By Larry Bernstein CEG CORRESPONDENT

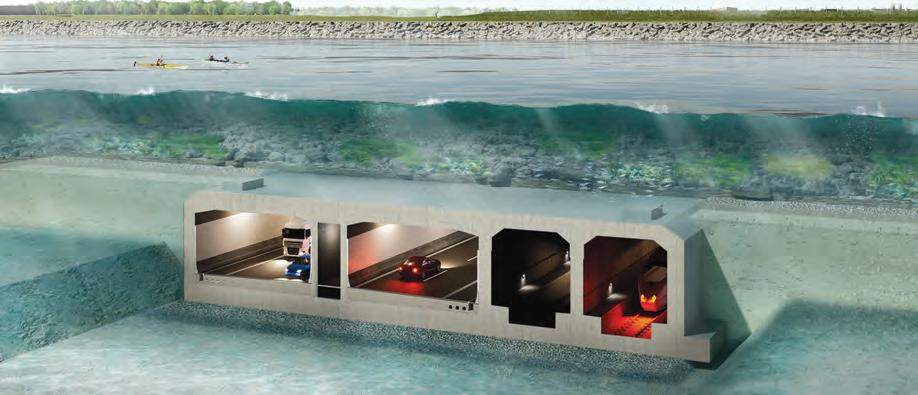

Travel between countries in Europe is like traveling between American states. Yet, some

connections are not so simple. Hence, the Fehmarnbelt tunnel, which will connect Germany to Denmark. Upon completion, the 18km (11.2 mi.) long tunnel will be the world’s longest immersed tunnel connecting the northern

By Lucy Perry CEG CORRESPONDENT

The trucking industry is overjoyed congressional transportation committee members have recognized the safety needs of truckers. Legislation was introduced this winter to

German island of Fehmarn and the south Danish island of Lolland. The tunnel will be a game changer in terms of traveling within the European Union, and its complex construction is

see TUNNEL page 94

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a problem.

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

8 ENGINEERS HARD AT WORK BEHIND SCENES TO REBUILD KEY BRIDGE

Overseeing all of it is James Harkness, chief engineer of the Maryland Transportation Authority (MDTA), who has been thrust into the largest project in the department’s history.

Mr. Elliott built a successful half-century career running Elliott & Frantz Inc., a heavy construction equipment dealership based in King of Prussia, Pa., founded by his father.

14 LONG BRIDGE

LONG BRIDGE SOUTH PROJECT

The project will help the Commonwealth of Virginia to modernize critical infrastructure to meet the needs of growing communities and industries.

16

ANNOUNCE

This collaboration aims to enhance the range of specialized equipment available to customers across West Virginia, Marietta, Ohio, Ashland, Ky., and Pikeville, Ky.

18 SPECIALTY RENTALS AND ATTACHMENTS CELEBRATES 25TH ANNIVERSARY

As Specialty Rentals and Attachments celebrates its 25th anniversary in 2025, the Hammonton, N.J.-based company is reflecting on its journey, growth and the values that have fueled its success.

Specializing in the restoration and certification of damaged cabs on heavy-duty machinery, Mano Engineering provides OSHA-compliant solutions that help businesses meet regulatory standards while maintaining operational safety.

24 WORLD OF ASPHALT 2025 DRAWS HEFTY CROWD IN ST. LOUIS

The World of Asphalt Show & Conference and AGG1 Academy and Expo visited St. Louis, Mo., for the first time, drawing more than 11,500 industry professionals between March 25-27, 2025.

Once called the Bergen-Passaic-Delaware Expressway, Interstate 80 in northern New Jersey was a $387 million mash-up of projects built more than 50 years ago.

The USDOT funding will go toward a transformational modernization of the area to provide safer and more inviting features for pedestrians and bicyclists traveling through the fast-growing Jersey City neighborhoods adjacent to the corridor.

36

JUST 42 CAPITAL PROJECTS

Officials announced that the city is saving 50 years of project time and $1.4 billion on just 42 current capital projects that are using the design-build method of contracting.

38 MECALAC SHOWCASES NEW REVOTRUCK SERIES DUMPERS AT NDA

The National Demolition Association (NDA) recently held its annual conference and event in New Orleans, attracting more than 1,300 demolition professionals. Attendees also engaged in informative meetings with industry vendors.

98 LIEBHERR APPOINTS NEW MANAGING DIRECTOR OF LIEBHERR USA CO.

Liebherr has appointed Hirohito Imakoji as managing director of Liebherr USA Co., a mixed sales organization supporting 10 product segments throughout the United States.

INNOVATION AT CONEXPO-CON/AGG ’26

Following the success of 2023’s event, showcasing the event’s significance as North America’s largest construction trade show, ConExpo-Con/AGG returns to the Las Vegas Convention Center on March 3-7, 2026.

ROKBAK MODEL RA30 OFF ROAD TRUCK: 30 TON CAPACITY WITH TAIL GATE, 276HP SCANIA ENGINE. AVAILABLE FOR SALE OR RENT! +N5027........................................................................ OFF RENT - CALL FOR SPECIAL PRICING!

NEW ASV RS75 WHEEL SKID STEER: OPEN ROPS, SUSPENSION SEAT, 74" BUCKET, 21.3 GPM, ELECTRIC PLUG ON BOOM FOR ATTACHMENTS, MAX CAB, UNIT# N4200......CALL FOR PRICE

ANACONDA DF410 SCALPING SCREEN: 2 DECK TRACKED SCREENING PLANT WITH LOW HOURS, UNIT# AG1381........................................................................................CALL FOR PRICE

ANACONDA TR75 TRACKED CONVEYOR: 42” X 75’ CONVEYOR, IT ALLOWS FOR STOCKPILING OR FEEDING OF A RANGE OF APPLICATIONS. THE TR75 HAS A VARIABLE SPEED CONVEYOR IN ORDER TO FACILITATE FOR DIFFERENT APPLICATIONS SUCH AS SAND, GRAVEL, AGGREGATES, COMPOST, COAL AND WOOD CHIP. WE STOCK A FULL RANGE OF SPARE PARTS AS A DISPLAY OF OUR COMMITMENT TO PROVIDE A DEDICATED AND RESPONSIVE SERVICE TO ALL OUR CUSTOMERS........................................................................................CALL FOR PRICE

