A scene from nighttime work in August 2025.

By Irwin Rapoport CEG CORRESPONDENT

The joint venture of C.A. Rasmussen Inc., the managing partner, and FBD Vanguard Construction Inc. began work on the California Department of Transportation’s (Caltrans) $143.7 million Interstate 405 Sepulveda Pass Pavement Rehabilitation Project on June 16, 2025. The project is designed to improve safety and mobility on a 10.2-mi. stretch of I-405 between the Los Angeles communities of Van Nuys and Westwood along the Sepulveda Pass.

Night operations started on June 24. The JV aims to complete the project in the winter of 2028-2029 based on a scheduled completion date of Aug. 19, 2027, followed by a 250-day plant establishment period.

see SEPULVEDA page 27

By Lucy Perry CEG CORRESPONDENT

Prefab or modular construction can be the solution to eliminate risk and changeability on construction projects. With the use of this construction method, contractors can avoid the possible impacts of fickle weather, transportation glitches and jobsite staging challenges — if the process, from start to finish, is well thought out. Prefabrication demands planning down to the smallest detail, and consideration of every possible project threat. see PREFAB page 22 Differing site conditions, material availability or design considerations, no matter how small the discrepancy, can render prefab components unusable.

Deutz Corp. has entered into an agreement to acquire the assets of OnSite Diesel, a Texas-based provider of heavy equipment repair services. The transaction is expected to close October 1, 2025.

Under the agreement, Deutz Corp. will continue to operate the OnSite Diesel brand, maintaining its reputation for servicing heavy equipment, including machines used for pipeline installation, rock quarry operations and landfill management. Deutz plans to retain all OnSite Diesel associates and will continue daily operations from the company’s Willis, Texas, facility, located just outside Houston.

OnSite Diesel is a family-owned business, launched in 2014 with one service truck and a single-bay shop. Today, with a fleet of service trucks and a larger custom-built facility, OnSite Diesel provides services to customers within a 250-mi. radius.

“We’re proud of the reputation OnSite Diesel has built over the years, and we’re excited to see it continue under Deutz Corp.’s leadership,” said Brent Nestor, president and owner of OnSite Diesel. “Our team remains dedicated to delivering the same reliable service customers expect, while also taking advantage of enhanced resources that will help us continue to evolve our business following the acquisition.”

Over time, Deutz anticipates leveraging OnSite Diesel’s capabilities across a broader footprint in new markets, reinforcing its role as a trusted partner across multiple industries. This acquisition will enhance Deutz’s United States presence and strengthen its ability to deliver exemplary service for an ever-growing catalog of off-highway equipment.

“The acquisition of OnSite Diesel represents our commitment to whole-machine service,” said Spencer McHugh, Deutz Americas head of M&A, strategy and field service growth. “With this expansion, we’re building on the foundation of our Deutz Power Centers, moving beyond engine and light equipment service to create a true one-stop-shop solution. We’re grateful to Brent Nestor and his entire team for their dedication to outstanding customer service, and we’re excited to build a better future together.”

For more information, visit deutzamericas.com. and onsite-diesel.com.

2019 John Deere 750K LGP, Stk#: HR-13327, EROPS, A/C, AM/FM Radio, 6,496 hrs., 6 Way Blade, 28" Pads $169,500

2023 John Deere 75G, Stk#: HR-1466, EROPS, A/C & Heat, Radio, 1,157 hrs., 23" Bucket, 91" Blade, 17" Rubber Pads $89,500

2017

185CFM, Stk#: HR-13670, 3,074 hrs., 125 PSI, 2,700 Eng. RPM, Weight 2,325 lbs. $12,500

2023 John Deere 35G, Stk#: HR-1469, OROPS, 764 hrs., 16" Bucket, 68" Blade, 12" Rubber Tracks $48,500

2017 Gehl RS6-34, Stk#: HR-1625, 6,000 lbs., 34 ft., 2,224hrs., 4WD $39,500

2018 Snorkel S3219E, Stk#: HR-13655, 550 lbs., 19 ft., 3,501 hrs., Electric Power $4,250

Deutz Corp. has entered into an agreement to acquire the assets of OnSite Diesel, a Texas-based provider of heavy equipment repair services. The transaction is expected to close Oct. 1, 2025.

The Historical Construction Equipment Association staged its 39th Annual International Convention & Old Equipment Exposition Sept. 18–20, 2025, on the grounds of the National Construction Equipment Museum in Bowling Green, Ohio.

The 2025 Big Dig of Northern Colorado expanded on its ongoing success, raising more than $131,000 in support of pediatric cancer research for the American Cancer Society (ACS) this year.

The Oklahoma Transportation Commission approved an $8 billion eight-year construction plan that will improve highways and bridges across the state, including upgrades to Interstate 35 and new safety projects.

The Golf Gods smiled on the 3rd Annual Werk-Brau Golf Outing to benefit Construction Angels, as the weather was great, smiles were plenty and there were many memorable shots (good and bad) — including a hole-in-one.

Towmaster announced Chris Pokornowski, who has served the company with distinction for 30 years, most recently as general manager has stepped down as of Sept. 26, 2025.

A major restructuring of Power Equipment Co. has taken shape over the past year and will culminate on Oct. 30, 2025, when it hosts a “Grand Reveal and Open House” at its new headquarters in Brighton, Colo.

FAE is broadening the fields of application for the PT300 tracked carrier with the introduction of the new SFM/PT multitask attachment, which can shred wood, crush stones and cut stumps or roots, all in one head.

Schweiss Doors was contracted by Dosteen Doors and Engineering Services to provide 228 liftstrap bifold doors for Nad Al Sheba Gardens. The bifolds will be used as garage doors for the new homes.

37

Stellar Industries announced that it is a 2025 Employer of Choice Award recipient. The Employer of Choice Award recognizes northern Iowa businesses that create a work environment where employees feel valued and supported.

46 CONTRACTORS IN ARIZONA, UTAH, TEXAS RECEIVE SAFETY AWARDS

Transportation construction companies from three states were recognized Sept. 29, 2025, for outstanding employee safety programs during the American Road & Transportation Builders Association’s national convention in Irving, Texas.

bidadoo and Clicklease announced a partnership that will unlock small equipment financing in the bidadoo lender partner network. This partnership will allow for easy and instant pre-approvals for buyers.

The DBIA will host the 2025 Design-Build Conference & Expo, Nov. 5-7 at the MGM Grand in Las Vegas, uniting the nation’s leading design-build innovators for three days of powerful programming, networking and celebration.

The Historical Construction Equipment Association (HCEA) staged its 39th Annual International Convention & Old Equipment Exposition Sept. 18-20, 2025, on the grounds of the National Construction Equipment Museum at 16623 Liberty Hi Road in Bowling Green, Ohio, where crowds took in running demonstrations of antique machinery.

The centerpiece of the weekend was the dedication of HCEA’s new 20,000-sq.-ft. museum. Designed with a vaulted clear-span hall and heated floor, the building allows cranes and shovels to be displayed with booms raised while improving year-round visitor comfort.

The project was fully funded through donations. Ken Taylor, president of Ohio CAT and an HCEA corporate member, played a pivotal role by launching the “Big Push” campaign and matching contributions dollar-fordollar up to $500,000. The effort surpassed its goal, with more than $727,000 raised.

HCEA’s collection now numbers more than 200 major machines, many of which are operated during the convention’s outdoor demonstrations — continuing the group’s mission to preserve and showcase the equipment that built America.

During the event, attendees toured the completed facility. After the show, HCEA planned to begin staging restored equipment in the new hall to create expanded, permanent displays.

With a larger, purpose-built home and strong industry support, HCEA’s convention continues to connect enthusiasts, contractors and families with living construction history — now under one roof designed for the next generation of preservation.

For more information, visit hcea.net. CEG (All photographs in this article are Copyright 2025 Construction Equipment Guide, except where noted. All Rights Reserved.)

and Margaret

and

host HCEA’s “The Bigger Dig” in 2026 at Kurt Kocher Farm, Concordia, Kan.

The Historical Construction Equipment Association (HCEA) staged its 39th Annual International Convention & Old Equipment Exposition Sept. 18–20, 2025.

Leaders of the event (L-R) Joe Kotkowski, chairman of the board; Mike Androcich, show chairman; and Tom Berry, archivist/editor — take in the

and earthmoving equipment

The official ribbon cutting at the new HCEA Museum served as the kickoff for the 39th Annual Convention, followed by guest tours and an evening banquet as the facility opened to the public.

HCEA volunteers Isaac Hobbs (L) and Dave Shively represented the association at its 39th Annual Convention. Hobbs, an HCEA scholarship recipient, attends the University of Northern Ohio in Lima, Ohio.

