GREENER T DAY

Greener Today: Celebrating our tenth issue and a new chapter in sustainability and service.

Welcome to our tenth edition of CRJ’s magazine –now called “GREENER TODAY!”

Why the change in name? We believe this reflects CRJ’s commitment to sustainable waste management and forestry solutions and aligns our vision to lead the way to achieve a greener future.

In this latest issue we showcase our latest developments in customer service, across all departments, from hire and sales, to parts and customer support activities across the UK.

Over these past few months we have participated in numerous charitable events as well as our very first celebratory “Open Day” event here at our HQ in Cheshire. This event proved to be a game-changer in continuing to help build our local, national and international business relationships as it opened our doors to customers and suppliers so they could experience at first hand the CRJ family in action!

We are excited to announce our newly developed ‘customer-in-mind’ CRJ Website. The website contains everything you need to know about what we do, why we do it and how we do it! This is a further milestone in improving our online presence for everyone who works with us.

In addition, we have also streamlined our Hires process by launching the CRJ Hires Hub. This hub focuses on our Hire fleet, one of the largest in the UK, and directs customers to explore all the options available for whatever machine they need. The key factor around the hub is to make the hires process as straightforward as possible, ensuring the efficient service for which CRJ is renowned.

With CRJ’s commitment to developing our teams, our mobile service team has expanded by establishing an in-house mobile welding team. They bring expert fabrication and hardfacing directly to your site. The intention is to reduce delays, extend your equipment life by using our trusted CRJ engineering team. All our welders are certified with excellent knowledge of our machines to give all our customers the confidence that our support services are secondto-none.

In addition, we have also welcomed new engineering apprentices and added more key personnel across the business to enhance our overall company skill sets and to boost our processes making it easier for all our customers to stay connected with us. As our business continues to grow at pace, we recognise the need to ensure all our teams grow to deliver the best service for everyone who works with us.

We appreciate every member of our staff for their dedication, and work ethic in making CRJ the best provider of material processing and recycling equipment in the UK.

Finally, a huge thank you to our loyal customers and suppliers, many of whom have been with us from day one. It is a pleasure to work with you every single day forming partnerships that helps drive sustainability initiatives across the country.

Regards,

Andrew Clarkson Managing Director

In the current economic climate, hiring heavy plant machinery for immediate projects or shortterm operations is a quick win that doesn’t rely on long term investment. With over 25 years of experience in equipment hire, we provide expert advice along with a range of benefits when you choose to work with us, and now with the new CRJ Hire Hub, we guarantee our customers will find the perfect fit with confidence.

Navigating the hub is effortless, if you know what you need, simply use our fast track form, where we will update you on machine availability within the hour. Or maybe you fancy browsing through our extensive fleet before booking? We’ve organised our fleet

into three categories - shredding, screening, and sorting. Click through the various machines on offer, technical specifications, and applications, allowing you to reserve the right machine/s for your operation.

Our inventory features top-tier equipment from renowned brands, including slow-speed and high-speed shredders, trommel screeners, picking stations, deck screeners, water baths, and more. This streamlined approach helps you match the right machine to your job requirements without hassle.

Comprehensive Support from Quote to Off-Hire We ensure a seamless experience and complete peace of mind from

AJ & Lucy, making equipment hire simple and stress-free

Meet Lucy Nicklin and AJ Atherton, our dedicated Hire Controllers. Backed by a team of seasoned professionals, with deep industry knowledge helping you get the right machine, at the right time, and at the right price.

We pride ourselves on our fleet of over 100 heavy plant machines for the waste management and forestry industries, available for short and long term hire, with the optional benefit of hiring one of CRJ’s highly trained operators. All machines are delivered and collected by our in-house transport team and maintained by qualified engineers, either in our on-site workshops or via our mobile service team. Each hire machine is thoroughly checked before and after deployment.

Our streamlined hire process saves you time and resources while delivering top-quality shredding, screening, and sorting equipment. From the initial consultation to delivery and setup, every step is handled with precision and professionalism. Customers benefit from access to state-of-the-art machinery that guarantees optimal performance and reliability, no matter the size of your operation.

We don’t just stop at delivery. CRJ provides ongoing support and maintenance nationwide, with prompt mobile engineer services and regular check-ups to ensure smooth, uninterrupted operations. Lucy and AJ, are always on hand to assist, your trusted link to a seamless, effective hire experience.

