By Eric Olson CEG CONTRIBUTING EDITOR

Almost seven months after the remnants of Hurricane Helene roared through western North Carolina and eastern Tennessee, causing billions of dollars in damage and claiming more than 100 lives between the two states, most major repair work has been finished in both states, particularly in Tennessee.

After its formation in the western Caribbean, the powerful Category 4

storm took aim on the southeast U.S., passing first through Florida, Georgia and South Carolina, before pounding the North Carolina-Tennessee border counties on Sept. 27, 2024.

Helene seemed to save its worst fury for the high-elevation Appalachian Mountains in North Carolina and Tennessee, where heavy rains ran off countless hills and peaks to engorge the area’s innumerable rivers and

By Lucy Perry CEG CORRESPONDENT

of Hurricane Helene.

Jacob Shuford May, 51, of Lexington, N.C., passed away on April 7, 2025. Known for his entrepreneurial spirit and love for the outdoors, May lived a life full o f passion and dedication.

The Lane Construction Corp. announced that it has received final acceptance from the Florida Department of Transportation (FDOT) for the I-275 Section 7 Phase 1 project in Tampa, Fla.

Thompson Tractor held its first “Thompson Technology” event of the year April 17, 2025, at its Montgomery, Ala., branch. This event marked the first of four technology demonstrations planned for 2025.

Construction is under way on a long-anticipated bypass road in Mandeville, La., that St. Tammany Parish officials said will connect two state highways, improve access to the town’s busy Pelican Park and ease traffic congestion in the area.

20

The Richmond Area Municipal Contractors Association (RAMCA) held its fifth annual Construction Rodeo and Expo April 17, 2025, in the Richmond City Stadium.

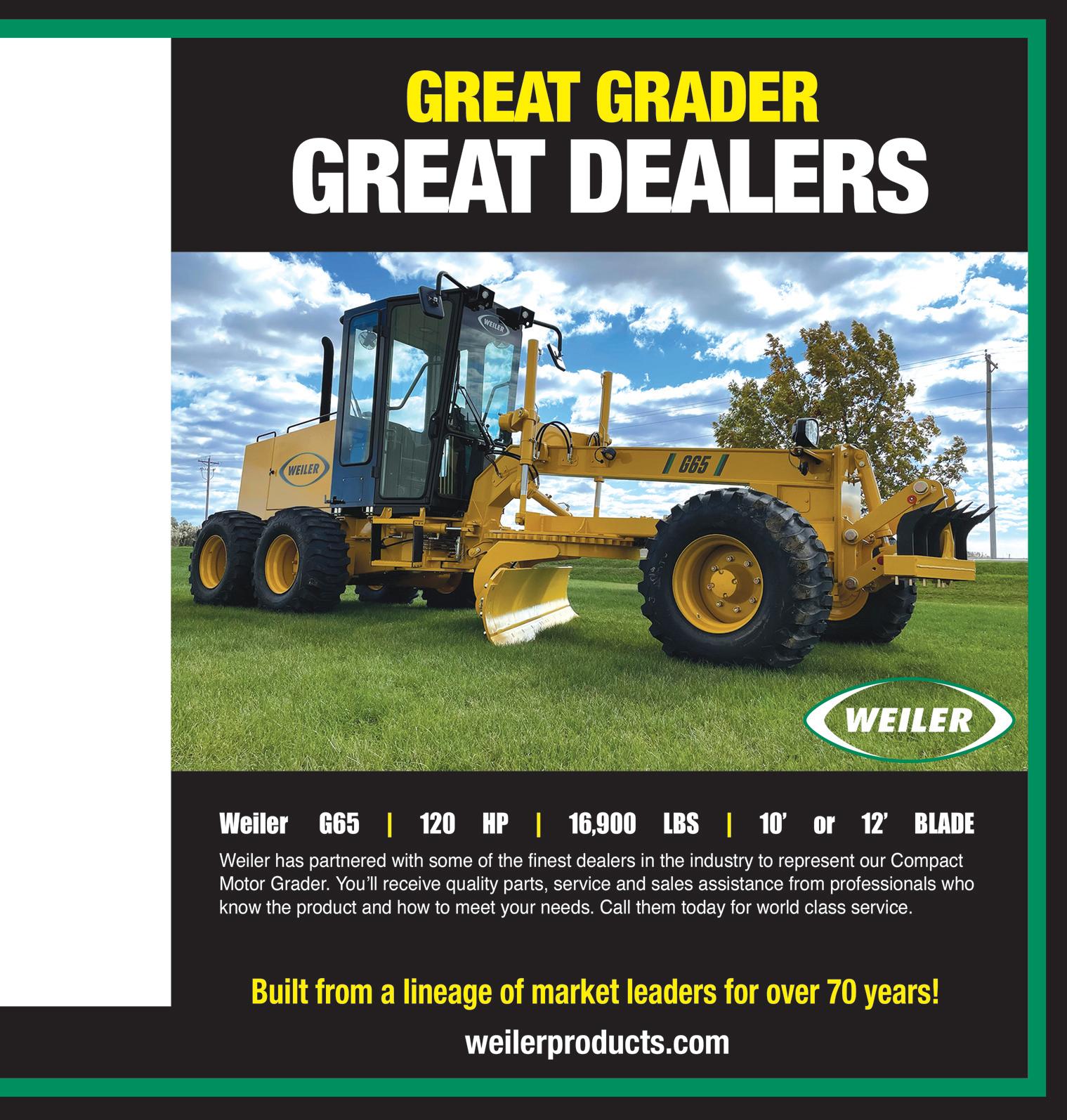

27 FAYAT GROUP WILL EXPAND ITS FAIRFIELD COUNTY OPERATIONS

FAYAT Group announced it is expanding its road equipment division operations in Fairfield County. The company's $13.7 million investment will create 75

30

According to the U.S. Bureau of Labor Statistics, in 2023, “about 45,700 openings for construction equipment operators are projected each year, on average, over the decade.

34

Trimble announced that Waukesha-Pearce Industries LLC. is the newest construction equipment dealer to become a Trimble Technology outlet. WPI will now sell Trimble aftermarket grade control technology.

36

$392M TO BUILD NEW GRAND HYATT MIAMI BEACH

Terra and Turnberry, two of south Florida’s leading real estate development companies, have secured $392 million in construction financing that will help advance their joint development of the Grand Hyatt Miami Beach.

57 YANMAR INTRODUCES LINE OF BRANDED ATTACHMENTS FOR CTLS

The Yanmar attachments include a full range of buckets, augers, trenchers, stump grinders, soil conditioners, breakers, sweepers, pallet forks, brush mowers, grapple rakes, grapple buckets and snow and grading blades.

