First-ever cases of HPAI confirmed in US ruminants

Poulsen urges biosecurity to protect herds

By Danielle Nauman danielle.n@dairystar.com

MADISON, Wis. — Many

Americans turned their attention toward March Madness last month.

The U.S. dairy industry found itself in the throes of its own version of madness as cows on dairy farms in Texas and Kansas began exhibiting symptoms of an illness later identied as highly pathogenic avian inuenza.

Dr. Keith Poulsen, director of the Wisconsin Veterinary Diagnostic Laboratory, spoke April 2 during a Professional Dairy Producer “The Dairy Signal.”

“The second week of March, farmers were dealing with an unknown morbidity event,” Poulsen said. “It was not acting like anything else we typically see on a dairy.”

As of April 9, the virus has been conrmed in 17 herds in six states: Texas, 9; Kansas, 3; New Mexico, 2; Idaho, 1; Michigan, 1; and Ohio, 1.

Farmers in the Texas panhandle began noticing a decrease in feed intake and reduced rumen motility as reported by rumination monitors. Cows suffering these symptoms were found to be second-lactation cows or older that were at least 150 days in milk.

The most unusual symptom was in the appearance of the milk of affected cows. While the cows did not

Farm transition gone right

Trust, patience bring dairy ownership to reality

By Abby Wiedmeyer abby.w@dairystar.com

HOLY CROSS, Iowa

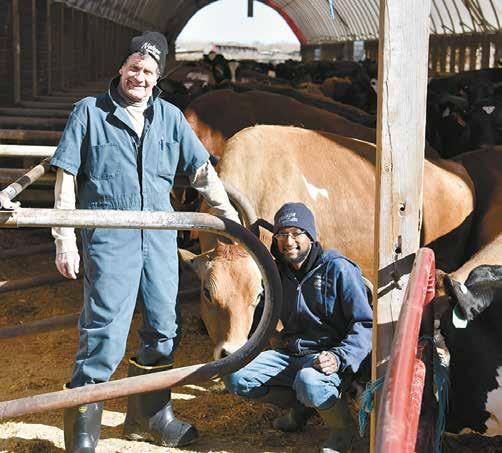

Before the ink dried on the land contract Robert Nosbisch signed with his mentors, Dan and Laurie Clemen, he was back in the barn milking cows as he had been doing for the past 12 years.

The only difference was that he was the proud owner of the farm and all the cattle and machinery on it.

“I didn’t know them from Adam when I started, and it has worked out well; I have no complaints,” Nosbisch said. “There was a lot of trust involved. You’ve got to have patience.”

Nosbisch milks 160 cows in a double-8 parallel parlor and crops 280 acres. His heifers are raised down the road in facilities of which he also assumed ownership.

The trust was established when Nosbisch was a dairy nutritionist for the couple. Fresh out of college, Nosbisch wanted to farm but wanted to try a career in nutrition rst.

Dan Clemen was looking for help, so Nosbisch began working part time to help with chores. Eventually, the desire to farm won. He quit his nutrition job to work as a salaried employee for Clemen for ve years.

A family of milk haulers

Swart passes love of job to next generation

By Jan Lefebvre jan.l@star-pub.com

PENNOCK, Minn. —

Darren Swart would take his son, Tanner Rohner, and his daughter, Taylor Rohner Swart, on milk routes when they were growing up. Little did he realize those experiences would lead them to follow in his career.

“They were both still in car seats when I brought them early on,” Swart said.

“They’d go along with me just to get out of the house and to play with the kids on the other farms.”

April 13, 2024 Volume 26, No. 4

A

“All dairy, all the time”™

Turn to HPIA | Page 8

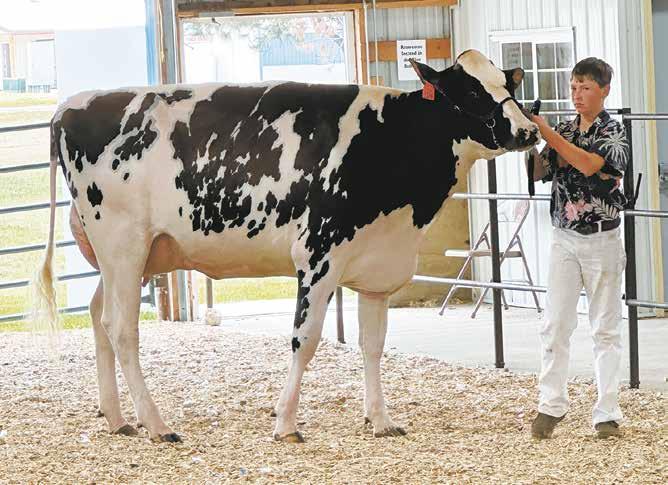

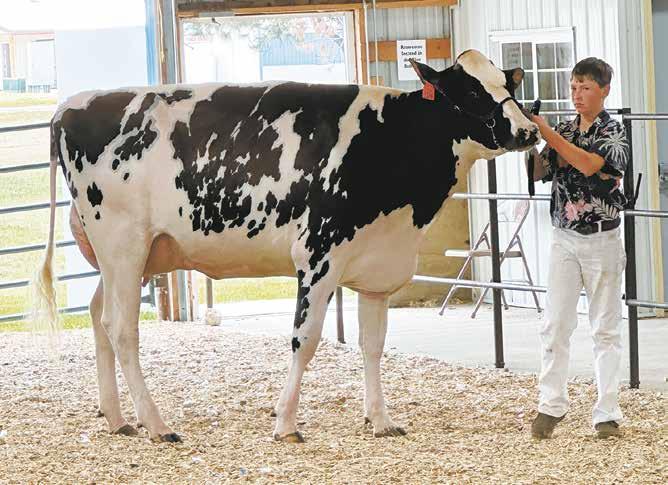

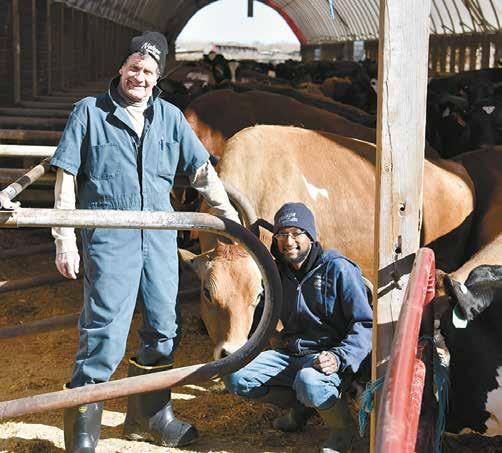

ABBY WIEDMEYER/DAIRY STAR

Robert Nosbisch milks cows Feb. 21 at his farm near Holy Cross, Iowa. Nosbisch completed a farm transi on a er working toward ownership for 12 years.

Turn to NOSHBISCH | Page 2

MARK KLAPHAKE/DAIRY STAR

Turn to SWART | Page 6

Tanner Rohner (from le ), Taylor Rohner Swart and Darren Swart gather by Darren’s truck April 2 near Pennock, Minnesota. The three family members are milk haulers.

Sign up for our Newsletter up for our Dairy St r Milk Break Visit dairystar.com to sign up!

Dr. Keith Poulsen Director, Wisconsin Veterinary Diagnostic Laboratory

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce)

320-248-3196 (cell) 320-352-0062 (home)

Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com Editorial Staff

Maria Bichler - Assistant Editor maria.b@dairystar.com

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com Consultant

Jerry Jennissen 320-346-2292

The goal for Nosbisch to take over the farm was mutual from the beginning. Nosbisch took over picking out bulls for breeding and making feed decisions and cropping plans within the rst couple of years of working for Clemen.

“He said if you are going to buy them all, you might as well pick the bulls,” Nosbisch said. “He took my opinion with a grain of salt but also showed me that sometimes it’s a long process, and you can’t have everything you want right away. It takes time to make money to pay for things you want to change.”

Before taking ownership of the operation, Nosbisch worked on

507-634-4413

920-979-5284

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell)

bob.l@star-pub.com

Mark Klaphake (Western MN)

320-352-6303 (ofce) • 320-248-3196 (cell)

halves for two years. On Jan. 1, he bought the rest of the cows and later that month purchased the rest of the ground on a land contract. Nosbisch said the Farm Service Agency has offered help through various beginning farmer programs.

Cows are housed in two freestall barns. Milking takes about 2.5 hours with the help of a part-time high school student and a full-time laborer. Nosbisch’s wife works off the farm, and their young son spends afternoons watching his dad milk cows.

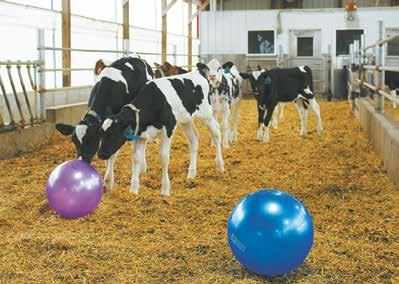

Calves are raised in a renovated hog barn with an automatic feeder. The upgrade came about ve years ago. Nosbisch said the ventilation

system leaves something to be desired but has been resulting in healthy calves thus far.

Heifers are brought back to the dairy once they are pregnant. Nosbisch would like to raise all the heifers on one site to eliminate trucking them back and forth.

Milk is shipped to Prairie Farms Dairy in Dubuque. Nosbisch credits the creamery for making the transition possible with good milk prices and a well-managed market. He was able to obtain the market right before the creamery implemented a quota system.