When you hire a machine from CRJ, you benefit from a company who has:

• The largest fleet in UK & Ireland, with a wide variety of machinery to choose from.

• Dedicated hire controllers backed by industry experts.

• Optional operator hire upon request

• Delivery & collection by our transport.

• In depth same day operator handover

• Insurance recognised fire suppression on every machine.

• Health checks conducted on all hire equipment, with a service schedule every 250hrs.

• Hire equipment swing programmebreakdown & replacement cover.

• No hidden costs.

• ISO 9001, 14001 & 18001, and Carbon Neutral certification.

We hire the following equipment on long or short term hire

• Slow-speed & High-speed Shredders

• Trommel & Deck Screeners

• Picking Stations

• Eddy Current & Density Separators

• Wash Baths

For more information about the hire equipment, contact Becky and the hires team.

becky.curley@crjservices.co.uk

01565 723886 (Option 2)

The groundbreaking HAAS Tyron Quick Change System, marking a major leap forward in maintenance efficiency and cost reduction.

Over the years, the recycling industry has occasionally accepted that high level equipment maintenance comes with significant downtime. Replacing major machinery components often meant days of labour, specialised tools, and costly man hours. But that’s no longer the case with the newly upgraded HAAS TYRON Shredder.

Maintenance Revolution: Downtime from Days to Hours

The new Quick Change (QC) System centres on a revolutionary modular approach that allows complete shredding unit exchange in record time. Unlike traditional systems requiring extensive dismantling and specialised expertise, the QC system separates the shredding unit entirely from the drive section, eliminating the need to access sensitive components like bearings or hydraulic lines.

As HAAS Recycling’s exclusive UK & Irish dealer, we offer this cutting-edge technology in both the diesel powered and hybrid HAAS Tyron 2000 XL 2.0 models.

Key technological advantages:

Modular Design Excellence: Changeable components (counter combs, breaker bars, rotor shafts) allow one machine to handle diverse materials without compromise.

Hydraulic Quick Change Innovation: Simple hydraulic slide-out mechanism requires only basic screwing and lifting for component access.

Unprecedented Speed: Shaft changes in under 90 minutes, complete chamber replacement in 45 minutes.

Flexible Configuration Options: Different shredding tools maximise equipment utilisation across various recycling applications.

Robust Engineering: Asynchronous planetary gearbox with large bearings and maintenance-friendly coupling ensures reliability.

Cost-Efficient Service: Rotor shaft reconditioning via welding (dedicated device or in-machine) reduces costs and complexity.

The newly upgraded HAAS TYRON Quick Change System maintains all the performance characteristics that have made it an industry standard, whilst adding a better service experience. The system’s design ensures that routine maintenance becomes a planned activity rather than an emergency disruption.

The separation of the shredding unit from the drive section represents sophisticated engineering that prioritises both performance and practicality. This approach protects sensitive components whilst enabling rapid access to wear items that require regular attention.

The Quick Change System represents more than just improved maintenance procedures. We acknowledge all heavy plant machinery requires consistent maintenance, even more so with heavy duty shredders like the HAAS Tyron. But by designing systems to minimise the negative impact of breakdowns and planned maintenance, HAAS Recycling demonstrates genuine understanding of customer needs.

Where traditional systems create maintenance challenges, the Quick Change System creates maintenance efficiencies.

This technology is a game changer for servicing both our hire fleet and third-party machines. What used to take over two days now takes under two hours, massively reducing downtime and boosting customer productivity.

This is going to revolutionise our operations, particularly our swing machine programme.

Deon Swanepoel Head of Engineering, CRJ

The HAAS Tyron 2000 XL 2.0 Quick Change unit is currently available to purchase from CRJ throughout the UK and Ireland.

becky.curley@crjservices.co.uk

01565 723886 (Option 2)

mike.symons@crjservices.co.uk

01565 723886 (Option 3)

Jenz HEM 542 - Demo Unit

PTO chipper (2024) 15hrs

Price: POA

Jenz HEM 700

High-speed shredder (2017) 8,100hrs

Price: POA

Each used machine has been quality checked by our expert heavy plant mechanics to ensure they are in good working condition.

Doppstadt AK640K

High-speed shredder (2022) +3,400hrs

Price: POA

Scan to view full range of used machines, ready to purchase, call 01565 723886 (3) or email enquiries@crjservices.co.uk.