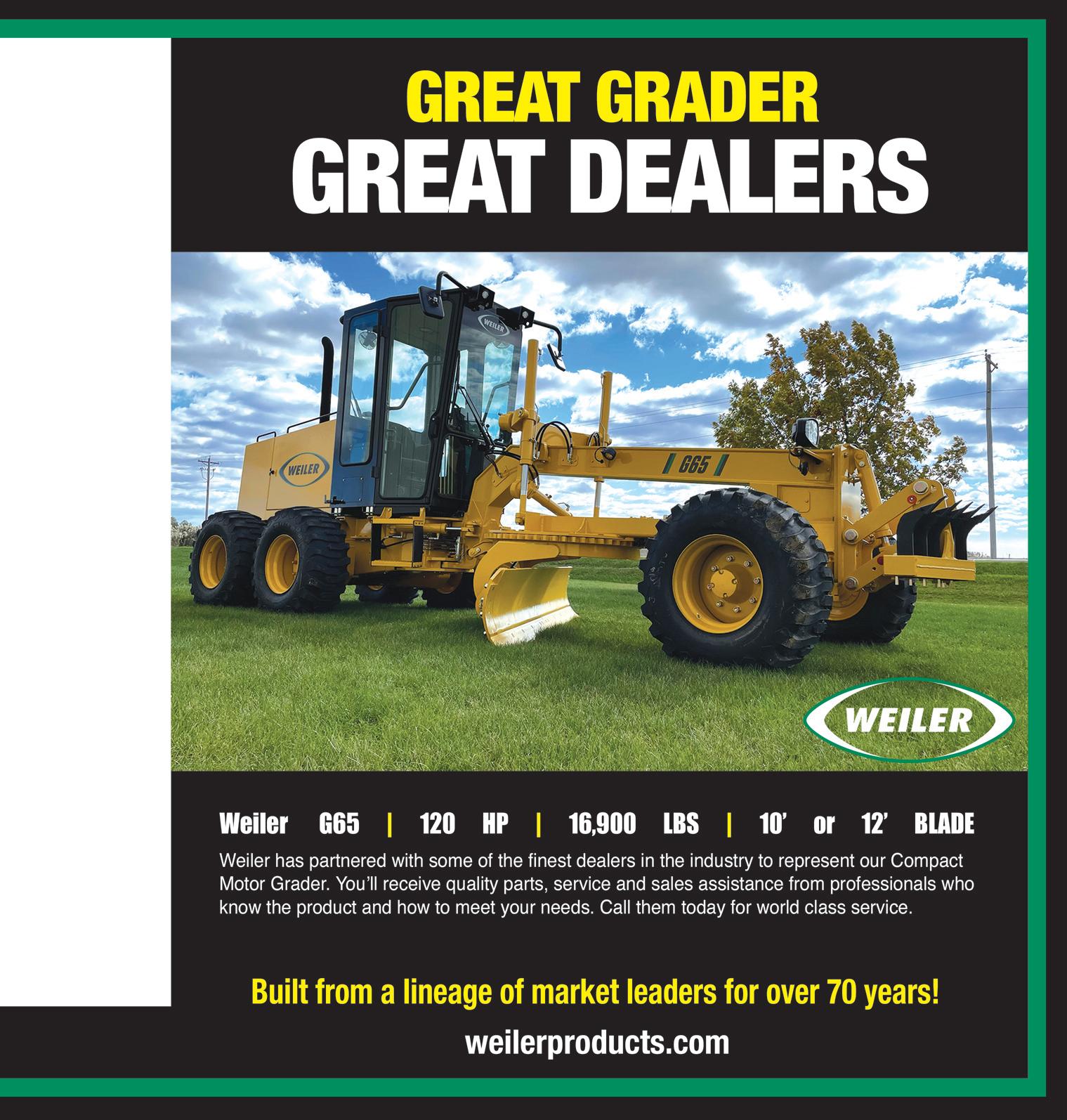

Bingham Equipment

binghamequipment.com

Tucson, AZ 520-889-6396

Cisco Equip

cisco-equipment.com

Artesia, NM 575-748-1314

Lubbock, TX 806-745-9595

Odessa, TX 432-550-9181

Ditch Witch of the Rockies

*Compact Equipment Only ditchwitchrockies.com

Nampa, ID 208-376-8394

Pocatello, ID 208-646-4360

Farm Equip USA

farmequipmentusa.com

Fruitland, ID 208-941-6000

G4 Const Equipment, LLC

g4hyundai.com

Commerce City, CO 888-987-3352

Jet City Equip

jetcityequipment.com

Oak Harbor, WA 360-675-4441

Marysville, WA 360-651-9079

Mecom Equipment

mecomequipment.com

Stockton, CA 209-466-5135

National Equipment Dealers

nedealers.com

Houston, TX 800-234-5007

Dallas TX 866-270-1700

Nueces Power Equip

nuecespower.com

Corpus Christi, TX 361-289-0066

Laredo, TX 956-725-0066

San Antonio, TX 210-310-0066

San Benito, TX 956-361-0066

Victoria, TX 361-576-0066

El Paso, TX 915-541-0066

Oklahoma Territory

Const Equip callotce.com

Oklahoma City, OK 866-339-6827

Oregon Tractor oregontractor.com

Roseburg, OR 541-679-6211

Porter Rents

porterrents.com

Corona, CA 951-674-9999

Lakeside, CA 619-390-1197

Pacoima, CA 818-834-0102 Wildomar, CA 951-678-9902

Powerscreen of Washington, Inc.

powerscreen-wa.com Helena, MT 253-236-4153

Powerscreen of Northern California, Inc.

powerscreenofcalifornia.com Dayton, NV 888-797-7276

Dixon, CA 707-253-1874

Rifle Equipment, LLC

*Compact Equipment Only rifleequipment.com

Rifle, CO 970-625-2580

R&S Industries Inc. rsindinc.com

Amarillo, TX 806-737-9410

Clovis, NM 575-769-8659

Tri-State Equipment

*Compact Equipment Only tristateequipmentrentals.com

Lake Havasu, AZ 928-680-6748

Fort Mohave, AZ 928-704-0101

Booth W42500, West Hall

March 3-7, 2026

Meet the contractor-strong, feature-rich machine that’s ready to carry the load for your crew. The all-new Hyundai HT38 CTL delivers 115 HP, a 3,807-lb. rated operating capacity, and 10’9” of lift height. All backed by Hyundai’s 3-year / 3,000-hour warranty.

What sets it apart? The features others charge extra for come standard:

•Hi-Flow Hydraulics•Lift-Arm Float

•Torsion Suspension•Auto Self-Leveling

•Reversible Fan•Rearview (Backup) Camera

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

•Pressurized Cab with Heat & A/C•Bluetooth + 8” Smart Touch Display

•Ride Control

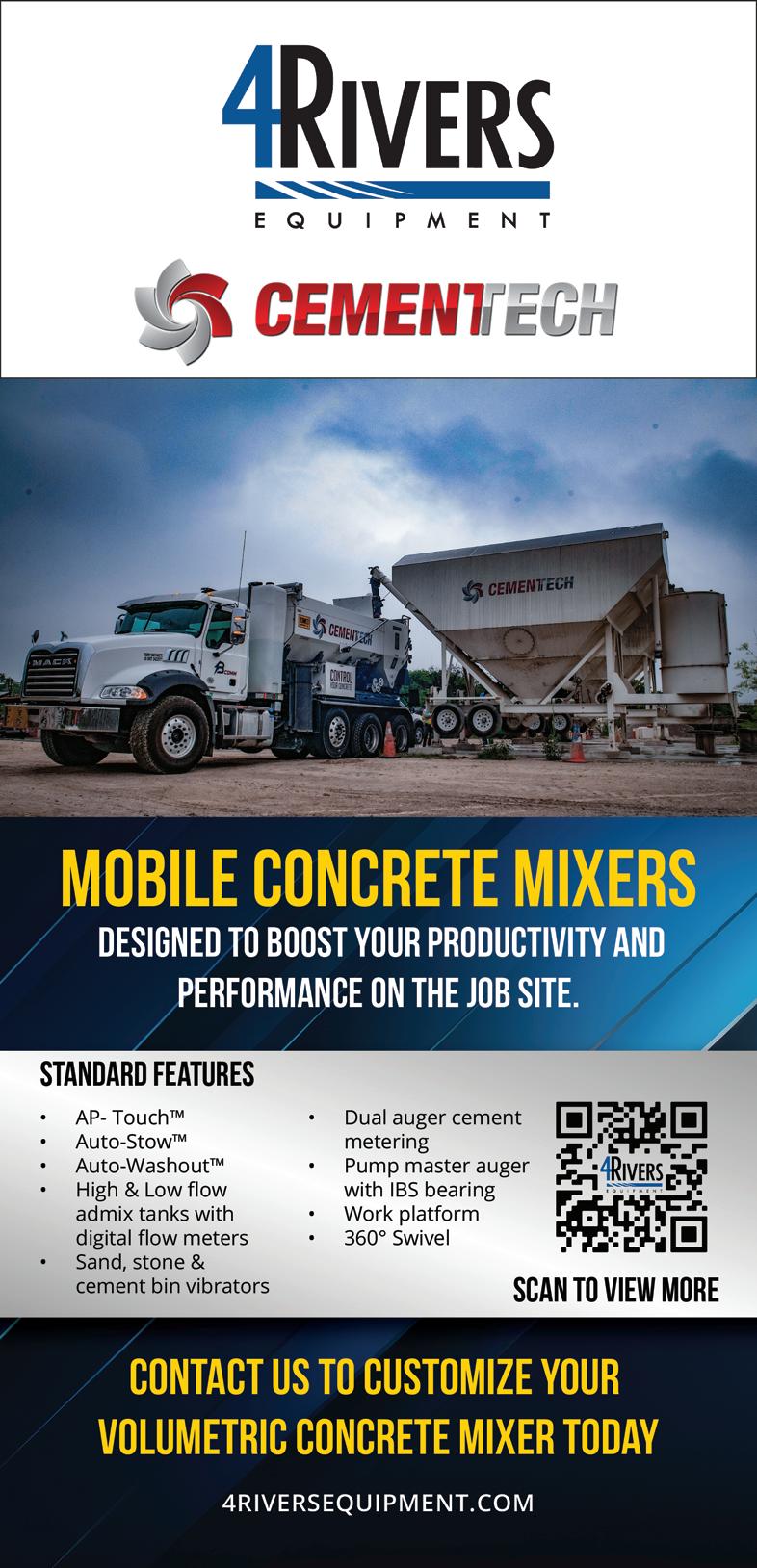

The 2025 Big Dig of Northern Colorado expanded on its ongoing success, raising more than $131,000 in support of pediatric cancer research for the American Cancer Society (ACS) this year.

Taking place on Sept. 6, 2025, and once again hosted by Richie Bros. Auctioneers in Longmont, Colo., the event sold out completely for the second year in a row.

4Rivers Equipment was once again one of the key sponsors of Big Dig of Northern Colorado 2025 and contributed by bringing a 70-ft. obstacle course and a variety of mini-excavators for children and families to operate. The event offered a fun, hands-on experience for kids while supporting a vital cause in the fight against childhood cancer.

“We are so grateful that the community supports this event,” said Rachel Befort, associate director of the American Cancer Society. “We have kids here today who are facing a cancer battle, and we have kids here that have faced that battle and won, so it just brings home the impact that ACS has on people right here in our community.”

