein steers. We milk in an 85-stall tiestall barn. We also have three part-time high school kids that help.

Aaron bought the brush from Centre Dairy about a year ago and installed it himself. Centre Dairy came out later and adjusted the mount and wiring. Since then, they have had zero issues. They have 70 cows and the majority of them love the brush. Aaron spoke highly of both Centre Dairy

AMY KYLLO/DAIRY STAR

A mixer dispenses feed Jan. 31 at Mulhern Dairy near Fountain, Minnesota. Mulhern Dairy has seen fewer cows off feed, be�er rumina�on, increased butterfat, and improved soil health and organic ma�er a�er removing alfalfa from the ra�on.

Mulhern’s other annual mix is Yield Max. It is planted after a cover crop is harvested. Mulhern lightly tills, drills in the mix and rolls the ground.

Plant time for this mix is approximately June 1 when the soil temperature is 60 degrees. The mix contains brown mid-rib sorghum-sudangrass, Italian ryegrass, medium red clover, berseem clover and hairy vetch.

Mulhern cuts this mix for the rst time at 45 days. His second cutting interval is 30 days, and his nal interval is 45 days.

Mulhern chops both mixes and stores them in bunkers. Mulhern said the annual mixes dry faster than alfalfa. A eld cut in the morning can be chopped the next afternoon.

Mulhern also said the summer annuals are more exible on cut times than alfalfa.

“If you run into some weather on either one of these, you are not going to lose much feed value like you do on an alfalfa,” Mulhern said.

Unlike alfalfa, he said the summer annual mix is not quick to have butyric acid. Forage put up at 65%-70% moisture does not suffer from a concentration of butyric acid like haylage.

In the fall, Mulhern plants cover crops within a couple of weeks of harvesting corn. He leaves his summer annuals to grow as a cover crop over winter.

If he does not have to spread manure on those acres, he will no-till corn into the remaining annuals mix in the spring.

Mulhern said that the annuals mix has positively impacted soil health.

“(There are) a lot of positives,” Mulhern said. “The organic matter with all the roots, the root system breaking up compaction, it’s done a lot.”

Mulhern’s herd eats a 60% forage diet. His milking herd ration contains about 22 pounds of corn silage and 9 pounds of annuals.

Mulhern said the digestibility of the annuals is excellent. He said they are sometimes too digestible and he is forced to include straw.

Rumination has also increased 5070 points, according to the SCR Heatime system the cows wear, after the switch to no alfalfa.

“My off feeds drastically went down when we weren’t feeding alfalfa,” Mulhern said. “Our rumination would go up on the ... activity system, and our off feeds would go down.”

Mulhern has also seen an increase of 0.10% in the herd’s fat test. His herd averages 90 pounds of milk with tests of 4.75% butterfat and 3.4% protein.

Mulhern’s nutritionist, Chad Kieffer, introduced the Mulherns to Daniel Olson of Forage Innovations, who shared the concept of removing alfalfa. Olson uses forage mixes in rations across the U.S. The Mulherns believed in the concept when Olson shared it during a farm visit.

“He’s an honest guy,” Mulhern said. “He’s doing it on his own farm. I’m always looking outside the box, looking for new ideas, willing to try about anything.”

What are the best aspects of being a mother and dairy farmer?

Steph DahlRushford, Minnesota

Fillmore County

270 cows

Tell us about your family and any special plans for your family this year. My husband, Josh, and I will be together 14 years this July. We have three awesome and hard-working little farmers. Our twins, Cash and Jaxie, will be 11 in a week, and Bricker is 8. God has blessed me as a wife and mother. This spring, we will be nishing off our heifer barn. The kids will have their rst 4-H county fair experience this summer. We are looking forward to a fun summer spending time with friends and family, helping Daddy with eldwork, planting owers, gardening, canning, enjoying the warmer weather, long days, late nights, sunsets and campres.

What are the best aspects of being a mother and dairy farmer? Being a mother is the best job in the world. I’m lucky enough to be a stay-at-home mom, and being a dairy farmer has been a dream of mine my entire life. We also homeschool our kids, so I get to be with them all day long. We get to work together through everything: school work, farm work and life in general. The kids and I take care of the calves. They keep us busy, but it’s so rewarding knowing these calves are the future of our farm and our milking herd. The calf barn is my happy place. Getting to work with my kids every morning and night and being around all the precious babies, how could you not be happy?

