February 2024

Hello, and welcome to the February Edition of Supplyline. This is the first edition for 2024.

We continue in this edition with regular updates relating to Industry Standards, Sterilising Technology Course information, and this year’s conference. Plus, this year it is the NZSSA’s 50th Anniversary. To celebrate this huge achievement, it was decided by the NZSSA Executive to change the NZSSA Logo to reflect this amazing milestone. This new logo will be in circulation for this year only and you can see it on the front cover of this edition of Supplyline.

Planning for this year’s conference is well underway. A conference venue has been chosen, which is the Aotea Centre in Auckland’s CBD. The conference committee along with MTANZ are very keen to put together a very exciting and informative conference for all attendees this year. If there is anything you would like to see included in this year’s conference, please let one of the conference organisers know.

Welcome to the first edition of Supplyline for 2024.

I hope that you have all managed to have some form of leave over the summer period in order to relax and recharge your batteries. I have just completed two weeks annual leave. The first week I decided to clear our cupboards etc. more of a summer clean than a spring clean. For the second week I decided to go off grid in the Wairarapa and just relax and catch up on reading that I wanted to do. If any of you like factual books I recommend that you try Bill Bryson’s “The Body- a Guide for Occupants”.

Anyway the break is over and it is back to the coal face. I hope that by now you or your department have purchased your copy of the new standard AS5369:2003. It has been the official standard since 15 December 2023. There is an official communication from the Ministry of Health regarding the new standard which I put on our NZSSA website. A copy of the communication letter is in this Supplyline for your reference.

Work is about to ramp up again on the requirements that we as a profession need to upgrade to satisfy the Ministry of Health that we are a profession. There is a lot of work and time involved in this.

There are a number of articles in this edition, covering a wide range of topics. Also included are two reports from members who attended the WFHSS World Congress in 2023. It is an exciting event to go to, wherever it is held in the world. I’ve been to two World Congresses over the years, and both were exciting and huge. The first was in London, England; the second in Brisbane, Australia. There are lots more trade displays at the World Congress that what we see at our own conferences and the products on display are usually new and exciting. If you ever get the opportunity to attend a World Congress, then go, you won’t regret it.

Take care everyone and stay safe,

Ngā mihi

Aileen Derby Editor NZSSA Supplyline2024 is a big year for the association. This is the 50th year of our being even though it is only our 48th actual conference thanks to Covid. The executive conference team of Sharon, Aileen and Anthony along with Britta from MTANZ are working very hard to bring you a very exciting conference this year in Auckland to celebrate or 50th Anniversary. Please be sure to register as early as possible as you don’t want to miss this one.

Last October I attended the WFHSS conference in Brussels, Belgium. I was joined there by our international scholarship winner Donna Dador from Southern Cross Hospital Christchurch. You can read my words on the conference in this edition of Supplyline.

As always feel free to contact me.

Shelagh Thomas President/NZSSAWe care for each other, showing kindness and empathy in all that we do.

We are committed to finding future focused solutions and take personal responsibility to be better every day.

Our diversity is our strength, we back each other and work together in partnership.

We are committed to doing the right thing by ensuring equity and hauora are at the heart of everything we do.

Here are some comments made by last year’s delegates.

“It was my first NZSSA Conference and I had a blast over the three days! I learned a lot and got to meet some wonderful colleagues. Te Papa was a great venue, and I really enjoyed the ‘Movie Night’ conference dinner.”

“Loved the venue. Enjoyed the presentations. Good speakers.”

“A well-organised event by all at NZSSA, you all deserve a round of applause!!! Thanks so much for a brilliant conference.”

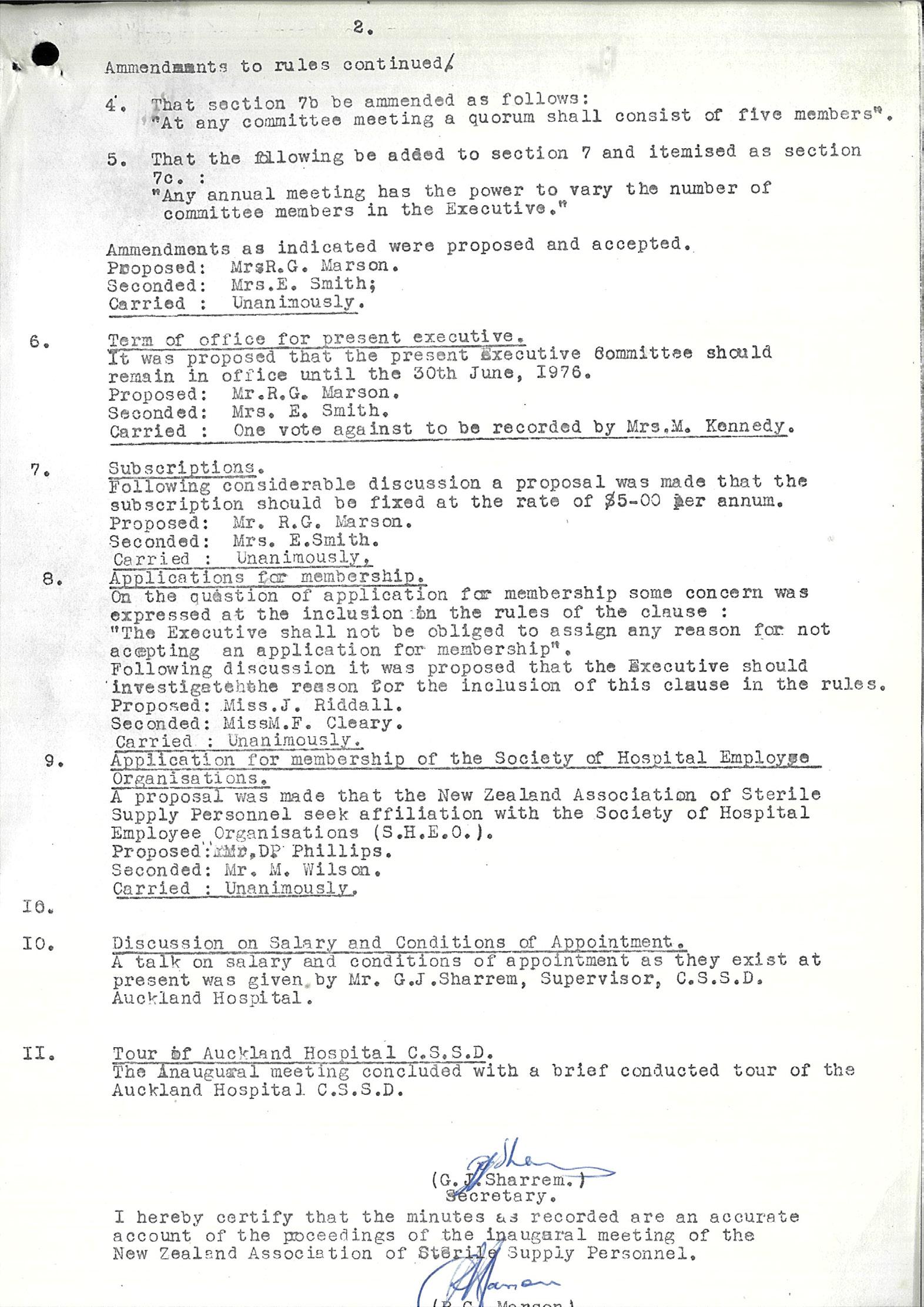

First, I would like to thank NZSSA for the scholarship that has unlocked a lot of doors and led me to envision a bigger and better SSD environment. I have attended several seminars and conferences in the past and it just keeps getting better each time. This was my first world conference, so that makes it more exciting and something that will stay in my memory for a long time. Everything was an experience, from the time I got the result from the NZSSA secretary Mr. Paul Moody, whom I have to say was amazing, organize and very good when it comes to communication and answering all my queries even before I’ve submitted my application, I have to say, (the best person for the role).The experience continued on, sorting all my documents, itineraries, informing my Southern Cross family about the news, to completing the whole conference with a bonus of visits to other nearby European countries near Belgium.

A little something about me, I was a registered nurse in the Philippines, worked in delivery nursing for 2 years then moved to Singapore and worked as a sterile supplies technician back in 2010, moved up and became SSD Team Leader and hold that position until I left, back in June 2015 to come here in New Zealand to study and work. I have to say it was never easy moving from one place to another, it is hard to leave people, your team has become your family as you tend to work together longer than any other activities that you do. Also because of adapting, learning, and understanding different standards, guidelines, work environment & Working in Health care in 3 different countries with different standards equips me with a lot of lifelong experience and thoughts

about the system and its processes. So, when I have heard about the conference, I was like, “Oh, I want to see, learn and experience how they do it in other parts of the world too” and what better way to do that than to attend a world conference such as WFHSS. I know it is a long shot because I know there are a lot of SSD technicians that are also aspiring to be part of that conference but hey, this just proves there is no dream too big or a goal too impossible if you put your heart and mind in it. So, I packed my bags and got on with my little adventure (This will be my first time travelling solo too) So you see, there are a lot of first times with this trip so, yeah let’s carry on with my little story.

From here to Brussels, it is about 24hrs flight, and I arrived there on a Tuesday Morning, I had met NZSSA president Shelagh Thomas personally for the first time, in the hotel reception. I had heard and read a lot of good things about Shelagh and her work but of course it is always better to meet people live and in action to get to know them better, true enough she is such a wonderful, down-to-earth, and truly knowledgeable person. I felt privileged to attend this conference with her.