Big Dig of Northern Colorado 2025 statistics:

• Attendance: 3,111 people

• Sponsorship: $78,000

• Ticket sales: $39,081

• Silent auction: $4,293

• Day-of revenue enhancers (hats, T-shirts, equipment rodeo, etc.): $3,970

• Champion fundraising: $1,400

• General donations: $2,102.02

• Credit card transaction fees: $2,183.45

• Total: $131,029.47 raised

For more information on the American Cancer Society, visit cancer.org.

(All photos by Ciera Wills, senior development manager for the American Cancer Society.)

The Oklahoma Transportation Commission approved an $8 billion eightyear construction plan that will improve highways and bridges across the state, including upgrades to Interstate 35 and new safety projects, news9.com reported.

The plan, which was approved on Oct. 6, 2025, covers the fiscal years between 2026 and 2033.

Transportation officials said the plan will focus on modernization, safety and longterm maintenance. Some other projects were pushed out of the eight-year window because of inflation and rising material costs, news9.com reported.

The Oklahoma Department of Transportation’s (ODOT) wish list includes the rehabilitation or replacement of 460 bridges, improvement of 675 mi. of two-lane

highways with faulty shoulders and improving the pavement of more than 2,800 lane mi., according to kosu.org.

Along with the construction plan, the commission reviewed a separate $500 million Asset Preservation Plan. That plan is designed to maintain the state’s existing interstate and highway infrastructure.

Oklahoma Department of Transportation Executive Director Tim Gatz briefed commissioners on the status of federal funding legislation and how it could impact state budgets for the next year. Gatz said the federal shutdown’s impact is minimal on current projects, news9.com reported.

“Where it will impact us is as we get further into federal fiscal (year) ‘26, the things like the construction contract lettings that have federal participation,” Gatz said.

“Without access to (a) new year's worth of appropriations, we will have to very carefully consider those future lettings as to which projects we can have on which projects we can't.”

But Gatz said the Federal Highway Administration’s National Construction Cost Index has climbed by approximately 63 percent since 2020, kosu.org reported.

Approximately 60 percent of ODOT’s funding is provided by the federal government, although those funds will soon expire and new authorization legislation hasn’t been passed, kfor.com reported.

The Transportation Commission, which is a nine-member board appointed by the governor and legislative leaders, meets each month to approve contracts and oversee the state’s transportation development.

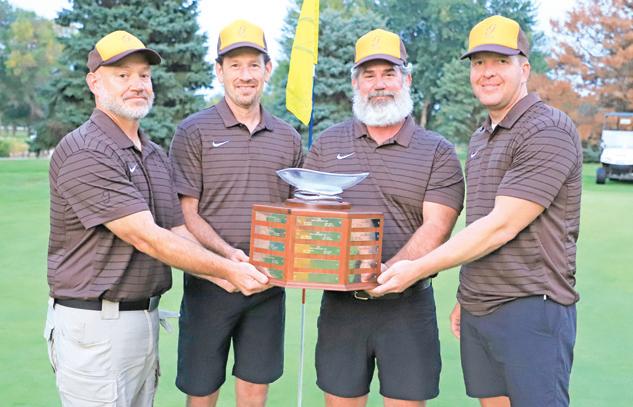

The Golf Gods smiled on the 3rd Annual Werk-Brau Golf Outing to benefit Construction Angels, as the weather was great, smiles were plenty and there were many memorable shots (good and bad) — including a hole-in-one.

Best of all, more than $100,000 was raised to aid families of fallen construction workers in Ohio. It was a beautiful day for golf and networking at the third annual event, which was held at Pinnacle Golf Club in Grove City, Ohio. The sold-out field of 32 foursomes included contractors across the state — from small operations to nationally known companies like Kokosing, Miller Brothers, George J. Igel, Ronyak Paving and The Shelly Company as well as construction suppliers and those allied to the industry.

In addition to the low score medalist honors, the day's festivities included a “closest to the pin” contest, as well as a unique putting contest — using a compact excavator fitted with a Werk-Brau Tiltrotator and a one-of-a-kind Werk-Brau putter head attachment.

“Wow — a huge shoutout to everyone who made today such a resounding success,” said Werk-Brau regional manager and golf outing chairman Neil Recker. “Once again, the construction industry showed up big time. Thanks to the golfers, sponsors, customers, partners and volunteers who made it a great day. Many Ohio families of fallen construction workers will be helped because of you.”

The team from Rudd Equipment took home medalist honors with a 56 in the closely contested scramble format, while the team of George J Igel scored a hole-in-one to claim the $10,000 prize. The raffle included many summer essentials including grills, coolers, unique dining experiences and more.

Special thank you goes out to Platinum Angel sponsors, Murphy Tractor, Alta Equipment, Ronyak Paving and The Shelly Company.

Additional sponsors from across the state and throughout the industry supporting the event included Exact Crane & Equipment Corp., National Tube Supply, R & J Cylinder and Machine, IC-Fluid Power, Ritchie Brothers, Purple Wave Auction, Jarrett Logistics, ARIS GET LLC, O.F. Machining, Chicago Tube & Iron, Valley Tool and Manufacturing, Trucco Construction, Leeco Steel, Columbus Equipment, Southeastern Equipment, Reco Equipment, NPK Construction, Kalida Truck Equipment, Stoepfel Drilling, Black Cat Wear Parts, Bailey, Wahl Marketing Communications, Hylant, Surety Bonds and Clouse

National sponsors of Fallen Angels include Advanced Drainage Systems, J. Alexander Law, John Deere, Dobbs Equipment, United Rentals, Friedman Legal, SimForMotion, Core & Main, Total Teks Group, Flagger Force, Wirtgen Group, GRH, U.S. Pipe, Heritage Construction & Materials, Werk-Brau, Case Construction, PSS Industrial Group, BOMAG FAYAT Group, Linder and American Traffic Safety Services Foundation.

Construction Angels is a nonprofit organization that provides immediate financial support and grief counseling to the children and spouse when a construction worker suffers a fatality on the job site. They are financially supported by many companies, organizations, unions and construction associations within the industry.

The Bureau of Labor Statistics estimated there are 7.2 million people working in the construction industry with projected steady growth over the next 10 years. OSHA reports there are well over 5,000 work site deaths each year in the United States, more than 20 percent are in the construction industry. This is approximately 4.5 construction workers killed per working day in the United States

“Huge thank you to the entire Werk-Brau team for another awesome event,” said Kristi Gibbs, Construction Angels CEO and founder/national executive director. “They really got the construction industry to show up and show out. Your hard work and dedication mean so much to the Ohio families that we serve. We are so grateful for your support and look forward to the years to come.”

For more information, visit constructionangels.us/.

Towmaster announced Chris Pokornowski, who has served the company with distinction for 30 years, most recently as general manager has stepped down as of Sept. 26, 2025. His career with the company is a story of growth, leadership and lasting impact.

Pokornowski began his career at Towmaster with the intention of taking on a short-term role before pursuing other opportunities. However, his talent and leadership potential quickly became evident. Starting on the production floor, he advanced through multiple positions, ultimately being promoted to leadership when Towmaster offered him a supervisory role. That pivotal decision set the course for a long and successful career.

Over the years, Chris held eight different positions within the organization, progressing from production laborer to general manager. His career path exemplifies Towmaster’s commitment to developing leaders from within.

“Anyone can make a difference and grow within the company,” Pokornowski said, underscoring the value of perseverance and dedication.

Throughout his tenure, Pokornowski witnessed significant changes in the equipment industry. He cites advancements in suspen-

sion systems, scaling technology and safety features as particularly influential, both for Towmaster and the broader industry. He also observed the steady growth in the size of

equipment, which has consistently challenged the trailer industry to innovate.

Looking ahead, he anticipates major developments with the eventual integration

of electric and autonomous vehicles into the towing industry, changes that will have profound implications for trailer design and electrical systems.

Among the many customer experiences Pokornowski has had, one stands out as especially memorable. When faced with a dissatisfied customer struggling with scaling issues, he worked directly with him to demonstrate proper trailer use. Pokornowski asked the customer to try the trailer under his direction. By the end of the day, the problem had been resolved and the interaction had transformed into a positive relationship.

For Pokornowski, this story reflects the importance of customer focus and the ability to turn challenges into opportunities.

Pokornowski plans to take time to rest before exploring the next chapter of his career. His parting advice to colleagues is both practical and inspiring.

“Don’t underestimate the impact you are making on the people around you.”

Towmaster extends its deepest gratitude to Chris Pokornowski for three decades of dedicated service, leadership and commitment to excellence. His contributions have left a lasting impact on the organization, and he departs with the respect and admiration of his colleagues. CEG

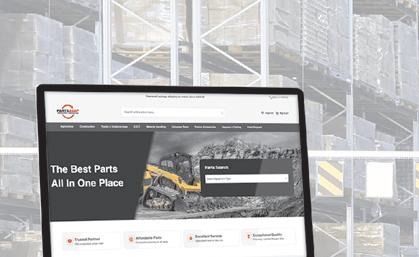

A major restructuring of Power Equipment Co. has taken shape over the past year and will culminate on Oct. 30, 2025, when it hosts a “Grand Reveal and Open House” at its new headquarters in Brighton, Colo.

“The new facility represents a significant investment in building, technology, and service capabilities for a headquarters that would properly represent the company’s new vision and commitment to growth,” Marc Dowdell, president of Power Equipment, said.

The 52,000-sq.-ft. building sits on 20 acres at 1575 County Road in Brighton — about 20 mi. north of downtown Denver. Another 8,000-sq.-ft. building is under construction and will be dedicated to additional parts storage. Power Equipment combined three existing facilities (PECO Denver, PECO Greeley and Powerscreening Henderson) into the new Brighton facility.

Among the features visitors will see are three Kardex Vertical Storage Automated Parts Management Systems; a centralized field service dispatch center, 12 25-ft.-by-80-ft. full-service bays, a heated wash bay, a clean/tool room under construction and a complete auto-lube system.

More than 40 OEM representatives will attend the reveal to discuss the latest productivity and technological advances from brands like Volvo, Superior Industries, BOMAG, Cedar Rapids, Powerscreen, Evoquip, Lippman and others.