Page 2 • Dairy Star • Saturday, April 13, 2024 North America dealers. DAIRY ST R ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378 Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com Deadlines The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication. Subscriptions One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute nal acceptance of the advertiser's order. Letters Letters and articles of opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The views and opinions expressed by Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC. The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces. POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. © 2023 Star Publications LLC Advertising Sales Main Ofce: 320-352-6303 Fax: 320-352-5647 Deadline is 5 p.m. of the Friday the week before publication Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com National Sales Manager - Laura Seljan (National Advertising, SE MN)

fax:

507-250-2217 •

laura.s@dairystar.com Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI)

• kati.s@dairystar.com

Con nued from NOSHBISCH | Page 1 Isaacson Sales & Service Lafayette, MN Dave's Repair Farm Equipment Hills, MN Northland Farm Systems Owatonna, MN Bodsensteiner Implement Company Elkader, IA Burco Sales Independence, IA Dee Implement Of Waukon Waukon, IA Kunau Implement Company Dewitt, IA Rexco Equipment Farley, IA Greiner Implement Company Ottumwa, IA Helmuth Repair Kalona, IA Beck Implement Elgin, MN Woller Equipment Swanville, MN Miller Sellner Slayton Slayton, MN Invest in Quality ® www.kuhn.com Visit your local KUHN Hay & Forage dealer today! FC 25 F & 30 SERIES | Triple Mower Conditioners 10'2" – 32'6" working widths MAXIMUM OUTPUT. OPTIMAL FORAGE. ® ® blades UP TO $4 , 000 OFF NEW FC MODELS CONTACT YOUR LOCAL DEALER: Offer ends: June 28, 2024 ABBY WIEDMEYER/DAIRY STAR

a farm transi on this year, making him the proud owner of this dairy opera on near Holy Cross, Iowa. The 280-acre farm is home to 160 cows and

family.

Robert Nosbisch completed

Nosbisch’s

Turn to NOSHBISCH | Page 5

How have your increased your role on the farm? First Section: Pages 15 - 16 FROM OUR SIDE OF THE FENCE: For additional stories from our other zone, log on to www.dairystar.com Dairy Star • Saturday, April 13, 2024 • Page 3 Clasemanns embrace robotic milking system Second Section: Pages 3 - 4 Long Prairie, MN Zone 2 Zone 1 A day in the life of the Kilburgs Second Section: Pages 12, 14 - 15 Bellevue, IA Kids Corner: The Maassen family Third Section: Pages 12 - 13 Maurice, IA Sonstegard specializes in fertility, conventional practices First Section: Pages 26 - 27 Hoffman, MN Lake City boys basketball team places second at state tournament First Section: Pages 32 - 33 Lake City, MN Behind the Emblem: Sleepy Eye FFA Third Section: Pages 10 - 11 Sleepy Eye, MN Columnists Ag Insider Page 10 First Section F Dear County Agent Guy Page 36 First Section Dea Ag P Firs The “Mielke” Market Weekly Pages 10 - 11 Second Section Veterinary Wisdom Page 37 First Section Vet W Pa P Fir F s From the Zweber Farm Page 38 First Section n F Zwe P Firs Country Cooking Page 22 Second Section C C P The NexGen Page 39 First Section Swart passes love of job to next generation First Section: Pages 1, 6 - 7 Pennock, MN Ellsworth, MN Timmers win PDCA Distinguished Breeder Award First Section: Pages 23, 25 Trust, patience bring dairy ownership to reality First Section: Pages 1, 2, 5 Holy Cross, IA

to Pine Country Bank! With our expertise and commitment to personalized assistance, we’re here to ensure that farmers have the resources they need to thrive in an ever-changing landscape. Contact us to learn more about our ag lending services:

Page 4 • Dairy Star • Saturday, April 13, 2024 FOR MORE INFO - CONTACT ONE OF THESE DEALERS... Lang’s Dairy Equipment, Inc. 2337 Millennium Rd. • Decorah, IA 52101 (563) 382-8722 295 East Main Street • Lewiston, MN 55952 (507) 452-5532 Precision Dairy Equipment 24548 IA-13 • Elkader, IA 52043 (563) 245-2560 Tri-County Dairy Supply, Inc. 4107 N US HWY 51 • Janesville. WI 53545 608-757-2697 Bob’s Dairy Supply 540 E. County Rd. A • Dorchester, WI 54425 (715) 654-5252 Eastern Iowa Dairy Systems 105 3rd Ave. NW • Epworth, IA 52045 (563) 876-3087 Farm Systems 58 Interstate Drive • Melrose, MN 56352 Brookings SD • (320) 256-3276 Leedstone 222 E Co Rd 173 SE, Melrose, MN 56352 (877) 608-3877 24260 Cty. Rd. 27 • Plainview, MN 55964 (800) 548-2540 1720 Freitag Dr. • Menomonie, WI 54751 (866) 467-4717 2580 9th St. E. • Glencoe, MN 55336 (877) 864-5575 Fuller’s Milker Center, LLC 423 U.S. 61 • Lancaster, WI 53813 900 US Hwy. 14 West • Richland Center, WI 53581 (800) 887-4634 Gorter’s Clay & Dairy Equipment 1400- 7th St. SE • Pipestone, MN 56164 (507) 825-3271 Redeker Dairy Equipment W12287 Liner Rd. • Brandon, WI 53919 (920) 346-5576 United Dairy Systems 210 N. Industrial Pkwy • West Union, IA 52175 (563) 422-5355 132 W 11th St. • Monticell, IA 52310 (319) 465-5931 Advanced Dairy LLC 9 State Rd. 29 • Spring Valley, WI 54767 (715) 772-3201 913 W. Main St. • Mondovi, WI 54755 (715) 926-5777 967 West Ave. N • West Salem, WI 54669 (608) 633-6690 2195 Hwy. 23 • Mora, MN 55051 (715) 772-3201 117 West Circle Dr. • St. Charles, MN 55972 (507) 932-4288 1449 Homecrest Ave SE • Wadena, MN 56482 (218) 632-5416 THE NEXT GENERATION IN ON-FARM WATER TREATMENT Chlorine Dioxide Technology Dirty Water? • Respiratory Issues • Scours • Crypto • Salmonella • E-coli GREATLY REDUCED: Pure 3000 CLEAN IT UP WITH Removes IRON, MANGANESE and SULFUR in water! HEALTHIER CALVES HEALTHIER COWS HIGHLY EFFECTIVE AGAINST: Prototheca • Staph Aureus Mycoplasma • Pseudomonas Chlorine-Dioxide Disinfectant / Sterilant • Calf hutches • Calf bottles • Calf nipples • Calf buckets Use EXSPOR

Fast and effective against ALL kinds of harmful substances including bacterial spores as well as bacteria, viruses and fungi! STOP BACTERIA WITH FOAM OR SPRAY ON • Parlor/milk room walls • Drains and more!

Dave

President/ Chief Lending

Tim Twardowski Senior Agricultural Lender (320) 632-9740 tim@pinecountrybank.com Chad Van Beck Senior Business Lender (320) 393-4200 chadv@pinecountrybank.com Mike Mastey Agriculture/Commercial Loan Officer (320) 333-9250 mikem@pinecountrybank.com LITTLE FALLS 1201 1st Ave. NE / 320-632-9740 RICE 750 Cty Rd 21 / 320-393-4200 ROYALTON 412 N. Hwy 10 / 320-584-5522

Empowering

for a sustainable tomorrow.

on:

Welcome

Cebulla Vice

Officer (320) 632-9740 dave@pinecountrybank.com

pinecountrybank.com

farmers

“We were milking the most we’ve ever milked right before the quota, so that helped us a lot,” Nosbisch said. “I haven’t had to buy any quota, and that’s also why we get paid more.”

Everything that is grown on 280 acres is used for feed. Additional corn and hay is purchased. Cows are fed a total mixed ration of corn and alfalfa. Feed is stored in silage bags, but Nosbisch plans to upgrade to bunker silos.

“Bags take up a larger footprint,” Nosbisch said. “We have all the equipment to use bunkers except the packing tractors. Bunkers take up less space.”

Nosbisch also plans to lean on technology for updates. First, he plans

to install activity collars on the cows within the next year to help with the challenges of breeding and move him toward his long-term goals.

“I’m going to do everything I can without building new to improve efciency and make things easier,” Nosbisch said. “For a smaller dairy like me, the goal is to make it protable with less labor.”

Nosbisch hopes that by becoming more efcient, he will be able to convert to a robotic milking system within the decade.

“If you don’t have goals, you’re just spinning your tires,” Nosbisch said. “You’ve got to take it day by day but also have some ambitious goals.”

Dairy Star • Saturday, April 13, 2024 • Page 5 320-836-2145 or 800-450-2145 www.famofeeds.com Check out our newly redesigned website to nd a Famo Feeds dealer near you! At Famo Feeds, we strive to provide the best support for your operation and work to accommodate your specific needs. From calf to cow and everything in between! TRUST THE EXPERTS • Milk Replacers • Starter Feeds • Protein Concentrates • Premixes • Minerals • Animal Health Products • Lick Tubs FEED THEM FAMO!

Con nued from NOSHBISCH | Page 2

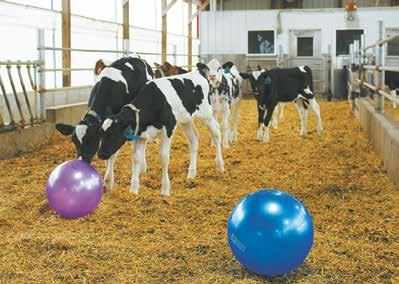

ABBY WIEDMEYER/DAIRY STAR

A calf drinks from an automa c feeder Feb. 21 at Robert Nosbisch’s farm near Holy Cross, Iowa. Calves are raised in a renovated hog barn.

Today, Rohner and Rohner Swart drive milk routes and ll in as relief haulers. Swart hauls milk for Meadow Star Dairy, owned and operated by Riverview LLP in Pennock.

With all three drivers hauling milk on various shifts, sometimes over 12 hours a day each, the family’s schedule can be hectic.

“I always run overnights, Taylor runs early mornings, and Tanner works for whoever calls — days and nights,” Swart said. “It’s a revolving door around here. It’s very odd if you see all three of us at home at one time.”

The trio hauls milk to plants in Litcheld and Paynesville. At times, they end up at the same plant at the same time.

“One time we were all at Litcheld, and the lab technician said, ‘You guys have hauled 12 loads of milk in here today; you lled a silo all by yourselves,’” Swart said. “A silo is just short of 600,000 pounds of milk.”

Milk haulers are not limited to their number of hours or miles per day. Swart said while it does not force haulers to limit their hours, it also leads to long days.

“The cows never stop milking, so we have to keep hauling,” Swart said.

The family is able to vacation together because haulers are willing to help each other.