After months of excitement and thousands of entries, Gregory P., a landscape

was

as the

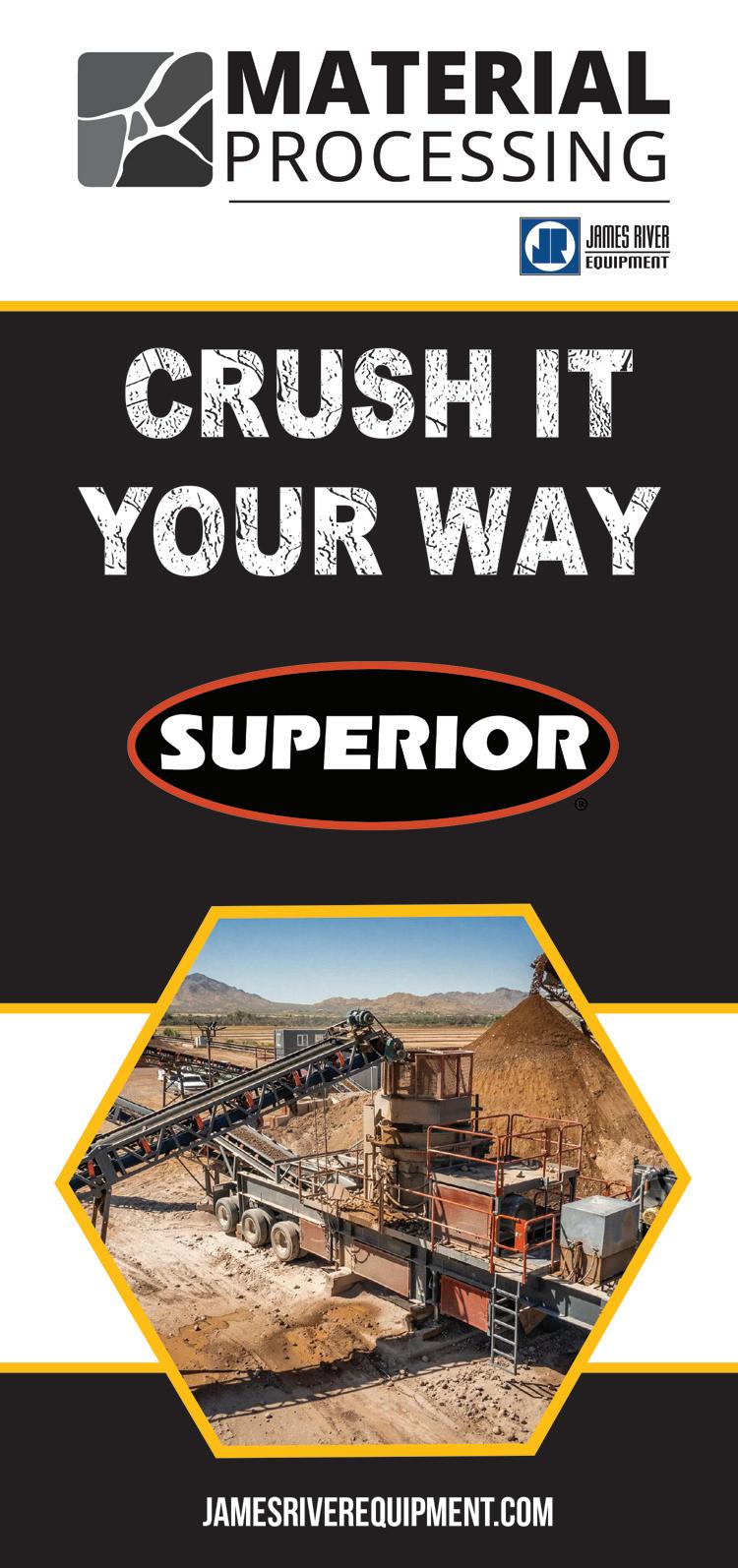

At Miller Creek Quarry near Rutherfordton, N.C., production hasn’t stopped since 1965 (the company has been in operation since 1949.)

Behind a massive granite wall face, operators navigate a fleet of heavy equipment through stockpiles of crushed stone for roads, construction sites and most recently hurricane recovery efforts in the wake of Hurricane Helene. For Danny Seay, who has managed this operation for decades of his nearly 50-year tenure with Thompson Contractors, equipment selection directly impacts every aspect of the quarry’s output.

“Downtime is your most costly problem,” he said, speaking from the practical experience of someone who’s witnessed equipment’s evolution from mechanical controls to digital precision. His focus remains on keeping the machines running, production flowing and meeting the growing demands of both public infrastructure projects and private development in the Carolinas.

Life in Stone

Seay’s history with Thompson Contractors spans nearly half a century. “I’ve worked here for nearly 50 years and started out doing much of nothing and ended up the manager,” he said.

Thompson Contractors itself has even deeper roots that date back to the 1940s. The family-owned corporation currently operates two rock quarries: Miller Creek Quarry near Rutherfordton, N.C., and Mill Spring Quarry in Polk County, N.C. Its product lineup serves primarily state projects and includes producing for customers in private industry, as well.

The company also helped serve unexpected needs, such as when Hurricane Helene washed out miles of roadways in western North Carolina during fall of 2024. Trucks were lined up outside the quarry for weeks as millions of tons of large-scale rock were hauled to recreate a structurally sound base to rebuild roads.

“We sell mostly to state projects, but there’s lots of private stuff because we make all sizes of [material],” Seay said. “On the roads, we furnish asphalt plants and some concrete but not a lot, but gravel for the base of the roads and that type of operation.”

Jacob Shuford May, 51, of Lexington, N.C., passed away on April 7, 2025. Known for his entrepreneurial spirit and love for the outdoors, May lived a life full of passion and dedication.

Born and raised in Lexington, Mr. May was a proud graduate of Lexington High School and later earned his degree from UNC-Charlotte. His vision and determination led him to establish May Heavy Equipment, which under his leadership evolved into National Equipment Dealers, where he continued to play an integral role as a partner.

Beyond his professional accomplishments, he had a zest for life that was evident in his love for golf, the great outdoors and farming. He leaves behind a legacy not just in business but also in the hearts of those who knew him.

Mr. May is survived by his fiancée, Amber Royal; his children, Jacob May Jr., Emerson May and Huntley May; and stepchildren, Sage Leonard, Salem Leonard and Staley Leonard. He also leaves behind his mother, Carol Myers May; and his broth-

His vision and determination led him to establish May Heavy Equipment, which under his leadership evolved into National Equipment Dealers...

er, Deems May, and wife, Susan, of Charlotte. He was preceded in death by his father, Bert May, whose guidance and lessons Mr. May cherished throughout his life.

In lieu of flowers, the family requests that donations be made to United Network for Organ Sharing, 700 N. Fourth St., Richmond, Va., 23219 or to the donor’s choice.

Jacob May

The Lane Construction Corp. announced that it has received final acceptance from the Florida Department of Transportation (FDOT) for the I-275 Section 7 Phase 1 project in Tampa, Fla.

The project marks a significant step forward in improving traffic flow, enhancing safety and supporting economic growth in the region.

The I-275 Section 7 Phase 1 project was designed to alleviate congestion, improve connectivity and provide a more efficient transportation corridor for commuters and businesses. Key enhancements include expanded lanes, improved on- and off-ramps, upgraded signage and modernized roadway infrastructure to accommodate the region’s growing transportation demands.

The newly completed section of I-275 offers numerous benefits, including:

• Reduced traffic congestion: additional lanes and improved roadway design helps ease rush-hour gridlock, allowing for smoother travel.

• Enhanced safety features: upgraded lighting, better road markings and modernized traffic signals improve visibility and reduce the risk of crashes.

• Economic growth: improved connectivity supports local businesses and enhances access to key commercial hubs, boosting economic

activity.

• Sustainable infrastructure: the project integrates environmentally friendly materials and designs to support long-term sustainability. In addition, two emergency generators were installed to power FDOT access cameras at the intersection of two critical evacuation routes. These generators ensure continued monitoring during weather events should the local/regional power grid shut down.

As Tampa continues to grow, infrastructure improvements like these will play a vital role in providing interstate access to tourist destinations, employment centers and the University of South Florida, as well as more efficient mobility of people and goods through the Tampa Bay area and the entire state of Florida. Lane continues to deliver some of Florida’s most critical infrastructure projects across the state — one of its key markets. Some active roadwork projects include the I-275/I-4 Downtown Tampa Interchange (DTI) and the Westshore Interchange in Tampa; Seminole Expressway/SR 417 Widening Project in Seminole County; and the I-4 and Sand Lake Road Interchange in Orange County. These projects reflect Lane Construction’s commitment to enhancing Florida’s transportation infrastructure through improved capacity, safety and connectivity.

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

Thompson Tractor held its first “Thompson Technology” event of the year April 17, 2025, at its Montgomery, Ala., branch.

This event marked the first of four technology demonstrations planned for 2025, each showcasing core Cat GCI Technology machines — including track-type tractors and excavators — as well as various machines featuring complementary technologies.

Key highlights at the Montgomery event included formation of an excavator dirt mound where customers could test out the 3D automatics on excavators — simulating a deep load out cut. Also featured were several track type tractors equipped with Cat factory 3D and other technologies, such as steer assist. A D3 track type tractor and a 330 excavator were equipped with Topcon 3D for contractors who prefer that source or technology for their 3D. This shows the flexibility of the Cat machines and that any of the 3D technologies work well on Cat’s platforms.

Also demonstrating flexibility was a Cat factory 3D-equipped 320 excavator that had a 450 MHz radio. This is not the normal 900 MHz radio used on Cat factory 3D and Trimble 3D machines. It is a different frequency that is mostly used on Topcon base stations.

“We wanted to show that our machines could utilize this frequency and work perfectly while receiving all the benefits of the Cat next gen excavators” said Brian Laughlin, Thompson CAT manager of specialty products. “We worked with SITECH and had a 120 motor grader equipped with 3D. A 265 skid steer loader with GB124 grader blade equipped with 3D showed a mini version of a grader blade with GPS. A Cat 980 wheel loader was displaying some factory Cat safety technologies — showing off its rear object detection system and surround view cameras. These Cat safety technologies are becoming a hot item with our quarry and aggregate customers.”

In addition to showing customers Cat safety technologies, Thompson Tractor technology specialists, including Stephen Rylee, were on hand to walk customers through Vision Link technology options and show VL productivity and how it can benefit customers’ needs.

see TECHNOLOGY page 22

Thompson Tractor product support representative, Derick Freeman (C) goes over the operation of the Cat 265 CTL with GB124 grader blade and how to maximize production using the added 3D system.

Operating the Cat 265 compact track loader with GB124 grader blade with Trimble 3D technology is Brandon Clifton of Kerr Enterprise, Lafayette, Ala.

Bruce

Brandon

and Austin

of Adams Construction, Auburn, Ala., compare their experience on operating the new Cat D6XE dozer in their quest for finding the technologies to meet their needs.

Construction is under way on a long-anticipated bypass road in Mandeville, La., that St. Tammany Parish officials said will connect two state highways, improve access to the town’s busy Pelican Park and ease traffic congestion in the area.

With a building cost of $34 million, the divided two-lane, 3.5-mi. road is for now simply called the “Mandeville Bypass” until residents choose a new name. When complete, it will link Louisiana Highway 1088 to U.S. Highway 190, with roundabouts at each intersection and ease traffic on La. 59, parish officials told the New Orleans TimesPicayune.

The plans also call for a multi-use path for bikers and pedestrians to run parallel to the bypass and connect to the Tammany Trace bike trail.

