By Jay Nachman CEG CORRESPONDENT

When the new Austin Convention Center opens in 2029, it will nearly double the site’s rentable square footage, increasing from 365,000 sq. ft. to 620,000 sq. ft. The new center will have six city blocks of below-grade space, including the new exhibit hall, truck loading dock and other support areas.

But first, the 365,000 sq. ft. of the current center must be torn down, a process that began in January with enabling work off-site on the utilities. The workers had to tie together two separate pieces of underground electrical “ductbank” so that the electrical feed to the Convention Center could be disconnected without affecting power to other nearby buildings on the same electrical grid.

Then, in April, crews began encapsulating the site with fencing followed by selective demolition and the salvaging of some of the existing building’s materials for re-use in the new building.

The $1.6 billion project is a 50-50 joint venture between JE Dunn Construction and Turner Construction. While the teams are totally integrated, each company takes the lead on its respective strengths. For example, JE Dunn has more experience with large excavations and concrete structures in downtown Austin, while Turner has more experience with convention centers and with long-span steel structures.

COVID-19 forced construction contractors to rethink their approach to a multitude of issues, including insurance coverage for projects. Since investing in supply-chain visibility, vendor vetting and risk diversification, today the industry is better positioned for whatever comes next.

the Wh Whatev eel Loader er your loaad is, Sons s to TACK sray has LE IT!

hablamos español

2019 John Deere 850K LT, Stk#: HR-1207, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,728 hrs., 90% U/C, 24" Pads, Multi Shank Rear Ripper, 14 ft. Wide ..................$179,500

hrs. Since Certified, Refurb. 2015., 4WD, IN445/50D710 Tires $69,500

2023 John Deere 130P, Stk#: HR-1435, EROPS, A/C & Heat, Radio, 1,465 hrs., 36" Bucket w/Hyd Thumb, 28" Pads, Rear View Camera $159,500

2018 Bell B30E, Stk#: 13464, EROPS, A/C & Heat, Radio, 5,453 hrs., 30 Ton Dump Cap., Auto Greaser, 23.5Rx25 Tubeless Tires $169,500

2020 John Deere 650K LGP, Stk#: HR-1182, OROPS, 6 Way Blade, 2,385 hrs., 24" Pads, 100% U/C, 10' 4" Wide $79,500

2021 John Deere 450K LGP, Stk#: HR-1232, OROPS, 6 Way Blade, 2,278 hrs., 24" Pads, 9' 7" Wide $79,500

2016 Cat 330FL, Stk#: 13598, EROPS, A/C & Heat, Radio, 7,301 hrs., 47" Bucket w/Manual Thumb, 31" Pads, Quick Connect. $139,500

2021

145X LC,

Aux. Hyd. $89,500

2020 Linkbelt 210X4EX, Stk#: HR-1322, EROPS, A/C & Heat, 5,445 hrs., 35" Bucket w/Hyd. Thumb, 31% Pads $99,500

2020 John Deere 750L LGP, Stk#: HR-1427, EROPS, A/C & Heat, Radio, 6 Way Blade, 7,194 hrs., 33" Pads, 13' 5" Wide ....$159,500

2019 Cat 330 GC TC, Stk#: HR-1122, EROPS, A/C & Heat, 6,169 hrs., Aux Hyd., 32" Pads, 47" Cat Bucket w/Thumb, 1.74 yd., AM/FM Radio, Bluetooth Phone Connection, Rear & Side Cameras. $159,500

A $70 million project restored water flow to the Milk River along Montana's Hi-Line, which is used by thousands for drinking water and irrigation, according to krtv.com.

Granite, in partnership with Contri Construction Co., announced the formation of Southern Nevada Construction Partners, a joint venture that was selected recently to work on two projects for the Southern Nevada Water Authority.

On June 8, 2024, a catastrophic collapse of a section of Wyoming Highway 22 over the historic Teton Pass severed the vital commuter link connecting residents of the Teton Valley in Idaho to Jackson Hole, Wyo.

16

The Scorpion provides contractors working in piling, drilling, tunneling or commercial construction with a flexible arm for placing concrete where needed without disrupting the jobsite.

The Athletics broke ground on a new $1.75 billion Las Vegas ballpark on June 23, 2025, starting a long process expected to end on the team’s 2028 Opening Day, according to reviewjournal.com.

AED, in collaboration with the American Free Enterprise Chamber of Commerce, has reached a stipulation agreement with the California Air Resources Board concerning the enforcement of California’s ACF rule.

Volvo CE is accelerating electromobility across the all-electric World RX championship through the use of its high-performing zero-emission solutions in building and maintaining the tracks at key locations around the world.

FAYAT Group announced a significant expansion of its Road Equipment Division in Fairfield County, S.C. The France-based company will invest $13.7 million to construct a new 100,000-sq.-ft. parts distribution facility in Ridgeway.

The Slag Cement Association announced the winners of its 2024 Slag Cement in Sustainable Concrete Awards. The winning projects were unveiled and celebrated during the ACI Concrete Convention in Toronto, Ontario, Canada.

The event featured machine demos, tours of Liebherr’s operations including the machine shop and parts warehouse and networking opportunities with the Liebherr earthmoving and material handling technology team.

44

2026 SUMMIT HEADLINER NIKKI HALEY

Associated Equipment Distributors (AED) announced that Nikki Haley will be the featured keynote speaker at the 2026 AED Summit in Dallas, Texas, Jan. 19-21, 2026.

44 UTILITY EXPO, NUCA

The Utility Expo announced a new partnership with the National Utility Contractors Association (NUCA) to host the National Equipment Operator Championships at the upcoming Utility Expo in Louisville, Ky.

HD Hyundai, headquartered in Seoul, South Korea, will merge its construction equipment divisions to create a new company, tentatively named HD Construction Equipment, effective Jan. 1, 2026.

ABRA Equipment Supply has announced its appointment as the exclusive North American distributor of Foxx Loaders. The first machines are now arriving at ABRA’s Fort Myers, Fla., facility.

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

A $70 million project restored water flow to the Milk River along Montana's Hi-Line, which is used by thousands for drinking water and irrigation, according to krtv.com.

On June 17, 2024, the St. Mary River Canal siphon failed catastrophically, prompting the U.S. Bureau of Reclamation to act.

In the following year, stakeholders including federal government agencies, tribal entities and contractors joined

forces to complete repairs ahead of schedule. Fifty-two percent of the project was covered federally, with the remainder covered by Montana shareholders.

By June 25, 2025, water was flowing again.

Krtv.com noted that subzero temperatures and generally extreme winter weather made the repairs a challenge.

Frozen ground and rock made digging and backfill difficult. A modified concrete mix had to be employed.

“Frozen concrete just doesn't work. We’ve got to heat

the concrete and make sure it doesn't freeze and keeping that temperature up until you've got full strength is what we're doing,” Gary Lundberg, project inspector, told krtv.com in February.

“The St. Mary Diversion Dam and Canal were completed in 1915 as part of the Milk River Project (Project) in north-central Montana,” according to the federal Bureau of Reclamation. “The dam is located near Babb, Mont., and approximately 0.75 mi. downstream from Lower St. Mary Lake. The existing dam consists of a 198-ft.-long and 6-ft.high concrete weir and sluiceway. It diverts water from the St. Mary River into the St. Mary Canal through the gated headworks structure for use by the Milk River Project.”

The Milk River Project Joint Board of Control noted that all the contractors for the project were Montana-based. NW Construction of Bozeman led the siphon replacement, working alongside Pro-Pipe Construction of Frenchtown, which handled the intricate welding of the 90-in. steel siphons. In all, 6,444 ft. were installed, krtv.com reported.

NW Construction crews also installed a drainage system around the pipes to ensure long-term durability.

Sletten Construction of Great Falls assembled the crucial structure that will support the siphon as it spans the St. Mary River. True North Steel in Billings fabricated the steel components.

NW Construction and Sletten Construction teamed up on the inlet and outlet structures, re-designed by HDR Engineering to handle the extreme hydraulic pressures at varying flow rates. These structures are substantial, with 40-ft. walls at the inlet, making them a significant focus of current construction efforts, krtv.com reported.

The Tribal Employment Resource Office (TERO) provided approximately 30 members of the Blackfeet Tribe to work across multiple companies and compliance offices.

Granite, in partnership with Contri Construction Co., announced the formation of Southern Nevada Construction Partners (SNCP), a joint venture that was selected recently to work on two projects for the Southern Nevada Water Authority (SNWA).

On June 23, 2025, Granite announced that SNCP was selected to deliver the preconstruction phase of the Paradise Hills Construction Manager at Risk (CMAR) project for the SNWA.

And two days later, Granite announced that the joint venture was awarded the Rice Pumping Station & Pipeline Project — part of the Horizon Lateral Program.

The Paradise Hills infrastructure initiative also is a cornerstone of SNWA’s Horizon Lateral Program, which is designed to enhance long-term water delivery, system reliability and regional redundancy.

The preconstruction contract will be completed in December 2026. Construction is anticipated to begin on Jan. 4, 2027, with completion expected by January 2030. Granite’s total estimated construction contract value is $240 million.

