Two Decades, $1.4 Billion: Atkinson Completes I-5 Project

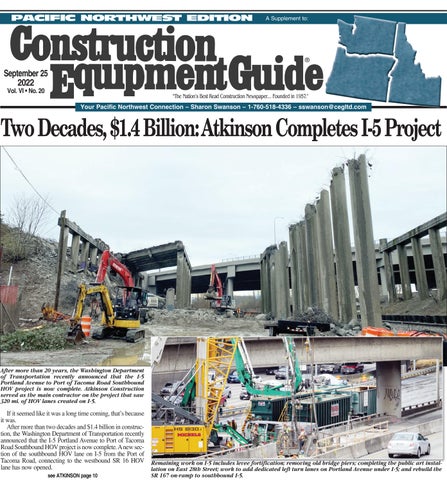

After more than 20 years, the Washington Department of Transportation recently announced that the I-5 Portland Avenue to Port of Tacoma Road Southbound HOV project is now complete. Atkinson Construction served as the main contractor on the project that saw 320 mi. of HOV lanes created on I-5.

If it seemed like it was a long time coming, that’s because it was.After more than two decades and $1.4 billion in construction, the Washington Department of Transportation recently announced that the I-5 Portland Avenue to Port of Tacoma Road Southbound HOV project is now complete. A new section of the southbound HOV lane on I-5 from the Port of Tacoma Road, connecting to the westbound SR 16 HOV has now opened.

PACIFIC NORTHWEST EDITION A Supplement to: Your Pacific Northwest Connection – Sharon Swanson – 1-760-518-4336 – sswanson@cegltd.com “The Nation’s Best Read Construction Newspaper… Founded in 1957.” September 25 2022 Vol. VI • No. 20

lane

Remaining work on I-5 includes levee fortification; removing old bridge piers; completing the public art installation on East 28th Street; work to add dedicated left turn lanes on Portland Avenue under I-5; and rebuild the SR 167 on-ramp to southbound I-5.see ATKINSON page 10

Page 2 • September 25, 2022 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide Our SOLUTIONS ARE MOVINGThePacific North-West Leader In Crane + Rigging Services Since 1947 Celebrating 75 Years Safety Is A Core Value. That’s Why We are industry leaders in crane + rigging • expert Crane operation services • expert rigging services • Specialized Haul + Transport Services • Comprehensive Machinery Moving Services • Engineering + Planning Services • Secured Storage Solutions • 9 Locations Across The North-West In Cran Celebrating Year ne + Rigging ServicesrsSSince 19477 Moving Service ComprehensiveService• Specialized Hau• expert rigging• expert Crane o• esMachineryl+Transport Servicesul + perationservices services SafetySafetyindusndusIs stry leaders in crane + s A CoreIs +WriggingWhyWearese 9 Locations Ac Acr• Secured Stora Storag• Engineering + P• O ross The North-West ge PlanningSolutionsServicesOurSOLUTTIONS ARE MOVIN G mm advances.key os Ctla. Atermat s tomet cn iWhe s amaket drSma elivers0 d1S 1As Xopco’ etails, dyroductivito p encrefffeedii nigsaed ff netniae mlpmis r tetft asuahex r wewor pif ao e,nignl eeseid hd tn. Angised eir wighte, lsize ranr bthem ofro h, tdevelopment hane torr mAfteaye rot flius b’t, iecna ,tsah fti. Wtnemtaer rod feee nht tuohti mf0 c1s 1revilet di r 4eie Tho ts tkna ficientefueld fnt agh tompach a cits wd outandsts10S 1Ae X ontinuousf ce oecada d usatlascopco iveo gd tengineere tlaw Aot hud oFin itpumimuxam dgee ehu tyo res aroducto popcs C .em PacWestMachiner y.com Pasco, WA 1249 North California Ave Pasco, WA 509.547.593399301 Spokane, WA 3515 N. Sullivan Rd Spokane Valley, WA 99216 509.534.5933 Eugene, OR 1550 Irving Rd Eugene, OR 541.302.376297402 Portland, OR 19255 NE Sandy Blvd Portland, OR 503.252.593397230 Mount Vernon, WA 4128 Cedardale Rd Mount Vernon, WA 98274 360.588.3083 Seattle, WA 8207 South 216th St Kent, WA 206.762.593398032