The conference did not start until Wednesday 18th October 2023. So that Tuesday as soon as I put my bag down, I went to see some places in Belgium, maximizing my time, I wandered around Brugge and took a quick look at Antwerp the following day before the start of the conference as the registration was not until 3pm on Wednesday.

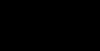

The conference was held in the Mont des Arts Convention center in Brussels, Belgium. There were 1,648 registered attendees at the conference. The venue was well thought out as it was in central Brussels, within walking distance of most of the tourist attractions, hotels, and train station. The first day was for the registration as well as the start of the set up for most of the stalls. I enjoyed seeing new developments with products and new innovations from different companies. I saw equipment that I have not seen before and probably will not have known the existence of unless I searched for it or saw it from other hospitals, such as the flexible inspection scope from LTA medical that allows you to check

and inspect rigid/lumen/cannulated instruments as small as 1.3mm that will show up on the screen. I also saw in action a wrapping robot which was cool. Another one that stood out to me was the Safeclean box from Bicarmed, it is medical equipment that basically acts like a washer cleaning tool that uses low pressure compressed air and sodium bicarbonate, the intention of this equipment is really good as it revolves around operator/ssd tech safety, good for the environment as it is biodegradable and it helps lengthen the instruments life span and reduce maintenance cost due to its claim of removing biofilm effectively reducing chances of oxidation, my concern is just the amount of time it will take the technician to do all the instruments and possible strain that it may cause on their back, so it might be another story for me. These along with other interesting discoveries and product improvements made me really realize the possibilities are just endless. You just must go out there and explore. Now, enough of that amazing equipment and innovations, moving on to the conference discussion itself, I find it innovative and tech savvy. To start with, the venue was amazing, very conducive for learning. It was my first time attending a conference with a live translator that was translating to 3 different languages which are English, German and French. You are wearing a headset to select the translation that you desire.

Here are the topics that have stood up for me, first is sustainability, this was titled “Hospital mining: The CSSD and OR as goldmine for new raw materials in the circular economy “in which they have presented the ways they are sorting the materials that we use in the operating room, segregating them, recycling them and transforming them giving them new life in different ways. That presentation in sustainability have open my eyes entirely of the things we could have done to do something, nothing is too small or too little if everyone is doing it. I know we already have sustainability initiative across the Southern Cross network and as soon as I got back, I have list down the things that we could do in our department to be involved and be active in the sustainability drive such as printing all our checklist back-to-back as we currently do not do this, it was never too late to start something good.

Another presentation that I liked and totally made sense to me was about the reduction of instruments in circulation. This includes optimization of the sets; it means that instruments in sets should be reviewed from time to time to ensure that they are still fit for their purpose and that no extra instruments sit in the set that ends up not being used all the time. It also consists of modernization and standardization of sets and instruments as well proper calculation of ideal back up / extra sets that we should have. This requires the support of key people in the theatre and the management team. The reduction of instruments in circulation directly impacts SSD efficiency and it also has an impact on cost of reprocessing, maintenance and life span of an instrument too.

It was also good to see the new purposely built facility in the US, where they have use state of the art technology, especially with their washers where instruments are automatically unloaded and delivered to different packing stations, and

it was quite interesting to know how much it has improved their manpower efficiency as evidence by the data that they have provided which shows decrease in staff sickness and promote efficiency.

I have only mentioned three topics here, because I might consume the whole newsletter haha. Kidding aside, the rest of the presentation are equally impressive and relevant, and I promise there was not a time that I doze of ��.I also want to acknowledge one of the best speakers I have ever listened too, whom is now my friend, and she is Belgian, her name is Hannah Siwe, her presentation was an investigation about a UVC LED device for medical devices where she explained one of the reasons for choosing LED over mercury lamp in re processing as LEDs allow for wavelength control. The wavelength control is because LED’s are available in wavelengths so you have a selection to choose from, for example 265, 270, 280 and so forth, whereas mercury lamps are generally either broad spectrum or 254nm peak. And the fact that these lamps contain mercury is also a big disadvantage personally. Her presentation was phenomenal as the delivery was exemplary.

Aside from all the learnings, product samples and amazing food, I am thankful for all the connections and new friends that I’ve made in that conference. I would like to acknowledge Shelagh Thomas NZSSA president and David Bellamy, president of FSRACA (Australia) for guiding me through and ensuring that i am not lost as well as keeping me company most of the time. And oh, I have to say, we did have some party too as there was a conference gala night which was held at Auto world Brussels, the ambiance, the welcome exhibition, the band, everything was perfection! I’m thankful for all the experience.

I really appreciate all the people that have made this journey of mine possible especially for my Southern Cross family and my CSSD team for all the love and support.

You want to know why this is my best trip yet? Aside from this is the first time I have attended a world conference this big, and this was my first time travelling by myself. This was also my first time going to Europe. So, after exploring few places in Belgium such as Brussels, Brugge, Antwerp and Ghent, I continued and went to few other countries just like what I have mention earlier, I took the train and went to Paris, France toured around and saw the magnificent Eiffel tower, eat some macaroons and have a glimpse of that famous Monalisa. Then took the train to Switzerland and be mesmerized by their beautiful landscapes and picture worthy mountains among others and that magical train ride from Chur to Tirano. For my last stop, I took the train from Tirano to Rome wherein I was able to tick one of my bucket lists, which was to come and see and feel the mighty Colosseum, since I was little girl and up to this time, I was always fascinated by its structure and its history, and this trip has made it all possible.

So, from the bottom of my heart. Thank you NZSSA.

Donna Dador Southern Cross Hospital

Reprocessing of medical devices with special reference to CreutzfeldtJakob disease and its variant: A review 20 years after the report of the German vCJD Task Force

M. Beekes1, M. Thanheiser 2, I. Zerr 3, M. Mielke 4

1 Prion and Prionoid Research Unit, Division ZBS 6 - Proteomics and Spektroscopy, Robert Koch-Institute, Nordufer 20 13353 Berlin, Germany; 2 Division 14 – Applied Infection Control and Hospital Hyiene, Robert Koch-Institute, Nordufer 20 13353 Berlin, Germany; 3 Clinical Dementia Center and National Reference Center for CJD Surveillance, University Medical Center, Robert-Koch-Str. 40, 37075 Göttingen, Germany; 4 Department 1 – Infectious Diseases, Robert Koch-Institute, Nordufer 20, 13353 Berlin, Germany

Preliminary remark

Over the past years, the Robert Koch Institute (RKI) has published various original and review articles on the risk and prevention of iatrogenic transmission of classic and, above all, variant CreutzfeldtJakob disease. In particular, two of these review articles, the first of which was published in the immediate context of the vCJD Task Force report (Beekes et al. Der Internist 2002; 43: 738–748) in terms of content and time, and the second as an (interim) review eight years later (Beekes M. Bundesgesundheitsblatt – Gesundheitsforschung – Gesundheitsschutz 2010; 53: 597–605), served as the basis for a new review now 20 years after publication of the vCJD Task Force report. To mark that date, this paper is now intended as a synthesis and update for the readership, which presumably has changed significantly over the course of the recent years. We have incorporated into the present paper from the aforementioned publications several text passages that did not need any changes. General reference will be made here to these text passages from our previous publications since they were not individually marked or referenced.

Abstract

The novel emergence of variant CreutzfeldtJakob disease (vCJD) in the United Kingdom in 1995/96 as a result of the transmission of bovine spongiform encephalopathy (BSE) agents from cattle to humans triggered a previously unprecedented crisis in Europe at the interface of animal health and human public health. This prompted Germany to reconsider, among other things, the practice of reprocessing medical devices with regard to the unconventional BSE/ vCJD pathogens, socalled prions (from “proteinaceous infectious particles”).

Keywords

Creutzfeldt-Jakob disease vCJD Task Force vCJD medical device reprocessing

In 2002, a vCJD task force set up with this objective presented recommendations for minimizing/reducing the risk of vCJD transmission through surgical instruments and other medical devices. According to these recommendations, routine reprocessing should combine at least two procedures that are also (at least partially) suitable for decontamination/inactivation of these pathogens if there is no identifiable risk of contamination with prions. In practice, this includes in particular careful cleaning (decontamination), preferably with alkaline detergents, and subsequent sterilization with moist heat (“steam sterilization”) at 134 °C with a holding time of 5 minutes. The validation of the processes is of great importance. From today’s point of view, the central recommendations of the vCJD Task Force for medical device reprocessing have

Review

Corresponding author:

PD Dr. Michael Beekes

Prion and Prionoid Research Unit

Division ZBS 6 – Proteomics and Spektroscopy

Robert Koch-Institute Nordufer 20 13353 Berlin, Germany

BeekesM@rki.de

Conflict of interest:

All authors confirm that there is no conflict of interest according to the guidelines of the International Committee of Medical Journal editors (ICMJE).

Citation: Beekes M, Thanheiser M, Zerr I, Mielke M. Reprocessing of medical devices with special reference to Creutzfeldt-Jakob disease and its variant: A review 20 years after the report of the German vCJD Task Force. Zentr Steril 2023; 31 (3): 145–158.

