By Cindy Riley CEG CORRESPONDENT

In western Mississippi, crews are replacing three bridges on State Route 16/149 over the Yazoo River Floodway Channels. The Mississippi Department of Transportation (MDOT) is overseeing the $27.9 million effort.

“All three bridges were approaching the minimum structure evaluation tolerance from our bridge inspection, with one posted for 23 tons gross for emergency vehicles,” said Joel Bellipanni, MDOT District 3 project engineer. “Each bridge was built in 1959 and had come to a point where it was no longer feasible to maintain them.”

The channel and the levee system surrounding it were constructed to help alleviate the Yazoo River flood water. It runs from the Yazoo River to the Big Sunflower River. So far, the contractor has completed Bridges A and C and is setting the structural steel for Bridge B.

“These bridges are more than 60 years old and

By Lucy Perry CEG CORRESPONDENT

Unmanned aerial vehicles (UAVs), or drones, are more commonplace tools on the job site as they are growing more sophisticated in technology and application.

UAVs have proven to be a critical tool over the past couple of years in assessing site conditions before and during construction. After the project is completed, these devices are valued for monitoring pavement and structural conditions. Savings, safety, mobility and reliability are incentives for their growing use.

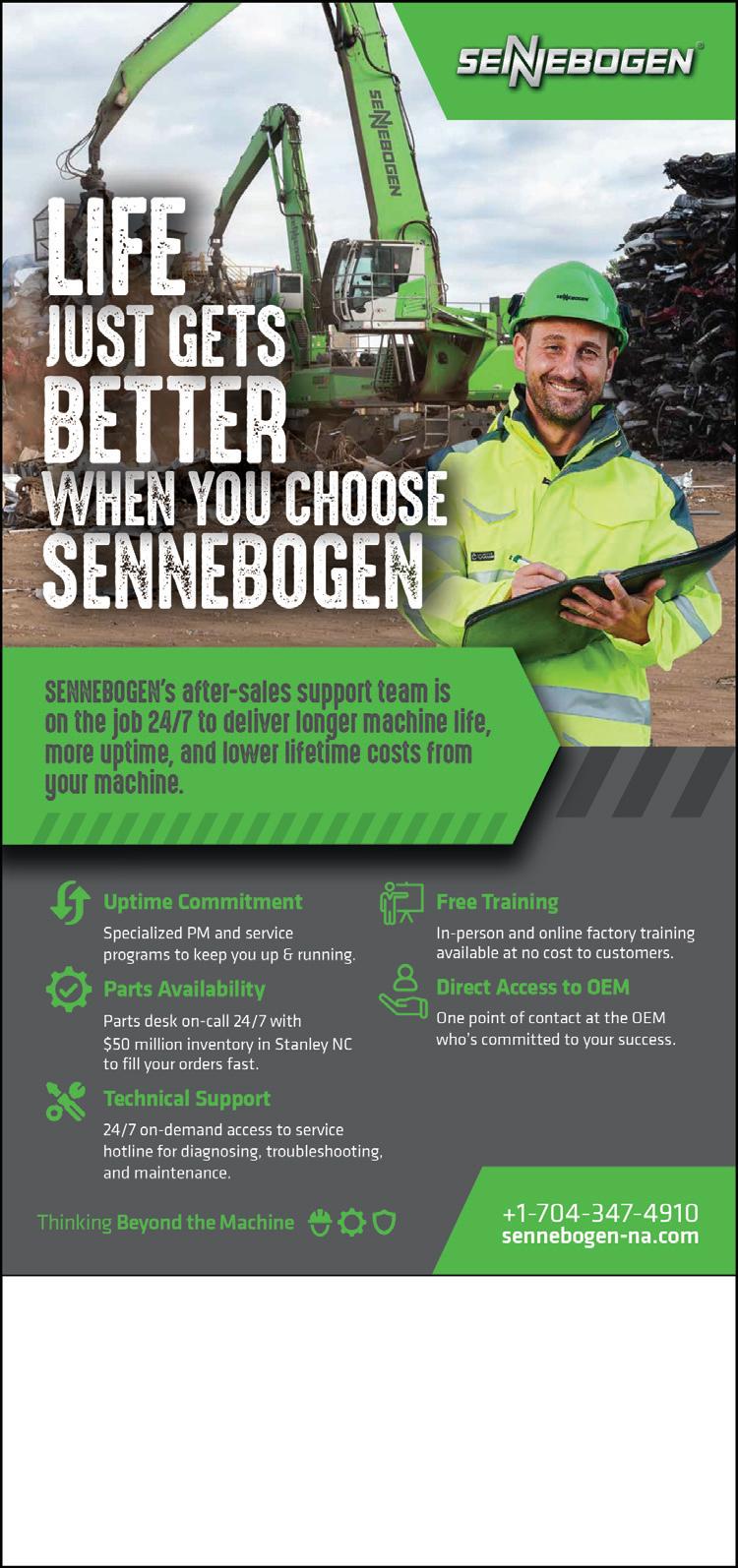

MEMPHIS, TN

3930 E. Raines Rd Memphis, TN 38118

800-432-8902 | 901-260-2310

MURFREESBORO, TN

2115 N. Thompson Ln Murfreesboro, TN 37129

877-200-5654 | 629-335-3077

GRAY, TN

364 Bob Jobe Rd Gray, TN 37615

855-201-7453 | 423-282-5462

COVINGTON, GA

10110 Roberts Way Covington, GA 30014

844-532-1110 | 770-788-0888

BIRMINGHAM, AL

825 31st Street N. Birmingham, AL 35203 844-344-8658 | 205-323-6108

THEODORE, AL

7651 Theodore Dawes Rd Theodore, AL 36582 844-891-6480 | 251-653-5955

SHREVEPORT, LA

5200 Hollywood Ave Shreveport, LA 71109

800-548-3458 | 318-621-0854

Liebherr completely redesigned its basic concept to offer customers more comfortable and intuitive products with even higher performance. The new Generation 8 crawler excavators feature more powerful engines for shorter load cycles and higher productivity, heavier counterweight for higher digging power and bucket capacities, all this while maintaining reduced fuel consumption.

Construction is under way in coastal North Carolina to replace the aging Lindsay C. Warren Bridge on U.S. Highway 64 over the Alligator River in Tyrrell and Dare counties, NCDOT announced Feb. 19, 2025.

C.W. Matthews Contracting Co., an infrastructure and asphalt construction company, recently wrapped up its third annual Asphalt Construction Rodeo at its corporate campus in Marietta, Ga.

Impact Rentals, based in Buford, Ga., will celebrate six years in business, marking steady and significant growth in the Southeast. With three locations in Georgia and one in Greenville, S.C., the company continues to expand.

18 SPACEX TO INVEST $1.8B FOR NEW LAUNCH OPS AT CAPE CANAVERAL

The effort includes at least $1.8 billion of SpaceX capital investment and will bring an estimated 600 new full-time jobs to Florida's Space Coast by 2030.

TDOT announced March 13, 2025, that Kiewit Infrastructure South Co. of Westlake, Texas, has been chosen as the construction manager and general contractor for the Interstate 55 bridge replacement project in Memphis, Tenn.

Associated Industrial Riggers Inc. has made a significant investment in its fleet with the purchase of a brand new 2024 Tadano AC 6.300-1 from Empire Crane Company.

INNOVATION

Showcasing the event’s significance as North America’s largest construction trade show, ConExpo-Con/AGG returns to the Las Vegas Convention Center on March 3-7, 2026, with new features and innovations.

The SMH Group announced the addition of CLM Equipment to its growing dealer network. CLM Equipment, a provider of heavy equipment solutions, is now an authorized dealer of Atlas and Mantsinen material handlers in La.

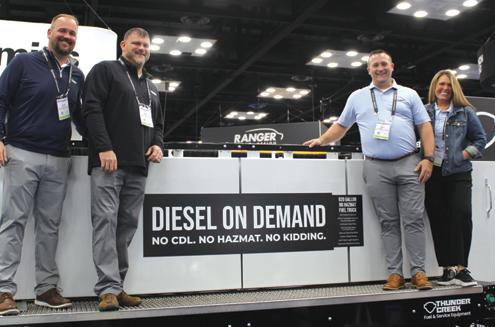

Work Truck Week 2025 was the biggest reunion yet, bringing together a verified 16,413 industry professionals from 31 countries and all 50 U.S. states March 4-7, 2025, at the Indiana Convention Center in Indianapolis.

With a primary focus on heavy-duty articulated dump trucks, the company also offers Fiori site dumper trucks and self-loading concrete mixers — products that are an excellent fit for the markets served.

