By Larry Bernstein CEG CORRESPONDENT

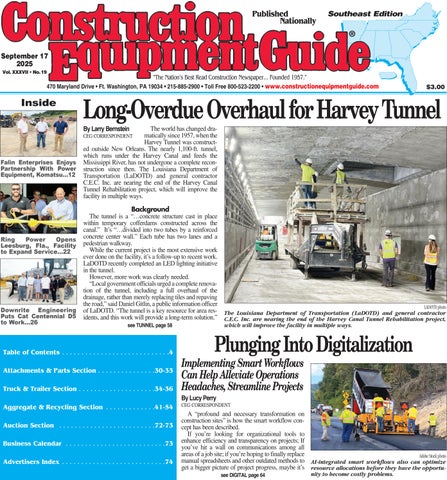

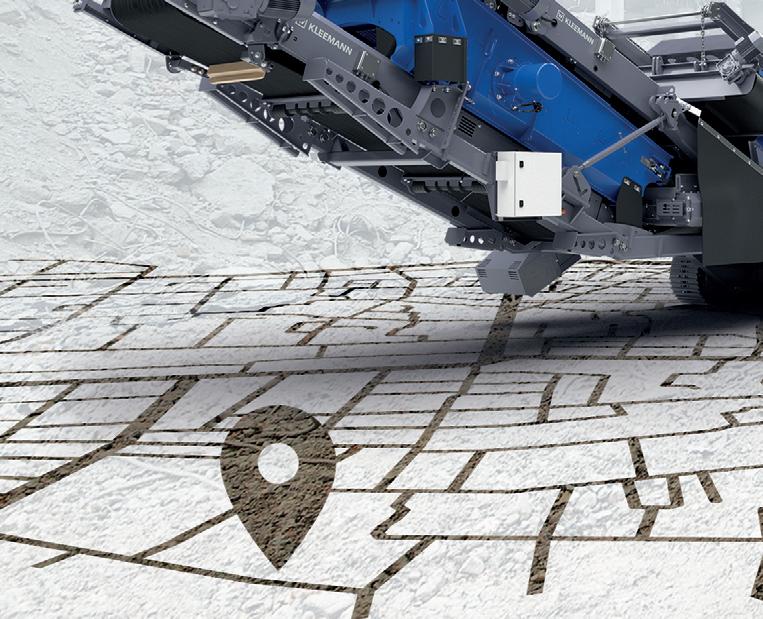

The world has changed dramatically since 1957, when the Harvey Tunnel was constructed outside New Orleans. The nearly 1,100-ft. tunnel, which runs under the Harvey Canal and feeds the Mississippi River, has not undergone a complete reconstruction since then. The Louisiana Department of Transportation (LaDOTD) and general contractor C.E.C. Inc. are nearing the end of the Harvey Canal Tunnel Rehabilitation project, which will improve the facility in multiple ways.

The tunnel is a “…concrete structure cast in place within temporary cofferdams constructed across the canal.” It’s “…divided into two tubes by a reinforced concrete center wall.” Each tube has two lanes and a pedestrian walkway.

While the current project is the most extensive work ever done on the facility, it’s a follow-up to recent work. LaDOTD recently completed an LED lighting initiative in the tunnel.

However, more work was clearly needed.

“Local government officials urged a complete renovation of the tunnel, including a full overhaul of the drainage, rather than merely replacing tiles and repaving the road,” said Daniel Gitlin, a public information officer of LaDOTD. “The tunnel is a key resource for area residents, and this work will provide a long-term solution.”

see TUNNEL page 58

Louisiana Department of Transportation (LaDOTD) and

C.E.C. Inc. are nearing the end of the Harvey Canal Tunnel Rehabilitation project, which will improve the facility in multiple ways.

Implementing Smart Workflows Can Help Alleviate Operations Headaches,

By Lucy Perry CEG CORRESPONDENT

A “profound and necessary transformation on construction sites” is how the smart workflow concept has been described.

If you’re looking for organizational tools to enhance efficiency and transparency on projects; If you’ve hit a wall on communications among all areas of a job site; if you’re hoping to finally replace manual spreadsheets and other outdated methods to get a bigger picture of project progress, maybe it’s see DIGITAL page 64

In a rapidly

the

When Jim Falin decided to open his own business as a young man in 1987, he did so in part to fulfill his boyhood dream of working with tractors. After buying his first piece of equipment, he hit the ground running.

UP

The zero-emission underground transit system connecting downtown Nashville and Music City Center to Nashville International Airport (BNA), the Music City Loop will take about 9 minutes to travel 9.5 mi. from BNA to downtown Nashville.

16 DOCUMENTARY COMMEMORATES 20TH ANNIVERSARY OF HURRICANE KATRINA

Nearly twenty years after Hurricane Katrina devastated the Mississippi Gulf Coast, the Mississippi Department of Transportation announced the release of a documentary that chronicles the restoration of infrastructure following the storm.

Ring Power Corporation, North and Central Florida’s authorized Caterpillar dealer, has officially opened its newest facility in Leesburg with a ribbon-cutting ceremony Aug. 14, 2025, attended by local dignitaries and community leaders.

Downrite recently purchased a Cat Centennial Edition D5 from Kelly Tractor, and when owner and president Sam LoBue saw the signature equipment piece, he looked back to a career built on hard work, trust and Caterpillar.

The leader of South Carolina’s transportation agency has been to so many groundbreaking ceremonies for highway projects that he has the whole routine down.

28

The latest analysis reveals that the CGA Index, which measures year-over-year damage trends, rose from 94.0 in 2023 to 96.7 in 2024, signaling that the industry is moving in the wrong direction in reducing damages to buried utilities.

The North Carolina Museum of History in Raleigh unveiled plans Aug. 27, 2025, for a sleek, modernized new home to show off the state’s treasures and artifacts — what it bills as an updated approach for a tech-savvy audience.

34 VOLVO TRUCKS LANDS ORDER: 264 NEW VNL TRUCKS TO AVERITT

Volvo Trucks North America customer Averitt Express has placed an order for 264 new Volvo VNL 860s. The deal marks one of the largest single orders for the new flagship sleeper model in North America to date.

36 STELLAR PROMOTES WORMAN TO PRODUCT MGT., SALES DIRECTOR

In this expanded role, Worman will continue to lead development strategy across product lines while also overseeing the company’s growing inside sales team.

52

John Deere unveiled new user capabilities within the John Deere Operations Center. Customers using the center can now benefit from streamlined parts ordering through the newly integrated Shop.Deere.com feature.

54 JCB NORTH AMERICA, NAHICA ANNOUNCE NEW PARTNERSHIP

JCB North America announced its partnership with the National Hispanic Contractors Association, reinforcing its commitment to advancing Hispanic participation, leadership and entrepreneurship in United States construction.

60 TRADE SHOW EXECUTIVE NAMES EQUIP EXPO FINALIST IN FOUR CATEGORIES

Equip Exposition was named a finalist for “Best Use of Technology and Data,” “Best New Launch,” the “Against All Odds Award,” and “The Greatest Trade Show of 2024” by the publication, which covers the exhibits industry. 60 MEADOWS RELEASES ENVIRONMENTAL PRODUCT DECLARATIONS

W. R. Meadows announced the release of third-party verified environmental product declarations (EPDs) for 16 of its most widely used solutions, marking a significant milestone.

66 AED WELCOMES MATT LAMY AS GOVERNMENT AFFAIRS MGR. IN D.C.

Based in AED’s Washington, D.C., office, Lamy will play a vital role in advancing the association’s legislative and regulatory priorities in both the United States and Canada.

In a rapidly growing region like Florida’s Tampa Bay, the transportation networks must evolve with intention, according to Gregory Slater, CEO of the Tampa HIllsborough Expressway Authority (THEA).

With that in mind, his agency seeks to “create a community-focused, future-ready transportation ecosystem that delivers realtime solutions today while enabling innovations prepared to evolve into the system of tomorrow.”

In an Aug. 20, 2025, article he wrote and released on the International Bridge, Tunnel and Turnpike Association (IBTTA) website, Slater reported that THEA’s commitment is reflected in its July approval of a $752 million Work Plan for Fiscal Years 2026 through 2031.

With $692 million dedicated to infrastructure construction, the six-year investment plan is the result of data-driven project selection, community feedback and a long-term vision grounded in THEA’s Strategic Blueprint, he said.

“Every project in our work plan is designed to achieve specific, measurable impacts to reduce congestion, improve safety and support the vitality of our region’s neighborhoods,” said Slater.

Among THEA’s major capital investments are:

• The South Selmon Capacity Project, which aims to increase the capacity of the existing Lee Roy Selmon Expressway to help meet anticipated growth. The project includes community enhancements such as noise walls, underpass improvements with pedestrian infrastructure and a dog park and

community space to activate public areas around the expressway.