Manuscript data:

Submitted: 28 September 2022; revised version accepted: 19 December 2022 (Reprinted from Hyg Med 1-2/2023)

Zentralsterilization | Volume 31 | 3/2023 145

proven to be sustainable with good practicability. The effectiveness of the recommended measures against prions has been confirmed on a broad basis in numerous studies. In line with the paradigmatically high demands that prions place on hygiene in the reprocessing of medical devices, this effectiveness in practice extends simultaneously to conventional pathogens such as bacteria, viruses or fungi. In perspective, this also applies at least in part to potential new challenges, such as those that have been discussed for some time with regard to selfreplicating protein particles of Alzheimer’s or Parkinson’s disease and other protein aggregation diseases.

In 1995/96, the emergence of a novel type of CreutzfeldtJakob disease (CJD) was observed among unusually young patients in the United Kingdom (UK). This human disease, which would later be designated as variant CreutzfeldtJakob disease (vCJD), differed significantly in terms of its aetiology, pathophysiology and clinical manifestations from the classic forms of CJD, constituting a novel independent disease within the group of transmissible spongiform encephalopathies (TSEs) or prion diseases. It was caused by infection with the agent of bovine spongiform encephalopathy (BSE), which was chiefly transmitted through contaminated food. BSE had been observed in cattle in the UK for the first time some 10 years earlier and subsequently assumed epidemic proportions. Against that background, the interspecies transmission of BSE to humans in the form of vCJD made this and other neurodegenerative prion diseases the focus of scientific, political and public health attention, with a severe impact in some cases on agriculture, consumer protection and the healthcare system.

In Germany, the emergence of autochthonous cases of BSE from 2000/2001, coupled with the epidemiological vCJD situation in the UK and other countries at that time as well as the decision in the UK to preferably opt for singleuse devices for those surgical instruments coming into contact with critical (e.g. lymphatic) organs, served as an impetus to review, among other things, the practice of reprocessing medical devices in Germany too. This was done against the backdrop of fears at the

time that the vCJD incubation period was possibly up to 30 years and as a result thousands of vCJD cases could occur in the UK [1]. At the same time, it was expected that vCJD would also emerge in other countries in and outside Europe, while it was still too early to make any sound statements about the further course of vCJD case numbers [2].

An inherent feature of new and crisis events affecting public health is that timely healthpolicy decisions have to be made on the basis of still incomplete data. Furthermore, the long incubation time of prion diseases meant that persons already carrying the causative agent were for a long time not identified with the diagnostic means and methods available, i.e. they could present an “unidentifiable risk” with regard to avoidance of iatrogenic transmission (e.g. through blood, blood products or contaminated surgical instruments). Besides, it was known that the pronounced tenacity of the CJD and vCJD agents called for a special combination of cleaning, disinfection and sterilization measures to minimize or relevantly reduce the risk of iatrogenic or accidental transmission of these diseases in healthcare settings.

At the invitation of the Robert Koch Institute and in collaboration with the scientific board of the German Medical Association (BÄK), a vCJD Task Force was set up to issue specific infection protection recommendations based on incomplete scientific data combined with applied experience. In 2002, this committee then presented recommendations in a report for minimizing the risk of iatrogenic transmission of vCJD through medical devices, especially surgical instruments [3].

At that time, many assumptions on the extent and future evolution of the problem were based on modelling and corresponding projections. Marking the 20 years that have passed since the publication of the vCJD Task Force report, this present article aims to give an overview of the history and the current status of differentiated recommendations for reprocessing medical devices in light of human prion diseases (especially vCJD) in Germany. Special attention will be paid to the recommendations compiled in response to prionrelated issues and which, going beyond the realm of prions, in general lent impetus to the medical device

reprocessing sector, had lasting effects and ideally will also be able to meet new challenges.

Creutzfeldt-Jakob disease and the emergence of its variant as a novel prion disease in humans

The disease that would later be designated as Creutzfeldt-Jakob disease was first described by Hans Creutzfeldt in 1920 and by Alfons Jakob in 1921 – independently of each other – in the scientific literature [4, 5]. Today, a distinction is made between four different types of CJD, which present as neurodegenerative diseases of the central nervous system with varying incidence [6]. These are sporadic, genetically mediated or transmitted types of disease. Most cases, around 85%, occur spontaneously especially in older persons aged between 60 and 70 years (sporadic CJD). Sporadic CJD (sCJD) has a relatively constant global incidence of around 1–2 cases per million inhabitants and year. Some 10–15% of CJD patients develop the disease because of mutations in PRNP, the gene encoding the human prion protein (familial or hereditary CJD), and in a relatively small number of cases the disease is caused by accidental transmission during medical procedures (iatrogenic CJD). In 1995, a hitherto unknown CJD variant (vCJD) which differed from these classic types of CJD was observed in the UK and the following year first described in the literature [7, 8]. vCJD seen predominantly in younger patients (originally observed median age was 29 years [7], current age range 11–74 years [9]) is distinguished from classic CJD by its characteristic aetiology, pathophysiology and clinical manifestations and constitutes a novel independent disease within the group of TSEs.

Classic and variant CreutzfeldtJakob diseases are assigned to the transmissible spongiform encephalopathies because of their transmissibility mediated by a characteristic infectious agent and their specific neuropathological course characterized by the formation of vacuoles in the brain tissue and progressive, partially spongelike degeneration of the brain, as seen under the microscope [10]. Other examples of these diseases in humans are GerstmannSträusslerScheinker (GSS) syndrome and fatal familial insomnia (FFI), both genetically mediated, as well as kuru (acquired).

Kuru is a human TSE transmitted through ritual cannibalism which emerged among the Fore people population group in Papua New Guinea [11]. Today, it is only of historical interest in clinical terms but in a certain sense is paradigmatic for BSE and of considerable information value with regard to vCJD. Since the introduction of epidemiological surveillance for kuru in 1957 around 2,700 cases of the disease have been reported, whereby a total of possibly more than twice as many people were affected because of the kuru epidemic, which had already lasted for a long time beforehand [12]. For a total

population of around 12,000, the mortality rate was as high as 35 deaths per 1000 inhabitants and year [11]. Whereas the mean incubation period in male kuru patients was 3–6 years [11], towards the end of the receding epidemic incubation times thought to exceed 50 years were also observed in isolated cases [13].

In animals, bovine spongiform encephalopathy (BSE), scrapie and chronic wasting disease (CWD) are wellknown examples of TSEs. In all TSEs propagation of the infectious agent occurs predominantly in the central nervous system and following its transmission to a new host the agent

can cause the clinical picture of TSE once again. Neither vaccinations nor effective chemoprophylaxis are available for TSEs. So far, it has not been possible either to treat these always fatal diseases causally.

The unconventional transmissible agent causing TSEs belongs to the pathogen class of infectious prions. Therefore, transmissible spongiform encephalopathies are often also termed prion diseases. According to the widely accepted prion hypothesis [14, 15], prions are infectious protein particles consisting mainly – if not exclusively – of

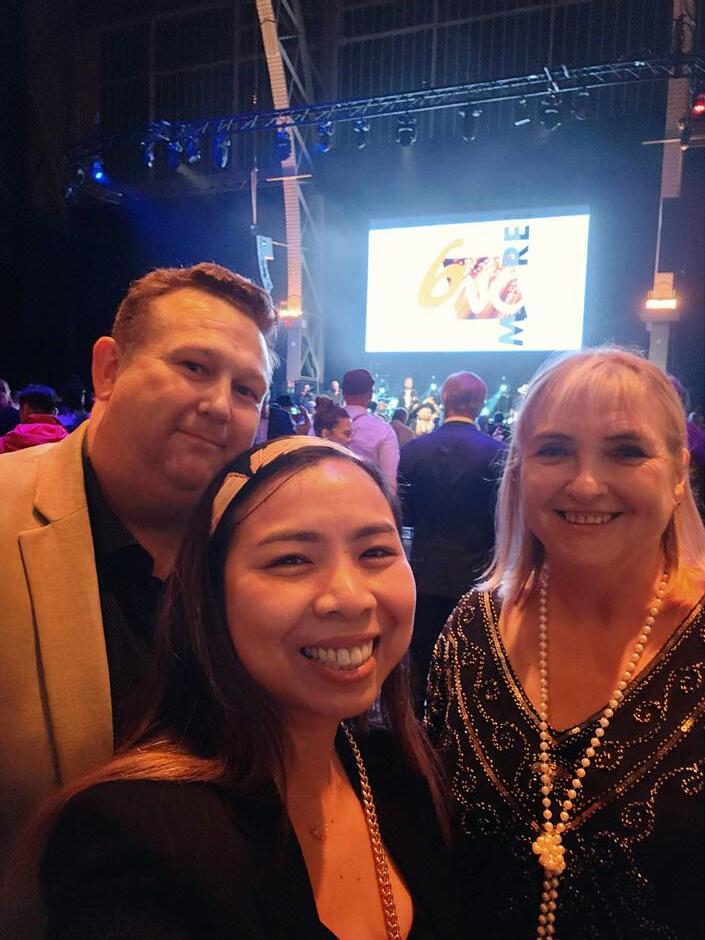

Figure 1: Mechanistic protein folding and aggregation model to explain the occurrence and propagation of infectious nucleation seeds of the prion protein (PrP) in transmissible spongiform encephalopathies (TSE) or prion diseases. Under certain circumstances (usually monomeric) PrP conformers can assemble spontaneously or because of genetic factors into ß-sheet-rich PrP aggregates, giving rise to self-replicating protein particles known as “seeds”. This initial seed formation (primary nucleation) is controlled by a high kinetic barrier. As an example, the primary nucleation of hamster PrP is shown here against a light blue

background, and the aggregation of PrP monomers (1) [123] to a PrPSc seed (2) is schematically illustrated [124, 125]. As soon as PrPSc seeds have been formed endogenously or have entered the body exogenously, they are able to rapidly recruit other PrP monomers and add them to their aggregate structure. During this elongation process the aggregation mass increases by continually adding PrP monomers to the ends of the growing particles. Furthermore, secondary nucleation may occur through the formation of other nucleation sites on the particle surface. When fragmentation of PrP seeds into smaller aggregates occurs,

the progeny seeds enter the replication cycle, expediting propagation of the pathological protein state. This figure was created with modifications based on a template published by Beekes elsewhere ([126]; licensed according to MDPI Open Access Policy. Credits for mounted image components: (1) RCSB Protein Data Bank (PDB) – 4YXL: High-resolution crystal structure of the cellular hamster prion protein (licensed according to PDB Privacy and Usage Policy), and (2) Structure of a hamster scrapie prion ([124]; licensed according to Creative Commons CC0 1.0 Universal (CC0 1.0) Public Domain Dedication).