Liebherr will display multiple machines at its booth, including the L 566 Z XPower wheel loader and the LH 22 M material handler. Liebherr experts also will be on site to answer any questions and provide assistance with equipment.

66

UNITED RENTALS AGREEMENT

Herc Holdings Inc., one of North America’s leading equipment rental suppliers, and H&E Equipment Services Inc. announced Feb.19, 2025, that H&E has terminated its prior merger agreement with United Rentals Inc.

JOHN DEERE TOUTS

John Deere is enhancing its portfolio of articulated dump trucks with the introduction of next-generation models, now featured across the 260 P-Tier, 310 P-Tier, 410 P-Tier and 460 P-Tier.

Construction is under way in coastal North Carolina to replace the aging Lindsay C. Warren Bridge on U.S. Highway 64 over the Alligator River in Tyrrell and Dare counties, the state Department of Transportation (NCDOT) announced Feb. 19, 2025.

The new bridge will replace the existing swing-span bridge with a modern two-lane, fixed-span, high-rise bridge on a new location just north of the current structure. The 3.2mi.-long bridge also will include two 12-ft. travel lanes with 8-ft. breakdown lanes.

Crews from Skanska began by driving the first concrete pile in the $450 million project into the bed of the broad river west of Manteo, the gateway to North Carolina’s Outer Banks.

The bridge pile is one of hundreds to be used as a foundation for the new structure, designed to replace the old swingspan drawbridge.

NCDOT officials expect the project to be completed in Fall 2029.

The current bridge, opened in 1960, is the main route to access the Outer Banks from the west, and a critical hurricane evacuation route. The swing span is maintained regularly, according to the agency, but is prone to occasional mechanical failures which force motorists to take a 99-mi.long detour.

NCDOT’s online project page noted that the new bridge also will improve river traffic, as more than 4,000 boats pass through the swing span each year.

The Lindsay C. Warren Bridge, also known as the Alligator River Bridge, has been rated “structurally deficient” by NCDOT inspectors.

“This does not imply that the 65-year-old bridge is unsafe, [but] it does mean the structure is reaching the end of its lifecycle and must be monitored, inspected and maintained on a more frequent basis,” NCDOT’s website said on its bridge construction project page. “The work to maintain the current bridge negatively impacts its ability to provide a reliable con-

nection between [the communities of] Columbia, Manns Harbor, Manteo and the Outer Banks.”

The environmental planning and preliminary design phase to replace the bridge began in early 2021 and finished in late 2022, the department said.

The existing bridge over the Alligator River is a vital link between the Outer Banks and the rest of North Carolina. However, approximately halfway across is a swing-span that brings traffic on U.S. 64 to a halt when it opens to let boats pass or occasionally breaks down and needs repairs.

Once finished, the new span will be wider and include shoulders and higher guardrails. It also will rise to 65 ft. above the channel, high enough to let boats pass underneath without stopping traffic on the road surface.

Demolition of the old Lindsay C. Warren Bridge is scheduled to start in Spring 2025 after the new bridge is completed, according to NCDOT.

The state agency and Skanska are moving ahead with construction of the new Alligator River Bridge even though the federal government has paused a federal grant that will help pay for it, the Raleigh News & Observer reported Feb. 21.

NCDOT was awarded $110 million for the Alligator River bridge from the bipartisan infrastructure bill approved by Congress in late 2021. It is one of two dozen grants the department received from the bill that the U.S. Department of Transportation (USDOT) has put on hold as part of the new administration’s efforts to re-evaluate federal spending.

State officials are counting on the federal grant to cover approximately a quarter of the project’s total cost and are getting started despite the government’s pause, said Tim Hass, a spokesperson of NCDOT.

“We are hopeful it is temporary, and the grant will move forward as awarded,” he said in an email to the Raleigh newspaper.

under way in coastal North Carolina to replace the aging Lindsay C. Warren Bridge on U.S. Highway 64

The USDOT announced the grant in January 2023, one of a handful nationwide designed to help state and local governments pay for difficult but critical projects.

Though chosen by the Biden administration, the bridge project has bipartisan support. U.S. Sen. Thom Tillis and former Gov. Roy Cooper announced the federal grant separately but almost simultaneously.

“I am proud to have advocated for this funding and thank local officials in both counties for their tireless advocacy for this grant as well,” Tillis said in a statement at the time.

The News & Observer noted that NCDOT has not received any guidance about the suspended federal grants.

That includes the largest one awarded to the agency worth nearly $1.1 billion to build the first leg of a high-speed passenger rail line between Raleigh, N.C., and Richmond, Va.

Gov. Josh Stein and state Transportation Secretary Joey Hopkins asked U.S. Transportation Secretary Sean Duffy about the status of that grant when Duffy visited western North Carolina to inspect last fall’s hurricane damage on Feb. 10, 2025.

“That’s one of the ones that’s a primary for us,” Hopkins said following their brief meeting with Duffy. “And we’re going to make a specific ask to try to get that one rolling.”

Among the other federal grants to NCDOT now on hold:

• $242 million to help replace the aging Cape Fear Memorial Bridge in Wilmington.

• $25 million to install wildlife crossings on U.S. 64 in Alligator River National Wildlife Refuge.

• $13.2 million to help the city of Wake Forest build a downtown train station as part of the Raleigh-to-Richmond rail project.

• $1.8 million to develop a plan to protect N.C. Highway 12 from ocean flooding in the Pea Island National Wildlife Refuge on the Outer Banks.

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

C.W. Matthews Contracting Co., an infrastructure and asphalt construction company, recently wrapped up its third annual Asphalt Construction Rodeo at its corporate campus in Marietta, Ga.

Twenty-eight of the company's asphalt machine operators signed up for the three-day competition. The first two days featured a series of qualifying rounds, with four winners from each day advancing to a championship round on the third day.

What began three years ago as an in-house training event aimed at advancing the skills of asphalt machine operators and fostering friendly competition has since evolved into a highly anticipated event.

The idea for the event was conceived by Scott Hall, the company’s asphalt construction division training manager, who was seeking a more handson experience for his operators beyond traditional classroom training. After researching other equipment rodeos in the earthmoving sector, Hall decided to create a similar event tailored to paving and compaction. This inaugural event was dubbed the “equipment rodeo” and has grown each year to include a full curriculum, written tests, timed obstacle courses, straight-line tests and more. Contestants also are evaluated on their teamwork, character and attitude. Daily machine walkarounds, a practice the company incorporates at any job site, also were part of the competition. This year marked the first inclusion of an asphalt planer in the event, reflecting the company’s belief that operators should be well-

versed in every piece of equipment critical to the efficiency of road-building projects.

The team behind the event’s success included Scott Hall, James Dylan Marbry, Mario Perez, Bobby Smith and Calvin Langston. To ensure impartiality, manufacturer and dealer representatives were selected as judges, with no input from C.W. Matthews.

“This is 100 percent educational for our employees,” said James Dylan Marbry, division trainer. “Some of the competitors have never even operated a roller on a job site before. We recognize the importance of cross-training and encouraging those interested to try something new.”

Marbry emphasized that while machine operation is crucial, the company’s primary focus is safety. “Our goal is to ensure our operators make it home safely at the end of each day.”

C.W. Matthews is fortunate to have a pool of talented operators who can step in for colleagues participating in the competition. Marbry also noted that the event serves to engage younger operators, helping them stay connected with the company and its culture.

see RODEO page 64

some operational expertise for contestants before they make a run at the compaction portion of the competition.

In 2025, Impact Rentals, based in Buford, Ga., will celebrate six years in business, marking steady and significant growth in the Southeast. With three locations in Georgia — Athens, Decatur and Buford — and an additional location in Greenville, S.C., the company continues to expand its footprint. Supported by a trusted shared-services partner that assists in key business areas, Impact Rentals is well-positioned for continued growth and success.

“Impact Rentals was founded to serve a single contractor, with a focus on providing exceptional service and reliable equipment,” said Angel. “Since then, we’ve grown significantly, expanding our reach across multiple rental markets and opening additional locations.”

Leading Impact Rentals is Scott Angel, who has 27 years of experience in the rental industry, having worked with several major rental outlets in north Georgia. Angel said that an opportunity came his way to start and grow a new rental organization, and the company has been thriving ever since.

Angel said that with the current growth trends, he could see the company opening two or three new locations every year for the foreseeable future. “We’re a young company — we’re in growth mode,” added Angel.

“What I’ve seen over the years with some rental businesses is that they say they’re all about service, but the service was lacking,” said Angel. “What we’re trying to do here is to be completely centered on what the customer needs and be centered on what the customer expects a rental company to provide to them — and then follow through.”