At CRJ, we help businesses cut costs and emissions with quality parts and expert care. But if your equipment isn’t maintained properly, how much is it really costing you?

In waste and forestry operations, machines like shredders and trommels are only as good as their up keep. Neglecting equipment maintenance can have serious consequences, ranging from costly breakdowns and unplanned downtime to reduced machine lifespan and safety risks. In high-demand industries such as waste management and forestry, even a single equipment failure can halt operations, delay projects, and result in significant financial losses. For example, worn shafts or bearings in a HAAS shredder can reduce throughput, increase energy consumption, and cause further damage if not addressed promptly.

Routine maintenance, such as cleaning, lubrication, and replacement of worn parts, is essential to ensure optimal performance and extend equipment life. Proactive care helps identify issues early, preventing expensive repairs and keeping operations running smoothly.

CRJ Parts supports this approach by supplying genuine components from trusted manufacturers including HAAS, Jenz, Pronar, and Bruce. For hardto-source items, our team can locate and deliver the right parts quickly, minimising delays. A proactive maintenance schedule, supported by high-quality parts, ensures machines remain operational. For instance, regular servicing of a Jenz chipper’s hydraulic system can prevent leaks and avoid costly downtime.

At CRJ, we’re committed to helping businesses achieve financial and environmental goals through effective equipment maintenance. Our extensive range of genuine parts from our machine partners, combined with our sourcing capabilities, ensures you get exactly what you need, when you need it. Our refurbished parts, backed by rigorous testing and a quality guarantee, offer a sustainable and cost-effective solution. By prioritising maintenance and partnering with CRJ Parts, you can reduce costs, minimise downtime, and contribute to a greener future.

Curious about this month’s giveaway?

Scan the code to follow us on social media, and discover our latest Parts Merch Deal!

Contact Alan and his team for a full list of aftermarket parts available.

alan.atherton@crjservices.co.uk

01565 723886 (Option 4)

Building on a successful partnership supplying reliable used equipment, Quill Energy recently invested in a new Jenz HEM 593 Z chipper, to boost productivity and maintain high-quality chip production

Founded in 2018, Quill Energy Ltd has built a strong reputation in the biomass and composting sector. With consistent success comes business investment in reliable machinery to ensure productivity and high-quality output.

• First Purchase: A used Jenz BA 725 was sourced and overhauled by CRJ’s expert workshop team. This provided robust chipping capacity at an accessible cost.

• Second Acquisition: To expand screening capabilities, Quill Energy trialled a used trommel screener on hire. After a successful trial, the screener was purchased outright.

Our relationship with Quill has been built on proven performance, while supporting their growth through quality part sales and refurbished machine sales.

Quill Energy faced several operational challenges:

• Equipment Reliability: Maintaining uptime in demanding biomass processing environments.

• Efficient Sizing: Producing consistent G100 and G50 chip sizes for various end users.

• Scalability: Ensuring machinery could adapt as business volumes grew.

Jenz chippers are renowned for performance, value, efficiency, and durability. With this in mind, Mike Symons, (CRJ Head of Sales), recommended the Jenz HEM 593 Z, ideal for consistent, high-quality wood chip, supporting Quill Energy’s operations today, and positioning the business for future growth. This delivery also marks a milestone, as the HEM 593 Z is the first new Jenz chipper CRJ has supplied to Ireland.

Since commissioning the Jenz HEM 593 Z, Quill Energy has seen significant benefits:

• Improved Productivity: Hydraulic blower with adjustable speeds allowing seamless loading into containers, and a D1.3 rotor for optimum chip quality and easy maintenance access.

• Enhanced Chip Quality: 1400mm wide in-feed and aggressive intake to handle timber up to 560mm diameter.

Hydraulic opening screen and pre-grips to switch between G100 and G50 chip sizing effortlessly.

• Operator Satisfaction: easy2 control touch screen in the operator’s cab for intuitive machine setup and quick adjustments.

Our after sale service includes scheduled servicing, parts supply, reactive breakdown cover, and a lifetime of specialised technical advice.

To learn more about the full range of Jenz machines or arrange a demo, contact Mike and his team.

mike.symons@crjservices.co.uk

01565 723886 (Option 3)

When every minute of machine downtime can mean lost revenue, how do you stay ahead? At CRJ, we’re raising the bar on equipment support with the launch of our in-house mobile welding team, bringing expert fabrication and hardfacing directly to your site.