What challenges do you have with your dual role? It is hard to juggle everything. Homeschooling the kids takes more time out of our day. Some days, it’s harder than others to get everything done in the barn in the morning and evening, keep the house semi clean, get caught up on laundry, get school work done, be able to eat meals at a somewhat normal time and squeeze fun in off the farm. That’s also the joy of it all. We can be somewhat exible, and it’s all my kids know. Farming is hard, as all farmers know. It can be so rewarding, but it’s also stressful, mentally and physically exhausting, and nancially draining. You don’t always feel appreciated. Somehow God has gotten us through the tough times on the farm, more than once, and we keep plugging away. I can’t imagine doing anything else. This is who we are.

What lessons from the farm do you instill in your children? Be cautious and careful in everything you do. Accidents happen so fast. Hard work pays off and feels good, and you will be rewarded in the long run. Teamwork. You’re never going to get anywhere in life by being lazy. Life isn’t always fair, and we don’t always get our way. Death is a part of farming, unfortunately, and it never really gets easier. You have to do the hard work before you get to do the fun work. Being late for and missing out on things is part of farming; get used to it.

What is a highlight of your dairy career as a mother? Raising my kids on the farm. It’s truly the best place in the world to raise them. They learn so many great life lessons. They develop a work ethic and compassion and love for all animals. I wanted to live on a farm my entire life. I am living my dream through Josh and I raising our kids here. Hearing them all say they want to farm when they grow up brings tears to my eyes.

What little things on the farm make you smile? Seeing my kids get along and work together. Seeing them be more responsible and do more things. Seeing them help Daddy and how great he is with them. A calf barn full of healthy calves. Seeing the big girls getting milked and remembering them as calves. Getting more color in our herd, which I’m always trying to do. Bringing new additions home.

What would be the perfect Mother’s Day gift? I’ve gotten cows for Mother’s Day before and semen and embryos once. Being able to spend the day with Josh and the kids would be perfect. They all know owers make Mommy happy, so that works too, even dandelions. A beautiful Brown Swiss or Red & White Holstein heifer calf, born on Mother’s Day, would probably be the icing on the cake. We’ve got a few due soon.

Tell us about your farm. Our farm name is Dead End Dairy. We live south of Rushford, Minnesota, and are fourth-generation farmers on our homestead. We live in a 118-year-old farmhouse (that I love) that Josh’s great-grandparents built. We have 420 tillable acres, and we milk 270 cows in a double-8 parallel parlor. We milk mostly Holsteins but have a handful of Brown Swiss, a couple Red & White Holsteins, lots of Brown Swiss-Holstein crossbreds,

Tammy Howe Hutchinson, Minnesota McLeodCounty 80 cows

Tell us about your family and any special plans for your family this year. Jaren and I have been married for 18 years. Jaren farms full time, and I work at Ridgewater College as the agriculture department coordinator. We have three kids. Austin is 13, nishing up seventh grade and is active in 4-H, trapshooting, B.A.S.S. Fishing Club and raises show chickens. Tanner is 11, nishing up sixth grade and is active in 4-H, football, lacrosse, trapshooting and B.A.S.S. Fishing Club. Taylor is 8, nishing up second grade and is active in 4-H, piano, dance and gymnastics. We went to Florida over spring break this year and have a busy summer planned with farming, sports activities, a family vacation in July, attending dairy shows and getting animals ready for the fair. We’ll try to get shing in when we’re not making hay.

What are the best aspects of being a mother and dairy farmer? Raising our kids on the farm is the best part of being a farming family. There are so many life skills and lessons learned that the kids don’t know are valuable until they get older. I love watching the kids have freedom to do the things they love: riding bike, four-wheeling, building a dock as a family out of pallets so the kids can go shing and duck hunting, and working together on the farm. Each person knows their role and responsibilities that need to be accomplished to get chores done each day.

What challenges do you have with your dual role? Time. There’s never enough of it. As the kids get older and are involved in more things, I become more of a taxi versus a farm mom. The to-do list on the farm never gets shorter, but the time to accomplish those things gets lled with activities, meetings, bills and housework. I know it’s a season of life though, and I’m here for it. I love watching the kids do what they love and seeing us all come together each day to accomplish daily farm chores.

What lessons from the farm do you instill in your children? The best life lessons are learned on the farm. A strong work ethic, responsibility, compassion and so much more. In my job, I work with a lot of industry professionals to connect our students with future employers, and these farm kids are highly sought after because of the skills they have by having a background in agriculture and the natural skills that are instilled in them by growing up on the farm. I’m proud to be raising three kids with those same skill sets.

What is a highlight of your dairy career as a mother? Being a fair mom and watching the kids do their thing, showcasing all of their hard work at the fair. Our kids show dairy, swine, poultry and have static projects that they bring to the fair. It’s a busy time, but the smiles on their faces as they achieve big goals and see their hard work pay off is one of my favorite times of the year.