ANACONDA FTR150 UNIT AG1353: MID SIZE FEED LOADER RANGE. FULLY EQUIPPED WITH 50' STOCKPILING CONVEYORALLOWS DFOR STOCKPILING OR FEEDINGA WIDE RANGE OF APPLICATIONS. INCLUDES OPTIONAL 2 DECK VIBRATING GRID......................CALL FOR PRICE

ASV MODEL RT50, ENCLOSED CAB WITH HEAT & AC, 15” RUBBER TRACKS, VERY LOW GROUND PRESSURE, AUXILIARY HYDRAULICS................................................CALL FOR PRICE

ASV MODEL RT50: ALL WEATHER CAB WITH HEAT AND AC, SUSPENSION SEAT, 15” RUBBER TRACKS, 60” BUCKET WITH BOLT ON EDGE, UNIVERSAL SKID STEER COUPLER, YANMAR TURBO DIESEL ENGINE, BLOCK HEATER, ATTACHMENT CONTROL KIT, REAR VIEW CAMERA, APPROXIMATELY 300 HRS, UNIT# 4310............................................................CALL FOR PRICE

SIMEX PLC-24 24" WIDE COLD PLANER WITH REVERSIBLE DISCHARGE CONVEYOR: CUTTS UP TO 7" DEEP, 16 DEGREE TILT, 27-40GPM DISSCHARGE CONVEYOR HELPS LEAVE A CLEANER CUT, WINDROWS MATERIAL BEYOND THE CARRIER FOR EASIER CLEAN UP, UNIT# AT4540......

$25,400

2020 BOBCAT T740: WITH CAB, HEAT & AIR EXCELLENT CONDITION, 1600 HOURS, HYDRAULIC COUPLER, 2 SPEED......................................................................................

$39,500

KOBELCO SK350LC-10, APPPROXIMATELY 2400 HOURS, 31.5” TRACK SHOES, 10’10” ARM, 2 WAY AUXILLIARY HYDRAULICS, HAND CONTROL PATTERN CHANGER, HEATED AIR RIDE SEAT, VERY GOOD CONDITION........................................................................................$183,000

AG1359, ANACONDA J12 JAW CRUSHER: IS AN AGGRESSIVE & POWERFUL MOBILE JAW CRUSHER. WITH THE PROVEN ABILITY OF THE UNIVERSAL CRUSHERS JAW CHAMBER 28" X 44" WITHIN AN INNOVATIVE ANACONDA TRACKED SOLUTION........................CALL FOR PRICE

BOMAG BW120AD-5: FOLDING ROPS, 47.2” WIDE

6063LBS. OPERATING WEIGHT, KUBOTA 33HP DIESEL, FRONT & REAR VIBRATORY, 3780 VPM, .020 IN AMPLITUDE, UNIT# N4537....................................$48,734 BOMAG BW120SL-5: FOLDING ROPS, 47.2” WIDE DRUMS, 5511LBS. OPERATING WEIGHT, KUBOTA 24.8HP DIESEL, FRONT & REAR VIBRATORY, 4320 VPM, .020 IN AMPLITUDE, UNIT# N4538..$45,995

MODEL ST1000 COLD PLANER/SOIL MIXER: 40” MILLING WIDTH, 9” MILLING & MIXING DEPTH. REQUIRES HIGH FLOW MINIMUM 33GPM. THREE LINE SYSTEM W/REMOTE. HYD. SIDE SHIFT & TILT, STABILIZATION FLUID/BINDING INJECTION PORTS. EXTREME DUTY.

As you read these words, the new Francis Scott Key Bridge is being built.

Not out on the Patapsco River, where vestiges of the old structure linger as a quiet reminder of its demise one year ago in the early morning hours of March 26, 2024, but in conference rooms and with computer models within task forces assigned to niche parts of its construction.

Overseeing all of it is James Harkness, chief engineer of the Maryland Transportation Authority (MDTA), who has been thrust into the largest project in the department’s history.

Before construction crews can get to work on the new span and its roadways, officials must expedite a design process that roughly 150 engineers will work on during any given week, the Baltimore Banner reported March 26, 2025.

The engineers’ local headquarters is an office building in an Anne Arundel County business park.

Designing and building a structure requires a series of problemsolving exercises. Engineers get in a room to discuss options, advantages, disadvantages over and over again. With an expansive team — specialists are based in at least seven states, as well as Europe, the MDTA said — each person brings a specific level of bridge-building experience to the table.

“That’s the part I enjoy, seeing that come together,” said Harkness in a recent interview with the Banner.

In March 2024, a 100,000-ton cargo ship, the Dali, lost power and plowed into a crucial support pier of the Key Bridge. The span’s swift collapse killed six construction workers and blocked the shipping channel to the Port of Baltimore for months.

But even as massive chunks of bridge debris remained in the water, rebuilding efforts began.

Typically, constructing a new bridge of this scale would require years of preparation. For instance, from contemplation to completion, building a new Harry W. Nice Memorial Bridge over the Potomac River took 16 years, while a potential replacement for

the Chesapeake Bay Bridge has been studied for years and is likely still at least a decade away from being finished.

The Key Bridge is expected to be completed in 4.5 years, or by the fall of 2028. Its estimated price tag — which, at up to $1.9 billion, is three times that of the smaller Nice Bridge — will be federally funded.

The speedy and massive undertaking is costlier than anything the MDTA has previously built and is the largest project of Harkness’ career.

The son of an architect, Harkness grew up in Philadelphia, Pa., had an early interest in math and physics and studied civil engineering at Penn State University. He later worked in the private sector in Baltimore before becoming the city’s traffic engineer, where he has been tasked with analyzing and improving Baltimore’s network of roads.

“I gravitated toward that public side just because I really liked the idea of how transportation projects benefit so many people,” he said.

The city manages some smaller bridges and, once Harkness joined the state transportation authority in 2014, he assisted with major projects, including the construction of the Nice Bridge.

But few engineers have worked on an emergency response — and accelerated construction — like what is needed for the Key Bridge.

And within minutes of the Dali

container vessel striking the Key Bridge, Harkness was notified.

His regular commute from his Carroll County home to the MDTA’s engineering offices in Dundalk regularly took him over the Key Bridge.

Many times, too, it provided him with a memorable morning vista.

“About this time of year, the 7 a.m. sunrise over [the] Tradepoint Atlantic area used to be one of my favorite views,” he said.

Port Authority officials plan for emergency scenarios with tabletop exercises, but the magnitude of the bridge strike was not something they had prepared for, he said.