Over recent months we’ve expanded our industry leading service and support department with the addition of fully qualified, mobile welders. Designed to reduce delays and extend equipment life, this new service is more than just convenient, it’s a game-changer.

With a key focus on the shredder shaft hardfacing, particularly those in the HAAS range, these components endure intense daily wear. Reinforcing them with a tougher surface layer significantly extends their operational life, enhancing both durability and shredding efficiency.

Historically, hardfacing work required external contractors or taking the machine off site to be serviced in our workshop. This approach often led to increased lead times, higher costs, and inconsistent repair quality.

To address these challenges, CRJ has brought mobile welding capabilities in-house. Our certified welders possess deep expertise in heavy plant machinery and wear issues faced by our customers across the UK and Ireland. Investing in a dedicated welding team guarantees delivering expert on-site welding without unnecessary delays, or off-site repairs.

Minimised Downtime: No need to “swing” machines out for off-site repair, our welders come directly to you.

Consistent Quality: All welding jobs are carried out to CRJ’s high standards, ensuring reliable performance and machine longevity.

Cost Efficiency: We now control the costs and pass these savings onto you.

Faster Turnaround: In-house teams mean we can react faster and avoid delays from third-party availability.

One-Stop Service: Whether you’re operating a fleet of machines or a single shredder, our goal remains the same, to keep your operations running smoothly and efficiently. With our in-house welders joining our network of mobile heavy plant engineers, we’re better equipped than ever to deliver on that promise.

For all service delivery queries, contact Darren and his team.

darren.taylor@crjservices.co.uk 01565 723886 (Option 1)

The addition of mobile welders is just the latest enhancement to the broad service support network we already provide. CRJ’s Service Delivery department is known for its rapid response and technical know-how. Across the UK and Ireland, we now operate over 10 fully equipped mobile service engineers ready to respond to breakdowns and service needs.

North West (& Ireland)

to sorters, our teams know the machines inside out and are supported by a robust infrastructure back at CRJ headquarters.

Each mobile team is coordinated by our dedicated in-house service controllers, who ensure quick deployment, efficient scheduling, and consistent communication with customers. That means no guesswork, just responsive, professional support when and where you need it. Contact the Service Delivery department for more info on 01565 723886 (option 1). A new layer to our already comprehensive service offering

Our service engineers handle everything from routine maintenance to urgent breakdown support across a wide variety of environmental and waste processing machinery. From shredders to screeners, washers

Setting a new benchmark in composting technology, the Pronar MBA 4512g combines exceptional throughput, intelligent process control, and unmatched operator comfort in one rugged, high-performance package.

Available exclusively through CRJ in the UK, the windrow turner is built to deliver faster decomposition, greater efficiency, and lasting durability, making it a formidable force in the organics recycling sector.

Pronar Windrow Turner MBA 4512g, first seen in the UK, on demonstration at the CRJ Open Day in May 2025.

Key technological advantages:

High-Performance Output: 1.2m diameter shaft delivers up to 3,000m³/hour throughput, handling windrows up to 4.5m wide and 2.2m high.

Fast, Flexible Operation: Shaft rotation up to 220 rpm with instant direction change, even during operation.

Advanced Compost Management: Optimises decomposition by releasing excess heat, evaporating or adding moisture, and aerating waste for faster results.

Built for Longevity: High-resistance steel knives, ploughshares, and scraper components for extended service life and reduced downtime.

Operator Comfort & Safety: Fully climate controlled cab, plus EN-15695 Cat. 4 air filtration for dust- and odour-free working conditions.

Learn more about the Pronar Windrow Turner by contacting Mike and his team.

mike.symons@crjservices.co.uk 01565 723886 (Option 3)