What little things on the farm make you smile? My owers; fresh-mowed grass; picking up the last bale of hay from the eld; heifers running around their cleaned pens, playing with the fresh bedding; and looking back at a busy weekend of completing farm projects as a family.

What would be the perfect Mother’s Day gift? I ask for the same Mother’s Day present each year, and my family knows it makes me so happy. Jaren and the kids all help me plant my owers and put fresh mulch on owerbeds throughout the yard. It’s something I can enjoy for the rest of the summer.

Tell us about your farm. At Howe Holsteins, we milk 80 registered Holsteins and have a custom heifer raising business. We milk in a tiestall barn and sell our milk to First District Association. We are the fourth and fth generations on our farm. Longevity is our breeding philosophy. Strong cows built to last.

a Jersey, a Milking Shorthorn and whatever else I can convince my husband into buying. We farm with Josh’s brother, Jon. We ship our milk to Foremost Farms USA. In addition to our calves, heifers and cows, we also have horses, a mini donkey, mini cows, dogs, cats, chickens and guineas. More to come, I’m sure.

Turn to OUR SIDE | Page 16

Albany, Minnesota

Stearns County

250 cows

Tell us about your family and any special plans for your family this year. We are a family of seven. My husband and I have ve children: Sophia, freshmen at the University of St. Thomas Minnesota; Isabella, 10th grade; Brady, seventh grade; Bo, fth grade; and Max, rst grade. The kids are all a part of 4-H and some are in FFA. We are not only busy on the farm but also off the farm, as all the kids are involved in sports which takes up most all our spare time. Our plans for the summer are to hopefully get on the lake and enjoy time together.

What are the best aspects of being a mother and dairy farmer? The best part about being a mom is hard to narrow down as there are so many things to be grateful for. A few things are the little moments like watching a movie together or having a campre together. The best part of being a dairy farmer is the exible schedule. I get my kids to and from school, and I am able to attend their sporting events and school activities. I also get to work with my husband. Combining being a mom and dairy farmer is really being a well-rounded family in so many areas, and I am blessed to have this opportunity to be home with my kids and husband.

What challenges do you have with your dual role? A challenge I face in my many roles is to slow down and nd time. I am juggling farm work, house work, meals, sporting events and a little bit of down time somewhere in there.

What lessons from the farm do you instill in your children? We try to instill a good work ethic in our kids, which will hopefully help them throughout their entire life. Each of the kids have their chores on the farm, and some have chores even before going to school each day. Hopefully, they learn to never give up no matter how hard something becomes.

What is a highlight of your dairy career as a mother? When we made the decision to build our robotic barn and seeing how the kids were so involved. They wanted to be a part of the start-up process and were just as excited as we were.

What little things on the farm make you smile? Our kids are involved in 4-H, and I really enjoy watching them show their dairy animals. After all the hard work they put in, it’s so rewarding watching their big smiles in the ring.

What would be the perfect Mother’s Day gift? A day at home with our family and grandparents, and I don’t have to cook for the day.

Tell us about your farm. We milk 250 cows in our robotic barn where our milk is then shipped to First District Association. We take care of everything at our farm, from the calves to the youngstock until they are ready to calve. Each of the kids has chores on the farm, and John and I take care of the everyday tasks.

Rachael Bushman Waukon, Iowa Allamakee County 110 cows

Rachael Bushman Waukon, Iowa Allamakee County 110 cows

Tell us about your family and any special plans for your family this year. Zack and I have been married for eight years. We have ve girls. We homeschool the oldest two. Sophia is 6 and in rst grade. Briella is 5 and in kindergarten. Joanna is 4, Ellianna is 1 and Eloise was born April 21. The girls all love to play around the farm, helping with calf chores, bringing cows home from pasture and catching a ride in the tractor.

What are the best aspects of being a mother and dairy farmer? Being able to do everything as a family. Not everyone has the ability to eat all three meals together every day of the week, but I’m thankful that we can. We work together, learn together, eat together and play together, and I love it. It’s fun to watch the kids grow, not only physically and scholastically but also in their work ethic and their expanding capabilities around the farm.

What challenges do you have with your dual role? It can denitely be hard to try to keep up with things. Between ofce work, chores, homeschooling, housework and raising kids, it can be hard to prioritize what needs to get done. There just aren’t enough hours in a day.

What lessons from the farm do you instill in your children? Hard work and not giving up. There are lots of opportunities to practice perseverance and to keep trying even when things get hard or seem impossible.

What is a highlight of your dairy career as a mother? We received the outstanding dairy family award in our county this year.

What little things on the farm make you smile? Going for walks to the pasture as a family on warm summer days. Seeing the kids’ excitement over a new calf. Fresh hamburgers that are more delicious than ones you could buy from a store. Everyone working hard together to get the job done.

