By Larry Bernstein CEG CORRESPONDENT

In the spring of 2012, the Mississippi Department of Transportation (MDOT) scheduled a project in Union County in the northeastern part of the state. However, two other projects came up that the state determined were more necessary. So, there was a lack of funding for the original project, and it stalled out. More than a decade later, the State Route 15 4-lane highway project was under way.

The north/south State Route 15 runs the entire length of Mississippi and is more than 300 mi. long. The 6-mi. section runs in Union County between Pontotoc and New Albany, Miss., in just two lanes. A traffic count was conducted on a nearby section of SR 15 — the ADT was 14,000. That’s the highest ADT for a two-lane route in the state.

“Many people travel on SR 15 for 30-40 miles to get to work,” said Brandon Smithey, resident engineer of MDOT.

Smithey, who is overseeing the project, added that a significant portion of the traffic is factory workers. Northeast Mississippi is the self-proclaimed furniture capital of America. The area is home to more than 30 furniture factories.

The team is installing two new bridges (northbound and southbound). The 302-ft.-long and 82-ft.-wide bridge will cross 110-ft.-wide King Creek. see MDOT page

By Lucy Perry CEG CORRESPONDENT

The road and bridge construction sector observed the National Work Zone Awareness Week in April, recognizing the critical need to keep drivers, the public and construction workers safe in road construction zones. In support of the industry, several states have announced the integration of smart technology into road and bridge projects to make sure everyone remains safe while navigating and working in these areas.

see ITS page 24

Adobe Stock photo Connected work zone devices transmit real-time data that allows drivers to navigate apps that provide audio alerts as they near work zones.

Construction on the University of South Florida’s new on-campus football stadium in Tampa will soon ramp up significantly following the project’s latest approval from the school’s board of trustees. The approval enables construction to begin in earnest, the Tampa Bay Times reported.

Blanchard Machinery hosted the local phase of Caterpillar’s Global Operator Challenge on May 15-16, 2025, at the Blanchard Farm in Columbia, S.C., bringing skilled heavy equipment operators together for two days of competition, precision and high-performance machine control.

For the landscapers, dealers, contractors, hardscape experts and outdoor power equipment manufacturers attending Equip Exposition for the very first time, it’s important to go into the trade show with a plan. Equip offers these tips to help firsttime attendees to plan for the best experience possible.

Weisiger Group, representing brands like Carolina Cat and LiftOne, announced that it has been selected as a 2025 U.S. Best Managed Company Gold Standard winner. The Gold Standard designation distinguishes honorees that have received the designation for four or more years.

Every day brings news of more corporate mergers in the United States or smaller companies losing their identities from having been acquired by bigger firms looking to broaden their sales territories. In the process, family-operated companies that have operated for decades are becoming increasingly scarce.

The guidance documents, which are available to view and download on AEM.org, were released in conjunction with AEM’s Celebration of Construction on the National Mall in Washington, D.C. They serve as resources to drive conversations and communications related to autonomy, cybersecurity and data.

Small, family-owned and operated businesses like Jerry Renfro’s contracting business in North Carolina put a great deal of trust in the people from whom they obtain their equipment. Unlike larger construction outfits that have the financial resources to better absorb the costs of equipment repairs or replacements.

2024 SALESPERSON OF THE YEAR.

Nashville, Tenn.’s Parman Tractor & Equipment was recently honored with having one of its veteran sales professionals being named by Takeuchi-US as the manufacturer’s 360° Dealer Salesperson of the Year for 2024. Parman’s Scott Syler, who has worked for three decades, accepted the award in mid-April.

Senate Environment and Public Works Committee Chairman Shelley Moore Capito received the American Road & Transportation Builders Association’s (ARTBA) highest honor for her leadership and bipartisan efforts to advance transportation infrastructure investment and policy.

The Fifth Annual Dobbs Equipment Golf Classic was held May 9, 2025, at the Ritz Carlton Golf Club in Orlando, Fla., and was another huge success. Dobbs holds this annual golf classic to support the Construction Angels, a non-profit that supports the families of construction workers killed on the job.

Modeled after Diamond's brush cutter Pro X, the mini-brush cutter Pro X is engineered to provide stand-on users — from farmers and construction contractors to landscapers and land management professionals — with another tool for their equipment toolbox.

54 SMALL-TOWN ROOTS TO GLOBAL IMPACT: STELLAR CELEBRATES 35 YEARS

Over the past three and a half decades, Stellar has grown from a small-town operation in Garner, Iowa, to a global force in the construction, waste and work truck industries. Founded in 1990, Stellar began its journey designing and manufacturing a domestic hydraulic hooklift.

56 LEER GROUP STARTS U.S. PRODUCTION OF SNUGTOP PRODUCTS

The celebration at LEER’s Elkhart facility marks the full return of United States-based production for SNUGTOP, which manufactures more than 400 truck cap products for a number of automotive brands. The production facility also enables SNUGTOP products to be available in all 50 states for the first time.

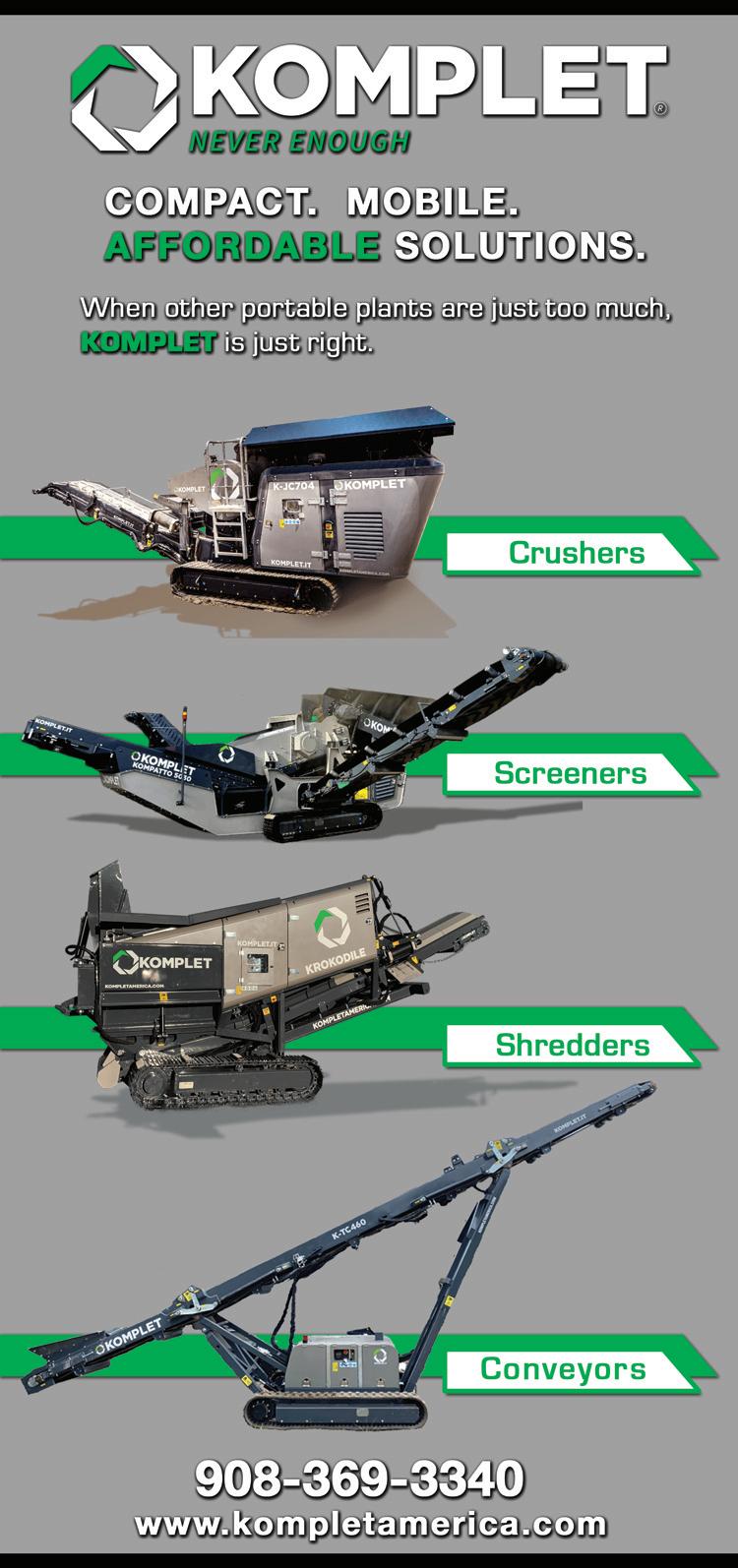

40 ARBOR NATURE GROWS WITH KOMPLET EQUIPMENT

42 PHOENIX CENTER RELEASES AGG INDUSTRY ECONOMIC SCORECARD

52 METSO COMPLETES ACQUISITION OF SWISS TOWER MILLS MINERALS

Construction on the University of South Florida’s new oncampus football stadium in Tampa will soon ramp up significantly following the project’s latest approval from the school’s board of trustees.