The project includes the installation of approximately 22,000 linear ft. of 120-in. steel water pipeline, featuring up to three trenchless crossings beneath critical infrastructure: an existing 108-in. water line, Interstate 11 and Union Pacific Railroad tracks. The pipeline also will include multiple valved outlets for future connections to Boulder City, the city of Henderson’s Reservoir R-8 and the Horizon Lateral pipeline.

A new 65 million gal. per day (MGD) pumping station will be constructed, with an initial operating capacity of 35 MGD. The facility will include a single-level pump building with mechanical, electrical, and disinfection systems, surge protection infrastructure, flow metering and advanced instrumentation and control systems. Site improvements will include civil grading, access roads, perimeter security and desert-compliant landscaping.

As the JV lead, Granite will perform clearing and grubbing operations, structure excavations and backfill, form/place/strip of concrete structures, installation of access

roads along the pipeline alignment, demolition and restoration of existing roadways and the full installation of all pump station structures and equipment.

Contri will be responsible for installing the 120-in. pipeline and associated appurtenances.

“This project showcases our joint venture’s local expertise and collaborative strength,” said Don Sawyer, Granite area manager. “Through SNCP, we’re delivering a high-value, future-ready water infrastructure solution that supports the long-term needs of southern Nevada.”

Meantime, the Rice Pumping Station and Pipeline Project will be among the first to advance into detailed design and construction as part of the Horizon Lateral Program.

The project scope includes the construction of a new 30 MGD pumping station at the existing Thomas Rice Reservoir and Pumping Station site. In addition, a 21,000linear-ft., 42-in. diameter steel water pipeline will be installed to convey water southwest to the Spring Mountain/Durango Reservoir site.

“This project exemplifies our commitment to building resilient infrastructure that supports the long-term water needs of southern Nevada,” said Chris Burke, Granite vice president of regional operations. “We’re honored to continue our collaboration with SNWA and Contri Construction Co. on this vital initiative.”

Granite’s involvement in the Horizon Lateral Program underscores its expertise in complex water infrastructure and its dedication to sustainable, community-focused construction solutions.

Granite was awarded a $2 million preconstruction services agreement in May 2025, with completion targeted for January 2027.

The project is expected to transition into a construction phase of $100-$120 million, with Granite’s portion being approximately $70 million.

The construction portion of the project is expected to begin in February 2027 and continue through March 2030.

For more information, visit graniteconstruction.com.

Case 580SR Backhoe/Loader, 1:50 scale ..............................................

Case 850B Angle/Tilt Dozer, 1:35 scale ................................................

Case DH4B Trencher, 1:35 scale

Case 9030B Excavator, 1:50 scale

Caterpillar AP-1000 Asphalt Paver, 1:50 scale ......................................

Caterpillar CB534 Double Drum Roller, 1:50 scale $40

Caterpillar D3 Track-Type Tractor, 1:50 scale $110

Caterpillar D4E Track-Type Tractor, new color, 1:50 scale ....................$75

Caterpillar D4E Track-Type Tractor, old color, 1:50 scale $75

Caterpillar D6H Track-Type Tractor, 1:50 scale

Caterpillar D7C Track-Type Tractor, 1:50 scale ....................................$110

Caterpillar D8L Track-Type Tractor, 1:50 scale

Caterpillar D8N Track-Type Tractor, 1:50 scale $110

Caterpillar D9N Track-Type Tractor w/black Tracks, 1:50 scale ..........$100

Caterpillar D9N Track-Type Tractor w/yellow Tracks, 1:50 scale ........

Caterpillar D10 Track-Type Tractor w/ ripper, 1:50 scale

Caterpillar D11R Track-Type Tractor, 1:50 scale

Caterpillar 225 Crane w/clamshell bucket, 1:50 scale

Aero Aggregates, the first vertically integrated manufacturer in North America to produce ultra-lightweight, foamed glass aggregate (UL-FGA), concluded its role in providing strong, yet lightweight backfill material for the Wyoming Department of Transportation (WYDOT) Teton Pass Big Fill Slide permanent repair project.

On June 8, 2024, a catastrophic collapse of a significant section of Wyoming Highway 22 over the historic Teton Pass severed the vital commuter link connecting residents of the Teton Valley in Idaho to the resort and tourism destination of Jackson Hole, Wyo.

Extreme weather, mudslides and roadbed failure required extensive repair efforts to quickly make the road passable and to then permanently solve for the steep slope and significant water management challenges associated with modern road construction

through the Teton Pass.

“The foamed glass aggregate provided by Aero Aggregates was the product of choice for the WYDOT ‘Big Fill Slide’ project on the Teton Pass,” said Pete Schexnayder of Ames Construction, the project’s general contractor. “The product not only allowed continuous placement, but it was also less susceptible to weather conditions, decreased the weight of mass exerting forces on the existing material below the embankment and was ecologically friendly for the surrounding national forest.”

The repair project involved reconstructing a 100-ft.-high embankment and incorporating drains into the slope. Instead of specifying the traditional stone or soils historically used as highway and infrastructure backfill material, the WYDOT team evaluated lightweight fills and proposed closedcell, foamed glass aggregate for its excep-

tional strength-to-weight ratio and water drainage properties.

The impacted Teton Pass highway section is expected to be fully reopened by mid-July, completing the infrastructure restoration.

Aero Aggregates is the only domestic producer of closed-cell, foamed glass aggregate using a dry-foam manufacturing process. The strength of the company's UL-FGA is comparable to traditional stone aggregate but is 85 percent lighter, making it easily transported and quickly positioned on site.

The product's exceptional flow rate, combined with the backing of Aero Aggregates’ geotechnical team and the expertise of WYDOT's engineer-of-record for the project, was critical for successfully completing this complex infrastructure repair efficiently and effectively.

The project, the tallest foamed glass aggregate slope stabilization in the United States

used approximately 60,000 cu. yds. of Aero Aggregates' sustainable, lightweight backfill material. Due to transport safety weight limits, shipping this volume of material would have required six times more truck runs if traditional fill materials had been used. This significant reduction in transportation meant fewer trucks, lower carbon emissions and more efficient project execution.

“Working with Ames Construction and the WYDOT engineering and implementation team on the Teton Pass repair was an exceptional collaborative experience," said Archie Filshill, CEO and co-founder of Aero Aggregates. “As a team of geotechnical engineers, we didn't just deliver aggregate; we provided a comprehensive technical solution that addressed both weight and water drainage concerns in the slope reconstruction.”

Aero Aggregates’ manufacturing process converts landfill-diverted glass into a chemically stable, non-leaching, rot-resistant, nonflammable and durable construction material. The foamed glass material used in this project was produced in Aero Aggregate’s manufacturing plant in Dunnellon, Fla., and was shipped via intermodal rail and truck to the Teton Pass. Curbside recycled glass for this project was sourced from the curbside recycling efforts of residents and small businesses in Central Florida.

Approved by 25 state DOTs, the reliability and broad acceptance of Aero Aggregate’s UL-FGA in highway and infrastructure projects is well-established.

For details, visit aeroaggna.com. (All photos courtesy of Aero Aggregates.)

At Smith Power Products, Inc. we understand the rigors of off-highway diesel engines and mobile machinery. Which is why our industrial products are designed to meet these tough everyday standards. We emphasize performance and reliability to provide you with a product that maximizes your production and profitability.

Our re-power capabilities cover a vast range of mobile machinery and our years of experience has taught us that proper installation is a key component in the second life of a machine.

Arizona Bejac Corporation www.bejac.com

GLENDALE 1 (800) 772-3522

California Bejac Corporation www.bejac.com

PLACENTIA

(714) 528-6224

SACRAMENTO

1 (800) 772-3522

ANDERSON 1 (800) 772-3522

VISALIA 1 (800) 772-3522

Colorado Power Screening, LLC. www.powerscreening.com

Bane Machinery www.banemachinery.com

DALLAS (214) 352-2468

FORT WORTH (817) 847-5894

TYLER (903) 597-6641

SALLT T LAKE CITY 1 (800) 772-3522

Washington Orion Equipment www.orion-equip.com

SEATTLE (800) 280-8124

VANCOUVER (800)280-8124

HENDERSON Utah Bejac Corporation www.bejac.com

(303) 287-0100

Idaho Central Equipment Co. www.centralequipment.us

JEROME (208) 324-8515

POCATELLO (208) 233-2850

Nevada Bejac Corporation www.bejac.com

LAS VEGAS

1 (800) 772-3522

RENO 1 (800) 772-3522

New Mexico Power Screening, LLC. www.powerscreening.com

ALBUQUERQUE (505) 345-4467

Wyoming Power Equipment ofWyoming, Inc www.power-equip.com

CASPER (307) 577-9700

LASVEGAS (800) 2808124

Oklahoma Central Power Systems & Services www.cpower.com p OKLAHOMA CITY (405) 324-2330

TULSA (918) 984-6565

Texas Nueces Power Equipment www.nuecespower.com

CORPUS CHRISTI (361) 687-2284

o. offers an extensive lin ing equipment and techn dlddf e distribution net e of earthmoving and ology in the USA. Main tdihb work (361) 433-0672

VICTORIA (361)4330672

LAREDO (956) 267-1495

SAN BENITO (956) 361-0066

VINTON (915) 201-4115

CONVERSE (210) 807-8216

Liebherr USA, C material handli t

HUMBLE (713)247-0066 components ar Liebherr or in c highest possib the entire drive variety of comp systems. Reach more informati e developed and manufactured in-house by lose collaboration with our partners to ensure the le quality standards.These components include and controltechnology, diesel engines, and a onents for hydraulics, gearboxes and electronic out to your local Liebherr distribution partnerfo on. e r (713) 2470066

Mecbo America, a division of Blastcrete Equipment LLC, brings a new product to its lineup: the Scorpion concrete crawler boom.