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • September 25, 2022 • Page 3 oMyKomatsu valueDiscoverthe f tabletphone,r ,aterialst mppor orl fatord p youfrommoreandstparerord us ssecc, aselematice tmachin entralizedr couu is ysomaty KM mykomatsu.komatsu www.modernmachinery.com Kent, WA (800) 669-2425 Rochester, WA (800) 304-4421 Spokane, WA (800) 541-0754 Boise, ID (800) 221-5211 Pocatello, ID (800) 829-4450 Billings, MT (800) 735-2589 Columbia Falls, MT (800) 434-4190 Missoula, MT (800) 332-1617 Eugene, OR (800) 826-9811 Portland, OR (800) 950-7779

Richards Transportation Moves Oversized Windmill in Idaho

More than 80 oversized loads departed the Port of Lewiston bound for Canada, a haul trip that will take place over the next 2.5 months, with the first load already transported. Richards Transportation is in the process of delivering windmill blades to Jenner, Alberta, with the largest loads measuring up to 325 ft. long and weighing 137,000 lbs.

“This first load is the only one currently scheduled and will provide an opportunity to refine the transportation plans,” Operations Engineer Jared Hopkins said. “After the initial run, we expect operations to increase in frequency.”

Nine loads will depart each week in groups of three from the Port of Lewiston to travel north on U.S. Highway 95 to Coeur d’Alene before heading east on Interstate 90 into

Montana. Three loads are expected to leave every other day, with each individual load departing roughly 30 minutes apart.Pilot cars will escort each load on the one-night journey, with flaggers in place to close the following intersections:

• State Highway 128 and U.S.-12/US-95 in Lewiston;

• U.S.-95 and Lincoln Avenue/Walnut Way in Coeur d’Alene; and

• I-90 and U.S.-95 interchange in Coeur d’Alene.

The transportation company arranged for a new on-ramp to help oversized loads make the turn from northbound U.S.95 onto eastbound I-90 in Coeur d’Alene. This ramp will not be open for other traffic. Traffic on the interstate will be

slowed down by pilot cars to allow each load to merge.

Given the length of the loads, navigating to and through Moscow will be especially slow-going and will require significant

“Thatclosures.section of U.S.-95 is windy and narrow and the loads will not be able to make those turns without taking up part of the oncoming lane, so we are shutting it down,” Hopkins“Givensaid.the extreme length of these loads and how narrow the highway section is in Moscow, the transport company will move each load at walking pace with staff on the ground to ensure that nothing next to the road is damaged,” Hopkins added.

New $15 Billion Mircon Chipmaking Plant Coming to Boise

BOISE, Idaho (AP) Chipmaker Micron’s planned $15 billion investment in a new factory in the company's hometown of Boise will help protect the United States from the vulnerabilities of a globalized semiconductor market, U.S. Energy Secretary Jennifer Granholm said.

“It is time to get America making things again, with American parts and American labor,” Granholm told a crowd of about 250 guests and Micron workers invited to a tentcovered dirt field for a ceremonial groundbreaking. The event included setting off a ground-clearing explosion far from the crowd that emitted red, white and blue smoke.TheU.S. and Europe are pushing aggressively to build chipmaking capacity and reduce reliance on producers that are now mostly based in Asia. Semiconductor businesses have also been trying to diversify their operations to avoid bottlenecks caused by problems, such as a natural disaster or pandemic lockdown, in a specific region.

Micron officials said that the high desert, sagebrush steppe area east of Boise is expected to have the largest chipmaking cleanroom, or fab, in the U.S. by the end of the decade, covering 600,000 square feet (55,000 square meters) and creating 17,000

jobs. Construction is expected to start in 2023, with some cleanroom working space ready by 2025 and expanding in phases.

Micron is among the nation's largest chipmakers, with product development sites in five other states and eight countries. Research and development is centered in Boise.Sanjay

Mehrotra, Micron’s president and chief executive officer, said the company is committed to investing in the Idaho community _ with an emphasis on STEM (science, technology, engineering, and math) education in both K-12 and higher education. He said the company would focus on reaching underrepresented and rural school populations.Micron

“will inspire young minds to build the STEM skills they need to succeed in our technology-based world,” he said.

In recent years, state Republican lawmakers have caused dismay among Idaho’s business community by launching attacks on public education spending, which succeeded in 2021 with a $2.5 million cut to universities despite a budget surplus.

Micron officials late last year announced plans to build a 500-worker, memory design center in Georgia, partly to take advantage of that area's education system. That sent

tremors through Idaho's business and politicalButlandscape.earlierthis year, lawmakers approved a record $300 million boost to education. And earlier this month, lawmakers added another $410 million from a budget surplus in a legislative special session that was called due to high inflation.

“We really needed this (semiconductor plant) in the U.S. and not overseas,” said Republican state Sen. Scott Grow, who attended the groundbreaking ceremony and has helped push through legislation beneficial to Micron. “To get a big outfit like this, and to get enough workers, we have to do all we can here in Idaho to help provide that kind of education so this can continue to grow, and they don't have to just bring in people from out of state.”