• The Whiting Street extension will improve downtown access and reduce expressway bottlenecks during event nights at Benchmark International Arena, home of the National Hockey League’s Tampa Bay Lightning.

• The full integration of next-generation ITS infrastructure, a new roadside tolling system and a new Operational Back Office System (OBOS).

• A series of resurfacing and preservation projects across Meridian Avenue, Brandon Parkway and the broader Selmon system.

Slater noted that the future of tolling — and transportation in general — is multidimensional and is why THEA is dedicating resources to community enhancements and technology upgrades as core components of its Work Plan.

From the upgrade of the Meridian Health Trail to new green spaces like the 12th Street Park and the Bay to Bay Boulevard Community Park, THEA is threading connectivity into every corridor within its reach.

“This mindset supports a more walkable, livable Tampa where the region expands from the downtown nexus and acknowledges the vitality of the neighborhoods under and around the expressway,” Slater said.

Technologically, THEA is making some of its most important system upgrades to date, including:

• replacing its current OBOS with a more

intuitive, modular and intelligent platform that empowers users and improves real-time reporting;

• expanding its Intelligent Transportation System (ITS) and deploying an Advanced Traffic Management System (ATMS) to improve responsiveness across the network;

• strengthening its Wrong-Way Detection System on THEA’s roadways; and

• taking its Connected Vehicle (V2X) integration, which the agency has championed since leading the U.S. Department of Transportation’s first Connected Vehicle Pilot Deployment in 2015, to the next level.

“All these efforts are rooted in securityfirst design and upgrades to safeguard operational and customer data,” according to Slater.

The entire $752M work plan funding is backed by a commitment to public value, fiscal responsibility and the return on investment experienced by THEA’s customers with every toll dollar entrusted to the agency.

“It’s why our board of directors unanimously approved the plan,” said Slater. “As Vincent Cassidy, our board chair, noted, ‘These investments are rooted in fiscal discipline, strategic planning and a deep understanding of what our community needs to thrive for generations to come.’ And that’s the guiding principle for us at THEA: to anticipate what’s next — and build it today.”

Noting that tolling agencies around the world are facing unprecedented challenges, from rising customer expectations to the rapid pace of technological advancements

and growing needs, he said THEA has learned that it can meet these challenges “if we center our work around the people we serve. They are the lens through which we make our decisions [for] our neighbors [and] our community.

“We hope our approach can serve as a roadmap or inspiration for other agencies in the IBTTA community,” Slater said. “As a mid-sized tolling authority with an urban footprint, THEA continues to demonstrate how strategic reinvestment, nimble leadership and a commitment to innovation can drive meaningful change.”

The Tampa HIllsborough Expressway Authority owns, manages and operates the Meridian Avenue, Brandon Parkway, Selmon Greenway and Selmon Expressway — the latter two of which are named after the late Pro Football Hall of Fame and Tampa Bay Buccaneers defensive end Lee Roy Selmon.

A 17-mi. all-electronic toll roadway, the Selmon Expressway, links Pinellas County, western Hillsborough County, downtown Tampa, Brandon and southern Hillsborough County. By feeding into the heart of Tampa, Selmon customers have an efficient and safe drive into the urban core. It also is the most direct route for residents and visitors commuting into and out of MacDill Air Force Base by reducing dangerous cut-through traffic along neighborhood streets.

THEA processes approximately 78 million toll transactions annually on the Selmon Expressway, serving nearly 4 million customers each year.

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

By Eric Olson CEG CONTRIBUTING EDITOR

When Jim Falin decided to open his own business as a young man in 1987, he did so in part to fulfill his boyhood dream of working with tractors.

After buying his first piece of equipment, the Virginiaborn Falin literally hit the ground running and the contracting company got off to a strong start.

Today, Sevierville, Tenn-based Falin Enterprises is recognized as one of the best firms of its kind in the eastern part of the state. Over its 38 years, the company has established itself as an expert in providing a range of services, including professional site preparation, precise earthmoving and comprehensive utility work for residential, commercial and government projects.

“When I was growing up, I always loved garden tractors and although my mom wanted me to go to college, I said I wanted to start running machines instead,” Falin said. “I first ran big equipment on surface mining jobs in Southwest Virginia. I later moved back to East Tennessee in 1985, went into business in 1987, and bought my first Bobcat skid steer. It took me about two weeks to get things rolling, but we’ve not run out of work since then.”

In the late ’80s, before concrete pumps became popular, Falin would transport concrete onto job sites where sidewalks were being formed.

“One of my first projects was carrying concrete over to Dolly Parton Parkway in Sevierville,” he said. “I did that for what seemed like a week and a half to two weeks along with some general cleanup work.”

From there, his business continued on an upward path to success and with that growth came the need for more equipment.

When Falin was contracted to work on helping to build ski chalets and rental homes in nearby Gatlinburg, Tenn., he decided to purchase a dozer and a compact rubber-tire backhoe.

“We stayed on Ski Gatlinburg the first couple years that I was in business because nobody else wanted to go up there and work on those steep slopes. During that time, we never came off the mountain with our equipment because there was so much work to do in preparing the residential

sites, such as putting in footings and septic systems.”

Working at the high elevations just outside Great Smoky Mountains National Park proved to be very challenging, Falin said, adding “Early on, there were some places where we probably should not have worked.”

But being a young company owner just starting out, he was understandably anxious for Falin Enterprises to make its name stand out in the local construction industry.

“I was just too determined and never turned down work,” Falin said. “I guess the word got out because we had many people call us and say, ‘So and so said you’re the guy that needs to do my job,’ and we would typically do them if we could.”

He added, “I love taking raw land and turning it into something people can use. I enjoy putting in a road or building a subdivision, and when I go back afterwards it is rewarding to see them full of nice houses.”

Beyond its residential projects, Falin Enterprises often is called upon to engineer a variety of other jobs, including the installation of Redi-Rock retaining walls, which he noted can be a little challenging.

“That was especially so at the University of Tennessee in Knoxville where we put up a wall right behind Neyland

Stadium,” Falin said. “Some of UT’s engineers said it couldn’t be done, but we developed and engineered it, and it is holding up very well. We had a lot of utility conflicts there that we had to work around, but in the end it worked.”

Currently, he and his team are building a new Weigel’s convenience store and truck stop off Interstate 75 in North Knoxville.

Weigel’s has become one of Falin Enterprises’ largest clients, he said, as the chain of stores can be found across East Tennessee from Crossville east to Chattanooga, and north to the Tri Cities of Johnson City, Kingsport and Bristol. Most of its more than 80 locations, though, are concentrated in the greater Knoxville area.

“They’re really expanding and growing, which has certainly helped our company as well,” Falin said. “Now, we’re in an e-mail chain with Weigel’s and part of their team — something that I find to be very rewarding.”

Another company that has turned out to be a valued partner for Falin Enterprises is Power Equipment, the southeastern construction equipment dealer headquartered in Knoxville. The company maintains branch locations across the whole of Tennessee, in addition to parts of Arkansas and Mississippi.

l e and oving, id hlt oncrete utilities, c earthm ork tasks ewsit ving, and asphalt pa s. agener

Elon Musk’s tunnel-building company, The Boring Company (TBC), is now hiring personnel for the construction of Nashville, Tenn.’s Music City Loop.

Billed as a cutting-edge, zero-emission underground transit system connecting downtown Nashville and Music City Center to Nashville International Airport (BNA), the Music City Loop will take about 9 minutes to travel 9.5 mi. from BNA to downtown Nashville.

Funded and operated by TBC, it will transport passengers in a fleet of dedicated Tesla vehicles (initially Model Ys and Model Xs) through an underground tunnel network to their destinations with no intermediate stops.

Trained drivers, referred to as Loop drivers, will operate the vehicles to enhance the passenger experience and provide an additional layer of safety, ensuring a personalized and secure ride, the company noted on its website.

The system is being developed with the goal of alleviating traffic congestion in the area.

“I’m really excited about this project,” said Tennessee Gov. Bill Lee in speaking to WKRN-TV in Nashville.

In the city’s downtown, the first dig for the tunnel was made in mid-August. As of Sept. 1, a large hole was visible at the site, illustrating the project’s progress so far.

TBC said discussions with state and local officials about the tunnel system began in March 2024, more than a year before the first public announcement was made.

The company is working with stakeholders on the final alignment of the Music City Loop, in addition to performing geotechnical borings and starting utility coordination.

“[TBC has] a great desire to follow the process as laid out by the state and to work with our [state] agencies,” Lee said.

Site preparation is planned to take place through September, and actual tunneling is

expected to begin within the last three months of the year. When it does start, one boring machine will be launched from the site near the Tennessee State Capitol. Eventually, the work will scale up to include at least six of the machines. TBC also plans to build at least three more tunnel launch sites as the work progresses.

The first operational segment of the Music City Loop is expected to open in the spring of 2027.

