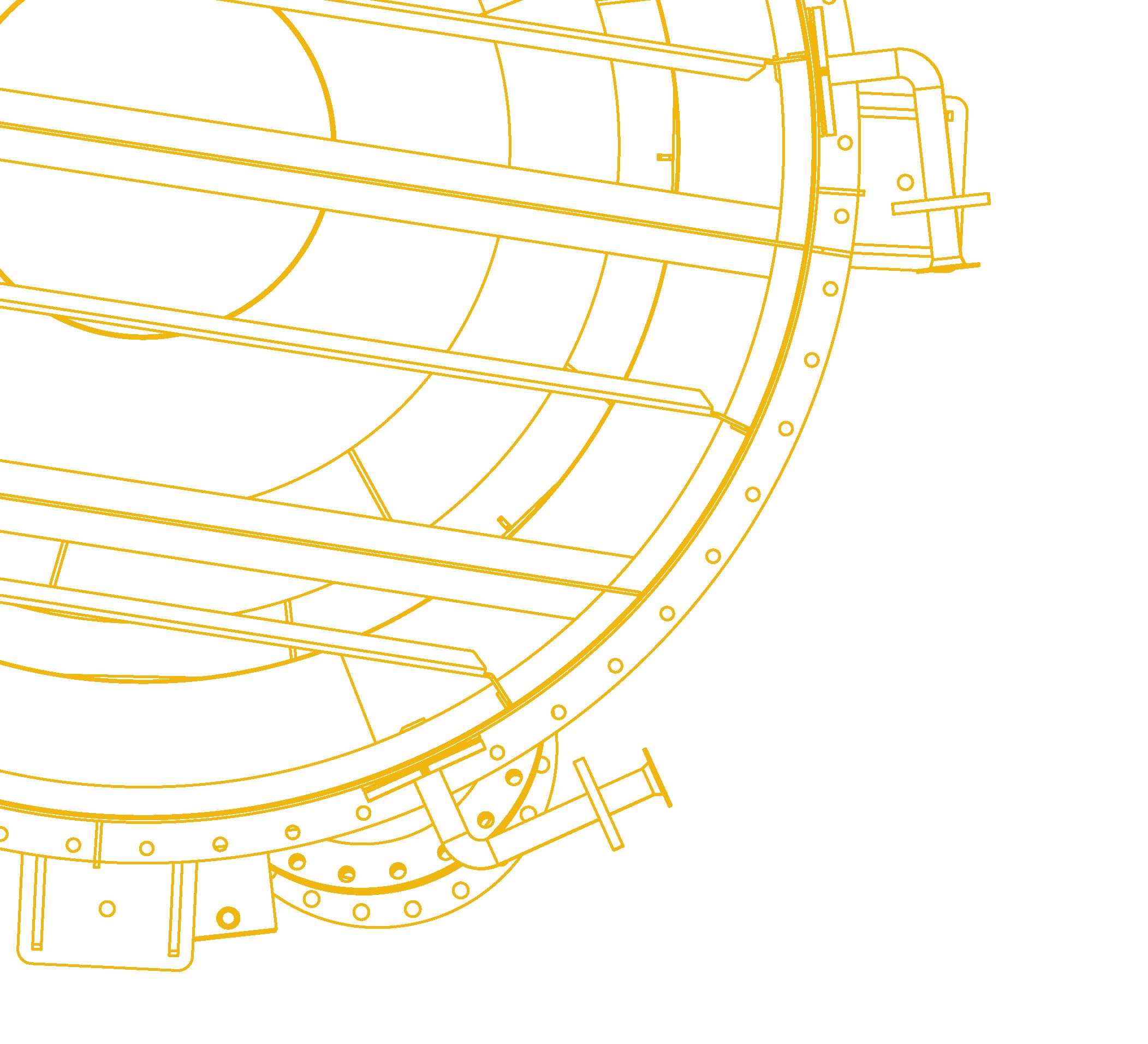

PureServ is PureteQ’s certified service organization that provides service and support to all brands of scrubbers and sensors. We encourage all shipowners to realise the full potential of scrubber systems by entering into a PureteQ Service Agreement to safeguard continuous operation, reliability and MARPOL compliance.

