AI CAM

AIoT People Counter Cam Design

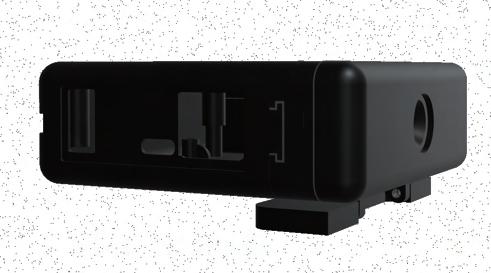

AI CAM is a hidden camera that functioned as a people counter inside a retail feild. Currently, the cam that applied in the specific retail is shoewned as the figure on the left. The retail company is willing to find another cheaper subtitution for the people counters, relative design considerations are listed as follow:

。The Cheaper the Better

���� retail stores, and more than one cam will be applied in each store.As a result, cheaper appearance for manufacturing will be more competitive when our customer is deciding which one to choose.

。A Cam but not a Cam

One of this retail corporation's DNA is creating a soothing environment for each customer. However, applying such people counters may create uncomfortableness, so the more unnoticeable it is, the more satisfying it will create toward the retail corporation.

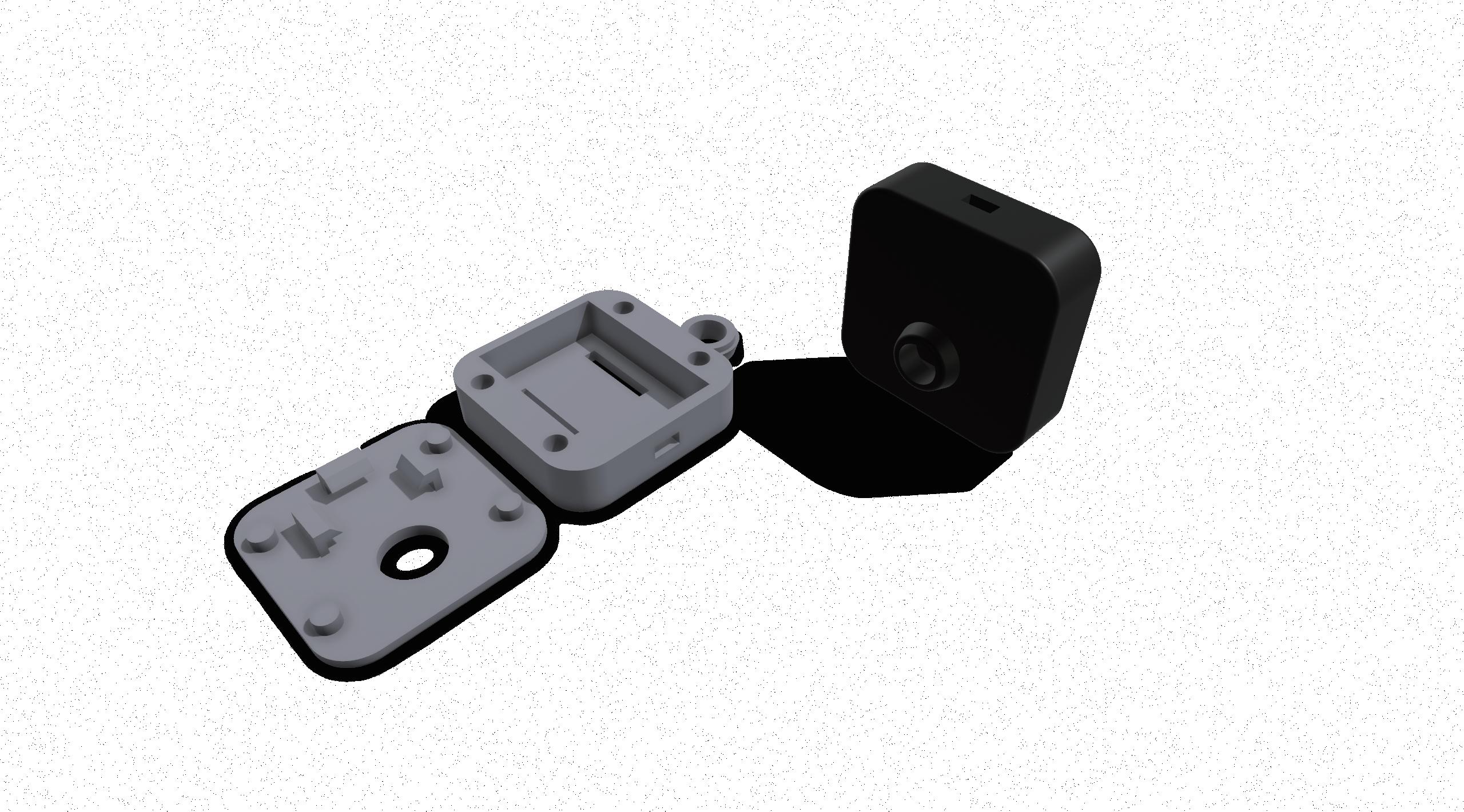

AI CAM eventually originated from other projects. Therefore, to evaluate the following developement of this people counter device, using the existed componets for creating a simple �d model and product moc-up is required for finding problem before starting feild appliance relatedf poduct developement.

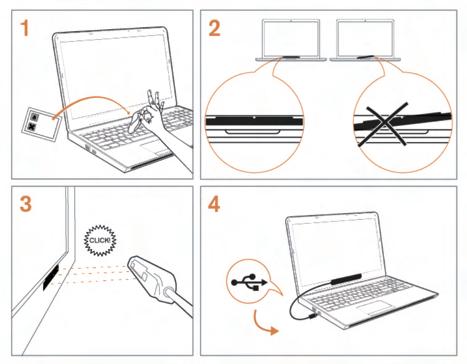

Slide Rail: Slide the SBC through the rail

Clip Up: Depend on the tolerance of �D printing

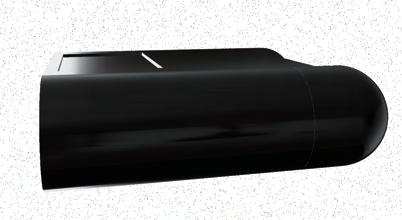

Black Outfit: Create Illusion when installed to TV.

Parts

Customer Visible Area

Problem:

Since this is a square sized camera, the shape is too obvious. Though it is small enough, illusion is unable to creat when applying to a rectangular TV. Therefore, revision that considers the shape proportion correspondency is needed.