What would be the perfect Mother’s Day gift? A day off, with time for a nap (for Mom).

Tell us about your farm. We bought our organic farm in 2016. We milk 120 cows and raise our replacement heifers. We milk three times a day in a parlor. We grow corn, oats and hay on just over 350 acres. A couple years ago, we switched cooperatives and started shipping to Kalona SuperNatural. We have one faithful employee who has been with us about three years and milks morning and afternoons on the weekdays, as well as Saturday mornings. My husband, Zack, and I do weekend milking and night milking.

Deanna Emmert Hancock, Minnesota Pope County 125 cows

Tell us about your family and any special plans for your family this year. I am married to Chris Emmert, and we have three beautiful girls: Alison, 9, Bailee, 7, and Kecia, 4. We like to nd special moments all around us: a surprise picnic, a day trip, a simple bonre or a ride in the tractor with the music turned up.

What are the best aspects of being a mother and dairy farmer? Dairy farming offers so many everyday life lessons. I am grateful I get to be beside my children to guide and experience things with them together.

What challenges do you have with your dual role? I read something a while back that stuck with me. “Let your children do dangerous things safely.” Let them learn and grow. Adjusting to my children’s independence and abilities while nding a balance with my motherly instincts and wanting to always keep them safe is a challenge for me.

What lessons from the farm do you instill in your children? There are so many to choose from. Of course, hard work, responsibility and accountability but also compassion, life and death, nature, teamwork and communication. The biggest of all is faith and to include God in every aspect of your life.

What is a highlight of your dairy career as a mother? The unexpected opportunity and decision to homeschool our children. It has been a big learning experience for us all but well worth the extra time we get to spend with our children and guiding them in their future.

What little things on the farm make you smile? I nd myself stopping and smiling often. When my girls learn new things or when they accomplish something they had been trying and nally have success. The pride on their face when feeding a rst-time bottle calf always makes me smile and so does watching them move calves. Also, when I see them help each other or their dad.

What would be the perfect Mother’s Day gift? A day of no cooking or cleanup. My older girls are learning to cook, so maybe it’s in my future soon.

Tell us about your farm. My husband and I milk 125 cows with two Lely robotic milking units. We raise our replacements and our feed. We also grow corn, soybeans, alfalfa and a bit of wheat. We love having our kids by our sides and learning as they grow.

Freeport, Minnesota Stearns County 90 cows

Tell us about your family and any special plans for your family this year. My husband, Charles, and I have two children. Our oldest, Cassidy, is married to Matt. They live in Browerville, Minnesota. She is pursuing a veterinary career. Joe is our youngest and completed a two-year program at Ridgewater College for agricultural power and equipment technician. Joe helps with milking and eldwork. This summer, we have multiple graduation parties, a family wedding and a family reunion to attend. In the winter, Charles and I like to visit someplace warm for a quick vacation.

What are the best aspects of being a mother and dairy farmer? Being able to watch my kids learn about life from the farm — not read about it but actually live life’s changes and challenges. Life, death and everything in between. I love being able to work with my family, most days.

What challenges do you have with your dual role? My biggest challenge has been living up to the standards that the women farmers in my life have set. I grew up on a hog farm and then a crop farm. My mother, Bev, took care of all aspects of farming as well as taking care of her ailing family when they needed her. She is a strong mother who believes in truth and equality for all. My mother-in-law, Millie, worked on the dairy farm, had a part-time job, had an immaculate home and volunteered in her community. These women are the examples that I try to live up to every day.

What lessons from the farm do you instill in your children? The most common phrase, “On the farm is the best place to raise a family,” is 100% true. I was able to teach my kids responsibilities and life lessons without having to quote examples, because they were living these values every day by participating in the farm life.

What is a highlight of your dairy career as a mother? There have been so many special occasions. Watching them get the tractor/combine ready for tractor day at school. The biggest highlight is knowing that both of my kids are responsible and kind adults. Anybody can call on either one of them for help, and they will be there. If they say they are going to do a job, you can bet they will do it and do it to the best of their ability.

What little things on the farm make you smile? Playing with kittens makes everyone smile. Raking hay on a warm, sunny day. Playing “Guess who’s the singer” in the milking parlor with Charles and Joe.

What would be the perfect Mother’s Day gift? The perfect day would be a winning Powerball ticket, not having to do chores that day and having a picnic with my whole family: parents, brothers and their families and my children.

Tell us about your farm. Charles and I own 320 acres and rent an additional 100. We milk 90 cows in a swing-12 parlor. Charles and I milk most mornings and evenings. Joe helps mornings and in the evenings when he gets off work from Greenwald Farm Center Inc. Charles and Joe do most of the eldwork. I pick rocks, rake hay and do the bookwork. We ship our milk to First District Association.