Parish officials said the roadway will be the most expensive ever built by the local government. The project is being built by Denley-Brown Contractors LLC in Baton Rouge.

“We have promised real roadway solutions to ease traffic and to boost safety and today, these promises have been delivered,” said St. Tammany Parish President Mike Cooper at the project’s rainy groundbreaking ceremony on April 7, 2025.

Approximately 3,500 vehicles are expected to use the road daily, he said. It is expected to be finished in two years, but the idea, which is decades old, has long been an ambition of many within St. Tammany Parish.

Discussions about a north entrance to Pelican Park, a nearly 500-acre recreation destination between La. 1088 and U.S. 190, date back to the late 1990s, according to Nixon Adams, who has been involved with the park since its inception in the 1980s and serves as the chair of St. Tammany Parish Recreation District No. 1, the park’s operator.

Its south entrance off U.S. 190 is “overwhelmingly crowded,” Adams said during an interview with the Times-Picayune. With more than a million visitors a year, according to its website, the popular recreation site boasts 32 athletic fields, seven indoor basketball courts, a convention center, an 18-hole disc golf course and pickleball courts.

Eventually, the Mandeville Bypass will serve as the primary entrance and exit for the park, Cooper said.

“We’re sure happy to see it coming,” Adams said of the new road.

Engineering work on the bypass project started approximately 10 years ago, the New Orleans news outlet noted.

Much of the land was in private hands and had to be purchased, said St. Tammany Parish

Council member Joe Impastato, who also was on hand for the proposed roadway’s ceremonial building start.

In 2022, Cooper proposed setting aside $24.5 million to build the road; however, the Parish Council at the time did not take him up on it, instead opting to wait to see if the state would pay the costs.

Then, in February 2024, with no state money forthcoming, a newly elected Parish Council decided to push the project forward, setting aside revenue collected through a 2 percent sales tax in unincorporated St. Tammany (On March 29, 2025, residents voted against renewing the tax, which will now be collected only until 2031.)

The Mandeville City Council and Recreation District No. 1 also have contributed funding.

“This is adding to our toolbox, to our roads that we’re going to maintain,” said Mandeville City Council member Arthur Laughlin. He added the highway will be owned by the parish, not the state and highlighted the drainage improvements that will be included with the bypass in the form of ditches running alongside it.

“Mandeville Bypass” is only the temporary nickname for the roadway, according to Cooper. A permanent name will be decided by a vote on the parish’s website where four proposed names will be listed: Adrien Rouquette Parkway, Brown Pelican Parkway, Buchawa Boulevard and Coyote Crossing.

Alex Dixon (L) and Blair Williams (R), both of Foursight Solutions, discuss the Topcon MC mobile system with Maiko Hewitt, executive director of RAMCA (Richmond Area Municipal Contractors Association). The MC mobile system increases efficiency while reducing wait times and staffing needs for small and mid-sized construction projects. MC mobile equips contractors with what’s needed to perform layout and onsite design options to build jobs and to verify the results.

The Richmond Area Municipal Contractors Association (RAMCA) held its fifth annual Construction Rodeo and Expo April 17, 2025, in the Richmond City Stadium.

Many local equipment dealers had machines on hand for the more than 100 guests to look over and in some cases operate.

New to this year’s rodeo were three mini-excavator competitions. James River Equipment, Hills Machinery and Carter Machinery all brought in mini-excavators to challenge members on their operating skills.

Travis Baker of Sargent Corporation claimed the title of “RAMCA’s Best Excavator Operator” by completing all three challenges with the least number of points deducted.

RAMCA was formed to represent the interests of utility, heavy, and highway constructors, and their industry associates, who perform work or conduct business in the greater Richmond metropolitan area. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

(L-R): Representing Carter Machinery’s rental and service operations are Austin Hammock, Latane Gilbert and Nolin Watkins.

(L-R): Ready to answer questions on the Komatsu PC210LCi-11 are Linder Industrial Machinery’s Gino Morin, Rich Fikis, Kerry Apperson, Sean McNutt and Colin Ridge. The PC210LCi-11 excavator with new intelligent machine control 2.0 delivers even higher productivity, efficiency and cost saving gains. New fully factory-integrated features limit under and over digging, increase ease of operation and maximize machine and attachment utilization.

James River Equipment had its versatile zero-tail swing John Deere 50P on display and available for guests to operate during the event.

Promoting jobsite safety is George McCray of Excel Truck Group with the Scorpion truck-mounted attenuator, which is hydraulically powered and ideal for stationary and mobile construction zones.

event.

First time operator of an MTS 3630 tractor with a 23-28 pull scraper and an added 3D system is Trae Hamm of Hydro Green Erosion Control, based in Auburn, Ala.

TECHNOLOGY from page 16

“On the allied side, we had a Mobile Track Solutions [MTS] 3630 SB tractor and a 28-yard scraper that had a 3D system attached to it,” Laughlin said. “This system indicated to the operator when they were above, below or at grade. There was a lot of interest in this machine throughout the day.”

The event wasn’t limited to earthmoving technology. Thompson Truck Source showcased a Hi-Vac X13

hydro excavator mounted on a truck chassis, designed for precise excavation around fiber optic lines. Also on display was an Autocar dump truck, reflecting Thompson’s recent dealership additions. Simon Jones, vocational truck and trailer sales representative, was available throughout the event to answer customer questions. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Autocar was recently added to the Thompson Truck Source offerings and vocation truck and trailer sales representative, Simon Jones was busy fielding questions about their newest truck line.

Watching the demo operators at work (L-R) are Andrew Kopecky, B&G Equipment and Supply, Birmingham, Ala.; Tyler Phelps, SITECH South, Birmingham, Ala.; and Nate Moran, Cat Construction Technologies, based in Savannah, Ga.

Border Rents

borderequipment.com

Augusta, GA 706-737-7253

Norcross, GA 770-609-8299

*Ditch Witch of Virginia ditchwitchva.com

Seaford, DE 302-629-3602

Chesapeake, VA 757-424-5960

Glen Allen, VA 804-798-2590

Manassas, VA 571-359-6081

*Ditch Witch Worx ditchwitchworx.com

Fort Lauderdale, FL 877-935-3656

Jacksonville, FL 866-254-1102

Plant City, FL 855-704-6828

Albany, GA 866-581-4914

Atlanta, GA 866-709-3712

Savannah, GA 888-298-0429

*Don Allison Equipment, Inc. donallisonequipment.com

Arley, AL 800-669-6450

First Choice Farm and Lawn firstchoicekubota.com

Brookland, AR 870-790-2301

Dyersburg, TN 731-882-1855

Eads, TN 901-616-5129

Mayfield, KY 270-856-4355

Savannah, TN 731-925-2141

Union City, TN 731-885-1315

*Forsythe Tractor forsythetractor.com

Shreveport, LA 318-687-1341

National Equipment Dealers

Carolinas

nedealers.com

Ashville-Fletcher, NC 828-628-3004

Charlotte, NC 704-228-0455

Clayton, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Columbia, SC 888-865-1002

Conway, SC 800-968-0754

Piedmont, SC 864-434-1154

Summerville, SC 843-501-0566

Wellford-Spartanburg, SC 843-501-0566

National Equipment Dealers

Florida

nedealers.com

Apopka, FL 407-401-8956

Fort Myers, FL 407-754-4646

Fort Pierce, FL 772-212-4043

Jacksonville, FL 904-664-0899

Tampa, FL 813-940-4405

National Equipment Dealers

Georgia

nedealers.com

Dallas, GA 770-445-9019

Douglas, GA 912-384-4664

Macon, GA 478-257-8300

Richmond Hill, GA 912-756-7854

Southern Lift Trucks

southernlift.com

Mobile, AL 251-278-2247

State Machinery

statemachineryeq.com

Kenner, LA 504-464-0431

Taylor Construction Equipment taylorconstructionequipment.com

Bessemer, AL 205-428-7050

Huntsville, AL 205-428-7050

Montgomery, AL 205-428-7050

Louisville, MS 833-773-3421

New Albany, MS 304-550-9825

Richland, MS 601-922-4444

LaVergne, TN 304-550-9825

Maryville, TN 662-773-3421

Van Keppel

vankeppel.com

North Little Rock, AR 501-945-4594

Van Buren, AR 479-474-5281

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See ...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze

...with confidence, knowing your new 115 hp Hyundai crawler dozer delivers the quality and value you expect from Hyundai, with the peace of mind that comes with our industry-leading warranty.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com.

FAYAT Group announced it is expanding its road equipment division operations in Fairfield County.

The company's $13.7 million investment will create 75 new jobs.

Founded in France in 1957, FAYAT, through its road equipment division, produces and assembles equipment for all steps of the road lifecycle — asphalt production, application, compaction, road maintenance, sweeping, cold milling, stabilization and recycling — as well as airport vehicles. The company operates in 170 countries and has more than 23,000 employees worldwide.

Located at 321 Blue Granite Pkwy. in Ridgeway, FAYAT will construct a new 100,000 sq.-ft. parts distribution facility to improve its aftersales support for customers throughout North America. The expansion also will allow FAYAT to increase its localization of production for road machinery at an existing facility in Fairfield County.