Company officials said they are in discussions to become the certified rebuild facility for the western United States for key OEM partners.

Power Equipment, or PECO, as known in the Rocky Mountain region, will turn 90 next year.

The company represents the Volvo Construction line of equipment in Colorado and northern New Mexico, but its reach extends well beyond the two states.

With five branches in Colorado (Brighton/Denver, Colorado Springs, Aurora, Grand Junction and Durango), two in New Mexico (Albuquerque and Farmington), plus Casper, Wyo., Kansas City, Mo., Salt Lake City, Utah, and Calgary, Alberta (Machinery Supply Canada), PECO has a large presence in the aggregate industry representing Superior Industries, Cedar Rapids, Powerscreen, Komptech, Lippman and Evoquip, plus heavy construction lines BOMAG, Takeuchi, Link-Belt Cranes, Exodus Global, Shearcore, Connect Work Tools, Etnyre, SnoGo and Bearcat.

PECO also recently absorbed another ML Holdings entity, the former Powerscreening LLC, the Powerscreen dealer of Colorado, Wyoming, New Mexico, Utah, southeast Idaho and Nebraska

PECO is part of ML Holdings — a private family office owned by Robert Matz, chairman, and son Dave Matz, president. The company also owns McLung Logan Equipment Co., Crane Service Inc. and Viably (Komptech North America.)

Along with its impressive new facility, PECO welcomed the following additions to its executive

team: Mark Kuhn, vice president of construction sales; Brad Bown, vice president of product support; Cade Seeley, director of aggregate parts; and Graham Lambert, director of centralized field service dispatch.

Dowdell said part of PECO’s ongoing mission will be focusing on quicker response times for customers’ service needs.

“For the front range of Colorado, for instance, we’ll house a centralized dispatch at the Brighton headquarters,” he said. “All calls will come into dispatch, where the necessary skill set will be identified. We’ll send an aggregate tech out on an aggregate call, while we might identify a top Volvo mechanic for a Tier IV final issue. Ultimately, the process will quantify the call, diagnose the problem utilizing telematics, and then send the right tech with the right tools.”

Dowdell said that “brick and mortar” is a somewhat antiquated business model, and that centralization is the future of the equipment business.

“When was the last time a contractor sent a piece of equipment to a branch to be fixed,” he said. “Almost never, as most are always a repair in the field. We are a logistics and finance company — right part, right application, right machine, right finance structure, right tech, right repair… right now.”

The facility also features modern training facilities, which Dowdell said will be important for the customer base.

“Everywhere I go and ask, ‘What more can PECO do for you,’ the answers always revolve around training,” he said. “Be it training on articulated truck operation or training on selecting the proper screening application in the aggregate world. We’ll provide the training and also offer the training space to our customers to use as they want.”

Dowdell said PECO bought 16 new service trucks this year to further increase support capabilities and decrease response time.

Results are encouraging, according to Dowdell.

“We’ve seen our market share increase by nearly 25 percent year over year. Sales are up 20 percent year over year and rental volume is up over 40 percent.”

Dowdell said the upside in Denver and the surrounding markets is huge.

“The market is great,” he said. “Plenty of federal funding, lots of heavy civil and heavy highway work. Obviously, we have a ton of rock, so material processing is critical for us. And then, of course, we have growing communities. This business has tremendous organic, as well as acquisition, growth opportunities.

“We have the right product lines and the right people. And we also have the capital necessary and the support of private ownership. Bob and Dave Matz are great owners.”

(All photos courtesy of Power Equipment Co.)

Epiroc has partnered with Luck Stone to deploy the first fully autonomous SmartROC D65 drill rig in the United States. This marks a historic milestone, as it is also the first fully autonomous surface drill delivered to the quarry market worldwide, according to the companies.

The SmartROC D65 MKII is equipped with Epiroc’s advanced automation technology and is capable of executing complete drill patterns without an operator in the cab. Compliant with the global mining guidelines group (GMG) Level 4 standard for full autonomy, the rig operates under remote supervision via Epiroc’s common automation panel (CAP) and link open autonomy (LinkOA) platform, enabling seamless data integration and fleet management.

“Luck Stone’s leadership and commitment demonstrate that autonomy in quarries isn’t future vision — it’s current reality,” said Ron Hankins, business line manager of Epiroc USA. “Our partnership is not about a proof-of-concept, it’s about meaningful operational gains that the next generation of drilling will bring in the U.S.”

Luck Stone, known for its early adoption of autonomous plants and autonomous haulage systems (AHS), continues to innovate for the industry, and the company views automation as a strategic investment in safety, operational excellence and talent attraction.

“Our philosophy has always been about doing the work in the best possible way,” said Chuck Stilson, senior director of engineering of Luck Stone. “Partnering with Epiroc on autonomous drilling aligns perfectly with that vision. We’re not only improving productivity and safety, we’re providing new opportunities for our associates and rethinking what’s possible in aggregates.”

James River Equipment, an Epiroc dealer, played a key role in facilitating delivery of the SmartROC D65 MKII and will be instrumental in providing the ongoing local service, training and technical support that are essential to ensuring the project’s long-term success.

The United States aggregate market is the largest globally and presents significant growth potential for autonomous technologies. Using the same automation platform proven in mining, the SmartROC D65 MKII makes it easy for any operation to scale toward full autonomy, according to the companies.

By enhancing operational safety, optimizing machine fleet size and addressing skilled labor shortages, this deployment represents a transformative shift in how quarries can operate.

Both Epiroc and Luck Stone have committed to sharing performance data following the implementation period, offering valuable insights for the broader industry and paving the way for future advancements in automation.

For more information, visit epirocgroup.com and luckstone.com.

for KLEEMANNs mobile coarse screening plants. Theyre built to take on

EVO MSS502 EVO MSS802 forKLEEMANN'smobilecoarsescreeningplantsThe and new applications can be a challenge for many scr C Even more selection to match your requirements! ey'rebuilttotakeon reening plants. Not so hanging locations www.wirtgen-group.com/mobiscreen-kleemann coarse screening plants. compact – it's up to you: The MOBISCREEN MSS 502 EVO | MSS 802 EVO were designed for outstanding flexibility and operability. Full-size or 802 EVO can easily adapt to new operating conditions. These machines screening parameter adjustment, the MOBISCREEN MSS 502 EVO and MSS pretty much anything. With their wide range of screening media and simple elephone: (615) 501-0600

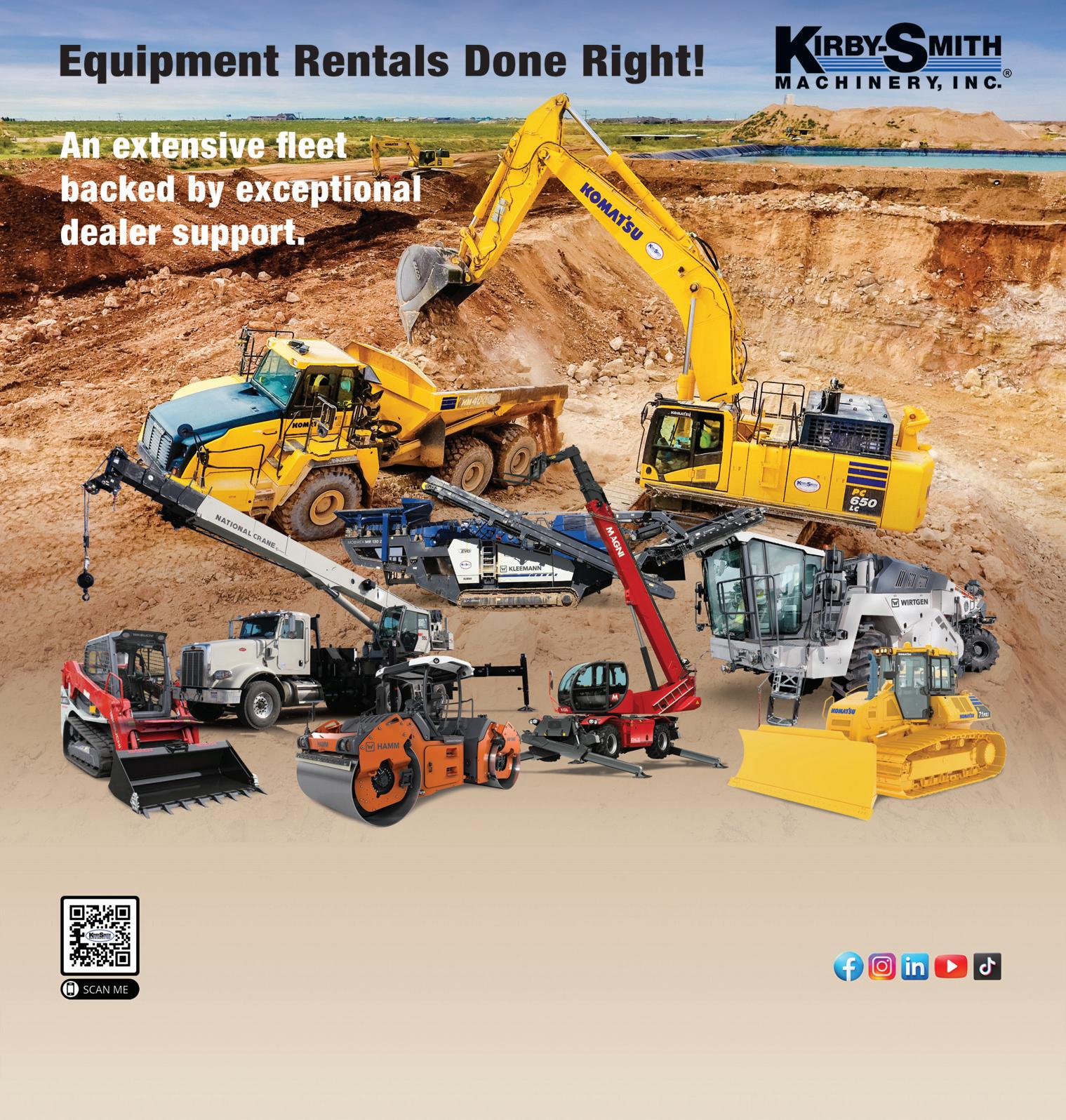

City, OK 405-495-7820 Tulsa, OK 918-438-1700 McAlester, OK 918-310-1550 Abilene, TX 325-692-6334