Nashville residents are already looking forward to the innovative way the Music City Loop will transform transportation in the area.

“There’s a whole untapped potential underneath our feet,” Nashville resident Nathaniel Lehrer told WKRN-TV.

“Anything that can save time when picking

up family or friends or you need to catch a flight [is] an awesome option to have.”

The transit system will be set up as alignments of two separate tunnels running inbound and outbound from Nashville’s airport. Each one will be dug approximately 30 ft. underground to avoid contact with utility lines.

TBC said its tunnel boring machines operate on a redundant navigation system with an accuracy of approximately 2 in. The digging machines and the support vehicles to be used on the project are zero-emission and all-electric.

The construction processes and tunnel designs used by TBC generate minimal

vibration and noise, according to the company, which claimed that pedestrians would feel less shaking from the tunnel than from a person walking next to them on the sidewalk.

In areas where the tunnel may run under private property, permission from the property owner is required. As the planning process continues, interested property owners will be asked to enter either a standard easement agreement with TBC, which would allow only a tunnel to be built under the land; or a station agreement, which would allow for a tunnel and a station.

Waste generated during the tunnel’s construction will be disposed of according to state regulations.

TBC is fully-funding the construction and operation of the Music City Loop project, the company announced.

Passengers will pay a fare to use the transportation system and even though fare prices have yet to be determined, TBC said that the costs to ride are likely to be lower than other transportation options.

Lee said the project is the fast lane to the city’s future.

“We’ve been trying to find ways — Metro Nashville has in particular — to develop transit in the city for a long time,” he said. “It costs billions and billions of dollars to build out transit systems. We now have an opportunity to have a transit system that costs the taxpayers nothing.”

The Music City Loop project also means that many new jobs are on their way to Nashville. TBC is currently searching for engineers, electricians, mechanics and operation coordinators, among other positions.

The Texas-based company said construction updates will be posted periodically in blog posts to its website and on X beginning around Oct. 1.

Nearly twenty years after Hurricane Katrina devastated the Mississippi Gulf Coast, the Mississippi Department of Transportation (MDOT) is announcing the release of a documentary that chronicles the restoration of infrastructure following the storm.

Now on YouTube, “MDOT Remembers Hurricane Katrina: 20 Years Later,” tells the story of Hurricane Katrina from the firsthand accounts of MDOT’s engineers and state leaders who were at the forefront of preparation, response and rebuilding.

“The vast destruction wrought by

Hurricane Katrina demanded an extraordinary response, and as usual, the people of Mississippi were up to the task,” said MDOT executive director Brad White.

“I’m very proud of the men and women of MDOT who were at the tip of the spear to literally clear a path to recovery as well as the MDOT engineers, consultants and contractors who worked tirelessly to rebuild infrastructure following the storm. This documentary is a testament

to the dedication of all those who helped the Mississippi Gulf Coast truly recover and the incredible resilience of south Mississippi residents.”

In the nearly 30minute video produced by MDOT’s public affairs division, the narrative that emerges is not simply a retelling of how bridges were rebuilt, it’s a behind-thescenes look at the major infrastructure recovery that took place and the men and

women behind the contracts, cranes and bulldozers. Former Gov. Haley Barbour, Southern Transportation District Commissioner Charles Busby, MDOT Executive Director Brad White, Former MDOT Executive Director Melinda McGrath and a host of former MDOT engineers are featured in the documentary.

The video serves as a time capsule for anyone curious about how connectivity was restored along the Mississippi Gulf Coast following a storm of epic proportions. The full documentary is now available on MDOT’s YouTube channel.

Border Rents borderequipment.com

Augusta, GA 706-737-7253

Norcross, GA 770-609-8299

*Ditch Witch of Virginia ditchwitchva.com

Seaford, DE 302-629-3602

Chesapeake, VA 757-424-5960

Glen Allen, VA 804-798-2590

Manassas, VA 571-359-6081

*Ditch Witch Worx ditchwitchworx.com

Fort Lauderdale, FL 877-935-3656

Jacksonville, FL 866-254-1102

Plant City, FL 855-704-6828

Albany, GA 866-581-4914

Atlanta, GA 866-709-3712

Savannah, GA 888-298-0429

*Don Allison Equipment, Inc. donallisonequipment.com

Arley, AL 800-669-6450

First Choice Farm and Lawn firstchoicekubota.com

Brookland, AR 870-790-2301

Dyersburg, TN 731-882-1855

Eads, TN 901-616-5129

Mayfield, KY 270-856-4355

Savannah, TN 731-925-2141

Union City, TN 731-885-1315

*Forsythe Tractor forsythetractor.com

Shreveport, LA 318-687-1341

National Equipment Dealers

Carolinas nedealers.com

Ashville-Fletcher, NC 828-628-3004

Charlotte, NC 704-228-0455

Clayton, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Columbia, SC 888-865-1002

Conway, SC 800-968-0754

Piedmont, SC 864-434-1154

Summerville, SC 843-501-0566

Wellford-Spartanburg, SC 843-501-0566

National Equipment Dealers

Florida

nedealers.com

Apopka, FL 407-401-8956

Fort Myers, FL 407-754-4646

Fort Pierce, FL 772-212-4043

Jacksonville, FL 904-664-0899

Tampa, FL 813-940-4405

National Equipment Dealers

Georgia nedealers.com

Dallas, GA 770-445-9019

Douglas, GA 912-384-4664

Macon, GA 478-257-8300

Richmond Hill, GA 912-756-7854

State Machinery statemachineryeq.com

Kenner, LA 504-464-0431

Taylor Construction Equipment

taylorconstructionequipment.com

Bessemer, AL 205-428-7050

Huntsville, AL 205-428-7050

Montgomery, AL 205-428-7050

Louisville, MS 833-773-3421

New Albany, MS 304-550-9825

Richland, MS 601-922-4444

LaVergne, TN 304-550-9825

Maryville, TN 662-773-3421

Van Keppel

vankeppel.com

North Little Rock, AR 501-945-4594

Van Buren, AR 479-474-5281

Loved for the features. Trusted for the performance.

Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without feeling like longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

The

Ring Power Corporation, North and Central Florida’s authorized Caterpillar dealer, has officially opened its newest facility in Leesburg with a ribbon-cutting ceremony Aug. 14, 2025, attended by local dignitaries and community leaders.

The 77,000-sq.-ft. facility, situated on 18.6 acres at 2887 South Street, represents a significant investment in Lake County’s industrial infrastructure and Ring Power’s commitment to serving customers closer to their job sites. According to the company.

The Leesburg branch is engineered for maximum operational efficiency, featuring 20 fully equipped service bays and an expansive 18,000-sq.-ft. wash rack facility. The location houses a comprehensive parts department with nightly delivery service and onsite hydraulic hose manufacturing offering same-day turnaround capabilities, according to Ring Power.

“This facility represents more than just expansion — it’s about bringing world-class equipment support directly to our Lake County customers,” said David Alban, Ring Power CEO and president. “Every aspect of this branch is designed to minimize downtime and maximize productivity for the contractors, municipalities and businesses we serve.”

The facility will maintain an extensive rental fleet including heavy construction equipment, Cat compact machines and aerial work platforms. Nearly 50 skilled technicians, sales professionals and support staff will operate from the location, providing comprehensive equipment solutions ranging from new and used sales to parts, service and rental support.

Leesburg Mayor Alan Reisman and Leesburg Area Chamber of Commerce CEO Sandi Moore joined Ring Power executives at the ribbon-cutting ceremony, highlighting the facility’s potential economic impact on the region.

The new branch strengthens Ring Power’s six-decade presence in North and Central Florida while positioning the company to better serve the growing construction, agricultural and industrial sectors throughout Lake County and surrounding areas.

For more information, visit www.ringpower.com.

(All photos courtesy of Ring Power.)

On the road to building South Florida, few names have moved more dirt — or stayed more loyal to the iron — than Downrite Engineering.

Downrite recently purchased a Cat Centennial Edition D5 from Kelly Tractor, and when owner and president Sam LoBue saw the signature equipment piece, he looked back to a career built on hard work, trust and Caterpillar.

“I bought my first piece of equipment from Kelly Tractor in 1984 at the age of 21,” LoBue said. “To now be one of the few to receive a 100year anniversary machine — I’m grateful. I have Cat in my blood.”

From that first purchase more than four decades ago, Downrite has grown into one of South Florida’s leading site development contractors, operating a fleet of hundreds of machines. And while the company briefly turned to other brands during the supply challenges of COVID-19, LoBue said they are working their way back to a fleet that’s nearly 100 percent Cat.

“Except for when we couldn’t get it during COVID, we’ve always been a Cat company,” he said.

The Centennial Edition D5, finished in Caterpillar’s battleship grey paint scheme, is both a nod to the brand’s history and a symbol of how far the industry has come.

As technology continues to evolve, the interface between operator and machine has become

increasingly intuitive.