In what USF President Rhea Law called a “red-letter” day for the university, the board on April 29, 2025, put its unanimous stamp of approval on spending $407 million for construction of a 35,000-seat stadium and an accompanying infrastructure project.

The approval enables construction to begin in earnest, the Tampa Bay Times reported, with the stadium set to be ready in time for the Bulls’ 2027 season opener against the University of Louisville.

“It’s a transformative moment for our university,” said Will Weatherford, chair of the USF board, during the 20-minute virtual meeting. “It’s about as big of a check as we’re ever going to write for anything at the University of South Florida. I’m a believer in measuring twice and cutting once. I think our team has done a good job of measuring here and trying to build in all the contingencies that you possibly can for a project of this size and scale.”

The final guaranteed maximum price tag includes $348.5 million in projected costs for the stadium and $47.9 million for what the Tampa school calls “east campus infrastructure” that includes utility and environmental investments, roadway plaza and walkway improvements, green-space development and security cameras.

An owner’s contingency (a reserve set aside to cover unexpected costs) totaling $10.5 million also was approved, the Times noted.

Earlier, in June 2023 USF trustees approved a $350 million projected cost for the new stadium. Since then, however, a

number of design and structural upgrades totaling an additional $8.5 million have been added to allow for possible stadium capacity expansions in the future, a build-out of academic space in the facility, vertical expansion of the Tampa General Hospital Center for Athletic Excellence and enhanced locker room amenities, in addition to the general cost of goods increasing over the past two years.

“In order for us to move to hopefully where we want to go potentially, with a lot of [athletic conference] realignment conversations out there — maybe a super conference coming at the end of the day — we wanted to be able to add on to this stadium from a capacity standpoint and also a revenue standpoint,” USF Foundation CEO Jay Stroman told the board.

Funding for the stadium includes $200 million in financing, which USF’s Jennifer Condon, the school’s chief financial officer, said “is conservatively invested in money market and one- to three-year treasury notes.” Equity contributions totaling $140 million include $50 million in capital gifts, $31.6 million in a capital-improvement trust fund, and $59.5 million in various license sales, she added.

USF trustees also approved $47.9 million in infrastructure upgrades needed as the university continues to develop the east side of the Tampa campus.

In recent years, USF noted in a news release, the school has added several new facilities, such as the Judy Genshaft Honors College building and a student Health & Wellness Center. Among the planned enhancements will be a new lift station, water main and stormwater facility, in addition to improved roadways, walkways and lighting.

Since the stadium’s formal groundbreaking ceremony late last year, site preparation has been ongoing on the USF campus.

The project team will now move forward with additional clearing at the site in May 2025 before full construction picks up shortly thereafter, the Tampa newspaper reported.

According to USF Bulls Athletics Director Michael Kelly, the construction timeline calls for final inspections to be completed in April or early May of 2027, giving athletes and staffers “the entire summer to move into the facility” in time for that fall’s USF Bulls football opener.

Site preparation by Manhattan Construction Co., an Oklahoma-based firm with an office in Tampa, one of three companies selected to manage the project, has been ongoing along the campus’ eastern fringe since mid-February 2025, according to the Times.

“The plan approved by the board of trustees represents another important milestone in the process to deliver a worldclass stadium that the USF community and all of our supporters can enjoy for generations to come,” Law said in a statement released by the school. “We are excited to see the construction take off on this iconic facility that will bring tens of thousands of fans to our campus, help build lifelong connections to USF and allow even more people to experience everything our university has to offer.”

In a joint statement, Stroman and Kelly, the co-chairs of the stadium planning committee, said, “With our plans in place and construction preparations under way, we’ve officially entered the next chapter in delivering USF’s on-campus stadium, set to open in 2027. This moment is the result of years of vision and planning. We are grateful for the passionate support of our donors, alumni, fans and the greater Tampa Bay area community. This stadium is being built by and for USF and we can’t wait to take this next big step together.”

NEW 2024 CAT 725

5,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

NEW 2024 CAT 730

6,000 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

(2) New 2024 Hydrema 922G 4x4

4,250 gallon water truck

0 hr machine with warranty, fully loaded New HEC tank and spray system

Equipment for Builds/Order

Rigid Water Tanks up to 18,000+ Gallons 4,500-6,000 Gallon Water for Tandem/6x6 Chassis, Heavy Duty Off-Road Construction

Complete NEW CAT Articulated & Rigid Builds (any size) available with HEC tanks/bodies

New Articulated and Rigid Water Tanks for all Sizes and Brands installation at our place or yours Current stock for CAT 725, CAT 730, CAT 740, CAT 773/775, Bell B30, Bell B40

Fuel, Fuel/Lube Builds available. Articulated or Rigid. Open for warm weather or Up to Arctic Level enclosed for extreme cold operation

(L-R) are Everette Brown and Gerald Infinger, both of Contour Mining and Construction in Columbia, S.C., and Gary Smith and Tyler Wallace, both of Morgan Corp. in Duncan, S.C.

(L-R) are Mitch Gildner and Colt Lax, both of Blanchard Machinery, and Nick Bradley, Martin Gasque and Daniel Hayes, all of East Lake Construction in Lexington, S.C.

Brandon Hydrick of South Carolina Pole &

S.C., looks over the special

in the original gray to

Caterpillar’s 100th year in business.

Blanchard Machinery hosted the local phase of Caterpillar’s Global Operator Challenge on May 15-16, 2025, at the Blanchard Farm in Columbia, S.C., bringing skilled heavy equipment operators together for two days of competition, precision and high-performance machine control.

This event is part of Caterpillar’s third Global Operator Challenge, the company’s largest and most ambitious challenge to date. Thousands of operators from more than 40 countries are expected to compete in local events worldwide, showcasing agility, resilience and versatility across a range of Cat machines and technologies.

At the Columbia event, participants were tested in three separate challenges using different pieces of equipment. Scoring focused on operator skill, safety, efficiency and effective use of integrated technologies such as payload management, grade control and user-assist features designed to optimize machine performance.

Winners from dealer-hosted events like this one will advance to regional semifinal competitions in fall 2025. From there, nine finalists will emerge to compete in the global finals, held in March 2026 at Caterpillar’s Festival Grounds exhibit during ConExpo-Con/AGG in Las Vegas. The grand prize: a $10,000 cash award or a trip for two (equal in value) to any Caterpillar location worldwide. CEG (All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Using a Cat D4 dozer, operators had to maneuver through a path while knocking balls off of cones, without knocking over the cone.

In part, the excavator portion of the operator challenge required operators to load material utilizing payload technology.

For the Cat compact track loader part of the challenge, operators needed to carry a bucket of water on the forks through an obstacle course with penalties for every quarter-inch of water spilled.

During the challenge, operators had to place a smaller tire vertically within a larger one.

For the landscapers, dealers, contractors, hardscape experts and outdoor power equipment manufacturers attending Equip Exposition for the very first time, it’s important to go into the trade show with a plan.

“Do your homework and make a schedule. Download the app ahead of time, book your hotel room now, and be sure to wear comfortable shoes,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), which owns and manages Equip Exposition, the international landscape, outdoor living and equipment exposition. The Equip app is sponsored by CASE Construction Equipment.

The show, which boasts more than a million sq.-ft. of exhibit space, is held Oct. 21-24 at the Kentucky Exposition Center (KEC) and drew more than 28,500 people last year.

Equip offers these tips to help first-time attendees to plan for the best experience possible:

Before the Show

Equip Exposition photo

For those attending Equip Exposition for the first time, it’s important to go into the trade show with a plan

1. Register now. If you’re registered, you will receive Equip’s regular emails about everything going on at the show. Sign up at EquipExposition.com for $30 before prices double to $60 on Sept. 5. On Oct. 20, the price doubles again. Don’t get stuck paying full price ($120) onsite.

2. Add education, certification classes and training to your registration before sessions sell out. Explore ways to grow your businesses, address common problems and develop employees. Other sessions will cover irrigation, pesticide management, tree and shrub pruning, outdoor lighting and more. Select classes, including the popular From Worker to Leader course, are available in Spanish.