Product View

Explode View

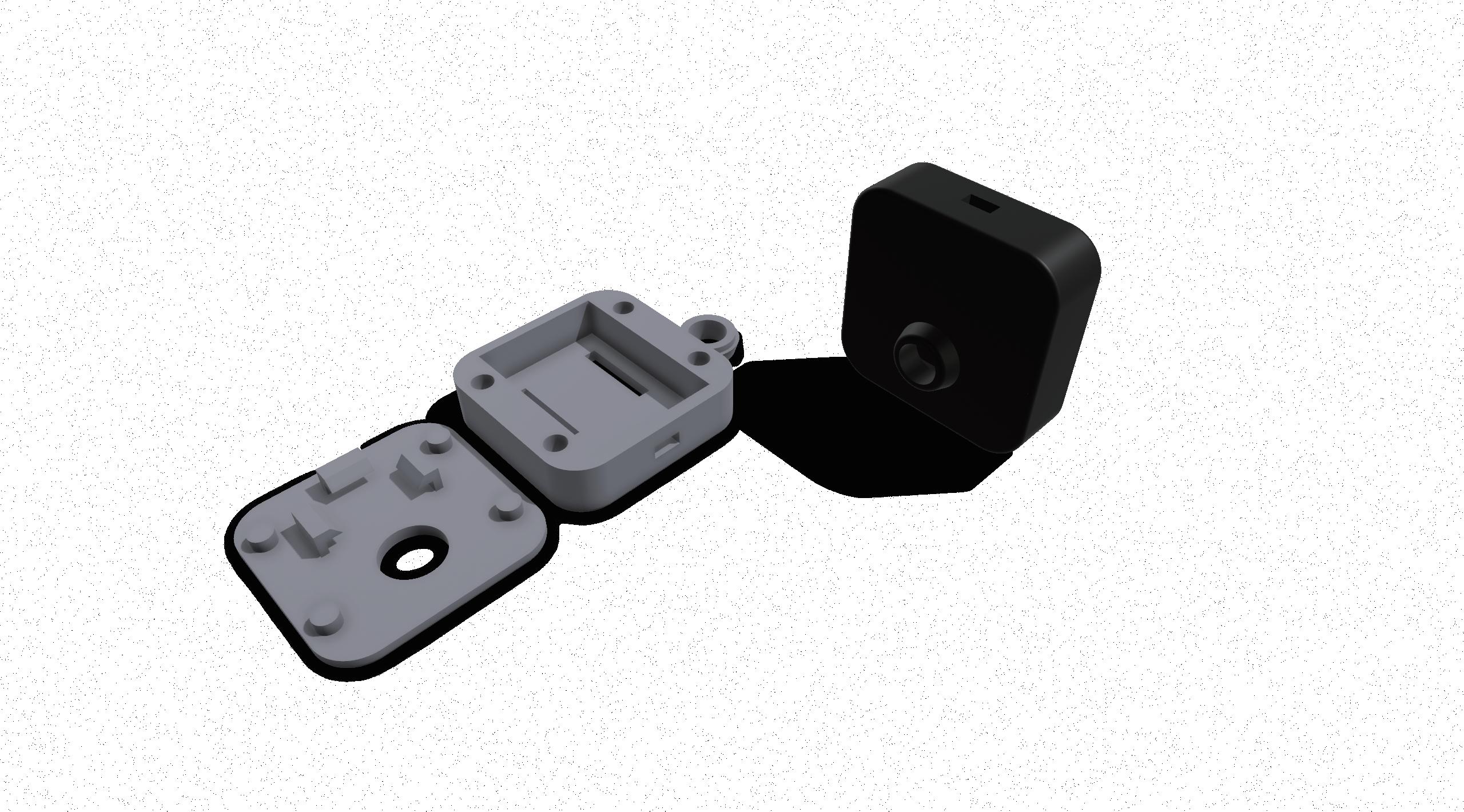

Product View

Explode View

In Mock Up �, the proportion of customer visible area had turned from sqare to rectangle, it is thiner and smaller.

Protective Cover: A Trandparent Acrylic Cover for protecting the lens

Clip Up: Depend on the tolerance of �D printing

Slide Rail: Slide the SBC through the rail

Product Size

Parts

Customer Visible Area ��*��

Produce Method �D Print � ��*��*��

Single Board Computer Size ��*��.�*�.�

Problem:

Small and Thin. However the following points should consider in the future design process:

a)Mounting Method

b)Cooling

c)The size adjustment of SBC: ��*��*��

d)Since the lense and SBC is seperated, connection of the SBC to cam, and also the capability of CAM rotaion should be considered