The company is stacked deep with talent, according to Angel.

“Paul Warren, our service director, comes from a contractor background,” Angel said. “He worked for several companies before coming to Impact. He understands what the customer is doing out there every day.”

Reflecting on the company’s growth, Angel said, "When we started this business, we grew the fleet with the intention to keep a newer, extremely well-maintained fleet — more so than other rental outlets — which results in far less hard downtime. We have well-trained technicians that keep up with the machines at a high level.”

Praising Warren’s dedication, Angel said, “Paul [Warren] is probably the most detailed person I’ve seen in my years in the business. He knows the history of the machines we own. He knows the detailed work orders for the history of each of the machines that we put out for sale or rent. How he does fleet maintenance sets an industry standard. After their rental life, our machines command more dollars at auctions because of their history and maintenance. All because of Paul.”

The Impact Rentals team is strengthened by experienced professionals like Josh Nelson, regional manager, and Nick Lentini, sales manager. According to Angel, the company’s field service dispatch has evolved into a highly efficient operation, while branch managers have grown into outstanding leaders, consistently delivering exceptional results.

Discussing Impact’s approach to customer service, Angel said, “All machines break down. It’s the response that makes the difference. We’re all about the details of timely field service. We shoot for less than a two-

hour time frame to be on someone’s job site to take care of their machine issues. If a job is a little further from one of our locations, we’ll quickly use an external source to meet the immediate need.”

Steven Anthony is another key staffer who recently joined the company as its hydraulic hammer specialist. Anthony has more than 20 years of experience with hydraulic ham-

mers and is quickly becoming an integral part of the company’s rental business opportunities.

Anthony said that the company not only rents hammers but also sells and rebuilds units. Impact Rentals is an authorized Okada full line dealer, service center, and parts distribution source, offering comprehensive support for Okada products. The company employs trained factory technicians and skilled rebuild specialists to ensure equipment is maintained to the highest standards.

“We also rebuild other hammer manufacturers,” Anthony added. “Our hammer rentals are always paired with a carrier machine appropriate for the hammer size. Each hammer machine is equipped with glass guards for rock protection and a greasing system. As part of our enhanced service, we provide operator training on hammer use and will even swap out the hammer or carrier machine if the application turns out to be heavier than expected.”

Impact Rentals has machine/hammer combos from skid steer machines all the way up to 100,000-lb. machines. A fleet of close to 40 well maintained machines with hammers including several 12,000-lb. and10,000-lb. hammer/carrier machine combos are available.

Angel’s philosophy is “providing service in a lack of service industry,” adding, “I just

It has been known for a while that SpaceX CEO Elon Musk’s Starship would eventually launch from Florida, but now SpaceX is saying it may happen as early as the end of this year as the aerospace company ambitiously confirmed that it is pushing to launch from Pad 39A at the Kennedy Space Center (KSC) by the end of 2025.

The news was publicly announced during the March 3 webcast of the Starship launch attempt from the company’s Starbase at Boca Chica, Texas.

“We plan to complete the Starship launch pad at Pad 39A later this year and pending the completion of the environmental reviews, SpaceX intends to conduct the first Starship launch from Florida … later this year,” said Christopher Gebhardt, a SpaceX spokesperson.

The effort includes at least $1.8 billion of SpaceX capital investment and will bring an estimated 600 new full-time jobs to Florida’s Space Coast by 2030.

“With 600 new full-time jobs and the historic addition of Starship launches from Florida, this expansion strengthens our economy, grows our aerospace workforce and solidifies our leadership in the next generation of space exploration,” said U.S. Rep. Mike Haridopolos. “This investment is a testament to SpaceX’s confidence in Florida’s central role in spaceflight, and we are proud to support the groundbreaking missions that will lift off from our shores.”

While SpaceX acknowledges the U.S. Space Force and Federal Aviation Administration environmental reviews are not set to be released until late 2025, construction of the giant Gigabay at KSC, which will be used to stack and finalize the 232-ft.-tall Super Heavy boosters (lower-stages) before flight, could begin as soon as April 2025.

Also, the new Starship tower standing at Kennedy Space Center Pad 39A, will likely be finalized shortly, Florida Today

noted.

SpaceX’s ambitious announcement noted that in expanding Starship operations into Florida, it would bring production and launch capabilities to the Space Coast as Starship flight testing, development and launch cadence continues to pick up pace at Starbase in Texas.”

The 380-ft.-tall Gigabay facility would fall short of NASA’s Vehicle Assembly Building, which has a height of 525 ft. But at its height, the new complex would still be a recognizable feature looming in the distance on the approach to Cape Canaveral and give the general public a glimpse of SpaceX’s next generation launch system.

The proposed SpaceX Gigabay will be an addition to SpaceX’s Robert’s Road facilities at KSC.

In total, SpaceX’s Starship towers more than 400 ft. in height, larger than any rocket ever built.

Its 33 engines give off 16 million lbs. of thrust at liftoff. For reference, the Saturn V moon rocket was only 363 ft. tall and had a maximum thrust of 7.6 million lbs. when launched.

Starship is not only planned to be SpaceX’s next workhorse rocket, but its upper stage also is being tapped by NASA to act as a human lander for the Artemis III mission, aimed at returning humans to the lunar surface no earlier than 2027.

If the Trump administration allows the plan to go forward, Starship will dock with the Orion spacecraft in lunar orbit before ferrying astronauts down to the Moon’s surface.

SpaceX also has repeatedly stated hopes of launching an uncrewed Starship to Mars by late 2026, when the planet will be close to Earth. This has been a stated goal of both Musk and President Trump. Should an uncrewed Starship to Mars happen in 2026, a crewed mission could follow two years later.

This timeline, though, also depends on how soon Starship can overcome its operational problems and begin to run smoothly. While a recent unmanned flight saw a successful booster catch, the ship was lost less than 10 minutes after liftoff when it broke up over the Turks and Caicos Islands.

It remains to be seen how Starship improves on March 3, 2025’s Flight 8, which was scrubbed shortly after lift-off due to a booster rocket issue.

As yet, Starship has not reached an orbital flight from Texas or successfully returned its upper stage to the launch pad, although by January 2025, SpaceX was able to twice catch the first-stage booster with the launch tower’s “chopsticks.”

Full return and reusability are planned for future flights, SpaceX said, and a return of the Starship to the KSC launch pad could come as soon as Flight 9, although no exact date has been determined.

The Tennessee Department of Transportation (TDOT) announced March 13, 2025, that Kiewit Infrastructure South Co. of Westlake, Texas, has been chosen as the construction manager and general contractor for the Interstate 55 bridge replacement project in Memphis, Tenn.

The company is a subsidiary of Nebraska-based Kiewit Corp., which is also overseeing the Interstate 30 Crossing project in Little Rock, Ark. as part of a joint venture with Massman Construction of Overland Park, Kan., Arkansas Business magazine noted. The first phase of that project, which included the replacement of the I-30 bridge over the Arkansas River, was completed in November 2024.

In a news release, TDOT said the contract for Kiewit’s newest bridge project is in the process of being finalized. In addition, the environmental review and compliance process for the work is wrapping up and design work already is

under way.

Parsons Transportation Group Inc., a division of Parsons Corp. of Chantilly, Va., is the project’s engineering and design firm.

Construction on the I-55 bridge is estimated to begin as early as the second half of 2025, according to Arkansas Business.

The U.S. Department of Transportation (USDOT) awarded TDOT $394 million to go toward half the cost of replacing the 75year-old bridge, which spans the Mississippi River between rural east Arkansas and Memphis, Tenn. TDOT received the landmark investment to replace the I-55 bridge in July 2024.

In addition to the funding from the Rebuilding American Infrastructure with Sustainability and Equity (RAISE) program, TDOT, using a state general fund allocation provided through the Transportation Modernization Act, and ARDOT have each committed up to $200 million — demonstrating a collaborative

effort to pay for the bridge replacement.

The federal award also marks the single-largest transportation investment in Tennessee state history.

The I-55 bridge, a vital link for national commerce, is set to undergo a comprehensive overhaul to add capacity, improve safety standards, ensure route resiliency and maintain optimal operational conditions. The new and larger structure also will be designed to meet modern seismic codes, as it sits on the New Madrid fault line.

“This project is building a stronger future for Tennessee,” said Butch Eley, who serves as both the state’s deputy governor and TDOT commissioner. “We are thrilled to partner with the U.S. Department of Transportation, Arkansas, and now Kiewit, whose proven track record will be invaluable to the success of this transformative project to enhance regional and national connectivity and safe-

ty significantly. We look forward to its positive impact on our state and country for decades to come.”

