COOPERATIVE PURCHASING MADEEASY.

ALBANY H.L.Gage SalesInc. hlgage.com

HUDSON AllegianceTrucks allegiancetrucks.com

ROCHESTER RegionalTruck&Trailer regionaltruckandtrailer.com

Add to your fleet with a cooperative contract.ContactyourInternational dealerfordetails.

LocalOption: OnondagaCountyContract

Class8#10914

Class4-7#11142

NationalOption: SourcewellContract

Truck#032824-NVS

Parts#080124-NVS

BINGHAMTON AllegianceTrucks allegiancetrucks.com

BROOKLYN AllegianceTrucks allegiancetrucks.com BRONX AllegianceTrucks allegiancetrucks.com

BUFFALO RegionalTruck&Trailer regionaltruckandtrailer.com

GENEVA RegionalTruck&Trailer regionaltruckandtrailer.com

LIVERPOOL AllegianceTrucks allegiancetrucks.com

NEWWINDSOR ArkelMotors,Inc. arkelmotors.com

NORTHHOOSICK AllegianceTrucks allegiancetrucks.com

ONEONTA AllegianceTrucks allegiancetrucks.com

PLATTSBURGH AllegianceTrucks allegiancetrucks.com

RONKONKOMA AllegianceTrucks allegiancetrucks.com

WATERTON AllegianceTrucks allegiancetrucks.com

WESTBURY SyossetTruckSales,Inc. syossettrucks.com

WESTBABYLON AllegianceTrucks allegiancetrucks.com

INSIDE

NEW YORK STATE STAFF

Volume 49, Number 539, August 2025

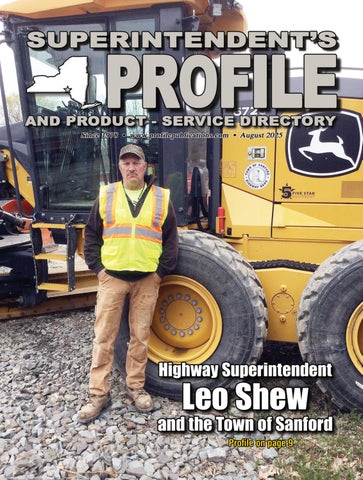

Highway Superintendent Leo Shew and the Town of Sanford........................................................9 Lots of news, products and services throughout!

President/Publisher Edwin M. McKeon Jr.