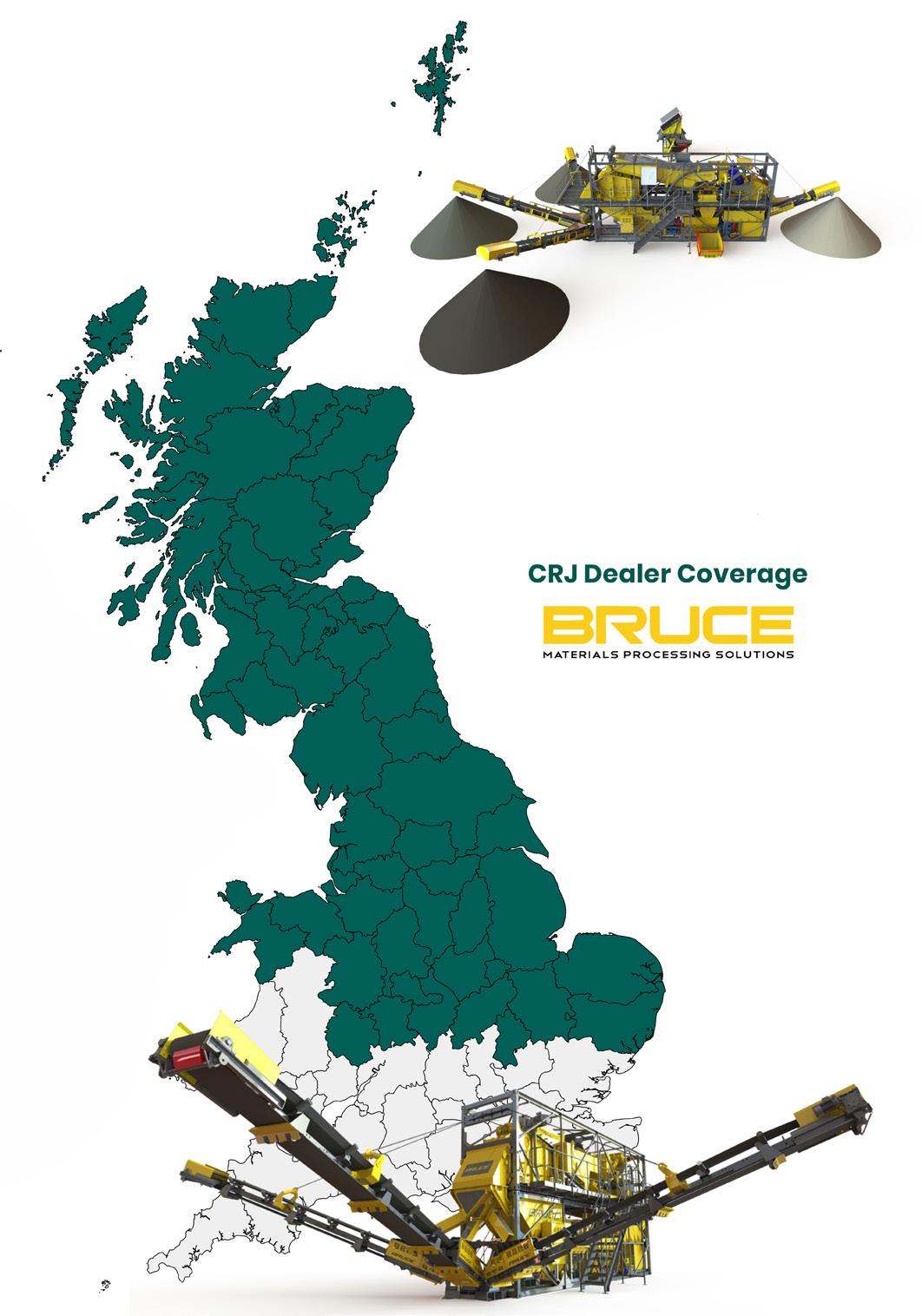

CRJ Services are delighted to announce the expansion of our Bruce Engineering dealership, now encompassing Scotland alongside our existing regions of Northern England, North Wales and the Midlands.

Since purchasing our first Bruce Waterbath in March 2021 to add to our hire fleet, we’ve been impressed by the exceptional product quality and OEM support. Shortly after, in October 2021, we signed a dealership agreement, representing Bruce Engineering across central UK, from Northumberland down to Cambridgeshire.

In this relatively short space of time, CRJ acquired a number of Bruce Waterbaths for our hire fleet, while selling multiple units to our customer base. In addition to this we have sold the larger Aggregate Washing Systems including the Bruce Washpod, and separately designed and developed bespoke systems which have been integrated with Tecnoidia Waste Water Treatment Plants.

Due to this success and coupled with CRJ’s strength and prominence in the Scottish Waste, Recycling and Forestry Markets, the decision was made to expand CRJ’s current region northward, to best represent the Bruce brand in this critical area.

This expansion allows us to provide turnkey solutions for customers, no matter how remote!