Several chipmakers last year signaled an interest in expanding their American operations if the U.S. government is able to make it easier to build chip plants. Samsung said in November it plans to build a $17 billion factory outside of Austin, Texas, and Intel broke ground last week on a $20 billon new computer chip facility in Ohio.

Micron’s $15 billion investment was made possible by last month’s passage of the CHIPS and Science Act, a $280 billion bill

aimed at bolstering U.S. competitiveness against China and avoiding another chip shortage like the one that derailed the auto and tech industries during the pandemic. The law sets aside $52 billion to bolster the semiconductor industry that, due to COVIDrelated supply chain constraints, has struggled to manufacture the chips.

Besides the CHIPS law, Micron also benefits from property tax breaks in Idaho. And lawmakers earlier this year passed legislation, signed by Republican Gov. Brad Little, that eliminates sales taxes on expensive equipment Micron will have to buy to produce the chips.

Of the 17,000 expected jobs, 2,000 will be employed directly by Micron and 15,000 are expected to come from other companies working in support of the new plant.

LaMarr Barnes, chief executive officer of Tokyo-based Kurita, said this company will bid to help create the supply of ultra-pure water needed for chipmaking. If successful, he expects to hire several hundred workers for the Boise area.

“We’d love to be able to do the work for this new fab, and if we do, we’d have to hire quite a bit of engineering staff,” he said.

Idaho Transportation Department photo Richards Transportation is in the process of delivering windmill blades from Idaho to Canada, with the largest loads measuring up to 325 ft. long and weighing 137,000 lbs.

Page 4 • September 25, 2022 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • September 25, 2022 • Page 5 OREGON Bend/Prineville(541)(503)Portland254-5100Eugene342-7700(541)447-5293 WASHINGTON www.triadmachinery.comSeattle/Tacoma(253)722-5560Spokane(509)534-1900Mt.Vernon(360)488-3948

Komatsu PC230F-11 Tackles Forestry Processing Locations

Forestry crews need equipment that can deliver exceptional performance in difficult environments. Control downtime and drive productivity with the robust, dependable and fuel-efficient Komatsu PC230F-11 processor. Delimb and cut and stack timber with this powerful and maneuverable processor, designed specifically to meet the demands of forestryLargework.treescan be moved more easily due to a powerful swing system and a large swing circle. With reach of up to 29 ft., the maneuverability of the PC230F-11 helps driveDesignedproductivity.witha high and wide undercarriage, powerful swing motor and ability to withstand high-debris conditions, the PC230F-11 is backed by service, easy access to parts and a warranty. Built to tackle demanding forestry processing environments, the PC230F-11 has exceptional reach, a high and wide rugged undercarriage

and a powerful swing system, according to the manufacturer.

Quick specs for the PC230F-11

• Net horsepower: 197 hp (147kW) @ 2,050 rpm

• Operating weight: 67,516 lbs.

• Swing torque: 58,334 ft.-lbs.

Engineered for High-Debris Environments

When operators are working in highdebris conditions, the robust wide-fin radiator is protected by heavy-duty forestry screens and a variable pitch reversing fan helps improve airflow.

Offering excellent ground clearance, the PC230F-11, provides reliable maneuverability in tough forestry environments due to a high and wide undercarriage designed with larger class-size components.

Operators can adjust quickly to a sudden

change in load weight without losing productivity with the Auto Power Max feature. It automatically senses the difference and reacts with a seven-second burst of additional horsepower to help pull the trees through, during the delimbing process.

Operator Comfort Supports Productivity

To reduce operator fatigue, the PC230F11 provides a quiet, comfortable work environment. Cabs are climate-controlled and equipped with Bluetooth technology. The cushioned air-suspension seat can be heated or Ancooled.extra-rugged exterior protects against falling limbs with a 1.26 in.-thick polycarbonate front window and metal designed to withstand demanding environments. The PC230F-11 features heavy-duty service undercover guards and rear compartment doors, and a right corner guard with a stan-

dard tree deflector.

Less Refueling

The Komatsu SAA6D107E-3 Tier IV Final engine is more fuel efficient than the prior Tier IV interim engines. Due to proprietary Komatsu engine technology, the larger size-class (PC290LL-11) factory-installed engine also powers performance.

Operators can spend more time on the job and less time refueling with the additional fuel storage on the PC230F-11. The tank is in the rear of the carrier and built into the counterweight, delivering double the fuel capacity. Because the fuel tank was moved to the rear, there is a large tool storage area on the side for the operator to store an extra 5-gal. bucket of oil, extra chains and other tools.For more information, visit www.komatsu.com.