Operations are expected to be online in the fourth quarter of 2025.

For more information, visit roadequipment.fayat.com.

Heidelberg Materials North America announced that it has completed the acquisition of Giant Cement Holding Inc. and its subsidiaries, Giant Cement Co., Dragon Products Co. and Giant Resource Recovery, from the Fortaleza, Uniland and Trituradora groups.

The acquired operations include a cement plant in Harleyville, S.C., and four associated distribution terminals; a joint-venture deep-water import terminal in Savannah, Ga.; cement and slag distribution terminals in Newington, N.H., and Thomaston, Maine; and a deep-water import terminal in Boston, Mass. The purchase also includes Giant Resource Recovery, an alternative fuel recycling business in the eastern United States.

“We are pleased to complete the acquisition of the GCHI assets and further strengthen our presence in the important southeastern U.S. and New England markets,” said Chris Ward, president and CEO of Heidelberg Materials North America. “We welcome the approximately 400 employees and the GCHI customers to Heidelberg Materials and look forward to the opportunities ahead.”

This latest acquisition by Heidelberg Materials reflects its continued focus on optimizing its portfolio in core markets, building a sustainable future and positioning the company as the front-runner on the path to decarbonizing the built environment and growing the circular economy in the construction materials industry.

When asked what his impressions were when he first saw the hurricane’s massive destruction, Patrick Black of Baker’s Construction Services said the scale of damage was “astounding.”

streams, turning even dry creek beds into raging floodwaters that swept away everything in their paths, including vehicles, homes and people.

The storm also collapsed or damaged many roads and bridges — no matter how well they were built — leaving local residents and tourists stranded until the infrastructure could be repaired.

Since last fall’s storm, though, most roads and bridges washed away in east Tennessee have been restored to reconnect vital supply routes, according to the Tennessee Department of Transportation (TDOT).

In fact, rebuilding efforts are continuing on the last few major state projects and interior roads in that part of Tennessee.

TDOT requested $510 million in federal assistance for its storm repairs and, by the end of March, had received $102 million, the agency said.

The major projects that remain, including bridges over the Nolichucky River, should be completed in the next few months, although one will not be open until 2026.

Most tragic, of course, was that 18 Tennessee residents lost their lives as a result of Helene’s impact.

Damage was even more horrific in neighboring western North Carolina, with the worst damage occurring in the greater Asheville area and other huge swaths of the Blue Ridge Mountains all the way north to Virginia. In all, approximately 105 people in the state died as a result of the storm.

In the hours after the hurricane’s passage through the region, both TDOT and the North Carolina Department of Transportation (NCDOT) began to quickly marshal various construction companies to the worst-hit areas to rebuild key roads, bridges and other infrastructure.

Among the building firms that were contacted by TDOT to make emergency repairs was Baker’s Construction Services, a contractor in Bluff City, Tenn., that employs more

than 100 people, the vast majority of whom make up its onsite crews.

Patrick Black serves as the company’s director of digital marketing. Part of his job is to accompany its crews to various job sites to record aerial video of the work via a cameramounted drone. He then posts his expertly-shot videos and photos onto YouTube and social media sites like Facebook to chronicle the company’s efforts.

When asked what his impressions were when he first saw the hurricane’s massive destruction, Black said the scale of damage was “astounding,” and could only compare it to one other disaster he had witnessed.

“I was pretty up close and personal with some of the California wildfires that happened several years ago close to where I lived at the time,” he said. “After evacuating and then coming back to see what was left, it was devastating to see places I knew that had been utterly destroyed.”

Black said the hurricane damage he came upon in East Tennessee was reminiscent of the wildfires, only “100 times worse.”

“There was a utility truck just lying in this shallow creek; it looked like a harmless little body of water but somehow it had grown powerful enough to take out this big truck,” he said. “Then, I saw houses, buildings, barns and farmland that were just swept away. To see a state highway completely washed out was an incredible sight.”

Just the day after the storm cut its path of destruction through the mountains, Baker’s was brought in to be a subcontractor for Maymead Inc., a Mountain City, Tenn., highway builder, materials production and asphalt paving outfit that operates in the region.

“We worked with Maymead on U.S. Highway 421 in and around Mountain City,” Black said. “Maymead has rock quarries right off U.S. 421 where the damage was, so they provided all the stone and we did all the earthmoving, rebuilt all the washed out sections of the highway and shored up critically damaged areas.

Black added that Baker’s “had another set of [Tennessee] state roads that we were working on where there were criti-

cal washout areas that needed shoring up with GSR [structural support] and other materials.”

They included Tenn. Highway 167 along its approach to the state’s rugged northern border with North Carolina. After crossing into the Tarheel State’s Ashe County, the route is known as Big Laurel Road.

It also represented the only North Carolina repairs performed by Baker’s Construction. By the end of October, the company had wrapped up all its work in the state.

At the very beginning of Baker’s hurricane response, its crews focused squarely on performing emergency road repair.

On U.S. 421, the company teamed with the state transportation agency, Maymead and other subcontractors, Black said, “to figure out, based on TDOTs ever-evolving plans,” the best way to rebuild eight sections of the highway that were damaged.

Baker’s reconstruction of the road around Mountain City took, Black added, “about 80 days to make sure the highway could open up paved and with new striping.”

During November, the contractor also began repairs on two other TDOT projects where Baker’s was the prime contractor: U.S. 321 from the town of Butler south to Elk Mills, then east to North Carolina; and Tenn. 81 between Jonesborough and Erwin.

“The only bridge that we have worked on was in Elk Mills along U.S. 321 where we poured new concrete to shore up one end of the damaged structure. That was a pretty recent job,” said Black. “Other than that, most of our stuff has been earthmoving, moving stone into place, and rebuilding subgrade.”

Baker’s also built a temporary road that led into the Riverview Industrial Park in the Unicoi County town of Erwin, where mass flooding from the nearby Nolichucky River caused tremendous damage and multiple casualties.

Savannah-Richmond Hill, GA

912-756-7854

Dallas, GA

770-445-9019

Douglas, GA

912-922-4242

Macon, GA

478-257-8300

Lexington, NC

866-629-3784

nedealers.com

Grimesland, NC 252-752-1500

Asheville-Fletcher, NC

828-628-3004

Charlotte, NC

704-228-0455

Clayton-Raleigh, NC 919-773-1424

Castle Hayne, NC 910-222-3900

Summerville-Charleston, SC

843-501-0566

Columbia, SC

888-865-1002

Wellford-Spartanburg, SC 864-284-4343

Conway-Myrtle Beach, SC 800-968-0754

Arkansas College/Luby

Instructors Chad Hathaway and Lyndell Deckard teach a dozen students per year the ins and outs of running dozers, excavators, skid steers, backhoes and more.

By Katherine Petrik CEG EDITORIAL ASSISTANT

Construction equipment operators are the driving force in building roads, bridges, buildings and other infrastructure. They work in all kinds of weather — blistering heat, frigid cold, rain — and in all kinds of conditions, depending on the project. Currently, there is a shortage of men and women entering the construction field to run these machines.

According to the U.S. Bureau of Labor Statistics, in 2023, “about 45,700 openings for construction equipment operators are projected each year, on average, over the decade. Many of those openings are expected to result from the need to replace workers who transfer to different occupations or exit

the labor force, such as to retire.”

North Arkansas College (Northark) in Harrison, Ark., is helping to prepare students for a career as an operator of construction machinery through its heavy equipment program. Instructors Chad Hathaway and Lyndell Deckard teach a dozen students per year the ins and outs of running dozers, excavators, skid steers, backhoes and more.

“We’re the only heavy equipment program in the United States that does real work on real job sites,” said Hathaway. “There’s not a whole lot of these heavy equipment programs around anymore, because they’re so expensive to operate.”

The program introduces students to operating heavy machinery and provides a credential for

entry-level positions in the industry. It also provides certification of basic operating skills to employers, according to the school’s website.

“I hear from companies that say they were looking for people and couldn’t find them,” Hathaway said. “There’s a huge gap in the workforce right now, especially for heavy equipment operation. So, we have companies coming to us and looking for operators all the time.”

The school lists the following learning outcomes of the program:

• Learn and understand the basic safety and operating procedures of the machines used in heavy equipment operations;

• obtain the operating skills of a hirable heavy equipment operator, suitable for any job site;

• have the ability to use the instruments to read grade and

make adjustments;

• know what materials to use and where to use them; and

• successfully complete the NCCER Core Curriculum and Heavy Equipment Operations for NCCER credentials.

Students are involved with a project at Boone County Regional Airport on a parking lot and road extension project.

see NORTHARK page 76

Mecbo America announced the launch of two products to the American market: the Cartrack P6 and P7.

These concrete pumps pair a powerful electric or diesel pump with a crawler undercarriage to maximize mobility and maneuverability on the job site.

The 150-hp P6 and 180-hp P7 place concrete at volumes of 104 to 144 cu. yds. per hour, making them an ideal solution for a wide variety of applications, including continuous flight augering, drilling, tunneling and commercial construction. A simple toggle radio remote control provides smooth handling and efficient operation, eliminating the issues seen when touchscreens interact with concrete covered gloves.