3. Book travel arrangements and hotel reservations. Last year, the show sold out the city’s hotels (some are on a complimentary shuttle route) and attendees booked 32,000 rooms.

4. Bring your teammates from your company (if you are a landscaper) or your contractor customers (if you are a dealer). Equip is a fantastic team building opportunity, through shared educational experiences and testing new equipment to having fun at concerts with one another. This makes acting on new knowledge and ideas when home easier.

5. Determine the top three business problems you are try-

ing to solve. Look at the speakers, exhibits and education offerings and identify the ones that will help you the most.

6. Download the Equip Expo app, sponsored by CASE Construction Equipment. The app is your event guide. It works with any Android or iPhone. Find the Event Schedule with start times for sessions and maps for the entire facility, where the biggest giveaways are held and more. Favorite events or locations to build a custom schedule.

7. Plan your route. Many attendees drive to the show so it’s important to map the route from your hotel to the Kentucky Exposition Center and other venues, and look at available shuttles or rideshares.

8. Learn the main areas of the show.

• The North Wing has registration, exhibits and badge pickup.

• The South Wing has exhibits, Mulligan’s Mutt Madness, the Education Center and easy access to the Outdoor Demo Yard and the UTV Driving Experience.

• The West Wing is loaded with exhibits and food options (as well as the rideshare pickup/drop off zone).

• Freedom Hall will host Tree Care Arena, sponsored by Altec.

At the Show

1. Don’t get stuck in traffic. For ease of entry, don’t use the

main gate at the show’s rush hour. If you are coming later than 10 a.m., use Crittenden Drive gate or the Preston Highway gate and park on the North side, which is the best way to enter the KEC. Leave via a similar route to avoid any bottlenecks at the main gate. Parking at the KEC during the show is free!

2. Start your day in the West Wing. Ride shares and shuttles will drop off at the West Wing and there will be food options available.

3. Avoid lines for badge pickup. Print your badge at the Welcome Reception, sponsored by Caterpillar, at Churchill Downs’ First Turn Club or in the North Wing at the Kentucky Exposition Center. More locations are scattered throughout Louisville hotels, the Airport and the KEC.

4. Talk with others. Equip is a city-wide event. People in your hotel elevator and restaurant are likely attendees. Take time to meet people as you navigate the halls, stand in line, or grab a bite to eat.

5. Have fun at the events. Go to:

• Welcome Reception at Churchill Downs sponsored by Caterpillar on Tuesday evening;

• Mulligan’s 5K Fun Run and Walk, sponsored by Active Dynamics, on Wednesday morning at 6:30 a.m.;

• the opening keynote on Wednesday morning will feature Jesse Cole, the founder of the Savannah Bananas, and is sponsored by Kress;

• 4th Street Live! on Wednesday;

• the Morning Show at Expo sponsored by Rehlko on Thursday morning;

• ENERGIZE on Thursday afternoon; and

• Big & Rich concert sponsored by Gravely on Thursday night.

After the Show

1. Follow up with the people you met at Equip. Swap ideas and remind each other to do “that thing you said you would do” when you returned home.

2. Put new ideas you picked up at the show into action. Take that leap, do the “new thing,” roll out better pricing, marketing, services and more.

3. Register for next year’s show. Planned for Oct. 20-23, 2026.

Registration for the show is only $25 through May 31, 2025 at EquipExposition.com.

Weisiger Group, representing brands like Carolina Cat and LiftOne, announced that it has been selected as a 2025 U.S. Best Managed Company Gold Standard winner.

The Gold Standard designation distinguishes honorees that have received the designation for four or more years. This recognition, sponsored by Deloitte Private and The Wall Street Journal, celebrates the outstanding achievements of private United States companies and their management teams.

“Being named a U.S. Best Managed Company Gold Standard winner for five

consecutive years is an incredible achievement, and a true reflection of the hard work, dedication and leadership across our entire organization,” said Amanda Weisiger Cornelson, president of Weisiger Group.

“Our focus has always been on creating value for our customers, empowering our employees and positively impacting our communities. This recognition is a testament to the collective efforts of our talented team, who drive our success every day. I am deeply proud of their unwavering commitment to excellence and grateful for their

contributions. Together, we continue to shape a brighter future for all those we serve.”

Applicants are evaluated and selected by a panel of external judges focused on assessing hallmarks of excellence in four key areas: strategy, ability to execute, corporate culture and governance/financial performance. They join a global ecosystem of honorees from more than 44 countries recognized by the Best Managed Companies program.

For more information, visit WeisigerGroup.com.

flexible

leasing plans that

By Eric Olson CEG CONTRIBUTING EDITOR

Every day brings news of more corporate mergers in the United States or, at the least, smaller companies losing their identities from having been acquired by bigger firms looking to broaden their sales territories.

In the process, family-operated companies that have operated for decades are becoming increasingly scarce. While the owners of the smaller outfits may end up realizing a tidy profit from the sale of their businesses, what often happens is that their customers lose the neighborly, hometown service they had long enjoyed.

But one North Carolina-based company recently saw fit to make a small ownership change while retaining the friendly one-to-one service that made it successful in the first place.

And make no mistake, the owners of CCS Equipment Sales have always been extremely proud to be a family-run company.

First opened in July 1998 in the town of Youngsville, northeast of Raleigh, the full-service construction equipment dealership today serves most of the eastern third of the Tarheel State.

From CCS Equipment’s three locations in the communities of Youngsville, Angier and Ayden, the company offers an impressive roster of machines including excavators, loaders and attachments to meet every construction need. In addition, the dealership is noted for staffing itself with expert service, rentals and parts professionals to best support its customers.

Among the product brands offered by the company are Takeuchi, LiuGong, Wacker Neuson and Toro. Besides CCS Equipment’s extensive selection of new machines, it also specializes in selling well-maintained used construction pieces, too.

The partnership of Charlie Snyder, Charles Davis and Steve Jeffries initially owned CCS Equipment, but Davis’s son, Logan, was recently able to purchase a quarter of his father’s shares in the business to become its newest propri-

etor along with the elder Davis and Snyder’s son, Todd.

“I have a lot of respect for my dad and Todd because over the last couple years, as I have gotten closer to this buyout, they have allowed me to explore new opportunities and look at new ventures, something that says a lot about them, especially my father, who is in his mid-60s — a point at which you often get more conservative in your business,” Logan Davis said. “But he has just let the horses out to run.”

The younger Snyder said he and his newest partner take inspiration from how CCS Equipment’s original ownership

group built the business from the ground up and see no reason to change the down-home method by which they operated it.

“Those three guys were some of the best salespeople you would ever find,” he said. “They really set the foundation for the company and how to properly treat folks. They are also why we have the opportunity to sell to people and prove that we can support them just as well.”

After having started out as a distributor of used construction machines, CCS Equipment brought on the Gehl line of products in 1999. Shortly after that, the dealership began to market and service Takeuchi-manufactured equipment.

Since then, several other model lines have been added to its inventory, according to Logan Davis, but the Japanesebased maker of excavators and compact loaders has remained the dealership’s flagship lineup.

“Takeuchi has definitely been our mainstay, although we have had a revolving line of different offerings,” he said.

“We have been a Toro dealer for quite some time now, as well as Wacker Neuson and have distributed LiuGong since 2017. We have also had some other ancillary products like Multiquip, which has been a partner of ours for a long while.”

Further evidence of CCS Equipment’s growth came in 2015, Davis said, when the company opened the first of its two branch locations in the Harnett County town of Angier, followed five years later by its new Ayden location further east in Pitt County.

Although each CCS Equipment branch was positioned to be convenient for customers in growing areas of the state, the Angier and Ayden stores, in particular, are in very rural areas of the state.

A trio of member-driven guidance documents to help promote the agreed-upon use of common language when representing the non-road equipment industry and discussing the topics of autonomy, cybersecurity and data were issued by AEM this week.

The guidance documents, which are available to view and download on AEM.org, were released in conjunction with AEM’s Celebration of Construction on the National Mall in Washington, D.C. They serve as consensus resources for association staff, members and industry peers to drive conversations and communications related to autonomy, cybersecurity and data.

“When it comes to aligning our members and our industry on ever-evolving issues and topics of importance, words matter,” said AEM Senior Vice President Curt Blades. “It’s why we leveraged the collective knowledge expertise of our membership to develop these guidance documents. Autonomy, cybersecurity and data impact our industry and our world in so many ways, and AEM is committed to helping ensure conversations and communications surrounding these topics are conveyed clearly, consistently and accurately.”