The Scorpion provides contractors working in piling, drilling, tunneling or commercial construction with a flexible arm for placing concrete where needed without disrupting the jobsite.

It is an economical enhancement for contractors who have a concrete pump but need an effective way to deftly move material to spots that are difficult or unsafe to reach using other methods.

“As concrete contractors grow and the scope of their work changes, many recognize the need for a boom. The Scorpion provides that benefit without the added expense of another pump,” said Blastcrete co-CEO Scott Knighton.

Previously, these obstacles created timeintensive and costly setbacks on projects, but the expansive reach of the Scorpion eliminates such concerns. This setup is particularly advantageous for work on highway overpasses or in large commercial buildings with tight spaces. It’s one of the safest ways available for getting concrete pumped up to high spots.

Contractors will benefit from a nimble design — because it has no stabilizers, the operator can keep pumping concrete while the machine is still moving, advancing speed and operational efficiency. Additionally, customizations are available for customers who want to reach higher than 52 ft.

The 10-ton Scorpion has a reach of 52 ft. vertically and 46 ft. horizontally, with a rotational span of 370 degrees — allowing operators to make just more than a full turn while extending over structures, landscaping and other difficult-to-reach or potentially dangerous areas.

All Scorpion concrete crawler booms come standard with a convenient, handheld radio control to move the boom and undercarriage. Power supply selections include a 50-hp electric motor or a 30-hp diesel engine with a soundproofing option. The arm folds up in a “Z” formation to make the machine easier to haul on a trailer.

For more information, visit mecboamerica.com, mecbo.it and blastcrete.com.

The Athletics broke ground on a new $1.75 billion Las Vegas ballpark on June 23, 2025, starting a long process expected to end on the team’s 2028 Opening Day, according to reviewjournal.com.

In 2023, the team chose a Mortenson-McCarthy joint venture as the construction manager for the ballpark. The JV previously joined forces on the $1.97 billion Las Vegas Raiders’ Allegiant Stadium. The JV will be responsible for preconstruction, estimating, scheduling, logistics, bidding, management of trade partners, labor relations and community engagement.

Crews started early groundwork in late April, in preparation for foundation work. A’s President Marc Badain said that work would begin immediately, reviewjournal.com reported.

That foundation work, as well as utility work beneath the stadium’s foundation, will continue throughout 2025, including the first concrete being poured, reviewjournal.com reported

Cranes are scheduled to arrive this month, allowing for vertical construction to begin in the months ahead.

“We’re on time,” Badain said. “I think you’re going to start seeing things go vertical very quickly here. You’re going to start to see a lot of development in the next couple of months.”

“Three years from now we are going to see the fruits of all that labor when in 2028 we have opening day out here on the Las Vegas Strip,” A’s owner John Fisher said during the stadium’s groundbreaking ceremony.

The team provided a year-byyear breakdown of projected milestones as the 33,000-fan capacity ballpark is constructed, according to reviewjournal.com

■ Concrete work to begin.

■ Tower cranes put into place.

■ First buttress added.

■ First concrete column set.

2026

■ Steel work begins.

■ First slab on grade to be poured.

■ Buttress construction to be completed.

■ Precast work to begin.

■ Suite finishings to begin.

■ Structural steel to be topped out.

■ Mega panel to be topped out.

■ First seat set to be installed.

■ Player clubhouses to be completed.

■ Playing field to begin being installed.

■ Completion of suites.

■ Enclosing of the stadium set to occur.

■ Completion of playing field installation.

■ Certificate of occupancy

awarded by Clark County once the stadium is substantially completed.

■ Opening day.

The ballpark is on the site of the iconic Tropicana Hotel in Las Vegas, which was demolished in just 22 seconds on Oct. 9, 2024,

after 67 years of operation. Controlled Demolition Inc. (CDI) of Phoenix, Md., handled the implosion of the two towers, which was preceded — in true Las Vegas fashion — by a sevenminute fireworks and 555-drone show. BIG photo

Associated Equipment Distributors (AED), in collaboration with the American Free Enterprise Chamber of Commerce, has reached a stipulation agreement with the California Air Resources Board (CARB) concerning the enforcement of California’s Advanced Clean Fleets (ACF) rule.

The agreement comes after CARB failed to obtain a Clean Air Act waiver from the Environmental Protection Agency (EPA) before the Trump administration took office. AED and its co-litigant

pursued legal action, challenging the ACF rule’s applicability to high-priority and drayage fleets.

Chief United States District Judge Troy Nunley of the eastern district of California signed the stipulation agreement and abeyance order. Under the terms of the agreement, CARB has committed to propose the repeal of the ACF’s high-priority fleet and drayage fleet rules by Sept. 1, 2025. Once repealed, AED’s lawsuit will be dismissed. In the meantime, the case will remain in

abeyance, and CARB has agreed not to enforce the contested rules against AED members — including any retroactive enforcement. Should CARB fail to repeal the rules, the agency has committed to a 120-day non-enforcement period, allowing AED sufficient time to refile its lawsuit.

“AED is pleased with this important step toward protecting our members from regulatory overreach,” said Brian P. McGuire, president and CEO of AED.

“This agreement ensures that our industry

will not be burdened by unrealistic mandates and allows us to continue advocating for fair, transparent and practical regulatory processes.” AED logo

Niece 8,000 gallon water tanks

installed on 40 ton Articulated Off Highway chassis. This combination is the workhorse of the dust control and water needs for quarries and large construction sites

The NWT9500 9500 Gallon water tank mounted on articulated truck. Pictured: Deere 460E with 9,500 gallon tank. Tanks come with 6X5 pumps.

The NFL3000 Off Road, Fuel and Lube Bed offers 3,000 gallons of diesel fuel.

The NFL10000 Fuel & Lube Can be mounted on any 100,000 lb rigid frame truck. Holds 10,000 gallons of diesel. 5 additional fluid tanks. Holds up to 3,000 gallons of oil.

Volvo CE is accelerating electromobility across the all-electric World RX championship through the use of its high-performing zero-emission solutions in building and maintaining the tracks at key locations around the world — mirroring the electric rallycross cars that will soon be racing on them.

As Official Track Building Partner, Volvo CE is tasked with building new features on existing racetracks or sometimes building courses entirely from scratch — in the most sustainable and efficient way possible and always under tight timeframes. The company also is tasked with maintaining the tracks and recovering crashed cars during the races themselves with its safety solutions. These challenges require power, precision and adaptability. Volvo CE's advanced electric machines are engineered to handle the unique challenges of shaping and maintaining these high-intensity circuits while reducing reliance on fossil fuels, according to Volvo. With their near silent operation, electric machines increase efficiency by making it possible to build tracks during the night or during unsocial hours.

By integrating electromobility into track construction, the company is demonstrating the strength of its sustainable solutions in demanding, real-world applications like motorsport. This year, the solutions are getter bigger and better with the inclusion of new mid-size machines like the L120 electric and L90 electric wheel loaders and the updated EC230 electric excavator, now boasting a full day of operation.

This approach to drive efficiency and sustainability both on and off the track, allows the partnership to maintain the fast-paced thrills of motorsport with a lighter carbon

footprint.

Volvo CE's commitment to sustainability extends beyond construction. The electricpowered CE Dealer team by Volvo Construction Equipment, the only gender-balanced team in World RX, returns to competition this season. It is a clear demonstration of how to combine high-performance motorsport with a bold, forwardthinking approach and brings the company's

performance-driven, purpose-led mindset to the track.

Bill Law, head of brand marketing and communications of Volvo CE, said, “The FIA World RX Champion-ship continues to be a fantastic format to raise awareness of the transition to a more sustainable future for construction and motorsport alike. Through an unbeatable mix of state-of-the-art sustainable power and digital innovation, we are proud to be leading the way for a new era of high-performing electromobility. Thanks to our continued partnership with the FIA, the 2025 season is set to be more dynamic than ever before.”

To keep up to date with the latest race schedule, visit fiaworldrallycross.com/calendar.