Editor In Chief Craig Mongeau

Sales Manager Kent Hogeboom

Production Mgr. John Pinkerton

Controller Judith Nixon

Circulation Mgr. Cathy Printz

Sales/Admin. Asst. Deby Hogeboom

Trade Show Manager Amanda Hogeboom-Guilfoyle

Consultant Bob Buckley

518/221-5159 E-Mail - khogeboom@cegltd.com

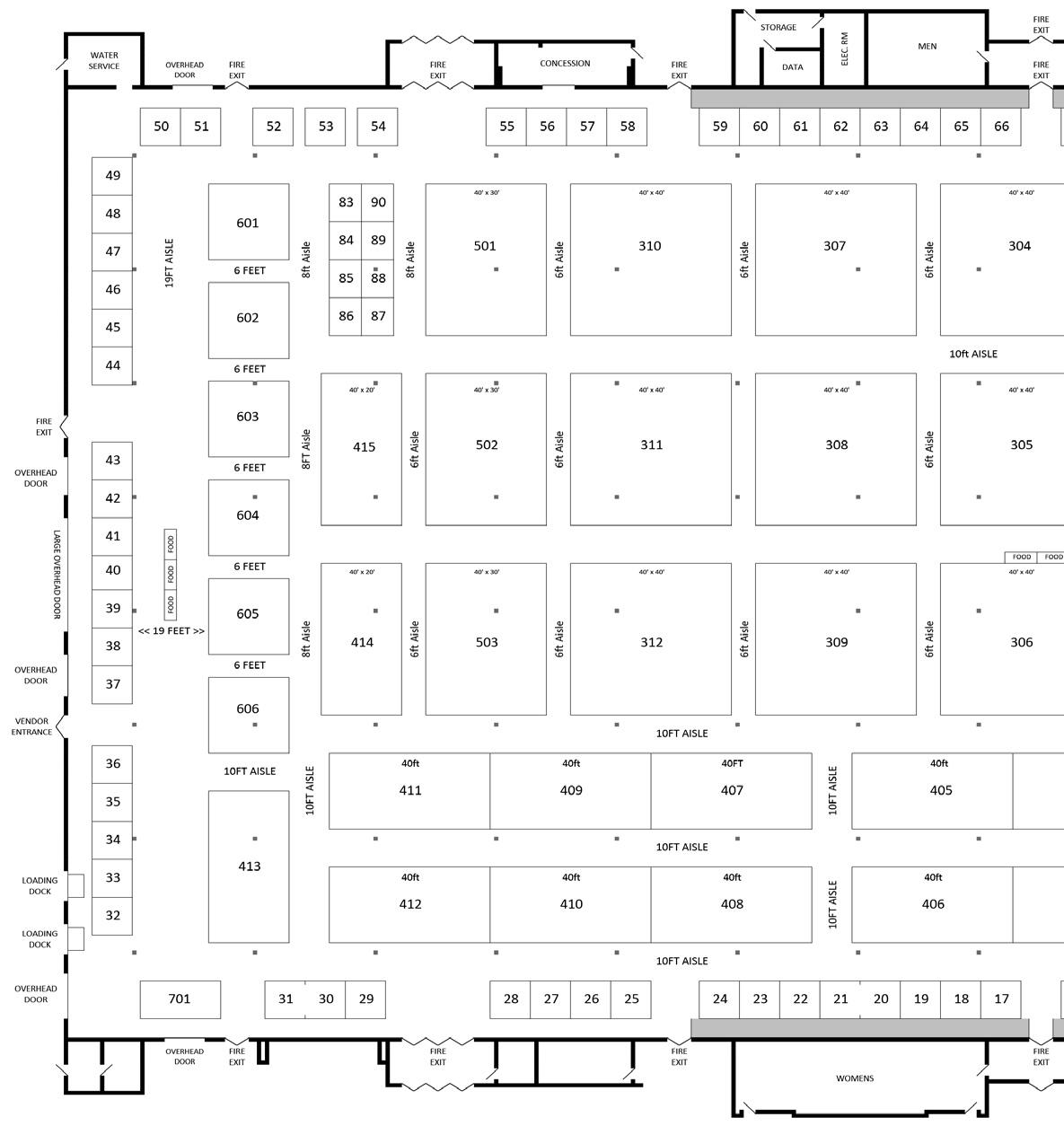

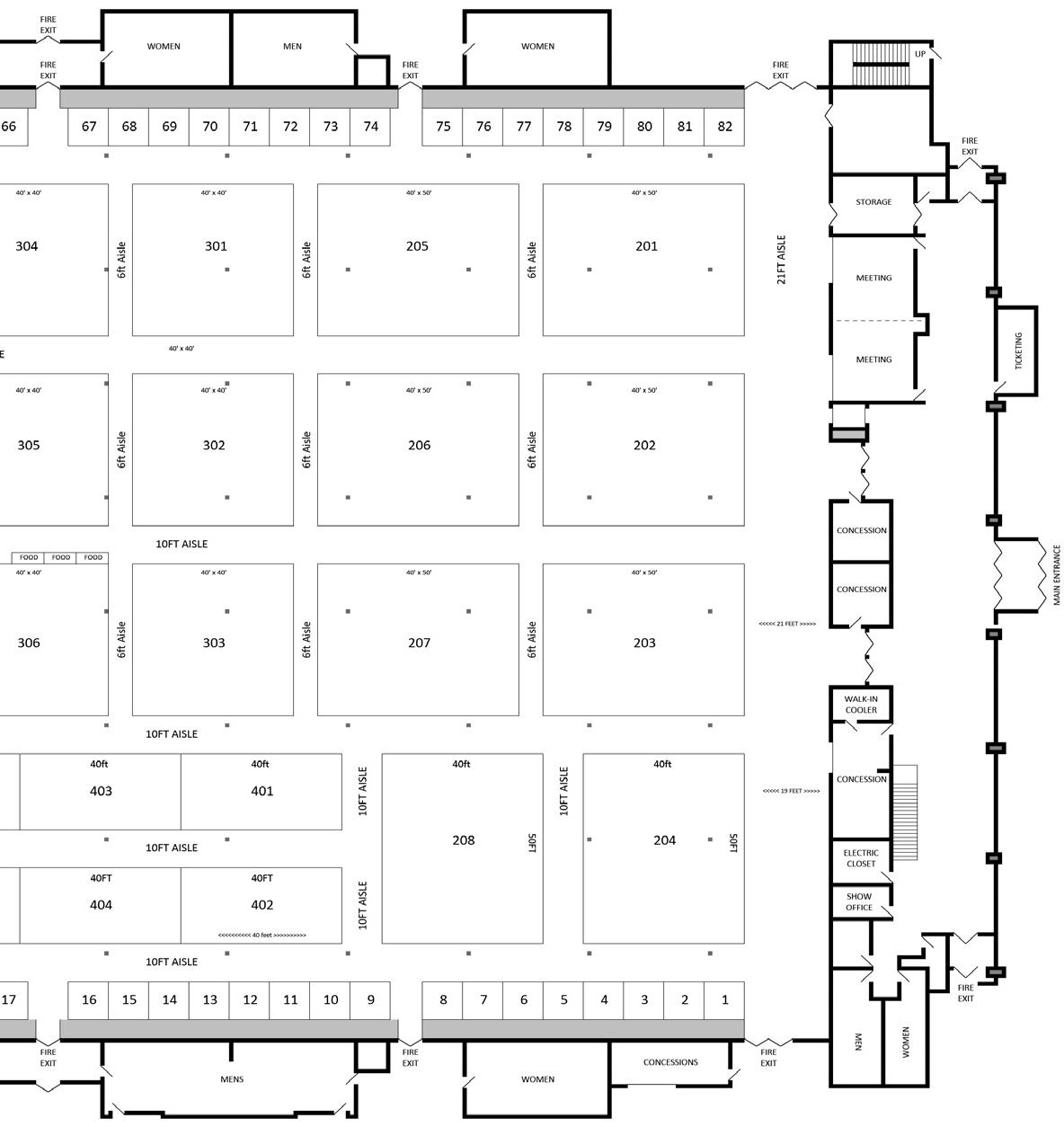

PRODUCERS OF THE ANNUAL NEW YORK STATE HIGHWAY & PUBLIC WORKS EXPO Amanda Hogeboom-Guilfoyle: General Manager of the NYS Highway & Public Works Show 518-396-7659 email: aguilfoyle@cegltd.com OCTOBER 29, 2025 • SYRACUSE, NEW YORK

Mailed 11 times a year by name, to every Town, County, Village and City Highway Superintendent, Public Works Director and D.O.T. official in NY State.

Subscriptions are available to all interested persons at a cost of $25.00 per year within the USA. To subscribe, send your check, voucher or money order for $25.00 to the address above. Single issues $3.00 each With the exception of Highway Superintendents, Public Works Directors & D.O.T. Officials, material may not be reproduced in any form without the written permission of the publisher.

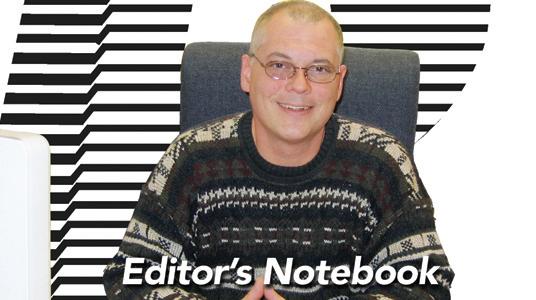

There’s been another development with New York State’s California Advanced Clean Trucks (or ACT) regulations. To review, on June 12, President Trump signed three resolutions approved by lawmakers barring California’s electric vehicle sales mandates and diesel engine rules, including its plan to end the sale of gasoline-only vehicles by 2035.