“Track-mounted pumps are not new to this market, but what we’ve done is add Mecbo’s patented Pulsar pump, which offers more power and lower maintenance demands,” said Blastcrete co-CEO Scott Knighton.

Mecbo’s patented Pulsar pump system features a long stroke, allowing the pump to push more concrete with less movement. That translates to greater output with less wear and tear on the pump, according to the company. In addition, the smooth pump performance virtually eliminates pressure fluctuation even when pumping long distances.

“With more than 75 years in the concrete pumping business, our team understands what customers want; and we work hard to give the best functionality to ensure easy and maintenance-free operation,” Knighton said. “They don’t need bells and whistles; they need a simple, rugged, efficient system.”

All Mecbo America products are serviced by trained and experienced service technicians and application specialists at Blastcrete Equipment LLC, according to the company. A full array of common wear parts are housed at the Blastcrete facility in Anniston, Ala., for fast and convenient shipping anywhere in the Americas, drastically reducing downtime. When working with Mecbo America, operators benefit from

reduced maintenance thanks to Mecbo’s patented pump system and Blastcrete’s dedicated customer support and robust spare parts program.

Both the Cartrack P6 and P7 feature two hatches to make routine maintenance easier. The Cartrack series can come with an optional water pump, compressor, hopper screen vibrator for harsh mixes, radio remote control and pipelines and accessories for specialized projects.

Mecbo America offers the P6 and P7 with several customization options. Both come standard with a crawler undercarriage but also can be installed on wheels or trucks. The diesel models have a soundproofing option for work at times and in areas where noise reduction is important. Safety was prioritized in designing the P6 and P7, as both feature a walkway with steps, handrails and lights.

For more information, visit mecboamerica.com.

KELLY TRACTOR www.kellytractor.com

Miami, FL

305-592-5360

Davie, FL

954-581-8181

West Palm Beach, FL 561-683-1231

Clewiston, FL 863-983-8177

Ft. Myers, FL 239-693-9233

RING POWER ringpower.com/paving

St. Augustine, FL 904-737-7730

Brooksville, FL

352-796-4978

Daytona Beach, FL 386-947-3363

Gainesville, FL 352-371-9983

Jacksonville, FL 904-714-2600

Lake City, FL

386-755-3997

Lakeland, FL 863-606-0512

Ocala, FL 352-732-2800 Orlando, FL

407-855-6195 Palm Bay, FL

321-952-3001 Sarasota, FL 941-359-6000

Tallahassee, FL 850-562-2121 Tampa, FL 813-671-3700

YANCEY BROS. CO.

www.yanceybros.com

Austell, GA

800-282-1562

Albany, GA

800-768-2892

Augusta, GA

800-446-5131

Bloomingdale, GA

800-482-1144

Brunswick, GA

800-299-5010

Calhoun, GA

800-752-9804

Columbus, GA

800-633-5240

Dacula, GA

800-545-2945

Macon, GA

800-633-5180

McDonough, GA

888-926-2392

Savannah, GA

800-755-8382

Statesboro, GA

888-764-6506

Valdosta, GA

800-755-6841

Washington, GA

888-678-3211

Waycross, GA

888-948-2443

THE CAT RENTAL STORE AT THOMPSON MACHINERY

TMRents.com

Columbus, MS

622-244-4610

Greenwood, MS

662-459-7210

Belden, MS

622-842-4322

Nashville, TN

615-291-5444

Memphis, TN

901-362-8883

Clarksville, TN

931-905-3902

Jackson, TN

731-988-4259

CAT

www.louisianacat.com

Alexandria, LA

318-443-2577

Baton Rouge, LA

225-296-0020

Belle Chase, LA

504-433-1350

Bossier City, LA

318-746-2341

Hammond, LA

985-340-2820

Lafayette, LA

337-837-2476

Lake Charles, LA

337-439-3601

Monroe, LA

318-323-1345

Praireville, LA

225-673-3480

Reserve, LA

985-536-1121

St. Rose, LA

504-904-7421

Trimble announced that WaukeshaPearce Industries LLC. is the newest construction equipment dealer to become a Trimble Technology outlet.

WPI will now sell Trimble aftermarket grade control technology to customers using Komatsu and Yanmar earthmoving equipment, including dozers, excavators, miniexcavators, motor graders and compact track loaders.

Trimble technology from WPI includes the Trimble Works subscription, which provides an easy entry-point, predictable monthly payment, upgrade flexibility, software and firmware maintenance and more, according to Trimble.

NC 704-795-3636 Ladson, SC 843-818-1954

Orlando, FL 407-855-6195 Tampa, FL 813-671-3700

Union City, GA 770-774-7300

MD 443-399-7100 Geismar, LA 225-251-7500 Akeny, IA 515-965-1000 Omaha, NE 402-894-9300

Belle Chasse, LA 504-394-7400 Salt Lake City, UT 801-297-8500 Phoenix, AZ 602-232-0660 Grand Prairie, TX 972-986-0910 Houston, TX 713-433-6411 Chesapeake, VA

757-935-4300 Winston-Salem, NC 336-582-7400 Billings, MT 406-206-2007 Aurora, CO 720-864-9842 La Vergne, TN 615-562-3979

Trimble Technology outlets are a new part of Trimble’s civil construction distribution strategy. By adding authorized resellers representing a wide variety of manufacturers to the Trimble distribution channel, it becomes easier for users of all machine types to buy, install and use Trimble technology for improved job site productivity and profitability, according to Trimble. WPI is dedicated to providing customers with essential technology for their earthmoving equipment.

“WPI has been evolving to provide its customers with the most innovative solu-

tions in the construction industry for more than 100 years and we are excited that the next phase of that evolution includes selling Trimble technology,” said Ron Bisio, senior vice president, field systems of Trimble. “Our goal is to make our technology accessible to users of all machine types through a network of new Trimble Technology outlets and we are moving quickly to make that vision a reality.”

“Establishing ourselves as a Trimble Technology outlet will enhance our ability to meet customers’ technology needs, allowing us to provide customized solutions and exceptional service,” said Lloyd French IV, divisional president of WPI. “Working with Trimble enables us to build deeper alliances with our existing customers and help forge new business relationships, demonstrating our unwavering commitment to growth and success.”

Trimble’s grade control systems integrate sensors, software and automation features to empower operators to work more productively. From the precise positioning of buckets and other implements, to the optimization of equipment usage, Trimble technology helps improve accuracy and safety while reducing equipment wear-and-tear and fuel consumption, according to Trimble.

For

Terra and Turnberry, two of south Florida’s leading real estate development companies, have secured $392 million in construction financing that will help advance their joint development of the Grand Hyatt Miami Beach, an 800room, 17-story property adjacent to the Miami Beach Convention Center.

The financing was provided by TYKO Capital, a New York-based multi-billion-dollar commercial real estate private equity and private credit investment management firm, backed by Elliott Investment Management.

As the pre-construction sitework is already completed, the financing paves the way for the project’s as-yet-unannounced groundbreaking, with delivery slated for late 2027.

“With construction financing in place and strong public support behind us, we are eager to bring this landmark hotel to life,” David Martin, CEO of Terra, and Jackie Soffer, chair and CEO of Turnberry, said in a joint statement. “Grand Hyatt Miami Beach will fill a longstanding gap in Miami Beach’s hospitality offerings, elevating the conventions and events that come to our community while creating jobs, new revenue and economic impact.”

Strategically located at 17th Street and Convention Center Drive, the hotel complex will provide seamless access to the newly renovated Miami Beach Convention Center. With resort-style amenities, the Grand Hyatt’s aim is to serve as the city’s first major convention hotel adjacent and connected to the venue, enhancing Miami Beach’s ability to attract major national and international clients.

Designed by Bernardo Fort-Brescia with Arquitectonica, a studio headquartered in Miami, the new hotel will feature 12 floors of guest rooms, including 52 suites with sweeping views of Miami Beach, along with four floors of meeting and ballroom spaces that will complement the convention center’s event programming.

Guests will be able to enjoy a resort-style pool deck with panoramic city views, a signature restaurant, lobby lounge and bar, as well as retail space designed to activate streetlevel pedestrian traffic. In addition, a climate-controlled skybridge will provide access between the Grand Hyatt Hotel and the Miami Beach Convention Center, enhancing connectivity and convenience for event attendees.

Grand Hyatt Miami Beach was years in the making, with plans for the hotel overwhelmingly approved by Miami Beach voters in 2018. The project is a key component of the city’s efforts to transform its Convention Center District into a more dynamic, walkable and economically vibrant hub.

“Grand Hyatt Miami Beach is a game-changer for major meeting and event planners and a transformative addition to our convention center ecosystem,” said David Whitaker, president and CEO of the Greater Miami Convention & Visitors Bureau. “With an unmatched location seamlessly connected to the [convention center] and just steps from world-renowned Miami Beach, this hotel creates a one-ofa-kind experience for meeting planners and attendees alike.

This addition solidifies our position as a top choice for highprofile conventions and meetings from around the globe.”

The financing news comes on the heels of a $75 million grant that the development was awarded through the Miami Beach Redevelopment Agency in late 2024, underscoring its role as a critical economic driver for the region. The grant reflects strong public and private support for the hotel’s potential to enhance the city’s global competitiveness as a premier destination for meetings, conferences and events.