PureteQ A/S designs built-to-fit maritime scrubber systems to shipowners who want to save money on fuel by continuing use of heavy fuel oil. The PureteQ Marine Scrubber System is one of the most energy efficient Exhaust Gas Cleaning Systems (EGCS) on the market. All PureteQ scrubbers come with a user-friendly control system with real-time remote access.

PureServ services all brands of scrubbers and sensors worldwide. When properly maintained, your scrubber system will deliver reliable performance throughout the lifetime of your vessel.

Our expert service team has undergone extensive training to help shipowners ensure continuous operation, reliability, and MARPOL compliance. We provide both on-site expertise and remote online support for all types of scrubber systems.

Clients with a PureteQ Service Agreement benefit from a dedicated service engineer. Having serviced thousands of scrubber systems—both PureteQ and other brands—we bring invaluable knowledge across all technologies. By combining technical know-how with years of hands-on experience, we know how to identify and resolve issues quickly and effectively.

A PureteQ Service Agreement is tailored to meet each shipowner’s specific needs, based on the vessel’s operational pattern and crew proficiency. While most shipowners prefer predictive and condition-based maintenance to minimize costs, our agreements are designed to ensure you only pay for what you need. A typical PureteQ Service Agreement includes (but is not limited to):

• One or more service visits to the ship (depending on crew proficiency)

• Crew training: initial and refresher sessions

• Certified service of Gas Analyzer (CEMS) and Water Monitoring System (WMS)

• Spare parts management and access to our safety stock (shipped within 24 hours)

• Remote monitoring of PureteQ Marine Scrubber Systems with internet connection, including:

- Online operational guidance for the crew

- Online guidance for spare part replacement

- Online monitoring to safeguard MARPOL compliance

• Upgraded software with voyage mode for energy optimization and automated VGP wash water compliance

• Manuals and video tutorials to support maintenance and operation

• Compliance and performance reporting, incl. Flag State and US Coast Guard reporting