Prior to this action, New York State government began requiring truck dealerships to sell a percentage of zero-emission vehicles, or ZEVs, for trucks weighing 8,500 lbs. or more, with those percentages required to grow at a steady rate for the next decade. Currently, while the regulation is paused, several states, including New York, have filed lawsuits seeking to reinstate ACT.

The new development came on July 7 when Utica Mack President Tom Heiland hosted a discussion between Assemblywoman Marianne Buttenschon and Department of Environmental Conservation Commissioner Amanda Leftonand. During this meeting, Heiland proposed a “Diesel for Dollars” program, which would work similarly to the federal “Cash for Clunkers” program.

Heiland’s idea is that the government would offer financial incentives to replace older diesel trucks with newer ones that emit far less emissions. Heiland said that 47 percent of trucks in the state are older than 2010, when the Environmental Protection Agency changed its standards to regulate the diesel fuel sulfur levels. These trucks, while not that old, were manufactured at a time when diesel emission technology was not as advanced as it is now. Both Buttenschon and Leftonand seemed receptive to this idea as a good compromise. We’ll continue to report this important issue, so stay tuned.

The N.Y.S Highway & Public Works Expo is no just two and a half months away and booth sales continue to be strong. The show is approximately 90 percent sold. Please contact Amanda Hogeboom-Guilfoyle, our trade show manager, at aguilfoyle@cegltd.com for details about exhibiting opportunities. Thank you very much. And look for more updates next issue. P

Craig Mongeau

Highway Superintendent Leo Shew and the Town of Sanford

When Leo Shew campaigned for the position of highway superintendent of Sanford in 2022, he took the stance that it’s a job, not a position. He wasn’t interested in the status of the title or the perks of the position. He vowed to put the needs of the town before his own and faithfully serve the community where he grew up.

He ran as a Democrat in a Republican township — and won. Every day since then, he’s been fulfilling that

“I wanted the job,” said Leo. “I worked to get the job, and now I’m going to do the job. You don’t work for any one individual in this job, you work for the taxpayers. I try to give them their money’s worth every

Serving Sanford

For the first six months Leo was on the job, he worked 6 a.m. to 6 p.m. six days a week. Much of that time was spent rebuilding. He re-established shared services agreements with other towns, as well as vendor relations, employee relations and relationships with the town government.

“It is very important to have a board that you can work with,” he said. “I am blessed to have both a town supervisor and a board that are interested and willing to work with me and back me up.”

The new town supervisor finalized an equipment committee, a building committee and two road committees. Leo then made changes to how the paperwork is handled in the office and redefined the deputy superintendent’s job description and opened up lines of communication with the deputy regarding the town’s roads and with the mechanic on where the tax dollars are best spent.

“The deputy and I document all day-to-day tasks, material usage per road and issues that come up,” Leo said.

He and the department’s mechanic document all repairs and service to the equipment and he began keeping rigorous track of the department’s spending.

“I am always aware that in this job, you are responsible for the safety and welfare of a lot of people and the highway department budget.”

On the Job Training

Leo is still new to the job, having previously been self-employed as the owner of two construction companies — in general construction and excavation.

“I like construction and dirt work, but every day I learn something in this job,” he said. To educate himself so that he can improve his performance, he attends highway school every year and takes intermittent classes throughout the year.

He said he’s getting “a little more in tune with the CHIPS program every year, but confesses that he knew little about the program, which makes up about a quarter of his budget, in his early days in

“Other town superintendents talked to me about it,” he said. “It’s tough to get the most bang for your buck out of CHIPS and know how much to cover out of my own budget.”

That budget is “right around $2 million,” with CHIPS allotment of approximately $500,00.

“We can easily spend $1,300 for tree removal,” he said. “Then, there’s blacktop, gravel, resurfacing and calcium chloride. I tried dust control oil last year; I try to stay up on new products and processes for keeping our roads in good shape. I was very impressed. It holds up, but it’s twice the price.”

During his first year in office, Leo had to deal with windmills. Northland Power had to seek permission and pay for installation. While that can be lucrative for the town, it also imposes a hardship. Each windmill is roughly 700 ft. tall and requires approximately 700 yds. of concrete per base.

“The roads took a beating,” he said. “They hauled rebar, concrete, sand, soil and windmill parts. It affected several roads. There was a huge amount of damage.”

continued on page 12

from page 9

It was his job, along with the town supervisor, to negotiate with the windmill company to make sure they repaired the roads.

Repairing road damage from windmill construction pales in comparison with what he had to contend with in his second year on the job.

Hurricane Debby hit the area on Aug. 9, 2024. The second hurricane of the 2024 Atlantic hurricane season and officially dubbed a slow-moving, destructive post-tropical cyclone, it caused record rainfall, widespread flooding, property damage and loss of lives in the eastern United States and Canada. New York Gov. Kathy Hochul declared a state of emergency.

Although Sanford’s neighboring townships sustained minimal damage, the small town in Broome County saw 40 roads affected by the storm.

continued on page 22

The town lost 2,600 ft. of Tennent Road from damage caused by Hurricane Debby in August 2024.

Hurricane Debby ravaged Wheeler School Road in August 2024.

5985 Court Street Syracuse, NY 1320 (315) 437-2611

17 Northway Lane Latham, NY 12110 (518) 220-9500 Road

“Friday, when the storm came, we had 13 roads closed,” Leo said. “By Saturday, we got down to just three [closed].”

In addition to washed-out roads, several pipes had shifted or separated due to the debris coming down the creek plugging them.

“We had holes 15 feet to 20 feet long and 8 feet to 10 feet wide,” Leo said.

Because there was more damage than the town could fix, he logged a lot of calls to various state entities, looking for help.

able, thereby gaining access to people trapped on the other side.

“It was stressful,” Leo said.

By January, the highway department got two roads open and two others with one lane open. They had lost 2,600 ft. of road, 5 ft. deep.

“The road was just gone,” Leo said.

