FOOD + BEVERAGE AND CONSUMER PRODUCTS

engineering | architecture | construction | consulting

SAFE, HIGH-QUALITY, VALUE-DRIVEN

facilities that fuel your growth and success.

EST. 1984

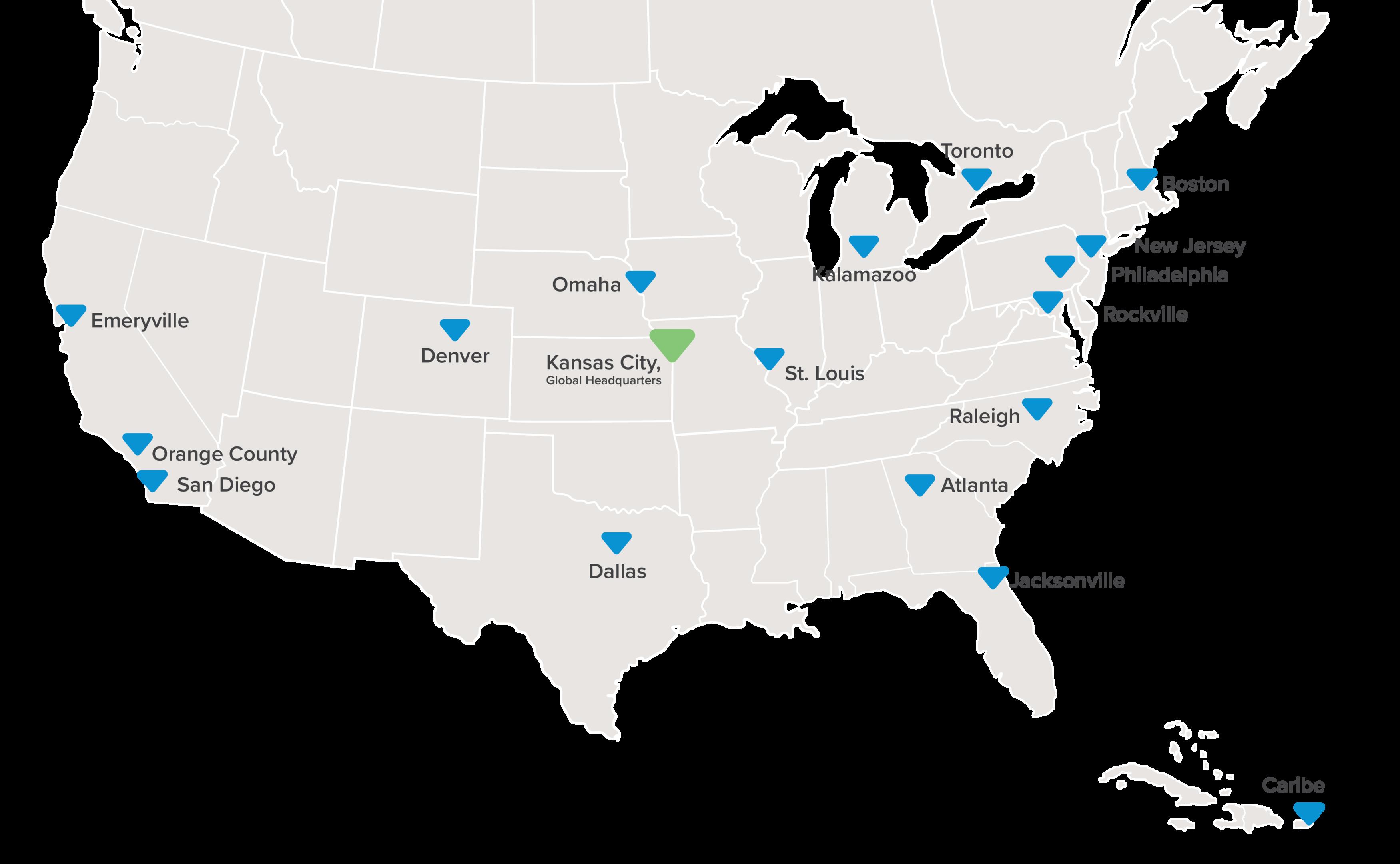

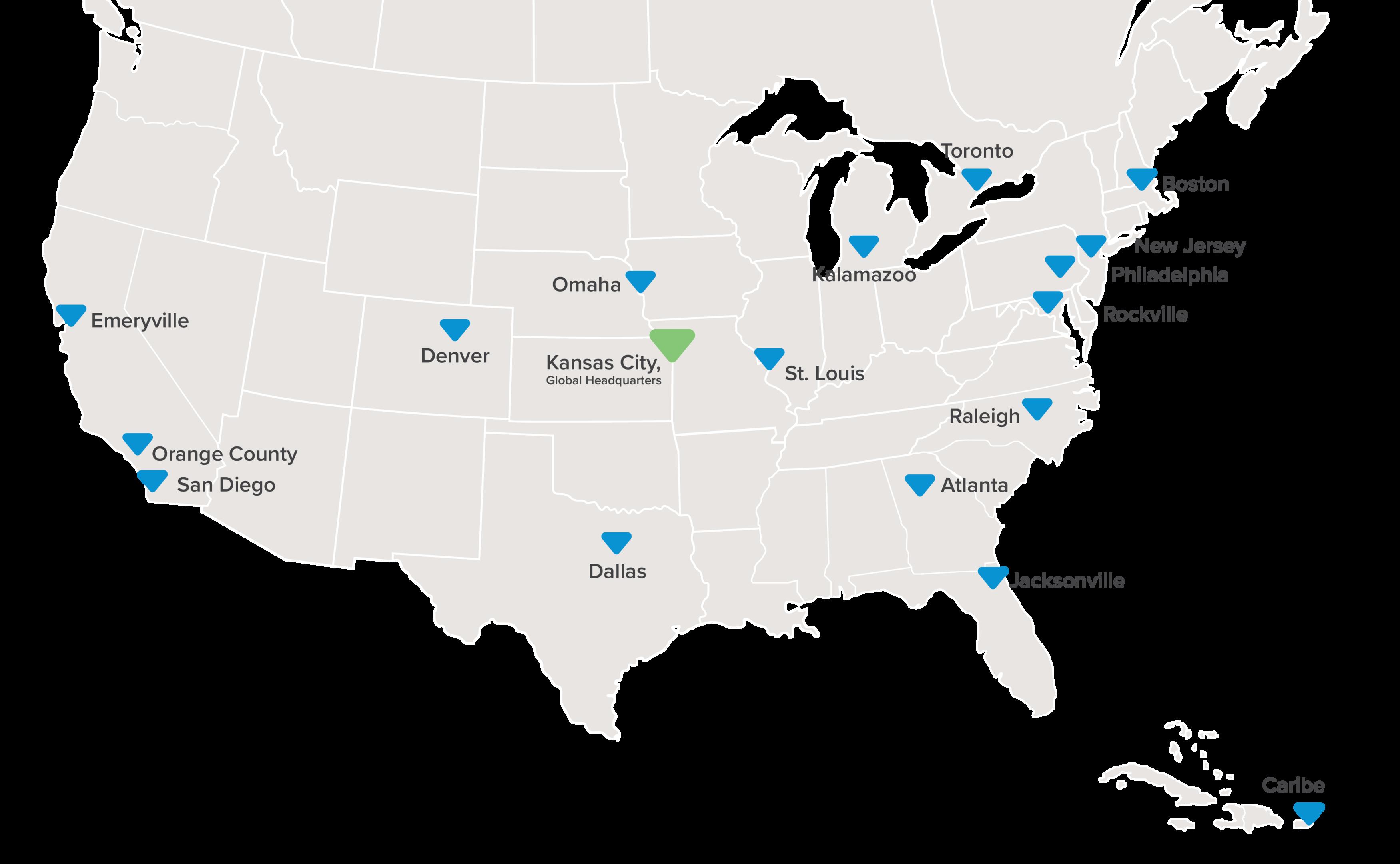

20 OFFICES

1300+ EMPLOYEES

PROJECTS IN 38+ COUNTRIES

30+ LEED CERTIFIED PROJECTS

6.5+ MILLION SAFE HOURS WORKED

OVERVIEW

3

Your partner through all phases Plan Design

Facility Network

Strategic facility planning

Sustainability services

Data management strategy

Control systems philosophy

Warehousing and logistics

Operations & Manufacturing

Process evaluations and simulations

Go-to-market product strategy

System debottlenecking

Compliance and regulatory

Food safety plans

Business case development

Conceptual to Detailed

Facility programming

Utility analysis

Operational technology (OT)

networks

Intelligent piping and instrumentation diagrams (P&IDs)

3D modeling

BIM/data centric documentation

Piping isometrics

Simulations for validation

Pre-construction

Program & project management

Estimating & budgeting

Scheduling

Value engineering

Life cycle costing

Construction planning

SERVICES

4

Improve Commission Build

Procurement

Specifications and standards

Bid leveling and negotiations

Submittal and change management

Factory acceptance testing (FAT)

Control panel design and construction

User acceptance testing (UAT)

Manufacturing equipment systems (MES) integration

Construction

Trade coordination

Conflict management

Cost control

Quality control

Safety and security management

Startup

Site acceptance testing (SAT)

Controls integration

Programming and tuning

System testing

Commissioning planning

FDA filings and Thermal Process Authority Service Turnover

Documentation, enhanced turnover package (ETOP)

Operator training

Support through first saleable product

Infrastructure Optimization

Operations improvement

Digital maturity assessments and roadmaps

Advanced analytics, AI/ML

Control systems support and upgrades

Facility, process, and food safety audits

Sustainability optimization

5

CRB has cultivated a dedicated roster of specialists focused on your markets.