Its developers also plan to introduce new public spaces, pedestrian-friendly promenades, bike-sharing stations and connectivity to public transit, aligning with Miami Beach’s broader sustainability and resilience goals while providing access to the city’s nearby Lincoln Road district.

“We are thrilled to introduce our Grand Hyatt brand to this key leisure and business travel market,” said Hyatt’s Group President of the Americas’ Pete Sears.

“Grand Hyatt Miami Beach will work to seamlessly blend the destination’s colorful, vibrant spirit with the brand’s bold architecture, inventive restaurants and luxury accommodations,” he said. “We look forward to offering guests and World of Hyatt members a new way to experience Miami Beach in a setting that will be as inspiring as the city itself.”

Major Developers in South Florida

Miami-based Terra is a worldwide development and investment company that creates communities, enhances neighborhoods and connects people. Led by David Martin, the firm was founded in 2001 and is now active across all major real estate asset classes, including multifamily apartments, luxury condominium and single-family residences, retail and office space, hotels and industrial properties.

The company also owns and operates a carefully curated portfolio of real estate developments valued at more than $8 billion that elevate quality of life, maximize the way in which people work, live and entertain; and innovate the urban and suburban landscape with an eye toward resiliency and sustainability.

A leading developer in its own right, Turnberry also is an owner and operator of numerous luxury destinations, from hotels and restaurants to residential, retail and mixed-use projects. Headquartered in Miami, it has developed more than $10 billion in commercial and residential assets, including approximately 20 million sq.-ft. of retail space, more than 7,000 apartments and condominium units, 1.5 million sq.-ft. of class-A office space, and more than 3,000 hotel and resort rooms.

Turnberry recently announced that it would develop the St. Regis Hotel and the St. Regis Residences in Nashville, Tenn. and, in partnership with another firm, it is developing SoLé Mia in North Miami, a 184-acre project that includes plans for more than 5,000 units and 1 million sq. ft. of retail and commercial space. Currently at SoLé Mia, Turnberry is completing construction on ONE Park Tower, a 33-story tower with 292 custom-designed residences.

CRYSTAL TRACTOR & EQUIPMENT

11863 US HWY 301 Hampton, FL 32044

352-770-0488

Crystaltractor.com

EQUIPMENT COMPANY

523 US Hwy 280 E Americus, GA 31709 229-924-0035

843 Pinehurst-Hawkinsville Rd Pinehurst, GA 31070 229-273-4333

perryequip.com

COASTAL EQUIPMENT SALES & RENTAL 922 Longwood Drive Richmond Hill, GA 31324 912-459-1155

www.acesalesandrentals.com

NEWMAN TRACTOR

2600 W State Road 60 W Bartow, FL 33830 863-777-5570

www.newmantractor.com

Vermeer Southeast announced the promotions of Monte Erritt to chief people officer, Dan Rockefeller to chief financial officer and Patrick McCollum to vice president of operations.

These promotions underscore the company’s dedication to leadership development and its vision to SHINE with excellence: serve others, honor God, improve continually, navigate by values and excel in relationships, according to the company.

Monte Erritt, previously vice president of employee development, steps into his role as chief people officer with a deep commitment to enhance the company’s culture and align it closely with Vermeer Southeast’s values. Starting his tenure in 1995, Erritt’s career at Vermeer has been marked by significant leadership roles, where he has been instrumental in fostering a workplace where team members thrive.

“Maintaining our culture and enhancing it further ensures that Vermeer Southeast continues to be a company people are proud to be part of,” Erritt said.

Dan Rockefeller began his career at Vermeer Southeast as a controller in 2005 and has played a pivotal role in shaping the financial and administrative strategies. As the newly appointed chief financial officer, Rockefeller continues to exemplify the SHINE principles through diligent stewardship of company resources, said the company.

“I’m grateful to serve at a company where our SHINE values resonate so deeply with my personal beliefs, ensuring we are the best stewards of the resources entrusted to us,” said Rockefeller.

Patrick McCollum has progressed through various positions since joining Vermeer Southeast in 2010 as an environmental sales representative. As the new vice president of operations, McCollum is recognized for his leadership underpinned by the SHINE principles, driving operational excellence and strategic initiatives.

“It’s not just about the titles; it’s about the opportunity to make a meaningful impact every day with our employees and customers,” said McCollum.

Scott Coley, CEO of Vermeer Southeast, highlighted the importance of these promotions.

“Monte, Patrick and Dan each bring a unique strength and vision to their new roles,” he said. “Their leadership qualities and deep commitment to our values are exactly what Vermeer Southeast needs as we aim to strengthen our operations and enhance our customer relationships and partner stronger.”

www.equipmentshare.com

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804 HEAVY MACHINES, INC. www.heavymachinesinc.com

120 Mann Drive Piperton, TN 38017 (Memphis) 800-238-5591

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

LINK-BELT MID ATLANTIC www.link-beltmidatlantic.com Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235 PARMAN TRACTOR & EQUIPMENT www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

1485 Bear Creek Pike Columbia, TN 38401 931-388-7273

MID SOUTH MACHINERY, INC. www.gomidsouth.com 3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

7422 Hwy 49 N Hattiesburg, MS 39402 601-268-2222

The Foundation believes this project will help close in on its mission to address professional education and workforce development. At the same time, Vision 2025 will bring more awareness to the benefits available for the equipment industry.

The Foundation is “challenging AED members to help create a strong and robust pipeline of skilled workers within the next four years.”

Launched in 2020, Vision has three areas of focus: schools with equipment technology programs, students within these programs and AED dealer members. The goal by 2027: 120 accredited college programs, 200 recognized high schools, 10,000 skilled technicians and 5,000 Foundation-certified technicians.

The initiative was conceived in 2019 after a Foundation study showed the industry would need to recruit 73,000 technicians over five years to meet demand.

“We had done a study with the college of William and Mary,” said Brian P. McGuire, Foundation president.

Job vacancies already were open twice the average length of time because the industry couldn’t draw people who were qualified, he said.

So, the Foundation board decided to call attention to the current situation and establish the tools to solve the problem for the future.

“The situation didn’t happen overnight, and it wouldn’t solve itself overnight,” said McGuire.

The Foundation determined the best course of action would be to start at the high-school level, to get younger students exposed to tech careers early.

“We have to let them see there’s a viable career path,” said McGuire.

Many of AED’s member dealerships are owned by people who came up as technicians, he added. Several CEOs of dealerships stated off as techs.

“Some go into sales from training as technicians. You can have a great career as a technician, but it’s also an on ramp to other areas of the business.”

The Foundation saw the need to help high-school students and their parents understand that these have the potential to be “six-figure careers,” he said.

It required conveying to parents, students and educators that ‘you can go into this career path and your employer will pay for your training, so you have no debt.’

Tim Watters, president of Hoffman Equipment, based in Piscataway, N.J., also sees a career in equipment technology can be a draw. He said the need for qualified

technicians is huge.

“And it’s going to get exponentially worse,” said Watters, AED Foundation chair. “I walk around our shop — we have 50 techs. So many of them are 50 years old plus, and a significant chunk are 60 years plus. Try to find a 30-year-old.”

There are a few, he said. “But there are so few it’s like gold to find someone who wants to work with their hands and be a technician.”

The industry, he said, needs to create a steady flow of kids interested in equipment technology careers.

“We need to implement learning opportunities in schools for students to come into the industry with a basic level of skills and confidence.”

The original goal back for the initiative in 2020 was to pledge $5 million by 2025. By 2022, it hit that number.

“So, our chair said let’s go to $10 million and go to 2027 with the overall goal to increase the number of accredited collages,” said McGuire.

At the same time, the Foundation would restart its high-school recognition program, which had gone dormant from its height of activity in the 1990s.

The initiative also set out to certify 5,000 technicians through the Foundation’s certification program.

“And to have 10,000 folks we could point to and say, ‘they’ve come into the workforce because of this initiative,’” said McGuire.

The Foundation currently recognizes 94 accredited colleges, which puts the initiative at 78 percent of its goal. There are 102 recognized high-school programs.

“Our goal was to build a high-school feeder program into accredited colleges,” said McGuire. “We’re at 52 percent of our goal with high-schools and 88 percent of our goal of certified technicians with just under 4,500. So, we will exceed that goal.”

Just under 6,000 technicians have entered the workforce because of the effort, he said.

“The exciting thing is — and the figures change weekly — we’re at just over $8.5 million pledged and we’ve collected $6 million,” he said.

Vision 2025 is “a little different” from most campaigns in that this money is being collected to spend.

“We are putting $5 million in a Foundation endowment to continue these efforts after pledging,” said McGuire. “We have brought on five staff to make sure we’re hitting what we need to keep donors satisfied.”

see CAREERS page 76

of the QH443E,

The QH443E electric cone crusher completes Sandvik’s electric train, which includes the UJ443E fully electric jaw crusher, the QE342e hybrid scalper and the QA452e hybrid triple-deck Doublescreen.

Sandvik Mobile crushing and screening announced the launch of the QH443E, its latest tracked cone crusher.