The New Yorker said he’d never seen roads damaged that bad and that Sanford had never experienced a storm like it. He attributed it to climate change and pointed out that his campaign emphasized that they’d have to work with a changing climate and that they needed upgraded, larger pipes to handle storm surge. One month after the storm, he warned the town board that they couldn’t see all the damage the hurricane created and that they should expect things to show up. from page 12

Some assistance came from the state, which loaned them four 6-ft. diameter pipes. More aid came from the surrounding townships, which provided men and equipment to repair the roads. More assistance came from Gerick Construction, which helped make a dead-end road pass-

continued on page 26

The crew installs new cross pipe on Tennent Road; Craig Card is operating the backhoe.

from page 22

LeoÊs Crew

One of the skills Leo brought with him from his business was the ability to work with a diverse group of people. He had run a mixed union/non-union shop, so he was accustomed to dealing with different types of employee situations.

The boss considers his crew of nine to be a “good mix” of seasoned employees and up-and-comers, with five HEOs, three MEOs and one mechanic. He said he’s blessed with a good deputy and a really good mechanic.

“He knows the trucks and is a really good mechanic [who] keeps good records on what has been done to each and every piece of equipment we have. He can weld and fabricate, as well.”

Experience goes hand-in-hand with talent.

“They need to know the roads during blinding snow,” Leo said.

continued on page 28

Deputy Dick Gifford oversees unloading of a crusher run on a cross pipe replacement on Vinegar Hill Road.

Tom Mills reworks gravel roads with the department’s John Deere 672G grader on Tarbell Hill Road.

Many of his crewmembers have been with the department a long time.

• Tom Mills, HEO: 38 years

• Andy Dagati, HEO: 17 years

• Scott Bowie, mechanic: 15 years

• Shaun Rynearson, HEO: 14 years

• Craig Card, HEO: 10 years

• Matt Barilla, MEO: five years

• Jason Eldrid, HEO: four years

• Jesse Caskey, MEO: three years

• Steve Logue, MEO: three years

• Dick Grifford, deputy superintendent

Leo also hires one part-time person during the summer. In his first year, he hired a female to clean sanders, run smaller trucks and do assorted tasks.

“She came from a good family and was ambitious,” he said. “She swept the floors at the end of the day. That was good for the guys to see a young person wanting to work.”

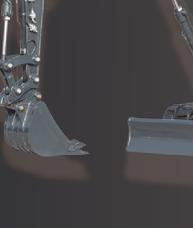

In addition to maintaining the department’s vehicles, mechanic Scott Bowie built a blade to put on the excavator bucket for cleaning under the guiderails.

“He designed a piece to push material under the guiderail using an old carbide,” Leo said. “The steel frame was mounted on an excavator. The bucket reaches over and back through the rail to pull out debris.”

Another time-saving device the Sanford crew developed was a system to raise and lower the road rake. Using the pump, the plow control on one of their one-ton pickups raises and lowers the road rake.

“We ran hydraulic lines from the front to the back of the truck and put a cylinder on the rake,” Leo said. “This saves getting out of the truck to raise or lower the rake when turning.”

Equipment Inventory, Wish List

The Sanford Highway Department equipment inventory includes:

• 2012 International 10-wheeler dump truck

• 2018 International 10-wheeler dump truck

• 2006 Sterling 10-wheeler dump truck

continued on page 32

The town of Sanford highway department crew (L-R) is Andy Dagati, HEO; Deputy Dick Gifford; Shaun Rynearson, HEO; Craig Card, HEO; Tom Mills, HEO; Scott Bowie, mechanic; Jason Eldred, HEO; Matt Barilla, MEO; Jesse Caskey, MEO; and Steve Logue, MEO.

• 2000 Autocar 10-wheeler dump truck

• 2009 Sterling single-axle dump truck

• 2006 Volvo 10-wheeler dump truck

• 2008 GMC 5500

• 2012 Ford F350 Super Duty

• 2018 Ford F550 dump truck

• 1998 Woodchuck chipper

• BOMAG blacktop roller

• 1987 Ingersoll Rand DD35 roller

• 2017 New Holland TS6 110 4WD tractor with an Alamo over-therail mower

• New Holland TL90 with front bucket

• 2019 Cat 420XE 4WD backhoe

• 2019 Cat 938M loader

• 1988 850 Gallion grader

• 2021 John Deere 672G 6WD grader

• 2015 Broce broom

• 2013 Volvo EW160D excavator

• 1996 Custom Country 20-ton trailer

• 2014 Cross Country 11,684-lb. trailer

• Two Army Surplus road rakes

The department needs a 15-ton rubber-track excavator, Leo said, and he has plans to update trucks and a chipper, but it’s the facilities that will get the real upgrade.

continued on page 34

Seen here is the salt storage at the department’s old pit where the new facility is being built.

Hurricane Debby caused major damage in the town.

More ditching takes place on Kenyon Hill Road while Steve Logue manages traffic control.

from page 32

“We’re setting up an equipment program, as this is one of a rural township’s year-to-year obstacles because equipment only costs more and more every year.”

The crew has been working out of a shop that Leo doesn’t even know the age of, but site work has begun on one of the three parcels owned by the town. The third town parcel is where they store stone and gravel and do pug milling, but it’s the second parcel that is undergoing big changes.