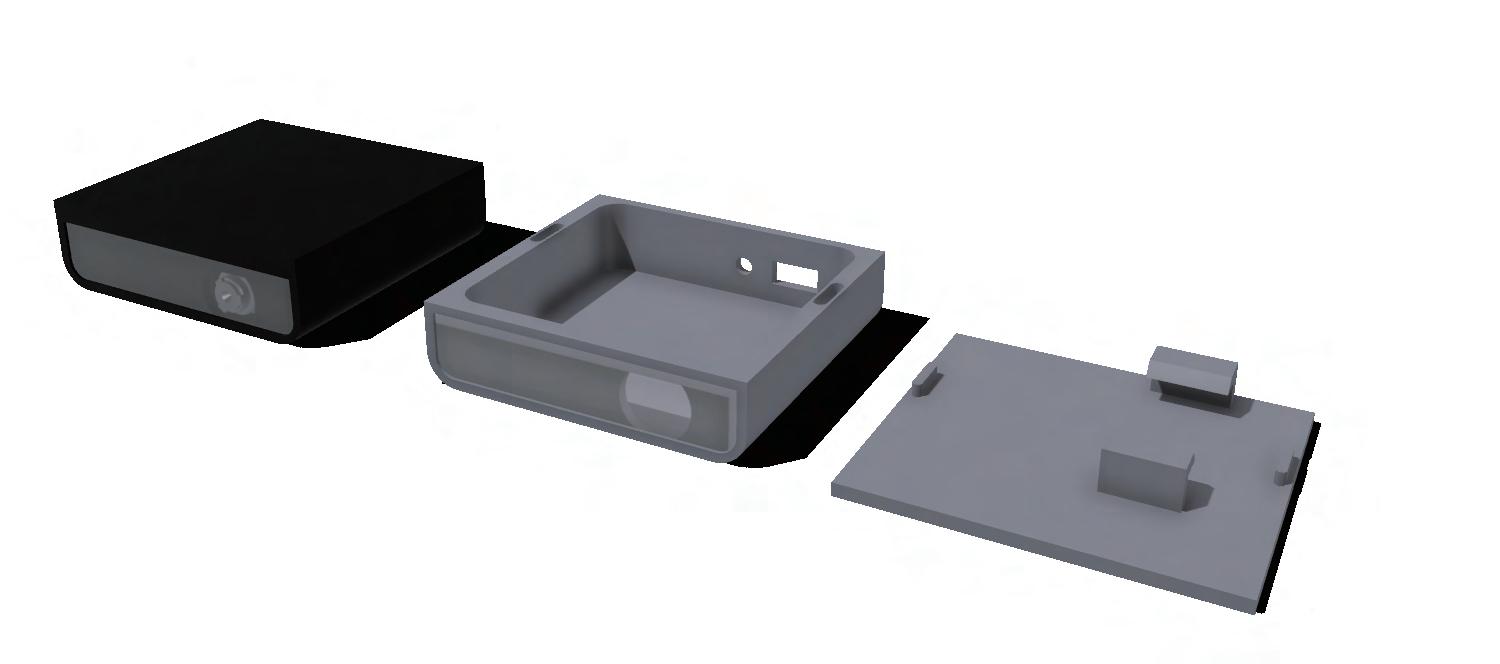

Based on the adjustment of the new SBC, an initial mock-up for the people countertr can AI CAM is designed

SBC Box: Mechanism for joint connection and also side cooling cutoff is designed.

SBC Box Upper Cap Stylish Cooling Opening can be found.

I/O Opening

SBC Box Bottom Cap Including mechanism for SBC installation

Camera Outfit A connective power supply hole to SBC in the back board

Joint: Controlling the rotation degree of the camera

Product Size

Parts

Customer Visible Area ��*��

Produce Method �D Print � ��*��*��

Single Board Computer Size ��*��*��

Showing how the cam rotation is controlled in specific angle

Problem:

Though the case is designed base on the new SBC, however

a)Mounting Method is still not applied

b)All the opening of this outfit is too big. SBC board is expose to customers, such situation do not acheive the qualification of EC safety regulations.

c)Too many components

d)The cam rotation mechanism can’t work automatically

e)Too large customer view space.

f)The flexibity of cam and SBC installation should be considered.

After the basic size of the SBC board is confirmed inb order to better concreating the concept for doing the AI Cam design: a series of cctv, webcam , and dashcam relative product researches was quickly viewed for improving the product design in a short time.

Base on the results of the relative product research, this prototype has two main feature. Firstly, a detachable camera and the SBC that can also assemble into one peice. Secondly, the SBC box that has two version: One with nameplate that subtitutes the stylish cooling opening in previous mock, while the other is the cooling opening on the left and right handsides.

SBC Box(With Opening):

The Cooling Opening of the SBC Box is located on the side for cooling, and also prevent dust falling from the top when applied ion the retail feild.

Mounting: The Mounting Device can be transfromed base on different angles, and the transformation of the AI CAM: detach with SBC or not Detach with SBC.

Parts

Customer Visible Area

Problem:

Though the case is designed base on the new SBC, however

a)Too many components, the hardware is hard to install.

b)Unable to install on all sides of TV frame.

Base on product researches on the website, I want to create an foldable “I”type clamp, but the force that helps it to clamp on the screen is base on the friction between the clamp and bezel, also the tension of the clamp. However, foldable mechanism will some how loosen these physical factors.