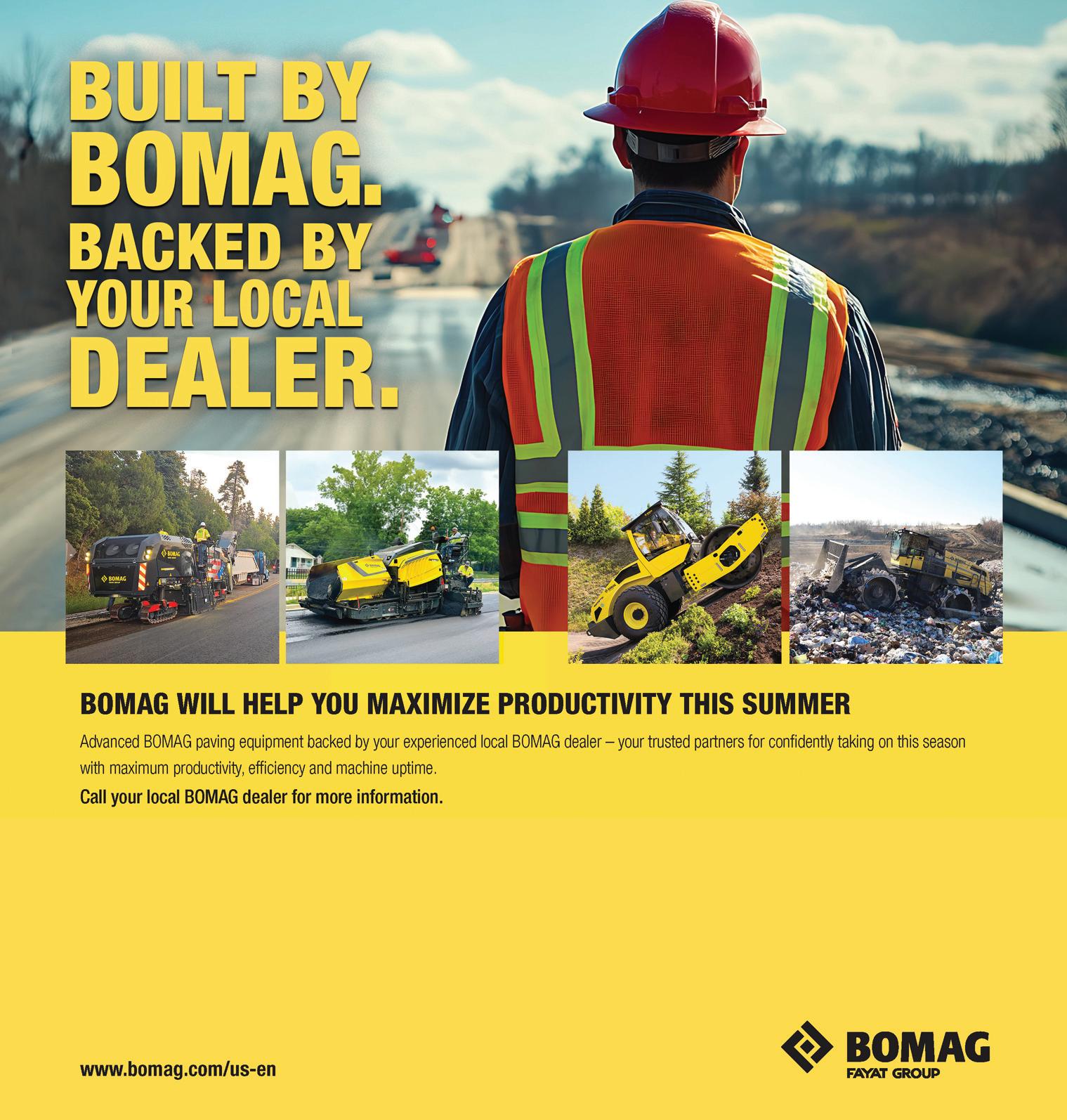

FAYAT Group announced a significant expansion of its Road Equipment Division in Fairfield County, S.C.

The France-based company will invest $13.7 million to construct a new 100,000-sq.ft. parts distribution facility in Ridgeway, creating 75 new jobs in the region.

Founded in 1957, FAYAT operates in 170 countries with more than 23,000 employees. Its Road Equipment Division manufactures

and assembles equipment for every stage of the road lifecycle — including asphalt production, application, compaction, sweeping, cold milling, stabilization and recycling — as well as airport support vehicles.

The new facility, located at 321 Blue Granite Parkway, will bolster FAYAT’s aftersales support for customers across North America and allow for greater localization of machinery production at its existing Fairfield

County site, according to the company. The expansion is expected to be operational by the fourth quarter of 2025.

“FAYAT moved its BOMAG North American headquarters to Fairfield County over a decade ago to better serve our customers,” said Rob Mueckler, general manager of FAYAT’s Road Equipment Division. “This new investment nearly doubles our footprint and is a testament to the success of that deci-

sion and the strength of the local workforce.”

South Carolina Gov. Henry McMaster welcomed the expansion.

“FAYAT Group’s investment once again proves that South Carolina provides existing businesses with the resources needed to find continued success,” he said.

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Closner Equipment

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Waller, TX 936-525-9949 PacWest Machinery

Portland, OR 503-252-5933

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Eugene, OR – Branch 541-302-3762 Power Equipment Company

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

www.tristatetruckandequip.com

Belgrade, MT 406-388-5818

Billings, MT 406-245-3188

Casper, WY 307-472-1818

Great Falls, MT 406-452-9551

Albuquerque, NM 505-345-7811 Tri-State Truck and Equipment

Rock Springs, WY 307-362-4000 Shafer Equipment

wwwshaferequipmentco.com

Sparks, NV 208-801-7772 Boxcer Equipment

www.boxcerequipment.com

Tulsa, OK 918-272-7237

By Lucy Perry CEG CORRESPONDENT

When the COVID-19 pandemic hit, the construction industry was forced to work around a multitude of issues, from logistics nightmares to materials bottlenecks to the ageold shortage of skilled workers. But with brains and muscle, the industry’s resilience prevailed. Today, the market faces similar challenges. But now, the market has the skills and experience to address whatever comes to pass.

“Post-COVID-19, there’s definitely been a step-change in how contractors manage supply chains,” Adrian Pellen told Insurance Business America magazine.

NFP’s North America head of construction, he said the strides the industry took are being tested by renewed volatility.

The fact is, the pandemic forced contractors to drop the just-in-time procurement models, Pellen said in the magazine article. Instead, they invested in supply chain visibility, vendor vetting and risk diversification. Today, they’re assessing vulnerabilities using AI, he said.

“Contractors are doing deep pre-qualifications of subcontractors, checking their financials and ensuring they’re local enough to be reliable.”

And on the material side, the industry overall is making efforts to diversify and domesticate sourcing. In both the United States and Canada, reshoring and nearshoring efforts are intensifying, Insurance Business America reported.

The United States has leaned into sourcing domestic lumber, particularly southern pine from the Southeast, while also facilitating cross-border steel flows with Canada.

“These are strategic shifts that are likely to stick,” said Pellen, who added that the broader trend is about resiliency.

Chiefly, he said, it’s about “being able to adapt quickly without compromising profitability.”

Inflation is creating its own worries for the construction industry, driving many businesses to study the contractual process with their insurance providers.

Back at NFP, Pellen noted that scrutiny is critical today because a business could find itself suddenly dealing with much higher costs due to inflation.

“So, there’s a question of who shoulders that burden,” he said. Also, price volatility has forced developers to stockpile materials.

While this strategy may hedge against future cost hikes particularly for steel and lumber, it also brings a fresh set of insurance challenges, said Pellen.

The shift away from the just-in-time model introduces storage risk, he said. “Stockpiling increases exposure to fire, theft and natural disasters.”

As a result, contractors and their providers are now building those factors into their risk mitigation strategies.

Less visible but just as impactful are project delays, said Pellen. Cost spikes can halt procurement and push back completion dates, he said. That pushback in turn can trigger a cascade of insurance complications that can result in disaster for an unprepared contractor.

Pellen cited as an example builder’s risk policies, which are priced based on expected construction value and set timelines. He explained that if a project is extended and material prices increase, the insurance premium also is likely to go up.

The bottom line is, these shifts are forcing insurers and clients alike to rethink how they price and structure insurance products, Pellen said. As a result, some contractors are exploring their options, such as automatic extensions or pre-negotiated terms for extended coverage.

With all these variables hitting the construction industry, it helps to have the ear of an expert. Insurers are more engaged than ever in helping clients find solutions, said Pellen. They’re discovering ways to build flexibility particularly for long-term projects where prices can quickly change, he said.

Frankly, planning for volatility is the new normal and the key to success, added Pellen.

“We’re advising clients to review their escalation clauses,” he noted in the Insurance Business America article. “Many policies allow for 5 percent, 10 percent or even 15 percent increases. But on large projects, that may not be enough anymore.”

As some insurers have pulled back, brokers have asked others to take larger shares of placements on infrastructure projects.

Darron Johnston, executive vice president of Amwins, said they may be asked now to take 20 percent to 30 percent.

“We’re asking for more capacity from more players,” which usually means increased coverage costs, he told Risk & Insurance magazine.

Finding adequate liability coverage for infrastructure projects has been a particular problem, per Aldo Fucentese, Liberty Mutual.

Chief underwriting officer for the practice serving large contractors, he said that has probably been the biggest pain in the market.