“We’ve all made good connections

in the industry, so we know which drivers to call if we need someone to drive for us,” Rohner Swart said. “That’s a nice part of the milk industry. You get so close by spending so much time together at the plants that everyone is willing to help anybody.”

Swart has been hauling milk since January 1998. The milk hauler for his dad’s farm asked Swart to help with hauling.

“I was only going to haul milk for a few years and then take over the family farm, but they offered me (to purchase) my own truck, and here I am, still hauling milk,” Swart said.

At rst, he worked on routes across Stearns County and found he enjoyed the job.

“It was the farmers and the families (that made the job a pleasure),” Swart said. “Instead of having one family, I had 30 families. The people and the kids — I really enjoyed it.”

When Rohner graduated from high school, he chose to work for Swart’s parents, Roger and Mary, milking cows on his dairy farm. A few years later, Rohner Swart was facing graduation.

“I had no idea what I wanted to do after graduation, and Dad suggested getting my (commercial driver’s license) and having that as a backup plan if whatever I wanted to do didn’t work

Page 6 • Dairy Star • Saturday, April 13, 2024 www.LangeAgSystems.com Specializing in Livestock Equipment and Construction, New and Used Bagging Machines, Silage Bags, Bunker Covers and Grain Storage! NRCS PRE-APPROVED TANKS Web: jptank.com Phone: (920) 948-2286 Email: jptankconcrete@gmail.com

Con nued from SWART | Page 1

MARK KLAPHAKE/DAIRY STAR

Taylor Rohner Swart unloads her milk truck April 3 at AMPI in Paynesville, Minnesota. She has been hauling milk since she was 18 years old.

Turn to SWART | Page 7 LARGE SELECTION OF USED MOTORS ON HAND FROM 1-10 HP 105 County Rd. 10 • Albany, MN 320-845-4690 WWW.AMPSRS.COM New Winco 50 KW PTO unit ..................Call Winpower 25/15 PT2 w/trailer, powershaft, load cable ...........$1,600 GENERATORS We Sell and Service Generators! Each WINCO PTO generator is designed using the highest quality components and the best workmanship available. Baldor 5 HP .........................................................$450 Century 5 HP .......................................................$450 Leroy-Somer 3 HP ...............................................$350 (2) GE 7-1/2 HP ...................................................$550 DeLaval 7-1/2 HP ................................................$550 GE 1-1/2 Stirator motor .......................................$175 WE STOCK FRACTIONAL TO 10 HP SINGLE AND 3-PHASE MOTORS! • quick • dependable • nearly 40 years experience WE ALSO DO MOTOR REPAIR O New Winco 100 KW pto unit - Call Pulaski Warehouse, Inc. 5777 Quarry Drive • Pulaski, WI 54162 Phone 920-822-3536 • Fax 920-822-5030 www.pulaskiwarehouse.com Your Complete Seed Dealer In Wisconsin BEST QUALITY • BEST PRICES! Brunner Seed, Corn & Soybeans, PWI Seed Corn • Alfalfas • Clovers • Grasses • Trefoil • Hay & Pasture Mixes Inoculants Seed Corn • Open Pollinated Seed Corn • Roundup Ready Seed Corn

Untreated Seed Corn

Forage Peas and Pea Mixtures

Seed Oats

Barley

Spring & Winter Wheat Soybeans Round Up Ready Soybeans

Rye Grain

Certi ed OrganicSeed • Lawn Grasses

Huge Selection of Bulk Garden Seeds • Deer Plot Seeds

Ask for pricing on Conservation Mixes PULASKI WAREHOUSE, INC. 5777 Quarry Drive - Pulaski, WI 54162 2-1/2 Miles South of Pulaski on Hwy. 32 or 2 Miles North of Hwy. 29 on Hwy. 32, Then 1/2 Mile East of Hwy. 32 on Quarry Drive Phone: 920-822-3536 HOURS: Mon.-Fri. 8-5; Sat. 8-Noon Call for NRCS & CRP mixes!

•

•

•

•

•

•

•

•

•

out,” Rohner Swart said. “I fell in love with driving, and I’m still here.”

Rohner Swart began her career in October 2021 when she was 18.

“I love everything about hauling milk — how you get alone time driving to and from the plant, but you’re still getting interaction with people and meeting new people all the time,” Rohner Swart said. “You still get to be around the cows without having to milk them.”

Soon, her brother obtained his CDL.

“Being around (my dad and sister), I thought it would be a good idea, and I started hauling milk last August,” Rohner said. “I’ve always liked to drive. Whenever my friends and I went on trips or to cattle shows, I was always the one driving.”

Even though the siblings had experience with driving tractors and hauling and backing up trailers, hauling milk was complex since the trucks have anywhere from 13-18 gears.

“When you’re accelerating, you’re going through all (the gears) within half a mile,” Rohner said.

Having three haulers in the family allows them to rely on each other.

Since Swart works nights, his daughter and son use his truck during the day at times. Swart also has a spare truck.

Once, when Swart’s truck broke down, they all needed the spare truck, so they shared it. The truck was on the road for 24 hours a day, three days straight. Swart, Rohner and Rohner Swart met each other on the road between their shifts to switch drivers.

Swart’s current truck is the fth truck he has owned during his nearly 26-year career. His trucks travel 300,000-400,000 miles before being replaced.

“I put on 10,000 miles a month,” Swart said.

The spare truck has 900,000 miles on it and has earned numerous nicknames through the years, the latest being “White Trash.”

“The nicknames change depending on how frustrated we are,” Swart said. “When it is really giving me trouble, my wife calls it ‘Satan’s Mistress.’ It is very well known among everyone at the plant.”

Swart, Rohner and Rohner Swart also rely on each other for staying alert on the road.

“If somebody gets tired, we can call and say, ‘Just talk to me for the next 20 minutes until I get to the plant,’” Swart said. “Once you get to the plant, you’ll start moving and wake up again. Then, you’re good to go.”

When one member of the trio meets another on the road, they wave to each other or ash their headlights in greeting. They also alert each other when weather is a concern. All

three said bad weather is about the only time their job is less than enjoyable.

“I’ve been in the ditch a couple of times, I’ve been sliding sideways down a driveway, I’ve had the whole truck sideways on the road, and I’ve had people spin out in front of me,” Swart said.

In his long career, Swart has witnessed changes.

“When I started, I had 14 stops a day and was hauling 42,000 pounds at my low and about 60,000 pounds at my high,” Swart said. “At my high, I had 35 farms, and now I have one. I haul four loads a day out of Meadow Star at about 220,000 pounds of milk a day. That’s how much the industry has changed.”

He has found that he pre-

CHECK OUT THIS EQUIPMENT

fers working nights, with a shift that usually runs from 7 p.m. to 7 a.m. or longer.

“You’d think running nights would be boring, but it’s relaxing, and there is not as much trafc,” Swart said. “Lately, the sunrises and the sunsets have been really pretty, and when driving overnight, I see a lot of shooting stars.”

Dairy Star • Saturday, April 13, 2024 • Page 7 715.223.2374 107827 County Rd N Colby, WI 54421 www.cherokeegarage.com NEW New Holland Workmaster 75 4WD, Rops, Loader $3,250 in Rebates Available 0 % Financing Available Used 2022 New Holland Powerstar 75 Cab, Heat, A/C, Loader, 4WD, 850 Hours Sale Price $47,500 Used – 2003 New Holland TG285 Cab, Heat, A/C, Powershift, 4WD Local Trade, Clean Unit $78,000 Used –1994 Agco 9655 Cab, Heat, A/C, 4WD, 18 Speed Powershift, 3 Remotes, 6230 Hours Sale Price $36,500 Used - 2020 Kubota MX6000 Cab, Heat, A/C, Loader, Hrs 66, Excellent condition $ 42,500 Used - 2008 New Holland TN70A 4WD, Rops, 810TL Loader, Powershuttle, Ready to Work! Sale Price $27,000 Used 1979 Ford TW10 2WD, Cab, Heat, A/C $17,500 Used 2014 New Holland FR850 380FPA Hayhead, 750BFI 10 Row Cornhead 3565 Engine Hrs, 2702 Cutterhead Hrs Completely field ready. Sale Price $183,000 Used 2011 Kuhn 900 Merge Maxx 2 In Stock $39,800 each Used New Holland DB313R 13’ Cutting Width, Rubber Rolls, Starting at $25,000 Used Kuhn FC883 & FC313 2 Pairs Available Choice $25,000 Used New Holland DB316R 16’ Cutting Width, Rubber Rolls, Excellent Condition $27,500

HAND! ON

ON

Con nued from SWART | Page 6

MARK KLAPHAKE/DAIRY STAR

Tanner Rohner washes his truck and trailer a er unloading milk April 3 at AMPI in Paynesville, Minnesota. Rohner started hauling milk last year.

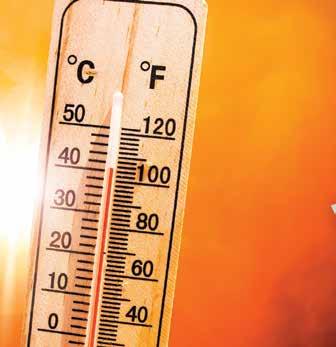

have mastitis, the milk took on a colostrum-like consistency. When milk conductivity caused the affected cows to be pulled out for examination, fevers ranging from 103-106 degrees were noted.

Farms saw nearly 10% of their herds being affected, Poulsen said, causing a signicant drop in overall production, with the production of affected cows dropping up to 30%.

The rate of incidence was fast, Poulsen said, with most cows exhibiting symptoms within four to six days of the initial cow. New cases in the herds typically tailed off by days 1012.

As common ailments were ruled out, farmers and their teams of animal health specialists began searching to nd answers.

Concurrently, the Minnesota Board of Animal Health announced March 20 that a young goat had tested positive for HPAI, the rst instance of a U.S. domestic ruminant contracting the virus. That goat resided on a property where a backyard poultry ock had been depopulated due to HPAI in February. The goats and poultry shared access to the same water source.

Meanwhile, affected farms in the Southwest began reporting dead birds on their properties. Additional testing commenced March 22. The U.S. Department of Agriculture’s Animal and Plant Health Inspection Service issued a press release March 25 conrming that cows on dairies in Texas and Kansas had tested positive for HPAI.