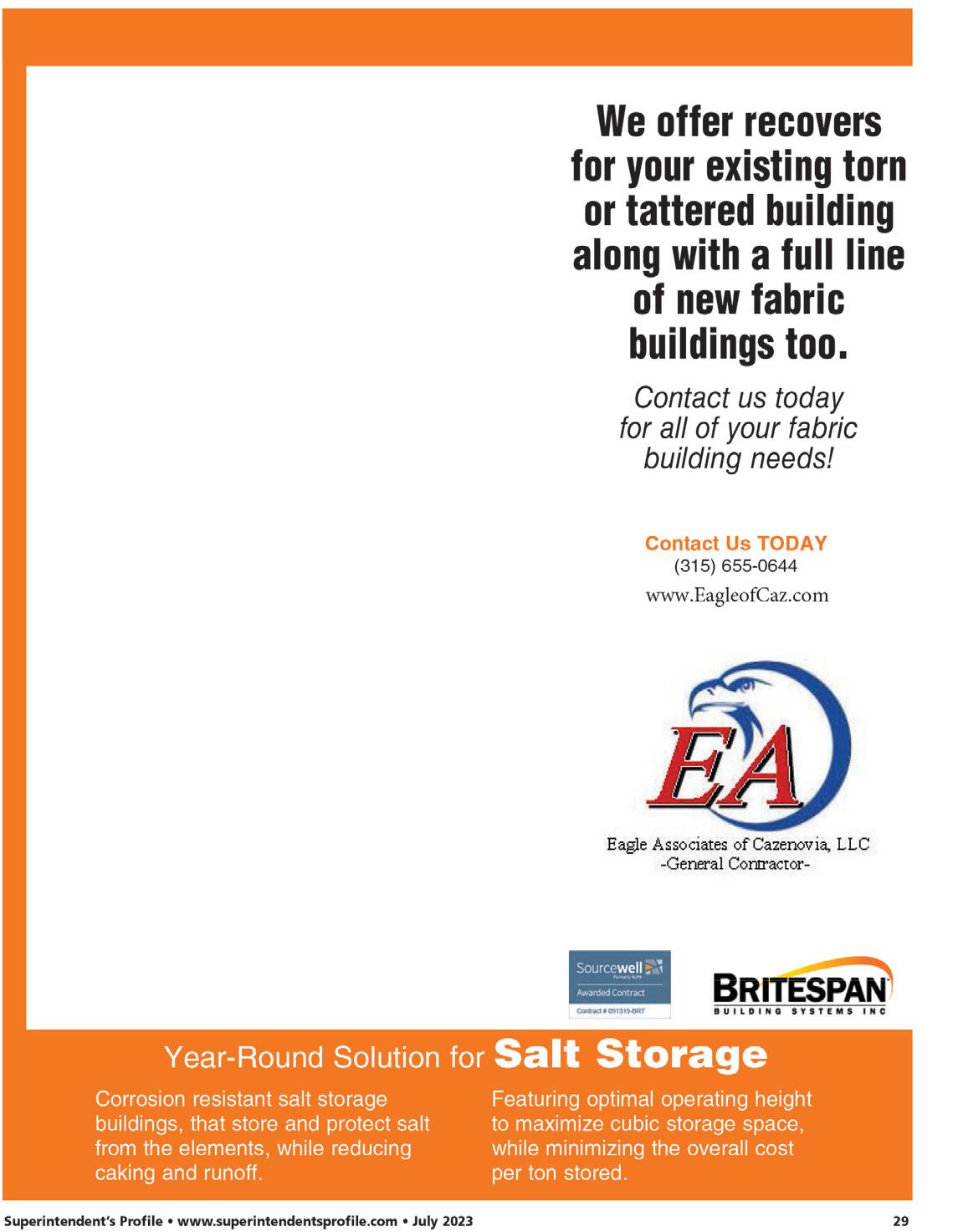

By September, the current site of the department’s 4,100-ton-capacity salt/sand storage building might be home to the new 180-ft. by 90-ft. shop, 60-ft. by 80-ft. cold storage building and a 100-ft. by 100-ft. salt building. “I hope to be in by September before I order salt,” Leo said.

The crew likes to mix a small amount of salt with the sand to keep it from freezing. They also add ¼ bucket of salt to sand for “hot loads.” Together, the crew clears 199 lane mi, 33 percent of which are gravel. This requires six plow routes, each of which takes four to five hours.

Home Turf

When they’re not clearing snow off the roads, the highway crew are working to improve them — the superintendent’s favorite part of the job. Work currently under way includes resurfacing roads and large pipe replacement.

“We try to do major overhauls on one or two sections of road every year,” Leo said. “There are a couple gravel roads I’d like to hardtop, but I have a lot of roads to get more manageable first.”

The town of Sanford sits on former farmland in the foothills of the Catskills, in the Finger Lakes region of New York southwest of Syracuse. It was first settled circa 1787 by William McClure, a surveyor employed to survey a tract of land known as Fisher and Norton’s Patent, aka Livingston’s Patent.

Among the early settlers was the Sanford family, originally from England. When land on the east side of the town of Windsor was divided off in 1821, the new town adopted the name of these early residents.

continued on page 40

The department replaces a cross pipe on Kenyon Hill Road; Tom Mills is loading the old pipe.

NEW in 2025

Electric Single Auger for 550 & 1-Ton

from page 34

A close community with a small-town feel, its current population is less than 2,500. Known for excellent schools, good restaurants, outdoor activities and a quiet atmosphere, the town has been attracting big city dwellers looking for a place to escape to, Leo said.

It’s been his home all his life and it’s where he lives with his girlfriend, Deb Proffitt. He has raised three girls and one boy here. His oldest girl is married, one lives in Windsor, and one lives in Albany, but his son is still in high school.

What’s not to like about Sanford? Breathtaking views of rolling hills, wooded valleys and lush vineyards are common. Leo pointed out that there are six large lakes in the area. He enjoys fishing for bass, perch, crappie and bluegill on Blueberry Lake when he has time, but between his job as highway superintendent and the side work in plumbing, electrical and remodeling he continues to do, there’s little time for other hobbies.

The department waits for yet another challenging winter to end.

Seen here is the existing highway department facility and offices, which was previously Queens Farms Dairy Hauling. continued on page 46

REBUILDS >

Beyond Roadwork

While the crew works 6 a.m. to 2:30 p.m., Leo often works longer hours. He’s on the cemetery board and his department is responsible for mowing the cemeteries. He also maintains the building and grounds for an old local theater, where he’s responsible for changing the marquee when new movies come to town.

Letting the public know about matters more urgent than the latest movie title is typically conducted by phone in the small town. He enjoys dealing with the public most of the time and makes sure he’s visible, so they know he’s “out there for them.” He tries to educate the residents on what his department is doing and why. “Usually, that takes care of the situation,” he said.

Dealing with employees has its ups and downs, he said.

“I try to keep in mind each employee is different. They have different personalities, different abilities and different ideas of what they want out of their job and time here.”

He keeps in contact with his crew via county-wide radio and works

particularly closely with his deputy and mechanic, as well as the town supervisor. He considers communication and cooperation of high importance in a job like this.

“Every day, you deal with people,” he said. “Everyone on the crew, vendors, subcontractors, engineers, taxpayers, the board, etc.”