More than 64,000 vehicles are projected to cross the bridge every day by 2050.

“The Arkansas Department of Transportation is pleased to partner with TDOT to construct a modern structure on a corridor that conveys many critical goods and services through the heart of our nation each day,” said ARDOT Director Jared Wiley. “We are thankful that TDOT was able to secure this historic grant award and are confident in Kiewit’s ability to deliver the project on time and budget.”

Kiewit is one of the largest engineering and construction firms in North America, with 31,000 employees and $17.1 billion in revenue in 2023.

“Kiewit is very pleased to have been selected to help deliver the bridge replacement project for the

Tennessee and Arkansas departments of transportation,” said Dave Miles, the company’s executive vice president. “We have a long history of safely building and engineering complex bridge and transportation projects across the United States, including in both [Tennessee and Arkansas]. We are excited to bring our experience and skilled workforce to this project, which importantly connects both states for people within and traveling through the region.”

While finalizing the contract with Kiewit for the construction manager, TDOT said it will continue to deliver this project. The decision is another progressive step using the Construction Manager/General Contractor (CMGC) alternative delivery method.

“CMGC is used for complex projects, aligning technical direction, organizational structure and budgets with the department’s strategic vision,” according to the state agency.

Associated Industrial Riggers Inc. has made a significant investment in its fleet with the purchase of a brand new 2024 Tadano AC 6.300-1 from Empire Crane Company.

This acquisition reinforces Associated’s commitment to providing lifting solutions for the most demanding job sites across the Southeast United States.

Associated specializes in a variety of services including rigging and machinery moving, crane rental, structural and custom fabrication, plant maintenance, turnkey plant relocation, civil and site work and more.

“Tadano has owned the R/T market for the past 20-plus years, with units that are bulletproof in design and dependability,” said Jim Burke, president of Associated Industrial Riggers. “This made it an easier decision to stay in the Tadano family line.”

The AC 6.300-1 boasts a main boom length of 262 ft. with a compact undercarriage design that enhances maneuverability in tight job sites, along with quick setup and teardown capabilities for increased efficiency. Associated elected for a model equipped with a luffing jib, which allows for an unparalleled strong chart and reach, making it an optimal choice for the evolving demands of modern construction, according to the company.

“Versatility is enormous with this unit,” Burke said. “This six-axle crane can go out as a fully dressed 350-ton crane with a luffer, or we can remove counterweights and quickly turn it into a 200-ton as needed. This allows us greater flexibility, reach and range for the marketplace.”

The decision to invest in this crane also was driven by growing customer demand.

“We’ve had a lot of customers asking us to help with bigger and bigger projects,” Burke said. “The 300-350-ton market seemed to have the greatest number of requests, which also helped us in the deci-

sion for this unit. When we looked to purchase it, it really boiled down to one word: value.”

The crane is already proving its worth, working on major projects at Walt Disney World and Universal Studios, according to the company.

By virtue of a long working relationship locally in New York State, the two companies were able to strike a deal on the AC 6.300-1 for Associated’s Orlando, Fla., branch. “Empire Crane Company has always helped us in the past and served us well,” Burke said. “We all know that buying specialized equipment is only as good as the

support you receive and the dealership that sold it to you.”

Burke noted Empire’s service and dedication as a catalyst for their ongoing partnership.

“[Empire Crane is] a family-owned business and the owners treated us just like we were part of the family,” Burke said. “Luke and Paul [Lonergan] are involved and available throughout all aspects of the deal — financing, licensing, service and product support. Josh Prentice in the service department made us a priority in shipping, setting up and commissioning this unit with ease. We thank you, Empire Crane Company.”

“We’re thrilled to make another deal happen with Jim Burke, Jerry Sanders and their crew at Associated Riggers,” said Paul Lonergan, owner of Empire Crane Company. “We’ve been lucky enough to do business with them for a number of years now and it’s always a pleasure. Thank you to Associated for not only trusting in the Tadano product, but Empire Crane.”

With the addition of the Tadano AC 6.300-1, Associated Industrial Riggers continues to enhance its capabilities, ensuring that it remains a trusted partner for complex lifting projects across the region, according to the company.

Following the success of 2023’s event, showcasing the event’s significance as North America’s largest construction trade show, ConExpo-Con/AGG returns to the Las Vegas Convention Center on March 37, 2026, with new features and innovations.

“The continued growth and success of ConExpo-Con/AGG has set a new benchmark for the industry,” said ConExpoCon/AGG Show Director Dana Wuesthoff.

“Building on this momentum, we will deliver an even more impactful event in 2026, continuing to provide unparalleled opportunities for networking, education and highlighting the latest innovations in the construction industry. We are especially excited to create new experiences and features for both attendees and exhibitors, making the 2026 event our most dynamic and engaging yet.”

The Ground Breakers keynote stage at ConExpo-Con/AGG provides an opportunity to raise awareness of the construction industry’s global contributions. Key topics include:

• Innovation in construction technology and practices;

• Public policy impacting the industry;

• Workforce development and addressing labor challenges;

• Sustainability and environmental responsibility; and

• Mental health and wellbeing in the construction sector.

Join ConExpo-Con/AGG during Women in Construction Week 2026 for the EmpowerHER workshop, a special event dedicated to addressing the unique challenges and opportunities women face in the construction industry. This program includes:

• Sponsorship opportunities to support and promote women-focused initiatives.

• Networking events fostering connections and community among women in the construction industry;

• Peer-led panel discussions and keynote presentations featuring industry leaders and experts; and

Recognizing the vital role of small businesses in the construction sector, the Small Business workshop addresses the

unique challenges faced by small business owners and provide:

• Networking events to build valuable connections for small business owners;

• Best practices and practical tools owners can bring home to immediately create pathways for success; and

• Sponsorship opportunities to support small businesses.

The Shop Talks and Walks workshop is a maintenancefocused program designed to provide attendees with practical solutions for everyday challenges. This program features:

• Special events focused on preventative maintenance, equipment efficiency and increasing uptime; and

• Educational opportunities focused on providing attendees with the tools to solve real-world challenges.

Border Rents

borderequipment.com

Augusta, GA 706-737-7253

Norcross, GA 770-609-8299

*Ditch Witch of Virginia ditchwitchva.com

Seaford, DE 302-629-3602

Chesapeake, VA 757-424-5960

Glen Allen, VA 804-798-2590

Manassas, VA 571-359-6081

*Ditch Witch Worx ditchwitchworx.com

Fort Lauderdale, FL 877-935-3656

Jacksonville, FL 866-254-1102

Plant City, FL 855-704-6828

Albany, GA 866-581-4914

Atlanta, GA 866-709-3712

Savannah, GA 888-298-0429

*Don Allison Equipment, Inc. donallisonequipment.com

Arley, AL 800-669-6450

First Choice Farm and Lawn firstchoicekubota.com

Brookland, AR 870-790-2301

Dyersburg, TN 731-882-1855

Eads, TN 901-616-5129

Mayfield, KY 270-856-4355

Savannah, TN 731-925-2141

Union City, TN 731-885-1315

*Forsythe Tractor forsythetractor.com

Shreveport, LA 318-687-1341

National Equipment Dealers

Carolinas

nedealers.com

Ashville-Fletcher, NC 828-628-3004

Charlotte, NC 704-228-0455

Clayton, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Columbia, SC 888-865-1002

Conway, SC 800-968-0754

Piedmont, SC 864-434-1154

Summerville, SC 843-501-0566

Wellford-Spartanburg, SC 843-501-0566

National Equipment Dealers

Florida

nedealers.com

Apopka, FL 407-401-8956

Fort Myers, FL 407-754-4646

Fort Pierce, FL 772-212-4043

Jacksonville, FL 904-664-0899

Tampa, FL 813-940-4405

National Equipment Dealers

Georgia

nedealers.com

Dallas, GA 770-445-9019

Douglas, GA 912-384-4664

Macon, GA 478-257-8300

Richmond Hill, GA 912-756-7854

Southern Lift Trucks

southernlift.com

Mobile, AL 251-278-2247

State Machinery

statemachineryeq.com

Kenner, LA 504-464-0431

Taylor Construction Equipment taylorconstructionequipment.com

Bessemer, AL 205-428-7050

Huntsville, AL 205-428-7050

Montgomery, AL 205-428-7050

Louisville, MS 833-773-3421

New Albany, MS 304-550-9825

Richland, MS 601-922-4444

LaVergne, TN 304-550-9825

Maryville, TN 662-773-3421

Van Keppel

vankeppel.com

North Little Rock, AR 501-945-4594

Van Buren, AR 479-474-5281

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

An analysis of available information was undertaken to identify drone applications, classify benefits, address challenges and suggest potential solutions.