Lindsay Winquist Alcester, South Dakota Union County 430 cows

Lindsay Winquist Alcester, South Dakota Union County 430 cows

Tell us about your family and any special plans for your family this year. My husband, Josh, and I have four kids: Alex, 21, Caden, 19, Emily, 15, and Jace, 10. Our oldest son is getting married in October, so we will be gaining another daughter, Grace, which we are extremely excited about.

What are the best aspects of being a mother and dairy farmer? The best aspects of being a mother and a dairy farmer is the feeling that I know what is going on and can prioritize our time. From the farm to a crazy busy life with our kids being involved in every sport, I love being able to prioritize things to make sure we are at our kids’ events. We’ve haven’t missed very many. It is very important to our kids that we show them they are the No. 1 priority and to also show them that it can be done. I never wanted the dairy to be a negative thing for my kids. We have been fortunate to have good help at the dairy so we can go on vacations together and not miss out on spending time with our kids. Like everyone says, time goes fast. We only have two kids left at home.

What challenges do you have with your dual role? Time management is always a challenge. With getting older and so many things going on all the time, I tend to forget things. So, I need to make lots of notes and to-do lists.

What lessons from the farm do you instill in your children? Hard work. Someone once told me that anybody who works on a dairy farm knows what hard work and dedication is. With our kids growing up on the farm and being very involved, they denitely have the hard work and dedication instilled in them.

What is a highlight of your dairy career as a mother? The best part about being in the dairy business and being a mother is always being together. From the time the kids were little, both Josh and I were around all day long with the kids. We did almost everything together. Being together is my favorite part. The kids never had to go to day care and were always very involved with everything on the farm.

What little things on the farm make you smile? The calves always make me smile. I’m a sucker for all babies. I also love it when my kids willingly help and show that they are enjoying their time spent with us.

What would be the perfect Mother’s Day gift? The perfect Mother’s Day gift would be to go out to eat with all of my kids and my husband. I love spending time with my family. Flowers are a bonus.

Tell us about your farm. My husband and I started the dairy from scratch right after we got married. We have a couple of full-time employees and a couple of part-time employees. Our two older boys are showing interest in coming back to the farm, so that is exciting. We milk in a double-12 parlor and sell our milk to Dairy Farmers of America Inc.

IA United

“We have seen good results with Udder Comfort™ through the years. We didn’t see that with other products we tried. We love what it does for our fresh cows, especially 2-year-olds. It gets swelling out fast, softening udders quicker for more comfortable milking. We really like the ease of use and doing fresh groups in the barn with the Udder Comfort Battery-Operated Backpack Sprayer. We do pre-fresh heifer groups once a week when we vaccinate. We do post-fresh heifers and cows every morning for 10 days after calving while in lockups for daily temps,” says Jim Rickert of Rickland Farms, Eldorado, Wisconsin.

Four generations farm 2000 acres and milk 975 Reg. Holsteins. They were profiled in a Sept. 2023 Holstein America on RFD-TV. (Watch it at https://qrco.de/Rickland or scan QR.)

“Udder Comfort makes the biggest difference,” Jim reports. “It pays to get fresh udders softer, faster, for better milking and more comfortable cows at the start

We wouldn’t be doing

if it didn’t pay.”

How many times a day do you milk, and what is your current herd average, butterfat and protein? We milk three times a day, and our rolling herd average is 30,800 pounds of milk with 3.8% butterfat and 3.2% protein.