Some days, he says he’s nothing more than an administrator — midlevel management. Other days, he’s not so sure it can be pigeonholed that way.

“At different times, you are an administrator, a laborer, a boss, a student, a teacher, a phycologist, a meteorologist, an engineer and a desk jockey.”

Wearing all those hats can be tricky, but Leo remembers at the age of five, he watched his dad, who worked in construction after leaving the Army.

“I learned to delegate,” he said, adding he set high standards for his crew. “I’m very particular, but not a perfectionist. I take pride in my work. It’s a tough job.” from page 40

continued on page 50

Seen here was damage on Farnham Road caused by Hurricane Debby.

New Apex in Pine Bush, NY

585-254-7140

www.empireradiator.com

Fuel Tank Restoration and Repair

We are the only full service fuel tank restoration and repair facility in up-state New York. New U.S. made aluminum tanks.

Radiators, Charge Air Coolers, Oil Coolers

New, Recores, Repairs, Custom Designed aluminum and copper brass

DPF, DOC, and EGR Cleaning

Controlled burn baking and dual forced air and suction ensures all cells are cleaned. Damaged fittings can be repaired or replaced

Burn Off Oven

Complete removal of paint and grease from your parts and equipment.

Fluid Lines

Hydraulic, including steel, AC and Brake lines

Other Services

Aluminum and steel welding. Press brake, mill, lathe, notchers and sheers. Wet and dry sand blasting, caustic boil out, acid and solvent cleaning, high pressure wash.

Next Election

It may be a tough job, but it’s one he’s always been interested in.

“I was friends with the superintendent before the one I replaced. We talked about the job a lot.”

Now that he’s got his dream job, his feelings about it haven’t changed. Proud of getting the town’s roads through a natural disaster, he said it’s hard to get everything done in four years, so he plans to run again when his term expires in 2026.

He believes his prospects for re-election are good, as he joked that “it doesn’t matter what you do in the summer; if you get people to work in the winter [by clearing the roads], you’ll get elected. In this job safety is a top priority for the crew and anyone traveling the town’s roads.”

Make no mistake about why he’ll run again: It’s not about the image or the perks, it’s about taking care of the town and leaving it in better shape than when he found it. P (All photos courtesy of the town of Sanford highway department.) from page 46

The crew cuts brush on Tarbell Hill Road.

The old road sand pit will be the site of the new facility.

Mohawk Police Benevolent Assoc.

Hosts Annual Touch a Truck Event

(L-R) are Larry Roe, driver of Heidelberg Materials; Rocco Perretta, quality control manager of Heidelberg; Jason Brewer, Heidelberg plant manager, Jordanville, N.Y. and Brad Sehn, operations manager, Heidelberg.

(L-R) are Carmen Newtown, highway superintendent of the town of German Flatts; Derek Newtown, part-time employee of the town of German Flatts; and Zachery Janis.

Attending the Touch a Truck event in Mohawk, N.Y., are Jeromie La Barge (L) and Sean Filkins, both highway maintenance workers of the NYS Department of Transportation.

The third annual Touch a Truck event, held June 20 in Mohawk, N.Y., brought the whole community together for a day full of excitement, thanks to the Mohawk Police Benevolent Association (PBA). Kids and families came out in masses to climb on vehicles, meet local heroes and have a blast.

Touch a Truck is all about letting kids get up close to the awesome vehicles they see around town. Fire trucks, police cars, construction rigs, ambulances and classic cars were all there, doors open and ready for curious hands. Officers and drivers were on hand to answer questions and share what they do every day. There also were crafts, face painting, food stands, a bounce house and local bands played while families relaxed and enjoyed the sunshine. The Mohawk PBA set up booths with safety tips and info. Officers chatted with families, making the police feel like friendly neighbors instead of distant authority figures. The best part? Kids left the event inspired and excited, with new respect for the people who keep Mohawk safe. P

(All photographs in this article are Copyright 2025 Superintendent’s Profile. All Rights Reserved.)

continued on page 56

brought the whole community together for a day full of excitement, due to the

The recent third annual Touch a Truck event in Mohawk, N.Y.,

Mohawk Police Benevolent Association (PBA).

Kids Enjoy Day With Equipment at Touch a Truck Event in Mohawk

from page 54

New York State Dairy in the Classroom provides children with educational resources on dairy farming and agriculture.

Hardhats, sponsored by Heidelberg Materials, countless sirens, trucks and equipment provided by local vendors all contributed to a great event.

The local Cub Scout organization had an ax throwing contest.

The New York State Environmental Conservation provided a display of local animal hides and skulls and educated kids about local wildlife.

(L-R) are Andrew Kroll, lineman; Ken Meade, lineman; and Andy Steele, supervisor of Mohawk Municipal Commission.

(L-R) are Luke Michael, operator; Michael Massaro, operator; and Vincent Gambacorta, truck driver of Massaro Services.

(L-R) are Dan Fox, laborer; Dan Goldstein, foreman; Salvatore Fresco, laborer; and Cameron Ritton of the village of Mohawk street department.

NYS OGS

Bobcat Company’s ‘Build Together, Play Together’ Benefits Local Parks

Bobcat Company is giving back to local parks in celebration of the National Recreation and Park Association’s (NRPA) Park and Recreation Month.

Bobcat Company gave back to local parks in celebration of the National Recreation and Park Association’s (NRPA) Park and Recreation Month.

Throughout July, Bobcat invited individuals to join in giving back to their communities. Participants were encouraged to share a photo on social media of Bobcat equipment doing work worth doing — whether it’s their own, a neighbor’s or a machine spotted at a park or a job site.

For every shared photo between July 1-31, 2025, Bobcat donated $10 to NRPA, with a goal to contribute up to $150,000 to support environmental preservation.

“Community is at the heart of everything we do,” said Laura Ness Owens, Bobcat vice president of brand and marketing. “Our partnership with the NRPA allows us to contribute to the creation of vibrant, sustainable park and recreation spaces that benefit people of all ages. These spaces are essential resources for individuals and families to connect, stay active and promote overall health — opportunities that enhance the fabric of communities and create stronger futures.”