The search-and-rescue efforts and the lengthy process to collect bridge pieces from the Patapsco River began immediately. There were also risk assessments to be made, such as ensuring that the remaining structures were not at peril of falling.

In a matter of weeks, though, the MDTA also had to produce a budget and preliminary timeline for the replacement structure, according to the Baltimore Banner.

Never did authority officials consider the possibility of not rebuilding the span, they said, a pledge that was also made by thenPresident Joe Biden, Gov. Wes

Moore and other elected officials.

As the owner, the MDTA is responsible for the bridge rebuilding effort and, ultimately, it contracted with a team of several companies, led by the national construction giant Kiewit, to take on the project. Some of those engineers work remotely and visit Maryland occasionally, but others were required to relocate to Baltimore.

As predicted by experts, the authority opted for a cable-stayed bridge, a type of span that has grown in popularity over the past three decades due to its affordability and how quickly it can be constructed. Towering pylons will be built with cables fixed to them; those cables, in turn, support the roadway.

The structure’s main span — which determines how far the bridge’s two piers are from shipping traffic — will be more than 3,300 ft. in length, making it one of the longest in the United States when completed.

There is an “honor and privilege” for engineers in building a bridge of this size, said Habib Tabatabai, a structural engineer at the University of Wisconsin at Milwaukee who has studied cablestayed spans.

“It is not a trivial project at all by any means,” he told the Banner. “It

is a significant structure.”

Preconstruction activities, such as soil analysis, began earlier this year, and information gleaned through that process will inform Harkness and the small army of engineers as they continue designing the new structure. For example, designers still have not finalized the type of pier protection the new bridge will utilize.

Meanwhile, Harkness is the chief engineer for the entire MDTA — not solely the Key Bridge — so he has other responsibilities. About two-thirds of his day-to-day work, however, is focused on the bridge rebuild, he said.

And much of it revolves around computer models.

“Engineers love models. We have models for everything,” he explained. “If we can model it, we’re going to try and [do so].”

Primarily, that calls for computer programs, but it also requires some physical structures such as a several-foot-long prototype of a bridge segment that has been tested in a Canadian wind tunnel. That is just one tiny component of the rebuild, though. To make their goals manageable, engineers have been assigned to a variety of task forces, each focused on a single segment of the project.

“It’s like the old joke, ‘How do you eat an elephant?’” Harkness said. “’One bite at a time.’”

New Model TAG25-32, 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Red and Black In stock

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. 3-axles air lift 3rd, 4-axles air lift 3rd & 4th, Black & Red........IN STOCK!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black or Red Paint........IN STOCK!

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

Rogers 35 Ton Gentle Riser, 24' deck, adjustable width bi-fold ramps, 275's on Aluminum, Extra lights and strobes, Rogers Green......IN STOCK!

Rogers Red................ IN STOCK!

Rogers 55 Ton, No-Foot, 25' deck, deep well pocket, depressed cross members, adjustable width bi-fold ramps. reinforced wheel covers, reinforced front slope & side rails. Safety Lighting Package, Strobes, 275's on Alum. outers, Air Lift 3rd. All Wheel ABS. Rogers Red and Black........ IN STOCK

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black or Red Paint, 24’ deck + 6’ tail, 8’ Air Ramps.................. IN STOCK!

James “Jim” Elliott passed away at the age of 78 after a courageous seven-year battle with amyotrophic lateral sclerosis (ALS).

Born on March 15, 1947, in Philadelphia, Mr. Elliott was raised in Haverford, Pa., and remained close to his roots throughout his life. He was the eldest son of Catherine O’Malley Elliott and Jumbo Elliott, the renowned Villanova track coach.

Mr. Elliott attended St. Aloysius and Malvern Prep for his schooling and went on to Villanova University, where he ran track and captained the golf team. After graduation, he built a successful half-century career running Elliott & Frantz Inc., a heavy construction equipment dealership based in King of Prussia, Pa., founded by his father. A well-known figure in the industry, Mr. Elliott will be remembered for his oldschool values and work ethic, his keen abil-

ity to inspire greatness in his colleagues and the pride he took in his family’s business.

Mr. Elliott is survived by his wife of 39 years, Carolyn (Carr); his three children Michael (Diana Gragg), Matthew (Bonnie Tsui) and Catherine (Christopher) Travaglini; his five grandchildren Zachary, Katelyn, Felix, Theodore and Claire. He considered his family his greatest accomplishment.

A lifelong golfer and student of the game, Mr. Elliott was most at home on the driving range spending hours helping others improve their swing, whether they wanted his advice or not. He loved his work, his faithful dog, Buddy, giving putts, eating York peppermint patties, nicknaming his friends and coaching, especially at the Academy of Notre Dame (Villanova) where he served as the girls’ golf coach. He was a passionate supporter of Villanova basket-

ball, Philadelphia sports and his children’s and grandchildren’s sporting events.

Mr. Elliott’s service was held March 29, 2025, at St. Thomas of Villanova Church on campus, 800 E Lancaster Ave., in Villanova, Pa.

The family said they owe a debt of gratitude to Massachusetts General Hospital and his ALS team of medical professionals, all of whom became part of the Elliott family. In lieu of flowers, donations can be sent in Mr. Elliott’s honor to the Healey & AMG Center at MGH for the Jim and Carolyn Elliott Fund for ALS Research. These can be made online at giving.massgeneral.org/donate/healey-center/ or by check to the MGH Jim and Carolyn Elliott Fund for ALS Research and sent to: Emily Monteiro, Mass General Hospital, Development Office Suite 540, 125 Nashua St., Boston, MA 02113-1101

James “Jim” Elliott passed away at the age of 78 after a courageous seven-year battle with amyotrophic lateral sclerosis (ALS).

Long Bridge Rail Partners (LBRP) — a joint venture of Trumbull Corp.; Fay, S&B USA Construction (Fay); and Wagman Heavy Civil Inc. — announced their selection by the Virginia Passenger Rail Authority (VPRA) as the design-build contractor for a key component of the Long Bridge Project to provide increased capacity for passenger rail over the Potomac River between Washington, D.C., and Arlington, Va.

The project will help the Commonwealth of Virginia to modernize critical infrastructure to meet the needs of growing communities and industries.