Plant-based/ Cell-based

MARKETS

Precision

Fermentation

Ingredients 6

Baking & Snack

Nutraceuticals Beverage Confectionery Consumer Products Dairy Pet Food Dressings & Sauces RTE/Prepared Foods 7

THOUGHT LEADERS

Our team is comprised of some of the brightest minds in the industry, all of whom offer a comprehensive understanding of the intricacies of your operating environment and the complexity of your industry. This team’s sole focus is bringing the right solutions to every stage of every project.

Jerry Steenhoek Senior Director, Automation Technology

Pablo Coronel, Ph.D. Senior Fellow, Food Processing & Food Safety, Regulatory

Renee Benson Senior Packaging Engineer

Matthew Beier Senior Process Engineer

THOUGHT LEADERS

8

Niranjan Kulkarni, Ph.D. Senior Director, Operations Improvement

Sydney Hamilton Strategic Facility Planner

Dennis Collins, AIA Architectural Group Leader

HORIZONS REPORTS

Chuck Brawley Senior Director, Construction Operations

CRB’s Horizons reports pool the talents and expertise of our leading subject matter experts to understand the conditions and forces affecting the food and beverage industry. Based on hundreds of surveys of industry leaders, our reports go deep on the critical trends driving the market and how companies can stay on the leading edge.

9

10

Integrated solutions for safe, high-quality, value-driven facilities that fuel your growth and success.

Scale up production or expand and improve a largescale operation. No matter your size or goals, you need an adaptable facility that quickly responds to consumers’ constantly changing tastes and meets increasingly strict regulatory standards.

We’ll design, construct, automate or consult to provide a solution that will help you:

• Increase production rates

• Optimize energy efficiency

• Improve speed to market

• Achieve food safety compliance

Have confidence in your project knowing that we understand the intricacies of your operating environment and the complexity of the food and beverage industry. From planning to production, you’ll get a safe facility that meets your budget and requirements, minimizes long-term operating costs and maximizes your return on investment.

FOOD + BEVERAGE

11

ONEsolution™: DELIVERED.

An Integrated Project Delivery Method for Regulated Facilities

ONEsolution is an integrated project delivery method that leverages the combined expertise and technical excellence of ONE project team to deliver your facility in a safe, lean and collaborative way.

ONEsolution aligns stakeholders on quality, cost and schedule, providing you with everything you need from initial planning through operational readiness.

Cost. Quality. Schedule. Pick three.

You know the old saying. “Cost, quality, or schedule. You can only pick two.” We’re throwing that out the window and disrupting the current state of the construction industry.

"We needed an engineering and construction partner who understood the specialized world of pet food. That's why we landed with CRB.”

Mark Sailer, Director of Engineering, KLN Family Brands (parent company of Tuffy’s Treats Company)

ONEsolution™

12

TUFFY'S TREAT COMPANY

Delano, Minnesota

Tuffy’s challenged CRB to design a facility to efficiently accommodate a range of contract manufacturing clients, while prioritizing product quality and safety to a degree not typically seen in the industry.

CRB’s ONEsolution team worked collaboratively with the client to leverage several core ONEsolution functions, including early team integration, project chartering, parallel design and construction activities, and zero-based scope and target value delivery.

Backed by these tools, our team delivered the advanced, hyper-flexible facility that Tuffy’s required, on their schedule—for $800,000 less than expected.

The completed facility, which is capable of manufacturing 9,000 pounds of semi-moist treats per hour, sets a new standard of flexibility and food safety for pet treat manufacturers worldwide. Its future-proof design will help Tuffy’s continue its upward growth for decades to come.

13

Clean facility design: DELIVERED.

In an industry that is moving toward better and more comprehensive consumer safety, the concept of cleanliness must be foundational — and there's no better place to set that expectation than the facility where your products are created.