Based on those tests, wild mi-

gratory birds were believed to be the source of the HPAI infection in dairy cattle.

“Cows aren’t dying,” Poulsen said. “We are not seeing the same thing we see in domesticated poultry. They are getting sick, decreasing in their milk production. Like any disease, though, as the affected cows have returned to milk, their lactation curves are typically muted.”

Poulsen said it is important to remember that so far, the incidence of disease is limited in the population of dairy cattle being affected.

“We don’t see it in transition cows or fresh heifers, replacement youngstock or steers,” Poulsen said. “We haven’t noted it in any of our beef or cow-calf populations in any state. So, what is different about those cows?

Why are we seeing clinical signs in those cows that go off feed and drop in milk? That is yet to be determined. It is odd, because typically when you talk about disease incidence and prevention, we focus on transition cows and youngstock.”

The Centers for Disease Control and USDA continue to assure people the health risk to the general public remains low. However, the CDC conrmed April 1 that a dairy farm worker in Texas exhibited symptoms of conjunctivitis, testing positive for HPAI after having contact with infected cows.

Poulsen reiterated that the risk to public health is low.

“All dairy producers need to know this: All pasteurized milk and cooked meat are safe for consump-

tion,” Poulsen said. “There is no reason for the consuming public not to trust the safety and wholesomeness of their food supply.”

Poulsen said that the biology of this strain of inuenza is not new.

“This is the circulating strain of inuenza we watched in Europe in early 2020,” he said. “In 2022, it made its way through the migratory bird population through North America, down into South America and back. We’re still seeing this in our wildlife population. So far, it’s been the worst foreign animal disease in U.S. history, because we have depopulated close to 100 million birds.”

This is not the rst time mammals have been affected by HPAI. Over 130 different mammalian species have been affected.

Page 8 • Dairy Star • Saturday, April 13, 2024 Lake Lillian, MN 1-800-THE-SILO CONTACT YOUR LOCAL DEALER TODAY! IOWA Post Equipment 712-476-4500 WISCONSIN Dorner Equipment Green Bay • 920-655-3215 St. Joseph Equipment Lacrosse • 608-769-7796 Swiderski Equipment Wausau • 715-551-7893 Ritchie Equipment Cobb • 608-623-2331 easyrakefacer.com SILAGE FACER www.easyrakefacer.com SILAGE FACER www.easyrakefacer.com PATENT #7,588,203, #8,011,608, #8,336,795 NO MOVING PARTS MAINTAIN CUT LENGTH STAY IN THE HEATED CAB CALL FOR YOUR ALL DEMO TODAY TOP PRICES PAID & CONTRACTING AVAILABLE Your Market For: Holstein Steers • Fed Dairy Cows • Lean Dairy Cows Your local area buyer for MN, IA and WI. Long Prairie Buying Station Bruce Belter • 507-429-0359 Holstein Steers • Lean Cows • Bulls • Fed Cows Tyrel Lembke • 877-300-9298 Long Prairie, MN Lean Cows • Bulls Dean Derricks • 920-655-4730 Green Bay, WI Holstein Steers • Fed Cows • Lean Cows Chad McQuade • 605-668-4275 Yankton, SD Lean Cows • Bulls Mike Baczwaski • 800-445-0042 Gibbon, NE Fed Cows • Lean Cows • Bulls Cody Ritter • 320-293-5212 • 320-732-8358 Long Prairie, MN Green Bay Dressed Beef

Con nued from HPIA | Page 1

|

9

Turn to HPIA

Page

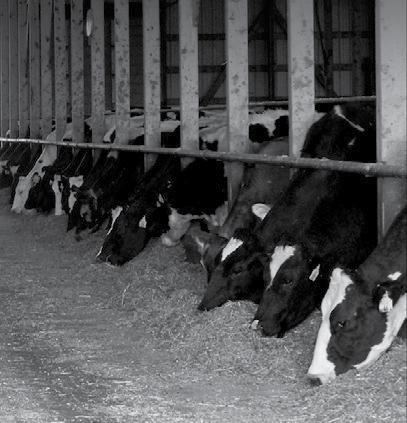

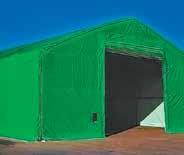

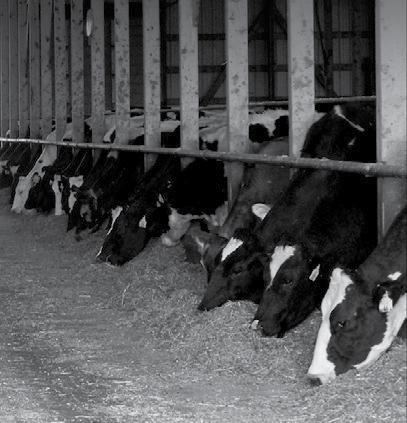

DANIELLE NAUMAN/DAIRY STAR

Holstein cows eat a total mixed ra on on a Wisconsin dairy farm. While no cases of the highly pathogenic avian inuenza have been detected in Wisconsin, as of April 9, there are 17 conrmed cases in six U.S. states.

“Most of our affected mammalian species are what we consider mesocarnivores, or scavenging carnivores,” Poulsen said. “They are eating dead birds, animals like cats and some hunting dogs in Nebraska. Right now, we’re talking about affected sea mammal populations that are scavenging dead birds in Washington. It’s a little different than our ruminant species; this is a new manifestation of the virus.”

Poulsen said the question to be answered is how the cows became affected and how the virus is transmitted.

“Cows don’t scavenge dead birds; they are herbivores,” Poulsen said. “It made us wonder if birds were the primary source. The topography in the panhandle of Texas is quite different than Wisconsin. It’s a desert, and the water sources are often shared by migratory birds.”

Following the movement of lactating dairy cattle from Texas and Kansas to herds in Michigan and Idaho, cow-to-cow transmission was noted.

“We’re still working (on) how that happened,” Poulsen said. “We know testing milk samples is a good way to identify it. We’re looking at if it could have been manure or urine, but the jury is still out. In people, we tend to spread u by aerosolization or coughing, but we know most animals don’t have respiratory disease.”

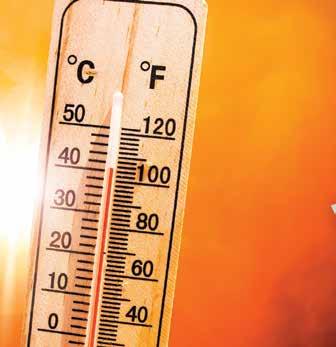

Poulsen said that in Wisconsin, migratory bird populations are monitored. The virus has been detected both last fall and this spring. He said that the virus is referred to as an enveloped ribonucleic acid virus, meaning it thrives in cold, wet weather.

The warm, dry weather in February and early March caused most of the migratory birds to move through the area quickly, although the migration is not yet over.

“Last fall was different,” Poulsen said. “It was warm, and due to the drought, the harvest was late. So, we saw migratory birds staying and comingling, because there was a lot of food available for them. We saw domestic poultry affected last fall, and we just nished the cleaning and sanitation earlier this year.”

As of April 2, Poulsen conrmed that no known cases of HPAI are present in Wisconsin. He urged farmers to be vigilant and bring concerns to their herd veterinarians immediately.

“If you see animals that present the symptoms of decreased feed intake and rumination, production drops, change in the appearance of milk or fevers, contact your veterinarian,” Poulsen said. “Those animals can be reviewed to see if they meet the criteria for testing.”

Poulsen said if a farm has animals that meet the case denition, the USDA will pay for testing up to 20 animals. That testing can be done by any accredited veterinarian.

“While HPAI is reportable, in Wisconsin and many other states, it is not actionable,” Poulsen said. “We shouldn’t be concerned about any quarantine, control zones or depopulation on these farms at this time. There is no indication for that at this time.”

Implementing biosecurity plays a vital role in protecting a dairy farm, Poulsen said.

“Many dairy producers ship calves to warm, dry climates because it is more efcient and cost-effective for health and productivity reasons,” Poulsen said. “We move cattle all over the country to be more efcient. That does institute risk, but we have a signicant infrastructure to diagnose and manage that risk. It’s not perfect, but it is pretty good.”

Poulsen recommends dairy farmers use the American Association of Bovine Practitioner’s guidelines for implementing biosecurity measures. That includes simple measures such as boot washes and increased sanitation. Others, such as quarantining new animals on the farm for 14-21 days, can be challenging.

“That is really hard to do on dairies, having facilities dedicated only to quarantining animals,” Poulsen said. “Dairy farmers should ask their veterinarians to go through those biosecurity protocols with them to see what they can do to safeguard and mitigate risk for any disease. Some things are going to be long-term plans. We need to think of the return on investment and the cost for biosecurity essentially as an insurance plan.”

The GEA RoboRebel refuses to conform to the past and is pushing a new path forward.

The RoboRebel rotating belt can handle a variety of feed piles. The smart sensor determines the load on the belt and adjusts the path of the robot automatically. When a large pile is detected, it turns into the pile and forces the feed towards the animal.

Working around the barn 24/7, you can be sure it is doing its job of providing your cows with optimal access to feed any time of the day and night.

Improved work efficiency

Better access to the feed

Efficient feed push-up can contribute to the reduction of refusals.

Improved animal health

Frequent feed pushing is beneficial on hoof health. Keeping feed within reach lowers the pressure on their front hooves and necks.

Improved milk production

Better bottom line

By keeping feed pushed towards the feed fence animals have access to feed and can increase dry matter intake.

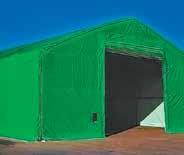

Dairy Star • Saturday, April 13, 2024 • Page 9 NELSON’S AGRI STRUCTURES Dean Nelson • Central and Northern Minnesota • Grove City, MN • 320-857-2633, Cell 320-699-3297 RIVERSIDE HOOP BARNS, INC. US Hwy. 75 At IA/MN Stateline • Steen, MN • 507-392-2870 • Fred A. Tilstra & Sons THE NO COMPROMISE FABRIC STRUCTURE DAIRY, MACHINERY & HAY STORAGE Commercial Agri Buildings Single and Truss Arch available from 20’-120’ wide Flo-Coat® Galvanized Steel Tubing Supplied by Allied Tube & Conduit Heaviest gauge steel in the industry Pre-engineered truss buildings ASK US ABOUT GOVERNMENT FUNDING FOR HAY STORAGE WE ALSO SELL REPLACEMENT TARPS! LAKESIDE HOOP STRUCTURES, LLC Eastern Minnesota and Wisconsin • Harris, MN • 651-248-6302 • Craig Moline Call 320-352-6303 to place your classied OR mail to: Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378 OR e-mail to: nancy.p@dairystar.com

the

times you want, the same way every time and without having to worry about it getting done.