Through its support of NRPA, Bobcat is fostering environments where communities can thrive.

“Build Together, Play Together” was the theme of this year’s Park and Recreation Month. In its 40th year of celebration, Park and Recreation Month uplifts park and recreation professionals and how they improve lives through the lasting impact of park and recreation programs.

“Park and Recreation Month is a time to honor the park and recreation professionals and agencies that make our communities stronger,” said Kristine Stratton, NRPA president and CEO. “We’re incredibly grateful for partners like Bobcat, whose unwavering support and shared commitment to the power of parks helps drive lasting impact. Their belief in the importance of local park and recreation spaces — places that foster well-being, build resilience and prepare communities for the challenges of today and tomorrow — is a true inspiration.”

For more information, visit www.bobcat.com/na/en

August 2025

Bobcat photo

John Deere introduces John Deere Path, a mapping solution designed to help operators navigate snow removal operations with precision.

John Deere Introduces New Path Snow Removal Mapping Solution

John Deere introduced John Deere Path, a mapping solution designed to help operators navigate snow removal operations with precision.

Snow-covered roadways present significant challenges, making it critical for operators to clear them effectively. With John Deere Path, operators gain a better sense of road edges and boundaries, when premapped, even in tumultuous winter weather conditions, according to John Deere

“Snow removal, especially in rural areas where visibility can be hindered, requires accuracy for safe and efficient operations,” said Matt Costello, product marketing manager, John Deere. “With a large percentage of U.S. roads located in snow-prone regions, John Deere Path is designed to give operators the confidence to navigate snow-covered roads, helping them stay on course to complete their work safely and reliably.”

Built on the technology of the John Deere StarFire receiver and G5 display technologies, John Deere Path, an option on John Deere motor graders and other plow equipment, provides operators with the ability to pre-map road boundaries before snowfall, creating precise guidance routes automatically sent to the John Deere Operations Center. During snow events, near real-time maps help operators maintain alignment with road edges, with audible alerts warning if the equipment moves too close to pre-mapped boundaries, helping to reduce accident risks and infrastructure damage.

The G5 universal display provides a clear, intuitive interface for confident navigation. Operators can visualize road edges and follow a guidance track overlayed on satellite imagery, with a visual error bar alerting

them to deviations and excessive drift. When road boundaries and obstacles are pre-mapped, the system also enhances obstacle awareness, such as mailboxes and curbs, while enabling operators to track and document completed work for efficiency, according to John Deere. Points of interest can be added at any time for changes on route or marking potential road maintenance areas after snow.

John Deere Operations Center plays a critical role in snow removal management. All mapped routes and completed work data are seamlessly integrated into the platform. John Deere Operations Center provides insights into total area plowed, machine location, duration of work and fuel usage when available, allowing fleet managers to make informed decisions and efficient resource allocation, according to John Deere.

John Deere Path is available as two optional solutions to meet the needs of a variety of operations. John Deere Path is specifically designed for John Deere motor graders, offering integration with machines from model year 2016 and newer. For customers with mixed fleets and older models, John Deere Path Universal offers a modem for a fully closedloop system, making it compatible with a variety of other machines like plow trucks.

By leveraging advanced mapping and precision technology, John Deere Path delivers a way to manage snow removal operations. With enhanced accuracy, improved operator awareness and integrated fleet management capabilities, John Deere Path helps keep roadways clear and communities moving.

For more information, visit JohnDeere.com.