CRJ Services provides a comprehensive range of wash plant equipment for sale, engineered for efficient material washing, fines recovery, and aggregate classification. Our heavy-duty solutions are designed to maximise material value while ensuring compliance with end-product specifications.

CRJ’s robust infrastructure makes them the ideal choice to represent our brand in this vital area, and we look forward to continued growth.

Thomas Haughey Dealer Manager, Bruce Engineering

Recognising that every business faces unique challenges, our approach begins with a comprehensive site assessment, material analysis, equipment installation and after-sale servicing.

Contact Rob Symons and Ben McQuaid today!

In the Press

Sustainability can no longer be a back-office, box-ticking exercise for businesses. It’s now an urgent, regulatory requirement. The UK government has set a legally-binding target to reach net zero by 2050. This demands businesses slash their carbon emissions and transform how they extract, use and dispose of raw materials and products.

Businesses in the waste management, forestry and quarrying sectors are at the forefront of this transition. Every machine bought, hired or disposed of has an environmental footprint. This is caused by a combination of resource extraction, manufacturing processes, energy consumption during operation and emissions from transportation.

The need to pivot to a sustainable operational model is clear. But meeting sustainability targets requires investment in technology, people and time, all of which can impact the bottom line. This potential trade-off has sparked an urgent question among leaders: how do they meet sustainability targets while also achieving operational growth?

Andrew Clarkson, managing director of CRJ Services, says innovation is a big part of the answer. The firm is the leading supplier of waste, recycling and forestry equipment in the UK and Ireland. The company works closely with OEMs (original equipment manufacturers) to develop more sustainable equipment that delivers a measurable impact on reducing the carbon emissions of their end customers.

“We worked with Haas, who supply and manufacture our shredders, to develop the hybrid shredder,” he says. “This uses a large electric motor to power the shredding process and a small diesel engine to power the tracks. The result is that it doesn’t produce any CO2 emissions whilst in operation.”

CRJ Services also collaborates with Pronar to develop a fully electric trommel - a machine that acts like a giant sieve to sort materials during the recycling process. By using an electric drive rather than a diesel-powered motor, businesses can significantly reduce the

amount of money they spend on energy to power the machine. Savings are also generated during maintenance as machines with electric drives don’t need replacement filters, oil or coolant.

Reducing energy consumption and carbon emissions is only one piece of the puzzle. Leaders are also under pressure to transition to a circular economy. This is a model of resource production and consumption that involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products for as long as possible.

CRJ Services positions itself as a partner for businesses undergoing this transition. Most dealerships purely sell equipment and machinery to end businesses, which must then be disposed of at the end of their lifespan. But CRJ Services actively works with its customers to extend their lifecycle. It does this by offering a repair and refurbishment service, as well as providing a range of OEM and quality aftermarket spare and wear parts for its equipment and machinery, which are fitted by a fleet of mobile engineers based across the country.

It also offers another service to make it easier for customers to adopt circular processes. “We don’t just sell equipment and machinery, we make them available for hire, too,” says Clarkson. ”This increases the lifespan of the equipment because we can repair and refurbish it in between hires and reduce the risk of underused equipment degrading and ending up in landfill. It’s also more cost-effective for businesses, because they don’t have to spend money on brand new technology.”

Internally, CRJ is investing in its own circular initiatives. The company recently spent £100,000 on an effluent water system. When equipment returns to its main site, it undergoes a washing process, which previously required a vast amount of water usage. But a closed-loop system means the water is now 100% recycled. “For us, it’s not just about making profit,” adds Clarkson. “We have a responsibility to drive sustainable change.”

In the future, change is also likely to emerge in the form of personalisation. As businesses

seek to scale their operations and increase the amount of waste they recycle, many want static machinery capable of processing larger amounts of material, but without the burden of increased emissions and cost. “We’re seeing a real drive to replace diesel,” says Clarkson. “Clients will often approach us with a specific site, a defined waste stream and a desired output. Then, we will design and build a plant tailored to their needs.”

Waste aggregate is another sustainability concern for businesses that is growing in importance. Aggregate refers to waste materials like concrete, asphalt, brick and other rubble generated from industrial projects. Increases in operational output mean an increase in aggregate. The challenge for businesses is to turn more and more of that waste back into reusable raw materials. To solve this, CRJ provides firms with wash plants. This is a complete system designed to remove impurities like clay, silt and dirt from aggregates such as sand and gravel, which can then be recycled into reusable materials for future projects.