a misfolded and pathologically aggregated isoform of the host’s own prion protein (PrP) [15]. The cellular prion protein is known as PrPC and its diseaseassociated isoform as PrPSc [15] or PrP TSE [16]. Replication of prions is thought to occur through nucleationdependent polymerization of the prion protein [17 – 19]. According to this concept, prions behave as quasi proteinaceous crystallization seeds that recruit endogenous PrPC and integrate it in misfolded form into their own oligomeric or polymeric aggregate structure. The seeding activity of PrPSc, which can be detected and quantified using sensitive analytical techniques such as protein misfolding cyclic amplification (PMCA) [20] or real-time quaking-induced conversion (RT-QuIC) [21], thus causes autocatalytic propagation of the pathological protein state (Fig. 1). According to that concept, different phenotype characteristics of various prion strains are molecularly encoded by conformational differences in PrPSc [9]. Often, such conformational differences are analysed on Western blot, known as PrPres typing, by studying the molecular weight (Nterminal truncation of the protein) and the glycosylation profile (occupancy of the two asparaginelinked glycosylation sites) of PrPSc after limited proteolytic digestion (generally by proteinase K) [9].

According to the prion concept, onset of familial types of CJD is explained by the fact that inherited mutations in the prion protein gene make the amino acid sequence of PrPC susceptible to structural conversion to the pathogenic isoform PrPSc. Likewise, endogenous misfolded prion protein is thought to be responsible for sporadic CJD. However, other than in familial CJD, the diseaseinducing PrPSc is not caused by a hereditary genetic defect but by a somatic mutation in the PrP gene or by spontaneous structural conversion of PrPC. Finally, acquired forms of CJD are thought to be due to the fact that infectious prion protein enters the body from the outside, for example through the administration of contaminated drugs or during medical procedures conducted with inadequately reprocessed instruments (iatrogenic CJD) or, as was soon suspected in the case of vCJD, through dietary exposure.

According to the current state of research, zoonotic infections with the

BSE agent from cattle are responsible for the vast majority of vCJD cases and the initial emergence of vCJD [8, 22, 23]. According to estimates more than 700,000 infected cattle entered the human food chain [25] in the United Kingdom alone, which was the country first affected by the BSE epidemic. With over 180,000 clinically diseased [24] and around 900,000 infected animals [25], it was also by far the country most severely impacted. Risk materials such as brain and spinal cord as well as separator meat resulting from the processing of spinal cord may have served as a vehicle for transmitting the agent to humans.

As a result, extensive precautionary and protective measures against BSE and its transmission to humans were taken [22, 26]. This has led to a sharp, now almost complete, decline in the number of BSE cases. Therefore, the infection risk presented by BSE to humans appears to be very low or virtually negligible following the effective interruption of infection chains between cattle and from cattle to humans.

However, there are more far-reaching health policy challenges that stem from the possibility of vCJD transmission from person to person (secondary infection) and – as seen already in the past – from iatrogenic and accidental transmission of classic forms of CreutzfeldtJakob disease. But a clear distinction must be made between issues around the potential transmission of, on the one hand, vCJD and, on the other hand, the classic forms of CJD. As regards the latter, various cases of iatrogenic transmission have been reported, albeit only in relatively small numbers [27, 28]. The infection sources and transmission routes implicated in these cases have been identified in the meanwhile and are in principle well under control. Yet, the experiences gleaned from BSE and vCJD, on the other hand, have engendered fears that the hazard potential emanating from the vCJD agent should possibly be deemed to be higher than the largely wellknown risks of transmission of the classic types of CJD.

Before describing in greater detail below the epidemiological situation regarding CJD and vCJD as well as the surveillance and risk assessment of these diseases and their risk management, especially in the context of medical device reprocessing, the clinical and

pathological distinguishing characteristics between CJD and vCJD will be briefly presented.

Variant CJD occurs in unusually young patients, predominantly in the third decade of life. By contrast, classic CJD patients usually develop the disease at a much older age, often in the seventh decade of life or later. The relatively high frequency of vCJD in comparatively young people is thought to be due to agerelated differences in dietary exposure to BSE [29] or to an age-associated increased susceptibility to infection [30]. The median survival time is around 14 months [6], much longer than the 4–7 months observed in the majority of sporadic CJD cases.

The clinical symptoms of vCJD are relatively uniform and are characterized by psychiatric signs of disease such as withdrawal, anxiety, depression and personality changes [31–33]. These symptoms may occur on their own in vCJD or may also be accompanied by various sensory anomalies, such as e.g. joint pain and paresthesia [34]. Additional neurological symptoms appear after around six months. These include visual disorders, progressive ataxia, involuntary movements, such as dystonia, myoclonus and chorea, as well as also progressive deterioration of cognitive abilities [35]. Unlike vCJD, in the classic types of CJD impaired memory and ataxia are often the earliest symptoms of disease [6]. Ultimately, the terminal stage of vCJD is similar to that of patients with sporadic CJD and is often characterized by akinetic mutism.

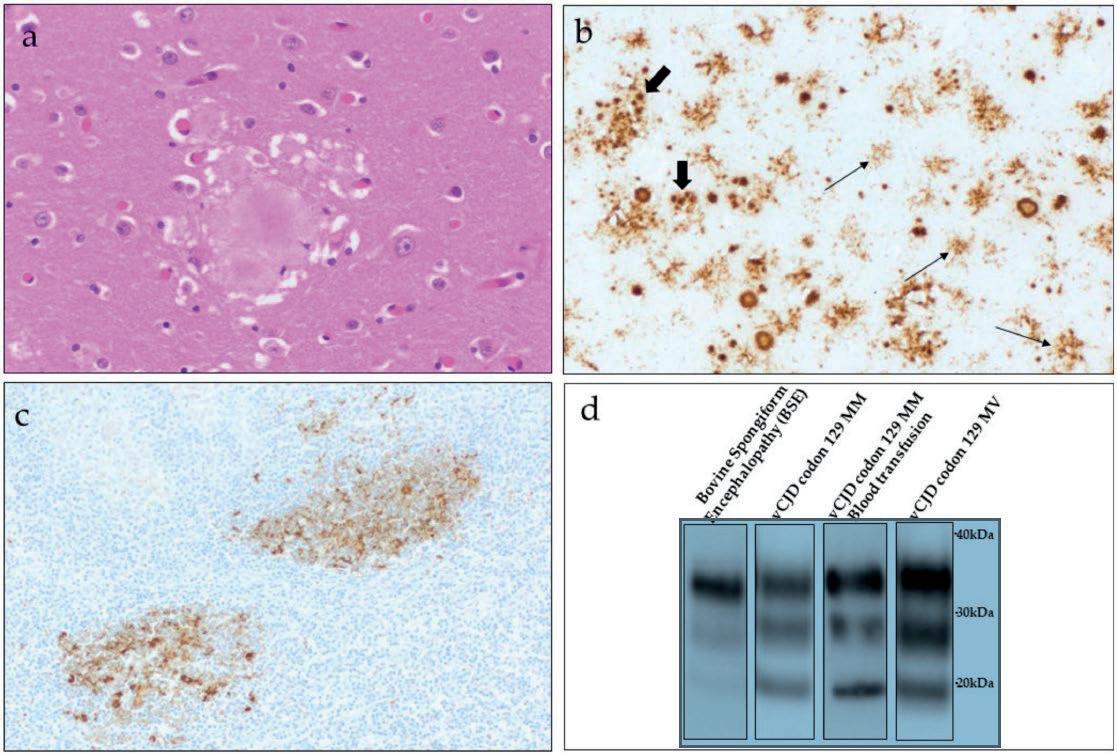

On histology and immunohistochemistry, vCJD exhibits strikingly uniform neuropathological characteristics. This is in marked contrast to the classic forms of CJD, which typically show more pronounced heterogeneity of the pathological phenotype [36, 37]. The most conspicuous characteristic of vCJD is the presence of numerous florid plaques in the cerebral and cerebellar cortex [36] (Fig. 2, a & b). With the exception of type MV2 sporadic CJD, florid plaques are only rarely seen in classic CJD. vCJD differs from classic types of CJD also in that the affected patients have more extensive deposits of PrPSc in peripheral tissues [38–40], particularly in the lymphoreticular system (Fig. 2, c) but, for

example, also in the autonomous and peripheral nervous system. By contrast, the PrPSc deposition pattern in classic CJD is significantly more concentrated in the CNS. However, on using highly sensitive methods in recent times prion infectivity or pathological prion protein and its seeding activity have also been found in the blood plasma [41], olfactory epithelium [42], spleen [43–45], skeletal muscles [44, 46, 47] and skin [47, 48], bone marrow [44, 49], different parts of the eye [50], ganglia of the peripheral nervous system [51] as well as in other peripheral tissues such as e.g. the lungs, liver or kidneys [44, 45, 47] of patients with sporadic types of CJD (sCJD). This should be taken into account in the same way as for vCJD (see below)

when evaluating the potential transmission risks of these forms of disease and formulating corresponding preventive measures, even if the exact correlation between the detection of sCJD prions or their seeding activity and their infectivity to humans has not been conclusively demonstrated so far in high sensitivity bio or in vitro assays.