Our Solutions

• Over 30 years of experience in clean process and facility design

• Extensive expertise in sustainable design, including LEED accreditation

• Integrated, in-house architects and engineers who can design, procure and deliver customized solutions all the way from design to construction

• Complete understanding of and adherence to HACCP and SQF principles, design and mechanical implications

• Design solutions that fully consider how people, processes and products move throughout the entire facility

Your Success

• Cross-discipline clean design that covers a complete spectrum of your facility requirements, including architecture, electrical, mechanical, plumbing, process engineering, control systems and more

• Clean design expertise that supports new product lines, increasing capacity, changing ingredient mix, automating processes, improving quality, speed or throughput, and more

• A holistic approach that works to ensure every component of your facility meets the highest standards of cleanliness

CLEAN FACILITY DESIGN

14

MARS CHOCOLATE NORTH AMERICA, LLC

Topeka, Kansas

CRB completed all phases of architectural and engineering design for the greenfield confectionery manufacturing facility. While Mars Chocolate North America (MCNA) is a global organization, the new facility is the first MCNA site built in North America in 35 years. Working with MCNA, CRB designed a state-of-the-art facility to meet sustainability goals and achieve LEED Gold certification.

In the completion of this project, we focused on delivering exceptional clean design solutions across every discipline and every aspect of this project. From the piping of liquid processes and handling of dry ingredients to open product conveyance and air handling, every aspect of the plant was designed to be lean and clean. Most tanks, hoppers, storage bins and processing skids were suspended. Where skids could not be supported from above, they were rested on smooth, stainless steel legs.

15

Food safety & regulatory: DELIVERED.

As new regulations put greater responsibility for food safety and quality on manufacturers, it’s critical to have an experienced, knowledgeable partner that can help you seamlessly navigate every important detail of every regulation.

Our Solutions

• Dedicated teams with operating environment experience that focus on food safety, sanitary design and regulatory compliance

• Food safety engineering that embeds safety into every step of every project

• 40 years of experience in clean environments, offering valuable expertise in the design of regulated facilities

• Expertise in allergen segregation and cross-contamination prevention

• Facility audits and food safety program expertise to identify compliance risks and develop a plan to prioritize needs and scheduling.

• Design and construction professionals to help you implement the plan and bring you into compliance

Your Successes

• Holistic approach that promotes food safety and compliance across all disciplines and all stages of a project — from planning to construction

• Clean design approach that can be right-sized for your budget and requirements

• Comprehensive regulatory expertise and support to ensure your facility is designed, constructed and operated to satisfy or surpass requirements

• Facility designed to minimize contamination risk

• Expertise to support your facility after it's operational to address the changing needs of consumers and regulators

FOOD SAFETY & REGULATORY

16

NORTH CAROLINA STATE UNIVERSITY FOOD INNOVATION LAB

The University wanted to create a plant-based food innovation lab built to Current Good Manufacturing Practice (CGMP) standards and regulated by the US Food and Drug Administration (FDA).

CRB provided a ONEsolutionTM execution strategy for the design and construction of the space, which consists of product development, research and quality assurance labs, CGMP rooms, processing areas, collaboration spaces, cold storage and equipment storage.

The result is the North Carolina Food Innovation Lab (NCFIL) which is the only one of its kind in the United States. While there are other university-based food innovation centers, this facility is the only one built to CGMP standards and regulated by the FDA. The lab serves as a hub for food manufacturing advancement, revolutionizing food processing in North Carolina.

17

Control systems integration: DELIVERED.

Eliminate islands of automation while ensuring operational readiness for a timely and successful delivery.

Whether trying to increase production, address labor shortages, resolve quality concerns, improve the agility of your operations or gain better data insights, eliminating silos of automation is essential. Incorporating control systems integration (CSI) into facility design, build, expansion or ongoing plant functionality can help achieve this goal.

Our Solutions

• Plan and determine automation and integration of processing and manufacturing systems

• Coordinate and manage stakeholders and vendors, paving the way for smoother execution

• Program, install and commission processing lines and equipment, to ensure they are fully functional before turnover

Your Successes

• Higher production rates

• Improved project delivery times

• Increase in safety onsite

• Reduced overheads

• Expanded data visibility

• Reduced startup time

• Consistent product quality

• Reallocation of human resources to more valuable tasks

CONTROL SYSTEMS INTEGRATION

18

CONFIDENTIAL CLIENT

REGULATED MANUFACTURING FACILITY

Inclusion of the Control System Integration team during the initial concept design phase delivered significant advancements for a regulated manufacturing facility design project. Control system functional requirements were an essential deliverable during concept development.

This early integration approach provided the team with a well-defined and streamlined pathway toward a fully-integrated project process, from project inception through commissioning and start-up.

19

Speed to market: DELIVERED.