• Service letters on system use, maintenance, and software updates

• 24/7/365 hotline support

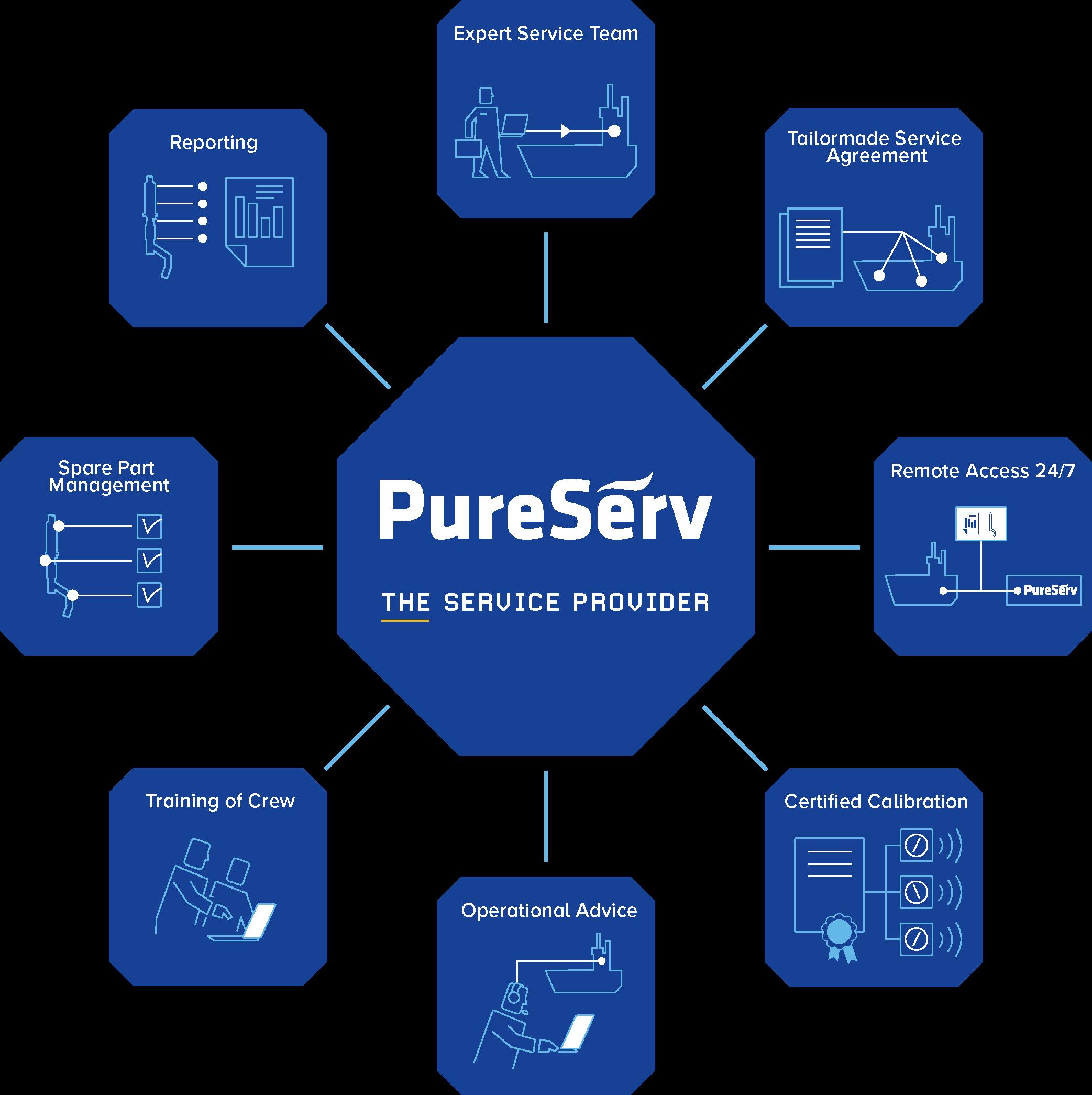

The PureteQ Scrubber Control System is at the forefront of digitalization, offering full 24/7 remote access. It can run in manual or fully automatic mode, depending on crew skills and client preferences, and provides real-time remote analysis, data monitoring, troubleshooting, and Flag State reporting.

The system enables PureteQ Service Engineers to perform updates and assist ship crews with operational tasks such as spare part replacement and error detection—ensuring MARPOL compliance and system reliability.

Logging hundreds of data points every second, the control system enhances energy efficiency, reduces operating expenditure (OPEX), and minimizes carbon footprint.

Online monitoring

System optimization

Reporting

Operational advice

Sparepart management

Software updates

IMO regulations require regular drydocking to secure vessel safety, integrity, and certification. PureteQ supports this with pre-drydocking inspections covering pumps, fans, internal structures, and compliance equipment. Our reports define clear work scopes to reduce risks, delays, and extra costs. We also attend vessels in drydock and keep a wide stock of spare parts for major brands. Drydocking is also the ideal time to consider retrofitting upgrades that align your ship with future environmental standards.

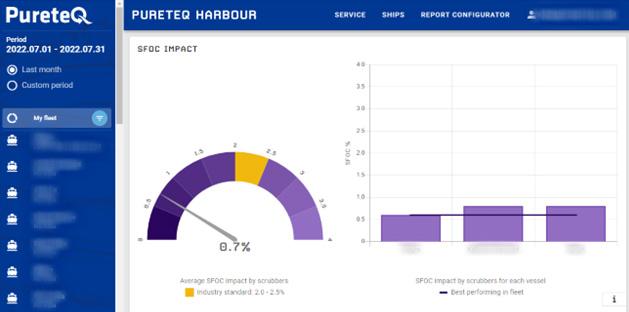

As part of PureteQ’s Service Agreement we offer clients access to our web-based Scrubber Performance Optimization Tool, Pure-SPOT, for environmental performance reporting and optimization of scrubbers throughout your fleet. Pure-SPOT facilitates MARPOL compliance monitoring, operational performance assessment (including its impact on Specific Fuel Oil Consumption - SFOC), and environmental performance reporting, encompassing reductions in CO2, sulfur, and particulate matter (PM).