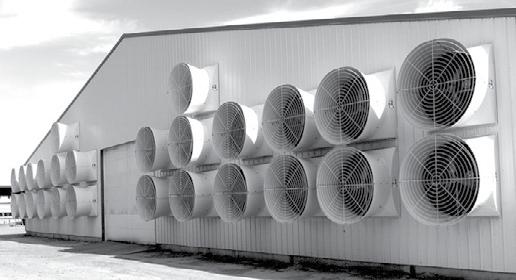

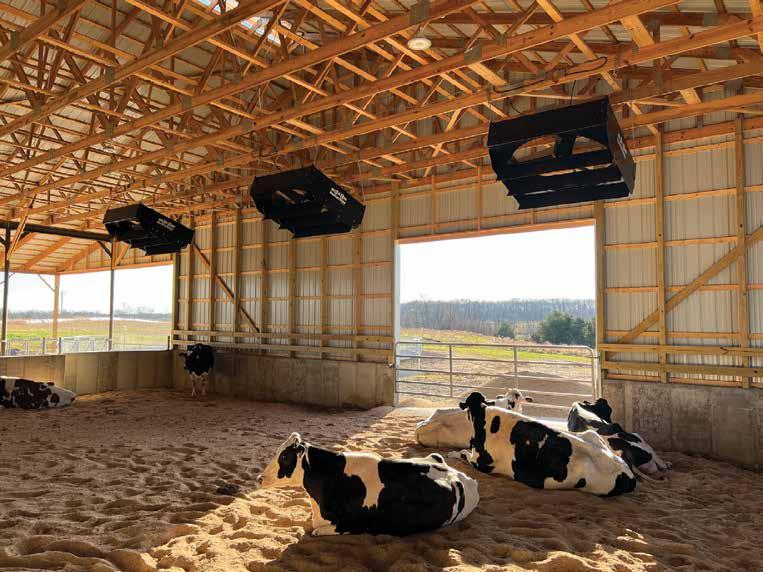

Describe your housing and milking facility. Our freestall barn was built in 2002 and is naturally ventilated. The free stalls are bedded with sand. We milk in the double-8 parallel parlor that we built in 2000.

Who is part of your farm team, and what are their roles? My wife, Barb, is the farm’s bookkeeper. Our son, Kyle, is in charge of breeding, and our son, Dave, is the herdsman and takes care of herd health. We all pitch in wherever we are needed, especially during the busy eldwork season.

What is your herd health program? Our veterinarian, Dr. Erika Nagorske, performs pregnancy checks every other week. We vaccinate all of our animals according to Dr. Nagorske’s vaccination schedule. It doesn’t pay to skimp on vaccines. Cleanliness is also important. We make sure that all of our milking equipment

is sanitized and that the free stalls are kept clean and dry and have fresh sand.

What does your dry cow and transition program consist of? All of our cows are given a 60-day dry period. Dry cows are housed in a separate facility and are fed a ration that includes corn silage, ground corn stalks and a grain mix. When it’s available, we will give them grass hay instead of corn stalks. Immediately after calving, fresh cows are given two Bovikalc boluses. We don’t have a transition program. Fresh cows go straight from the maternity pen into one of our lactating groups.

What is the composition of your ration, and how has that changed in recent years? Our lactating animals are given a total mixed ration that consists of corn silage, haylage, cottonseed and a custom grain mix. We quit using dry hay in our lactating ration a few years ago because it got too expensive to buy. We have found that using haylage instead works just ne.

Tell us about the forages you plant and detail harvest strategies. We plant silage corn and alfalfa. We keep our

|

We apply manure immediately after each cutting. We were able to harvest ve cuttings of alfalfa last year.

What is your average somatic cell count, and how has that affected your production? Our SCC typically ranges from 78,000 to about 100,000, which is good enough to get us into the Minnesota DHIA top 100 milk quality leaders. Keeping our SCC low has helped us maintain high milk production levels.

What change has created the biggest improvement in your herd average? Our mixer has helped increase our average the most, followed by going to three-times-a-day milking. Before we got the mixer, we would feed the cows baled hay with silage and a grain mix fed separately.

What technology do you use to monitor your herd? All of our cows have activity and rumination collars. The collars tell you right away if a cow is in heat or is feeling sick. We also put activity collars on

alfalfa elds for three or four years before rotating them back to corn. Our goal is to harvest our corn silage and

haylage at 68% moisture. We cut our alfalfa before it reaches the bud stage and let it lie for a day before we chop it.

JD C350 2023, #571477............................................................................

JD 468 Silage Special 2010, Twine, 4 ft. bales, 19300 BC, #567833 ........ $15,000

JD 458 2011, Twine, 4 ft. bales, 200 BC, #576430 ..................................... $15,900

JD 568 2009, Twine & Surface Wrap, 5 ft. bales, 16500 BC, #570611 ........ $18,900

JD 568 2010, Twine & Surface Wrap, 5 ft. bales, 14683 BC, #559585 ........ $19,900

JD 568 2009, Twine & Surface Wrap, 5 ft. bales, 14389 BC, #570459 ........ $19,900

Claas 380 2015, Surface Wrap, 4 ft. bales, 5200 BC, #567694 .................. $21,100

JD 854 Silage Special 2013, Twine & Surface Wrap, 5 ft. bales, 7864 BC, #573441 ................................................................................

JD 469 2015, Twine & Surface Wrap, 4 ft. bales, 21000 BC, #570101

JD 569 2016, Surface Wrap, 5 ft. bales, 14000 BC,

JD 560M 2018, Twine & Surface Wrap, 5 ft. bales, 8000 BC, #574492

JD 560M 2020, Surface Wrap, 5 ft. bales, 10500 BC, #573915

JD 460M 2020, Twine & Surface Wrap, 4 ft. bales, 11886 BC, #574791 .....