After feed distribution, the RoboRebel pushes the feed towards the feed fence,

number of

Con nued from HPIA | Page 8

PROTECT AGAINST SLIPS & FALLS

• Traction in all directions

• Reduce animal stress

• Aids in heat detection

• Cost effective & practical

Human case of HPAI reported

We offer grooving & scarifying

CALL TODAY!

www.bestfootingconcretegrooving.com

Tell the advertisers you saw their ad in the Dairy Star!

A dairy worker in Texas has tested positive for highly pathogenic avian inuenza. The Centers for Disease Control and Prevention said the case is relatively mild with the only symptom being a case of pink eye. The patient was treated with u medication and told to isolate. This is only the second person to be diagnosed with this subset of avian inuenza, with the rst case being in Colorado two years ago. This would be the rst time HPAI jumped from birds to cattle to people. According to an agency news release, “This infection does not change the H5N1 bird u human health risk assessment for the U.S. general public, which the CDC considers to be low.”

No impact to human health or the milk supply

national milk price,” Schmidt said. “Because the vast majority of our milk goes to cheese and cheese is the low market price right now, our average milk price in the Midwest is not close to the national average milk price. Our dairy farmers are telling us DMC isn’t providing the support that they had typically come to expect.” DMC payments kick in when margins are at $9.50 per hundredweight or less. Due to increased costs, Schmidt said that the margin should increase to $10 cwt. AMPI would like to see changes to the DMC program when the farm bill is completed. Schmidt remains hopeful that a farm bill will pass this year, but her optimism is cooling with it being an election year.

By Don Wick Columnist Ag Insider

Attorney general gains protections for dairy farm employees during litigation

After the U.S. Department of Agriculture conrmed the presence of HPAI in a small number of dairy herds, the National Milk Producers Federation executive vice president of communications and industry relations Alan Bjerga was quick to assure the dairy industry. “We’re not seeing disruptions in milk supply or an animal health crisis, but we’re keeping an eye on it because it’s something new,” Bjerga said.

No long-term impact on dairy cattle

The HPAI cases in Texas and Kansas dairy herds will not have a signicant impact on milk prices. “If you look at the numbers, we look at this maybe impacting milk production by 1%-1.5% over some period of time,” said Mike North, principle, Ever.Ag. “There’s not going to be this big lightning bolt; it’s not going to be like the stories we heard about large chicken ocks with avian u euthanized.” North, who is also a past president of the Dairy Business Association, said dairy cows may exhibit u-like symptoms for two or three weeks. Once it’s done, production returns to normal. “Milk quality returns to normal and safety is never a problem through that entire period,” North said.

MN House ag committee update on HPAI

The Minnesota House agriculture committee heard an update on HPAI after the virus has infected dairy cattle, goats and one human. Minnesota Board of Animal Health executive director Dr. Brian Hoefs said their agency is working with other agencies and organizations to form protocols for mitigating risk to livestock and caretakers. Hoefs said those handling raw milk should wear personal protective equipment. “I grew up on a dairy farm,” Hoefs said. “We dipped a pitcher in the milk for breakfast every morning. Not a good idea in light of this information.” Pasteurized milk is safe to handle and consume.

Additional scrutiny for large dairy farms

A bill that triggers a full environmental impact statement for farms with more than 10,000 animal units was reviewed in the Minnesota House environment and natural resources committee. Minnesota Farmers Union president Gary Wertish testied in favor of this bill. “Our members do have questions about what a natural disaster, emerging animal disease, a human disease that affects workers or other disruptions would mean for such a large operation,” Wertish said. “I think more about the social and economic effects that are more fully addressed with an EIS.” Daryn McBeth represented the Minnesota Milk Producers Association, speaking against this bill. McBeth described the current environmental regulations as robust and a mandatory EIS would just add cost and time to any project. “To say to a dairy enterprise from another state or western Minnesota that has seen its share of dairy expansion in the last 20 years that you’re not welcome in Minnesota would be sending the wrong message at a time when our farmer-owned dairy processing plants are already struggling,” McBeth said. The bill was held over for possible inclusion in an omnibus later in the session.

Adjustments sought in DMC calculation

USDA’s Dairy Margin Coverage triggers a payment for participating farmers when the difference between the all-milk price and the average feed price falls below a certain level. DMC was triggered in 11 of the 12 months in 2023. Associated Milk Producers Inc. vice president of marketing Sarah Schmidt said the risk management program was working as intended. “That said, the calculation for that program uses a

The Minnesota Attorney General’s Ofce has reached a temporary injunction with Evergreen Acres Dairy in Paynesville. With this announcement, employees at ve facilities in Stearns County and one in Redwood County will be paid while legal action continues. The Minnesota Attorney General’s Ofce sued the dairy farm in January for failing to pay workers and charging rent for poor quality housing.

Bongards releases earnings

Bongards reported 2023 earnings of $29.5 million on sales of $822 million. Patronage earnings of $19.7 million resulted in a 20% cash payment to members of 26 cents per hundredweight. In addition, Bongards will revolve the remaining half of the 2013 equity in the amount of $4 million. Checks will be made before Aug. 1.

Milk output increases

Milk production in the 24 major dairy states totaled 17.4 billion pounds in February. That’s up 2.4% from one year ago. In Minnesota, milk cow numbers dropped 7,000 head in the past year, but milk production rose 1.5%. South Dakota had the biggest increase in milk production, up 14.8%. That was helped by the addition of 19,000 cows to the state’s dairy herd.

Climate-Smart program pays eco-friendly farmers

The USDA is rewarding farmers for adopting climate-smart agricultural practices. At the Central Plains Dairy Expo in Sioux Falls, South Dakota, Minnesota Milk Producers Association CEO Lucas Sjostrom said Midwest dairy farms are eligible for these funds. “We have $50 million available for farmers in the Upper Midwest,” he said. Details for eligibility are being negotiated.

Alfalfa variety selection should not be ignored

Insects and diseases continue to evolve. According to Land O’Lakes Inc. alfalfa and forage specialist

Jeff Jackson, seed treatments and new chemistries can help, but variety selection also has a role. “If you’re not paying attention to variety selection and nding the varieties that will work best in your soil type, it can be a pitfall to getting a stand established,” Jackson said.

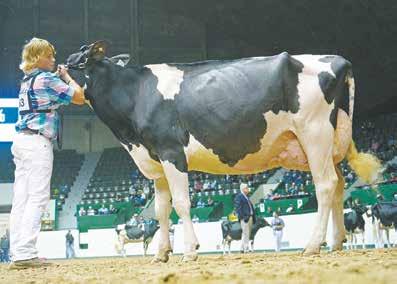

WDE recognition announced

World Dairy Expo has announced its 2024 award winners. Jim Barmore, Marty Faldet and King Hickman of GPS Dairy Consulting LLC in Lakewood, Minnesota, are being recognized as the Industry People of the Year. Former Semex CEO Paul Larmer, of Guelph, Ontario, is being honored as the International Person of the Year. Larson Acres Inc., which milk 2,800 cows at Evansville, Wisconsin, is home to the Dairy Producers of the Year. The award ceremony will be Oct. 2.