Pure-SPOT aligns with the new IMO regulations on EED(X)I & CII on a well-towake basis. It enables crossship and fleet knowledge sharing among crews, resulting in cost reductions. The cost savings are calculated by comparing the expenses of using HFO with scrubbers vs. compliant fuel. Our analysis incorporates findings from the SINTEF report and actual tests conducted by third parties on sailing installations.

Pure-SPOT features the measuring of MARPOL compliance, operational performance (impact on SFOC) as well as environmental performance reporting, such as CO2, sulfur and particulate matter reductions

When onboard training is not possible, PureteQ offers a comprehensive online training package (requires a stable internet connection). Training in scrubber systems covers the full setup—from sea chest to overboard pipes. The crew will learn:

• The location of all key components and which require special attention

• When and how to maintain components

• When, where, and how to replace or repair parts

• How to navigate the scrubber control system

• How to perform operational analysis on the scrubber panel

During onboard training, the crew learns by doing—practicing common activities such as filter replacement, sensor calibration, and other routine tasks.

To ensure seamless access to training and remote services, we provide Internet for Remote Assistance Services (IRAS): a complete hardware and software solution for WiFi access in ship engine rooms, enabling real-time support—even next to a running genset or the main engine.

The permanent installation is delivered with a flight case including a SIM card, a heavy-duty tablet, and a noise-cancelling headset, enabling direct video and audio communication with a PureteQ Service Engineer.

Some type-approved components must be calibrated by a certified engineer to maintain MARPOL approval of the Exhaust Gas Cleaning System (EGCS).

PureteQ Service Engineers hold the necessary certifications and experience to validate and calibrate the gas analyzer (Continuous Emission Monitoring System – CEMS) and other components in full compliance with manufacturer requirements—offered at favorable rates.

As part of the PureteQ Service Agreement, PureServ also provides a sensor replacement program for PAH and turbidity sensors. Ships are notified well in advance of required calibration and will receive a newly calibrated sensor before returning the old one to PureServ.

Dedicated and certified marine engineers and naval architects form the core of our service team.

No matter where your vessel is located, PureteQ Service Engineers can be dispatched from Europe or Asia to support scrubber systems—either on-site or through the secure PureteQ remote system, depending on the vessel’s condition and client requirements.

Our service team assists crews with maintenance activities as well as the calibration and validation of sensors.

Clients who purchase a PureteQ scrubber receive a list of recommended spare parts upon project completion. Critical spare parts from our safety stock are shipped within 24 hours (or within 3 working days for clients without a Service Agreement).

We supply Original Equipment Manufacturer (OEM) components at competitive prices. For clients with a PureteQ Service Agreement who operate other brands of scrubber systems, we evaluate the installation and recommend which parts should be stored on board and which can be supplied from PureteQ safety stock in Asia or Europe.

A PureteQ Service Agreement is all you need to service your scrubbers and sensors of all brands:

• 24/7/365 hotline service

• Spare parts management

• Training of crew

• Operational advice & reporting

• Certified calibration & sensor replacement program

General service & troubleshooting: service@pureteq.com

Spare parts & components: spares@pureteq.com

Urgent and emergency service matters are handled 24/7/365 through one of our service hotlines:

Denmark (Svendborg): +45 3699 0222

USA (Houston): +1 (832) 460 1019

Hong Kong, China: +852 8192 5114

Japan: +81 50 5532 6875