LBRP was selected to deliver the South Package of Virginia’s $2.3 billion Long Bridge Project, which includes construction of a new two-track railroad bridge and an adjacent bicyclepedestrian bridge over the George Washington Memorial Parkway and Potomac River. The work site will be upstream of the existing Long Bridge, spanning from south of the Jefferson Memorial by Ohio Drive SW to Arlington County south of the George Washington Memorial Parkway.

At completion, the two new tracks will enable separation of passenger and freight rail traffic across four tracks to enhance transportation connectivity and efficiency in the region. The new infrastructure will benefit Amtrak travelers from Boston to Miami and regional commuters using the Virginia Railway Express.

Additionally, the bicycle-pedestrian crossing will connect regional residents and visitors from the Jefferson Memorial and East Potomac Park to the Mount Vernon Trail and other northern Virginia amenities. Following design of the new bridges, heavy

construction on the South Package is expected to begin in the fall of 2026 and estimated for substantial completion in 2030.

The lead designer on this project is STV, a leading professional services firm that plans, designs and manages infrastructure projects across North America.

“The LBRP team is committed to delivering this cornerstone project of regional infrastructure improvements to enable expansion of Virginia rail service to meet future demand,” said Mark Gentile, president of Trumbull Corp.

“With more than 75 years of heavy civil construction experience and extensive design-build expertise in bridges, rail projects and other complex infrastructure, Fay brings innovative solutions for design, efficient construction and safety that will help LBRP deliver this transformational project on time and on budget for the VPRA,” added Ryan Surrena, president of Fay.

“Wagman relishes the opportunity to partner in the delivery of this generational project,” said Greg Andricos, president and COO of Wagman Heavy Civil Inc.

For more information, visit www.trumbullcorp.com, www.shikunusa.com and www.wagman.com.

(Photos courtesy of Virginia Passenger Rail Authority.)

•

Leslie Equipment Company announced a new partnership with KEMROC, a manufacturer of excavator attachments. This collaboration aims to enhance the range of specialized equipment available to customers across West Virginia, Marietta, Ohio, Ashland, Ky., and Pikeville, Ky.

KEMROC is known for its excavator attachments designed for applications such as demolition, trenching, mining, tunneling and soil mixing. Its commitment to engineering excellence aligns seamlessly with Leslie Equipment’s dedication to providing top-tier machinery and support to its clientele, according to the companies.

By integrating KEMROC’s attachments into the company’s inventory, Leslie Equipment continues its tradition of offering solutions tailored to the evolving needs of the construction industry. Customers can now access a broader selection of equipment designed to improve efficiency and performance on demanding job sites, according to the company.

By Craig Mongeau EDITOR IN CHIEF

As Specialty Rentals and Attachments celebrates its 25th anniversary in 2025, the Hammonton, N.J.-based company is reflecting on its journey, growth and the values that have fueled its success.

Before founding Specialty Rentals, Bob Harrell gained valuable experience in the heavy equipment sector. Straight out of college, Harrell began his career in a parts department at an equipment dealership and would eventually work in multiple roles at multiple companies, spending time as a sales manager at several dealers across New Jersey.

While working in these roles, Harrell noticed a gap in the market. Contractors, who only needed specialized attachments for short-term projects, were often left with no option but to either buy expensive equipment or work without the right tools. He saw an opportunity: contractors needed access to high-quality, specialized attachments without the hefty investment, and there wasn’t a reliable solution in place. This realization would lead him to take a leap of faith and found Specialty Rentals and Attachments in 2000.

The business began in Winslow, N.J., where Harrell started with a modest fleet of rental attachments sourced from various dealers. But as the business grew and its reputation spread, so did the need for more space and a larger operation. In 2010,

Specialty Rentals moved to a new larger facility in Hammonton, N.J. Today, the business operates on seven acres of land, with a 3,000 sq.-ft. office and four service bays.

From the start, Specialty Rentals set itself apart by offering a unique service — renting heavy equipment attachments alongside the machinery itself. Unlike traditional dealers who focused on selling equipment, Specialty Rentals understood that many contractors only needed machinery for short-term projects. Harrell’s decision to provide both machines and attachments for rental proved to be a game-changer. Today, the company offers a wide range of equipment rentals, from 16,000-lb. excavators to 180,000-lb. machines, available with more than 125 different attachments.

Specialty Rentals carries attachments from leading manufacturers such as Genesis, Rammer, Fecon, Kenco and many others. These attachments are all new, ensuring that contractors have access to top-tier equipment that meets the highest standards of quality, according to the company. Specialty Rentals also offers used equipment and attachment packages for customers who decide to purchase after renting.

What truly sets Specialty Rentals apart, however, is its unwavering commitment to customer service, according to the company. Approximately 85 percent of the company’s business comes from rentals, but what keeps customers coming back is the service they receive.

“We treat every customer with respect, providing fast, reliable solutions whenever issues arise,” said Bobby Harrell, the company’s vice president and Bob’s son. “Whether it’s a minor maintenance issue or a more significant breakdown, Specialty Rentals is known for its quick response times, often dispatching our technicians

within the hour to minimize downtime.

“Our reputation is everything,” he added. “We have customers who keep coming back because they know we’re going to take care of them … no games, just honest, hard work.”

The company maintains a fleet of service trucks, along with a team of skilled technicians, welders and fabricators who work hard to keep equipment in top condition. The company also has the ability to customize attachments for specific job sites, ensuring that every customer gets exactly what they need.

For Bobby Harrell, the story of Specialty Rentals is not just about business; it’s a story about family. Bobby has been with the company for nearly 15 years, learning from his father every step of the way. In particular, Bobby admires his father’s reputation and integrity.

“There’s not a single person out there who has a negative thing to say about him,” Bobby said. “He’s been in this business for 40 years, and he knows when to take risks and when to play it safe. He’s built this business on honesty, and I try to do the same.”

Bob’s approach to business has not only helped the company grow but also cultivated a strong team. Several employees, including one technician who has been with the company since day one, have remained loyal to Specialty Rentals for over two decades. This low turnover rate has been crucial in maintaining the quality of service the company is known for.

As Specialty Rentals and Attachments enters its 25th year, the future is bright. The company continues to grow, serving customers up and down the East Coast and across the country from Maine to Florida to Texas, and even internationally in places like the Bahamas and Bermuda.. The goal remains the same: to provide the best equipment and the best service possible to every customer.

But even as the company looks to the future, it doesn’t forget its roots.