The three guidance documents were the direct result of months of collaboration between AEM member company representatives serving on the association’s Ag and CE Technology Leadership Groups. While they are not intended to be comprehensive or all-encompassing viewpoints on autonomy, cybersecurity and data, the documents do contain both industry use cases and everyday examples. Ultimately, they help guide information sharing inside and outside of the industry, with lawmakers and regulators, with customers and equipment end users, and with the general public regarding:

• the implementation of autonomy in the non-road equipment industry;

• the levels of cybersecurity for machine data today; and

• how data moves among different layers.

Non-road equipment is designed to execute specific functions relative to its intended applications and tasks in nonroad environments in agriculture and construction. Construction worksites, farm fields, dairies and feedlots, areas of animal husbandry, etc., are dynamic environments defined by fences or other boundaries with some level of restriction for access or entry.

These do not apply to on-road operation of non-road equipment.

For more information, visit AEM.org/Insights.

By Eric Olson CEG CONTRIBUTING EDITOR

Small, family-owned and operated businesses like Jerry Renfro’s contracting business in the western North Carolina mountains put a great deal of trust in the people from whom they obtain their equipment.

Unlike larger construction outfits that have the financial resources to better absorb the costs of equipment repairs or replacements, similarly sized companies like Jerry Renfro Inc. in the Mitchell County town of Bakersville, northeast of Asheville, rely on their preferred dealerships to provide them with great value and help keep costs down.

In Renfro’s case, he has been lucky enough to buy many of his machines from The Ironpeddlers, including two recent purchases of excavators made by SANY America.

The Ironpeddlers is based just east of Charlotte in the city of Monroe. Its other Tarheel State locations are in Asheville, Raleigh and Wilmington. The company also has branches in the South Carolina cities of Greenville/Duncan and Florence; its Savannah, Ga., and London, Ky., locations focus solely on aftermarket OEM parts and other used components.

RenfroÊs Hard Work Propels

Him to 35 Years of Success

A self-made person of great faith and drive, Renfro has

been running his own business for 35 years, beginning in March 1990. Prior to that, he was employed by another contractor during the weekdays.

At the same time, each night and on Saturdays, he worked for himself.

“I did that for about five years so I could do things my own way and get enough business to where I felt like I could go on my own full-time,” he said. “I started with nothing more than a Lowe’s riding lawn mower, a Ryobi weed eater and an old beat up pickup truck, but I just kept going at it.”

Today, though, Renfro oversees the company, leaving the day-to-day operations to his two sons, Heath, age 30, and Hudson, age 23, as well as a crew of six. To complete the family enterprise, Jerry’s wife, Tammie, expertly runs the office.

“We do everything from mowing to working on driveways to doing hardscapes and building retaining walls — pretty much whatever our regular customers need,” he said.

The contracting company’s hardscape work is managed by Heath Renfro and involves constructing paver patios, outdoor kitchens with fire pits and retaining walls, he said.

Jerry Renfro Inc.’s crews are usually kept busy installing housing pads and walls for a number of high-end residential developments scattered across the region. Many of them are ridge-top homes, which afford residents with breathtaking views of some of East Coast’s highest peaks.

By Eric Olson CEG CONTRIBUTING EDITOR

Nashville, Tenn.’s Parman Tractor & Equipment was recently honored with having one of its veteran sales professionals being named by Takeuchi-US as the manufacturer’s 360° Dealer Salesperson of the Year for 2024.

Parman’s Scott Syler, who has worked for three decades, accepted the award in mid-April at the Takeuchi-US 2025 Dealer Summit in Scottsdale, Ariz.

He was chosen as the equipment maker’s top performer out of a field of 44 salespeople who earned Salesperson 360° Award status in 2024.

Dealer 360° awards recognize Takeuchi dealers across the United States and Canada for excellence in sales performance, facilities, training, marketing/parts and service, the company said.

In addition, the equipment maker said in an announcement that the program “incentivizes Takeuchi salespeople to develop a well-rounded approach to selling … equipment by challenging them to achieve various educational and sales milestones throughout the year.”

Shay Klusmeyer, the central/western division sales manager of Takeuchi-US, said, “Scott has more than 30 years of equipment sales experience, and he puts that expertise to work every day for Parman Tractor and Takeuchi.

“Being named [our] top dealer salesperson is no small feat; it requires a ton of focus and hard work,” she added. “We sincerely thank Scott for his outstanding performance and dedication to the Takeuchi product line.”

When initially asked just what he did to achieve the distinction, the humble Syler provided a succinct answer.

“We sold a lot of equipment, including many different models and attachments, and we checked off a lot of boxes,” he said.

A few moments later, Syler elaborated that through Parman, he has been very successful of late in moving a mixture of mini-excavators, track loaders, wheel loaders and a variety of attachments that the company had not sold in the past.

He also acknowledged that Middle Tennessee’s dynamic marketplace, along with it being a highly desirable location for retirees from the north, has contributed to the region’s construction surge in recent years.

As a result, Parman Tractor has been able to capitalize on those factors, Syler said, to increase the dealership’s bottom line.

“That has definitely been the case,” he said. “Our national market is one of the hottest in the country and is a big contributor as to why we’ve been so successful over the past five years.”

Parman Tractor first became a Takeuchi distributor more than 20 years ago, said Colin Hockenberger, Parman’s CEO. In 2023, the Tennessee dealership

was the recipient of the North American Takeuchi Dealer of the Year award.

For more than a half-century, Takeuchi has been a leader in the compact equipment industry, having developed the world’s first compact excavator in 1971, followed in the mid-1980s with the introduction of the first compact track loader, the company said.

Together, those machines became extremely popular products in the United States market and led to the manufacturer introducing other lines of compact equipment, including its wheel loaders, crawler dumpers and attachments – all of which are sold at Parman Tractor.

Today’s Takeuchi’s extensive dealer and service network across North America is supported by its state-of-the-art training, parts and distribution facility near Atlanta, Ga.

During his time working with Takeuchi products for Parman, the largest machine Syler has sold is the TB290, he said, a compact excavator that sports a mid-size design.

Among the more unique Takeuchi models that Syler sold recently, he added, was a TB257FR, the newest excavator in the FR (full-rotating) series. It features a side-to-side (STS) offset boom coupled with a tight tail swing to give the operator a clear line of sight to the work equipment, enabling it to rotate fully with very little overhang.

“The customer used artificial intelligence to spec out a machine for a pipe-laying application and AI pointed to the Takeuchi TB257FR, and Parman Tractor in Nashville as the place he needed to go,” Hockenberger said. “The gentleman was a believer in what AI could do, and it helped us sell a machine.”

He said that seeing Syler recognized as the manufacturer’s Salesperson of the Year just one year after Parman was honored by Takeuchi was an affirmation of the hard work and commitment that Syler has always applied to his job.

“Scotty cares about his customers and products more than anybody we know,” said Hockenberger. “He represents Parman’s motto, ‘Totally Outrageous Customer Service’ really well. Just watching him work and his care for the product and the customer exceeds that of any other sales representative that I have come across.” CEG

Senate Environment and Public Works Committee

Chairman Shelley Moore Capito received the American Road & Transportation Builders Association’s (ARTBA) highest honor for her leadership and bipartisan efforts to advance transportation infrastructure investment and policy.

Established in 1960, the ARTBA Award recognizes outstanding contributions that have advanced the broad goals of the association. Recipients have included governors, more

Established in 1960, the ARTBA Award recognizes outstanding contributions that have advanced the broad goals of the association.

than 25 U.S. senators or representatives, two U.S. secretaries of transportation and dozens of top leaders and executives from government and the transportation construction industry private sector.

During her 24 years in Congress, Sen. Capito has been an ardent champion of increased federal funding and streamlining the permitting process to accelerate the delivery of transportation improvements.

In 2021, she played a pivotal role in crafting a five-year, $450 billion highway and public transit reauthorization bill, the largest surface transportation investment increase in 65 years. She worked to build support for final passage from her Senate colleagues. The measure became the centerpiece of the Infrastructure Investment & Jobs Act (IIJA), the November 2021 enacted infrastructure law.

Sen. Capito remains a leading voice to ensure the law is implemented as intended by Congress, and she is currently working to develop the next highway and public transit bill, due by Oct. 1, 2026.

For more information, visit artba.org

Intelligent transportation systems (ITS) play a role in smart technology. The use of communication-based information and electronics technologies are central.