“Insurance used to be around 1 percent of a project’s value,” Pellen told Insurance Business America. “Now it’s closer to 2 percent or 3 percent, and in places like New York, it’s hitting 10 percent. That has a massive impact on project

Insurers in the United States are shying away from writing the coverage in a class of business known for attracting litigation that sometimes results in huge awards.

The Slag Cement Association (SCA) announced the winners of its 2024 Slag Cement in Sustainable Concrete Awards.

The winning projects were unveiled and celebrated on April 2, 2025, during the spring ACI Concrete Convention in Toronto, Ontario, Canada.

“It was a remarkable turnout for exceptional slag cement projects at this year’s Slag Cement in Sustainable Concrete Awards.” said Nick Brimley, SCA membership and marketing director. “It has been inspiring to see SCA’s awards program grow as it continues to celebrate the incredible use of slag cement in concrete construction.”

Fourteen construction projects from across the United States and Canada were chosen to showcase the broad applications of slag cement and its impact on creating more durable and resilient concrete. These construction projects were awarded in six categories. The categories include infrastructure, high performance, architectural, durability, innovative applications and lower carbon concrete. Two slag cement research projects also were honored in this year’s program.

The 2024 Slag Cement in Sustainable Concrete Construction Award winners included: Infrastructure

• Replacement Fuel Bulk Storage Facility, Niagara Falls, N.Y.

• Ohio DOT IR 70, SR 29 Interchange, Roundabout, West Jefferson, Ohio

• Expand Cargo Apron — Phase V, Middletown, Pa.

High Performance

• TSX Broadway, Palace Theater Redevelopment, New York City, N.Y.

• The Couture, Milwaukee, Wis. Architectural

• River Sol, Bend, Ore.

• 760 Ralph McGill Parcel “B” Hotel, Atlanta, Ga. Durability

• MHC Kenworth, Cheyenne, Wyo.

• Concrete Pavement Intersection for Middle Road, Hanover Street, Newbury, Mass.

Innovative Applications

• Testing, Implementation of Low-Carbon ASTM C1157 Slag Cement Mix, New Carlisle, Ind.

• Advanced Nuclear Material Research Center (ANMRC), Chalk River, Ontario, Canada

Low Carbon Concrete

• The Seattle Storm Center for Basketball Performance, Seattle, Wash.

• Crossroads North Building 11, Van Buren, Mich.

• Use of Innovative Sustainable, Durable Materials in Concrete Pavements, Monticello, Minn.

The 2024 Slag Cement in Sustainable Concrete Awards Research Award winners included:

• Using Slag Replacement for Enhanced Performance of High-Limestone Cements, Christian Pavlidis, University of Toronto

This project demonstrated how blended cements and supplementary cementitious materials play an important role in reducing clinker contents as part of the plan to achieve industry carbon reduction targets in North America. Research has shown evidence of a synergistic relationship between raw limestone and slag in cement for improved microstructural

properties and improved durability.

www.arnoldmachinery.com

Las Vegas, NV 702-642-9000 Phoenix, AZ 602-414-1900 Tucson, AZ 520-294-7677 Albuquerque, NM 505-895-1565

Currently, the CSA A3001 and ASTM C595 standards allow for the use of Types GUL (IL) and GULb (IT) cement with a maximum of 15 percent interground limestone, but higher levels of limestone maybe needed to allow, for example, LC3 and other proposed blended cement systems. In this study, six concrete mixtures were cast with 5 to 25 percent limestone content and 0 to 50 percent slag replacement to determine if higher-limestone cements can provide equivalent performance to currently allowed Type GU and Type GUL cements with and without slag cement replacement.

Results showed that in mixtures with 50 percent slag, cements with 25 percent limestone were most effective at mitigating ASR, reducing sulfate expansion and limiting chloride ingress. These mixtures also gained comparable seven-day strengths to GU and GUL15 cements with 50 percent slag, reduced permeability and showed similar performance in freezing and thawing and de-icer salt scaling tests.

• Practical Implementation of Internally Cured Slag Cement Concrete Using Superabsorbent Polymers, Chibueze Sylvester Ajuonuma, Purdue University

This project investigated the practical implementation of internally cured slag cement concrete using superabsorbent polymers (SAP) to enhance hydration, mitigate shrinkage and improve long-term performance. The focus is on addressing challenges associated with slag cement’s slower hydration and shrinkage tendencies, which can affect strength development and durability in conventional applications. The significance of the study lies in its potential to revolutionize slag cement usage by demonstrating its feasibility for high-performance and sustainable construction.

SAP provides internal curing by releasing stored water gradually, ensuring sustained hydration and mitigating autogenous shrinkage. The project involved evaluation of the performance of six concrete mixture with Type 1L cement, 30 percent wt. slag cement replacement, 0.2 percent SAP and colloidal nanosilica (4 oz/cwt). Comprehensive characterization was conducted to evaluate workability, air content, strength (compressive — 7, 28, 56, 90, 365 days) and flexural (at four days driven by opening to traffic requirements), durability (rate of water absorption, drying shrinkage, scaling resistance, chloride penetration depth and resistivity) and hydration kinetics.

The study highlights that incorporating superabsorbent polymers (SAPs) into slag concrete improves its workability, sustains hydration and enhances durability. This study aims to evaluate the performance of these innovative concrete mixes in real-world applications and underscores the practical benefits of internally cured slag cement concrete, offering a durable and eco-friendly alternative to conventional cementitious materials for modern infrastructure.

For more information, visit slagcement.org/awards. Slag Cement Association logo

www.ascoeq.com

Beaumont, TX 409-212-8100 Brenham, TX 979-836-6641 (North) Houston, TX 281-987-1990 (South) Houston, TX 713-649-0940

www.beeequipmentsales.com

Lubbock TX

806-745-1511

866-796-3211

www.closner.com

Schertz, TX 210-732-2131

Rhome, TX 817-708-9108

Manor, TX

512-272-8200

Waller, TX 936-525-9949

www.romco.com

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Dallas (Carrollton), TX 214-819-4100

Ft. Worth, TX 817-626-2288

Longview, TX 903-758-5576

Midland, TX 432-234-9409

San Antonio, TX 210-648-4600

Stephenville 254-266-2871

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

Pellen said contractors and their insurance providers are negotiating for higher thresholds these days. Clients also are being encouraged to think longer-term when it comes to insurance coverage, he said.

“Delays are more likely, so we’re asking whether it makes sense to place policies with automatic extension options or longer base durations,” Pellen added.

Especially when it comes to public entity infrastructure construction, insurance providers have a vital role in protecting both the project and their client.

Contractors operating in an “uncertain market” require careful underwriting, Marcus Henthorn told Risk & Insurance.

The managing director of Gallagher, he said there are myriad “headwinds” that challenge infrastructure project launches. Proper coverage is one of them.

“I think one of the biggest is labor — there’s a chronic shortage of labor across the country.”

Construction labor shortages, along with inflation, supply-chain issues are among factors raising building costs and creating delays on some projects.

“It makes it harder for our clients to understand the true exposure, when [a project] is going to finish and what it’s going to look like,” Henthorn said. “That concern translates into the underwriting community.”

So much so that public entities can’t do without a willing and healthy insurance market. Without adequate coverage and a surety bond market to guarantee performance and payments, the risk to build would be too great, say experts.

“Insurance is absolutely critical,” said Fucentese. “A lot of different lines come into play and if you don’t have surety capacity, you can’t even get started.”

Finding coverage has gotten somewhat harder for contractors on large infrastructure projects.

According to Risk & Insurance, many on the provider side believe the picture is not one of total doom and gloom

Johnston believes tough times tend to create opportunities for insurers willing to commit capacity. That bodes well for contractors.

“Markets tend to step up,” he said. So, as the public sector deals with the “heartburn,” insurers are working to generate more capacity to support this space.

“We’d love to have more competition to ultimately deliver a better product to the client,” Johnston said.

tor full of risks and uncertainties, the construction industry, by nature, has no choice but to be resilient.