“We just want to thank all of our customers for their loyalty over the last 25 years,” said Bobby. “Without them, we wouldn’t have a business. And we’re grateful to have such a great team of employees who’ve been with us for so long.”

All photos courtesy of Specialty Rentals and Attachments.

In industries where heavy equipment is essential, safety remains the top priority. Mano Engineering, in collaboration with Hurst and Henrichs MN Ltd. Structural Engineers, is at the forefront of ensuring the protection of machine operators through its Rollover Protective Structure (ROPS) and Falling Object Protective Structure (FOPS) re-certification services.

Specializing in the restoration and certification of damaged cabs on heavy-duty machinery, the company provides OSHAcompliant solutions that help businesses meet regulatory standards while maintaining operational safety.

Mano Engineering has successfully recertified equipment from leading manufacturers such as Caterpillar, Komatsu and John Deere. Its expertise and commitment to safety ensure that equipment operators remain protected from the risks associated with rollovers and falling objects, according to the company.

Replacing an entire cab can be an expensive and time-consuming process, often leading to significant equipment downtime. Re-certification is a much better way to restore structural integrity while keeping costs low and minimizing disruption to operations. Mano Engineering’s streamlined process ensures that businesses can maintain safety standards without the burden of full cab replacement.

Before and after pictures of a cab that was repaired and re-certified.

According to Mano Engineering, it follows a meticulous, fourstep process to ensure that each ROPS and FOPS system meets stringent safety regulations. These include:

• Pre-Check Evaluation — The process begins with a thorough initial assessment. Clients are required to submit images of the unit that needs re-certification. A highly experienced structural engineer carefully reviews the images to determine if re-certification is viable. If the unit is deemed repairable, the process moves to the next stage.

• Onsite Collaboration and Repairs — Once the unit is approved for re-certification, the Mano Engineering team schedules an onsite visit. Certified welding professionals conduct necessary repairs under close supervision, ensuring that all work adheres to OSHA and industry safety standards. Throughout this stage, the team provides real-time photo updates to the structural engineer for continuous monitoring.

• Engineer’s Approval and Final Inspection — Following the completion of repairs, the structural engineer rigorously evaluates the updated photos and repair work. If additional reinforcements are required, recommendations are provided to further enhance the structure’s integrity. Only after a comprehensive review does the engineer formally approve the repairs.

• Issuance of Certification and Compliance Placard — Upon final approval, the equipment receives an official metal compliance placard, signifying that it meets all required safety standards. In addition, a professional safety certificate is issued by a registered engineer, providing clients with documented proof of compliance for regulatory and operational purposes.

Understanding the urgency of equipment downtime, Mano Engineering offers express solutions, including next-day service options for clients who need rapid certification. Their mobile capabilities allow them to bring expert-level re-certification directly to job sites.

“Our process is designed to be as seamless and efficient as possible, ensuring that our clients receive safe, compliant and fully certified equipment in the shortest time frame possible,” said Dan Eldredge, sales manager of Mano Engineering. “We take pride in providing comprehensive safety solutions that allow businesses to maintain productivity without compromising on protection.”

According to the company, Mano Engineering’s reputation for delivering reliable, high-quality re-certifications has made it a trusted name in the industry. Its partnership with Hurst and Henrichs — a company with 25 years of experience — further reinforces its commitment to structural integrity and operator safety.

For companies in need of fast, onsite ROPS and FOPS re-certification, Mano Engineering offers a process backed by years of expertise and industry compliance.

For more information, contact Dan Eldredge: dan@manoengineering.com or 651/271-7747; Giridhar Addagudi, CEO: giridhar@manoengineering.com or 952/210-7209; and Prahasith (PK), engineer/inspector: pengineering@manoengineering.com or 682/386-1014.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

The World of Asphalt Show & Conference and AGG1 Academy and Expo visited St. Louis, Mo., for the first time, drawing more than 11,500 industry professionals between March 25-27, 2025.

The event, which was held at America’s Center Convention Complex, featured a record of more than 230,000 sq. ft. of display space, giving 430 asphalt industry

At the Astec Industries booth, (L-R) are Marc-André Séguin of Pavages Maska of Quebec, Canada; Eric Couture of Pavages Maska; and Maxime Petrin of Montreal Tracteur of Quebec, Canada, stand in front of the Roadtec RX-405 cold planer, which features an operator camera awareness system with a 360-degree operator view.

manufacturers a chance to display equipment and tout their services.

“This success is a direct result of the collaboration and hard work of all our partners, exhibitors, and staff,” said Brittany Schmidtke, World of Asphalt show director. “The momentum and growth in the asphalt and aggregates industry is evident by what we saw exhibited on the show floor

and ultimately provided a richer experience for our attendees.”

Fifty-nine percent of the attendees were under age 45, and 10 percent were women. Visitors traveled from across the country and abroad, some traveling as far as Australia, England, Argentina, Mexico and Nigeria.

Attendees engaged in more than 120 educational sessions

through the People, Plants and Paving and AGG1 Academy. These conferences covered a range of topics essential to the asphalt and aggregates industries.

A few of the most popular sessions included “Lean Principles: It’s About People, Process and Change,” “Unleashing the Power of Intentional Leadership: Leading Yourself to Lead Others,” “Autonomous Quarry Trucks

(L-R): Donny Nash and Jack Guebard of Road Widener of Floyds Knobs, Ind., describe the EZ Grader road widener to Andrew Molina of Bee Equipment Sales in Lubbock, Texas, and Pat Slattery of ROMCO Equipment Co. of Houston, Texas.

101,” “Extreme Ownership for Business and Life,”

“Laydown Best Practices” and “Compaction 101: Doing the Right Things, the Right Way.”

Running concurrently with AGG1 was the NSSGA annual convention, which featured the announcement of the 2025 NSSGA leadership, including board chair Ted Baker II of Blue Water Industries, and the presentation of the Barry K.

The annual membership meeting keynote was a moderated discussion by football legend Archie Manning. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.) see WOA page 44

used PA140

Just in for Teardown, TL1225D

ML701857 telehandler, Machine had 3800 hours when torn down

Once called the Bergen-Passaic-Delaware Expressway, Interstate 80 in northern New Jersey was a $387 million mash-up of projects built more than 50 years ago.

Today, one is not working out well.

In early February 2025, a sinkhole 11 ft. in diameter opened up along the eastbound lanes just west of the interstate’s New Jersey Highway 15 overpass near Wharton. After the collapse, New Jersey Department of Transportation (NJDOT) officials said they found 90 spots to check for possible instability or voids in the area.