The authors sought to understand the current body of knowledge covering the usage of drones for roadway condition monitoring (D-RCM).

Taraneh Askarzadeh, Raj Bridgelall and Denver D. Tolliver wanted to determine how that might help address ongoing issues.

According to an ASCE abstract, the trio explored the implications for new theories, management and impacts to society that arise from D-RCM.

Cost and time savings, safety enhancements, improved mobility and reliability are the primary drivers behind D-RCM adoption, said ASCE.

Applications categories included condition monitoring, situation assessment, network mapping, asset monitoring and construction inspection. Challenges, such as visual line-of-sight maintenance, limited flight time, payload capacity and engineering errors were found.

Emerging potential solutions included terrain-following features, optimizing battery capacity-weight balance and employing trained personnel.

“Importantly, the study reveals considerable cost benefits and impressive return on investment of up to 980 percent,” said the abstract.

This revelation positions drones as “a promising, cost-effective tool for infrastructure management.”

The technology has “profound implications for theory, management and societal impacts of DRCM applications.”

Aerial photography company The Drone Life would agree about the profound implications.

“With live drone feeds, multiple team members can simultaneously review construction progress, ensuring quick, tactical decision-making,” said Allred. “A single drone flight can detect errors in fine grading or equipment placement, allowing crews to make corrections immediately.”

And for more in-depth analysis, drone data can be processed with advanced software within hours, offering teams precise insights for ongoing adjustments.

Drones also serve as a valuable legal safeguard. If a safety dispute arises timestamped drone footage can verify site conditions on any given day.

“This documentation not only protects contractors from liability but also reinforces a strong commitment to site safety,” said Allred. “Ultimately, drone data helps teams catch mistakes early, reduce costly rework and keep projects on track.”

The company sees major benefits to UAV technology for road and highway construction that can be applied just as well to tracking pavement conditions.

Christian Allred believes drones are revolutionizing highway construction by offering the industry the capability to make informed decisions on projects.

In a blog post for The Drone Life, Allred said crews are able to precisely conduct site surveys, monitor earthwork progress and oversee pavement placement.

“Real-time insights from UAVs not only enhance productivity but also improve safety and reduce project costs,” he said, offering a top five benefits list:

Drones are transforming how engineers assess terrain before road construction even begins, said Allred.

With advanced aerial surveying capabilities, UAVs can capture highly accurate, subcentimeter-level data.

The data offers crucial insights into soil conditions, elevation changes and potential obstacles to improve planning and reduce unexpected construction costs.

“Before asphalt paving begins, drones ensure the ground surface aligns with design specifications,” said Allred. “They even optimize haul route planning, reducing fuel

costs and project timelines.”

Leveraging physical markers placed across the site, drones achieve survey-grade accuracy once possible with costly traditional surveying methods, he said.

2.

Drones provide real-time aerial insights that significantly enhance on-the-ground decision-making.

By hovering above a construction site, UAVs can monitor supply levels, track equipment status and identify inefficiencies. The devices offer project managers the information to reallocate materials, report damages and adjust schedules before small issues escalate into costly delays.

3. Faster Data Collection

One of the main benefits of using drone technology in road construction in general is speed.

To send an engineer on foot to collect the same data with a handheld camera can be an incredibly slow process, Allred said.

“Drones can cover large stretches of road and they can capture far more data from various angles.”

Another reason drones can collect data faster is that they are not slowed down by on-the-ground hazards, he added.

“Site material, equipment and traffic can get in the way when you’re on foot,” said Allred. “But drones can map entire corridors, problem-free, from the air.”

“In the end, road construction surveys that used to take several weeks can now be done in a matter of days with drones,” he said. “And drones can give you more frequent reports while staying incredibly cost- and time-efficient.”

4. Visual Documentation

UAVs also provide better visual documentation of each layer of the road as it is laid.

Capturing aerial drone footage of each one before moving on to the next allows you to keep a detailed visual progress record as you go, said Allred.

5. Enhanced Worker and Site Safety

“Drones play a crucial role in improving worker safety and site security,” he said.

By capturing aerial data, UAVs eliminate the need for personnel to inspect hazardous areas, reducing the chance of accidents.

“Their bird’s-eye view also helps crews identify and mitigate potential dangers

The SMH Group, a distributor of material handling equipment, announced the addition of CLM Equipment to its growing dealer network. CLM Equipment, a provider of heavy equipment solutions, is now an authorized dealer of Atlas and Mantsinen material handlers in La.

This partnership further strengthens the availability and support of these brands across key markets in the southern United States CLM Equipment has locations in Lake Charles, Lafayette and New Orleans, La.

“The partnership with CLM Equipment is an exciting development for us,” said Tim Hyland, vice president of the SMH Group. “Their dedication to excellence and deep industry knowledge makes them an ideal partner to represent Atlas and Mantsinen. We are confident that CLM’s customers will benefit from access to our advanced equipment and top-tier support.”

“CLM is not just a typical business with employees, customers and suppliers,” said Floyd Degueyter, president and CEO of CLM Equipment. “Ours is a partnership, a team — all working together to develop our communities and after 59 years we are still committed to building strong, lasting relationships.”

The SMH Group now has a network of eight dealers in 21 states that offer specialized equipment solutions from Atlas and Mantsinen for port operations, recycling, scrap metal, demolition, waste management, logging and several other industries.

Atlas material handlers range in size from 44,000 lbs. to 125,000 lbs., including the Atlas 200 MH and the Atlas 520 MH. The german-engineered machines are known

worldwide for fast cycle times, optimized handling and extended life span, according to Atlas.

The Finnish-made Mantsinen material handlers pick up where Atlas leaves off. The Mantsinen 60 is 160,000 lbs., and the gigantic Mantsinen 300 is one of the largest machines of its kind in the world, tipping the scales at more than 900,000 lbs. and with a reach more than 130 ft., according to

The Mantsinen 300 is one of the largest machines of its kind in the world, tipping the scales at more than 900,000 lbs. and with a reach more than 130 ft., according to Mantsinen.

Mantsinen.

By bringing Atlas and Mantsinen into its lineup, CLM Equipment expands its ability to serve industries that require specialized high-performance material handling solutions. Customers in Louisiana. will now have local access to a broader range of cutting-edge equipment, backed by CLM Equipment’s expert sales and service teams, according to CLM.

Caterpillar D3 Track-Type Tractor, 1:50 scale - $110

Bucyrus Erie 22B Cable Shovel,1:50 scale

Bucyrus Erie 22B Cable Backhoe,1:50 scale

Case 580D Backhoe/Loader, 1:35 scale ................................................

Case 580E Backhoe/Loader,1:35 scale

Case 580SR Backhoe/Loader,1:50 scale

Case 850B Angle/Tilt Dozer,1:35 scale ..................................................

Case 1845B Uni-Loader,1:35 scale

Case DH4B Trencher,1:35 scale

Case 9030B Excavator,1:50 scale ............................................................

Caterpillar D6H Track-Type Tractor,1:50 scale $90

Caterpillar 953 Traxcavator,1:50 scale

Caterpillar 955L Traxcavator,1:50 scale ..................................................$60

Caterpillar 988B Wheel Loader,1:50 scale $100

Caterpillar 988F Wheel Loader,1:50 scale $100

Caterpillar C-591 Pipelayer,1:70 scale ....................................................$70

Caterpillar D9N Track-Type Tractor w/black Tracks,1:50 scale $100

Caterpillar D9N Track-Type Tractor w/yellow Tracks,1:50 scale $100

Caterpillar D8L Track-Type Tractor,1:50 scale ......................................$100

Caterpillar D7C Track-Type Tractor,1:50 scale $110

Caterpillar D10 Track-Type Tractor w/ ripper,1:50 scale $100

Caterpillar D11R Track-Type Tractor,1:50 scale ......................................$75

Caterpillar D4E Track-Type Tractor, new color,1:50 scale $60

Caterpillar D4E Track-Type Tractor, old color,1:50 scale

Caterpillar AP-1000 Asphalt Paver,1:50

416 Silver Backhoe/Loader,1:50 scale

Caterpillar 936 Wheel Loader,1:50 scale

Caterpillar 438C Backhoe/Loader,1:50 scale ..........................................

Caterpillar 225 Crane w/clamshell bucket,1:50

Komatsu D155AX-5 Dozer w/ ripper,1:50 scale

Massey Ferguson 516 Skid Steer Loader,1:32 scale

Blue Diamond Attachments announced its full line of brush cutter attachments.