Large trees can be moved more easily due to a powerful swing system and a large swing circle. With reach of up to 29 ft., the maneuverability of the PC230F-11 helps drive productivity.

Page 6 • September 25, 2022 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • September 25, 2022 • Page 7 PacWestMachiner y.com Pasco, WA 1249 North California Ave Pasco, WA 509.547.593399301 Spokane, WA 3515 N. Sullivan Rd Spokane Valley, WA 99216 509.534.5933 Eugene, OR 1550 Irving Rd Eugene, OR 541.302.376297402 Portland, OR 19255 NE Sandy Blvd Portland, OR 503.252.593397230 Mount Vernon, WA 4128 Cedardale Rd Mount Vernon, WA 98274 360.588.3083 Seattle, WA 8207 South 216th St Kent, WA 206.762.593398032

Lakeside Industries Performs Emergency Pavement Project

After a spring and summer of slowdowns, lane closures and bumpy roads, the Northwest Region Emergency Pavement Repair project is under way in King, Snohomish, Skagit and Whatcom counties.

The $7 million effort began in January with Gov. Jay Inslee’s Emergency Proclamation during a winter of heavy snow and cold that damaged miles of infrastructure.This project, awarded to Lakeside Industries, encompasses more than 80 work sites on three interstates, 12 state highways and four bridge decks for a total of approximately 20 mi. of pavement repair.

While some of the work will involve daytime lane reductions, Washington State Department of Transportation Project Engineer James Harper said the bulk of the repairs have been scheduled for low-travel times.“We don’t want to add more inconvenience to drivers who have spent the last several months navigating these rough patches of road,” Harper said. “We’re especially sensitive to folks who are planning to travel.”

Interstate 90 North Bend Repair

This project will repair some of the roughest areas left over from a record-setting win-

ter. That includes a quarter-mile long stretch of westbound I-90 that has been stripped of drivable surface between Exits 31 and 32 in North Bend, resulting in a right lane closure since January. The work on I-90 is expected to be completed by end of September.

The damage is the result of the cold, wet winter weather and extra wear-and-tear from slowing traffic in snowy conditions. That

combination created perfect conditions for what are known as frost heaves that heavily damaged the road surface.

WSDOT maintenance crews determined the level of deterioration in North Bend required more than a patch job — it needed a full re-construction. That means grinding off the layer of damaged pavement and laying down a fresh surface of hot mix asphalt

— which dries very quickly but can’t be applied during wet weather.

“The extra rainy spring pushed back our ability to fix a lot of these problems,” said Harper. “That and the size of this fix meant a longer timeline.” Once the project is finished, travelers will enjoy a smoother ride for years to come. The contractor aims to complete construction by April 2023.

Lakeside Industries photo

The $7 million effort began in January with Gov. Jay Inslee’s Emergency Proclamation during a winter of heavy snow and cold that damaged miles of infrastructure.

Lakeside Industries photo

The $7 million effort began in January with Gov. Jay Inslee’s Emergency Proclamation during a winter of heavy snow and cold that damaged miles of infrastructure.

Page 8 • September 25, 2022 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide ZEROHARRMLOGGING G DCFOM e they arModern Machiner RYYEQUIPMENT.COMRES RYY..COMODERN MA or DC Equipment/e Dealer fexclusiv CHINERY TR FALCON WINCH ASSIST FALCON GRAPPLE CLAW

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • September 25, 2022 • Page 9 columbiawesternmachinery.com 11125 SW Tonquin Road Sherwood, Oregon 97140 (503)-454-0902 Email us - sales@columbiawesternmachinery.com

Contractor Builds 320 Mi. of HOV Lanes to Transform I-5

include many other improvements:

“After 15 years of construction, this final Tacoma/Pierce County HOV Program project will complete HOV connectivity from SR 16 south of Tacoma to downtown Seattle,” Atkinson Construction said in a statement.

The latest milestone concludes of a series of projects that are part of the Tacoma/Pierce County HOV Program that builds 320 mi. of HOV lanes on I-5, SR 16 and SR 167 in Pierce County, approximately 35 mi. south of Seattle.

Atkinson Construction, based out of Renton, Wash., served as the general contractor for the massive project, a subsidiary of Maryland-based Clark Construction. Over the course of 22 years, numerous other construction companies had a hand in building the project. They included Bechtel, Hamilton Construction, Jacobs, Kiewit Pacific, Max J. Kuney Company, Mowat Construction, Skanska USA, Scarsella Bros., Tri-State Construction, Woodworth and Company and WSP USA.