Work zone ITS is meant to enhance transportation and improve safety and mobility in and around work zones, according to the Federal Highway Administration.

“A work zone ITS deployment can be focused around safety or mobility, but often supports both goals and can also enhance productivity,” said the agency.

“The systems are portable and temporary in most cases, although some deployments may use either fixed infrastructure or become a permanent system.”

FHWA has an entire website devoted to providing guidance on ITS implementation in work zones. The goal is to assist public agencies, design and construction firms and industry.

That includes developers, manufacturers, distributors, packagers and providers of devices, systems and programs, as well.

The agency believes work zone ITS is one possible operational strategy an agency can include in a transportation management plan (TMP).

The federal website summarizes key steps for successful implementation, using a systematic approach.

“These steps include assessment of needs, concept development and feasibility, detailed system planning and design and procurement,” said the fed.

It also involves system deployment and system operation, maintenance and evaluation, said FHWA.

In fact, transportation agencies across the country are using ITS to make travel through and around work zones safer and more efficient. Electronics, computers and communications equipment are used to collect information and process it in order to take appropriate action.

The technology can help agencies with traffic monitoring and management, provide traveler information and incident management. It also can enhance the safety of both the road user and the worker, said FHWA. With ITS, capacity can be increased and enforcement improved.

The technology tracks and evaluates contract incentives and disincentives for performance-based contracting and aids in work zone planning.

Many ITS applications offer a combination of benefits for state agencies, said the agency. At the same time, they keep road workers safe.

The North Carolina Department of Transportation (NCDOT) was selected to host the national work zone awareness campaign this year.

Transportation leaders, hosting for the first time, stressed the importance of motorists slowing down and staying alert to protect road workers and other drivers.

New smart technology is helping the state agency make sure that happens every day in work zones, said Joey Hopkins, state transportation secretary.

At the awareness week kickoff event, Hopkins said NCDOT has deployed connected work zone devices that transmit real-time data. The data allows drivers to navigation apps that provide audio alerts as they near work zones.

The agency also has installed flashing arrows, automated flagging assistance devices as well as portable traffic signals to keep vulnerable road crews safe.

During last month’s work zone awareness week, Florida

transportation officials stressed the benefits of a smart work zone program. Noting the state has always had a smart program, Daniel Smith told WPBF in West Palm Beach that the state has advanced its technology and strategies.

Smith, a state traffic systems manager, said smart cones are one example. With a built-in sensor that activates a loud siren, the cone alerts workers.

“If one gets knocked off, it’ll set off a siren for the rest of them and let the workers know that there’s something entering the work zone.”

Ranger Construction sees much potential in smart devices. Mark Ligon, vice president of safety and risk management, told CBS12 he is excited to see it in use.

A Ranger employee was killed by a hit-and-run driver in a road construction zone in 2023. Ligon said with more warning he might’ve escaped fatal injury.

“Whether, in fact, he would’ve been able to, we don’t know that,” Ligon said. “But at least it would’ve given him the opportunity.”

One camera device mounted on a vehicle emits a siren, giving workers a few seconds to get out of the way if a driver is coming right at them.

With a long-range digital camera, radar and AI component it watches oncoming traffic approaching the road workers’ work zone, said Jason Lee.

CEO and founder of SmartCone Technologies, Lee said the device can see up to a mile down the road.

“So, together inside the computer that’s in our device, it takes the radar, it tells the unit ‘Hey, we got lots of traffic coming at a certain speed.’”

The AI camera begins watching traffic behavior. If traffic behavior is questionable, the device flashes a light and sends a message, Lee said.

The messages are received by workers via watch, and they can run to the cone placed in a safe spot that they can reach in a hurry.

The goal is to give them at least five seconds warning before an approaching driver might hit them, said Lee.

“What we’re trying to do is give people awareness to

make a better decision as fast as possible.”

Smith said the Florida Department of Transportation (FDOT) also uses trailers with AI cameras and drones to enhance safety. More visible on local major construction sites, these devices keep workers safe and let FDOT make real-time adjustments from a remote traffic center.

Smith called the technology “the nerve center of surface transportation” and have proven invaluable for controlling traffic in work zones. For instance, on one project, site managers discovered that construction barrels were not placed in the most strategic spot.

“You didn’t really notice it on the ground, but with a camera up on a pole, you did notice it,” said Smith. “We’re able to move these traffic barrels around to just reduce conflict. So, people aren’t swerving in our lanes and trying to drive places they shouldn’t be.”

He told WPBF he believes smart work zones are costeffective, usually amounting to less than 0.1 percent of the project cost.

FDOT owns the equipment, so the agency can deploy it wherever and whenever it’s needed.

ITS is revolutionizing the way we travel by integrating advanced technologies into transportation networks, said Rohan Salgarkar.

Executive vice president of sales for business intelligence provider Markets and Markets Inc., Salgarkar believes ITS is transforming our mobility.

“In a traditional system, traffic flow was regulated through timers, pressure plates, and pedestrian buttons,” he said.

“However, smart intersections have revolutionized this approach,” using a combination of to detect pedestrians and vehicles, he added.

These systems enable more accurate and efficient traffic management. In smart intersections, vehicles can automatically begin braking to avoid accidents. Streetlights can now see ITS page 66

The Fifth Annual Dobbs Equipment Golf Classic was held May 9, 2025, at the Ritz Carlton Golf Club in Orlando, Fla., and was another huge success.

To kick off the outing, a cocktail reception was held the night before at the club.

Dobbs holds this annual golf classic to support the Construction Angels, a non-profit that supports the families of construction workers killed on the job. This year saw another tremendous turnout with 33 foursomes competing for some great prizes and bragging rights for the year. Dobbs vendors, staffers, customers and business partners all turned out to help raise more than $209,000 for Construction Angels.

First place winners were the foursome of Kyle Phelps, Quality Precast; Adam Wallace, Command Alkon; Jason Hilley, Mid Coast Aggregates; and Matt Coonrod, Arcosa Crushed Concrete. The second place team was Sean Ireland, Mike Reinke, Jack Calandros and Robert Burr of Prince Contracting, Tampa, Fla. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

On the course representing NPK and providing snacks, drinks, NPK swag and displaying the Dobbs Equipment Top 10 North America Dealer Award are Scott and Lynn McEver.

Kristi Gibbs of Construction Angels accepts the big check for more than $209,000 from Dobbs Equipment Vice President Augusto Salles.

Border Rents

borderequipment.com

Augusta, GA 706-737-7253

Norcross, GA 770-609-8299

*Ditch Witch of Virginia ditchwitchva.com

Seaford, DE 302-629-3602

Chesapeake, VA 757-424-5960

Glen Allen, VA 804-798-2590

Manassas, VA 571-359-6081

*Ditch Witch Worx ditchwitchworx.com

Fort Lauderdale, FL 877-935-3656

Jacksonville, FL 866-254-1102

Plant City, FL 855-704-6828

Albany, GA 866-581-4914

Atlanta, GA 866-709-3712

Savannah, GA 888-298-0429

*Don Allison Equipment, Inc. donallisonequipment.com

Arley, AL 800-669-6450

First Choice Farm and Lawn firstchoicekubota.com

Brookland, AR 870-790-2301

Dyersburg, TN 731-882-1855

Eads, TN 901-616-5129

Mayfield, KY 270-856-4355

Savannah, TN 731-925-2141

Union City, TN 731-885-1315

*Forsythe Tractor forsythetractor.com

Shreveport, LA 318-687-1341

National Equipment Dealers

Carolinas

nedealers.com

Ashville-Fletcher, NC 828-628-3004

Charlotte, NC 704-228-0455

Clayton, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Columbia, SC 888-865-1002

Conway, SC 800-968-0754

Piedmont, SC 864-434-1154

Summerville, SC 843-501-0566

Wellford-Spartanburg, SC 843-501-0566

National Equipment Dealers

Florida

nedealers.com

Apopka, FL 407-401-8956

Fort Myers, FL 407-754-4646

Fort Pierce, FL 772-212-4043

Jacksonville, FL 904-664-0899

Tampa, FL 813-940-4405

National Equipment Dealers

Georgia

nedealers.com

Dallas, GA 770-445-9019

Douglas, GA 912-384-4664

Macon, GA 478-257-8300

Richmond Hill, GA 912-756-7854

Southern Lift Trucks

southernlift.com

Mobile, AL 251-278-2247

State Machinery

statemachineryeq.com

Kenner, LA 504-464-0431

Taylor Construction Equipment taylorconstructionequipment.com

Bessemer, AL 205-428-7050

Huntsville, AL 205-428-7050

Montgomery, AL 205-428-7050

Louisville, MS 833-773-3421

New Albany, MS 304-550-9825

Richland, MS 601-922-4444

LaVergne, TN 304-550-9825

Maryville, TN 662-773-3421

Van Keppel

vankeppel.com

North Little Rock, AR 501-945-4594

Van Buren, AR 479-474-5281

Loved for the features. Trusted for the performance.

Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without feeling like longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

The primary element of the construction is the addition of two parallel lanes along 6 mi. of Highway 15 in Union County. Upon project completion, the existing highway will serve as the northbound lanes, while the additional roadwork will cater to southbound traffic.

The traffic patterns mean southbound experiences the lion’s share of traffic during the morning commute, and northbound is jammed in the evenings.

“While there are relatively few accidents on the roadway, when they do happen, they wreak havoc,” Smithey said. “It’s hard to get around when an accident occurs, and drivers could be forced to take a multi-mile detour.”

The other roads in the area are primarily rural, typically narrow, and not well-paved.

The primary element of the construction is the addition of two parallel lanes along 6 mi. of Highway 15 in Union County. Upon project completion, the existing highway will serve as the northbound lanes, while the additional roadwork will cater to southbound traffic.

Once the team completes the new lanes, MDOT will switch traffic to the new alignment and work on another project element. The existing lanes also are being repaved.

The team is restabilizing the subgrade with cement and new lifts of asphalt due to the deterioration of the existing asphalt pavement. On the north end of the project, the team is creating a new alignment for the northbound traffic to cross the King Creek bridge.

Less than 1 mi. of the current highway is being completely redone. The team is restabilizing the subgrade with cement and new lifts of asphalt due to the deterioration of the existing asphalt pavement. On the north end of the project, the team is creating a new alignment for the northbound traffic to cross the King Creek bridge.

The project will impact three existing bridges. One bridge is being widened to match the width of the larger highway. The team also is installing two new bridges (northbound and southbound). The 302-ft.-long and 82-ft.-wide bridge will cross 110-ft.-wide King Creek.

Note that the team had to redesign the first .5 mi. of the project from what it was in 2012. The original design was to have a divided 4-lane to cross King Creek, but there was a conflict with a natural gas pipeline valve station in the planned centerline for the southbound lanes.

The estimate for relocation of the valve station was $12 million, and the 2012 estimate for bridge, grade and drain for that 6-mi. section of road construction was $11 million. Due to that significant cost, MDOT went back and made the deci-

The construction budget for the widening of SR 15 is just below $59 million. The team is half a million over budget, due to rising costs of asphalt and other materials.

sion to extend the 5-lane out of the New Albany city limits and to cross King Creek to just past the pipeline. This allowed MDOT to proceed within existing ROW and construct the newly proposed alignment at a significant cost savings to the department.

King Creek is home to the Mississippi silvery minnow (note: it can be found in other states and waterways as well), which is considered an endangered species.

“Because we’re dealing with an endangered species, we have to be extra cautious,” Smithey said. The team made sure to be as efficient as possible. They also cleared and stabilized the creek bank. We were able to strip the banks, do some minor grade adjustments to banks, place geotextile and riprap, and place super silt fence to stabilize that in permanent position in just four days to minimize exposure.”

By all appearances, most of the stretch of highway sits in an idyllic location. There are trees and fields in the vicinity.

Diamond Mowers introduced the mini-brush cutter Pro X, delivering precision, power and reliability in one compact package.

Modeled after Diamond's brush cutter Pro X, the minibrush cutter Pro X is engineered to provide stand-on users — from farmers and construction contractors to landscapers and land management professionals — with another tool for their equipment toolbox.

This attachment transforms a stand-on or stand-behind track loader into a powerful land-clearing tool that tackles trees, cuts through dense brush and grinds stumps to ground-level, empowering operators to take on a broader range of tasks and jobs, according to Diamond Mowers.

“This attachment is engineered specifically for the miniskid steer market and adds a new dimension of capability that empowers operators to clear land faster, reduce manual labor and maximize their equipment investment,” said Nate Cleveringa, vice president, engineering and product management of Diamond Mowers. “It packs all the power and performance of our brush cutter Pro X in a streamlined profile designed for those who value relentless durability and optimal versatility.”

The mini-brush cutter Pro X features a spindle-driven blade system with 25 percent more cutting capacity than standard models, enabling operators to slice through dense brush, thick vegetation, and trees up to 5 in. in diameter with ease. The 42-in. cutting width is ideal for tackling everything from landscaping and property reclamation to urban lot clearing and maintaining parks, trails and forest preserves. The direct-drive spindle also delivers smooth and efficient power from the motor to the blades for consistent cutting performance so operators can handle tough materials without compromising on precision.

“The spindle system replaces the more traditional gearbox, which can be prone to wear and tear under heavy loads,” said Cleveringa. “This design reduces mechanical complexity, resulting in greater durability during heavy-duty operations.”

The steel construction of the mini-Pro X is 25 percent thicker for enhanced durability, according to Diamond Mowers. Furthermore, the offset design of the bolt-on attachment plate allows operators to shift the plate across the front of their carriers to minimize track marks that would normally be left behind. This is particularly useful for precision tasks such as trail clearing or vegetation management near sensitive areas and affords greater flexibility when maneuvering in tight spaces and working near edges, fences or other obstacles.

said Cleveringa. “It replaces manual clearing and empowers operators to tackle a wide range of tasks efficiently and reliably without needing to call in additional trades,” said Cleveringa. “This versatility leads to greater

productivity and profitability.”

To help protect operators and ensure long-term usability, the mini brush cutter Pro X also features:

• universal safety guarding — to minimize the risk of

injury while working in challenging environments, polycarbonate safety glass shields operators from flying debris and other potential hazards during operation, according to the company.

• hydraulic hose protection — hoses are enclosed in a thin spiral wrap, offering safeguarding, an enhanced level of durability, and resistance to wear and tear, according to the company.

• castle nut fasteners — providing an added layer of protection, the castle nut system locks cutting blades in place and positions them closest to the ground during operation. Under significant stress or impact, the secure fit reduces vibrations and ensures that, in the event of a blade compromise, failure is isolated to the blade and the attachment continues to operate safely, according to the company.

“Reliability and performance are crucial for professionals working in challenging environments and were top priorities in the design of this attachment,” said Cleveringa. “Field testing has shown that the spindle-driven double blades and castle nut system perform well in rigorous conditions. The design handles heavy workloads and minimizes downtime by reducing the frequency of maintenance and repairs.”

You will find the parts you need at MOBRO Marine, Inc. We purchase in bulk directly from the manufacturers to maintain our large inventory. We also have a large inventory of long-lead time parts for cranes that can’t be found anywhere else. Not only does this mean we have the part you need in stock, it also saves you money. Because we buy in volume, we can buy for less and pass the savings on to you.

Our large inventory keeps construction equipment performing at optimum levels. We offer same-day shipping on most partsyou’ll experience minimal downtime. We are a full-service company. We not only supply parts, but we also service and repair construction equipment and cranes of any type.

Savannah-Richmond Hill, GA

912-756-7854

Dallas, GA

770-445-9019

Douglas, GA 912-922-4242

Macon, GA

478-257-8300

Lexington, NC

866-629-3784

nedealers.com

Grimesland, NC 252-752-1500

Asheville-Fletcher, NC

828-628-3004

Charlotte, NC

704-228-0455

Clayton-Raleigh, NC 919-773-1424

Castle Hayne, NC 910-222-3900

Summerville-Charleston, SC 843-501-0566

Columbia, SC 888-865-1002

Wellford-Spartanburg, SC 864-284-4343

Conway-Myrtle Beach, SC 800-968-0754

www.equipmentshare.com

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804 HEAVY MACHINES, INC. www.heavymachinesinc.com

120 Mann Drive Piperton, TN 38017 (Memphis) 800-238-5591

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

LINK-BELT MID ATLANTIC www.link-beltmidatlantic.com Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235 PARMAN TRACTOR & EQUIPMENT www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

1485 Bear Creek Pike Columbia, TN 38401 931-388-7273

MID SOUTH MACHINERY, INC. www.gomidsouth.com 3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

7422 Hwy 49 N Hattiesburg, MS 39402 601-268-2222

Arbor Nature, headquartered in Hilton Head, is one of the largest tree care professionals in South Carolina’s coastal region.