Blue Diamond skid steer, compact track loader, mini skid steer, excavator and mini excavator brush cutters have been widely accepted by contractors in North America for their ability to handle site prep and clearing. Because of that success, the company has grown its offering — now providing heavy, extreme and severe duty models — designed to handle any job, large or small.

Blue Diamond provides 13 different models of brush cutters for use with mini skid, skid and track loaders:

• 36 in., 42 in. and 50 in. mini skid steer closed front

• 36 in., 42 in. and 50 in. mini skid steer open front

• 60 in. and 72 in. heavy duty models

• 60 in. and 72 in. extreme duty models

• 72 in. severe duty model

• 44 in. swing arm cutter

• 84 in. dual motor brush cutter

The company also offers seven mini excavator and excavator brush cutter models:

• 60 in. extreme duty for excavators

• 60 in. severe duty for excavators

• 36 in., 42 in. and 50 in. heavy duty for mini excavators

• 42 in. severe duty for mini excavator

Blue Diamond Attachments offers a few

key differentiators that add performance and value to its brush cutters, versus an add-on from the manufacturer.

• All Blue Diamond brush cutters are engineered for specific applications to fit different classes of machines with different power levels as well.

• Blue Diamond has parts in stock and live support to back its products.

• Blue Diamond attachments are designed to work with all equipment brands.

• Blue Diamond ships each brush cutter ready to use, versus other options on the market where additional hoses or oils are required.

“Our full line of brush cutters offer landscapers, contractors, farmers, municipalities and more the breadth and depth of attachment they need to get any job site cleared,” said Drew Truan, chief operating officer at Blue Diamond Attachments. “Our full line of cutters are compatible with most OEM machines and are supported by Blue Diamond and our extensive dealer network.”

The brush cutter attachments come with the Blue Diamond Satisfaction Guarantee, and all are backed by a 1-year warranty. For more information, visit www.bluediamondattachments.com.

(All photos courtesy of Blue Diamond Attachments.)

You will find the parts you need at MOBRO Marine, Inc. We purchase in bulk directly from the manufacturers to maintain our large inventory. We also have a large inventory of long-lead time parts for cranes that can’t be found anywhere else. Not only does this mean we have the part you need in stock, it also saves you money. Because we buy in volume, we can buy for less and pass the savings on to you.

Our large inventory keeps construction equipment performing at optimum levels. We offer same-day shipping on most partsyou’ll experience minimal downtime. We are a full-service company. We not only supply parts, but we also service and repair construction equipment and cranes of any type.

Mongo Attachments, a leader in heavy equipment solutions, announced the launch of its new high-performance ProGrade forestry mulcher line. Designed for excavators from 7,000-26,000 lbs., this line expands Mongo’s offerings and sets a new standard in land-clearing technology.

The ProGrade forestry mulchers feature an innovative bite-limiting design that maintains optimal rotor RPMs while requiring only 15-35 gpm hydraulic flow. That ensures superior performance across a range of challenging terrains and vegetation densities.

“Our new ProGrade line builds on the success of the Gen 2 forestry mulcher by addressing the evolving needs of operators tackling high-intensity projects,” said Adam Drummond, general manager of Mongo

Attachments. “We’re not just expanding our product line: We’re redefining what’s possible in land clearing, while complementing our existing offers. This new addition ensures every customer has the right tool for the job, whether they need our trusted Gen 2 or the advanced capabilities of the ProGrade series.”

The ProGrade forestry mulcher delivers enhanced versatility and performance, according to the company. Its design features non-proprietary teeth, a precision-balanced drum with access panels and an offset drum for efficient tree addressing. According to Mongo, this mulcher is built to excel in challenging environments. It features a reinforced shell for durability, a convenient kickstand, an adjustable back gate and an included mount and hose kit.

The introduction of this mulcher line reinforces Mongo’s dedication to providing comprehensive solutions for the industry. Customers can now select from a broader range of attachments, all backed by Mongo’s reputation for quality and service.

The ProGrade Mulching Head is available through authorized Mongo Attachments dealers.

For more information, email sales@mongoattachments.com or visit mongoattachments.com.

TRAMAC, a wholly owned subsidiary of Montabert, designs and builds stationary boom systems that pair perfectly with Montabert variable-speed breakers to productively break oversize rocks prior to primary crushing.

TRAMAC offers nine models of stationary boom assemblies for rock breakers that — depending on the model — provide horizontal reach from 14 to 65 ft., 170 to 360degrees of swing arc, and 1,500 to 13,000 ft. lb. of hammer impact. Boom weights range from 5,850 to 55,000 lb. and accommodate hammer weights from 1,098 to 9,920 lb. Standard across its entire boom line, TRAMAC builds rugged cylinders of highstrength steel and welded construction from chrome-plated, high-tensile steel rods. Heavy-duty, oversize pins are fitted with replaceable aluminum bronze bushings.

Self-aligning spherical bushings on the

cylinder rod and barrel end ensure long equipment life. An extremely strong, lowprofile base of shaped plate steel attaches easily to any platform foundation, according to the manufacturer.

TRAMAC also offers a number of boom, HPU, hammer and control options, as well as custom design services. For more information, visit tramac.com and montabert.com.

Montabert photo TRAMAC offers nine models of stationary boom assemblies for rock breakers that — depending on the model — provide horizontal reach from 14 to 65 ft., 170 to 360-degrees of swing arc, and 1,500 to 13,000 ft. lb. of hammer impact.

Tod Gilbert (L) of VMAC and Christina Arrington of Stealth Power unveil the VMAC E30 battery electric-powered rotary screw air compressor featuring 92 percent more run-time per charge.

From Purple Wave Auctions (L-R) are Dan Harly, sales director; Savannah Shugart, field events and marketing specialist; and Adam Cripps, regional operations director, United States East.

Joel Stutheit (L), senior manager, and Tucker Perkins, president and CEO, both of Autogas Development, at the 2025 Work Truck Show. The Propane Education and Research Council (PERC) promoted the benefits of propane as a fuel source for commercial vehicles, highlighting its potential for cleaner emissions.

Work Truck Week is more than a trade show — in fact, many regular attendees describe it as the commercial vehicle industry’s annual reunion. Work Truck Week 2025 was the biggest reunion yet, bringing together a verified 16,413 industry professionals from 31 countries and all 50 U.S. states March 4-7, 2025, at the Indiana Convention Center in Indianapolis.

Work Truck Show exhibit space was sold out, with 549 companies filling the exhibit hall and new Exhibitor Pavilion with the latest vehicles, equipment and technology.

Produced annually by NTEA — The Work Truck Association, Work Truck Week encompasses The Work Truck Show, Green Truck Summit, NTEA Annual Meeting, Ride & Drive, educational programs and more. It’s designed to provide industry professionals with opportunities to explore the

At the extensive Godwin Group booth (L-R) are Jake Bergo, fleet and commercial sales of Dave Syverson Truck, Albert Lea, Minn.; Brad Hicks, southeastern sales representative of Godwin Group; and Adam Syverson, inventory manager, Dave Syverson Truck Center.

latest trucks, trends and technology; discover new ideas; and connect with the people and companies they need to thrive. This is the third year in a row North America’s largest work truck event has set a new attendance record.

“The commercial vehicle industry certainly showed up in Indianapolis this year,” said Steve Carey, NTEA president and CEO. “With new products on every aisle, impressive engagement in educational sessions and lively networking events, we couldn’t have asked for a better week. People were excited to be there and are already actively looking forward to next year. Even before we closed the doors on Work Truck Week 2025, many company representatives were sharing their plans for product introductions and suggestions for new educational sessions at Work Truck Week 2026.”

Chris Talbot (L) and Lucas Sigurdson of Buyers Products had many products on display at the Work Truck Show and showcased the light duty MX 75 II snowplow primarily for residential use with low profile heated lights, built and sourced in the United States.

Federico Palove (L) of Curry Supply with Albert Ribeiro of Wilcox Bodies as Ribeiro celebrates 50 years with the company. Curry Supply is among the largest distributors of Wilcox Bodies in the United States. see NTEA page 37

Work Truck Week 2025 kicked off March 4 with Green Truck Summit, a full-day immersion into advanced commercial vehicle technology. As the industry grapples with an uncertain regulatory environment, Jennifer Brace, chief futurist of Ford Motor Company, delivered a keynote address

Chris Shallenberg of PALFINGER helped introduce the enhanced PALPRO 43 mechanics truck with new features like 52-in. compartments and a load moment indicator system.

designed to help attendees develop a framework to better prepare their operations for the future. A verified 715 participants attended Green Truck Summit sessions throughout the day.