Speaking to this shift, LoBue said, “You don’t have to be an operator anymore to run most of them. If you can run a video game, you can pretty much run one of these machines.”

More than anything, LoBue sees the dozer as a testament to the relationship between Downrite and Kelly Tractor.

“I’m just grateful to the Kelly family for helping me,” he said.

And as the Centennial Edition dozer begins its work, it joins a legacy fleet at Downrite that has helped build South Florida’s roads, communities and infrastructure for generations — with plenty more ground still to cover.

Chris Kelly, president, Kelly Tractor Co.; David Erkelens, senior vice president of sales, Kelly Tractor Co.; Katherine Kelly, executive vice president, Kelly Tractor Co.; Sam LoBue, owner and president, Downrite Engineering; Ana Blanco, credit and finance manager, Kelly Tractor Co.; and John Lynch, sales representative, Kelly Tractor Co.

The leader of South Carolina’s transportation agency has been to so many groundbreaking ceremonies for highway projects that he has the whole routine down.

Signs were printed, fancy shovels were readied and, since it was the middle of August, an air-conditioned spot — the welcome center in Hardeeville — was booked for the celebration of an $825 million project on Interstate 95 to untangle another traffic mess in one of the fastest growing states in the U.S.

Justin Powell has been around for a halfdozen of these projects in his nearly seven years at the South Carolina Department of Transportation (SCDOT). He oversees an agency whose reputation and results have turned around in the past eight years. Over that time, an influx of money raised South Carolina’s gas tax 12 cents under his predecessor Christy Hall, pushing it up to 28 cents a gallon.

A decade ago, SCDOT was spending $2.7 billion on roads; today, the agency is about to pass $7 billion in highway construction. It is a far cry from 11 years ago when the SCDOT secretary before Hall — who continually told lawmakers his job was to “manage the decline of the state highway system” — resigned after being pulled over for driv-

ing under the influence on a weekday morning, according to the Associated Press. He was the third transportation department director in two years.

“Thanks to the trust from the [state] General Assembly in 2017, we’ve delivered what we were asked to do,” Powell told the AP during a recent interview in his office.

The Aug. 14 ceremony in Hardeeville, at the southern tip of the state, marked the start of a 10-mi. project to widen I-95 to three lanes in each direction and replace the bridges over the Savannah River at the Georgia state line. The site has long been a bottleneck that often stalls traffic on one of the nation’s busiest highways.

Elsewhere in the Palmetto State, crews are working on a $2 billion project to iron out the place where Interstates 20, 26 and 126 all meet in the capital city of Columbia.

In addition, construction is under way on an effort that will eventually expand two travel lanes to three in each direction along 70 mi. of I-26 from Charleston to Columbia. Part of that includes a new, multi-million upgrade of the I-26/I-95 interchange, southeast of Orangeburg.

The AP noted that soon, the state plans to reconstruct the I-526 half loop around Charleston, which could cost up to $7 billion.

And it is not just interstate work that is being planned across South Carolina.

A decade ago, nearly half the pavement on the 41,000 mi. of the state’s roads was in poor shape. Since then, more than a quarter of South Carolina’s roadways have been repaved.

In addition, thousands of bridges built in the 1950s and 1960s are now reaching the age when they need to be replaced.

As Powell’s agency finishes digging out of the hole of decades of neglect, he is well aware South Carolina has added 1.5 million people over the past 25 years. Many complaints he hears have shifted from rough roads and potholes to traffic congestion.

“This is not little ol’ South Carolina anymore,” he said. “The interstate system was built back when South Carolina had about 2.5 million people. We’ve got this dual challenge of maintaining what we have and dealing with significant growth pressure.”

In the past, SCDOT had long been dogged by corruption and horse trading where

favored legislators got road projects that were funneled to their friends. Case in point: In 1935, the state’s governor sent a militia armed with machine guns to the highway commission after the board refused to seat his appointees, according to the AP.

Today, Powell and his agency have received unprecedented support from lawmakers who changed the agency’s structure.

Despite that, the SCDOT still has its critics. The conservative Freedom Caucus asserts the agency is not spending money wisely enough and wants to use artificial intelligence to overcome what it terms burdensome regulations without a lot of details.

The group also wants to turn roadbuilding and improvements over to the counties. South Carolina is only the 40th biggest U.S. state in terms of area but has the fourth largest state-maintained road network. SCDOT controls three times as many miles of roads as Florida.

Powell gets the idea, but said unwinding nearly a century of state control would be difficult. Counties would need money, and many would also require an influx of new machinery and knowledge.

“It took us 90 years to get here,” he said. “It would probably take us that long to find our way out.”

THE BEST PARTS ALL IN ONE PLACE B N HE BE O T PAART EST P TS

Common Ground Alliance (CGA) published its 2024 Damage Information Reporting Tool (DIRT) Report.

The latest analysis reveals that the CGA Index, which measures year-over-year damage trends, rose from 94.0 in 2023 to 96.7 in 2024, signaling that the industry is moving in the wrong direction in reducing damages to buried utilities.

The annual DIRT Report provides the most comprehensive accounting of damages to buried power, water, fiber, natural gas and other utility lines in the United States and Canada. This year’s report analyzed 196,977 unique damage reports from 2024, finding that despite organization-level success stories and sector-specific improvements, the industry is not on track to meet CGA’s “50-in5” goal of reducing damages by 50 percent over five years.

“The 2024 DIRT Report makes it clear: Incremental change is not enough,” said CGA President and CEO Sarah K. Magruder Lyle. “We know what works — effective, balanced enforcement, accurate mapping and timely locates — but without coordinated investment and accountability across all stakeholders, damages will continue to rise alongside ever-increasing construction activity. The stakes for public safety, service reliability and economic productivity are simply too high to accept the status quo.”

The 2024 DIRT Report shows that the top 10 root causes accounted for 85 percent of all reported damages, with patterns remaining remarkably consistent year-over-year. Utility work particularly water/sewer and telecommunications/CATV — dominated nine of the top ten root causes, underscoring the need for targeted, sector-specific interventions.

The leading causes were:

• failure to notify 811 (24.54 percent);

• excavator failed to maintain clearance after verifying marks

(16.07 percent;

• facility not marked due to locator error (11.94 percent);

• marked inaccurately due to locator error (8.58 percent);

• improper excavation practice not listed elsewhere (6.75 percent);

• excavator dug prior to verifying marks by potholing (4.94 percent);

• facility not marked due to no response from operator/contract locator (4.71 percent);

• excavator failed to shore excavation/support facilities (3.27 percent);

• marks faded, lost or not maintained (2.17 percent); and

• facility not marked due to incorrect facility record/map (2.16 percent).

“The CGA Index tells us that damages are tracking with construction activity — not with the improvements we know are possible,” said Louis Panzer, executive director of North Carolina 811 and co-chair of CGA’s data reporting and evaluation committee. “The solutions are in front of us. What’s needed now is the will to implement them at scale, across every sector and with consistent accountability.”

Analysis of data from eight 811 centers revealed that excavators faced an average 38 percent chance of being unable to start work on time due to incomplete locate responses. States with active enforcement programs for facility operators to properly locate and provide positive responses achieved significantly higher on-time rates than those without — suggesting the challenge is solvable with the right policies.

Unpredictability of locate timing not only delays projects but

can also erode excavator confidence in the 811 process, potentially contributing to the top root cause: failure to notify 811.

CGA’s board of directors issued a statement highlighting the attention these findings demand. The statement reads in part:

“We call upon the industries we represent — each a critical stakeholder in damage prevention — to commit immediately to the systemic enforcement mechanisms, targeted investments and coordinated accountability measures outlined in the 2024 DIRT Report.

The 2024 DIRT Report calls for systematic, enforceable standards and targeted sector interventions to reverse the upward damage trend, including:

• Reduce damages caused by failure to contact 811 beforehand through improved enforcement of both 811 notification requirements and locate timeliness via stronger penalties for noncompliance, “best value” locator contracts, GPS-enabled mapping and transparent on-time performance metrics.

• Targeting high-risk sectors — particularly water/sewer and telecom — with contractor training, investments in mapping improvements and contract reforms.

• Scaling proven practices from organizations that have successfully reduced damages to the industry as a whole.

• Implementing balanced enforcement that holds all stakeholders accountable, not just excavators.

• Accelerating data-driven decision-making by improving DIRT reporting quality and participation.

The complete 2024 DIRT Annual Report, along with the Interactive Dashboard featuring data from 2022-2024, is available at dirt.commongroundalliance.com.

The North Carolina Museum of History in Raleigh unveiled plans Aug. 27, 2025, for a sleek, modernized new home to show off the state’s treasures and artifacts — what it bills as an updated approach for a tech-savvy audience.

Slated to open in the fall of 2028, the rebuilt museum will add 40,000 sq. ft. of gallery space without changing the building’s footprint and bring the total sq. ft. to 200,000 for the more than 150,000 items in its collection.