This new electric unit has been designed with a focus on sustainability and productivity, according to Sandvik.

The new QH443E is Sandvik’s flagship Q-Range electricdriven cone plant. It takes a significant step toward bridging the gap between tracked mobile, wheeled portable and stationary plants by combining electric drives and track mobility on a single platform.

The QH443E electric cone crusher completes Sandvik’s electric train, which includes the UJ443E fully electric jaw crusher (launched in 2023), the QE342e hybrid scalper and the QA452e hybrid triple-deck Doublescreen (both launched in 2022).

The QH443E features a new heavy duty feeder design and is equipped with electrically driven components. Its advanced design allows for operation through a connection to an external electrical grid supply or on-board generator, providing flexibility and reducing operational costs.

The integration of the latest generation of fuel-efficient engines further enhances flexibility, allowing the unit to be operated via HVO (hydrotreated vegetable oil) or diesel when required, maximizing uptime while lowering emissions and operating noise, according to Sandvik.

Due to the electrification of the onboard components, running the QH443E via the genset can result in up to 25 percent* fuel savings and a 78 percent* reduction in hydraulic oil usage compared to previous generations.

*Test results and calculations are to be considered as

results reached under certain and controlled conditions. These test results and calculations should not be treated as specifications and Sandvik does not guarantee, warrant or represent the outcome of test results or calculations in any or all circumstances.

The QH443E is designed to maximize uptime and boost output. With the versatility and reliability of the Sandvik CH440 Hydrocone, constant liner performance (CLP) and Hydroset CSS adjustment, this crusher delivers superior power transfer and precision crushing, according to Sandvik. The new Optik automation system and My Fleet remote monitoring provide 24/7 fleet management, geo-fencing and remote operator support, ensure continuous crushing and optimal performance.

Engineered to operate in the most hostile environments, the QH443E is ideal for large quarries and mines. Its robust design, featuring a unibody mainframe and premium components, ensures durability and strength. The load-sensing system for the feeder drive, camera and level sensor guarantees continuous crushing, while the choice of chambers, throws and settings allows for customization to suit a wide range of applications, according to Sandvik.

“Safety is paramount in the design of the QH443E,” said Sandvik. “The unit includes remote camera viewing of the crushing chamber, 270- degree access around the crusher for

easy maintenance and mandatory audible and visual warnings for safe operation. Our extensive global distributor and sales support network ensures that you receive the best support for your operations.”

The QH443E is available to order in the European market now through Sandvik Mobile’s global network of sales areas and distributors and will be available globally later in 2025.

The QH443E is available to order in the European market now through Sandvik Mobile’s global network of sales areas and distributors and will be available globally later in 2025.

MOBISCREEN MSS 802 EVO

IMPRESSIVE FROM A TO Z. Thanks to its robust design and extensive range of screen linings, the MSS 802 EVO can easily adapt to changing locations and new operating conditions – making it ideal for a wide variety of applications. The coarse screening plant features an intuitive system control that reduces the risk of operating error. And all relevant functions can be operated from a safe distance for increased work safety. The MOBISCREEN MSS 802 EVO –the heavy-duty, versatile solution in natural stone and recycling. www.wirtgen-group.com/kleemann

Tuscaloosa, AL 205-752-0621 Panama City, FL 850-763-4654 Pensacola, FL

Exodus Global and its family of companies — ShearCore, OilQuick Americas, Connect Work Tools, RockZone Americas and BladeCore — partnered with Volvo Construction Equipment at the National Demolition Association Live Demo.

“This collaboration brings together cutting-edge technology and industry-leading expertise to showcase the future of demolition,” said the company. “Attendees will witness firsthand how our innovative attachments, combined with Volvo’s powerful equipment, enhance safety, efficiency, and productivity on the job site. Don’t miss this opportunity to see the latest advancements revolutionizing the demolition industry.”

Here’s what visitors could see in action:

• Volvo EC18 Electric with a CWT CHG2 hydraulic breaker;

• Volvo ECR88D with the all-new Connect Work Tools CS15 mobile shear (debuting at the live demo);

• Volvo EC400FSB equipped with an OilQuick OQ80 quick coupler, Connect Work Tools CWP3000R pulverizer, and ShearCore FC35 concrete processor;

• Volvo EC400FHR with an OilQuick

OQ80, ShearCore FC25 concrete processor and FS25 mobile shear;

• Volvo EC500FHR with an OilQuick OQ90 quick coupler, Connect Work Tools

This collaboration brings together cutting-edge technology and industry-leading expertise to showcase the future of

demolition...

CG40 grapple and ShearCore FS45 mobile shear; and

• Volvo EC950 with a ShearCore FS95 mobile shear.

Steve Cianci, vice president Americas distribution management, welcomes everyone to the Metso press conference.

Metso introduced three cone crushers, HP600e, HP800e and HP900e, to its Nordberg HPe series.

The units maintain HPe features while extending the series to larger crushing capacities for both aggregates production and high-demand mining applications.

“The evolution of Metso’s cone crusher technology brings multiple benefits and presents a true step change in terms of performance, uptime, serviceability and application coverage,” said Ilkka Somero, product manager of HP cones of Metso’s Aggregates business area. “We are excited to expand the Nordberg HPe series and bring to market a wider offering of these highperformance crushers fit for different production purposes.”

“Efficiency is the key to meeting the industry’s needs,” said Nicolas Gallay, director of gyratory and large cone crushers of Metso. “With the robust new HPe units, we can offer performance, longer lifetime and higher cost efficiency to our customers.”

HP600e and HP900e are an evolution to the existing range, built and based on proven technology. HP800e is a new addition to the series with a

Ilkka Somero, product manager of HP cone crushers, goes over the many features of the Nordberg HP 600e cone crusher.

crushing size option of 600 kW/800 hp.

All three units come with two modern automation platform options: IC70C and MCP. Metso’s automation systems provide better visibility, monitoring and control of the crushing process and enable connection to remote monitoring and further digital services, according to Metso.

Nordberg HP600e, HP800e and HP900e units offer:

• high performance with up to 15 pecent more capacity and 35 percent greater crushing force, due to enhanced kinematics and higher power installation;

• new optimized crushing chambers, head spinning reduction and ring bouncing detection to reach optimum capacity and maximum wear life;

• complete drive and sub-frame for safe and faster installation while reducing dynamic load by up to 70 percent; and

• a new feed cone lifting tool, allowing for safer maintenance when changing wear parts.

(compared with equivalent cone

crushers in the same class.)

Upgradability is a core philosophy of the HPe Series. Previous-generation crushers can be enhanced with the latest e-features or upgraded with modernized components, according to Metso.

Metso offers a range of upgrades for existing Nordberg HP Series cone crushers, allowing operators to boost performance and efficiency by integrating the newest HPe features or other advanced options. Due to product development and interchangeability of parts, upgrading is seamless and costeffective, according to Metso.

In addition, Metso provides installation and commissioning, inspections, refurbishment and shutdown support, life cycle services agreements as well as a comprehensive wears and spares offering.

All upgrades and services are planned and executed to the highest standards. Metso’s distribution network offers an additional layer of support and services by providing localized expertise, rapid response times and tailored service solutions.

(All photographs in this article are Copyright 2025 Construction Equipment Guide.)

5038 Buford Hwy. Norcross, GA 30071 770-582-0377

Blue Ridge, GA 706-632-3777

Cumming, GA 770-887-6119

Hiawassee, GA 706-970-3077

McDonough, GA 770-957-3370

Villa Rica, GA 678-952-2037 Perry, GA 478-987-1173

6301 Old Rutledge Pike Knoxville, TN 37924 865-546-1414

10644 Lexington Drive Knoxville, TN 37932 865-218-8800

1825 Veterans Boulevard Sevierville, TN 37862 865-595-3750

9960 Airport Parkway Kingsport, TN 37663 423-323-0400

4066 South Access Road Chattanooga, TN 37406 423-698-6943

215 Interchange Drive Crossville, TN 38571 931-456-6543

www.gatewaydealer.com

Bobcat of Charleston North Charleston, SC 843-725-6330

Bobcat of Columbia Columbia, SC 803-933-9996

Bobcat of Greenville Piedmont, SC 864-269-3600

Bobcat of Spartanburg Spartanburg 864-342-9003

Bobcat of Savannah Bloomingdale, GA 912-236-5588

Bobcat of Seneca Seneca, SC 864-873-8908

Bobcat of Clarksville Clarksville, TN 931-436-9555

Bobcat of Nashville La Vergne, TN 615-941-4000

Bobcat of McMinnville McMinnville, TN 931-488-4767

Bobcat of Maury County Columbia, TN 931-981-9909

8255 NW 58th St Miami, FL 305-592-5360

801 E Sugarland Hwy Clewiston, FL 863-983-8177

2801 Reese Rd Davie, FL 954-581-8181

9651 Kelly Tractor Dr Ft. Myers, FL 239-693-9233

5460 Okeechobee Blvd West Palm Beach, FL 561-683-1231

6301 Old Rutledge Pike Knoxville, TN 37924

865-546-1414

10644 Lexington Dr Knoxville, TN 37932 865-218-8800

1825 Veterans Blvd Sevierville, TN 37862 865-595-3750

9960 Airport Pkwy Kingsport, TN 37663 423-323-0400

4066 South Access Rd Chattanooga, TN 37406 423-698-6943

215 Interchange Dr Crossville, TN 38571 931-456-6543

541 Alfred Thun Rd. Clarksville, TN 37040 931-552-5496

667 Horace Lewis Rd. Cookeville, TN 38506 931-646-3200

1245 Bridgestone Blvd. LaVergne, TN 37086 615-256-2424

3565 New Tullahoma Hwy. Manchester, TN 37355 931-461-5000

1291 Corporate Ave. Memphis, TN 38132 901-332-3051

3199 S Frontage Rd. Columbus, MS 39701 901-401-7011

4350 US-641 Camden, TN 38320 731-584-2732

2000 Airways Blvd Jackson, TN 38301 731-988-4240

4545 Columbia Pike Thompson’s Station, TN 37179 615-744-7850

1808 US-82 Greenwood, MS 38930 662-453-5233

761 Hwy 6 West Oxford, MS 38655 662-371-4440

421 Wallace Dr Belden, MS 38826 662-680-8948

That community, along with the greater Asheville, N.C., area, received the most national attention as a result of hurricane’s rampage. Impact Plastics, a company located on the downstream side of the Erwin business complex, lost six of its employees when they drowned trying to escape the floodwaters.