Finally, the specific PrPres type of vCJD, known as type 2B, serves as a characteristic molecular signature of this disease. PrPres type 2B like PrPres type 2A seen in cases of sporadic CJD is characterized by an unglycosylated fragment size of around 19 kDa, but unlike type 2A has a clear preponderance of the diglycosylated moiety on the electrophoretic band [36, 52] (Fig. 2, d).

Since to date CJD or vCJD can only be definitively diagnosed in autopsy or biopsy CNS tissue samples, in suspected cases of CJD/vCJD a neuropathological examination should be carried out whenever possible to confirm the diagnosis [53].

Risk parameters for person-to-person transmission of vCJD Important risk parameters for personto person transmission of vCJD are the infective power/infectivity and dose of the agent, the incubation time and the time window during which, in particular, unidentified asymptomatic carriers can pass on the infection, the potential modes and routes for transmitting the prion agent as well as the prevalence of pre or subclinically infected carriers (which will be explained in detail at the end of this paper).

The vCJD agent and its characteristics BSE in cattle and vCJD in humans are caused by similar, hitherto not observed, TSE agents known as BSE and vCJD agents [22, 23]. BSE/vCJD prions can be clearly distinguished biologically and biochemically from the causative agents of the classic types of CJD, i.e. sporadic, familial and iatrogenic CreutzfeldtJakob disease [54–57]. BSE prions have caused in the cattle population of the United Kingdom alone an epidemic involving a total of more than 180,000 cases of clinically diseased animals. This seems all the more remarkable since this agent was probably transmitted predominantly via a very inefficient, i.e. peroral, infection route. The infective potential of this new prion strain has also been underlined by its transmission from cattle to humans, whereby the agent was apparently likewise able to breach perorally a, in principle protective, species barrier; that barrier no longer applies in secondary transmission. Accordingly, there is an obvious infection risk to the recipient from transmission of vCJD agents between humans [23].

In patients with clinically manifest vCJD the highest infectious titres or concentrations of PrPSc, serving as a biochemical marker for the infectious agent, are found in the brain, spinal cord and eye. Tonsil and spleen tissues as well as other components of the lymphatic system (lymph nodes, thymus, gutassociated lymphoid tissue) exhibit infectivity and PrPSc less consistently and in lower quantities [58]. Besides, PrPSc has also been detected in parts of the peripheral nervous system, adrenal glands and rectum [59] as well as in the skeletal muscles [58] and in other organs and tissues (liver, pancreas, kidneys, uterus and skin) [60]. As stated in the following section, blood may also contain critical doses of vCJD prions and be able to transmit the disease.

Within what time window can vCJD prions from infected carriers be passed on? No conclusive answer can be given as such to this question because, among other things, the mean incubation period of vCJD is not known. In principle, the incubation time in prion infections depends on various factors such as the agent strain, host species,

agent transmission route, PrP genotype and infectious dose. In analogy to the shortest incubation time observed for iatrogenic CJD following peripheral infection, an incubation period of at least 4.5 years is assumed for primary BSE infection in humans [8]. Presumably, the incubation period is likely to be longer because primary vCJD infection, unlike iatrogenic CJD, must cross a species barrier. Mathematical modelling estimates came to the conclusion that subject to various assumptions, some of which were necessarily uncertain, the mean incubation time for primary vCJD infection in carriers with the methioninehomozygous MM genotype at PRNP codon 129 was about 15 years [30, 61]. In three cases of secondary transmission via nonleukodepleted erythrocytes the incubation times, i.e. the interval between transfusion and onset of vCJD symptoms, were between six and 8.5 years in the transfusion recipients. These were all homozygous for methionine (MM) at codon 129 of the prion protein gene (a known risk modulator for human prion diseases [9]) [62–64]. This genotype – compared with the heterozygous MV or homozygous VV genotype – is apparently associated with increased susceptibility and/or a shorter incubation time for vCJD infection.

Various findings demonstrate that the infectious agent can in principle apparently be passed on by infected carriers already months to years before the onset of symptoms. For example, PrPSc was detected in archived appendix specimens harvested from two patients eight and 24 months before onset of clinically manifest vCJD [40, 65]. Besides, vCJD was apparently transmitted in four cases through blood and in one other case possibly through plasma withdrawn between 17 months and 3.5 years (blood) [62–64, 66] and six months (plasma) before onset of disease in the donor [67].

There is no evidence that vCJD (or CJD) can be transmitted during normal social or nursing contacts or naturally via the air. Rather, disease transmission requires iatrogenic or accidental introduction of the agent into the recipient. Whether the latter will go on to develop infection and how long that takes to progress to clinical vCJD depends

among other factors, apart from the transmitted infectious dose, also on the exposure route. Intracerebral inoculation is the most effective transmission route for prions. The findings from animal models have revealed that the intravenous, intraperitoneal, subcutaneous or peroral routes are around 101, 102, 104 and 105, respectively, times less effective [22, 23].

Because of the relatively early and widespread distribution of the vCJD agent in the body of clinically asymptomatic carriers, there is a potential risk of transmitting this infectious agent during medical procedures through blood and blood products, transplants/grafts, drugs or other materials of human origin as well as through surgical (or dental) instruments and other medical devices. Furthermore, there is a hypothetical occupational infection risk, for example, in hospitals and medical/dental practices, research laboratories, anatomy or pathology departments, forensic medicine as well as in the undertaker sector. Accordingly, extensive recommendations and guidelines have been drawn up at international and national levels to prevent accidental and iatrogenic transmission of vCJD [68, 69]. Advantageously, these are also effective against transmission risks of sporadic CJD or other human types of TSEs.

It goes without saying that the recommended safety measures are not of a static nature, but must be updated and adapted to the respective new situation with advancing scientific knowledge or a change in basic or operational conditions. Careful consideration must always be given to the extent to which protective measures against vCJD could give rise to problems in other areas of the healthcare sector and to whether the expected benefits justify possible or predictable adverse effects and costs. Serving as a basis for evidencebased decisionmaking, research into TSE makes an important contribution to that end.

The following section will now first give an overview of the prevention of healthcare associated (nosocomial) transmission of vCJD and CJD through surgical instruments and other medical devices before presenting the current state of vCJD surveillance and epidemiology.

Reprocessing of surgical instruments and medical devices with regard to CJD/vCJD

The pronounced tenacity of TSE agents calls for specific prophylactic principles as well as a careful choice of cleaning, disinfection and sterilization measures to minimize the risk of iatrogenic or accidental transmission of classic or variant CJD in healthcare settings.

In order to address this challenge and minimize the transmission risks through possibly inadequately reprocessed instruments, the use of disposable instruments was considered in the UK for frequent surgical procedures, and specifically recommended there for tonsillectomies, because of the developing vCJD situation there at that time. However, due to the associated surgical drawbacks as well as the occurrence of, in some cases, severe bleeding following tonsillectomies performed with single-use instruments [70], this did not appear to be a feasible or sustainable option.

In view of their unusual tolerance against conventional cleaning and inactivation processes, prions, and hence also the CJD and vCJD agents, present a special challenge when it comes to reprocessing invasive, especially surgical, instruments and other medical devices [71, 72]. The preventive measures aiming at risk mitigation include, among other things, risk stratification of patients, tissues/organs and the type of medical intervention. They include differentiated guidelines on risk management and specific instructions for medical device reprocessing tailored to the respective risk. In Germany (which to date has had no vCJD case) the vCJD Task Force in 2002 issued precautionary recommendations to minimize the risk of vCJD transmission from medical devices, especially surgical instruments [3].