Long considered boxy and closedoff inside, the renovations feature an 8,000-sq.-ft. atrium encased in glass, allowing for gatherings of up to 1,000 people inside.

But along with its open-air design, the history museum pledges to embrace a more hands-on, interactive experience aided by podcasts, YouTube content and rotating exhibits.

An affiliate of the Smithsonian Institution, the museum also is a division of the N.C. Department of Natural and Cultural Resources.

Upgrades will include a relocated

of the expansion, according to the museum.

“These investments will preserve North Carolina’s history and provide a safe, modern facility for generations to come and ensure the museum can better serve our statewide community,” the museum said in a news release on its website.

“We’re the state’s storytellers,” C.J. Roberts, director of the Division of State History Museums, told the Raleigh News & Observer. “We’re the state’s treasure keepers. Through our building, we are sort of the community gathering space. It is a farfriendlier, more inviting entrance.”

entrance on the northside of Bicentennial Plaza for improved accessibility, new climate control systems to protect the museum’s 150,000-plus artifacts and critical infrastructure improvements such as leak repairs and a new freight elevator.

Additional classrooms, a new restaurant, community spaces and offices are also part

The facility is on track to reopen to the public in 2028.

“This project is about honoring the trust North Carolinians place in us to care for their history,” said Roberts. “We’re building a space worthy of the stories, artifacts and traditions that define our state — so they can be preserved and shared for generations to come.”

The N.C. Museum of History dates to 1994 at its location in downtown Raleigh. The museum closed in October 2024 after announcing its plans to renovate the building over two to three years. Originally called the “Hall of History,” the facility has occupied its space on East Edenton Street since it first opened, just across from the state Capitol Building. It draws nearly 500,000 visitors a year, especially schoolchildren on field trips.

The museum’s $225 million facelift is being paid for, in part, with $180 million from the state’s budget, and the rest through private donations raised by the N.C. Museum of History Foundation.

North Carolina Museum of History officials wanted a project that aims to rethink design and add classroom space while also updating needed infrastructure changes in the 30-year-old building, including leak repairs and a new freight elevator.

Since its closing 11 months ago, the bulk of the work has involved moving the artifacts into nearby specialized storage spaces, a task that required transporting items as small as a shard of pottery and as large as Richard Petty’s stock car.

The added space inside comes partly through the new atrium but also by moving heating and air-conditioning units up to the roof.

This allows the museum to display a larger share of its overall collection. Most museums, Roberts told the Raleigh newspaper, show only about 5 percent of what they hold.

And while the museum’s exterior will keep its general shape, it will include more wood detailing and much more glass.

“In many ways the facade will be similar,” Roberts said, “but different.”

Pages 30-33

Blue Diamond Attachments photo Blue Diamond Attachments introduced its line of hydraulic breakers, designed for construction, demolition and quarry applications, including underwater jobs.

Blue Diamond Attachments introduced its line of hydraulic breakers, designed for construction, demolition and quarry applications, including underwater jobs.

The comprehensive line includes 12 models and are compatible with excavators, mini-skid, skid steer and compact track loaders.

Blue Diamond breakers offer key differentiators that add performance and value:

• Blue Diamond’s comprehensive lineup enables contractors to select specialized breakers engineered specifically for their machines, with models available for equipment ranging from 1,500-lb. mini track loaders to 55-ton class excavators, providing the perfect match for any application, according to Blue Diamond.

• Blue Diamond breakers feature a solid mono-block design milled from a single piece of steel rather than assembled sections held together with tie rods that stretch, eliminating the most common maintenance issue, according to Blue Diamond.

• All Blue Diamond breakers feature a unique vibration dampening system consisting of a polyurethane (poly case) shell that wraps around the mono-block and sits inside the Hardox steel outer casing. This design is

The comprehensive line includes 12 models, and are compatible with excavators, mini-skid, skid steer and compact track loaders.

the quietest breaker in the industry, significantly reducing vibration transfer to the host machine, protecting hydraulic components, pins and bushings from excessive wear while improving operator comfort, according to Blue Diamond.

• For maximum versatility, many of Blue Diamond models feature interchangeable mounting brackets, allowing a single breaker to be moved between different host machines including excavator to skid steer, by simply transferring the unit to a compatible mount. This flexibility dramatically increases use and return on investment, according to Blue Diamond.

• Self-regulating. All Blue Diamond Breakers have a self-regulating valve that protects them from over pressurization, excessive flow and back pressure. This also increases productivity when switching between host machines or in rental applications, eliminating the need to test the machine’s hydraulic pressure and flow before operation, according to Blue Diamond.

• The Anti-blank firing means Blue Diamond breakers will not operate unless pressure is applied to the tool. This feature prevents internal damage from dry fir-

You will find the parts you need at MOBRO Marine, Inc. We purchase in bulk directly from the manufacturers to maintain our large inventory. We also have a large inventory of long-lead time parts for cranes that can’t be found anywhere else. Not only does this mean we have the part you need in stock, it also saves you money. Because we buy in volume, we can buy for less and pass the savings on to you.

Our large inventory keeps construction equipment performing at optimum levels. We offer same-day shipping on most partsyou’ll experience minimal downtime.

We are a full-service company. We not only supply parts, but we also service and repair construction equipment and cranes of any type.

ing while the attachment is not engaged with material. In addition, recovery from anti-blank firing is the quickest in the industry, ensuring productivity is maximized, according to Blue Diamond.

“We believe we offer the best hydraulic breakers in the industry,” said Drew Truan, chief operating officer of Blue Diamond Attachments. “When a 1-year warranty period is the industry standard, and we offer 3-year coverage, it goes to show just how confident we are in the durability and reliability of all Blue Diamond Breakers.”

The hydraulic breakers feature four tool configurations — a moil point, a chisel tool, a pyramid tool and a blunt tool. Each tool type is manufactured from high-grade, heat-treated steel with precision machining to ensure proper fit and maximum energy transfer from the piston to the material being broken. Tools are easily interchangeable with minimal downtime, allowing operators to select and change the tool in the field without additional wrenches or keys.

All Blue Diamond hydraulic breakers come with the Blue Diamond satisfaction guarantee and are backed by a 3-year warranty.

information, visit bluediamondattachments.com.

Volvo Trucks North America customer

Averitt Express has placed an order for 264 new Volvo VNL 860s. The deal marks one of the largest single orders for the new flagship sleeper model in North America to date.

The trucks will join Averitt’s fleet of more than 4,600 vehicles, more than half of which are Volvo trucks. The investment reflects a growing trend among major carriers to accelerate fleet upgrades that improve fuel economy, lower operating costs and provide premium driver amenities to attract and retain top talent.

“This order from Averitt Express is a strong vote of confidence in the all-new Volvo VNL and in our long-standing rela-

tionship,” said Peter Voorhoeve, president of Volvo Trucks North America. “We are proud that more than half of Averitt’s fleet carries the Volvo badge, and we look forward to supporting their drivers with trucks that were designed to change everything about comfort, efficiency and safety.”

The all-new Volvo VNL was engineered for fuel efficiency, delivering up to a 10 percent improvement over the previous model through advanced aerodynamics and powertrain refinements.

“Our drivers are at the center of everything we do, and these new Volvo VNLs reflect that commitment,” said Barry Blakely, president and chief operating officer of Averitt Express. “The advanced safety

features, the outstanding driver comfort and the fantastic fuel economy help us operate more efficiently and sustainably while giving drivers a more comfortable experience on the road.”

The new trucks also feature Volvo’s most efficient idle management technology to reduce engine idling when parked. The proprietary integrated Volvo Parking Cooler uses the onboard 24-volt battery system to power the cab’s air conditioning when parked, lowering fuel costs, reducing engine wear and providing drivers with a quieter, more comfortable resting environment, according to Volvo.

The new trucks will be assigned to Averitt’s most tenured drivers and are expected to deliver meaningful fuel savings and emissions reductions while enhancing driver comfort during both work and rest periods.

With the trucking industry facing intense competition for skilled drivers and ongoing pressure to improve fuel economy, orders like Averitt’s show how carriers are investing in trucks that deliver both a premium driver experience and measurable operating cost savings.

For more information, visit volvotrucks.us/.

Stellar Industries announced the promotion of Tim Worman to director of product management and inside sales.

In this expanded role, Worman will continue to lead development strategy across product lines while also overseeing the company’s growing inside sales team.

Eric Janssen, current director of inside sales, will remain with Stellar and transition to a project management role.

Worman joined Stellar in 2019 as a product manager. Since then, his contributions have helped strengthen Stellar’s market position through strategic product development, customer-focused innovation and strong cross-functional collaboration, ultimately landing him the role of director of product management in 2021.