AI could also play a transformative role. Early applications in waste separation are already reducing landfill dependency by improving accuracy and speed. “We’re already working with manufacturers to explore AI and while it’s too early for us to predict exactly how it will evolve, its potential is evident,” says Clarkson. “Smarter, more automated systems can maximise recycling rates and optimise efficiencies in energy uses.”

The future of the industry is clear: machines and equipment that last longer, run cleaner and recycle more. Businesses that embrace innovation and frame sustainability as a competitive advantage to win new customers, rather than a cost centre, will create a greener and more profitable future. Those who delay it or treat it as a box ticking exercise will quickly fall behind.

Written by Alec Fenn

Published in The Times 25 September 2025

On Friday, 16th May 2025, CRJ proudly welcomed industry professionals, supply partners, and members of the local community to CRJ HQ in Knutsford, Cheshire, as we marked 25 years of innovation and excellence. Our milestone event, themed “25 Years Forward: Shaping Sustainable Solutions”, highlighted our commitment to driving sustainable advancements in the industry while creating an engaging and memorable experience for everyone who attended.

The exclusive Friday event was designed for our industry guests and featured:

Supplier Meet-and-Greets: Visitors connected with leading OEM suppliers (from HAAS, Jenz, Pronar, Bruce, and Kentek) and explored the latest innovations.

Delicious food was cooked over an open flame, accompanied by a variety of drinks.

Site Tours: Attendees enjoyed an insider’s look at our state-of-the-art facilities.

Exclusive Prize Draw: Congratulations to Dave Hodgkinson from EMR on winning our Open Day competition, a VIP headquarters and facility tour at HAAS-Recycling in Germany.

The celebrations continued on Saturday, 17th May 2025, when we opened our doors to the wider community for a family-friendly day.

Visitors enjoyed more machine demonstrations, family entertainment, and refreshments. It was the perfect opportunity for local residents to join the celebration and experience CRJ up close.

Thank you to those that were able to attend our Open Day, if you were unable to make it, you can always contact us to arrange a site visit.

We were thrilled to mark 25 years of pushing boundaries and delivering sustainable solutions. Hosting this event was our way of thanking our suppliers, customers, and the community while showcasing the exciting future ahead.

Rob Symons Strategic Projects Director,

CRJ

As the UK & Ireland partner, CRJ were invited to attend the exclusive Jenz Dealer Event 2025, which included unveiling the latest innovations in chipper and shredder technology.

New and upgraded machines:

• Hackthor self-propelled chipper

• Next-generation HEM 5400 Z and HEM 5600 Z PTO chippers

• New drum and cooler technology

• Advanced easyprotect shredding tools.

Located right next to the Pronar factory, Pronar’s permanent exhibition space is over 10ha, showcasing their whole portfolio of recycling and other specialised machinery. As exclusive dealer for Pronar Trommels in the UK and Ireland, we visited Pronar for the unveiling of this incredible centre.

Recently, members from CRJ represented the UK and Ireland at the latest HAAS Dealer Day in Germany. They had the opportunity to connect, learn, and grow from:

• In-depth technical sessions

• Hands-on training

• Live demos of the new HAAS Tyron QC Shredding Unit

• Dealer networking

A huge thank you to everyone who supported the CRJ ‘Muddy Buddies’ team in completing Tough Mudder ‘25 - together we raised an incredible +£8800 (excl Gift Aid) for Dementia UK!

On behalf of everyone at Dementia UK – our nurses, our team, and the families we support – thank you.

Kate & Mia Challenge Events Team, Dementia UK

At CRJ, our purpose is clear: to empower the UK’s recycling efforts with innovative, sustainable solutions.

Our 2025/2026 Sustainability Plan reflects our commitment to minimising our environmental impact, strengthening communities, supporting our people, and delivering exceptional value to our customers and suppliers.

Vision: We strive to improve the quality of life in the communities where we operate.

• By choosing CRJ, customers and suppliers join a network that invests in community development.

• Our outreach programs and events create opportunities for brand collaboration, jointly investing in community development.

• Schools outreach to educate future generations.

• Volunteering and matched fundraising initiatives.

Vision: We aim to be our customers’ partner of choice.

• Our customers benefit from tailored recycling solutions that enhance operational efficiency.