Trivia challenge

The average retail price for a gallon of whole milk was $4.01 in 2023. That answers our last trivia question. For this week’s trivia, what are the ofcial colors of FFA? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Page 10 • Dairy Star • Saturday, April 13, 2024 REISERIMPLEMENT Waukon,IA 563-568-4526 AfterHours: Ken563-380-3137•Dave563-380-8680 www.reiserimpl.com CHECKOUTTHE 7700SERIES Used Equipment PLANTING/TILLAGE MISCELLANEOUS TRACTORS ‘20 Kinze 3660, 16R30, bulk fill ‘12 CIH 1250, 16R30, bulk fill ‘97 Kinze 2600, 31R15” DMI 530B Disc Ripper CIH MRX690, 5 shank disc ripper disc JD 980 Field Cult., 44’ w/harrow CIH 4800 30’ Field Cult, w/3 bar coil tine harrow BUILT TO KEEP GOING. BECAUSE A FARM NEVER SLEEPS. Kory 185 Gravity Box, 250 bu w/gear Brent 640 Gravity Box Loftness 20’ Stalk Shredder, NICE!! ‘08 AGCO 3000 corn head, 8R30, poly JD 146 loader w/bucket Skid Loaders HAY & FORAGE ‘14 MF 9770 SP, w/9196 double conditioning rolls, 1,200 hrs Hesston 565A Round Baler ‘20 MF 3983 Hicap Rake, 12 wheel ‘19 Kuhn GA7501 Rotary Rake ‘22 MF 1393, 13’ Disc/Mow Cond. ‘16 Pottinger NovaCat Triple Mower w/rolls ‘17 JD 835 9’ MoCo, center pivot JD 946, hyd. swing, rubber rolls ‘14 CIH DC112 Disc Mow/Cond. Gehl 2450, 15’ hydro swing JD MX7 3PT Brush Mower Patz Bale Chopper ‘21 Rhino 3150-15’ Batwing Mower ‘00 MF 6270, MFWD, loader ‘21 MF 2850, CAH, hydro, loader, ONLY 139 HOURS! IH 966, 9,000 hrs. MF GC2400, 60” deck, 500 hrs. MF GC2400, 60” deck, 600 hrs. ‘21 MF GC1723, ldr., mower, 180 hrs. ‘18 MF 1705, 60” deck, 200 hrs. MF 285 w/MF loader ‘22 JD 3039R, CAH w/JD loader, 148 hrs. Farmall H ‘11 MF 8947 Telehandler, 3,000 hrs. ‘18 Bobcat 3400 SideXSide, C/H, 6,700 hrs. ‘16 Bobcat E50, long arm, thumb, 1,510 hrs. ‘18 Bobcat E50 long arm, 700 hrs. ‘20 Bobcat V923 Telehandler, 1,100 hrs. ‘15 Bobcat T870, SJC, highflow, 1,700 hrs. ‘22 Bobcat T770, 200 hrs. ‘20 Bobcat T770, 240 hrs. ‘21 Bobcat T770, highflow, 958 hrs. ‘19 Bobcat T770, SJC, 500 hrs. ‘20 Bobcat T770, CAH, highflow, SJC, 765 hrs. ‘20 Bobcat T770, SJC, 300 hrs. ‘18 Bobcat T770, SJC, 2,400 hrs. ‘14 Bobcat S770, 3,200 hrs. ‘18 Bobcat T770, A91, highflow, SJC, 2,000 hrs. ‘07 Bobcat T300, CAH, 1,900 hrs. ‘12 Bobcat S650, 9,000 hrs. ‘16 Bobcat S590, 3,900 hrs. ‘20 Bobcat S570, 2900 hrs. ‘19 Bobcat S570, CAH, SJC, 2,100 hrs. ‘14 Bobcat S570, ACS, CAH, 4,800 hrs. ‘13 Bobcat S570, CAH, 3,400 hrs. ‘15 Bobcat T550, ACS, Open Station, 1,855 hrs. ‘02 Bobcat S300 ‘20 Gehl R220, 1,000 hrs. ‘15 Gehl R190, 1,900 hrs. ‘04 Deere 250 Series II, 5,000 hrs. ‘13 Mustang RT2100 track ldr. 3,000 hrs ‘23 NH L318, C&H, 1,400 hrs. ‘21 Bobcat S76, SJC, 1,500 hrs. ‘20 Bobcat S76, 233 hrs. ‘22 Bobcat S64, 4,100 hrs. ‘21 Bobcat T76, SJC, 600 hrs. ‘21 Bobcat S76, CAH, SJC, 1,800 hrs. Bobcat T76 ‘23 Bobcat T64, CAH, 13 Hours! ‘21 Bobcat T64, 577 hrs. ‘22 Bobcat S64, SJC, 4,100 hrs. ‘21 Bobcat 564, foot, 2,900 hrs. ‘21 Bobcat S64, SJC, 2,700 hrs. ‘19 Bobcat E26 Mini Ex, OS, 700 hrs.

BEST FOOTING CONCRETE GROOVING Strum, WI 715-579-0531

Hey!

Sign-up for Dairy Margin Coverage ends April 29

Polzin encourages producers to protect against market surprises

By Stacey Smart stacey.s@dairystar.com

MADISON, Wis. — Enrollment in the Dairy Margin Coverage program typically takes place in the fall.

Without the passing of a farm bill last year, DMC received an extension and enrollment was pushed back to the new year.

April 29 is the last day that farmers can sign up for the DMC program at a Farm Service Agency ofce.

“When you enroll for 2024, it will retroactively go back to January,” said Leonard Polzin, dairy markets and policy outreach specialist at the University of Wisconsin-Madison Extension. “We did trigger a payment in January and February, and you would receive that.”

During a webinar March 22, Polzin shared details of the program and reasons producers should consider signing up.

“This is a continuation of the previous program that was in place last year, and except for some small tweaks, the program remains the same,” he said. “Coverage levels and premiums have not changed and will continue for another 12-month period. Once a different farm bill goes through, we would

look at changes at that time.”

Polzin said the ease and simplicity of the DMC program makes it compelling to consider.

“It’s not something you have to actively monitor like futures and options,” he said. “The FSA ofce takes care of knowing when payments are triggered and sending off the payments, etc.”

Following the same mechanics as last year, the program is based on the national average milk price, also known as the all-milk price, minus the value of the feed ration, which is the estimated price to produce 100 pounds of milk.

“There is no ration that perfectly ts everybody’s farm,” Polzin said. “The program tries to take the feed equivalent of fat, protein, carbohydrates and energy, and calculate them to nd that ration for 100 pounds of milk.”

When enrolling in the program, Polzin said there are two things to consider: percentage of coverage and coverage level. Farms can insure 5%-95% of their historic production level. Polzin said most people choose the maximum amount. The coverage level ranges from $4-$9.50 per hundredweight of margin coverage, with most people selecting coverage on the higher end.

The rst 5 million pounds of annual production is covered in Tier 1 of the program, and everything greater

Turn to DMC | Page 12

“Troubleshoot issues and analyze all aspects of the dairy.”

What do you like about the Dart program?

ability to customize reports to help analyze the trends on the farm.

Why did you decide to use Dart and how long have you been using it on your dairy? I’ve been using Dart for 13 years. It’s a very user friendly program that we could not only input and manage our cow information but also build reports, graphs, and lists to help troubleshoot issues and analyze all aspects of the dairy.

Which Dart features do you use the most? I use Dart for all my animal records, ID, treatments, matings and genetic data, but I probably use the pocket dairy on my phone the most. I can take all the info with my anywhere I go.

What are some other DHIA tests you use? We also use DHIA for Leukosis and Johnes testing.

Tell us about your farm. My wife Robyn and I milk 180 cows with my sister Jocelyn and dad Jim. We raise our own heifers, have a commercial ock of sheep and farm around 350 acres primarily for feeding the livestock.

6,700 hrs. .....................$65,000

CIH 8920, 2WD, 7,900 hrs. .....................$59,000

CIH 8920, 2WD, 4,100 hrs ......................$72,000

CIH 8920, FWA, 2,600 hrs ....................$110,000

CIH MX240, 4,700 hrs .............................$85,000

CIH MX220, FWA, 3,600 hrs. ..................$88,000

CIH MX120, 2WD, 3,800 hrs. ..................$72,000

CIH MX120 w/loader ...............................$75,000

CI 7220 w/6500 hrs., 2W ......................Coming In

CIH C90, 4,000 hrs. ..............................Coming In IH 5088, 7,100 hrs. ..................................$26,000

IH 1466 restored, new 20.4x38

Firestones ..............................................$38,000

IH 1486, 6000 hrs. ................................Coming In IH 1456, cab ............................................$22,000

IH 1086, 9,700 hrs. w/ldr. ........................$23,000

IH 1066, no cab .......................................$13,500

IH 1086, 5,000 hrs. ..................................$24,000

IH 686 ......................................................$14,000

TILLAGE

CIH Tigermate II, 26’ ...............................$28,000

CIH Tigermate II 26’ w/rolling basket.......$32,000

CIH Tigermate 200 w/basket, 34’ ............$42,500

CIH

CIH

CIH

CIH

Dairy Star • Saturday, April 13, 2024 • Page 11

Sauk Centre, MN Buffalo,

763.682.1091 www.mndhia.org DHIA: Now MORE than ever

MN

Peter Beck Flying Cow Dairy Princeton, MN • 180 cows

like the

I

Quality Consistency KLC Farms Roasting, Inc. 320-352-3326 Visit www.roastedbeans.com Preferred By Bovines Everywhere Get your cows attention • Energy • Protein • Amino acids • Bypass protein Protein Feed them KLC Roasted Soybeans! GREENWALD FARM CENTER FARM Greenwald, MN • 320-987-3177 WWW.GREENWALDFARMCENTER.COM Twine, Wrap & Net Wrap IN STOCK! GREAT SELECTION OF USED GRAVITY BOXES ON HAND! CIH 527B .................................................$17,500 CIH 530C Ripper, nice.............................$38,000 JD 2700 5-shank ripper ...........................$17,000 DMI Tigermare 26’ field cultivator ............$16,000 DMI 900 ripper ................................................Call DMI 530B lead shank ..............................$16,500 Glencoe 7400 8-shank disc chisel .............$9,000 HAYING & FORAGE EQUIP. Sitrex QR12, QR10, QRS rakes ....................New Many sizes of rakes available All Sizes of Sitrex Rakes ........................On Hand GRAVITY BOXES & GRAIN CARTS Many Sizes of Gravity Boxes...................on Hand Demco 450 ..............................................$12,500 Demco 550 ..............................................$14,500 Brent 657 gravity box, green & black.......$23,000 Brent 644, green ......................................$17,500 Brent 644, tarp & fenders ........................$21,000 J&M 540 box, red ....................................$13,500 J&M Green 385 gravity boxes ...................$5,000 J&M 385, red .............................................$5,000 Killbros 387 ................................................$9,000 MISCELLANEOUS New Red Devil 8’ Snowblowers.............On Hand Brillion XL32 32’ packer ...........................$36,000 H&S 3137 370 bu. manure spdr ..............$23,000 USED TRACTORS CIH 9330, FWD, PTO, 3 pt., 2,800 hrs. .$125,000 CIH 8940, FWA, 1,800 hrs. ..................Coming In CIH 8920, 2WD, 3,500 hrs ......................$84,000 CIH 8920, 2WD,

Tigermate 200, 28’ w/rolling basket..$40,000

Tigermate 200 28’ w/basket .............$37,000

RMX 340 28’ w/mulcher ...................$44,000

Various Sizes of Rock Wagons On Hand Mandako Land Rollers All Sizes DO YOU HAVE AN UPCOMING AUCTION? Advertise It In The Call (320) 352-6303 for more information. DAIRY ST R★

3800 16’ disc ......................................$9,500

than that is covered in Tier 2. The margin coverage level for Tier 1 ranges from $4-$9.50 cwt, while Tier 2 ranges from $4-$8. Premiums are 0-15 cents cwt for Tier 1 and $0-$1.813 for Tier 2.

“The price is a fairly good deal for producers,” Polzin said. “When you compare the cost per hundredweight of DMC versus other products, it is quite cost competitive, especially in that rst 5 million pounds of production.”

Polzin encouraged dairy farmers to use the DMC decision tool at dmc.dairymarkets.org to determine premiums and payments.

“Make sure you select the appropriate year, 2024, in the top left corner when using this site,” Polzin said.

The most signicant change to the DMC program is the way that historic production is stated in sign-ups. Prior to this year, previous production history and supplemental production history were both listed. This year, the two have been combined and are being called DMC production history.