With more than 37 years of experience in the truck equipment industry, Worman brings a unique combination of engineering, sales leadership and product development expertise to his growing role. As the director of inside sales, Worman will focus on aligning sales support resources to better serve Stellar’s distributor network and end customer.

“Tim’s passion for the work truck industry and his deep knowledge of our product lines make him the ideal person to

take on this expanded leadership role,” said Tim Davison, vice president of sales and marketing of Stellar. “His ability to translate customer feedback into actionable improvements, while also supporting internal teams and sales efforts, will be invaluable as we continue to grow and evolve.”

Reflecting on his new position, Worman said, “I’m excited to take on the new responsibilities that come with leading the inside sales team and continue building on the momentum we’ve created on the product development side. Inside sales is a critical part of the customer experience and I am looking forward to working more closely with the team to support our partners and deliver the high-quality solutions Stellar is known for.”

In this new capacity, Worman will continue to drive innovation and operational excellence across both the product and inside sales teams. This shift aligns with Stellar’s ongoing investment in leadership that supports long-term growth and strengthens the company’s commitment to delivering

and solutions to its customers.

For more information, visit stellarindustries.com.

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804 HEAVY MACHINES, INC. www.heavymachinesinc.com

120 Mann Drive Piperton, TN 38017 (Memphis) 800-238-5591

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

LINK-BELT MID ATLANTIC www.link-beltmidatlantic.com Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235 PARMAN TRACTOR & EQUIPMENT www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

1485 Bear Creek Pike Columbia, TN 38401 931-388-7273

MID SOUTH MACHINERY, INC. www.gomidsouth.com 3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

7422 Hwy 49 N Hattiesburg, MS 39402 601-268-2222

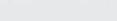

Metso is launching data-driven performance services to empower the mining industry with faster, fact-based issue resolution.

Metso’s data-driven performance services are a set of innovative equipment performance solutions designed to help customers prevent production losses, avoid safety risks and ensure consistently optimized operations. data-driven performance services offer harmonized service capabilities that cover the entire minerals processing flowsheet.

Metso’s transformative data-driven solutions are a combination of intelligent thresholds, advanced analytics and AIenabled diagnostics capable of capturing and describing complex cases for faster action. The analytics and AI capabilities are complemented by Metso’s continuously expanding global network of data-driven experts to ensure consistent and responsive service delivery. The enhanced remote monitoring and troubleshooting capabilities reduce the need for on-site inspections and resident experts.

“Data-driven performance services empower mining operations to move from reactive to predictive, insight-driven decision making,” said Arttu-Matti Matinlauri, vice president of minerals segment digital of Metso. “Based on our analysis from live customer cases, the data-driven performance services solutions have cut issue resolution times up to 50 percent by having the data available for analysis when issues arise. Whilst proactively monitoring the equipment on behalf of our customers, on average, we have identified a potential risk every 1,400 hours of operation, saving over 8 hours of production per solved case. These risks would have otherwise been missed by our customers.”

According to Metso, the data-driven performance services are designed for site maintenance and operations teams to maximize equipment availability, reliability and performance through two scalable service levels:

• Data-driven technical support provides fast and factbased troubleshooting and issue resolution. Through live equipment data, Metso’s experts can improve first-time fix rates and reduce production losses. The expanded data-driven expert network ensures consistent delivery of services.

• Data-driven condition monitoring enables early detection of equipment related issues and failures through continuous remote monitoring. AI-powered analytics and expert diagnosis ensure prioritized actions, reducing unplanned downtime and safety risks, improving availability, uptime and performance. Combined with life cycle services, Metso can conduct the corrective actions efficiently on-site.

“As an original equipment manufacturer, Metso is in a unique position to understand the multitude of different operating modes and equipment related failure mechanisms impacting performance and how they are identifiable from

data,” said Matinlauri. “This knowledge has been accumulated over decades of valuable collaboration with our customers and complemented with data from connected equipment and processes. We are excited to deepen our collaboration by harnessing our vast knowledge base to improve our customers’ performance through data-driven performance services.”

Metso is committed to advancing the digitalization of the mining industry. Data is at the core of fact-based decision making. Analytics and AI enable minerals processing and metals refining plants to maintain and improve their performance. Metso believes in empowering plant operators,

metallurgists, maintenance crews and site management with data-driven solutions to get the most out of combining site and OEM expertise with insights.

Metso’s data-driven minerals processing and metals refining solutions help plant operations and maintenance take the next leap on five levels: Measurements allow accurate data to be collected. Stability is achieved through managed control systems. Availability is enhanced with algorithms continuously monitoring equipment ensuring reliability. Productivity is maintained by automating process and equipment control adjustments in real-time. Optimization and planning provides a view to the future through simulations to adapt to changing conditions.

For more information, visit metso.com/portfolio/data-driven-performance-services/.

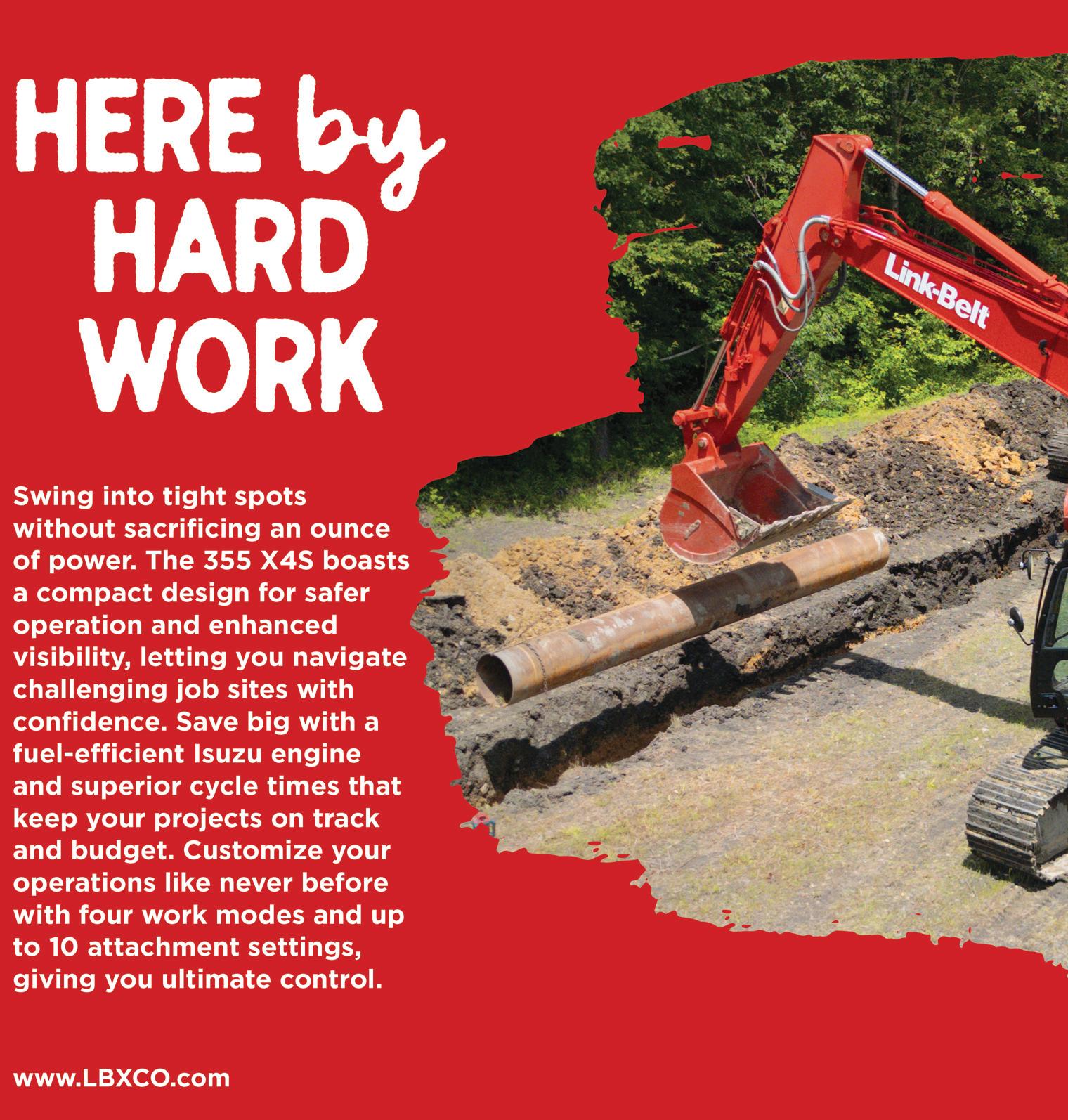

DEVELON announced its newest wheel material handler: the DX270WMH-7, built for tough recycling jobs and configured to conquer them. The machine is designed to elevate operator productivity, enhance safety and optimize material movement at recycling and solid waste facilities, according to the company.