Weeks later, an even larger sinkhole opened there, leading to the full closure of the highway, NorthJersey.com reported March 24, 2025. State officials still do not know, or will not say, what exactly has caused the sinkholes. The extent of the problem is unclear, as is a lasting solution.

The I-80 stretch from Denville to Roxbury was built generally to parallel U.S. Highway 46 through north Jersey as part of the Interstate Highway System, conceived in the mid-1950s. The idea was to use the federal program and its dollars to carry U.S. 46’s traffic through Dover, Wharton and other “bottleneck areas,” the Paterson Evening News reported in August 1959.

The section appropriately started where U.S. 46 narrows from four lanes to two heading west.

S.J. Groves and Sons of Woodbridge built the stretch from Mount Hope Road to N.J. 15 for $5.5 million in time for the highway’s opening in the fall of 1959, according to a report from the Paterson newspaper at the time.

One year later, the 3.7-mi. section of I-80, where the 2025’s sinkholes have appeared, running from N.J. 15 to Howard Boulevard, was opened to traffic. The state’s Highway Department awarded that $6.7 million contract to George M. Brewster & Son of Bogota, then Bergen County’s largest road contractor and a key builder of the New Jersey Turnpike.

It appears the sinkhole problem, however, may have far more to do with how and where the highway was built than by whom, noted NorthJersey.com. Decades before the construction, Wharton was an iron mining town and its mine district follows a linear trajectory cutting northeast from Mine Hill to Mount Hope.

Dozens of mines were dug throughout the area. Some were short-lived and never amounted to much. Others cut more than 1,000 ft. into the fault-laden ground in search of iron-bearing magnetite amid belts of dense gneiss.

New Jersey’s iron mines may be long

NJDOT photo

In early February 2025, a sinkhole 11 ft. in diameter opened up along the eastbound lanes just west of the interstate’s New Jersey Highway 15 overpass near Wharton.

Roads and buildings also have been constructed on or near these sites, adding to the risk.

closed, but development in the northern part of the state continues to run up against the effects of past mining, noted the 2024 New Jersey State Hazard Mitigation Plan.

Subsidence remains a concern, as some abandoned mine locations and their associated shafts, openings and entrances are mapped inaccurately, the state said. Others have been improperly filled and capped, a situation potentially made worse by the considerable seismic activity in the Tewksbury area last year.

Replogle Steel Co., and old U.S. Geological Survey records placed the mine’s primary shaft in that general area, with under workings to the southwest and northeast that are hundreds of feet underneath the highway down to below sea level.

NorthJersey.com learned from 1958 survey reports conducted before the freeway was built that most of the ore was extracted northeast of the shaft before it closed in 1896, and the shaft itself had “caved” by the time I-80 was constructed through Wharton.

DEP officials have marked the modern geographic information system maps “authoritative,” but metadata warnings have said that the map last updated in December 2023 is not verified by DEP officials and is it not authorized or endorsed by the state, the online news source reported.

Beyond the accuracy of even modern maps, none are thought to include all the shaft openings, test pits, entrances and even entire mines that were constructed during New Jersey’s history as a mining hotspot prior to westward expansion.

Mines are scattered throughout north Jersey’s Highlands, but records — especially those predating the mid-19th century — are often unreliable, said Alexander Gates, a Rutgers-Newark geologist.

Gates said he has not studied Interstate 80’s sinkholes specifically but believes the region’s mining history is a likely factor.

Towns and oversight officials may have required mapping, but early shafts were lit by candles, and compasses were mostly useless due to magnetite in the rock. As a result, mine tunnels may not run in the expected directions, and older shafts could be closer to the surface than previously thought, Gates said.

“Miners followed the veins,” he added.

Northern New Jersey’s rock is particularly hard, but if a mine shaft is near the surface, constant vibration from traffic could trigger a collapse, according to Gates.

Roads and buildings also have been constructed on or near these sites, adding to the risk, the 2024 plan noted.

The New Jersey Department of Environmental Protection’s (DEP’s) GPSbased mapping system pinpoints the location of the Mount Pleasant Mine as south of I-80 and west of N.J. 15, or directly under the Avalon Wharton housing complex, which lies just to the south of the sinkhole zone.

A 101-year-old map, complete with underground mapping from the local

Officials at the DEP would not comment on the highway sinkholes’ possible connection to the area’s mines and directed questions to NJDOT, which also declined to answer inquiries about the sinkholes’ suspected cause, whether it be from a mine collapse, construction flaws, or a combination of those and other factors.

In the past, officials with the state Geological and Water Survey, a division of the New Jersey DEP, have said the area’s

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS........................................$88,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXTENDAHOE, TOOL CARRIER..................................................................................$32,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXT HOE, TOOL CARRIER, TURF TIRES, BHOT SET TO CAT......................................$29,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE.... $99,995

CHIPPERS:

EXCAVATORS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................................

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER........................................................................................

$105,000

$149,995

2019 KOBELCO SK140RLC, 2192 HRS, CAB, HVAC, HYD THUMB, FRONT BLADE, RUBBER TRACK PADS......................................................

$109,995

2023 KOBELCO SK140RLC-7, 288 HRS, CAB, HVAC, BLADE, THUMB, COUPLER........................................................................................

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED........................................................................................

$169,995

$169,995

$295,000

SKID STEER LOADERS:

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD COUPLER, 78” BKT, BACKUP CAMERA................$69,000

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS..................................$45,000

2021 NEW HOLLAND C332 TRACK SKID STEER, 787 HRS, CAB HVAC, PILOT CONTROL, 2 SPEED, HIGH FLOW, BLOCK HEATER............$47,5000

TRACTORS:

2012 CASE MAX110, CAB, HVAC, 6380 HRS, 4WD, LOADER, 3PT HITCH, 3 SETS REAR REMOTS, AG TIRES......................................................$42,000

$29,995

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..........................................

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH..........................................................................$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP......................................................................................................$64,995

SCREENERS:

2021 VIBROSCREEN

VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE................................................................................$195,000 NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........$179,995

2015 KUBOTA KX080-4, CAB, HVAC, HYD THUMB, STEEL TRACKS W/RUBBER PADS..........................................................................................