Crews punched the final checklist by restriping southbound I-5 from the King County line to the Port of Tacoma Road to finish opening the new southbound lane. Remaining items for Atkinson include levee protection along the Puyallup River; removing old I-5 bridge piers; rebuilding the SR 167 on-ramp to southbound I-5 and adding dedicated left turn lanes on Portland Avenue under I-5.

New East L Street Bridge Opens

As part of this project, crews replaced the East L Street bridge spanning I-5. The new bridge has wider lanes, wider sidewalks and has dedicated bike lanes in each direction. The East L Street bridge was removed and replaced to accommodate I-5 widening beneath it.

Another highlight of the overall I-5 project was replacing the more than 60-year-old I-5 Puyallup River Bridge with a new bridge built to current seismic standards that is straighter and wider. Work on this $325 million section began in 2019. The southbound bridge included a 223-ft. girder that is the longest prestressed girder manufactured in the United States. In all, the bridge consists of nine spans and 84 girders.

In addition to new HOV lanes, these projects

In addition to new HOV lanes, these projects included many other improvements such as safety (additional merge lanes, wider shoulders, improved ramp alignments, curves and improved lighting); traffic and operations (improved mobility due to additional capacity, better roadway alignments and the relocation of onramps and exits); environment (noise barriers at select locations to minimize traffic noise, enhance or expand nearby wetlands and improved methods to treat storm water runoff); and an intelligent transportation system (ITS).

• Safety: Additional merge lanes, wider shoulders, improved ramp alignments and curves and improved lighting;•

Traffic and Operations: Improved mobility due to additional capacity, better roadway alignments and the relocation of on-ramps and exits;

• Environment: Noise barriers at select locations to minimize traffic noise, enhance or expand nearby wetlands and improved methods to treat storm water runoff;

• Intelligent Transportation System (ITS): New closed-circuit traffic cameras, more electronic signs for traveler notifications, highway advisory radio broadcast trans-

see ATKINSON page 14

ProjectTimelineConstruction

February 2019

WSDOT executed a contract with Guy F. Atkinson Construction/Jacobs Engineering. Construction began.

April 2019

Construction crews removed the East L Street overpass to allow Interstate 5 to be widened.

February 2020

The first 54 bridge girders were installed on six of the nine bridge spans on the new southbound I-5 Puyallup River Bridge.

January 2021

Crews installed the final 30 bridge girders on the last three spans of the new bridge

June 2021

First travel lane opens on new southbound I-5 Puyallup River Bridge

December 2021

Fifteen girders on the East L Street bridge installed over I-5.

April 2022

All southbound I-5 travel lanes moved to new southbound I-5 Puyallup River Bridge.

June 2022

Northbound I-5 from SR 16 to Port of Tacoma Road is moved to final alignment. New general purpose lane opens.

August 2022

New HOV lanes open.

Atkinson Construction, along with the Washington Department of Transportation, recently completed the bulk of construction work for the $1.4 billion HOV project in Tacoma, Wash.

ATKINSON

Part of this project included the building of a new southbound I-5 Puyallup River Bridge.

Page 10 • September 25, 2022 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

from page 1

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • September 25, 2022 • Page 11 DREAMDOER’STHESeetheHyundaidifferenceyourselfatyourlocaldealerorhceamericas.com. To learn more about the what the new Hyundai A-Series machines can offer your business, contact your Hyundai dealer today. ©2022 Hyundai Construction Equipment Americas. All Rights Reserved. Loved for the features. Trusted for the performance. Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without feeling like it. OAK HARBOR (360) 675-4441 MARYSVILLE (360) 651-9079 WENATCHEE (509) 888-8181 (800) OFFICE@JETCITYEQUIPMENT.COM292-4441