Recommendations/guidelines for identifiable CJD/vCJD risks

In the vCJD Task Force report previous guidelines for Disinfection and Sterilization of Surgical Instruments for Suspected Creutzfeldt-Jakob Diseases [73] and for Patient Care and Instrument Sterilization for CJD Patients and Suspected CJD Cases [74] were extended to the effect that instruments and other medical devices used for patients with an identifiable risk of vCJD (clinical suspicion of probable or possible vCJD) are in principle

to be disposed of safely as far as practicable. Where neurological diagnosis is inconclusive, instruments and other medical devices should at first be safely quarantined. If disposal presents a special technical and/or economic problem, such as e.g. with flexible endoscopes, it was recommended that equipment pools should be established at appropriate centres for specific procedures carried out on CJD patients. Endoscopes used to that effect are returned afterwards for specific reprocessing. For endoscopes used on vCJD patients reprocessing has not been considered. Further information and contact details can be found at http://www.cjdaufbereitung.unigoettingen.de/

Procedures in cases where there are no identifiable CJD/vCJD risks

In particular, in view of the problem of possibly unidentified vCJD infection, the vCJD Task Force aimed to recommend a generally applicable reprocessing process that counteracted the theoretic risk of transmission from pre or subclinical CJD/vCJD carriers without essentially changing the usual procedure used to reprocess surgical instruments and other medical devices. Furthermore, the recommended processes should take account of potential crosscontamination of instruments during cleaning and also be suitable for heatsensitive (thermolabile) medical devices. According to the statement issued by the vCJD Task Force, surgical instruments and other medical devices should therefore in principle be reprocessed as per the recommendation jointly compiled by the Commission for Hospital Hygiene and Infection Prevention (KRINKO) and the Federal Institute for Drugs and Medical Devices (BfArM ) in November 2001 [75], and combine at least two procedures that are also (at least partially) suitable for decontamination/inactivation of TSE agents. This includes, in particular, thorough cleaning in an alkaline environment followed by sterilization with moist heat (steam sterilization) at 134 °C with a holding time of 5 minutes (the efficacy of this sterilization process was confirmed only recently in a new study for vCJD and sCJD (VV2) prions [76]).

In terms of sustainable and practical implementation, a combination of a) primary decontamination comprising intensive cleaning and b) validated

standardcompliant sterilization appeared more suitable than a mere extension of the sterilization time to 18 minutes.

Updating the recommendations for reprocessing medical devices pursuant to Section 8 (previously Section 4) of the Medical Device Operator Regulation (MPBetreibV)

In 2012, the Recommendation of the Commission for Hospital Hygiene and Infection Prevention (KRINKO) at the Robert Koch Institute (RKI) and of the Federal Institute for Drugs and Medical Devices (BfArM) entitled “Hygiene Requirements for Reprocessing Medical Devices” was fully updated [77]. A key element of this update was that in a new Annex 7 the “Measures for minimization of the transmission risk of (v) CJD through medical devices” were described in specific details. Underlining the statement by the vCJD Task Force, this sets out specific measures that can be applied to an identifiable (or suspected risk) as well as when there is no identifiable risk of (v)CJD. In addition, special measures to be observed when using flexible endoscopes with regard to (v)CJD are presented there separately.

The preventive measures recommended by the KRINKO and BfArM when there is no identifiable risk are met when at least two procedures that are also (at least partially) suitable for decontamination/inactivation of prions are combined [77]. Such processes include e.g. a thorough cleaning process with a demonstrated cleaning efficacy (aimed at reducing the protein load as per the KRINKO and BfArM Recommendation to < 100 µg per medical device) followed by steam sterilization at 134 °C with a holding time of 5 minutes. What is important here is avoidance of thermal or chemical fixation of prion proteins prior to reprocessing. Thorough cleaning is of paramount importance because the efficacy of the subsequent inactivation processes would be jeopardized by prior protein fixation, whereas suitable cleaning processes can greatly reduce the prion contamination load.

A key aspect in light of the KRINKO and BfArM Recommendation relates to appropriate validation of the reprocessing processes. This requirement, which is also legally stipulated in Section 8

MPBetreibV, plays a major role especially with regard to the specific characteristics of prions resulting in their high tolerance against various decontamination/inactivation methods [78, 79]. Apart from the crucial importance of a validated cleaning step targeting prions during reprocessing (see above), sterilization too calls for special care. Based on the current state of knowledge, steam sterilization at 134 °C, as already mentioned above, is an effective prion inactivation method. Other classic steam sterilization processes at 121 °C (and e.g. 15–20 minutes holding time), which are used at times in the healthcare sector, have no or only a slight inactivating effect against the highly temperatureresistant human prions. Even for steam sterilization at a temperature of 134 °C, where already the heat-up phase would suffice to kill or inactivate all bacteria, viruses and fungi, including the spores of the bacterium Geobacillus stearothermophilus which are used at times as bioindicators in steam sterilization, observance of a holding time is prescribed for inactivation of prions [76]. This highlights the practical importance of also providing thermoelectric evidence during validation that throughout the entire holding time of 5 minutes saturated steam at 134 °C can act upon all external and, as applicable, also internal surfaces of the instruments or other medical devices being reprocessed.

In 2004, the RKI published a paper on testing and declaration of suitable processes for the inactivation and removal of prions when reprocessing medical devices [72]. In line with that endeavour, various approaches were taken in recent years aimed at developing new processes and formulations for prionicidal disinfection with improved material compatibility and cleaning performance (to eliminate as far as possible prion contaminations), and also endowed to some extent with activity against bacteria, viruses and fungi, in addition to prions. Recent studies [80, 81] demonstrate that prions are not just a problem but also serve as an excellent paradigm for the reprocessing of surgical instruments and other medical devices. This appears to be all the more significant since good practice stipulates that when reprocessing medical

devices, hygiene requirements be tailored as far as possible to the most resistant pathogens, i.e. the infectious agent most difficult to inactivate or eliminate.

In recent years, the scientific literature has published articles and comments increasingly advocating that, in the interest of preventive patient care, medical device reprocessing processes be designed such that they are also effective against selfreplicating proteinaceous seeds from other protein aggregation diseases, such as e.g. Alzheimer’s or Parkinson’s disease [82–84]. Since the KRINKO and BfArM Recommendation for reprocessing medical devices already ascribes great importance to the removal of protein contamination and at least partial decontamination/ inactivation of prions, it is indeed also addressing this potential new development [85]. The findings of pilot studies suggest various experimental or commercially available detergents and disinfectants, possibly together with subsequent steam sterilization for 5 minutes at 134 °C, are able to reduce by a factor of 100 protein soils consisting of amyloid-β (Aβ), tau and α-synuclein aggregates from Alzheimer’s or Parkinson’s disease from test surfaces of surgical steel [86, 87].

To date, there is no experimental or epidemiological evidence of transmissibility of e.g. Alzheimer’s or Parkinson’s disease by selfreplicating protein particles and, as such, no justification either for any additional specific recommendations for reprocessing medical devices with regard to Aβ, tau or α-synuclein seeds. However, laboratory tests have demonstrated that intracerebrally transmitted inoculates that contained pathological Aβ, tau or α-synuclein aggregates led to stimulation of misfolding and aggregation of endogenous forms of these proteins in the brain of the recipient animals [88–91]. Similar effects have also been detected for Aβ in the meantime in humans who had received dura mater grafts or growth hormone products obtained from deceased donors [83, 92–94]. Whether this could be associated with acceleration of genetically predisposed types of disease or with other adverse health effects below the threshold of full disease transmission is unclear and is being currently under research. Pending further clarification, this speaks in

favour of inactivating or removing as far as possible any potential contamination involving selfreplicating protein seeds also from, what are thought to be, nontransmissible protein aggregation diseases when routinely reprocessing gastroscopes, colonoscopes and other medical instruments.

vCJD today - surveillance and epidemiology

At the time of compiling the Task Force Report, many assumptions on the extent and future development of vCJD were based on modelling and corresponding projections. It is therefore interesting to retrospectively review how the situation actually unfolded over the past 20 years.

Surveillance of human prion diseases

Following the emergence of BSE, human prion diseases have also come into the focus of systematic epidemiological surveillance in the United Kingdom since 1990 in order to be able to detect any changes in their occurrence and presentation as early as possible [95].

In 1993, an international CJD surveillance programme (EUROCJD) was set up with the participation of the following countries: Australia, Germany, Italy, Canada, France, Netherlands, Austria, Switzerland, Slovakia, Spain and United Kingdom); in 1998, this was extended to other countries (Belgium, Denmark, Finland, Greece, Iceland, Israel, Ireland, Norway and Portugal) (NEUROCJD) (http://www.eurocjd. ed.ac.uk). EUROCJD and NEUROCJD, like CJD surveillance in the United Kingdom, were also coordinated by the National CJD Surveillance Unit in Edinburgh. In other countries too, such as the USA and Japan, various forms of systematic surveillance of human TSEs were implemented. In Germany, in compliance with the Infection Protection Act (IfSG), disease and death cases of human spongiform encephalopathy (apart from familial hereditary types) must be reported to the competent Public Health Office. The Robert Koch Institute (RKI) monitors the disease situation on the basis of the reports forwarded from the Public Health Offices. In addition, Germany has a National Reference Centre (NRZ) for the surveillance of CJD (and vCJD). The Prion Research Group at the Department of Neurology of the University Medical Center

of Göttingen (UMG) was designated in 2006 as the National Reference Centre for Transmissible Spongiform Encephalopathies (NRZ-TSE). Its mission is to conduct epidemiological surveillance and research for prion diseases in Germany as well as provide consultation services to German physicians on diagnosis, treatment and infection control/ hygiene measures (http://cjd-goettingen.de/).

Occurrence of vCJD within and outside the United Kingdom

So far, 233 deaths of confirmed or probable vCJD have been reported worldwide [96]: in addition to 178 cases from the United Kingdom, there were 29 other cases from France, five from Spain, four from both Ireland and the USA, three from each the Netherlands and Italy, two from each Portugal and Canada as well as one case each from Saudi Arabia, Japan and Taiwan [97]. In the two cases each from Ireland and

the USA as well as in at least one case from each Canada and Japan it is assumed that the affected patients were exposed to BSE in the United Kingdom in the 1980s or early 1990s. Another patient from the USA is said to have been infected as a child in Saudi Arabia [98].