“A wheel material handler needs to be more than powerful — it should be smart, adaptable and a true partner to the operator,” says Brian Kim, heavy excavator product manager of DEVELON.

“The DX270WMH-7 delivers on all fronts. Its exceptional versatility allows operators to complete a range of recycling tasks. And it features our -7 Series cab design and safety technologies, allowing operators to work longer, more comfortably and with greater peace of mind.”

Manufactured in-house for agility and precision, the DX270WMH-7 wheel material handler makes light work of even the heaviest loads, such as car bodies and other bulky materials. Using a grapple or magnet attachment, the machine effortlessly moves and positions materials across recycling yards and solid waste facilities. The machine’s chassis design provides better lifting and a more durable undercarriage to minimize downtime, according to DEVELON.

DEVELON photo

Wider front and rear outriggers on the DX270WMH-7 create a larger base that improves stability.

With a nearly 3-ft. longer reach and elevated cab, the DX270WMH-7 helps position operators for better productivity when loading trucks, containers and railcars at busy sites. Operators can work with full visibility of the site from the standard hydraulic cab riser. This feature allows an operator to safely enter the material handler’s cab at ground level.

Once inside the cab, the operator can raise the cab hydraulically to the preferred height and then begin working, according to DEVELON.

The DX270WMH-7 material handler is equipped with a new virtual wall setting. The feature stops the machine’s boom and arm from hitting surrounding objects, helping the operator work confidently in tighter spaces and minimizing machine downtime.

Built with comfort in mind, the new DX270WMH-7 features a fully adjustable heated air-suspension seat and heat and air conditioning, letting operators customize their level of comfort. It also features joystick steering in addition to the standard steering wheel, giving the operator the option of steering the machine without taking their hands off the joystick.

The machine comes with an 8-in. LCD monitor that displays machine diagnostics and controls to improve performance. Bluetooth hands-free radio and MP3 audio let operators listen to their favorite content while keeping their hands free to work the controls.

Wider front and rear outriggers on the DX270WMH-7 create a larger base that improves stability, especially when operators are working with higher lifting capacities. The machine’s outriggers extend the footprint of the machine by creating a larger, wider area of contact with the ground.

A new collision prevention feature keeps the machine’s

photo

DEVELON announced its newest wheel material handler: the DX270WMH-7.

grapple attachment and cab from colliding during operation.

In addition, the DX270WMH-7 is outfitted with an around view monitor (AVM) camera system that provides up to 360 degrees of visibility for a bird’s-eye view of the equipment and its surroundings. Operators can choose to only have a rearview camera to improve visibility all around.

Other key safety features include front and rear LED working lights for enhanced visibility in low-light settings, seatbelt warning for operator safety and an alarm to identify the machine on the site.

The DX270WMH-7 wheel material handler provides operators with easy access to maintenance points and service

DEVELON photo

The machine’s chassis design provides better lifting and a more durable undercarriage to minimize downtime, according to DEVELON.

procedures. It has an engine aftertreatment system with no diesel particulate filter (DPF) to minimize maintenance. This means the machine does not require a regeneration process to burn off accumulated soot.

The machine also features an air inlet mesh to keep fresh air flowing to the engine and a reversible fan to keep the machine cooler and keep debris out for less maintenance.

My DEVELON fleet management, a digital telematics platform for managing equipment, comes standard on the new machine. This diagnostic tool is available on all -7 Series machines and monitors the health, location and productivity of DEVELON equipment from a user-friendly mobile app and website.

For more information, visit develon-ce.com/en.

8255 NW 58th St Miami, FL 305-592-5360

801 E Sugarland Hwy Clewiston, FL 863-983-8177

2801 Reese Rd Davie, FL 954-581-8181

9651 Kelly Tractor Dr Ft. Myers, FL 239-693-9233

5460 Okeechobee Blvd West Palm Beach, FL 561-683-1231

6301 Old Rutledge Pike Knoxville, TN 37924

865-546-1414

10644 Lexington Dr Knoxville, TN 37932 865-218-8800

1825 Veterans Blvd Sevierville, TN 37862 865-595-3750

9960 Airport Pkwy Kingsport, TN 37663 423-323-0400

4066 South Access Rd Chattanooga, TN 37406 423-698-6943

215 Interchange Dr Crossville, TN 38571 931-456-6543

541 Alfred Thun Rd. Clarksville, TN 37040 931-552-5496

667 Horace Lewis Rd. Cookeville, TN 38506 931-646-3200

1245 Bridgestone Blvd. LaVergne, TN 37086 615-256-2424

3565 New Tullahoma Hwy. Manchester, TN 37355 931-461-5000

1291 Corporate Ave. Memphis, TN 38132 901-332-3051

3199 S Frontage Rd. Columbus, MS 39701 901-401-7011

4350 US-641 Camden, TN 38320 731-584-2732

2000 Airways Blvd Jackson, TN 38301 731-988-4240

4545 Columbia Pike Thompson’s Station, TN 37179 615-744-7850

1808 US-82 Greenwood, MS 38930 662-453-5233

761 Hwy 6 West Oxford, MS 38655 662-371-4440

421 Wallace Dr Belden, MS 38826 662-680-8948

Mason Tractor Company www.masontractor.com

5038 Buford Hwy. Norcross, GA 30071 770-582-0377

Blue Ridge, GA 706-632-3777

Cumming, GA 770-887-6119

Hiawassee, GA 706-970-3077

McDonough, GA 770-957-3370

Villa Rica, GA 678-952-2037 Perry, GA 478-987-1173

Savannah, GA 912-208-5349

Waverly Hall, GA 706-582-3193

Tree Care

Stowers Machinery Corporation stowerscat.com/bandit

6301 Old Rutledge Pike Knoxville, TN 37924 865-546-1414 10644 Lexington Drive Knoxville, TN 37932 865-218-8800 1825 Veterans Boulevard Sevierville, TN 37862 865-595-3750

9960 Airport Parkway Kingsport, TN 37663 423-323-0400

4066 South Access Road Chattanooga, TN 37406 423-698-6943

215 Interchange Drive Crossville, TN 38571 931-456-6543

ARE NO MA ,, ATTCH FOR A B From roadways to right-of to road clearing, get your w more efficiently than ever machinery! Choose from d sizes to suit your needs. C yours or to request a dem , BANDIT® -ways, lot clearing ork done faster and before with Bandit ifferent styles and all today to reserve onstration.

John Deere unveiled new user capabilities within the John Deere Operations Center.

Customers using the center can now benefit from streamlined parts ordering through the newly integrated Shop.Deere.com feature. Customers with factory maintenance plans can add parts for scheduled services directly to their cart and complete purchases with confidence and ease.

“We are continuously evolving John Deere Operations Center to simplify and enhance our customers’ digital experience,” said Katie Voelliger, product marketing manager of John Deere. “Customers can review, create and save factory-recommended or customized maintenance plans within Operations Center and manage all equipment maintenance in one convenient location.”

This streamlined fleet maintenance management process enables users to plan maintenance intervals, order parts online and monitor machine health efficiently in near real time, through one interface. This helps customers increase uptime through better management of preventative maintenance for their equipment fleets.

Within the center, fleet managers also can log completed maintenance tasks with details such as costs, photos, documents, repair notes and service history to support machine life cycle management. Customers and their approved John Deere dealers or preferred service providers can jointly monitor and manage maintenance plans, helping to stream-

line communications for more productive operations.

Lastly, customers using the John Deere Equipment Mobile application can benefit from the new Shop.Deere.com feature as well, enabling simplified parts ordering from a variety of customer platforms.

For more information, visit johndeere.com.

jamesriverequipment.com

Asheville, NC 828- 667-0176

Charlotte, NC 704-597-0211

Garner, NC 919-772-2121

Greensboro, NC 336-668-2762

Greenville, NC 252-758-4403

Fayetteville, NC 910-424-1200

Wilmington, NC 910-675-9211

New Bern, NC 252-679-7590

Ashland, VA 804-798-6001

Chesapeake, VA 757-998-4880

Fishersville, VA 540-337-3057

Manassas Park, VA 703-631-8500

Richlands, VA 276-596-9440 Salem, VA 540-380-2011

Stephenson, VA 540-667-9777

beardequipment.com

Jacksonville, FL 904-296-5000

Lake City, FL 386-752-9544

Ocala, FL 352-732-4646

Palatka, FL 386-325-6268

Perry, FL 850-584-9200

Tallahassee, FL 850-575-5600

www.powerequipco.com Chattanooga, TN 423-894-1870 Kingsport, TN 423-349-6111

Knoxville, TN 865-577-5563

LaVerge, TN 615-213-0900 Memphis, TN 901-346-9800

Saltillo, MS 662-896-0283

dobbsequipment.com

Riverview, FL Main office 813-620-1000 Parts 813-621-4902

Miami, FL 305-592-5740

West Palm Beach, FL 561-848-6618

Orlando, FL 407-299-1212

Fort Myers, FL 239-334-3627

Lutz, FL 813-995-0841

Daytona, FL 407-299-1212

Pompano Beach, FL 954-977-9541 (Parts) Sarasota, FL 941-960-2004 (Parts) Melbourne, FL 321-234-3344 Andrews, SC 843-983-7337

Aynor, SC 843-358-5688

Ladson, SC 843-572-0400

Simpsonville, SC 864-963-5835

Walterboro, SC 843-539-1420

West Columbia, SC 803-794-9340

www.tec1943.com Birmingham, AL 205-591-2131

Alabaster, AL 205-621-2489

Anniston, AL 256-831-2440

Decatur, AL 256-355-0305

Dothan, AL 334-678-1832

Huntsville, AL 256-851-2222

Mobile, AL 251-457-8991

Montgomery, AL 334-288-6580

Tuscaloosa, AL 205-752-0621

Panama City, FL 850-763-4654

Pensacola, FL

850-505-0550

Columbus, GA

706-562-1801

Hoschton, GA

706-654-9850

Calhoun, GA 706-879-6200

JCB North America announced its partnership with the National Hispanic Contractors Association (NAHICA), reinforcing its commitment to advancing Hispanic participation, leadership and entrepreneurship in United States construction.