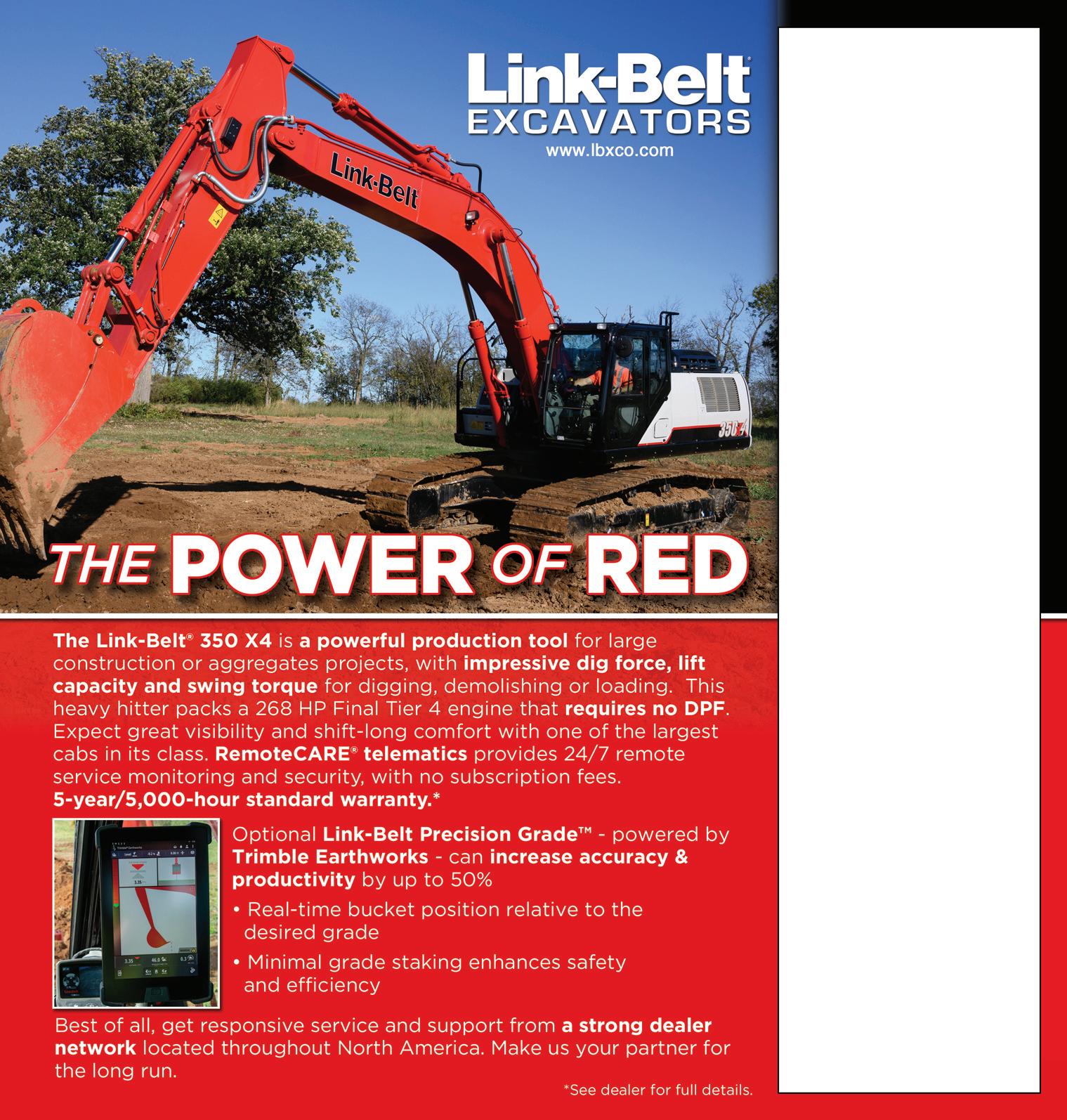

Volvo CE’s New L200H Extends Log-Handling Abilities

Volvo Construction Equipment has launched the new L200H High Lift wheel loader in North America, featuring a 27 percent increase in lifting capacity and a 13 percent larger grapple than the L180H model it replaces.

This, combined with a stronger base unit, means the L200H High Lift can handle more timber per hour, upping productivity and driving down operating costs, according to theAmanufacturer.newloading unit features a reinforced lift arm system, cross beam and rotator unit. This increases the machine’s maximum lifting capacity from 19,401 lbs. on the L180H High Lift to 24,600 lbs. Grapples come in a range of shapes and sizes to suit site requirements with Volvo design that embodies half a century of high lift know-how.

To accommodate this extra capacity and ensure the stability of the loader, larger 875-type low-profile L4 tires come standard.“Volvo CE introduced the world’s first high lift wheel loader in 1974, and with the L200, we’re continuing our tradition of producing high-performing, low TCO machines,” said Stephen Roy, president, Region Americas, Volvo CE. “We’re really proud of this purpose-built design.”

Chip Off Old Block

With the ability to stack logs to almost 23 ft. high — 60 percent higher than a conventional wheel loader — the Volvo High Lift arm design makes the most of timber yard storage capacity. The L200H High Lift makes it easy to reach any log on the stack due to 360-degree rotation and the ability to tilt.

The new, stronger rotator unit is maintenance-free and features an integrated dampening system that also improves stability.