Figure 3a shows the annual vCJD mortality rate for the UK and France, the countries most affected by the disease. The highest number of deaths per year in the UK was in 2000 with 28 cases and has tended to decrease continuously thereafter. In France, the highest number of cases was observed in 2005 and 2006 (six cases each year). The last vCJD death reported so far from the UK was in 2016 and from France in 2019.

Figure 3b gives the annual number of vCJD cases in the United Kingdom and in the EU (without UK) compared with the course of the number of BSE cases reported there. This highlights how vCJD followed in the wake of BSE.

In Germany, there has so far been no case of vCJD. An overview of the

number of CJD cases in Germany can be found at: http://cjd-goettingen.de/ aktuell/aktuelle-zahlen/

Apart from the vast majority of primary cases of vCJD infections caused by the transmission of BSE from animals to humans, there were in the United Kingdom also four cases of secondary infection through blood as well as one presumed case of secondary transmission through a plasma product. Three of the transfusion recipients developed vCJD [62–64], in both other cases the recipients of transfusion [66] and plasma product (a factor VIII concentrate) [67, 99] died without vCJD symptoms from another cause.

Of the 233 vCJD cases who to date have undergone complete genetic analysis, apart from a single case all were in persons who were homozygous for methionine (MM) at codon 129 of the prion protein gene. The remaining vCJD case was the first pathology-confirmed case of vCJD in the UK in a methionine/valine (MV) heterozygous patient [100]. This rekindled fears of a

Figure 3: (a) Annual deaths from vCJD in the UK and France, the countries most severely affected by the disease, 1993–2022. Reproduced with modifications from: European Creutzfeldt-Jakob Disease Surveillance Network (EuroCJD; https://www.eurocjd.ed.ac. uk/data). (b) Number of annual vCJD cases in the United Kingdom and EU (without UK) compared with the course of the numbers of BSE cases reported from there, 1988–2013. Reproduced with modifications from: European Centre for Disease Prevention and Control (ECDC; https://www.ecdc.europa.eu/en/vcjd/facts).

potential second wave of vCJD in persons with different PRNP codon 129 genotypes. These concerns were further bolstered by the findings from experimental transmission studies in “humanized” transgenic mice, i.e. with different human PRNP codon 129 genotypes (HuMM, HuMV and HuVV). This indicated that all three PRNP codon 129 genotypes exhibit staggered susceptibility to vCJD infection (MM > MV > VV) and that the genotypes MV and VV are possibly associated with longer incubation times [101].

Based on early estimates, which were, however, still fraught with great uncertainties at that time, it was expected that in total there would be some 100 to 80000 (or more) cases of vCJD in the United Kingdom [102].

Based on later calculations, the United Kingdom was expected to have by 2040 between 150 and 6000 cases of primary vCJD infection [103]. In Germany, based on early estimates, which again were fraught with great uncertainties, it was expected there would be by 2040 several 100 (400–600) primary vCJD cases [104]. That figure compared with around 4000 classic CJD cases expected in Germany for the same period of time. Fortunately, the current situation is much more favourable with so far 178 vCJD cases in the UK and no case to date in Germany. Whether the number of cases will increase again in the future, for example in persons with genotypes other than MM at codon 129 of the prion protein gene, cannot be predicted with certainty at present.

Against that background, various more advanced epidemiological studies were carried out in the UK to estimate the likely maximum number of cases of primary vCJD infections expected there as well as the risk of secondary transmission from sub or preclinical infection carriers.

To estimate the prevalence of unidentified possible vCJD carriers in the British population for a more accurate assessment of the risk of secondary vCJD transmission through blood transfusion and, as applicable, other

medical interventions, in a large scale anonymized survey 11,109 appendix specimens obtained during routine appendectomies were examined for pathological prion protein deposition (Appendix study I) [105, 106]. In the absence of a reliable blood test for vCJD, that approach was based on the observation that all the cases of clinically manifest vCJD examined exhibited pronounced abnormal PrP accumulation in lymphoreticular tissues. Examination of the appendix specimens obtained between 1995 and 2000 identified abnormal prion protein deposition in three donors from the birth cohort 1961–1985. If the abnormal PrP accumulation detected in these cases is a reliable indicator for the presence of a pre or subclinical vCJD infection, based on the study the authors estimated the vCJD prevalence in the United Kingdom’s population between 1995 and 2000 would be 237 infections per 1 million inhabitants (95% confidence interval: 49–692 per 1 million), i.e. 1 case per 4000 inhabitants. If one estimates from the study findings the incidence of pre/subclinical vCJD infection in the age group of 10 to 30 year olds (accounting for around 83% of the group sampled), it would be expected that in that group 3,808 persons (95% confidence interval: 785–11.128) were incubating vCJD. Another investigation of initially 63,007 tonsil samples (obtained from elective tonsillectomies performed in England and Scotland between January 2004 and September 2008) did not, however, yield, any confirmed positive results [107].

Noteworthy is that in all the cases of pre or subclinical vCJD infection reported at that time abnormal PrP deposits were found in the appendix (or spleen) but not always in the tonsils. In February 2008, the Spongiform Encephalopathy Advisory Committee (SEAC) issued a statement on the apparently contrasting results (albeit still formally consistent within the confidence intervals) of the appendix vs tonsil study. Based on that, the SEAC viewed the findings of the appendix study conducted by Hilton et al. [105] as being the most robust indicator for the vCJD prevalence [106, 108].

In a second appendix study the appendectomy samples from a larger birth cohort (1940–1981; n = 32,441) were examined (Appendix study II). Sixteen positive samples were found – again

with a wide confidence interval – pointing to a higher vCJD prevalence of 493 per 1 million, or one case per 2000 inhabitants [109]. The findings of the two appendix studies raised additional concerns due to the fact that the positive appendix samples were from patients with all three PRNP codon 129 genotypes [109, 110].

An additional study (Appendix study III), which after interim analysis in 2016 [111] was finally published in March 2020 [112], ultimately confirmed a similar prevalence to that previously seen in the second appendix study. Admittedly, in that study appendix samples were examined from persons presumed to have not come into contact with the BSE agent (i.e. either had their the appendix removed before 1980 and thus prior to the BSE epidemic or were born after 1996, following the introduction of protective measures to interrupt the infection chain via human food). This led the study authors to believe that the UK population may have been exposed to the BSE agent already for a longer time than originally thought or that there is a low prevalence of abnormal PrP in lymphoreticular tissue that is not associated with the manifestation of vCJD.

Kuru and BSE are impressive examples of the ability of prions to cause outbreaks of TSEs of epidemic proportions under certain conditions among humans or animals. At the same time, BSE has cast light on the considerable zoonotic risks that animal prion diseases can present to humans, whereby epidemiologic data from the kuru epidemic indicate that the incubation time of acquired TSE in humans may be more than 50 years.

In that sense, as the BSE situation unfolded there appeared to be an urgent need at that time to take extensive precautionary and protective measures against the transmission of BSE between cattle (as well as to other animal species) and from cattle to humans.

As a result, the infection chains between cattle and from cattle to humans were effectively interrupted, which meant that the human infection risk from BSE is in the meantime deemed to be extremely low. In retrospect, however, it can also be said that because of the initially unidentified BSE spread the

infection chain between cattle and humans was effectively broken only after at least hundreds of thousands, and possibly millions, of persons had already been exposed to the BSE agent. The fact that to date “only” 178 and 233 deaths have been observed in the UK and worldwide, respectively, is very much due to the presence of an apparently strong species barrier [113, 114] that biologically greatly hampered transmission of the BSE agent to humans. At the time of the emergence of the initial vCJD cases, the strength of that protective species barrier was still of course unknown, something that must be borne in mind when assessing the modelbased risk estimates at that time [e.g. 102], which from today’s perspective make the case numbers projected back then appear to be much too high.

There is, of course, no protective species barrer when it comes to transmission of vCJD and other human TSE between humans. Therefore, back then BSE raised fears that unidentfied infection chains between people could in the worst case lead to extremely widespread transmission as seen in BSE itself or kuru. Due to this potential risk, special attention was therefore also paid to comprehensive protective measures for the prevention of secondary vCJD transmission from person to person e.g. through blood and blood products, organs and tissues or contaminated surgical instruments and other medical devices.

Against that background, the vCJD Task Force issued recommendations for reprocessing medical devices with special reference to CreutzfeldtJakob disease and its variant 20 years ago. In doing so, like many other groups involved in vCJD crisis management, it had to in some cases take action in the interest of infection protection already before reliable data were available. Despite these obstacles, from today’s perspective, these key recommendations of the vCJD Task Force for medical device reprocessing have proven to be sustainable with good practicability. The effectveness of the recommended measures against prions have been confirmed on a broad basis in numerous studies (see, for example, original data and referenced sources in: [76, 79, 115–120]). This effectiveness also extends in practice to conventional pathogens such as bacteria, viruses or fungi because of the paradigmatically

high hygiene demands made by prions on medical device reprocessing [80, 81, 121]. Perspectively, this may also apply at least partially to potential new challenges in the form of selfreplicating protein seeds from protein aggregation diseases such as Alzheimer’s or Parkinson’s disease [85, 86, 122].