JD 569 2015, Twine & Surface Wrap, 5 ft. bales, 4200 BC, #574587 ..........

JD 560M 2020, Surface Wrap, 5 ft. bales, 9462 BC, #567629 ...................

JD 560M 2019, Twine & Surface Wrap, 5 ft. bales, 6000 BC, #554127 .......

JD 560M 2021, Twine & Surface Wrap, 5 ft. bales, 8233 BC, #557166 .......

JD 460M 2020, Twine & Surface Wrap, 5 ft. bales, 6248 BC, #574583 .......

JD 560M 2019, Surface Wrap, 5 ft. bales, 4300 BC, #573416 ....................

JD 560M 2019, Twine & Surface Wrap, 5 ft. bales, 5339 BC, #574784 .......

JD 450M 2021, Twine & Surface Wrap, 4 ft. bales, 2950 BC, #577084 ....... $44,500

JD 560M 2019, Twine & Surface Wrap, 5 ft. bales, 3542 BC, #574981 ....... $44,900

JD 560M 2018, Twine & Surface Wrap, 5 ft. bales, 4500 BC, #568316 ....... $44,900

JD 560M 2023, Surface Wrap, 5 ft. bales, 7233 BC, #580417 .................... $45,900

JD 460M 2021, Twine & Surface Wrap, 4 ft. bales, 7574 BC, #574793 ....... $45,900

JD 560M 2020, Surface Wrap, 5 ft. bales, 3950 BC, #574425 ....................

JD 560M 2020, Twine & Surface Wrap, 5 ft. bales, 5555 BC, #574701 .......

JD 560M 2020, Twine & Surface Wrap, 5 ft. bales, 2955 BC, #570458 .......

JD 560M 2021, Twine & Surface Wrap, 5 ft. bales, 6257 BC, #570539 ....... $48,900

JD 460M 2019, Twine & Surface Wrap, 4 ft. bales, 2487 BC, #564617 ....... $49,900

JD 560M 2021, Surface Wrap, 5 ft. bales, 5157 BC, #574523 ....................

JD 560M 2020, Twine & Surface Wrap, 5 ft. bales, 2300 BC, #575077

JD 460M 2021, Twine & Surface Wrap, 4 ft. bales, 1600 BC, #572264

Contact one of the following dealers to learn more:

IOWA

Prairie Land Ag Supply Inc. Rock Valley, IA 712-476-9290

United Dairy Systems, Inc.

West Union, IA 563-422-5355

Monticello, IA 319-465-5931

WISCONSIN

Advanced Dairy Spring Valley, WI 715-772-3201

Bob’s Dairy Supply Dorchester, WI 715-654-5252

Ederer Dairy Supply Plain, WI 608-546-3713

DeLaval Dairy Service Kaukauna, WI 866-335-2825

Joe’s Refrigeration Inc. Withee, WI 715-229-2321

Mlsna Dairy Supply Inc. Cashton, WI 608-654-5106

Professional Dairy Services Arlington, WI 608-635-0268

Redeker Dairy Equipment Brandon, WI 920-346-5579

The Scharine Group Inc. Whitewater, WI 800 472-2880 Mt Horeb, WI 800-872-3470

MINNESOTA & SOUTH

DAKOTA

Farm Systems

Melrose, MN

320-256-3276 Brookings, SD 800-636-5581

Advanced Dairy Mora, MN

320-679-1029 Pierz, MN

320-468-2494

St. Charles, MN 507-932-4288 Wadena, MN 218-632-5416

Has been a quality market for MN dairy farmers for over 100 years. MN producers provide one of the country’s most distinctive brands of cheese that is still made using the same Old World craftsmanship and has been combined with cutting-edge technology to produce cheese that delivers unforgettable taste with unparalleled quality. MN Dairy farmers and Bongards, quality that stands the test of time. We offer a competitive base price, premiums, and the best eld representatives in the industry.

13200 Co. Rd. 51 Bongards, MN 55368 (952) 466-5521

Fax (952) 466-5556

110 3rd Ave. NE Perham, MN 56573 (218) 346-4680

Fax (218) 346-4684

Con nued from TOP PERFORMERS | Page

like to show dairy cattle, so we always keep a few show cows around for them.

What is your breeding pro-

and what role does ge-

play in your

Our

is

registered Holsteins. Mating suggestions are made by a Semex computer program. All of our breeding choices are made with a low SCC, good type, high production and sound udders in mind. Our grandkids

List three management strategies that have helped you attain your production and component level. Our mixer has helped us make a balanced ration on a consistent basis. The activity collars have helped us a lot when it comes to breeding and monitoring herd health. We use sexed semen, so we always have more heifers than we need. This allows us to be choosy when we decide which heifers should join our milking herd.