TX 254-261-1370 Lubbock, TX 806-745-2112 Odessa, TX 432-333-7000 www.kirby-smith.com

TX 806-373-2826 Chico, TX 940-678-5046 Dallas, TX 214-371-7777

Ft. Worth, TX 817-378-0600

Christi, TX 361-289-0066 Laredo, TX 956-725-0066 San Benito, TX 956-361-0066 Victoria, TX 361-576-0066

astecindustries.com

613 S. 4th Ave Mansfield, TX 76063 817-473-2110

3871 IH - 10 W. Freeway Exit 693 Columbus, TX 78934 979-732-6902

www.texasbearing.com

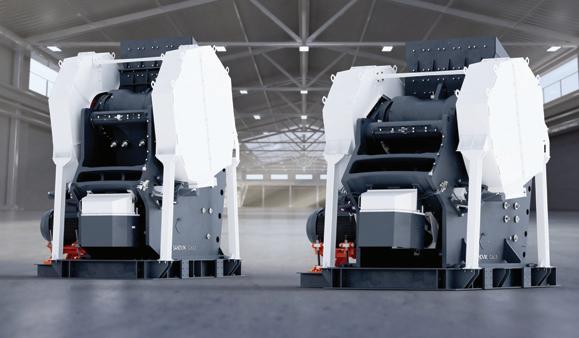

The new upgraded Sandvik jaw crusher range is another step forward in ensuring performance for its customers’ crushing operations.

Merging new jaw crusher capabilities and design with the existing standards of the entire Sandvik range was a natural next step, according to Sandvik. Sandvik jaw crushers are now better equipped to deliver the performance customers expect from a global leader in mining and quarry solutions.

“Our new upgraded jaw crushers are now more aligned with the full Sandvik range,” said Martin Johansson, global product manager, jaw crushers. “They give our customers even more ability to secure safety, improve productivity and availability, reduce costs and accelerate sustainability with a partner they can count on.”

Upgraded Sandvik jaw crushers are engineered to the same specifications for seamless compatibility with the full range of Sandvik solutions and now come with a 3-year standard warranty.

uniformity of structural components and parts, logical service access points and clearer role-based documentation ensure shorter times to full productivity with less need for local engineering or additional training.

The Sandvik jaw crushers also are now equipped with the new ACS-j system, simplifying monitoring and control of lubrication, hydraulic settings and eccentric shaft bearing temperature. The information is accessible through a web interface, providing customers with oversight and control of components and crusher metrics that help maintain optimal crushing performance and availability through troubleshooting.

• new hydraulic wedge setting adjustment;

• synchronized retraction arrangement;

• improved power pack;

• upgraded guarding;

• new ACS-j monitoring and control system; and

The latest Sandvik jaw crushers come complete with the features customers need for plug-and-play primary and tough material crushing. New and improved Sandvik jaw crushers now include even more of the safety, performance, availability and sustainability benefits customers expect from Sandvik solutions:

• clear role-based user documentation.

The upgrades to Sandvik jaw crushers put focus on Sandvik’s commitment to safety. The ability for hydraulic wedge setting and retraction adjustments reduces operator exposure to unnecessary risk. An improved guarding system advances the unique Sandvik uniform safetyengineering integrated in past solutions, ensuring the new jaw crushers are as safety-first and foremost as our customers need them to be, according to Sandvik.

The new upgraded Sandvik jaw crushers come with a welded main frame and material quality improvements and are delivered complete with everything needed for fast and seamless integration with a customer’s existing operation. The smaller footprint,

“Sandvik is proud of the positive circularity impact we make through the design, manufacturing and operation of our jaw crushers,” said the company. “From the high energy efficiency of our main motor to the compact all-in-one footprint to the fully recyclable materials used in their design, manufacturing and operation, Sandvik jaw crushers are a natural fit in sustainable quarry and mining operations.”

For more information, visit home.sandvik/en.

“Embracing prefab technology can mitigate risk and diminish uncertainties within any given construction project,” said Makenna Ryan, a civil engineer of Procore.

In a blog post on the construction software provider’s website, Ryan and writer Cait Bladt talked about the pros and cons of modular construction.

“By adopting this approach, contractors can reduce the impact of inclement weather conditions and other factors that delay the project timeline,” they said.

Prefabricated components have become mainstream in the transportation industry for bridge construction, drainage systems and modular pavement installs.

On bridge projects, the most common modular components include beams, girders, deck segments and pier caps, according to Ryan.

The various pieces are manufactured off site and transported to the job for onsite assembly.

On water and wastewater projects, said Ryan, concrete pipes, boxes and drainage structures are installed to manage water flow around infrastructure.

Modular sections of pavement are quickly assembled on road and high projects to create durable driving surfaces, he said.

Prefabrication offers advantages in keeping a project on track, especially when schedule management is critical.

Prefabrication enhances site logistics by “streamlining the construction process,” said Ryan, particularly on job sites with limited space.

“Since prefabricated components are manufactured in controlled factory environments, the need for onsite storage of raw materials is drastically reduced.”

These components can be delivered just in time for installation, he said, minimizing the duration and extent of onsite material handling and storage.

The just-in-time delivery model benefits urban construction sites, where space is at a premium. Plus, the storage of excess materials on an urban site can impede traffic flow and increase safety hazards.

Ryan also pointed out that with immediate installation upon arrival of prefab parts, the construction timeline is accelerated. This rapid installation also reduces the environmental impact of material waste, he said.

“The reduction in onsite activity correlates with fewer disruptions to the surrounding community and a more organized and efficient job site,” said Ryan.

Precision, in both the manufactured component and the installation phase is improved with modular construction.

Ryan said building elements in a factory with precision equipment allows for greater control over measurements and tolerances.

This control, in turn, ensures each component is produced to exact specifications and with uniform quality, he said.

“Design tools and manufacturing technologies further enhance this accuracy, reducing human error and material discrepancies,” said Ryan.“This meticulous attention to detail guarantees that the components fit together seamlessly during installation.”

Quicker and more accurate installation results on the job site when modular components are assembled there as all parts are designed to connect perfectly

“The result is an overall increase in the quality of the fin-

Adobe Stock photo Transporting and storing project components can be the greatest hamstrings in prefab construction. The challenges of trucking oversized components requires careful planning and coordination.

ished structure, with reduced need for adjustments and rework,” said Ryan.

Risk management involves controlling variables and prefabrication offers control of nearly every variable in the component’s construction.

By shifting component construction from the job site to the “predictable confines” of a factory, prefabrication allows for a more methodical approach.

The timeline for construction “becomes more reliable, and quality checks can be conducted more thoroughly in a dedicated facility,” said Ryan.

With prefabrication, the risks associated with weather, site conditions and labor are mitigated before the components reach the building site, he added.

“These proactive measures ensure that potential problems are identified and resolved in advance.”

This, in turn, reduces the likelihood of costly and timeconsuming issues arising during the crucial stages of on-site assembly, said Ryan.

The construction method can virtually eliminate delays caused by adverse weather conditions or the need for specific environmental settings for materials.

“Moreover, the ability to conduct comprehensive testing and refine aesthetic details within a factory setting ensures that components arrive on-site,” said Ryan.

It also guarantees they arrive “in a state of near perfection, ready for immediate assembly.”

Frontloading the production and quality assurance phases in modular construction allows for parallel site prep, said Ryan, and expedites build time.

“The culmination of these factors is a streamlined construction process where speed is matched by an uncompromised commitment to quality,” he said.

Labor issues plague the construction industry. But one of the biggest benefits of prefab construction, in Ryan’s eyes, is maximized labor efficiency.

“By bringing together specialized labor in a controlled setting, construction teams can focus on precision and quality,” he said.

And they can operate in tandem without the distractions and variables found at traditional construction sites.

“This not only improves the quality of work but also enhances safety and reduces overall project costs, allowing specialists to focus on their craft,” he said.

For all its rewards, prefabrication is not without its risks. The process requires careful planning and consideration to fully realize the benefits.

Pages 23-26

MUSKOX has released the T-Tach Torsion attachment, designed to deliver smoother, more efficient operations on uneven ground. First introduced in May 2025, the T-Tach is available to order direct from the company and through MUSKOX’s dealer network.

MUSKOX, based in Grand Forks, N.D., has built a reputation for durable, operatorfocused equipment. The company’s flagship MUSKOX Snowblower line showcases this commitment with back-drag technology, pivoting auger system, glide plates and rubber cutting edges that deliver safer, faster snow removal, according to MUSKOX. The T-Tach builds on that legacy of innovation.

The T-Tach is a torsion attachment engineered to complement, not replace, the equipment operators already own. It enhances performance and comfort while extending the life of existing implements, according to the company.

MUSKOX has released the T-Tach Torsion attachment, designed to deliver smoother, more efficient operations on uneven ground.

Key features include:

• Four independent torsion axles that flex to match uneven terrain, maintaining constant down pressure.

• Noise and vibration reduction, which improves operator comfort and reduces stress on the machine.

• Universal compatibility with any quick-attach plate up to 12,000 lbs., safe at speeds up to 20 mph.

• Enhanced ground contact, providing steadier, more consistent performance for snow removal, grading, scraping and more.