Concept �: No Mounting

Any kind of mounting will resulting our product unable to achieve our goal: A Cam but not a Cam. Therefore, anykind of invisible cam-screen attachment method was ideated via sketches.

Both Methods contains two part, and also able to apply on any angle ant position of products. However, they also have shortages: for Mi Cam �, electronicstatic should be applied on glossy surface. While, Tobii Pro Nano, still require sticks to stick on the bezel, so finding a blend method that brings little damage to bezel is something need to be considered.

Anti glue electronicstatic stick is installed without damage, and no trace is left during loading and unloading.

This kind of screen eye tracker is attached depending on magnectic force and also the click base on the bumps and pits of the clipping device

Prototype No. � has two main component: a detachable camera with intergrated mounting kit and a SBC case with velcro glued. These two main components can also be assemble into one peice.

Mounting: Detachable camera with intergrated mounting kit in bottom

SBC Case: With velcro glued on its back for mounting it on the TV back cabinet

Product Size

Parts

Customer Visible Area

Produce Method �D Print � ��*��*�� ��*��

Single Board Computer Size ��*��*��

Prototype No.� explode view has considered the construction of wires and SBC inside the AI Camera, preventing short circut and also the unstabily of SBC board installation.

Wires are needed for connecting detachable Ccamera and SBC Case, it is importantfor preventing wire shortage, due to the high temperature of all these electronid when the device is working. THerefore a boarch is used for seperating the factors that will cause short circuit.

Slots

Considering for easy SBC assembly, slots are grown on the components for limiting the SBC movements.

·A

Since mounting method is not decided. Therefore, tape is used as the temporary mounting method for the AI Cam.

A cable with a rotatable head serve as the joint inside the AI Cam as the joint for controlling the angel of the AI Cam

·Able to mount AI CAM without SBC detached through all the bezels of ��”TV

·Seperate the components for mounting

Consider about the amount for limit production, engineering plastic is choosed as the manufacturing method, however there are some limitaion of such production way, including finding the specific thermoplatic that has such engineering property also the the appearance of this designed product should be able for manufacturing.

Problem

Base on the DFM limitations, the appearance of AI Cam has changed three times, while the result remains unaesthetic. Possibility of finding other manufacturing methods should be considered.

After Various �D printing for the various version of AI Cam for fullfilling the DFM of Engineering Plastics. Various design qulification can not be able to achevie. Which the most serios problem is when turning from limit production to massive production, such product appearance can’t achevie the demand. So changing the product appearanc base on its function and massiver production method should be considered.

A one peice camra that contains a detachable camera, a SBC case, and an hidden mounting kit.

I/O Port

To prevent the interference fit between SBC Case- detachable camera wire connection and the cale when plug in to the I/O port. Beside establishing the I/O port in the device, it’s design on the either side of SBC case.

Cable Slot

Slot is created for storing the connection wire making the camera neat and clean.