Over the years, the company has experienced tremendous growth while staying true to its mission: caring for people, their properties and their trees. So committed is Arbor Nature to this mission that it offers a satisfaction guarantee—final payment is due only once the customer is completely satisfied.

According to COO Courtland Babcock, Arbor Nature has undergone a significant growth curve in recent years.

“Not only has our tree care service expanded by building a strong customer base and through strategic acquisitions, we’ve also diversified into other businesses,” Babcock said. “These include a dumpster and portable toilet service, a land clearing company and the development of a construction material recycling facility.”

As part of a rebranding effort, Arbor Nature is unifying all its business units under the Arbor Nature name and repainting approximately 100 company vehicles. The company now employs approximately 150 people.

Arbor Nature also operates a transfer station permitted to receive construction debris such as wood waste, concrete and asphalt. According to Babcock, the market for construction material recycling on Hilton Head Island was “ripe for the taking.”

“The area has seen a surge of people moving in permanently,” he said. “Many homes weren’t built for full-time residency and are now being demolished to make way for

new construction.”

At the core of Arbor Nature’s recycling operation is a Komplet K-JC 704 compact jaw crusher, capable of producing material from 1-in. to 4-in. minus. This machine allows the company to create both coarse and fine materials, which are either resold or reused on company projects.

Each day, loads of concrete, asphalt and other debris arrive at Arbor Nature’s yard for processing. The cost savings of using recycled concrete as a base material are substantial. Babcock said that granite, once trucking is factored in, can cost up to $85 per ton — whereas Arbor Nature sells recycled concrete for $25 per ton.

“For a typical 2,000-square-foot driveway requiring 100 tons of base material, the savings can be around $5,000,” he said. “That’s a huge advantage when bidding on a project.”

Another benefit to customers is Arbor Nature’s Hilton Head location.

“Most aggregate suppliers are located at least 10 miles from the island, which drives up material and delivery costs,” Babcock said.

To meet rising demand, Arbor Nature is actively exploring additional recycling sites in Beaufort and Jasper Counties.

The Phoenix Center released its 2025 aggregates industry scorecard on April 9, 2025.

The scorecard assessed the aggregates industry’s impact on the U.S. economy at the national, state and county levels. This is an update to the Center’s 2017 Scorecard, as it provides a new look at the economic advantages after the passage of the Infrastructure Investment & Jobs Act (IIJA) in 2021.

The scorecard shares that the aggregates industry continues to be a significant contributor to our nation’s economic well-being. The implementation of IIJA, which included approximately $350 billion for fed-

eral highway programs over a five-year period in states and federal projects, showcases the positive effects on the United States economy. The industry supports $171 billion in national sales, $55 billion in national earnings (i.e., labor compensation) and nearly 729,000 jobs across a wide range of occupations and industries.

“Our members provide and support the aggregates materials used for residential, commercial and govern-

ment construction projects, as well as transportation infrastructure including roads, highways, bridges and railroads,” said NSSGA Interim CEO Michele Stanley. “This scorecard proves that the growth of the aggregates industry is necessary for the growth of our overall economy.”

The industry’s economic impact creates a ripple effect on the broader economy. For every job in the aggregates industry, an additional 5.95 jobs across other industries are supported throughout the economy. Each dollar of earnings creates another $4.95 of earnings in other sectors, and each dollar of industry sales produces another $3.29 of sales in other industries.

ARBOR from page 40

In addition to concrete recycling, the company also processes wood waste into high-quality mulch, available to both local landscapers and customers.

The Komplet crusher — an investment of approximately $200,000 — was a strategic purchase for Arbor Nature’s recycling goals.

“It’s highly portable, weighing only 26,455 pounds and much more affordable than traditional crushers,” said Babcock. “We wanted a new machine for reliability and warranty coverage. Crushing is a tough job — we didn’t want to inherit someone else’s problems.”

The portability of the crusher allows Arbor Nature to bring it directly to demolition sites, enabling onsite recycling and further cost savings.

The machine delivers a production rate of approximately 60 tons per hour at a 1-in. setting and up to 90 tons per hour when the jaws are fully open (producing 4–6-in. material). Oversized debris is first broken down using a hydraulic hammer and excavator, passed through the crusher and cleaned using a cross-belt magnet to remove metal. A second pass produces properly sized materials. Fines — necessary for creating sellable crusher run — are stockpiled for reuse.

Arbor Nature recently expanded its Komplet fleet with the addition of a Kompatto 221 mobile double-deck screener and a K-TC 460 tracked mobile conveyor. This strategic investment allows the company to screen crushed material into three separate end products — maximizing material recovery and resale opportunities.

see ARBOR page 50

This 74 hp 27-in. x 16-in. Komplet jaw crusher is the backbone of Arbor Nature’s concrete recycling operation.

MOBISCREEN MSC 952 AND 953 EVO – even more performance with a 9.5 m 2 screen surface

MOBISCREEN MSC 702 AND 703 EVO –compact and efficient with a 7 m 2 screen

HIGH FLEXIBILITY AND FIRST CLASS SCREENING RESULTS. The MOBISCREEN MSC EVO screening plants are characterised by high application versatility, excellent transport characteristics and fast set-up times. Precise results with a very wide variety of feed materials and low consumption are guaranteed –where flexibility meets precision. The effi cient MSC EVOs thus impress with top performance values across the board.

www.kleemann.info

dobbsequipment.com Riverview, FL

813-620-1000 – Main office 813-621-4902 - Parts Miami, FL 305-592-5740 West Palm Beach, FL 561-848-6618 Orlando, FL 407-299-1212

Fort Myers, FL 239-334-3627

Lutz, FL 813-995-0841 Daytona, FL 407-299-1212

SC

Pompano Beach, FL 954-977-9541 (Parts) Sarasota, FL 941-960-2004 (Parts) Melbourne, FL 321-234-3344 Andrews, SC 843-983-7337

Pensacola, FL 850-505-0550 Atlanta,

SC

Tuscaloosa, AL 205-752-0621 Panama City, FL 850-763-4654

8255 NW 58th St Miami, FL 305-592-5360

801 E Sugarland Hwy Clewiston, FL 863-983-8177

2801 Reese Rd Davie, FL 954-581-8181

9651 Kelly Tractor Dr Ft. Myers, FL 239-693-9233

5460 Okeechobee Blvd West Palm Beach, FL 561-683-1231

6301 Old Rutledge Pike Knoxville, TN 37924

865-546-1414

10644 Lexington Dr Knoxville, TN 37932 865-218-8800

1825 Veterans Blvd Sevierville, TN 37862 865-595-3750

9960 Airport Pkwy Kingsport, TN 37663 423-323-0400

4066 South Access Rd Chattanooga, TN 37406 423-698-6943

215 Interchange Dr Crossville, TN 38571 931-456-6543

541 Alfred Thun Rd. Clarksville, TN 37040 931-552-5496

667 Horace Lewis Rd. Cookeville, TN 38506 931-646-3200

1245 Bridgestone Blvd. LaVergne, TN 37086 615-256-2424

3565 New Tullahoma Hwy. Manchester, TN 37355 931-461-5000

1291 Corporate Ave. Memphis, TN 38132 901-332-3051

3199 S Frontage Rd. Columbus, MS 39701 901-401-7011

4350 US-641 Camden, TN 38320 731-584-2732

2000 Airways Blvd Jackson, TN 38301 731-988-4240

4545 Columbia Pike Thompson’s Station, TN 37179 615-744-7850

1808 US-82 Greenwood, MS 38930 662-453-5233

761 Hwy 6 West Oxford, MS 38655 662-371-4440

421 Wallace Dr Belden, MS 38826 662-680-8948

ARBOR from page 44

When paired with Arbor Nature’s K-JC 704 crusher, these units create a streamlined, closed-loop system that increases efficiency, reduces handling costs and supports higher-volume processing. The ability to produce multiple products on site not only enhances profitability per load, but also strengthens Arbor Nature’s competitive edge when bidding on commercial and municipal projects, accelerating ROI across their recycling operations.

Babcock praised Komplet’s post-sale technical support. “Troubleshooting has been rapid — via phone, text, or email at all hours,” he said. “Warranty repairs are handled

within 24 hours, and parts are always in stock. The machine consumes just four gallons of fuel per hour and is easy to maintain. It generates about $750 per hour in revenue, giving us a fast return on investment.”

The crusher also features an intuitive Bluetooth-enabled remote control that allows operators to manage all functions from inside an excavator or skid steer. The interface resembles a Garmin fish finder, with user-friendly menus and softtouch buttons.