Solving Common Challenges Operators often face equipment

bounce, loss of contact and fatigue when working over uneven surfaces. The T-Tach addresses these issues directly by improving stability and reducing vibration, according to the company. This results in more efficient jobsite operations and less wear on both the operator and the machine. The T-Tach allows users to get more out of their current buckets, blades, snowblowers or other implements — delivering better results without costly equipment replacement, according to MUSKOX. MUSKOX offers a 30-day risk-free trial, giving operators the chance to experience the benefits before committing. For more information,

2023 CAT 320 $185,000

SN MYK30580, 1010 hrs, Los Angeles, Quick Coupler, AC, Extra Piping Line, Grade 2D Payload, 42" Bucket

Medium & High Pressure lines, Quick Coupler, 35" Bucket, Rubber Pads Window Guard, AC, NO DEF needed

2018 CAT 962M $120,000

SN SA810301, Los Angeles, New Tires, AC, 3.6m3 Bucket, CPM Payload

2014 CAT 950K $99,000 SN FER00813, 6835 hrs, Los Angeles, 23,5R25 Tires, AC, 3.3m3 Bucket

2022 CAT 323 $165,000 Los Angeles, 2370 hrs. Piping Line, CAT 7.1 Engine, AC, 45" Bucket 1.31yd3

2018 CAT 910M $94,000 SN H2200631, 58 Hrs, Los Angeles, 1.m3 Bucket, AC

2021 CAT 313GC $105,000

SN NFZ10493, 965 Hrs, Los Angeles, Quick Coupler, AC, Piping Line, 35" Bucket, 28" Track, Thumb Available at extra cost

FAE is broadening the fields of application for the PT300 tracked carrier with the introduction of the new SFM/PT multitask attachment, which can shred wood, crush stones and cut stumps or roots, all in one head.

The new SFM/PT can shred trees and vegetation up to a diameter of 14 in.; crush stones up to a diameter of 8 in.; and cut buried stumps up to a diameter of 18 in. It can work down to a maximum depth of 12 in.

This model is recommended for managing woodlands and forests, for creating firebreaks and for working near electrical lines or oil and gas pipelines. Due to its ability to work below the topsoil, it also is ideal for clearing or converting wooded or stony land.

The key features of this head include the interchangeable wear-resistant Hardox inner plates, the hydraulic hood for effective control of the dimensions of the final product, the transmission with side gearbox which maximizes power to the rotor and the adjustable Hardox counter blade.

The SFM/PT joins the other heads available for the PT300 carrier: forestry mulchers, forestry tillers, stump cutters and dozer blades.

For more information, visit fae-group.com.

SEPULVEDA from page 1

The federal aid project is replacing sections of two lanes in each direction from Victory Boulevard to Mulholland Drive; repairing sections of other lanes along the primary corridor between West Los Angeles and the San Fernando Valley; restoring/replacing two overhead sign structures; replacing 98 sign panels; and upgrading 6,400 ft. of metal beam guardrail and nine curb ramps.

Matthew Osborne, C.A. Rasmussen’s project manager, said that the project includes more than 6 mi. of concrete pavement lane replacements, 45 individual slab replacement locations, 564,000 sq. yds. of existing concrete pavement grinding, 47,000 tons of HMA leveling course and 56,000 tons of RHMA cap.

“We are rehabilitating the primary corridor between West Los Angeles and the San Fernando Valley — a route that experiences heavy, continuous traffic while serving crucial commuter and commercial needs, including access to the Los Angeles International Airport,” said Lauren Walike, a Caltrans public information officer. “[In addition to] improving the safety and mobility along I-405, [it] sustainably extends the pavement life. [The work will] result in the restoration of nearly 92 lane-miles overall. Additionally, [the new] roadside sign panels will improve wayfinding.”

The job went out to bid in September 2024 and was awarded in March 2025.

“This section of the I-405 is one of the heaviest-traveled corridors in California,” Osborne said. “As such, the roadway has been deteriorating in several areas, resulting in cracking and rutting in the existing pavement.”

“Other than the heavy traffic, the other challenges of this project will be 22 extended weekend closures where a large portion of the entire project’s work will take place,” Osbourne said. “Extensive planning and resources will be required to accomplish this.”

The JV is dealing with both concrete and asphalt lanes.

Crews installed K-rail barriers on June 24 along I-405 through the Sepulveda Pass. Night work, which involves lane closures, should run from 9 p.m. to 6 a.m. with at least two lanes remaining open.

To expedite construction, there will be 20 to 25 55-hour extended weekend partial closures.

The JV has a sizable construction yard. Vanguard set up a concrete batch plant within it.

“On regular workdays, no major trucking activities are

anticipated between 6 a.m. to 9 a.m. and 5 p.m. to 7 p.m.,” Walike said. “The contractors will have intermittent traffic lookouts while accessing the yard to ensure safety of workers and motorists.

“Nearby areas can expect noise sources, including backup alarms and truck activity. The contractors will comply with the Storm Water Pollution Prevention Plan and implement dust control and street sweeping as needed. It may set up a batch plant to produce aggregates and/or concrete.”

Crews operated in the Sepulveda Pass area of I-405 for about six weeks in anticipation of the first extended weekend closure.

At this point, the JV has completed several lanes between Sunset and Wilshire boulevards. Over the next six months, crews will cover between Mulholland Drive and Wilshire Boulevard.

The overall work job is not without its challenges.

“This project is using a barrier transfer machine — a road dipper machine — that transplants a barrier into a live lane,” Osborne said. “We’re using it for the 55-hour lane closures. It is pretty new to the industry and something we have not used before. We‘re getting the hang of it now. This system picks up 40-inch pieces of barrier and places them laterally up to 18 feet without the use of a crane.

“It has been used in a couple of major cities, such as the

George Washington Bridge in New York City, to open up southbound and northbound lanes during the day. They have been used in San Diego as well. It is definitely easier and faster to set than standard K-rail.

C.A. Rasmussen and Vanguard have partnered on previous projects.

“We just finished a project with them on I-605 with a similar project scope,” said Osborne. “It went well.”

Vanguard is responsible for the concrete pavement and the approach slabs.

“In August, we began the work on the approach slabs,” Osborne said. “It will continue through December, and then we ‘ll move over to the other phase to start on the lane replacements.”

The approach slab element uses operators with excavators for demolition and structural backfill.

The asphalt and concrete pavement repairs and replacement of sections of I-405 are ongoing.

“We‘re completing the paving during the extended weekend closures,” said Osborne, “while Vanguard is working on the approach slabs with the movable barrier system when the road is closed. There are also nightly closures for asphalt paving, along with cold and base-course paving, insulation of the rubberized course and the HMA paving.

see SEPULVEDA page 42

A residential paradise is growing out of the desert in Dubai, and Schweiss Doors is playing a major role in creating this new residential Eden.

Nad Al Sheba Gardens, a new neighborhood from real estate developer Meraas, will provide luxury living in the fast-growing city of the United Arab Emirates.

Schweiss Doors was contracted by Dosteen Doors and Engineering Services to provide 228 liftstrap bifold doors for Nad Al Sheba Gardens. The bifolds will be used as garage doors for the new homes and vary in size ranging from 18 to nearly 25 ft. wide and between 8 to 10 ft. high. Crews from Dosteen install the bifold doors and clad them in an aluminum ribbed paneling that coordinates with the community’s modern design.

This huge order of doors required coordination and communication between Dosteen and the team at Schweiss Doors over several months. The doors were split into two different orders, and shop drawings for each door had to be created and approved, a process that took about a month for each order of doors.

Once the drawings were approved by Dosteen, Schweiss could begin manufacturing the doors. Construction of the first 93 doors started in July 2024 and was completed in March, just as the building of the second order of 135 doors began. All of the doors are planned to be completed by the end of summer.

On Aug. 4, representatives from Dosteen and Nad Al Sheba Gardens came to Schweiss Doors to get a first-hand look at the operation and check in on the progress of the second order of doors. The visit included a tour of the man-

ufacturing facilities at Schweiss, as well as a meeting with company ownership and members of the sales and design team. The visit was a success, and the second order of doors will soon begin the long trip to Dubai.

Dosteen set up the shipping for all the doors, and it isn’t a short journey.

It begins at Schweiss Doors in Hector, Minn., where the doors are loaded into shipping containers and delivered to a port on the East Coast of the United States. The containers are then loaded on to a shipping freighter and travel across the ocean to a port in Oman.

The final leg of the journey gets the doors to Dubai and the busy construction site of the Nad Al Sheba Gardens. The first order of doors has already reached the site, and installation is well under way.

The Gardens, when completed, will have both standalone villas and townhomes along with a long list of amenities including swimming pools, running trails, parks, retail spaces and a

Number one of Ryan’s list is interface management — ensuring prefabricated components from different production sites fit together perfectly upon assembly.

Some materials are more forgiving when it comes to misaligned connection points, said Ryan. Wood and steel are two examples.

But, he said, regardless of the material prefabrication requires meticulous planning and precision engineering to avoid costly on-site adjustments.

“Successful interface management eliminates potential errors in manufacturing and is pivotal in maintaining project timelines and budgets.”

The next modular construction con is liability, which Ryan said can be challenging in prefab construction.

This challenge happens particularly when issues arise from interface management discrepancies.

“The responsibility for components that do not seamlessly integrate … should be clearly defined by the contractual agreements,” he said. “It is important for all parties involved, from the general contractor to the modular fabricator, to understand where liability rests for each element.”

Contractors should make sure project contracts clearly outline responsibility for defects or mismatches. This will ensure that parties are aware of their obligations and potential liabilities from the outset, said Ryan.

“In industries such as oil and gas, it is common for the general contractor to assume the bulk of the risk,” he said.

“This centralized liability model ensures accountability but also empowers the contractor to factor this risk into their

under way.

school.

and installation

The development will be constructed over several phases, as units are sold, with home prices starting near $2 million. The most recent phase under construction is scheduled to be completed by the end of the year.

For more information, visit bifold.com.

pricing structure.”

By proactively managing contracts and liabilities, said Ryan, prefab construction can maintain its efficiency advantage.

At the same time, the construction method can assure equitable risk distribution among stakeholders.

The transportation and storage of project components are often the greatest limitations to prefab construction.

“Virtually anything can be prefabricated with the right equipment, sufficient space and adequate infrastructure to transport it,” Ryan said.

But the unique challenges of transporting oversized components, such as wind turbine blades or bridge sections, requires careful planning and coordination.

Ryan believes the success of a prefab project can be credited to logistics as much as the actual construction.

“For example, the average prefabricated blade for a wind turbine is about 120 feet long,” he said.

That is more than double the length of a typical tractor tailor, already difficult to navigate through turns in many suburban areas, he said.

“Transporting an item of this size requires specialized route planning, considering the increased turning radius and weight of the item.”