Driveline That Takes Pressure Off

The L200H High Lift also is light on its feet, is able to

travel over rough terrains at speed, can work comfortably on uneven ground and exerts minimal stress on paved surfaces. That’s because of its four-wide tires and articulated steering. These capabilities simplify site preparation and keep site maintenance costs manageable, according to the manufacturer.Anew

external axle oil cooling system reduces the temperature of the axles, which in turn increases their lifetime and that of the brakes. It also includes an oil filter that keeps the axle oil clean for longer, increasing the oil change interval to 4,000 hours (or 18 months).

Gear shifting has been optimized to suit the new increased workloads, resulting in fast acceleration and smooth operation. Proven technologies such as OptiShift, which integrates the Reverse-By-Braking function and torque converter with lock-up, further support fuel efficiency.

Technology Where It Matters

The L200H High Lift is the first high-lift variant to be compatible with Load Assist, Volvo’s suite of apps that is accessed from the in-cab Co-Pilot display and designed to enhance productivity and profitability.

The On-Board Weighing app provides real-time insights into the grapple’s payload to help eliminate overloading, underloading, reweighing and wait times. The Operator Coaching Advanced app helps operators use the loader to its full potential by providing real-time information and guidance.Load Assist also includes a tire pressure monitoring system, which provides the ability to check the pressure and temperature of air-inflated and hydro-inflated tires from the comfort of the cab. Considering that the correct tire pressure can cut fuel consumption by 2 to 4 percent, and add 6 to 10 percent to tire life, this is a valuable cost-saving tool.

Nice Place to Spend Day

Volvo CE cabs are known for their spacious design, ergonomic layout and outstanding visibility. The L200H High Lift even comes with a choice of seats. A specially designed multi-function lever ensures precise control of the hydraulics, and operators can personalize settings from their smartphones.Toreduce

operator fatigue and improve productivity, the optional Comfort Drive Control gives operators the opportunity to steer the machine using a lever instead of the steering wheel — particularly effective for fast-paced truck unloading.And

because operators must be constantly aware of what’s happening around their machines, a new optional front-view camera provides additional visibility at the front of the machine and even on top of the stack, with the view displayed on a dedicated in-cab monitor.

Downtime Down, Service Simplified

Long service life, reduced maintenance requirements, straightforward access to service points and a range of complementary services all help keep maintenance costs down and uptime to a maximum. Like its predecessor, the L200H High Lift is easy to service — its cab can be tilted to 30 degrees or 70 degrees. Combined with an electronically operated engine hood, this makes gaining access to work on the machine

Inspectingstraightforward.andcleaningthe engine compartment also is easier, due to additional handrails on both sides of the machine. Thousand-hour engine service intervals and quick drain/fill connectors make changing the hydraulic oil, transmission oil, engine oil and front axle oil fast and easy.

For more information, us/products/wheel-loaders/l200hhl/.https://www.volvoce.com/united-states/en-visit

Volvo CE has built upon its L180H High Lift wheel loader design to create the all-new L200H High Lift, featuring more lifting power and larger capacity grapples.

Page 12 • September 25, 2022 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • September 25, 2022 • Page 13 EASYDURABLETOUSE DOUBLE HIGHOSCILLATIONDRUM&FREQUENCY www.sakaiamerica.com (800) 323-0535 Roads must be built. Worlds must be connected. www.jetcityequipment.com 33345 SR 20 Oak Harbor, WA 360-675-4441 Marysville, WA 360-651-9079 Wenatchee, WA 509-888-8181 columbiawesternmachinery.com 11125 SW Tonquin Road • Sherwood, Oregon 97140 503-454-0902 Email us - sales@columbiawesternmachinery.com

Years-Long Project Will Improve Tacoma Highway System

mitters and traffic data collectors. Each of these tools helps WSDOT better manage traffic and improve communication with the traveling public.

Previous Phases of Project

Construction activities for this massive project have ramped up over the last three years. Since 2019, aside from the addition of HOV lanes, crews have completed the following:

• Built a new southbound I-5 Puyallup River Bridge;

• Removed all but a few remaining pieces of the old northbound and southbound I-5 Puyallup River Bridge;

• Widened I-5;

• Replaced the East L Street Bridge;

• Added new auxiliary lanes;

• Installed enhanced lighting, stormwater collection

and filtration improvements; and

• Replaced aging pavement.

About Project

This project is part of the Tacoma/Pierce County HOV Program, a series of highway projects to provide operational improvements and high-occupancy-vehicle (HOV) lanes on Interstate 5, State Route 16 and State Route 167. Through Tacoma, heavy I-5 traffic creates frequent congestion. HOV lanes will help ensure that transit, vanpools and carpools move efficiently through the corridor, especially when traffic is congested in the adjacent generalpurpose lanes. This reliability tends to increase ridership in multi-passenger vehicles and thereby helps ease demand in the general-purpose lanes, making the overall highway system work better for everyone.