“Choosing a crusher from a company 800 miles away wasn’t easy,” Babcock said. “But the service has been outstanding — overnight parts, proactive support and excellent

reliability.”

Arbor Nature is currently using a larger impact crusher to increase capacity and is planning to expand its onsite crushing services, including asphalt recycling for parking lot and demolition projects.

With its growing recycling operations, the right equipment and focus on sustainability, Arbor Nature continues to thrive, proving that its motto — caring for their customers, their trees and their properties — is not only professional, but just simply smart business. CEG

(All photos courtesy of Komplet.)

Metso has received the relevant regulatory approvals and completed the acquisition of its long-time partner Swiss Tower Mills Minerals AG (STM).

STM’s expertise in vertical grinding mills strengthens Metso’s comminution solutions portfolio for the mining industry, playing a vital role in energyefficient solutions for the diverse needs of customers and enabling Metso to provide enhanced service levels to customers using stirred mill technology.

“We warmly welcome our colleagues from Swiss Tower Mills Minerals to the Metso team,” said Piia Karhu, president, minerals of Metso. “Our collaboration on innovative grinding solutions and services combining, for example, the well-established HIGmill and Vertimill vertical grinding solutions and HRC high-pressure grinding roll technology has yielded significant results for our customers. And now that we are one team, our customers can expect even more.”

“Mining customers value Metso’s vast expertise and the comprehensive

nature of our technology and services solutions,” said Christoph Hoetzel, senior vice president, grinding of Metso. “We see a trend towards optimized technology combinations and multi-stage grinding approaches. These solutions improve energy efficiency and reduce carbon emissions, in addition to enhancing productivity with optimized operating costs. The HIGmill is a cornerstone for energyefficient comminution circuits.

Combined with Metso’s innovative flotation solutions like the Concorde Cell, it enables maximized throughput as well as superior recovery.”

“Swiss Tower Mills Minerals was founded in 2011 with the vision of achieving outstanding grinding performance and unparalleled energy efficiency with vertical stirred mills,” said Oliver Zlamal, CEO, Swiss Tower Mills Minerals. “Our joint journey with Metso began a year later, in 2012, when Metso was granted exclusive rights to sell the HIGmill equipment.

Over the past few years, we have built a fantastic team and developed innova-

tive solutions that are now ready to be scaled within a bigger structure. We are delighted that the STM experts and technology will find a new home at Metso.”

Metso’s stirred milling technologies portfolio consists of Vertimill, HIGmill and Stirred Media Detritor (SMD) mills. These mills are based on gravityinduced and fluidized technologies, allowing for an equipment solution for all comminution circuits in secondary, tertiary, fine, ultrafine, regrind and lime slaking applications. Metso has more than 50 years of experience in developing, testing and delivering stirred mill technology, including a large installed base. Stirred mills are part of the Metso Plus offering.

Metso supports its minerals and metals refining customers with end-toend solutions and services ranging from testing, equipment and digital solutions to comprehensive service and

capabilities.

5038 Buford Hwy. Norcross, GA 30071 770-582-0377

Blue Ridge, GA 706-632-3777

Cumming, GA 770-887-6119

Hiawassee, GA 706-970-3077

McDonough, GA 770-957-3370

Villa Rica, GA 678-952-2037

Perry, GA 478-987-1173

Stowers Machinery Corporation stowerscat.com/bandit

6301 Old Rutledge Pike Knoxville, TN 37924

865-546-1414

10644 Lexington Drive Knoxville, TN 37932 865-218-8800 1825 Veterans Boulevard Sevierville, TN 37862 865-595-3750

9960 Airport Parkway Kingsport, TN 37663 423-323-0400

4066 South Access Road Chattanooga, TN 37406 423-698-6943

215 Interchange Drive Crossville, TN 38571 931-456-6543

Bobcat of Charleston North Charleston, SC 843-725-6330

Bobcat of Columbia Columbia, SC 803-933-9996

Bobcat of Greenville Piedmont, SC 864-269-3600

Bobcat of Spartanburg Spartanburg 864-342-9003

Bobcat of Savannah Bloomingdale, GA 912-236-5588

Bobcat of Seneca Seneca, SC 864-873-8908

Stellar Industries celebrates its 35th anniversary this year, marking a legacy of innovation, growth and customer-centric service.

Founded in 1990 by three entrepreneurs — Francis Zrostlik, Jim Vlaanderen and Gary Bomstad — Stellar began its journey designing and manufacturing a domestic hydraulic hooklift. Over the past three and a half decades, Stellar has grown from a small-town operation in Garner, Iowa, to a global force in the construction, waste and work truck industries.

“We are incredibly proud of the 35 years of progress Stellar has made,” said Dave Zrostlik, president of Stellar. “What began as a small, dedicated team working tirelessly to create reliable, high-quality products has evolved into a company that impacts industries across the globe. Our employees have been the key to our success. Some of them have been with us since the very early days of the company’s existence, bringing their passion and expertise to every product we create. The company’s accomplishments reflect their hard work and the relationships we’ve built with our customers and distributors.”

Stellar’s journey has been marked by products and innovations. In 1999, the company introduced its first telescopic service crane. Since then, Stellar has continually expanded its product portfolio, offering solutions such as patented aluminum mechanic truck bodies, tire handling equipment, hooklifts and more.

In 2023, Stellar achieved a monumental milestone by becoming 100 percent employee owned. The transition to 100 percent employee ownership has further deepened the sense of commitment and pride within the workforce, allowing each team

member to directly benefit from the company’s growth and achievements. Stellar now has more than 800 employee-owners, each of whom is integral to the company’s dayto-day operations and long-term strategy.

“This transition to 100 percent employee ownership was a game-changer for us,” said Zrostlik. “This shift has further cemented a culture of accountability and shared success, where everyone is aligned in driving Stellar forward. It’s a powerful incentive for excellence because every employee has a personal stake in our continued success.”

Since its founding, Stellar has not only built a strong foundation through the design and manufacturing of its own equipment but has also grown through strategic acquisitions that have fueled its expansion.

Stellar has strategically acquired other like-minded companies to broaden its product offerings and strengthen its position

within the industry. These acquisitions have allowed Stellar to expand into new markets and further solidify its leadership in the work truck solutions sector.

One of the most significant acquisitions in recent years was the purchase of Elliott Machine Works of Galion, Ohio, another rural American-based company that shares Stellar’s commitment to quality. By bringing Elliott Machine Works into the Stellar portfolio of products, the company added a renowned line of fuel trucks, lube trucks, water trucks, lube skids, vacuum tanks and other mobile service equipment. This acquisition not only expanded Stellar’s reach into new markets but also aligned with its core values of providing reliable, durable equipment that meets the evolving needs of industries across the globe.

Though Stellar’s roots are firmly planted

in the heartland of America, the company’s impact is felt on a global scale. The company was recently recognized with the prestigious E Award for exports, honoring its success in expanding its global footprint.

Stellar’s presence at bauma 2025 in Germany, marking the company’s first appearance at the international exhibition, reflects its growing reach.

Alongside its global growth, Stellar has remained deeply committed to its local community. The company’s foundational values are rooted in the belief that success should benefit not only the business but the area it calls home. Since its 30th anniversary, Stellar has made several significant contributions to the community. These include the donation of a collaborative robot (cobot) to North Iowa Area Community College (NIACC) to enhance its advanced manufacturing program.

In addition, Stellar’s commitment to local youth is evident in the development of the Stellar Sports Complex, a facility that provides opportunities for recreational sports and community engagement. By investing in the development of its local infrastructure, Stellar has helped ensure that its success not only benefits the company but fosters growth, education and opportunity for future generations in Garner and beyond.

As Stellar celebrates this notable anniversary, Zrostlik looks ahead with excitement. “Reaching 35 years is an incredible milestone, but we’re not stopping here,” said Zrostlik. “We’re continuously looking for new challenges and ways to improve. The future is bright, and we’re ready to take on the next problem and find innovative solutions for it.”

For more information, visit stellarindustries.com.

Leer Group recently relaunched and announced nationwide expansion of United States-based production of its SNUGTOP-brand products.

The celebration at LEER’s Elkhart facility marks the full return of United States-based production for SNUGTOP, which manufactures a lineup of more than 400 high-quality truck cap products for a growing number of automotive brands. The production facility also enables SNUGTOP products to be available in all 50 states for the first time, while improving overall lead times,

enhancing product quality and strengthening customer service.

The production facility currently employs approximately 176 people; LEER has added 37 new team members and anticipates adding more than 30 additional jobs during the next 60 days.