In a market dominated by constantly shifting consumer tastes and market trends, speed is everything. Success often means being first. But more important than being first is being right. We move you and your projects forward by helping you achieve that perfect balance between speed and quality.

Our Solutions

• ONEsolution™ — our comprehensive, single-source solution that:

• Delivers integrated engineering, architecture, construction and consulting services

• Facilitates early collaboration between our planning, design and construction teams

• Maximizes resources

• Optimizes schedules

• Eliminates redundancies

• Streamlines processes

• Reduces project delivery time

Your Successes

• Increased revenue and market share

• Sustained competitive advantage over other manufacturers

• Enhanced ability to quickly meet the needs of consumers with new products

• Increased operating and financial efficiencies

• Improved reputation as an industry leader

SPEED TO MARKET

20

CONFIDENTIAL CLIENT

BAKED GOODS FACILITY

A baked goods client came to us with the need to double their production capacity in an effort to meet a major, immovable deadline. They needed to achieve this while maintaining existing operations, meaning they could only afford complete shutdowns in no more than three- to four-hour increments.

For this ONEsolution™ project, we completed the design and managed equipment recommendations, vendor coordination, equipment installation and construction. Our team developed and delivered creative solutions that fully considered our client’s tight shutdown limits. As a result of this approach, our client was able to meet their deadline and increase production while also maintaining existing operations throughout the entirety of the project.

21

Sustainability: DELIVERED.

Modern food manufacturers are under heightened pressure to transform their operations and space portfolios into beacons of conservation and innovation. CRB's team of sustainability specialists combine business-minded sustainability strategies with specialized knowledge and hands-on experience to help you achieve your sustainability goals.

Our Solutions

• Sustainability roadmaps

• Sustainability charrettes

• Green Building certifications

• Equipment lifecycle utility assessment

• Sustainability solutions matrix

• Carbon reduction strategies

• Energy modeling

• Computational fluid dynamics modeling

• Whole building lifecycle analysis

• Water mapping and optimization

• Operational cost optimization

Your Successes

• CapEx and OpEx savings

• Optimized facilities to maximize energy savings, heat and water recover

• Zero-carbon goals met

• LEED, WELL & Fitwel certification

• Minimize environmental impact

• Conserve resources and create healthier, more resilient environments

• Site-level actions aligned with corporate-level sustainability goals

SUSTAINABILITY

22

MYCOTECHNOLOGY, INC.

MUSHROOM FERMENTATION PRODUCTION PLANT

CRB provided ONEsolutionTM design and construction for the new headquarters and fermentation process plant. The facility is capable of producing 4,000 metric tons of plant-based protein per year. The facility was delivered with sustainability in mind. These efforts were recognized with the award of Food Engineering magazine’s 2020 Sustainable Plant of the Year.

The process re-uses process condensate, wash water and reverse osmosis reject water to feed the cooler, for an estimated water savings of 1.26 million gallons per year. The continuous sterilization unit uses heat recovery for higher efficiency and improved product quality, effectively using 50% of the steam, cooling, and chilled water services as compared to a system without heat recovery.

23

Packaging: DELIVERED.

Your business relies on packaging that protects products and draws consumers’ attention, enabled by a packaging process that runs optimally and consistently. Packaging engineering can unlock business advantages and increase efficiency, cutting straight to your bottom line.

Our Solutions

• Experience with a broad spectrum of packaging line design projects

• Specialized packaging line layout ensuring optimal support for input, output, utilities, and footprint considerations

• Packaging line design consultation services

• Network of vendor relationships that can lead to more tailored solutions

• Clear understanding of requirements for regulated industries

• Simulations developed and customized to identify the most effective solutions

• Packaging R&D: design, testing, and commercialization of primary, secondary, and tertiary packages

Your Successes

• Safe, efficient, and sustainable packaging processes that adapt, grow, and scale with your business

• The ability to introduce new packaging with efficiency and reliability

• Improved speed to market, operating efficiencies and labor costs

• Packaging line solutions that fit your budget and facility requirements

• A packaging approach that makes best use of your facility and the way products and people flow through it

• Innovative packaging designs and processes for improved shelf presence

PACKAGING

24

Winston-Salem, North Carolina

25

HERBALIFE

WM. WRIGLEY JR. COMPANY

Yorkville, Illinois

MARS CHOCOLATE NORTH AMERICA, LLC

Topeka, Kansas

ST. LOUIS BREWERY | SCHLAFLY BEER

Maplewood, Missouri

ROI + improved operating efficiencies: DELIVERED.

In the food and beverage market, every resource matters. It’s why we deploy teams comprised of market experts who specialize in driving continued growth and success by optimizing every step of every process.