(All photos courtesy of Washington Department of Transportation.)

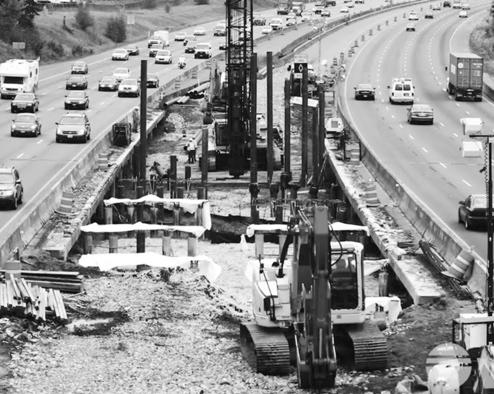

Crews installed the longest single-piece, prestressed concrete girder manufactured in the U.S., coming in at a length of 223 ft., according to Concrete Products.

Part of the I-5 widening included building a new southbound I-5 Puyallup River Bridge and removing the old I-5 Puyallup River Bridge.

Crews have been ramping up construction activities on this project since 2019 when they removed the East L Street overpass.

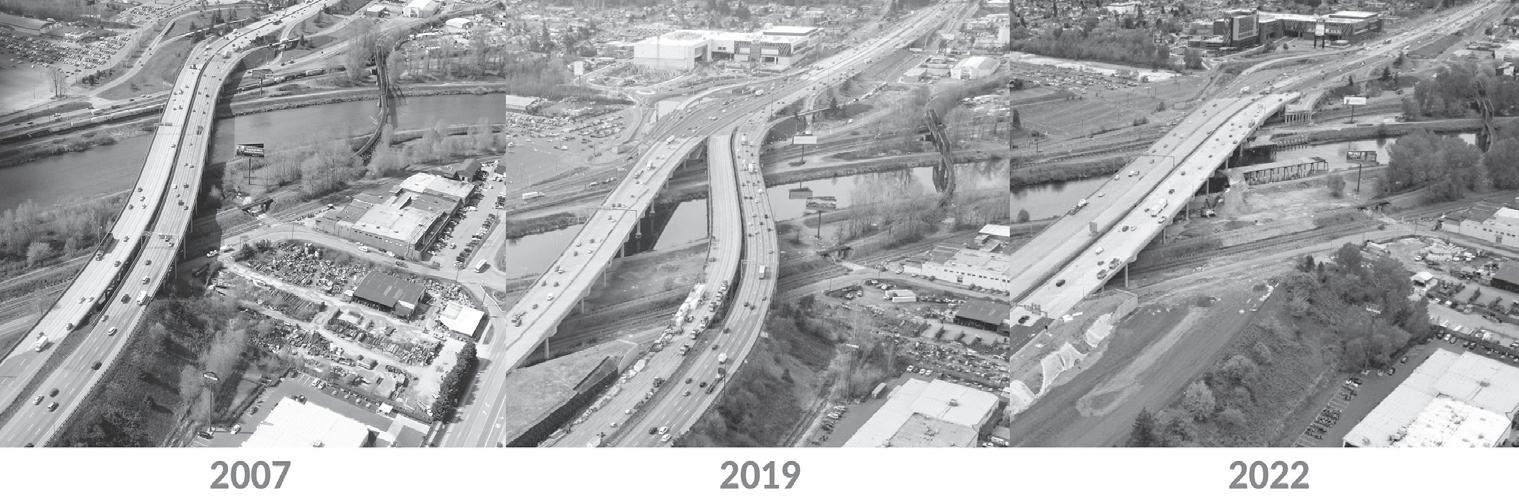

An aerial view of the timeline of construction for the I-5 HOV project over the years.

ATKINSON from

Page 14 • September 25, 2022 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

page 10

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • September 25, 2022 • Page 15 PACIFIC NORTHWESTERN PUBLISHING Issue# Closing Publishing 22 October 12 October 23 24 November 9 November 20 26 December 7 December 18

Page 16 • September 25, 2022 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide BU Di ILD gMo MOR re. E O MORE. R EXPECTMOREFROMYOUREXC TOR.CAVAT ea areexcavatorsKOBELCO, ache eone dort mgeoe tmad d KOBELCO -USA.COM 18060 Des Moines Memorial Dr. Seattle, WA 98148 3909 NW Fruit Valley Rd Vancouver, WA 98660