“We were told by city officials that we were needed to stabilize the flood-soaked ground and put in a road that the park’s businesses can use to come in and start recovery from the flood damage,” Black said. “It was the only other work in Tennessee we did that was not a state project.”

The rest of Baker’s efforts have been reconstructions from start to finish, he added.

“We completed our [State Road] 81 job two months early, which involved rebuilding about 1,200 feet of total washout on a portion of the highway right next to the Nolichucky River. Our crews went in, stripped out the old material, built it back and had it paved.”

To illustrate the amount of earthmoving and concrete that Baker’s handled on its two completed projects along U.S. 421 and Tenn. 81, Black said that at the first roadway site, “somewhere around 160,000 tons of materials was used, mostly the GSR, and that’s a lot of truckloads coming in and out of the work zones.

“For Tenn. 81 in Erwin, it was somewhere between 30,000 to 50,000 tons of rock.”

Currently, the only hurricane-related work being carried out by Baker’s is on U.S. 321, one of only five infrastructure projects left to be rebuilt by TDOT and its construction partners.

The 24-mi.-long stretch of highway being repaired runs from Tenn. 67 near the town of Butler to U.S. 421 in North Carolina and will

not be fully open until Labor Day weekend, according to Mark Nagi, TDOT’s regional communications officer. If it is completed by then, he said, the full reopening would be just a few weeks before the first anniversary of the Helene disaster.

The current road closure is on the Tennessee side from Montgomery Road to Poga Road in the Elk Mills community.

Nagi said other aspects of Baker’s U.S. 321 project include establishing and maintaining traffic control, erosion protection and sediment control measures, pipe extensions and repairs, grade work, construction of rock buttresses to repair washout areas and paving operations.

“I think the largest of our projects is going to end up being U.S. 321 because there are five separate sections for us to work on,”

Black said. “While SR 81 was one continuous washout, U.S. 321 has multiple areas like that, including the large retaining wall with the MSE [mechanically stabilized earth] system that can be seen on the drone video I made.”

Baker’s also conducted blasting on U.S. 321 because, he said, “the first thing to do in that bad washout area was to strip out all the unusable soil down to the bedrock” due to so many little springs located there.

“And in the places where the water needed to drain down, we ended up blasting to create enough room for not only the wall system to be installed but also to put in large drainage boxes where those springs feed,” Black said. “On both U.S. 321 and SR 81, there was spring water flowing to one side of the highways right where they washed out. That means it’s important that this construction provides the proper drainage so that water does not undermine either road.”

As its road repairs progressed through

November, the major challenge ahead for Baker’s and its crew members was the usually harsh winter weather that was certain to descend on its work sites high in the Appalachians.

“It was a challenge but, luckily, we didn’t have a really wet winter — just cold — and our guys really plowed through,” said Black. “A lot of the work our people were doing wasn’t really interfered with; only when we had heavy snow did we have to stop working. For the most part, it was still possible for the crew to dump rock into place and compact the material.”

At the start of the U.S. 421 road repairs, when TDOT and its contractors were in a rapid-response mode, he said, Baker’s also had to deal with a constant, sometimes headache-inducing stream of design changes.

“TDOT was working on the fly to change things as new challenges came up and solutions were needed quickly. In contrast, the work on SR 81 and U.S. 321 had a more consistent flow and, aside from the weather, everything else went fine.”

Black admitted, though, that a spate of infrastructure design changes is fairly common for any disaster recovery effort.

“It was surprising to me that any of the reconstruction was done so quickly, considering the amount of storm damage that was present,” he added. “The mere fact that they can figure out a design, get it to us so rapidly and we are able to make changes as we go along is amazing.”

Part of Baker’s success in performing its road repairs so expertly is due to its veteran crews.

“Every one of our project superintendents have been around for a long time,” said Black. “We also had some newer guys working on these repairs and rebuilds, so it has been a good mix. In addition, our survey crew utilizes GPS data and flight surveys that we use with topographical information

and LIDAR, meaning we have some of the best technology available to make sure we’re getting accurate results.”

During its work to repair the region’s roads and highways, he said that Baker’s used its Cat earthmoving equipment, including D6s and excavators, to push rock and dirt, as well as the contractor’s rollers, compactors and compact skid steers to place some of the select backfill.

Black added that approximately 90 percent of its equipment is manufactured by Cat and supplied to Baker’s by Knoxville-based Stowers Cat. The full-service dealership also provides Baker’s with its expert technical and parts support.

Besides the U.S. 321 road repairs that Baker’s is still working on, the remaining four projects being shepherded by TDOT all involve replacing or repairing bridges, according to the state agency. They include:

• In Carter County, Tenn., 67/91 is closed at the Doe River Bridge. It is slated to open on May 31 (Memorial Day).

• Tennessee Highway 107 in Greene County also is shut down at the Nolichucky River Bridge where beam placement is ongoing. TDOT expects the structure to reopen to traffic around June 23.

• Another Nolichucky River bridge along Tenn. 81 in Washington County is getting a beam placement, as well and also is set to open in late June.

• Nearby, Washington County’s Tenn. 353 bridge over the Nolichucky has remained closed since the storm. Nagi added that the work there has only recently gotten started and will be the state’s “last project to be completed.” He estimated it will reopen on May 22, 2026. CEG

(All photos courtesy of Baker’s Construction Services.)

Caterpillar is strengthening its lineup of material handlers with the launch of the Cat Next Generation MH3032 material handler.

Positioned to plug the gap between the MH3026 and MH3040, both already on the next generation platform, the new MH3032 calls on the same criteria to deliver performance, durability and reliability in a 30 MT technology-driven design.

“Material handling is all about efficiency,” said Vincent Migeotte, Caterpillar senior product and sales consultant. “How can you move and sort materials — waste, scrap or recycling — in as little time as possible, with as few moves as possible, using as little fuel as possible, and all without compromising safety or operator comfort?

“That’s the essential principle of our next gen architecture,” he added. “Keeping control over operating costs, without sacrificing performance. It’s those parameters that come to the forefront in the MH3032.”

With a near-15 m reach, the MH3032 is available with both drop-nose and straight-stick options for maximum configurability. Typical scrap materials are no challenge for the standard Cat orange-peel grapple with its 1 m³ capacity, while a 20 kW generator option puts magnet attachments into play for even greater onsite versatility, according to Caterpillar.

“Ease of operation and optimum productivity are provided by Cat Payload, the built-in technology that allows operators to see how much they’re lifting in each load and to constantly monitor tonnage output, said Caterpillar. “Also fitted as standard on the MH3032 is Cat 2D E-fence,

Caterpillar photo Caterpillar is strengthening its lineup of material handlers with the launch of the Cat Next Generation MH3032 material handler.

which keeps the arm within a predefined work area away from the elevated cab, providing greater operator confidence while protecting the machine from damage and helping improve site safety. This is combined with a new Swing Assist feature, which automatically stops the swing motion at an operator-defined preset point.”

“Technologies like these not only help reduce the operator fatigue associated with repetitive tasks but also help improve site safety,” said Migeotte. “Optimized movements also mean incremental improvements to time and fuel consumption.”

The safety theme continues into the material handler cab, where an in-cab monitor displays dual external camera views to maximize visibility and hazard awareness, according to Caterpillar.

Although the MH3032 joins the material handler lineup as a completely new model, it uses components common to the rest of the MH3000 Next Generation range.

Power for the MH3032 follows the same principle: its Cat C7.1 engine is one of Caterpillar’s most modular — and most compact — power units, meeting U.S. EPA Tier IV Final, EU Stage V, and Japan 2014 emission standards or emitting equivalent to U.S. EPA Tier III and EU Stage IIIA based on regional availability, according to Caterpillar. Deployed in the MH3032, it’s coupled with long-life filters, fewer hoses and fewer check points to allow extended maintenance intervals for further operational savings.