• Suppliers gain from streamlined partnerships that prioritise sustainability.

• By working with CRJ, you’re choosing a partner committed to your success and aligned with your values.

Vision: We are committed to minimising our environmental impact wherever possible.

• Accessing and enforcing recycling processes and improvements throughout the business.

• Prioritising eco-friendly waste management processes, enabling our customers to meet their sustainability targets while benefiting from efficient recycling solutions.

Vision: We aim to make CRJ a great place to work by listening to employees and acting on their feedback.

• Enhancing involvement and communication within CRJ.

• Promoting reward, recognition, and appreciation.

• We’re investing in learning and development.

• Retain IIP Silver Accreditation and maintain a quarterly employee engagement score.

• For our customers and suppliers, this translates to reliable, high-quality service from a team dedicated to excellence.

We offer our customers recycling solutions that reduce waste, lower costs, and support your sustainability goals. Our renewable energy initiatives and carbon reduction efforts help you meet regulatory requirements and appeal to environmentally conscious stakeholders. For suppliers, partnering with us means joining a supply chain that values ethical practices and community impact, enhancing your brand’s credibility. Together, we’re working together to create positive changePeople. Planet. Purpose.

Introducing you to our dedicated Workshop Team Leaders, Deon Swanepoel, Dale Hamlett and Charles Jansen van Vuuren, while exploring the influences shaping their leadership approach and the strategies they use to guide their teams on a day to day basis.

Deon

Head of Engineering

Previously working within the South African mining industry, Deon now oversees our multiple workshop sites. Bringing +25 years of heavy plant machinery experience and an innovative mindset to our full suite of products and services. Deon started as a Heavy Plant Mechanic, working his way up to Head of Engineering. As a rugby mad family, Deon invests his free time supporting his son and daughter who play for several Cheshire rugby clubs, in addition to servicing and maintaining generator lights used for evening games.

Through hard work and continuously striving to deliver the best, Dale & Charles have risen from Heavy Plant Mechanics to active hands on team leaders. In their new roles, they mentor teams of mechanics and engineers, passing on their wealth of experience and knowledge, while ensuring our hire and third party machinery is maintained to a high standard of safety, efficiency, and performance.

Over the last two years at CRJ, Dale has shown the kind of leadership qualities that reflect our company values at their best - integrity, excellence, and teamwork. When he is not working on a shredder or screener, he can be found restoring cars, renovating his family home, or spending time with family in the picturesque valleys of North Wales.

Charles brings passion and precision to his role, overseeing performance management and professional development for his workshop team, reflected in his consistently high standard of work. Off the clock, a family man by heart, Charles can be found spending quality time with his family (& dogs). An avid MMA (Mixed Martial Arts) competitor, Charles trains and fights to raise funds for multiple UK charities.

Highly respected by their peers, Dale and Charles pass on their passion for excellence and technical expertise, from the inner workings of hydraulics to the specialised skills behind welding. Under Deon’s guidance, their leadership unites our teams to deliver the best, always prioritising our customers’ needs, keeping CRJ at the forefront of the waste management, recycling, and forestry industries.

Pronar mobile trommel screeners are ideal for processing a wide range of materials –including soil, compost, municipal waste, coal, aggregates, and biomass.

As exclusive UK & Ireland Pronar trommel partner, CRJ brings you an unbeatable offer: 0% finance on all new Pronar Trommels for a limited time only (offer ends 31 October 2025). CRJ will cover the interest costs, meaning you pay no interest during the finance term.

Elevate your waste, recycling, or forestry operation with a Pronar screener and flexible payments that keep your cash flow strong.

As the trusted leader in the UK and Ireland, CRJ delivers unmatched service and support to help your business thrive.

Contact us today!

Mike Symons Head of Sales 01565 723886 (Option 3)

CRJ Services Ltd is a comprehensive waste, recycling and forestry equipment solutions provider, operating throughout the UK and Ireland. Renowned within our industry for quality, in both the machinery that we provide and the service that we deliver.

Ben McQuaid

Strategic Project Director 01565 723886

Becky Curley Head of Key Accounts and Hires 01565 723886 (Option 2)

Rob Symons

Strategic Project Director 01565 723886

Alan Atherton Head of Parts Sales 01565 723886 (Option 4)

Darren Taylor Head of Service Delivery 01565 723886 (Option 1)