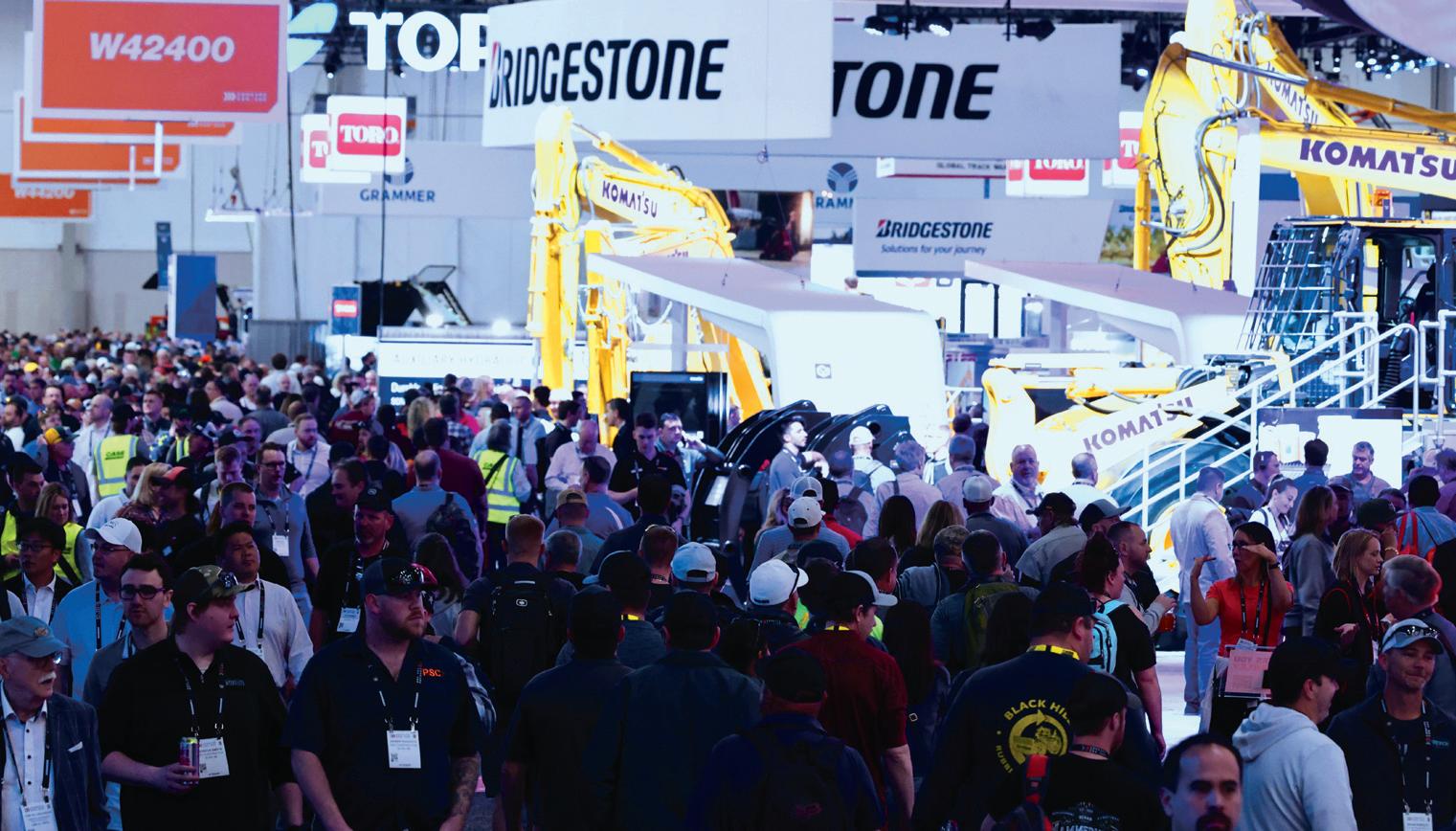

Writing for Smartbrief, Evan Milberg noted that “despite muddy conditions,” the AEM marked its Celebration of Construction on the National Mall in May.

Despite labor shortages — Milberg noted that 45,700 job openings are projected annually — the industry has found reasons to collectively exhale.

Members of the AGC responded to a poll indicating that they were less concerned about tariffs than they were weeks prior.

Only 27 percent of respondents said they were more concerned, and 66 out of 107 said they had not felt pressure to expedite work because of concerns.

Further, AGC found in a May 15 poll, 57 percent of respondents indicated some level of support for the Trump administration’s peak tariffs on China.

Contractors are concerned about equipment theft, which the American Rental Association said is a $100 million crisis annually for the rental industry. In fact, more than 360 machines disappear each month, the ARA reported, and many are stolen through fraudulent rentals rather than break-ins.

SmartBrief’s Milberg wrote that rig thieves have been known to pose as legitimate customers, using false identities to obtain equipment they quickly resell. This quick-flipping leaves little chance of recovery for the equipment owner and is why ARA launched its Equipment Rental Guard ID verification program.

At its construction celebration the Associated Equipment Manufacturers stressed how vital the industry is to local and state economies.

SmartBrief noted that the U.S. equipment manufacturing industry supports 2.3 million jobs and contributes roughly $316 billion to the economy every year. At the same time, it generates $714 billion in total output and $47 billion in tax revenue, according to AEM.

Its economic impact is felt nationwide, and the ripple effect extends through manufacturing, the supply chain and consumer spending from employee wages.

On average, employees in the industry earn $89,700 annually, according to the SmartBrief article.

Pellen of NFP believes while the road ahead for construction is uncertain, the industry will navigate forward.

Sharper focus on supply-chain management, more sophisticated insurance planning and a willingness to adapt new

Because

and strategies can only help, he said.

closner.com

6532 East Highway 114 Rhome, TX 76078

817-708-9108

21910 FM 2252 Schertz, TX 78154 210-732-2131

13800 FM 973 N Manor, TX 78653 512-272-8200

18851 GH Circle Waller Industrial Park Waller, TX 936-525-9949

ascoeq.com

5980 S M L King Jr Pkwy Beaumont, TX 77705 409-746-5102

202 I-35 Frontage Road Belton, TX 76513 254-613-1500

2800 Hwy 290 E Brenham, TX 77833 979-836-6641

1875 N Earl Rudder Fwy Bryan, TX 77803 979-779-8942

1512 Neptune Dr. #9706 Clinton, OK 580-323-3422

2019 Airport Fwy Euless, TX 76040 817-283-2844

980 N Sam Houston Pkwy E Houston, TX 77032 281-987-1990

6203 Long Drive Houston, TX 77087 713-649-0940

27500 E University Drive Aubrey, TX 76227 972-441-2726

12805 US-290 E Manor, TX 78653 512-272-8922

7100 SW 3rd Street Oklahoma City, OK 73128 405-789-6812

902 SE 9th Avenue Perryton, TX 79070 806-435-7773

1920 S East Loop 410 San Antonio, TX 78220 210-333-8000

3600 US-82 Sherman, TX 75090 903-893-7586

401 FM 148 Terrell, TX 75160 972-563-2171

12210 E 1st Street Tulsa, OK 74128 918-437-5085

2602 E Front Street Tyler, TX 75702 903-593-0201

2900 Henry S Grace Fwy Wichita Falls, TX 76302 940-687-2726

beeequipmentsales.com

2506 East Slaton Highway Lubbock, TX 79404 806-745-1511 855-813-3775

nixonegli.com

2044 S. Vineyard Avenue Ontario, CA 91761 909-930-1822

800 E. Grant Line Road Tracy, CA 95304 209-830-8600

2750 Marion Drive Las Vegas, NV 89115 702-342-8100

Liebherr photo Attendees were able to get hands-on knowledge from Liebherr product experts at the Liebherr LES 2025 open house.

Liebherr Equipment Source Newport News held an open house at its Hampton Roads facilities.

The event featured machine demos, tours of Liebherr’s operations including the machine shop and parts warehouse and networking opportunities with the Liebherr earthmoving and material handling technology team.

Attendees were able to participate in multiple machine walkarounds including the R 914 K, R 924 and R 945 crawler excavators, PR 736 dozer, L 546 wheel loader, TA 230 articulated dump truck and the LH 30 material handler. The LRT 1090-2.1 rough terrain crane, THS 110 D-K crawler concrete pump and 42 M5 XXT truck mounted concrete pump also were on display.

open house event.

Liebherr’s manufacturing and wide range of construction machines make them crucial to working fleets across many industries, according to the company. From earthmoving to road construction and civil engineering, demolition, quarrying, rail construction and material handing, Liebherr offers solutions for every challenge on nationwide construction sites. Each of these machines also offers innovative technologies, assistant systems and in-house components to support vital applications throughout the U.S.

Liebherr Equipment Source is a full-service provider of new and used Liebherr earthmoving and material handling equipment based in Virginia, Maryland and North Carolina. In addition to sales, they offer a range of services including equipment rentals, parts supply and service support to meet the diverse needs of their mid-Atlantic customer base.

Liebherr USA’s operations and distribution network ensure that products and services are accessible across the

Liebherr photo Liebherr product managers shared information on the PR 736 dozer.

entire United States. This broad reach allows Liebherr’s dealers and partners to support a wide array of industries with reliable and high-quality equipment solutions. For more information, visit liebherr.com/en-us/.

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050

Buffalo, TX 903-322-7150

Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013

Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

www.geehm.com

5461 S. Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

5400 Raley Blvd. Sacramento, CA 95838 916-375-3540

45051 Industrial Drive Fremont, CA 94538 510-955-1170

Abilene, TX 325-692-6334

Amarillo, TX 806-373-2826

OK 918-438-1700

Hewitt, TX 254-261-1370

Lubbock, TX 806-745-2112

Chico, TX 940-678-5046 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

c ) ol (IMC r achine Cont anced autom tes with adv yg . ned plans ou an help y ation

efully design w and car e

face to design sur uickly

Odessa, TX 432-333-7000 www.clairemontequipment.com San Diego, CA 858-278-8351 Escondido, CA 760-739-9100 Fontana, CA 909-429-9100 Imperial, CA 760-355-7700

Indio, CA 760-863-5558 San Diego, CA 858-278-8338

apcoequipment.com North Las Vegas, NV 702-871-7474

equip-pros.com

Mission, TX

888-750-EQPROS

scottequip.com

Fontana, CA 800-316-0327

Santa Fe Springs, CA 562-777-0775

Temecula CA 951-355-3085

ttjequipment.com Jasper, TX 409-384-4611

Longview, TX 903-803-3365

Lufkin, TX 936-634-3365

cpower.com Midland, TX 432-248-8344

San Antonio, TX 210-591-6807

Corpus Christi, TX 361-737-0049

Oklahoma City, OK 405-324-2330 Tulsa, OK 918-984-6565

Woodward, OK 580-256-6014

stewartandstevenson.com Albuquerque, NM 505-881-3511

Denver, CO 303-287-7441

El Paso, TX 915-790-1848

Lubbock, TX 806-745-4224

Wichita Falls, TX 940-322-5227

Associated Equipment Distributors (AED) announced that Nikki Haley will be the featured keynote speaker at the 2026 AED Summit in Dallas, Texas, Jan. 19-21, 2026.