Our Solutions

• Metrics-based decision-making focused on maximizing all resources

• Data-driven approach to facility design

• A comprehensive understanding of your operating environment

• Expertise across an extensive range of disciplines

• Unique approach and toolset to analyze operations and cost structure, identify savings opportunities and develop specific plans with forecasted, quantifiable ROI

Your Successes

• Facility tailored to your exact budget and requirements

• Maximized ROI

• Improved flexibility

• Reduced operating costs

• Reduced cost of goods to the consumer

• Process improvements

• Improved labor utilization

ROI

26

CONFIDENTIAL CLIENT

NUTRITIONAL

POWDER MANUFACTURING

UPDATING PRODUCTION SCHEDULE TO INCREASE THROUGHPUT

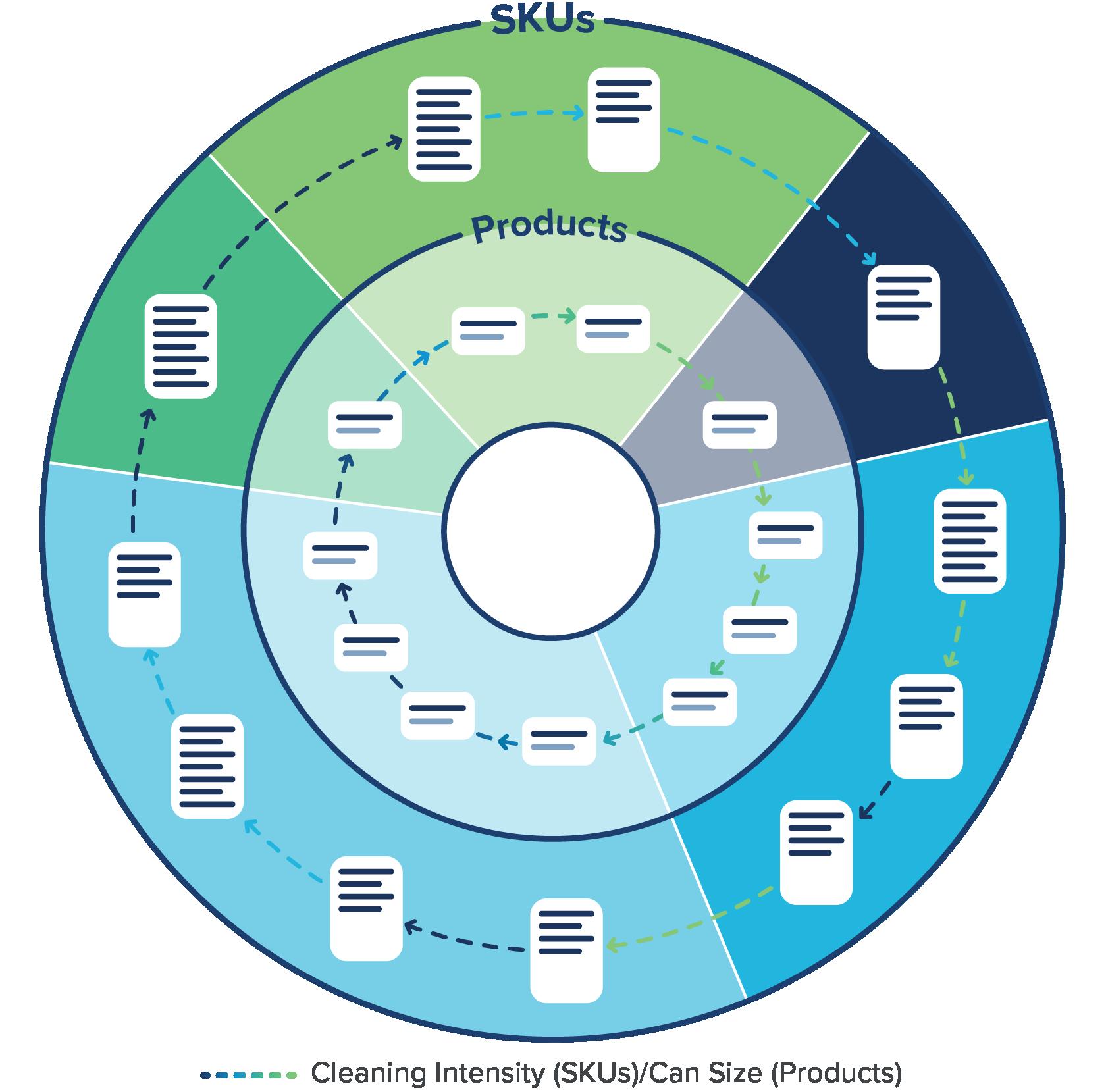