“The Hispanic contractor community plays a vital role in building America’s infrastructure,” said Marc André Dubois, vice president, marketing of JCB North America.

“Our collaboration with NAHICA reflects JCB’s deep-rooted commitment to empowering diverse entrepreneurs by providing access to the innovative equipment, training and flexible financing solutions. We’re proud to support this hardworking community as they lift higher, reach further and dig deeper to shape the future of construction.”

Through this sponsorship, JCB and NAHICA will work to expand access to business development resources, technical training, business financing alternatives and mentorship for Hispanic contractors nationwide.

NAHICA President Sergio Terreros said, “JCB’s involvement is a powerful step forward for our members. Together, we’re creating pathways for Hispanic-owned businesses to thrive, generate jobs and strengthen the construction industry nationwide.”

The partnership with NAHICA follows JCB’s recent announcement regarding its plans to double the size of its facility being constructed in San Antonio, Texas, to one million sq. ft. This major expansion underscores JCB’s long-term commitment to United States manufacturing and job creation, particularly in a region with a strong and growing Hispanic workforce.

For more information,

At the construction site for the Weigel’s store in Knoxville, Falin called upon Power Equipment when his crew was faced with excavating solid rock, a seemingly difficult proposition that could slow down the project.

“Well, it was not a problem after we rented an Antraquip AQ-4XL rock cutter with grinding heads on it from Power Equipment,” Falin said. “We equipped a Komatsu 360 excavator with that cutter, and it just ripped right through that rock. The material was aggravating because we had used hydraulic hammers, but they didn’t bust the rock too well. That cutter, though, had no problems with it and made the rock into reusable material.”

As a result of the expert care and attention it has extended to Falin since 2022, Power Equipment has a rock-solid relationship with his construction business.

“We lean on them a little bit and each time they treat us right,” he said. “We’ve also been really excited about some of the machines that we have purchased from Power. So far this year we have bought two small Komatsu dozers — its D39 and D51 models — and we’ve placed an order to buy a PC238 excavator. Over the previous two or three years, we purchased a large Komatsu PC360 excavator and a midsize D71 dozer and have been very happy with how they have worked.”

Falin credits Joey Baker, his Power Equipment territory manager in the Knoxville store, for possessing expert knowledge of the dealership’s machines and their capabilities.

“Joey’s not your typical sales rep, I would say, but more of a field guy in that he tells us what other contractors have seen in this or that piece of equipment. Plus, he is always there for us when we need him. Power has been very good to us, as has Komatsu. We always buy Komatsu’s extended warranties, but there have really not been many issues with either company.”

Falin Enterprises has four Komatsu machines in its fleet at the moment; prior to three years ago, however, the construction firm did not have a single Komatsu among its rolling stock.

So, what made Falin turn to Power Equipment and Komatsu after using other dealers and equipment brands for so long?

He prefaced his answer by explaining that although the upfront purchase price is always a key element of the process, the value you get from trading in a machine after putting as much as 6,000-7,000 hours on it is equally important.

“That’s because when it’s time to have those older machines worked on more, we prefer just to move them instead. That’s something we’ve learned over the years. So, when we decide to return that machine, we give the dealer the opportunity to trade it for a comparable machine.

“But what we found is that some dealers would offer me bottom dollar for a machine that they had earlier said was going to bring me more at the end,” he added. “Power, though, typically offers me 10 to 15 percent more for that same machine at trade-in time. That’s a big thing and is the biggest reason I now go with Power Equipment.”

He added that other dealers, too, “would wear us out with road mileage and service truck charges. We don’t get that charge from Power Equipment at all, and the Komatsu warranty covers travel time and mileage.”

As a result of the expert care and attention it has extended to Falin since 2022, Power Equipment has a rock-solid relationship with his construction business.

Buying equipment and trucks is often much easier to do these days, Falin said, than finding good people to operate them.

“It can be a tough challenge. We’ve been trying to bring in some younger people and train them along with the senior people that we already have. The company bought three new trucks this year from our local Mack dealer, and when he told me he had 10 more for sale just like them, I said, ‘I'll buy all of them if you’ll put drivers in them for me.’”

The people that are employed by Falin, he said, are a hardworking bunch and their skill sets are another key to the contracting company’s success.

Among them is Eric Chambers, a man for whom the term “hard worker” fits like a glove — a fact that Falin recognized quickly upon his arrival.

“Eric has been with me almost 13 years and when he first joined us became one of our lowest paid guys,” said Falin. “But he didn’t care how hard the work was, he just kept growing and stepping up to the point that he’s now my highest paid employee. Eric is more of an operational guy that keeps these jobs moving along. Although I’m not into big job titles, I call him my general superintendent.”

With Falin now spending much of his time concentrating on his company’s development business, much of the dayto-day running of the construction side of the firm has been left in the capable hands of Chambers.

“The company’s continued growth has enabled me to go out and invest in land and property development,” said Falin. “We’ll go out and buy a 30- to 70-acre tract of land and put a subdivision in or figure out the best use for it. For instance, we just sold a 38.5-acre piece of property in the middle of Sevierville where a campground is to be built.

“The best part about right now is that our business is really doing well and we’re able to make these investments,” he added. “Then, I can bring Falin Enterprises in to develop these properties and do all the needed infrastructure work before turning around and selling it or whatever else we plan to do.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

LINDER INDUSTRIAL MACHINERY www.linder.com

Florida

Bradenton • 941/755-5722

Ft. Myers • 239/337-1313

Jacksonville • 904/786-6710

Ocala • 352/629-7585

Orlando • 407/849-6560

Pembroke Pines • 954/433-2800

Plant City • 813/754-2727

West Palm Beach • 561/863-0570

North Carolina

Asheville • 828/681-5172

Charlotte • 980/777-8345

Fayetteville • 910/483-3892

Greensboro • 363/792-3412

Greenville • 252/695-6200

Raleigh • 919/851-2030

Wilmington • 910/254-2031

South Carolina Columbia • 803/794-6150

Greer • 864/877-8962

Myrtle Beach • 843/486-8090 North Charleston • 843/486-8080 Virginia Bealeton • 540/439-0668 Chesapeake • 757/485-2100

TN

423/349-6111

865/577-5563 LaVergne, TN • 615/213-0900 Memphis, TN • 901/346-9800 Saltillo, MS • 662/869-0283 Little Rock, AR • 501/823-4400

Decatur • 256/355-0305

Dothan • 334/678-1832

Huntsville • 256/851-2222

Mobile • 251/457-8991

Montgomery • 334/288-6580

Tuscaloosa • 205/752-0621 Florida Panama City • 850/763-4654

Pensacola • 850/505-0550

Georgia Albany • 229/435-0982 Atlanta • 404-366-0693

Augusta • 706/798-7777

Calhoun • 706/879-6200

Columbus • 706/562-1801

Hoschton • 706/654-9850

Kennesaw • 678/354-5533

Macon • 478/745-6891

Savannah • 912/330-7500 www.wpi.com

Louisiana Alexandria • 318/408-3099

Baton Rouge • 225/800-3711

Kenner • 504/467-5906

Broussard • 337/362-4331

Bossier City • 318/746-5272

Sulphur • 337/287-9455

The project includes cleaning; mechanical, electrical and structural rehabilitation; tile removal and replacement; crack sealing; pump; and HVAC rehabilitation. LaDOTD has been forced to close the tunnel multiple times due to water leaks that are the result of structural damage. In addition, it wasn’t up to specifications regarding air control and fire control.

The team also is installing mitigation measures to prevent floodwaters from entering the surface transportation systems (sealing work) and strengthening systems that remove rainwater from these systems (pump work).