Haley will be joined by a lineup of additional keynote speakers, including First Sergeant Matt Eversmann (Ret.), economist Lauren Saidel-Baker, and an expert OEM panel moderated by Marc Johnson of Pinion Global.

“We are honored to welcome Ambassador Haley to the 2026 AED Summit,” said AED President and CEO Brian P. McGuire. “Her bold leadership and global perspective, combined with the incredible lineup of speakers, will bring valuable insight to this year’s event.”

Haley’s keynote will be presented as part of “Dinner and a Conversation” — an engaging and candid onstage dialogue between Haley and McGuire. The dinner event will offer attendees a rare opportunity to hear firsthand insights from one of the most influential figures in American politics and global diplomacy.

Haley made history as the youngest governor in the country and the first minority female governor in America. Under her leadership, South Carolina became a powerhouse in economic development, earning the nickname “The Beast of the Southeast.” As U.S. ambassador to the United Nations, Haley was widely recognized for her principled leadership, commitment to U.S. interests and outspoken advocacy for human rights. She was named one of Time Magazine’s 100 Most Influential people in the world and one of Forbes’ World’s 100 Most Powerful women.

In addition to Haley, the Summit will feature First Sgt. Matt Eversmann (Ret.), whose story was portrayed in Black Hawk Down, sharing leadership lessons on resilience and strategic decision-making from his military experience. Marc Johnson of Pinion Global, a trusted advisor to equipment dealerships, will moderate the OEM Panel and economist Lauren Saidel-Baker of ITR Economics will provide essential macroeconomic analysis to help attendees make data-driven decisions for 2026 and beyond.

The AED Summit is the premier event for the equipment industry, uniting distributors, manufacturers and service providers from around the globe. The 2026 Summit will deliver world-class educational programming, unparalleled networking opportunities and invaluable strategic insights to help industry leaders drive their businesses forward.

For more information, visit aedsummit.com.

The Utility Expo announced a new partnership with the National Utility Contractors Association (NUCA) to host the National Equipment Operator Championships at the upcoming Utility Expo in Louisville, Ky.

The new championships, spearheaded by NUCA, will bring together skilled equipment operators from across the country to compete in a series of hands-on events designed to test precision, control and safety in utility related tasks. Events will include games like hole-in-one putting, soccer, cornhole and a pipe placement challenge. All games are performed using construction equipment.

“This partnership with NUCA adds an exciting and interactive new dimension to The Utility Expo Experience,” said Brianne Somers, show director of The Utility Expo. “Our industry thrives on skill, ingenuity and community, and these championships put all three front and center. It’s a great way to celebrate our workforce, recognize operator mastery and give attendees a real sense of what utility professionals do every day.”

“This partnership with NUCA adds an exciting and interactive new dimension to The Utility Expo Experience.”

Brianne

Somers The Utility Expo

The competition will span two days, with qualifying rounds on Oct. 8, 2025, and the championship prize awarded on Thursday, Oct. 9, 2025. Participants will rotate in a bracket-style format. Finalists will be ranked by cumulative points and time, with a sudden-death round and time extension used in the event of a tie. Prizes will be awarded to first, second and third place finishers.

“Competition can be fun in the construction industry and The Utility Expo is an exciting opportunity for NUCA and AEM to come together for a challenging, safe and enjoyable event that showcases the skills of operators,” said Ed DeNeale, NUCA director of safety. “We will have some of the best equipment operators in the United States competing for the top prize–more importantly, bragging rights. We’re really pleased to have the opportunity to bring something different to this well-known show.”

Participants will have the opportunity to familiarize themselves with the equipment and event configuration on Oct. 7, 2025, during open practice hours. Official judging will be provided and safety guidelines will be strictly enforced. NUCA and The Utility Expo will work closely to ensure liability coverage and operator oversight.

These new championships reflect The Utility Expo’s continued focus on creating high-value experiences for attendees, and showcasing the practical skills that drive the utility and infrastructure industries forward

For more information, visit theutilityexpo.com.

www.PacWestMachinery.com

8207 South 216th Street

Kent, WA 98032 206-762-5933

Mount Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR 541-302-3762

Spokane Valley, WA 509-534-5933

Pasco, WA 509-547-5933

1519 W Belt Line Road Carrollton, TX 75006 214-819-4100

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Ft. Worth, TX 817-626-2288

Houston, TX

713-937-3005

Longview, TX 903-758-5576

Midland, TX 432-234-9409

San Antonio, TX 210-648-4600

Corpus Christi, TX 361-881-4891

Mercedes, TX 956-565-0100

Stephenville, TX 254-266-2871

www.wpi.com

12320 S. Main Street

Houston, TX 77035 713-723-1050

1720 Hicks Street Tomball, TX 77375 281-351-9016

2077 N. Craig Drive Buffalo, TX 75831 903-322-7150

8903 Memorial Blvd Port Arthur, TX 77640 409-721-5305

5732 S MacArthur Drive Alexandria, LA 71302 318-408-3099

7502 Pecue Lane Baton Rouge, LA 70809 888-973-9767

125 E Airline Hwy Kenner, LA 70062 888-974-0532

The demolition, which will be completed in the fall, is being accomplished without explosives. For the mechanical demolition, the companies are using a 750-ton long-reach excavator with a 130-ft. boom and hydraulic shear/claw that grabs and cuts concrete and steel off the building. It is joined by a 550-ton and 650-ton excavator, both with claws, to pull down smaller sections, as well as smaller pieces of equipment for sorting and managing the debris.

“They’re track excavators that are modified to have special arms and equipment on them that allows them to do precision demo,” said Chris Cordeiro, general superintendent of JE Dunn Construction.

While the demolition continues on the site, the placement of an earth retention wall begins on Aug. 1. Once a section of the building is demolished, another team will be right behind, installing a concrete soil retention diaphragm wall along the perimeter so that excavation can begin. This concrete diaphragm wall is poured in vertical panels into the earth.

The diaphragm wall will use a specialized cutter that will create 22-ft.-wide vertical excavations into the dirt and rock. These vertical panels are poured one by one creating a continuous concrete wall within the earth around the perimeter of the building.

“It’s sometimes called a slurry wall, but is basically a concrete wall system, 60 ft. down into the rock,” Cordeiro said. “They cut down into the dirt and rock and fill the excavation with slurry to prevent cave-ins and they start creating a diaphragm wall, called a diaphragm because we’re basically retaining the soil. We have such a high water table, it also helps keep the water and moisture from getting into the hole when we start excavating.”

“It cuts off the water and holds the earth back so that we can dig,” added Greg Euston, vice president of JE Dunn Construction. “It’s unlike a typical excavation or most typical excavations you see around town where we start digging and then the earth retention system goes in as you dig. In a diaphragm wall, the entire earth retention system is put in first, and then you dig out inside of it.”

After each 22-ft-wide hole is dug, a crane will drop a reinforcing steel cage into the excavated hole. Then the concrete is pumped down to the bottom of the hole and as they fill the hole from the bottom up, the slurry gets displaced and pumped out.

“A vertical edge form is used on either side of the wall panel so that after the concrete is cured, they have a nice clean edge to their wall. So, when they dig out the next section, they can pour to that and you have your two different wall panels coming together,” Euston said.

When completed, there will be a linear retention system of 3,000 ft. consisting of approximately 150 panels. “The entire perimeter is going to be a big basement wall,” Cordeiro said. The diaphragm wall will be finished in the spring of 2026 and excavation will continue through the summer of 2026.

Euston said the diaphragm wall also doubles as the new building’s foundation system, supporting the structural steel and concrete structure that will bear on the diaphragm wall.

Chuck Baldwin, a project executive of joint venture partner Turner, said, “Convention centers are getting upgraded and replaced all across the country, and one of the features, or selling points, is to be able to sell exhibit hall space and ballroom space and to a smaller degree, meeting room space, with long spans without columns.”

When the steel spans across a larger area, it means fewer columns and more uninterrupted area, he said.

The trusses, he said, will stitch across from one diaphragm wall on the east side to a diaphragm wall on the west side at grade and lend integrity to the entire structure. Perpendicular to the trusses, there will be a series of infill beams that create enough structure for a corrugated metal deck, which will support a cast-in-place concrete elevated deck.

The structural steel will start to be positioned in June 2026.