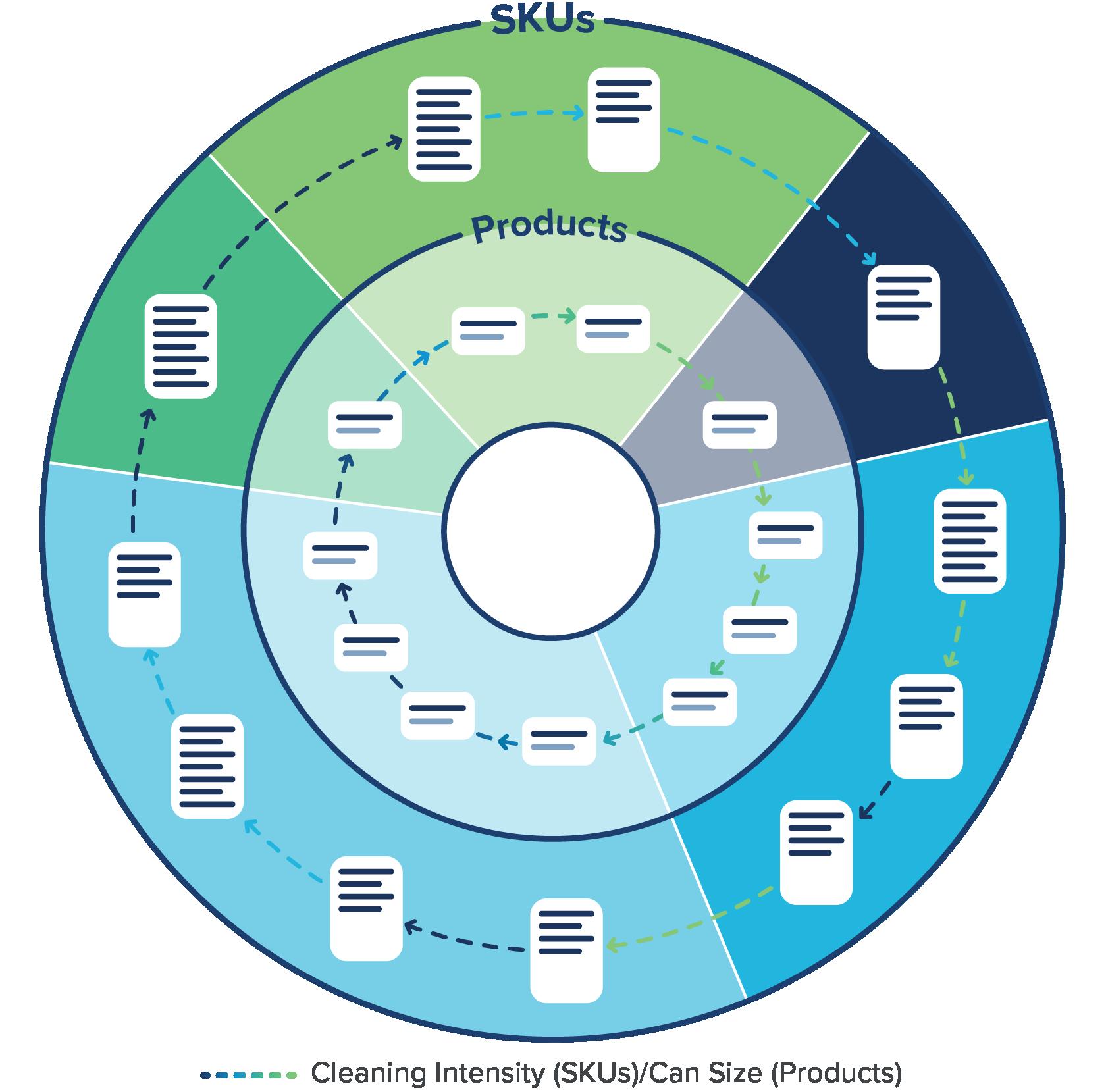

A nutritional powder manufacturer called on CRB operations improvement specialist to update an existing product wheel of over 200 products. Our consulting team's new and more efficient changeover and cleaning schedule resulted with:

• Decreased flushing losses by 40%

• Increased OEE for dryers by 13%

• Increased OEE for packaging line by 8%

• Increased throughput by $9.7 MM annually.

27

CONFIDENTIAL CLIENT

NUTRITION MANUFACTURING

IMPROVING PRODUCTION OPERATIONS, OPTIMIZING LABOR EFFICIENCIES AND REDUCING OPERATING EXPENSES

A nutrition manufacturing company that produces and packages liquid and powder nutritional products asked CRB for a study to improve production efficiencies and reduce operating expenses.