MISCELLANEOUS:

$55,000

AFE ROTARY FORESTRY HEAD, SKID STEER MOUNT $17,995

$19,995

2003 TEREX HR16 MINI EXCAVATOR, CAB, HEAT, 3253 HRS, HYD THUMB, RUBBER TRACKS, 4 TON..................................................................

2018 YANMAR VI080-1A, CAB, HVAC, 1351 HRS, THUMB, RUBBER TRACKS............................................................................................

$59,995

HLA 96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT. HEAPED$3000 KUBOTA KX080 EXCAVATOR TO SKID STEER COUPLER ADAPTOR $3,199 48” REVERSE LUG GRADING BUCKET, FITS KUBOTA 57&55, NEW CONDITION..........................................................................................

WHEEL LOADERS:

2022 AVANT 528LX, 40 HRS, CAB W/HEAT, 51” BUCKET, 43” ROTARY BROOM, LIKE NEW CONDITION........................................................$46,995

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER........ $39,995

2000 NEW HOLLAND LW80, CAB W/HEAT, 10,000 HRS, COUPLER BKT AND FORKS, PERKINS DIESEL ENGINE, WAS NURSERY MACHINE $24,995

2007 Noram 65ET ##135-00182, A/C cab, Front Scarifier, 10ft blade, Cummins Turbo engine, PS Trans., 6F/R, limited Slip rear Diff., 4X6 drive.. Asking: $87,000

2017 Weiler P385B #RM555-2372, 1,670 hours, asphalt paver Cat C3.4 engine, 8ft 2in x 15ft 6in electronic screed.............. Asking: $125,000

2023 AMMANN ARX26.1, #165-05121, 52.0 hours, 7,672 lbs., 47.2in Dbl. drum, Kubota engine........ Asking: $35,000

(Rochester), New

Fax: 585-924-7624 Email: tdelany@americanequipmentllc.com 585-924-5480 ext. 520 www.americanequipmentllc.com

The Port Authority of New York and New Jersey (PANYNJ) announced Jan. 13 that it had received a $25 million grant through the U.S Department of Transportation’s American Infrastructure with Sustainability and Equity (RAISE) program to transform the 12th Street corridor on the New Jersey side of the Holland Tunnel.

The USDOT funding will go toward a transformational modernization of the area to provide safer and more inviting features for pedestrians and bicyclists traveling through the fast-growing Jersey City neighborhoods adjacent to the corridor, while also improving vehicle travel times in the corridor and likely reducing traffic accidents by more than half.

The new design seeks to balance the needs of drivers using the tunnel with those of nearby communities and residents looking to access schools, workplaces, mass transit and housing in the area, according to a news release by PANYNJ.

In addition, the transformation project aims to bring together an area undergoing significant housing development and growth, but which is currently divided by the roadway serving as the New Jersey entrance to the Holland Tunnel. Officials hope that the more inclusive and safer design will further drive Jersey City’s economic vitality, inviting more business opportunities while significantly improving safety and air quality through the corridor.

“Ensuring that our residents are able to get from place to place safely and efficiently is critical to the success of our entire region,” said New Jersey Gov. Phil Murphy. “This project will not only enhance safety for the residents of Jersey City but will also improve the quality of life for all New Jerseyans traveling through the Holland Tunnel.”

The current 80-ft.-to-90-ft. crosswalks across 12th Street can be difficult to safely navigate for pedestrians, particularly children and the elderly, PANYNJ acknowledged. The lengthy crosswalks also necessitate longer red-light cycles to allow pedestrians enough time to cross safely.

By modifying the roadway, the bistate agency will reduce the length of crosswalks to enhance pedestrian safety and, in turn, allow for improved vehicle travel times with shorter red-light periods at each of the corridor’s four intersections.

The revamped roadway design and multimodal improvements are expected to cut all crashes by at least 60 percent in the corridor.

Additionally, the revamped roadway design and multimodal improvements are expected to cut all crashes by at least 60 percent in the corridor, with a projected 82 percent reduction in collisions involving pedestrians and a 78 percent reduction in accidents involving bicyclists.

Furthermore, PANYNJ’s enhancements are anticipated to decrease fatal crash rates in the corridor below the averages for the state and within Hudson County. Likewise, the rate of accidents involving injuries also is

rowed roadway will be repurposed for the benefit of the area’s growing number of pedestrians and bicyclists, with an overarching goal of improving safety, quality of life and community connectivity.

PANYNJ noted that community benefits of the project align with the agency’s goals of transforming its legacy infrastructure to incorporate more shared use of spaces whenever possible, such as the additions of biking infrastructure and amenities at the World Trade Center campus, the Midtown Bus Terminal, the Goethals, Bayonne and George Washington bridges, and at LaGuardia Airport.

The new design seeks to balance the needs of drivers using the tunnel with those of nearby communities and residents looking to access schools and more.

In his remarks, PANYNJ Executive Director Rick Cotton said, “This project reflects the Port Authority’s focus on delivering forward-thinking infrastructure that prioritizes both efficiency and environmental sustainability. By reimagining the 12th Street corridor, we’re enhancing safety and mobility while fostering economic growth and a stronger sense of community in a rapidly growing area.”

The new 12th Street design in Jersey City calls for modifying the current roadway width from Jersey Avenue to Marin Boulevard to reflect the reduction from six lanes to four lanes that was implemented in 2020 to better align vehicles as they approach the tunnel’s tolling gantries.

expected to drop substantially below the county’s average and will be near the statewide average.

Smoother traffic flow will likely have a multitude of positive effects for the surrounding community, too, including improved air quality.

Traffic modeling suggests reduced vehicle idling time will decrease the 12th Street corridor’s annual greenhouse gas emissions by at least 70 metric tons per year and will save drivers 6,300 hours per year.

The Port Authority believes improved infrastructure for pedestrians and bicyclists will also encourage more travelers to utilize sustainable modes of transportation when moving through the neighborhood and encourage new development that is less reliant on automobiles.

Remaining space from the newly nar-

Other 12th Street improvements include:

• Wider sidewalks, curb extensions and bump-outs with ADA compliance to help ease pedestrian navigation and provide drivers with better visibility and sightlines.

• A new two-way bike lane along 12th Street, separated from the roadway, which connects to the Jersey City waterfront, along with new north-south bike paths that will provide a critical connection to the city’s planned bike lane network.

• New energy-efficient LED light fixtures.

• Nature-based stormwater management solutions such as porous pavement and rain gardens to mitigate flooding and reduce untreated sewage runoff into the Hudson River by up to 1.2 million gal. per year.