John Deere photo

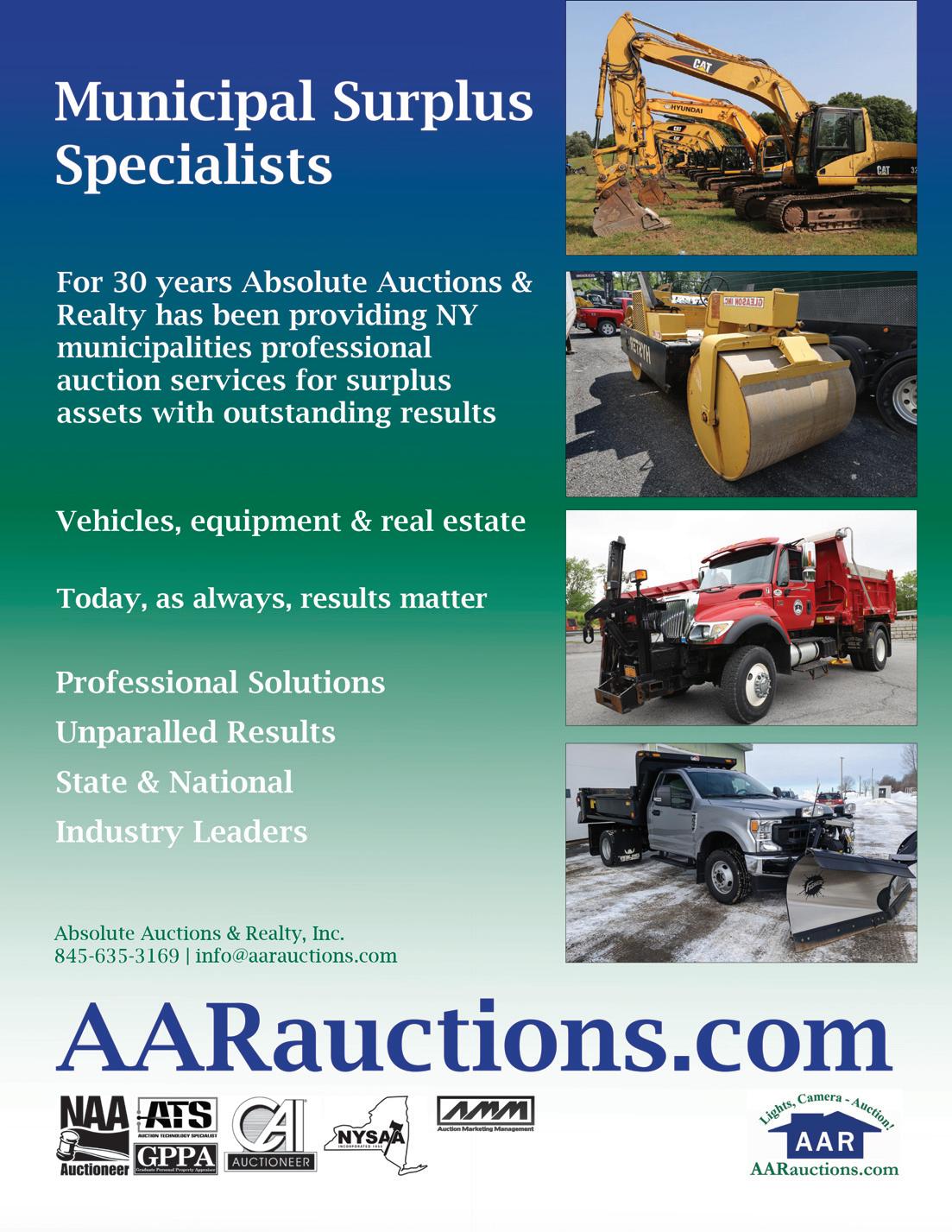

BOSS Celebrates 40 Decades of Innovation, Releases New Products

Founded in 1985 in Iron Mountain, Mich., BOSS began with a snowplow design aimed at meeting the rigorous demands of commercial snow removal experts. Over the past 40 years, the company has consistently introduced new solutions.

Marking four decades in the snow and ice management industry, BOSS Snowplow announced the release of four new products: Cold Front technology, SL4 LED headlights, the SmartTouch+ universal controller and TEV.

“Cold Front technology, SL4 LED headlights and SmartTouch+ represent the next generation of innovation in snow and ice control, delivering smarter, more connected tools that maximize efficiency, visibility and control,” said Jody Christy, vice president of BOSS Snowplow. “By adopting this technology now, contractors and fleet managers are adding technology that builds confidence, adds efficiencies and elevates their fleet’s performance at the highest level for years to come.”

Introducing 2025-26 Product Lineup

• Cold Front technology: This electrical system simplifies snowplow and spreader wiring, streamlines vehicle integration and eliminates the traditional 13-pin plug. By combining power, ground and control wires into a single connector, Cold Front technology simplifies installation and boosts performance across select BOSS plow models, according to BOSS. Note: Cold Front technology is not compatible with 13-pin (SL3 headlight) systems.

• SL4 LED headlights: These headlights offer brightness and visibility, featuring ClearBeam technology that provides more than 200 degrees of vision, expanding the operator’s field of view. Integrated turn signals, parking, warning and accent lights ensure comprehensive safety and visibility from all angles, according to BOSS. Note: SL4 LED headlights are not compatible with 13-pin (SL3 headlight) systems.

• SmartTouch+ universal controller: The SmartTouch+ controller offers instant responsiveness and universal compatibility with all BOSS Cold Front technology plows. Its modern, intuitive interface allows operators to seamlessly control plow functions and SL4 headlights, enhancing both efficiency and customization, according to BOSS. Note: SL4 LED headlights are not compatible with 13-pin (SL3 headlight) systems.

• TEV: BOSS Snowplow’s first Trip-Edge V-Plow, designed to prevent damage to both the plow and vehicle when striking low profile obstacles. The design maximizes the capabilities of equipment, improving traction and maneuverability in snow and ice. TEV will be the first product that will have both the new SL4 headlights and Cold Front Technology, according to BOSS.

These products will be standard on models including the DXT, XT, TEV and Super Duty (excluding the 10-ft. HD DXT) for the 2025-26 season.

For more information, visit www.bossplow.com

Cold Front technology

Boss Snowplow photo

SL4 LED headlights Boss Snowplow photo

TEV Trip-Edge V-Plow

Boss Snowplow photo

SmartTouch+ universal controller

Boss Snowplow photo

& Joan Hacker

Hacker's Packers Inc. has merged business with Binghamton Truck Body located at 13 Spud Lane, Binghamton, NY 13904. Binghamton Truck Body will be representing Pak-Mor, Swaploader, Gal Fab, Stellar and all the products we handle. Mike Burr will be in charge of operations. Please contact Mike at 607-693-2064 as the phone number will remain the same.

Blue Diamond Attachments Offers Full Line of Snow Removal Attachments

Blue Diamond Attachments announced its full line of snow removal attachments. Led by the all-new heavy duty snow blower, the full line of Blue Diamond snow removal attachments is purpose-built and can be outfitted on skid and track loaders as well as compact tractors.

Designed to make quick work of everything from a light dusting to the most heavy and wet snow, Blue Diamond offers nine different models of snow removal attachments including:

• An autowing snowplow blade

• A heavy-duty series multipurpose blade

• A six-way dozer blade

• A snowplow V blade

• A standard duty multipurpose blade

• An extreme duty snow blower

• The new heavy duty snow blower

• A heavy-duty snow pusher

• A standard duty snow pusher

Blue Diamond Attachments offers some key differentiators that add performance and value to its snow removal line, versus an add-

on from the manufacturer, the company said. Examples include:

• The Blue Diamond autowing blade has mechanical wings allowing for automatic adjusting from scoop mode to wind row position as the operator angles the plow.

• The extreme duty snow blower has a highpressure bypass system that eliminates the need for sheer pins during sudden stops.

• The heavy-duty snow pusher is designed with a rolled moldboard to the snow load live to reduce the host machine horsepower needed to move large snow loads. It also uses thicker wear shoes, heavier side plates, and a vertical brace ties the cross-braces together to spread out the impact forces.

“Our line of snow removal attachments offers landscapers, contractors and municipalities the exact attachment they need, no matter the type of snow on the ground,” said Drew Truan, chief operating officer at Blue Diamond Attachments. “Like all of our attachments the snow removal line is compatible with most OEM machines and all are supported by Blue

Blue Diamond Attachments photo Designed to make quick work of everything from a light dusting to the most heavy and wet snow, Blue Diamond offers nine different models of snow removal attachments.

Diamond and our extensive dealer network.”

The full line of snow removal attachments come with the Blue Diamond Satisfaction Guarantee, and all are backed by a 1-year warranty.

For more information, visit www.bluediamondattachments.com.