FSA has revised regulations to allow eligible operations to make a one-time adjustment to established production history. This adjustment combines previously established supplemental production history with DMC production history for farms participating in Supplemental DMC during a prior coverage year.

“It’s possible to include new supplemental history that you have not previously included by talking to someone at your FSA ofce,” Polzin said.

About 75%, or 17,000, of dairy operations in the U.S. enrolled in the DMC program in 2023 and received nearly $1.3 billion in payments, averaging $75,753 per operation.

“We’re probably going to hit that again this

year,” Polzin said. “We’re very close to 100% participation in Wisconsin for dairies with established production history if you take out farmers who don’t sign up based on religious reasons. There is big utilization of the program, and we’re seeing quite a bit of benet to producers when we come across years that are not so positive in margin.”

Polzin said Wisconsin, New York, Pennsylvania and California are major utilizers of Tier 1 coverage with substantial pounds enrolled in the program.

The all-milk price is hovering around the $20 mark, but feed costs have come down quite a bit, Polzin said. Corn has dropped off recently, and soybean meal is coming down as well, bringing relief to feed costs.

The current forecasted period is not showing any DMC payment triggers, and farmers have asked Polzin why they should sign up in 2024.

“We’ve seen corn prices fairly low in the past, but there is no guarantee they’re going to keep going down,” Polzin said. “They could very well come back up again too. If milk prices continue to have additional down pressure, then it’s not unrealistic to have payments triggered over the next 12 months.”

When looking at the forecast in recent enrollment periods, Polzin said it was not uncommon for a portion of the year to look like it would not generate many payments, but as time went along, a lot of payments were made. This happened in 2023.

“It’s really hard to be bullish on price when we have so much production capacity coming online in the U.S. at the moment,” Polzin said.

Between now and the rst part of 2026, over $7 billion in production is slated to come online in dairy processing capacity. Tight demand and less-

than-favorable exports give Polzin reason to believe the industry could see price pressure that will weigh negatively on milk prices.

“The price has been holding fairly steady recently, and while it’s better than 2023, it is not a resoundingly strong milk price,” Polzin said. “To say that we’re out of the bottom for the dairy price cycle with only good news going forward is a tough claim to make.”

Polzin said the market response has been on the supply side, as production remains strong despite shrinking cow numbers.

“Until we see a response on the demand side come back fairly strong, it is a big ask of the market to deliver high prices, especially at Class III to hold us at good margins for a period of time,” Polzin said. “There are enough unknowns at the moment to warrant signing up for DMC.”

CONVENTIONAL SEED CORN SALE

Great price on worlds top hybrids. Non GMO grain is earning market premiums (up to $2 over CBOT). We offer proven, complete weed control programs for less than technology cost!

Maximize returns and IMPROVE YOUR BOTTOM LINE!

ORDER EARLY AND SAVE MORE!

Page 12 • Dairy Star • Saturday, April 13, 2024 BOSS RT • 18 TO 40 FOOT MODELS • 8’ 1” INSIDE WIDTH FATBOY RT • 26, 30, 36 FOOT MODELS • 9’7” INSIDE WIDTH MEYER MANUFACTURING CORP. DORCHESTER, WI • 800-325-9103 MEYERMFG.COM BIG TIME! DORCHE MEYER IS YOUR ONE-STOP SHOP FOR FORAGE TRANSPORTATION. OUR XL VERSIONS HAUL BIG LOADS FOR BIG PRODUCTIVITY! O N. P N INDUSTRY-LEADING FEATURES! SIZES UP TO 2,500 CUBIC FEET! 9140RT 9130RT 1036RT MINNESOTA A & C Farm Service, Inc. (TMR Mixer Dealer) Paynesville, MN Fluegge’s Ag, Inc. Mora, MN Gorter’s Clay & Dairy Equip. Pipestone, MN Hammell Equipment Inc. Chat eld, MN Eitzen, MN Harmony, MN Rushford, MN Midwest Machinery Co. (Full Line) Caledonia, MN Princeton, MN Glencoe, MN Wanamingo, MN Glenwood, MN Howard Lake, MN Midwest Machinery Co. (Forage Boxes Only) Alexandria, MN Sauk Centre, MN Schlauderaff Implement Co. Litch eld, MN Werner Implement Co., Inc. Vermillion, MN Wingert Sales & Service Plainview, MN IOWA K&A Farm Equipment, Inc. Strawberry Point, IA Scherrman’s Implement Dyersville, IA Monticello, IA SOUTH DAKOTA Pfeifer Implement Co. Sioux Falls, SD Tractor Central Arcadia, WI Cameron, WI Chippewa Falls, WI Durand, WI Granton, WI Menomonie, WI Mondovi, WI Sheldon, WI West Salem, WI Westby, WI WISCONSIN Hupf’s Repair Center Beaver Dam, WI Johnson Tractor, Inc. Janesville, WI Luxemburg Moter Company Luxemburg, WI Midwest Machinery Co.(Full Line) Osceola, WI CALL OR SEE YOUR LOCAL DEALER FOR COMPLETE DETAILS!

Con nued from DMC | Page 11

A BETTER BOTTOM LINE!”

“FOR

DEALER INQUIRES WELCOMED

320-237-7667 KLEENACRES.com

Dairy farmers are under attack by the National Milk Producers Federation

Thomas L. Olson, Black River Falls, Wisconsin

The National Milk Producers Federation has a National Dairy FARM Environmental Stewardship program.

This program is designed to lower greenhouse gas emissions from dairy cattle. This program is the height of hypocrisy.

According to the Dairy Management Inc. website, the U.S. dairy herd produces 1.3% of the nation’s greenhouse gas emissions. (NMPF provides a link to this information on their website.) The transportation industry produces 28%, according to the U.S. Environmental Protection Agency.

According to a study conducted by Virginia Tech and the U.S. Department of Agriculture, if the U.S. dairy herd was somehow removed, it would only lower greenhouse gas emissions by 0.7%.

If you are confused, you are not alone.

The NMPF website contains many pages about their different programs, so it is easy to research their ideas.

As dairy farmers, we have survived the FARM program because we had to. Dairy product buyers demanded that we abide by these rules. I am afraid that this National Dairy FARM Environmental Stewardship program will add a very costly economic burden on already struggling dairy farmers.

I urge each and every one of you to get ahead of this mess and tell your raw milk handler that we, the dairy producer, do not want this mandated on our dairy farm. The raw milk handler needs to make clear to the nished product buyer that they will not mandate this program on dairy farms. The nished product buyer needs to go to the NMPF website so they can see for themselves the hypocrisy.

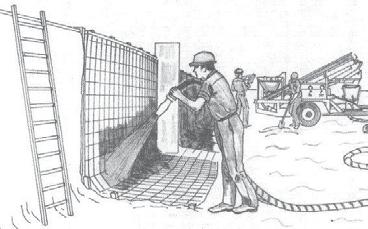

Dairy Star • Saturday, April 13, 2024 • Page 13 Learn more at edneyco.com | 888.443.3639 Designed with the demands of today’s Farmers & Contractors in mind to deliver the highest output and reliability. Balers, Hay Rakes, Mowers, and Much More! Hay Production Equipment R O T O T I L L E R COMMITMENT • QUALITY • DURABILITY • RESULTS Visit www.silverstarmetals.net for details and options on attachments Dealer Inquiries Welcome GET YOUR TILLING DONE WITH SILVER STAR SILVER STAR METALS LLC 715-229-4879 • Skid steer Quick Attach • Heavy Duty 7 gauge deck • Dual Drive Motors • 81” tillage width • Tillage Depth 4-6” • Enclosed Oil Bath THESE QUALITY ATTACHMENTS ALSO AVAILABLE: • Concrete Chuter • Brush Cutter • Roto-Tiller • Pallet Fork • Wood Splitter • Brush Grapple • Dirt Buckets • Driveway Grader • Bale Bedders • Mini Attachments • Trailer Mover • Sk • He • Du • 81” Till SILV WISCONSIN CONCRETE RESTORATION Jetcrete Pneumatically Applied Concrete

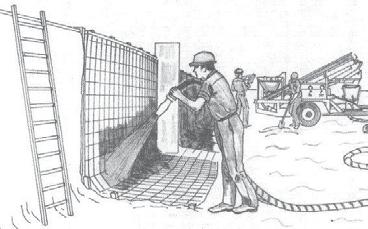

Silo Relining

Barn Walls and Basement Resurfacing

Bunker Silo Wall and Deteriorating Barn Walls Restoration

steel

to bunker walls

gauge

•

•

•

Approximately 1” of

reinforced material added

6

heavy duty wire mesh installed SERVING IA, MN, WI, IL AND SD CONTACT: 800-866-7327 • 563-586-2425 AND CELL 563-419-4279

LETTER TO THE EDITOR

FIELD ’S 608-437-5561 Your Material Handling Source Trusted sales and service since 1966 Mt. Horeb, WI FUTURO Enables liquid manure from a free stall barn to be transferred underground to a long-term storage Futuro with manual inlet and outlet guillotines and fitted with a 16” diameter suction pipe The suction pipe can be installed with the opening facing upwards or downwards, downwards is ideal when the manure is laden with sand. The Futuro is a low energy pump equipped with robust vales. It allows transfer of manure containing a small amount of bedding, such as sawdust, wood chips, chopped straw and sand. The Futuro can be fitted with a hopper to collect manure from a cross-gutter cleaner or skid-steer loader. It can also pump the contents of a reception pit by means of a suction pipe. Dairy manure Freestall barns Maximum consistency - 5” Straw & Hay Sawdust Sand Separated fiber * Mandatory to have air risers in the evacuation line

Page 14 • Dairy Star • Saturday, April 13, 2024 SAUK CENTRE, OFF I-94 ON THE CORNER OF HWY. 28 & 71 SOUTH We Have Equipment Coming out of our ears! 2017 Penta 9630HD #22133 - $72,500 New Nuhn 0738 Call 2010 Houle EL48-6D6100 #2384 - $59,900 Kuhn Knight 8150 #2284 - $59,500 New Fair Mfg 7830TD Call Jamesway 6X8 #2238 - $16,500 Jamesway 117400836 #2288 - $13,900 Artex SBX700 #2385 - $75,900 New Hagedorn HydraSpread Extravert 5290 - Call Hagedorn Hydra-Spread 410 #2407 - $20,900 Haybuster CMF830 #21112 - $49,900 Kuhn Knight SLC126 #2291 - $42,900 2011 Supreme Intl 500T #2268 - $42,500 2018 Penta 8030HD #22140 - $72,500 2020 Hagedorn Hydra-Spread Series II 2277 #2382 - $38,900 2021 Kuhn Knight VTC1120GII, #23130 - $195,000 Meyer 9530 #2351 - $95,900 Trioleit Solomix 2-2800ZKX-T - Call Highline CFR650 Top Gun #23119 - $30,500 NDE 552 LP #2281- $12,500 2018 Artex SB600 #23121 - $49,000 New & Used Ready to go! Ja M i n n e s o ta ’s LargestFeeding and ManureHandli n g D e a rel Ifyouhavea barn, we haveasolution. www.dairylandsupply.com

from our side our side OF THE FENCE THE

How have you continued to increase your role on the farm?