A major draw of Work Truck Week is the ability to check out what’s new in the industry. Dozens of companies launched products,

Tyler Havens, product manager of Stellar Industries, Clear Lake, Iowa, shows the newest products in Stellar’s utility body drawer and lighting enhancements.

announced business relationships, celebrated milestones and showcased technology developments at this year’s event.

Attendees who wanted time behind the wheel of commercial vehicles with the latest advanced fuels and technology needed to look no further than Ride & Drive. This unique event March 5-6 let hundreds of

Nicolas Vazquez Conde of Go Power! with the Phantom, a charging system that combines solar and alternator charging for commercial vehicles.

attendees drive or ride in 20 vehicles spanning Classes 2-8, including all-electric vans, trucks and chassis, as well as internal combustion vehicles featuring advancements to improve fuel utilization and reduce greenhouse gases or particulate matter.

see NTEA page 38

11301 Reames Road Charlotte, NC 28269 980-859-4680

125 Wilsons Mills Rd. Extension Smithfield (Raleigh), NC 27577 919-938-8145

141 Brickyard Rd. Lexington (Columbia), SC 29072 803-520-0032

6325 Central Avenue Pike Knoxville, TN 37912 865-766-2571

Making its debut on March 6, Commercial Vehicle Data Exchange and Reception attracted professionals interested in uncovering and expanding the commercial vehicle industry’s data ecosystem. It was part of the extensive educational program focused on providing insights and strategies for enhancing operational growth. Other sessions covered industry

trends, vehicle engineering and compliance, government regulations, exclusive updates from 15 chassis OEMs, workforce development, fleet management, vehicle propulsion and sustainability solutions, and more.

Attendees who purchased a Green Truck Summit or Work Truck Week Conference Package can access on-demand educational content through April 14 by logging in to

their WTW25 Planner at wtw25.mapyourshow.com/8_0/login/login.cfm and selecting on-demand.

Industry professionals caught up with colleagues and made new connections at the Opening Reception, the Generation Next Leadership Workshop and Networking Reception, the Commercial Vehicle Data Exchange and Reception and the NTEA Annual Meeting with Keynote Speaker

Mike “Coach K” Krzyzewski, head men’s basketball coach of Duke University (19802022).

Work Truck Week returns to Indiana Convention Center March 10-13, 2026. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide, except where noted. All Rights Reserved.)

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804 HEAVY MACHINES, INC. www.heavymachinesinc.com

120 Mann Drive Piperton, TN 38017 (Memphis) 800-238-5591

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

LINK-BELT MID ATLANTIC www.link-beltmidatlantic.com Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235

www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

1485 Bear Creek Pike Columbia, TN 38401 931-388-7273

MID SOUTH MACHINERY, INC. www.gomidsouth.com

3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

7422 Hwy 49 N Hattiesburg, MS 39402 601-268-2222

Fiori America is a division of Bell Trucks America Inc., based in Houston, Texas.

Authorized by the Fiori Group of Modena, Italy, Fiori America is the master distributor of Fiori construction products in the United States. With a primary focus on heavy-duty articulated dump trucks, the company also offers Fiori site dumper trucks and self-loading concrete mixers — products that are an excellent fit for the markets served.

As a full distributor, Fiori America manages national new equipment and parts sales, warranty claims processing and aftersales support directly from its offices in Houston. Working with 30 dealers nationwide, the company is actively expanding its dealer network to enhance availability and service.

The Fiori site dumpers are available in 5ton, 9-ton and 12-ton load capacities. The 5ton model features four-wheel drive and an articulating frame for superior maneuverability. The 9-ton and 12-ton models incorporate both four-wheel drive and four-wheel steering, ensuring excellent operation in challenging underfoot conditions.

All dumpers are powered by Kohler engines, hydrostatically driven and equipped with ROPS/FOPS air-conditioned and heated cabs. The 180-degree rotating operator stations, safety cameras and 180-degree swivel dump beds provide precise material handling in confined spaces.

“We have found the Fiori dumpers to be simple but reliable — essential for sites where large dump trucks cannot gain access,” said Neville Paynter, president of Fiori America and Bell Trucks America.

“They are ideal for urban construction, demolition sites, parks, cemeteries, golf courses,

landscaping, agriculture and road maintenance. Additionally, they offer excellent rental returns due to their low maintenance requirements, ease of transport and included two-year warranty.”

Fiori’s self-loading mixers are a gamechanger for concrete contractors looking for complete control over their projects. Materials can be loaded either as super sack premix or raw material using a bucket attached to the front of the mixers.

Operators use an in-cab computer system to set mixing requirements, manage water inflow from onboard tanks and control additive inflow, ensuring precise batch quality. The mixed material is then poured via a maneuverable chute, and the in-cab computer produces a batch ticket to maintain speci-

fication accuracy. A built-in high-pressure cleaning wand ensures easy cleanup between batches.

There is no waiting for ready-mix deliveries, no weather uncertainties and no expensive pumping solutions — just arrive, drive, batch, clean and go.

Fiori’s self-loading mixers are available in 4-cu.-yd. and 6-cu.-yd. batch sizes, featuring all-wheel drive, four-wheel steering and hydrostatic transmission powered by Kohler engines. The company also offers an offroad, four-wheel-drive, four-wheel-steering transit mixer with a 7.2-cu.-yd. capacity.

Beyond standard applications, Fiori products serve as versatile utility base chassis cabs. The 9-ton site dumper chassis has been adapted to accommodate a 2,000-gall. water

tank equipped with water sprayers, a spray bar and a water cannon for efficient site dust suppression.

Alan Boyes, territory manager of Fiori America and Bell Trucks America, said, “Fiori products are designed to be simple, low maintenance and easy to transport, making them ideal for any job site. They are robust, reliable and feature best-in-class technology to maximize productivity.”

Fiori America is continuously seeking new dealers interested in expanding product lines with high-quality sales and rental offerings. As a master distributor, the company is well set up to provide support to dealer networks.

For details, visit belltrucksamerica.com. (All photos courtesy of Fiori America.)

Hailing from County Tyrone, Northern Ireland’s “home of crushing and screening,” Omega Crushing and Screening has developed a range of plug-in, dual power, electricdrive jaw crushers which deliver reliability, fuel savings and low/zero-emissions operation.

The Omega project was conceived when the team became aware of an interest in the market for a more simply-designed machine which contained fewer complex electronic and hydraulic components, and which would be straightforward to both operate and maintain.

While the Omega machines themselves are powered by either the mains electrical supply or an on-board generator, all of their main components also are electrically driven, such as the head and tail drums of the conveyors and the motors that run the feeders.

“Many quarry machines today have become very high-tech, whereas the user often wants a simple, user-friendly machine,” said Anthony Carlin, technical support director. “The control panel is very straightforward — there are no parameters or PLCs that you need to look at. It also uses a three-phase electrical system which is quite easy for electricians to work on.

“We have also done away with the complicated hydraulic toggle tensioning system on the crusher and gone back to the single drawback rod tensioning system. This, combined with hydraulic wedge adjustment makes it simple and reliable,” he said.

With other manufacturers now offering dieselelectric hybrid machines, Omega Crushing and Screening has chosen to take the next step in this direction and make its offering fully electric. The crushers can be plugged into the power grid and run without any diesel power input.

Alternatively, when an external power source is not available, the wheeled and tracked models share a dual-power option. This means the machines can run off an onboard 220 kVa powerpack with a Stage V/Tier 5 Deutz engine.

Among the benefits of electric power is the ability of the machine to run without producing exhaust gases.

Sales Director Colin Daly described how the clean-running crushers have found a niche with some customers in urban applications.

“As all three models in our range can run on mains elec-

tricity, all three are being used in metropolitan areas where emissions are an issue. For example, we recently sold a machine in Bulgaria. The company that bought it was going to work on a government project where particular emissions targets had to be hit. Our machine was a perfect fit as it could work on mains power and produce zero emissions,” he said.

Another strength of the Omega machines is the dramatically lower fuel consumption they offer in comparison to conventional hydraulic machines. When running on mains

electricity, fuel burn is reduced to zero. Even when using the onboard diesel generator, the J1065 range consumes fuel as low as 10 litres per hour, a saving of approximately 10-12 litres versus a similar hydraulic-drive machine.

Lastly, the electric drive is capable of operating efficiently in the world’s most extreme climates. Omega has recently completed a sale of a machine to the United Arab Emirates, where daytime temperatures can exceed 40 C and hydraulic machines can only run at night. In contrast, another Omega customer is operating a crusher in northern Norway, where lows of -20 C are experienced.

Omegas range consists of tracked, wheeled and static jaw crushers. Launching later this year, the range will now expand to include cone crushers and screens.