JERRY NELSON/DAIRY STAR

The freestall barn at Pedley Holsteins was built in 2002 near Ocheyedan, Iowa. It features natural ven la on, s r fans and stalls that are bedded with sand.

Tell us about your farm and your plans for your dairy in the next year. My wife, Barb, and I have been married for 49 years. I have milked cows my entire life. I started farming on my own on a rented farm in 1976 with a John Deere 4020 and a vebottom plow. I moved here

and bought out Dad in 1991. At that time, we had 60 cows and 30 heifers. I worked with my dad and my uncle until they retired. Kyle and Dave take care of all of the farm’s repair work. They also do custom eldwork such as planting corn and hauling manure. Our plans for the next year are to simply keep on improving on what we have.

JERRY NELSON/DAIRY STAR

The double-8 parallel milking parlor at Pedley Holsteins was completed in 2000 near Ocheyedan, Iowa. Their 300 registered Holsteins are milked three mes a day.

JERRY NELSON/DAIRY STAR

Diva, a Red & White Holstein show cow who lives at Pedley Holsteins, is wearing a collar that monitors her ruminaon and ac vity near Ocheyedan, Iowa. All of the cows and breeding-age heifers are equipped with ac vity collars.

SUNRISE AG CO-OP Buckman, MN • 320-468-6433

LEAF RIVER AG SERVICE Bluffton, MN • 218-385-2559

FARMERS ELEVATOR COMPANY Waupun, WI • 920-324-3593

ADELL COOPERATIVE Adell, WI • 920-324-3593

CHIPPEWA VALLEY DAIRY SUPPLY Stanley, WI • 715-644-2350

GLACIAL PLAINS CO-OP Benson, MN • 320-843-3999

GLACIAL PLAINS CO-OP DeGraff, MN • 320-843-5634

GLACIAL PLAINS CO-OP Sunburg, MN • 320-366-3456

Conventional wisdom says that you get what you pay for. And conventional wisdom is right. You won’t find CRYSTALYX® in the bargain aisle, but it’ll always get the optimal performance out of your cattle. Whether it comes in a steel or plastic barrel, or our sustainable BioBarrel®, CRYSTALYX® is more than just a supplement. It’s an investment.

ELROSA GRAIN AND FEED Elrosa, MN • 320-697-5515

PRAIRIE FARM SUPPLY Belle Plaine, MN • 952-873-4234

HOLDINGFORD MILL Holdingford, MN • 320-746-2281

ALBANY FEED SHED Albany, MN • 320-845-2303

LUXEMBURG FEED SERVICES, INC St. Cloud, MN • 320-252-1513

UNITED FARMERS CO-OP LeSueur, MN • UFCMN.com • 507-665-6421

MINNEAPOLIS — The name Natalie Clemenson has been announced multiple times in youth gatherings in recent years, but never as it was April 23 in Minneapolis.

Clemenson and several thousand people heard the name at the same time when she was named Minnesota state FFA reporter at the conclusion of the 95th Minnesota FFA Convention.

With the announcement, she became one of six state ofcers selected through a rigorous interview process conducted by a nominating committee of students, adults and former state ofcers.

“My rst reaction was of being extremely blessed and grateful,” Clemenson said. “Serving as a state ofcer has always been a life goal … since attending my rst (FFA) convention as an eighth grader and seeing the leadership there.”

ects. She previously won the state’s FFA dairy evaluation event, and their rst-place team went to nationals. Similarly, her 4-H dairy judging team won the Minnesota 4-H contest in 2023 and then won the national contest, with Clemenson as high individual.

She said those accomplishments were wonderful, but this one is somewhat different.

“Both (judging and state ofce) have been goals, but they are a little bit different,” Clemenson said.

Through her role as a state FFA ofcer, she can serve others and be a true leader. Judging is a more independent activity.

“Both require hard work and dedication, and they take time to achieve,” Clemenson said. “But through this state ofce, I can give back more.”

Giving back to her means making chapter visits and encouraging fellow FFA members. It also means being on hand for state FFA camps and planning the 2025 state FFA convention.

Natalie Clemenson (third from le�) is selected as the Minnesota FFA state reporter alongside fellow officers Lauren Stoel (from le�), Kaiya Grossman, Torri Gunderson, Cole Sundeen and Emma Braford April 23 during the organiza�on’s state conven�on in Minneapolis, Minnesota. The University of Wisconsin-River Falls freshman is from an 85-cow dairy farm near Goodhue, Minnesota. Turn to

Clemenson said her aunt, Sarah Clemenson Berzold, and several extended family members had also been state FFA ofcers, serving as an-