Product Size

Parts

Customer Visible Area

��*��

Limit Produce Method Vat PhotoPolymerization � ��*��*��

Mass Produce Method Plastic Mold Injection

Single Board Computer Size ��*��*��

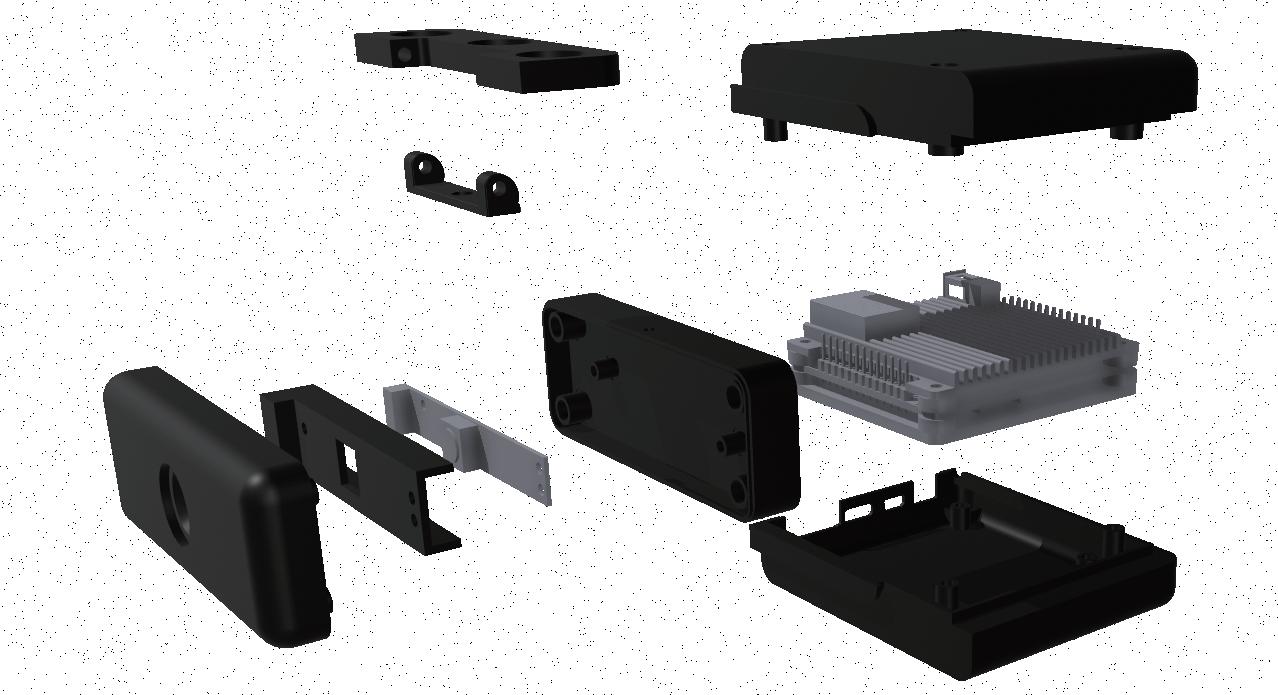

Prototype No.� explode view has considered the construction of wires and SBC inside the AI Camera, preventing short circut and also the unstabily of SBC board installation.

Mounting Kit: Magnetic Base

Mounting Kit: Shaft

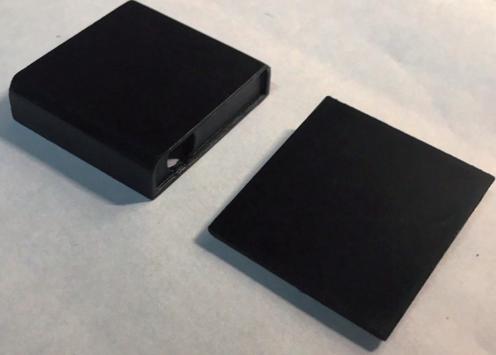

Base on the delicate model, consider about the overall situation during mounting in concept proof throughout �D printing, also the manufacturing methods. The developement of the delicate model had turned in to two version: For Limit Production & For Massive Production

When mounting AI CAM on television, the cable that plug into mthe SBC board can be easily seen by the customer annd recognize as a CAM.

In concept proof process, we found that although camera holder of AI CAM can protect the camera, the FOV of the device with be effected.

As mentioned, the tolerance of the manufacturing methods that are used on limit production and massive production differs, as the result the assembly mechanical strucuture acheving the DFM of these two production differs.

High accuracy and low tolerance of Vat PhotoPolymerization allowing us to construct an easier structure serve as slider mechanism.

Lower accuracy and high tolerance of model injection resulting that relative design should consider elasticity as the method for solving the relative problem

Explode View: AI CAM (Limit Production)

SBC Upper Case

SBC Board

Camera Back Cover

Camera Front Cover

Assembled Without Paint Applied

SBC Lower Case

Mounting Kit: Magnetic Base

Mounting Kit: Shaft

Product Size

Parts

Customer Visible Area

Manufacturing Method Vat PhotoPolymerization

Single Board Computer Size ��*��*��

Сheaper, Better, CAM But Not A CAM.

An AIoT Based People Counter Camera

Cruise CH Yang

Cruise CH Yang