Omega currently has a strong presence worldwide and some of the major markets it currently has presence includes UK, Europe, USA and South America. Omega’s emphasis on quality and service has secured it strong relationships globally with its partners.

Omega recently won the Best in Quarry Equipment Manufacturing at the Machinery Movers Industry Awards 2024.

Concrete isn’t just the backbone of modern construction — it’s also the key to its future.

MB Crusher take a closer look at how to efficiently recycle concrete using its solutions.

Recycling concrete isn’t just an option anymore — it’s a necessity. In many parts of the world, landfills are reaching capacity and environmental concerns are growing. In others, transportation challenges and rising costs make logistics more difficult. As the industry moves toward sustainability, the focus is shifting to smarter ways of managing concrete waste.

The solution is simple: Don’t just demolish — recycle, reuse, reinvent.

Instead of seeing used concrete as waste, look at it from a different perspective — right from the excavator cab — as MB Crusher’s attachments transform it into valuable materials for new projects.

Construction and demolition companies face increasing environmental regulations. But those who choose MB Crusher attachments have discovered a way to transform waste into a valuable resource — right on site, according to the company. Here’s how it works

• Attach an MB Crusher bucket — Compatible with any brand of excavator, MB Crusher buckets turn demolition sites into on-thespot recycling centers.

• Crush concrete — The powerful jaws break down reinforced concrete with ease, even separating iron rebars.

• Reuse material immediately — Once processed, the crushed material is ready for backfilling, road foundations or new construction projects, cutting down the need for fresh aggregates.

In short, by equipping heavy machinery with an MB Crusher attachment, operators create a closed-loop system that converts rubble into high-quality recycled aggregates, according to the company.

MB Crusher attachments are designed to work with any brand of excavator, according to the company. Plus, MB Crusher offers a wide range of units that fit carrier machines as small as 6.5 tons — turning them from simple diggers into powerful mobile crushers. Whether you’re using loaders, skid steers, mini-, midi- or large excavators, there’s an MB Crusher unit ready to get the job done.

From Demolition to Railway Infrastructure With a Large Excavator

A Liebherr 954 excavator equipped with an MB Crusher BF135.8 turned a massive pile of concrete rubble into high-quality roadbed material for a new railway project — eliminating waste and cutting costs.

Simplifying Tight-Space Logistics

A Caterpillar machine fitted with an MB BF70.2 crusher bucket effortlessly transformed concrete waste into reusable material, reducing transportation and disposal expenses.

Backhoe Loader Becomes Mobile Jaw Crusher

A JCB 3CX 8-ton backhoe loader, equipped with an MB-L160 crusher bucket, reclaimed debris from a house renovation and repurposed it into a durable driveway surface — turning waste into a functional, eco-friendly upgrade.

For more information, visit www.mbcrusher.com.

Metso will present its latest offering for the aggregates industry at the bauma 2025 international construction machinery trade fair.

“After a hiatus in 2022, we are thrilled to be part of bauma 2025,” said Renaud Lapointe, president, market area Europe and Central Asia of Metso. “This event is a fantastic opportunity to showcase our latest innovations and sustainable solutions as well as demonstrate how Metso’s cutting-edge technology can drive customers’ productivity and efficiency in the aggregates industry. We look forward to engaging with our partners and customers to shape the future of our industry together.”

“This year marks a notable milestone for Metso as we celebrate the 40th anniversary of the groundbreaking Lokotrack mobile crushers,” said Metso. “This key highlight will be featured at bauma and all our events and trade shows throughout 2025, as we celebrate this achievement with our customers, partners and industry peers.”

At bauma 2025, Metso will be featuring:

• Nordberg HPe Crusher Series: Metso will launch the latest crushers in the series — designed to improve performance and efficiency in tough environments.

• Mobile crushers and screens: The latest updates on Metso’s current Lokotrack and Nordtrack track-mounted crushers and screens range. Introducing the EC range models alongside the “Build Your

Own” tool, allowing you to customize your own Lokotrack EC jaw or cone crusher.

•Metso HRC8 Crusher: Designed to transform quarry waste streams into valuable, sellable materials such as manufactured sand.

• Screening solutions: screening technology ensuring optimal screening performance precise material separation, easy maintenance and maximized productivity.

• Aftermarket offering and support: Metso has a wide range of aftermarket solutions to match your targets for all process stages. Innovations include new wear part products for improved lifetime and performance.

• Metso’s continuously developing digital solutions: To keep your operations running smoothly and efficiently. With intelligent instruments and software solutions, you will get more out of the process with less, thus enabling more profitable, efficient and sustainable production, according to Metso.

•Quarry solutions: Tailored crushing and screening plants, quarries with pre-designed modules and portable plants, which are ideal for one to two years of crushing operations in one location.

• Slurry handling: Advanced slurry handling and classification solutions for aggregates including pumps, hydrocyclones, valves and hoses designed to maximize efficiency, reduce wear and improve uptime, according to Metso.

Tuscaloosa, AL 205-752-0621 Panama City, FL 850-763-4654 Pensacola, FL

need to be replaced,” said Michael Flood, MDOT spokesperson. “Replacing these three bridges will give residents and businesses a safer and more efficient set of bridges to carry loads across SR 16/149 that will last for many decades. This is a big win for Yazoo County and surrounding areas.”

According to Flood, construction is expected to be finished in 2025, but that could change.

“This was the anticipated completion date at the start, and there is a lot of time left on this project. We are currently on pace to meet that date, at least to get the road open to traffic

by then. Both the contractor and MDOT were able to coordinate with landowners to adjust the phasing of this project and expedite the construction of Bridges A and C.

“We are on schedule to open the road to traffic by the end of 2025, but if the weather proves to be a factor at the end of the year, it could push us into the early construction season of 2026.”

To date, Flood said the elements have not been a huge issue for crews.

“There have been surprisingly good working conditions. Working in the Mississippi Delta can be challenging

in the winter and spring with flooding and mud, but to this point we have not experienced any major delays due to weather.”

Regarding the complete closure of SR 16/149 between W. Leeve Road and Whittington East Levee Road in Yazoo County, northbound traffic is detouring via SR 3 to U.S. 49W north. Southbound traffic is detouring via U.S. 49W south to SR 3 south.

“As with any road closure, a lot of motorists are inconvenienced, several of our employees included,” see YAZOO page 56

Underground hard rock mining operations looking for versatile solutions now have two more options: Komatsu has introduced the new Z3 series of medium-size class development jumbo drills and bolters to its lineup, further broadening the manufacturer’s selection of offerings for the underground mining industry.

The Z3 machines are built on a universal platform and designed with a focus on modularity and efficiency. This focus offers improved productivity that can help reduce service and maintenance costs across operations. The Z3 also boasts universal operator controls, simplifying user adoption and increasing training efficiency.

The new series expands Komatsu’s current underground hard rock offerings by adding the ZJ32 and ZB31 medium-size class drill and bolter.

Komatsu photo

The new series expands Komatsu’s current underground hard rock offerings by adding the ZJ32 and ZB31 mediumsize class drill and bolter.

Key features include innovative technology, such as a newly designed ground support installation system developed in collaboration with JENNMAR that utilizes their J-LOK P pumpable resin. In addition, the machines’ drilling attachments have limited moving mechanical parts and offer a simple design for smooth operability, resulting in reduced cycle times and increased drifter uptime compared to competitors in the same size class, according to the manufacturer.

“Our Z3 product line was designed to meet the evolving demands of our underground hard rock mining customers,” said Johan Kempe, product director, Underground Drills, Komatsu. “The common platform on which both machines

are built enables the interchangeability of parts and service, boosting operational productivity for customer operations.”

In the near future, additional battery and intelligent machine control models of the Z3 series will be added to the lineup to provide customers with a comprehensive range of offerings to meet their demands. This product family of diesel and battery-powered machines will offer innovative solutions to support underground mining operations with a pathway toward autonomous operations.

For more information, visit www.komatsu.com.

5038 Buford Hwy. Norcross, GA 30071 770-582-0377

Blue Ridge, GA 706-632-3777

Cumming, GA 770-887-6119

Hiawassee, GA 706-970-3077

McDonough, GA 770-957-3370

Villa Rica, GA 678-952-2037 Perry, GA 478-987-1173

6301 Old Rutledge Pike Knoxville, TN 37924 865-546-1414

10644 Lexington Drive Knoxville, TN 37932 865-218-8800 1825 Veterans Boulevard Sevierville, TN 37862 865-595-3750 9960 Airport Parkway Kingsport, TN 37663 423-323-0400

4066 South Access Road Chattanooga, TN 37406 423-698-6943