Our operations improvement team conducted a dock-to-dock modeling study, resulting in:

• Site-wide savings of $3.8MM annually

• Headcount reduction for the entire site by 40%

• Cycle time reduction in MH&D procedures by more than 50%

ROI

28

T. MARZETTI

DRESSINGS AND SAUCES MANUFACTURING FACILITY

PROVIDING 30% INCREASE TO PRODUCTION KITCHEN’S WEEKLY THROUGHPUT

CRB was asked by T. Marzetti to increase utilization within an existing facility's manufacturing kitchens. Our consulting team performed an operations study, running multiple operational scenarios to explore potential improvement opportunities. The most significant improvement was realized from adjusting the production schedule. This change could be implemented with no CapEx investment.

This study resulted in:

• More than 20%-point increase in kitchen utilization

• About 30% increase in weekly throughput

29

CLIENTS

Abbott Nutrition

Arbor Brewing Company

Bausch & Lomb Inc.

Bayer AG

BlueTriton Brands Inc.

Boulevard Brewing Co.

Bridgestone Corp.

Campbell's Soup Company

Capstone Nutrition

Cereal Ingredients Inc.

Chiquita Brands LLC

Church & Dwight Co., Inc.

Conagra Brands

Corbion

doTERRA International

DSM

DuPont Nutrition & Health

E. & J. Gallo Winery

Fareva Group

The Folger Coffee Company

Freshpet

Frito-Lay North America, Inc.

General Mills Inc.

Gerber Products Company

Glanbia plc

GlaxoSmithKline plc

Golding Farms Foods, Inc.

Gordon Food Service

Harlan Bakeries, LLC

Herbalife International of America, Inc.

The Hershey Company

Hill’s Pet Nutrition, Inc.

Horseshoe Beverage Co.

Hudson Henry Baking Co.

ICL Group

Illume Candles

Independent Stave Company

J&J Snack Foods Corp.

Johnson & Johnson Services Inc.

Kalsec Inc.

Kemin Industries, Inc.

Kerry Group plc

Keurig Dr Pepper Inc.

Kikkoman Corporation

Klondike Cheese Co.

The Kraft Heinz Company

Land O'Lakes, Inc.

Litehouse Inc.

Mars Chocolate

North America, LLC

Mars Symbioscience

Mary Kay Inc.

Mead Johnson & Company, LLC

Meati Foods

Mondelez International, Inc.

Monsanto Company

Mother Murphy’s Laboratories, Inc.

McCormick & Company

Mountaire Farms

MycoTechnology, Inc.

Nature’s Way Products, LLC

Neways International

North Carolina Food Innovation Center

Ocean Spray

Pearl Valley Farms, Inc.

Pharmavite LLC

Polykon Manufacturing LLC

Post Holdings, Inc.

The Procter & Gamble Co.

R. Torre & Company, Inc.

Reckitt Benckiser Group plc

The Republic of Tea

Rust-Oleum

The Saint Louis Brewery

Simmons Foods, Inc.

Synergy Labs

Trilliant Food and Nutrition, LLC.

Tuffy's Treat Company

Unilever

Upside Foods

Uptown Bakeries

USANA Health Sciences

Visalia Dairy Company

Walden Farms LLC

WellPet LLC

Wildtype

Wixon, Inc.

Wm. Wrigley Jr. Company

Yamco LLC

CLIENTS

30

WHAT OUR CLIENTS ARE SAYING

"The team at CRB delivered a facility design that met all of our expectations. The ease of collaboration with CRB enabled us to overcome difficult requirements that resulted in setting industry benchmarks in clean manufacturing design.”

— Site Engineering Manager | Mars Chocolate North America

"This was a ‘non-standard’ application, and CRB’s thought process was innovative in terms of material handling and dealing with multiple equipment vendors in a concerted fashion.”

— Director of Operations | Kemin

"Our selection and use of CRB has proven to be the key element of success in our basis of design project. The CRB group is a unique blend of talents in academic knowledge, experience and creativity. Each team member is resourceful and qualified, yet at the same time highly participative in soliciting ideas and inputs on project elements and alternatives. Their approach has been to provide extensive knowledge and experience overlaid with a very strong customer service mentality. It has been refreshing to work with a group of such capacity, responsiveness and professionalism.”

— Vice President, Quality Systems/Project Director | Confidential Client

31

THE RELENTLESS PURSUIT OF SUCCESS. YOURS.TM

crbgroup.com