Ryan believes that most often the limitations of prefabrication are due to restraints in both manufacturing and transportation.

“If an item is being carried across a bridge, will it support the weight?” he said.

And, if the item has to be hoisted into place, is the crane

powerful enough to get it there?

“These are the types of questions that need to be answered before committing to a specific prefab project,” said Ryan.

Finally, there are design changes. “If there’s one thing that is virtually guaranteed on any construction project, it’s change,” said the civil engineer.

Whether it’s differing site conditions, material availability or design considerations, even small changes can render prefab components unusable, he said.

“Prefabricated components are manufactured based on design specifications and site assessments.”

As a result, said Ryan, any discrepancies between the expected and actual site conditions can lead to complications.

“For instance, unusual soil characteristics or subterranean obstructions may require on-the-fly adjustments to prefabricated foundation elements,” he said. “Similarly, design changes made after the commencement of prefab production can lead to costly rework.”

Changes can even render existing components unusable if they no longer align with the revised design.

That’s why stringent design freeze policies are often implemented on construction projects, in addition to thorough and regular site evaluations.

“Despite these challenges, the key to successful prefab construction lies in diligently managing the design phase,” said Ryan.

It also lies in ensuring comprehensive site analysis to prevent expensive and time-consuming setbacks, he added. CEG

For more information on concrete news, visit CEG's Web site at www.constructionequipmentguide.com.

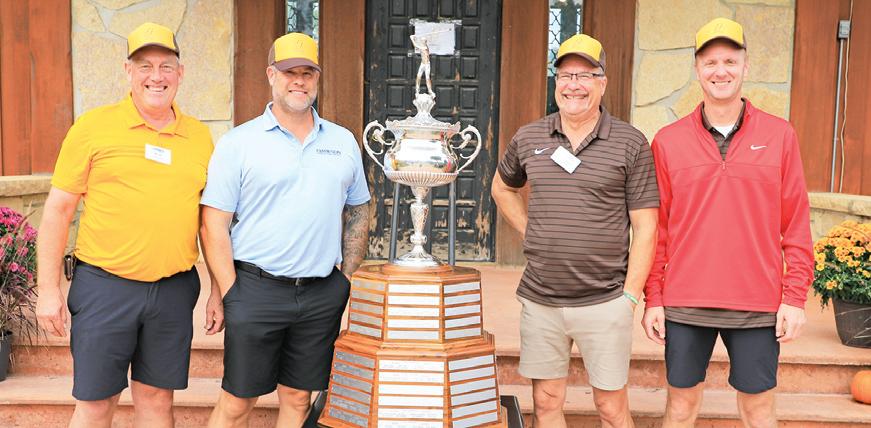

Approximately 328 guests from the United States and Canada were welcomed to Ida Grove, Iowa, Sept. 16 and 17, 2025, for GOMACO Invitational #43. The event consisted of two days of golf and camaraderie, as well as to celebrate GOMACO’s 60th anniversary.

There were 258 participants in the two-person Putting

Tournament and 328 in the four-person Scramble Tournament. The GOMACO Invitational is the company’s annual golf event, which was held at the Ida Grove Golf and Country Club and three surrounding golf courses, including Holstein, Mapleton and Schleswig.

The GOMACO Invitational began at the Ida Grove Country Club with the Putting Tournament. Teams of two

putters were computer generated to participate on four different greens on the course, with the top team from each green advancing to the Putting Championship. This year’s championship team was Jeremy Bahe of Croell, Inc., in New Hampton, Iowa, and Ashleigh Johnson of A Concrete in Johnstown, Colo.

see GOMACO page 32

The Contractors’ Shoot-Out featured six teams of three GOMACO contractors competing in a five-hole competition, with the highest scoring team eliminated on each hole. This year’s Contractors’ Shoot-Out Champions were Tim Grethey of Millstone Weber LLC, in Saint Charles, Mo.; Jeremy Bahe of Croell Inc., in New Hampton, Iowa; and Todd Horky of Concrete Plus, in Sioux City, Iowa.

The Invitational Scramble Tournament, a best ball competition, was held on four area golf courses. Computer-generated teams of four golfed 18 holes, with each course crowning a champion. The champion team from each of the four courses then played in a three-hole shoot-out at the Ida Grove Country Club to earn the title of GOMACO Invitational #43’s “Grand” Champion.

The highest scoring team was eliminated on each hole until only one remained. The “Grand” Champion team was from the Mapleton golf course and included Joe Stoltz of Turck Inc., Bondurant, Iowa; David Martin

which was nine under par.

Winning the Holstein tournament were Ryan Hanson of Endeavor Business Media, Naperville, Ill.; David Barthel of Faris Machinery, Commerce City, Colo.; Joe Schmidtlein of the Rasmussen Group, Des Moines, Iowa; and Drew Roberts of Absolute Concrete Construction, Granger, Iowa. They finished the Holstein tournament with a score of 60, which was 10 under par.

The champion team from Schleswig included Steve Baker of Baker Enterprises,

Waverly, Iowa; Eric Striegel of IFP Motion Solutions, Cedar Rapids, Iowa; J.B. Closner of Closner Equipment Co., Rhome, Texas; and Cody Oswalt of Kiewit Corporation, Omaha, Neb. They finished the Schleswig tournament with a score of 62, which was eight under par.

The Concrete Foundations Association (CFA) announced the installation of three distinguished leaders to its Legacy Committee: Lance Jordan, formerly of Stephens and Smith Concrete Construction; Mark Saldana of Saldana Concrete; and Van Smith of Hudson Valley Concrete Pumping Inc.

The appointments honor their contributions and long-standing service to the concrete foundation industry and the association.

These individuals have demonstrated exceptional leadership and commitment throughout their careers, particularly during their service on the CFA board of directors. Their efforts have been instrumental in advancing the association’s mission, supporting its members and driving industrywide progress. Each has left an impact through their dedication to CFA events, resources and strategic development, making them exemplary additions to the legacy committee.

Jordan’s tenure on the board was marked by his stabilizing leadership during the economic recession, a critical period for the association. His persistent efforts helped ensure the CFA’s continuity and fostered a collaborative environment for members.

Saldana’s service was defined by his passionate involvement in strategic planning, which formalized the mission and vision that guides the association today.

Smith brought dynamic energy to the board, championing the “Projects of the Year” program and passionately sharing his expertise in construction education and technology.

“We are excited to announce these individuals as new members to the legacy committee,” said James Baty, CFA executive director. “Their lifelong devotion to the industry inspires us all. We are thrilled to have the opportunity to honor these hardworking CFA members as new legacy committee members and acknowledge their dedication and contributions.”

Nominations for the legacy committee are conducted each spring, with the final list of candidates ratified by the board of directors to recognize leaders who have built a lasting legacy within the CFA.

In 2018, the Concrete Foundations Association’s (CFA) board of directors established a legacy committee to honor the rich tradition of service to the association on behalf of the industry. This committee, comprised of association leaders, cultivates awareness for the industry, is dedicated to the mission of the association, and elevates the service of the members to the entire industry. For more information, visit cfaconcretepros.org/.

of Northstar Power LLC, Ankeny, Iowa; Dane Peters of TOPCON, Livermore, Calif.; and Tyler Hansen of Power Systems Inc., in Chanhassen, Minn. They won the Mapleton tournament with a score of 60, which was 10 under par.

The Ida Grove tournament champion team members included Brad Pohlmeier of Clarkson Construction Co., Kansas City, Mo.; Chris Kipp of Murr Inc., Edwardsville, Kan.; Kevin Van Den Top of State Steel Supply Company, Sioux City, Iowa; and Brad Zobel of GOMACO. They finished the Ida Grove tournament with a score of 61,

GOMACO Corporation is a leader in concrete construction equipment with headquarters in Ida Grove, Iowa. GOMACO equipment will slipform concrete streets and highways, airport runways, curb and gutter, sidewalks and recreational trails, safety barrier, bridge parapet and irrigation canals. Support equipment includes grade trimmers, concrete placers, concrete placer/spreaders and texturing and curing machines.

The company also offers equipment to finish flat slabs, bridges and slopes. GOMACO will consult on unique concrete paving applications and equipment needs. Products are offered through a worldwide distributor network for local sales, parts and service expertise. For more information, visit gomaco.com. (All photographs in this article are courtesy of GOMACO.)

Power Curbers Cos. announced the acquisition of Miller Formless Systems.

The acquisition was finalized on Aug. 29, 2025, marking a significant milestone in the continued growth of both organizations.

Founded in 1970, Miller Formless has a long history of manufacturing slipform machines that have served contractors worldwide. By joining forces with Power Curbers Cos. home to the Power Curbers, Power Pavers and Anvil American brands, this acquisition strengthens the combined company’s market leadership, expands product offerings and enhances service and support for customers worldwide.

Miller Formless will continue to operate under its own brand name. Power Curbers Cos. remains committed to preserving the company’s legacy while introducing operational efficiencies that will benefit customers in machine delivery, parts availability and after-sales support, according to Power

“This acquisition represents more than just growth — it’s about uniting two businesses that share a deep commitment to quality and customer success,” said Stephen Bullock, president of Power Curbers Cos. “Miller Formless has been a trusted name in the industry for over five decades, and we are honored to carry that legacy forward while offering an even greater range of solutions to contractors.”

Together, Power Curbers, Power Pavers, Anvil American and Miller Formless will now provide contractors with a comprehensive lineup of concrete paving solutions, from extruded curb machines to mainline highway pavers.

“We’re thrilled to couple the 5700-D multipurpose machine, the compact M1000 and the M8800 barrier machine, giving contractors an unmatched lineup of machines designed to meet a wide range of project needs,” Bullock said.

For more information on snow-clearing equipment and spreaders, visit CEG's Web site at www.constructionequipmentguide.com.

“Snow removal, especially in rural areas where visibility can be hindered, requires accuracy for safe and efficient operations.”

Matt Costello John Deere

John Deere introduced John Deere Path, a mapping solution designed to help operators navigate snow removal operations with precision.