When completed, the new center will be the world’s first zero-carbon-certified convention center, setting a precedent for environmental responsibility in the industry.

A structure can’t be built without any carbon, Euston explained. There is a baseline established for how much carbon would normally be expended to build a building the size of the convention center. Zero carbon certification comes from a 20 percent reduction in that baseline. The contractors are taking steps both large and small to achieve that goal.

More than 90 percent of the existing building is going to be reused or recycled, including concrete, rebar, structural steel and metal studs.

The biggest contributors to the carbon footprint are concrete and steel and the builders are putting a lot of effort into finding steel and other materials that have reduced carbon impact in their mixes.

“We’re trying to achieve the carbon reductions in all elements within the new building and where it’s impossible to get there, which is the case with some of them, then as a team we’re looking for other places where we can maybe beat those goals to make up for it,” Euston said.

To the extent possible, the contractors are using electricor solar-powered equipment on site to reduce diesel fuel usage and exhaust. This may include solid-state electrical generators in lieu of diesel-powered generators. They also are tracking fuel usage throughout the project.

There are approximately 100 workers on the site now but, at the peak of construction, there will be up to 1,000 trade partners on site. CEG

(All photos courtesy of JE Dunn Construction.)

equip-pros.com

Mission, TX 956-369-1811

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO 816-415-6787

Wichita, KS

316-789-7370

Yukon, OK 405-324-2330

Maryland Heights, MO

314-427-4911

Liberty, MO

806-415-6700

Tulsa, OK 918-984-6565

When you’ve got job that requires a site to be prepped or cleared, you need attachments you can trust to get the job done right the first time. At Blue Diamond Attachments, we’ve got your back.

Our family of brush cutters are purpose built to provide optimal performance on your skid and compact track loaders, mini loaders and full line of excavators. Providing you exactly what you need to get to the next phase of your project on – or even ahead of schedule.

So, whether the job is large, small or somewhere in between, Blue Diamond brush cutters are designed to handle it. Choose Blue Diamond – where all we do is elevate everything you do.

Clear your way to increased productivity by scanning the QR code or visit us at www.BDACutters.com!

ABRA Equipment Supply has announced its appointment as the exclusive North American distributor of Foxx Loaders. The first machines are now arriving at ABRA’s Fort Myers, Fla., facility.

With coverage spanning the entirety of North America, ABRA is actively seeking partnerships with equipment dealerships and rental companies that are looking to expand into one of the fastest-growing segments in the industry.

Foxx Loaders are designed for reliability and versatility, making them ideal for a wide range of markets including construction, landscaping, municipalities, agriculture, tree service, snow removal, land ownership, and general material handling.

Key features of Foxx Loaders include:

• North American-based support staff for timely assistance and expert guidance.

• Kubota engines with direct OEM support, ensuring trusted performance and service.

• High Flow models available for compatibility with modern, highdemand attachments.

• All-steel construction, eliminating the cracking and fading issues commonly found with plastic body panels.

• Rear-seated operator design, offer-

ing superior weight distribution, balance and a lower center of gravity compared with traditional front-seated models.

• OEM-quality components from trusted partners for enhanced durability and performance.

Service and support of the Foxx line will be delivered through ABRA’s growing network of quality dealers, backed by a dedicated internal team

focused solely on Foxx Loaders.

Additional benefits for customers include a two-year/1,000-hour warranty, a U.S.-based parts and support team, and the confidence of 30 years of manufacturing expertise.

For more information, e-mail Scott Tjelmeland, vice president of business development ABRA Equipment Supply at ScottTj@foxxloaders.com.

CEG

Oklahoma City, OK 405-917-9191

- TEXAS (Formerly Four Seasons Equipment) www.NEDealers.com Houston, TX • 800-234-5007 Dallas TX • 866-270-1700

www.nuecespower.com 7510 IH-37 Access Rd., Corpus Christi, TX 78409 361-289-0066 Laredo, TX • 956-725-0066 San Antonio, TX • 210-310-0066 San Benito, TX • 956-361-0066 Victoria, TX • 361-576-0066 El Paso, TX • 915-541-0066

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

CHART from page 50

see CHART page 62

The DEVELON DL280-7 wheel loader is a versatile and high-performing earthmoving machine. It is an ideal size for many of today’s bustling construction job sites.

As part of the DEVELON -7 Series nextgeneration wheel loaders, the DL280-7 delivers exceptional productivity, durability, reliability, safety, operator comfort, fuel economy and versatility, according to the manufacturer.

Displayed at World of Concrete with a 3cu.-yd. bucket, the 189.1-hp DL280-7 is designed for a variety of tasks, including scooping, carrying materials and loading. The machine has a dump height of 9 ft. 3 in. and is available in a high-lift configuration for additional dump height and reach.

As part of the DEVELON -7 Series next-generation wheel loaders, the DL280-7 delivers exceptional productivity, durability, reliability, safety, operator comfort, fuel economy and versatility, according to the manufacturer.

A durable box frame provides optimal balance, lifting capacity and load distribution. The frame’s articulating design enhances structural rigidity and extends the machine’s lifespan.

Additional performance features include standard ride control for added comfort, reduced cycle times, higher travel speeds, less material loss and higher productivity when loading and carrying material. The wheel loader’s limited slip differential allows the wheel with the most traction to receive the proper torque, providing enhanced tractive effort and maneuverability in tough terrain.

“Upgraded features in -7 Series machines include strong ZF heavy-duty axles and larger bucket capacities, for select models, to carry more and maximize productivity,” said Bill Zak, DEVELON wheel loader product manager.

“The redesigned cab in our next-generation wheel loaders provides 14 percent more glass for enhanced visibility and operator comfort. A standard touch screen displays all important settings and information on one monitor for easy access. Operators can view critical machine functions and control machine settings, rearview camera, heating and cooling and more.”

Standard premium features for the DL280-7 include the following:

• Auxiliary hydraulic spool

• ZF heavy-duty axles

• MY DEVELON fleet management (telematics)

• Rearview camera

• Smart key

• Smart Touch display

• Transparent Bucket technology

Safety features for the DL280-7 include a backup alarm, object detection system, optional around view monitor (AVM) camera system, rearview camera, Transparent Bucket technology and more.

For more information, visit na.develonce.com/en.

(All photos courtesy of DEVELON.)

Safety features for the DL280-7 include a backup alarm, object detection system, optional around view monitor (AVM) camera system and rearview camera.

Turlock, CA • 209-632-3931

Fairfield, CA • 707-425-9545

Merced, CA • 209-726-4600

Modesto, CA • 209-538-0911

Newman, CA • 209-862-3760

Santa Rosa, CA • 707-586-1790

Stockton, CA • 209-948-5401

Tulare, CA • 559-686-0054

Ukiah, CA • 707-468-5880

Woodland, CA • 530-615-2828

Madera, CA • 559-674-2496 Fresno, CA • 559-485-9090 CLM EQUIPMENT CO. INC. www.clmequipment.com

Lafayette, LA 337-837-6693 Lake Charles, LA 337-625-5942 St. Rose, LA 504-433-7999

BANE MACHINERY INC. www.banemachinery.com

Dallas, TX 800-594-2263 Ft. Worth, TX 800-601-2263 Tyler, TX 800-594-2200

COLUMBIA WESTERN MACHINERY Columbiawesternmachinery.com 11125 SW Tonquin Road Sherwood, OR 97140 503-454-0902

Volvo CE announced the introduction of a new series of wheel loaders.

The first five models to launch are the L150, L180, L200 High Lift, L220 and L260. In addition to a fresh design, these machines boast fast cycle times, improved fuel consumption, operator comfort and the latest technology, according to Volvo.

The new-generation wheel loaders will be gradually introduced across select markets in 2025. This series marks the third product lineup that Volvo CE has overhauled in the past year, following the launches of new excavators and articulated dump trucks.

“These loaders are a big step forward in technology and design and I think customers will be impressed,” said Eric Yeomans, product manager. “Our launches over the past year have been quite ambitious, and that’s because we’re committed to improving and tailoring our products and services to meet the evolving needs of our customers.”

Cycle times will shrink and operators will be happier due to new load-sensing hydraulics (for better responsiveness and faster lifting and lowering), automatic bucket leveling (from both dump and curl positions) and an intelligent auto bucket fill option that automates the throttle, lift and tilt hydraulics for a consistent fill every time, according to Volvo.

Smart control, a fuel-efficient engine mode, now is activated by default when the machine turns on, lowering fuel consumption by up to 4 percent without compromising productivity. The new loaders also are compatible with HVO (hydrotreated vegetable oil), which reduces greenhouse gas emissions compared with conventional diesel.

The all-Volvo powertrain delivers stability and efficiency by synchronizing the transmission, engine and axles. The converter offers increased torque output for better performance at low speeds, while reduced gear step intervals provide faster acceleration and smoother operation. Technologies like Volvo OptiShift and reverse by braking also decrease cycle times and extend component lifespan.

For dependability in the most demanding applications, Volvo torque parallel linkage delivers high breakout torque and parallel movement throughout the lifting range. A wide selection of purpose-built buckets and attachments further enhances versatility, according to Volvo.