Grace Jeurissen Lester Prairie, Minnesota McLeod County 105 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy?

During my freshman year of college, I realized how much I missed being involved in the everyday activities on the farm.

I took advantage of the time I spent on the farm prior to that point, so I moved home and went to a two-year agriculture program to take more technical and hands-on farm-related classes. I want to pursue dairy farming because I enjoy the variety of tasks I get to do every day. I love working with cattle and nding ways to be efcient at my job while working toward ensuring success for the future of our family farm.

How have you continued to increase your role on the farm? While in college, I took courses in livestock reproduction, nutrition and did a foot trimming course. I continue to study updated bull proofs and breeding trends. I make most of the breeding selections on the farm. I work fairly independently on the farm, which gives me the choice to decide which task I should prioritize that day.

What is the most enjoyable chore to do on the farm? I enjoy looking through bull books and selecting which cows get bred to which bulls. I like to see what the calves turn out like. I like milking as well, but because of my more limber physical ability, I do most of the freestall work while my parents do most of the milking.

What excites you about the future of the dairy industry? I see potential in the technological advances we have at our ngertips. From cow health to employee and labor management, modern technology helps ease the challenges that come with running the family farm. Farming isn’t an easy occupation. Having ways to free up time gives us the chance to hone in on other areas that need attention.

What challenges do you have as you embark on your career? Farm transitions are a difcult part of every young farmer’s career. Challenges such as varying milk prices and increased cost of inputs, among other things, are a challenge that will always be prevalent. My grandpa dealt with it, my parents dealt with it, and someday, that will be something I manage. Another challenge is the physical demands that come with life on a farm. I’m not the biggest person, so there are tasks I struggle with physically.

Tell us about your farm and your plans for the dairy this year. We milk 105 cows, primarily Holsteins, in a double-12 parallel parlor. We ship to First District Association in Litcheld, Minnesota. We also farm 500 acres. We are 100% family run. I work with my parents every day, and on weekends, when he isn’t at school, my brother, Sam, helps with equipment maintenance and repair. We are putting in new stall mats in the freestall barn and repairing our heifer lot this year. We are looking into purchasing additional bred heifers to ll our barn. I also have rst-generation crossbred calves due toward the end of the year that I’m excited to experiment with.

Deaken Beavins Mahnomen, Minnesota Mahnomen

County

240 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy? Growing up, I’ve always had a heart for cattle, especially dairy cows. I’ve always been fascinated by the dairy industry and how important milk is in our everyday lives. I’ve had an outstanding work ethic since a young age. During the summer, as a kid, I had a part-time job helping a friend on his farm. I absolutely loved getting in the fresh air, driving tractor and stacking wagons of square bales. As a kid, I went to a lot of farm shows as well as dairy cow shows with my dad. I realized I had a passion for farming at young age.

How have you continued to increase your role on the farm? Over the past eight years that my dad and I have been milking cows, I’ve been taking on more responsibilities. I mix all of the rations every day, keep the bedded packs bedded and occasionally help in the parlor if needed. I also help with the eldwork along with both facility and equipment maintenance. I’ve also invested in a couple pieces of equipment.

What is the most enjoyable chore to do on the farm? I enjoy mixing feed the most, because I like knowing what the intakes are as well as knowing that the cows are getting the correct amount of each commodity and forages to best t their nutrition needs. I also enjoy mixing feed every day, because I know that every bucket of haylage and silage that goes into the mixer was put up with pride and is of high quality.

What excites you about the future of the dairy industry? A few things that excite me about the future of the dairy industry are dairy equipment, dairy genetics and the science behind crop growth, because it all keeps improving.

What challenges do you have as you embark on your career? A few challenges I have are the same challenges every dairyman faces. One of the challenges is hired help. It is hard to nd good and reliable help. Another challenge is the cost of equipment nowadays. The low and inconsistent cost of milk makes it difcult.

Tell us about your farm and your plans for the dairy this year. My dad, Jeff, and I are milking 240 cows in a double-6 parallel parlor. The majority of the herd are Holsteins. We do have a few crossbreds in the herd. Our milk is shipped to Bongards in Perham, Minnesota. Within the next year, we plan to update our milking facility and slightly remodel one of the freestall barns. A while back, we purchased enough Dairymaster monitoring collars to put on the whole herd. My goal is to continue to grow the herd and become more self-sufcient, so I’m not relying as much on hired help.

Riley Pundsack Freeport, Minnesota Stearns County

130 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy? I knew I wanted to farm at a young age. I liked being outside and working with equipment. There is just something about not having to work for someone else and watching the work you put in show for itself.

How have you continued to increase your role on the farm? I’ve increased my role in the farm by not hiring out as much of the eldwork and doing more of our own. We used to hire out plowing, planting and spraying, pretty much everything. Now, we do most of it on our own. I’ve taken a bigger role on xing day-to-day things like maintenance on the robotic milking systems and farm equipment. I’ve become more involved in calf and cow care. I treat the sick calves, and I also do all the breeding on the farm.

What is the most enjoyable chore to do on the farm? Doing eldwork is one of the most enjoyable things to do on the farm. I really enjoy planting because of the pace and the peacefulness. I like watching what you put in the ground come out and develop into a plant. It’s a nice way to get out and relax most of the time.

What excites you about the future of the dairy industry? Seeing what new technology they come out with to help manage and care for the cows more.

What challenges do you have as you embark on your career? Learning about new ways to manage the animals and utilizing all the new technology that they come out with for milking systems.

Tell us about your farm and your plans for the dairy this year. I farm with my parents, Keith and Roxanne, and we milk around 130 cows with two Lely robotic milking units. Our milk is shipped to First District Association in Litcheld, Minnesota. In the years to come, I would like to expand our heifer facility and hopefully one day put up a calf barn to help keep their environment more controlled for calf health. We may add one or two more robots in the years to come.

Dairy Star • Saturday, April 13, 2024 • Page 15 Turn to OUR SIDE | Page 16

www.norbco.com 67962 State Hwy 55, Watkins, MN 55389 • 320-764-5000 MA KING COW COMFORT OUR PRIORITY Curtain SystemsVentilation SystemsFreestall SystemsHeadlocks

Anna Butler

Browerville, Minnesota

Todd County

80 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy? I knew from a young age I wanted to farm. I was outside any chance I had. I was always helping my brothers with their chores, or they would get me up at 5 a.m. to help them at the neighbor’s farm. I was Dad’s helper. Anytime he would come into the house to ask if someone could come and help, I was the rst to jump up and volunteer. It got me out of the house and out of helping in the house. I considered a career in dairy because I love working with animals, being outside, doing eldwork and being able to continue the family dairy. I honestly don’t think I could ever have a job sitting at a desk somewhere.

How have you continued to increase your role on the farm? I pretty much do just about everything on the farm. There are still a few things I’m learning, but with farming, you are always learning something new every day. I do most of the selecting of bulls we use for A.I. I read up on the different breeds we use and consider which bulls to use on each cow. I look at components, body depth/dairy frame, and feet and legs. I do a lot of the tillage in the spring. I do some planting and cutting of hay, raking and wrapping. I haul manure and help with harvest in the fall. I also help with the maintenance and repair of tractors and machinery as well as the milking equipment. I am also getting into the bookkeeping and record keeping side of the farm.

Malorie Thorson Waverly, Minnesota

Wright County

250 cows

When did you know you wanted to be a farmer, and why are you considering a career in dairy? My love for the dairy industry has always been a prominent part of my personality. Ever since I was little, I have been helping my mom with chores around the farm and enjoying every minute. My love for the industry only grew when I got to share my passion with consumers at the county fair or dairy princess events. My parents saw this and inspired me to always pursue a career that I love and am passionate about. I want to pursue a career in the dairy industry, because I know the impact it makes on consumers and our nation, along with the pride I feel being a part of less than 1% of the population.

How have you continued to increase your role on the farm? I have continued to increase my role on the farm by helping with herd health management. I have mastered the collar monitoring system, implemented vaccinations and herd health practices, and implemented reproductive health protocols.

What is the most enjoyable chore to do on the farm? I love morning milking. I can think about the upcoming day ahead and plan out what needs to get done, so I can set goals for myself and be more productive. Morning milking is also a time where I can see the sunrise and remind myself of the beautiful life that God has blessed me with.

What is the most enjoyable chore to do on the farm? I enjoy doing all the chores, but my favorite is raising calves. I have been in charge of calves ever since I was little. It’s always fun to see what color of calf you will get from a cow with all the crossbreeding we do. It is rewarding to watch them grow and see how my hard work has paid off when they come into the barn as cows. I enjoy hearing all the compliments I get for how my calves look.

What excites you about the future of the dairy industry? Being able to keep the small family farm life going for the next generation. Being with a cooperative that supports small family farms and continues to grow.

What challenges do you have as you embark on your career? Mother Nature. She always bats last. Keeping up with all the new regulations that keep coming out every year. Having to work twice as hard to keep the family farm going, as it seems that all the small family dairy farms are selling out at a fast pace. Another challenge I face is nding help on the farm, as my parents are looking to slow down.