Snow-covered roadways present significant challenges, making it critical for operators to clear them effectively. With John Deere Path, operators gain a better sense of road edges and boundaries, when premapped, even in tumultuous winter weather conditions, according to John Deere

“Snow removal, especially in rural areas where visibility can be hindered, requires accuracy for safe and efficient operations,” said Matt Costello, product marketing manager, John Deere. “With a large percentage of U.S. roads located in snow-prone regions, John Deere Path is designed to give operators the confidence to navigate snow-covered roads, helping them stay on course to complete their work safely and reliably.”

Built on the technology of the John Deere StarFire receiver and G5 display technologies, John Deere Path, an option on John Deere motor graders and other plow equipment, provides operators with the ability to pre-map road boundaries before snowfall, creating precise guidance routes automatically sent to the John Deere Operations Center. During snow events, near real-time maps help operators maintain alignment with road edges, with audible alerts warning if the equipment moves too close to premapped boundaries, helping to reduce acci-

John Deere photo

John Deere introduces John Deere Path, a mapping solution designed to help operators navigate snow removal operations with precision.

dent risks and infrastructure damage.

The G5 universal display provides a clear, intuitive interface for confident navigation. Operators can visualize road edges and follow a guidance track overlayed on satellite imagery, with a visual error bar alerting them to deviations and excessive drift. When road boundaries and obstacles are pre-mapped, the system also enhances obstacle awareness, such as mailboxes and curbs, while enabling operators to track and document completed work for efficiency, according to John Deere. Points of interest can be added at any time for changes on route or marking potential road maintenance areas after snow.

John Deere Operations Center plays a critical role in snow removal management. All mapped routes and completed work data are seamlessly integrated into the platform. John Deere Operations Center provides insights into total area plowed, machine location, duration of work and fuel usage when available, allowing fleet managers to make informed decisions and efficient resource allocation, according to John Deere.

John Deere Path is available as two optional solutions to meet the needs of a variety of operations. John Deere Path is specifically designed for John Deere motor graders, offering integration with machines

from model year 2016 and newer. For customers with mixed fleets and older models, John Deere Path Universal offers a modem for a fully closed-loop system, making it compatible with a variety of other machines like plow trucks. By leveraging advanced mapping and precision technology, John Deere Path delivers a way to manage snow removal operations. With enhanced accuracy, improved operator awareness and integrated fleet management capabilities, John Deere Path helps keep roadways clear and communities moving.

For more information, visit JohnDeere.com.

Blue Diamond Attachments announced the launch of an addition to its full line of snow removal attachments.

Available for skid steer loaders, the new Blue Diamond heavy duty snow blower provides excellent performance under both wet and dry snow conditions. With an 11-in. chute diameter, the new snow blower attachment is built to evacuate high volumes of snow quickly and comes in cutting widths from 62 to 96in.

Key features of the new Blue Diamond heavy-duty snow blower include:

• High tensile steel ribbon flighting. To deliver even the heaviest wet snow to the awaiting fan, the Blue Diamond snow blower uses machine formed hand welded 19-in. augers made with high tensile steel ribbon flighting to provide strength and durability.

• A five-blade fan. A standard 26-in. diameter five blade fan not only moves high volumes of snow quickly, but also features tighter tolerance to the housing increasing velocity of the snow exiting the chute.

• A manual pin-style deflector. Blue Diamond snow blowers come with a manual pin style deflector allowing a true set it and forget approach to blowing snow.

• Adjustable skid shoes. The heavy-duty snow blowers come equipped with adjustable

skid shoes extending the life of the cutting edge and helping to protect surfaces from damage commonly associated with snow removal.

• A hydraulic rotator. The hydraulic rotator on the chute is ideal for skid steer loaders with cabs or for contractors/property managers needing to make frequent adjustments.

• Hydraulic line check valves. The valves prevent reverse rotation and allow the motor to overrun after the valve is shut off.

• Various plug features. This feature allows for virtually any skid steer to be used with the heavy-duty snow blower.

“The addition of this heavy-duty snow blower to our line of snow removal attachments could not come at a better time for contractors and municipalities who are looking to update or upgrade their existing fleet,” said Drew Truan, chief operating officer of Blue Diamond Attachments. “Our new snow blower is compatible with most OEMs, it’s built to withstand the harshest of winters and it is supported by Blue Diamond and our extensive dealer network.”

The new heavy-duty snow blower attachment comes with the Blue Diamond satisfaction guarantee and are backed by a 1-year warranty.

For more information, visit bluediamond attachments.com.

Larson Cable Trailers introduced the electric LCT-7500 E, the first electric-powered fiber installation trailer that delivers the efficiency, durability and reliability crews demand while addressing the industry’s growing need for sustainable equipment solutions, according to Larson.

The fiber optic cable installation industry has traditionally relied on gas-powered equipment, contributing to emissions and noise at job sites across the country. Larson Cable Trailers’ electric LCT-7500 E offers an alternative that addresses these environmental concerns while maintaining and improving operational performance.

Gas-powered cable installation trailers have been the industry standard, but they come with environmental costs:

• direct emissions from engine operation during cable pulling and setup;

• fuel consumption across multiple daily job sites; and

• engine noise that can disrupt residential and commercial areas.

The electric LCT-7500 E addresses these issues directly:

Emission elimination: Zero on-site emissions from the trailer itself, reducing the environmental impact of fiber installation projects.

Noise reduction: Significantly quieter operation improves working conditions for crews and

Industry influence: As contractors adopt electric equipment, it demonstrates that sustainable alternatives are viable for heavy-duty cable installation work.

Regulatory preparedness: Positions contractors ahead of potential emission regulations in urban areas and environmentally sensitive zones.

Market access: Enables contractors to bid on projects in areas with strict emission requirements or noise ordinances.

While individual trailer conversions provide localized benefits, wider adoption across the industry could meaningfully reduce the environmental footprint of fiber network expansion. The LCT-7500 E demonstrates that electric alternatives can meet the performance demands of cable installation work, according to Larson.

The transition to electric equipment represents a practical step forward for an industry essential to digital infrastructure development. The LCT-7500 E demonstrates that environmental responsibility and operational effectiveness can be effectively aligned in the fiber installation sector.

For more information, visit larsoncabletrailers.com.

Stellar Industries announced that it is a 2025 Employer of Choice Award recipient, presented by the Mason City Globe Gazette.

The Employer of Choice Award recognizes northern Iowa businesses that create a work environment where employees feel valued and supported. Stellar was nominated for this award by its employees who believed the company held the qualities necessary to hold this title. Those qualities include a strong commitment to quality of life, consistent feedback from leadership, support and flexibility for family and personal matters and recognition of employee contributions.

“We are incredibly proud to be recognized with the 2025 Employer of Choice Award,” said Dave Zrostlik, president of Stellar. “It’s an honor to know that our employee-owners felt Stellar is worthy of this recognition. This award reflects the dedication that everyone at Stellar has for creating a culture where employees are invested, engaged and happy.”

The acknowledgment highlights Stellar’s ongoing commitment to creating a positive work environment and investing in its employees and local communities. As a 100 percent employee-owned and -operated company, Stellar focuses on the personal and professional growth of every team member, from interns to leadership.

“The employee-owner mindset means that when Stellar succeeds, so do its people,” said Zrostlik. “That shared success not only helps deliver quality products to Stellar customers, but also fosters an environment where employees feel fulfilled and satisfied to stay.”

In 2025, Stellar is celebrating 35 years of continued success. Through product innovations, thoughtful business investments and acquisitions and a commitment to its dedicated workforce, Stellar continues to provide great products to industries and businesses around the world.

For more information, visit stellarindustries.com.

Tucson, AZ

520-579-0261 Phoenix, AZ

602-437-0351 Spokane, WA

509-536-7300

El Cajon, CA

619-448-0770 Corona, CA

800-491-9004

Ditchwitchwest.com

Lewiston, ID 208-743-0866

Snohomish, WA 360-863-2552

Richland, WA 509-578-5900

Petersandkeatts.net

nixonegli.com

25015 S McQueen Road Chandler, AZ 85249 602-463-3772

3300 E. Michigan Street Tucson, AZ 85714 520-649-2858

SEPULVEDA from page 27

The existing concrete pavement being replaced will be excavated to a depth of 2.1 ft. and replaced with 0.7 ft. of class 3 base, 0.35 ft. of LCB-RSC, and 1.05 ft of JPCP-RSC.

The new lanes are based on a JPCP-RCS, .75-in. WMA-SP and .75-in RHMA-G-SP.

The asphalt is being removed with a Wirtgen 200 cold milling machine. Concrete pavement will be removed with excavators.

The times for the concrete to cure and for the asphalt to settle vary.

For its paving operations, C.A. Rasmussen is using Hitachi 225 and CAT 345 excavators, a Roadtec paving machine and a Roadtec SB2500E shuttle buggy.

An additional aspect of the paving operation was the removal of two sections of Type 60 concrete barrier totaling 1,000 ft. This work was completed with a Cat 345 excavator with a hydraulic breaker.

The upgrading of the curb ramps will be a minor operation.

“They are all in the same locations, and the work will probably happen next spring,” said Osborne. “It‘s just breaking the back with a breaker, grading and pouring them back.”

The two overhead sign structures will be manufactured.

“They generally have a six-month lead time for structures of that size,” Osborne said.

The upgrading of the guardrail is scheduled for later in the project and should take about two months.

Weekend closures have 30 Rasmussen, 20 Vanguard and 10 subcontractor personnel on site. C.A. Rasmussen has hired close to 20 subcontractors.

Regarding recycling, the milled asphalt concrete will be sent to the asphalt plant to be recycled and reused in the production of HMA/RHMA.

CA Rasmussen has a large fleet, but this type of project can take a toll on equipment.

“We have a 24/7 mechanic on call,” Rasmussen said. “A lot of the wear and tear is mainly cutting edges and teeth on excavators, and then the hydraulic hoses on the breakers that

experience a lot of pressure. “We have our maintenance division that handles all of our equipment repairs. They‘ve been at it for a long time.”

C.A. Rasmussen rents much of its equipment from Sunbelt Rentals and buys machinery from Coastline Equipment. CEG

(All photos courtesy of Caltrans.)