Whereas the proposed measures of the vCJD Task Force have been widely evaluated and validated in experimental studies for medical device reprocessing, this has partially been done only to a lesser extent for other areas of BSE/ vCJD risk management. In some cases, therefore, there has been a lack of robust data to provide evidencebased answers to critical questions and objections about the necessity, appropriateness, or duration of certain measures to combat and prevent BSE/vCJD. From today’s perspective, accompanying research concepts for systematic evaluation of the manifold measures applied would therefore have been beneficial. This underlines the usefulness of a critical retrospective review of the infection control measures taken at the outset and subsequently also with regard to new, comparable events, in order to be able to readjust as best as possible where necessary and achieve the greatest possible understanding for and acceptance of the respective health policy crisis management.

Parts of this paper have been taken with the kind permission of Springer Nature from the following previous publications: 1) Der Internist. Aspekte zur Risikoabschätzung und Prävention nosokomialer Übertragungen der klassischen und varianten CJK [Aspects on risk assessment and prevention of healthcareassociated (nosocomial) transmission of classic and variant CJD]. M. Beekes, M. Mielke, R. Kurth; Copyright © 2002 Springer. 2) Bundesgesundheitsblatt – Gesundheitsforschung – Gesundheitsschut z. Die variante CreutzfeldtJakob Krankheit (vCJK). [Variant Creutzfeldt-Jakob disease (vCJD)]. M. Beekes; Copyright © 2010 Springer.

1. Europäische Kommission, CORDIS Forschungsergebnisse der EU. In den nächsten 30 Jahren Tausende von vCJKFällen im VK? https://cord

iseuropaeu/article/id/16496 thousandsofvcjdcasesintheukinthenext30 years/de. 2001.

2. Die bovine spongiforme Enzephalopathie (BSE) des Rindes und deren Übertragbarkeit auf den Menschen. Gemeinsame Information des Robert KochInstitutes (RKI), des Bundesinstitutes für gesundheitlichen Verbraucherschutz und Veterinärmedizin (BgVV), des PaulEhrlichInstitutes (PEI), und des Bundesinstitutes für Arzneimittel und Medizinprodukte (BfArM). Bundesgesundheitsbl – Gesundheitsforsch –Gesundheitsschutz. 2001;44:421–431.

3. Die Variante der CreutzfeldtJakobKrankheit (vCJK). Epidemiologie, Erkennung, Diagnostik und Prävention unter besonderer Berücksichtigung der Risikominimierung einer iatrogenen Übertragung durch Medizinprodukte, insbesondere chirurgische Instrumente – Abschlussbericht der Task Force vCJK zu diesem Thema. Bundesgesundheitsbl – Gesundheitsforsch – Gesundheitsschutz. 2002;45:376–394.

4. Creutzfeldt HG. Über eine eigenartige herdförmige Erkrankung des Zentralnervensystems. Z Ges Neurol Psychiat. 1920;57:1–18.

5. Jakob AM. Über eigenartige Erkrankungen des Zentralnervensystems mit bemerkenswertem anatomischem Befunde (Spastische Pseudosklerose – Enzephalomyelopahie mit disseminierten Degenerationsherden). Deutsch Z Nervenheilk. 1921;70:132–146.

6. Watson N, Brandel JP, Green A, Hermann P, Ladogana A, Lindsay T, et al. The importance of ongoing international surveillance for CreutzfeldtJakob disease. Nat Rev Neurol. 2021;17:362–379.

7. Will RG, Ironside JW, Zeidler M, Cousens SN, Estibeiro K, Alperovitch A, et al. A new variant of CreutzfeldtJakob disease in the UK. Lancet. 1996;347:921–925.

8. Will RG, Ironside JW. Portrait of Variant CreutzfeldtJakob disease. In: Hörnlimann B, Riesner D, Kretzschmar H, editors. Prions in humans and animals. Berlin, New York: De Gruyter; 2006. p. 204–209.

9. Ritchie DL, Peden AH, Barria MA. Variant CJD: Reflections a Quarter of a Century on. Pathogens (Basel, Switzerland). 2021;10:1413.

10. Hörnlimann B, Riesner D, Kretzschmar HA, Will RG, MacDiarmid SC, Wells GAH, et al. Historical Introduction. In: Hörnlimann B, Riesner D, Kretzschmar HA, editors. Prions in Humans and Animals. Berlin, New York: de Gruyter; 2006. p. 3–27.

11. Liberski PP, Gajos A, Sikorska B, Lindenbaum S. Kuru, the First Human Prion Disease. Viruses. 2019;11.

12. Hörnlimann B, Alpers MP. Portrait of Kuru. In: Hörnlimann B, Riesner D, Kretzschmar HA, editors. Pr ions in Hu

mans an Animals. Berlin, New York: de Gruyter; 2006. p. 187–194.

13. Collinge J, Whitfield J, McKintosh E, Frosh A, Mead S, Hill AF, et al. A clinical study of kuru patients with long incubation periods at the end of the epidemic in Papua New Guinea. Philos Trans R Soc Lond B Biol Sci. 2008;363:3725–39.

14. Prusiner SB. Novel proteinaceous infectious particles cause scrapie. Science. 1982;216:136–144.

15. Prusiner SB. Prions. Proc Natl Acad Sci USA. 1998;95:13363–83.

16. Brown P, Cervenakova L. A prion lexicon (out of control). Lancet. 2005;365:122.

17. Come JH, Fraser PE, Lansbury PT. A kinetic model for amyloid formation in the prion diseases: importance of seeding. Proc Natl Acad Sci USA. 1993;90:5959–63.

18. Harper JD, Lansbury PT, Jr. Models of amyloid seeding in Alzheimer’s disease and scrapie: mechanistic truths and physiological consequences of the timedependent solubility of amyloid proteins. Annu Rev Biochem. 1997;66:385–407.

19. Soto C. Prion hypothesis: the end of the controversy? Trends Biochem Sci. 2011;36:151–158.

20. Saa P, Cervenakova L. Protein misfolding cyclic amplification (PMCA): Current status and future directions. Virus Res. 2015;207:47–61.

21. Candelise N, Schmitz M, Da Silva Correia SM, Arora AS, VillarPiqué A, Zafar S, et al. Applications of the realtime quakinginduced conversion assay in diagnosis, prion straintyping, drug prescreening and other amyloidopathies. Expert Rev Mol Diagn. 2017;17:897–904.

22. Beekes M, Kurth R. BSE und CreutzfeldtJakob Krankheit – Gesundheitspo litische Bedeutung für die Bundesrepublik Deutschland und Europa. Dtsch Med Wochenschr. 2002;127:335–340.

23. Beekes M, Mielke M, Kurth R. Aspekte zur Risikoabschätzung und Prävention nosokomialer Übertragungen der klassischen und varianten CJK. Internist (Berl). 2002;43:738–748.

24. Hörnlimann B, Ryan JB, MacDiarmid SC. The course of the BSE epidemic –Retrospective epidemiological considerations. In: Hörnlimann B, Riesner D, Kretzschmar HA, editors. Prions in Humans and Animals. Berlin, New York: de Gruyter; 2006. p. 449–463.

25. Anderson RM, Donnelly CA, Ferguson NM, Woolhouse ME, Watt CJ, Udy HJ, et al. Transmission dynamics and epidemiology of BSE in British cattle. Nature. 1996;382:779–788.

26. MacDiarmid SC, Infanger P, Hörnlimann B. BSE Control Internationally recommended approaches. In: Hörnlimann B, Riesner D, Kretzschmar H,

editors. Prions in animals and humans. Berlin, New York: De Gryuter; 2006. p. 620–662920.

27. Uttley L, Carroll C, Wong R, Hilton DA, Stevenson M. CreutzfeldtJakob disease: a systematic review of global incidence, prevalence, infectivity, and incubation. Lancet Infect Dis. 2020;20:e2–e10.

28. Brown P, Preece M, Brandel JP, Sato T, McShane L, Zerr I, et al. Iatrogenic CreutzfeldtJakob disease at the millenium. Neurology. 2000;55:1075–81.

29. Cooper JD, Bird SM. UK dietary exposure to BSE in beef mechanically recovered meat: by birth cohort and gender. J Cancer Epidemiol Prev. 2002;7:59–70.

30. Boëlle PY, Cesbron JY, Valleron AJ. Epidemiological evidence of higher susceptibility to vCJD in the young. BMC Infect Dis. 2004;4:26.

31. Heath CA, Cooper SA, Murray K, Lowman A, Henry C, MacLeod MA, et al. Validation of diagnostic criteria for variant CreutzfeldtJakob disease. Ann Neurol. 2010;67:761–770.

32. Zeidler M, Johnstone EC, Bamber RW, Dickens CM, Fisher CJ, Francis AF, et al. New variant CreutzfeldtJakob disease: psychiatric features. Lancet. 1997;350:908–910.

33. Spencer MD, Knight RS, Will RG. First hundred cases of variant CreutzfeldtJakob disease: retrospective case note review of early psychiatric and neurological features. BMJ. 2002;324:1479–82.

34. Macleod MA, Stewart GE, Zeidler M, Will R, Knight R. Sensory features of variant CreutzfeldtJakob disease. J Neurol. 2002;249:706–711.

35. Zeidler M, Stewart GE, Barraclough CR, Bateman DE, Bates D, Burn DJ, et al. New variant CreutzfeldtJakob disease: neurological features and diagnostic tests. Lancet. 1997;350:903–907.

36. Head MW, Ironside JW, Ghetti B, Jeffrey M, Piccardo P, Will RG. Prion diseases. In: Love S, Budka H, Ironside JW, Perry A, editors. Greenfield´s Neuropathology. Volume 2. Boca Raton: CRC Press; 2015. p. 1016–86.