• New landscaping, trees and vegetation to beautify the area, with plant selections aimed at improving air quality and reducing noise.

• Improved technology to detect and intercept oversized vehicles, as well as cars and trucks carrying hazardous materials before they can cause delays and/or damage around the tunnel portal.

“I am proud to have helped secure funding for this transformational project that will directly benefit Jersey City families, commuters, and small businesses,” said New Jersey U.S. Rep. Rob Menendez, D-8th

District. “With this $25 million grant, we are not only creating a safer travel experience for cyclists and pedestrians, [but] we are also prioritizing sustainability and improving the surrounding community as a whole.

“I’m grateful to the Department of Transportation for their commitment to our shared vision for our district and we will always work to tackle the urgent transportation and infrastructure needs of our community.”

The Port Authority plans to conduct targeted outreach during the design process for the new 12th Street corridor in Jersey City, including input from community-based organizations, local government representatives, small business and local economic development organizations, and environmental sustainability groups, to ensure they have a role in shaping the appearance of their community.

The design process is expected to be finalized in 2028, with construction anticipated to be complete by 2031.

Construction activity associated with the effort also will continue PANYNJ’s industry-leading commitments around partnering with minority, women-owned, disadvantaged and service-disabled veteran-owned (MWSDBE and SDVOB) businesses on agency projects.

All contracts issued by the agency have goals of 20 percent MBE and 10 percent WBE participation, in addition to 3 percent SDVOB, commensurate on the availability of firms.

The Port Authority of New York and New Jersey is a bi-state agency that builds, operates and maintains many of the most important transportation and trade infrastructure assets in the country. For over a century, the agency’s network of major airports; critical bridges, tunnels, and bus terminals; a commuter rail line; and the busiest seaport on the East Coast has been among the most vital in the country — transporting hundreds of millions of people and moving essential goods into and out of the region.

The agency’s historic $37 billion, 10-year capital plan includes unprecedented transformation of the region’s three major airports — LaGuardia, Newark Liberty and JFK — as well as an array of other new and upgraded assets, including the $2 billion renovation of the 93-year-old George Washington Bridge.

Its annual budget of $9.4 billion includes no tax revenue from the states of New York or New Jersey, or from the city of New York.

Deputy Mayor of Operations, Meera Joshi and Commissioner Thomas Foley of the NYC Department of Design and Construction (DDC) announced that the city is saving 50 years of project time and $1.4 billion on just 42 current capital projects that are using the design-build method of contracting.

The projects, including at DDC, the New York City Housing Authority (NYCHA), and New York City Health and Hospitals (H+H), are on track to be completed more than two years faster and with anticipated 10 percent cost savings compared to projects using the traditional system of lowest bidder contracting. The announcement coincides with the release of the Design-Build Program 2024 progress report to the New York State Legislature, tracking progress in the city’s growing design-build program.

Joshi and Foley joined the NYC Department of Social Services (DSS) on Feb. 18, at the $128 million Brownsville Multi-Service Center at 444 Thomas S. Boyland St. in Brooklyn to celebrate the completion of the building’s concrete superstructure, which was built in just seven months using design-build. DDC is managing the project for DSS and anticipates delivering the entire center at least two years faster than would be possible with lowest bidder contracting and with cost savings of at least $12 million for taxpayers.

“Today’s major construction milestone at Brownsville Multi-Service Center demonstrates that with the right tools, announcing a project and waiting years to see progress can be a thing of the past,” said Joshi. “Designbuild is already showing tremendous potential, shaving decades off capital projects at NYC DDC, NYCHA and NYC H+H — and avoiding millions in unnecessary costs. Building on this success, our Capital Process Reform Task Force is advocating for Albany legislators to expand alternative delivery to increase the impact, translating these results to more project types — saving taxpayer dollars and delivering for New Yorkers.”

“We are introducing a new era of city project delivery. Design-build is speeding up projects, reducing delays, saving money and delivering important capital projects faster than we’ve ever been able to before outside of emergency situations,” said Foley, who last month was named chair of the National Board of Directors of the Design-Build Institute of America (DBIA). “We said for years that design-build and other forms of contracting outside of the lowest bidder system were the best ways to improve capital project delivery and it’s proving true. This shows that we can also use other alternate contracting methods such as CM-Build and progressive design-build responsibly and effectively.”

“New York City’s commitment to designbuild is transforming how public projects are delivered, demonstrating the immense benefits of collaboration, efficiency and innovation,” said Lisa Washington, CAE, CEO and

executive director of the DBIA. “The NYC Department of Design and Construction has been a national leader in advancing DesignBuild Done Right, and under Commissioner Foley’s leadership — both at DDC and as

DBIA’s national board chair — design-build continues to prove its value in saving time and taxpayer dollars. DBIA is proud to support these efforts and advocate for even see NYC page 78

Following demolition of a former community center on the site, work on the concrete superstructure for the new $128

Brownsville Multi-Service Center in Brooklyn began in July 2024 and was completed in seven months using design-build.

MAINE Heavy Machines, Inc.

www.heavymachinesllc.com

SKOWHEGAN (207) 858-0051

MASSACHUSETTS

Quality Fleet Service

SOUTH PORTLAND (207) 550-0014

www.qualityfleetservice.com

EVERETT BROCKTON

(888) 267-3857

SOUTH HADLEY (413) 213-0632

(833) 444-6373

MARYLAND Liebherr r Equipment Source

www.liebherr.com

BALLTTIMORE (410) 379-3994

NEW JERSEY GT Mid Atlantic, LLC. wwwgtmidatlanticcom

TOTOWA (973) 785-4900

VINELAND (856) 697-1414

NEW YORK

Tracey Road Equipment, Inc.

www.traceyroad.com

ALBANY (518) 438-1100

KIRKWOOD (607)7755010

HENRIETTTA A (585) 334-5120

QUEENSBURY (518) 793-9688

PENNSYLVLVVAANIA RECO Equipment, Inc. www.recoequip.com

CRANBERRY TWP (724) 779-4646

(315) 788-0200

SYRACUSE (315) 437-1471 ADAMS CENTER FREEHOLD (732) 780-4600 (607) 775-5010

Tracey Road Equipment, Inc.

MARCY (315) 765 8746 www.traceyroad.com

WILKES-BARRE (607) 775-5010

VIRGINIA Liebherr r Equipment Source www.liebherr.com

MANASSAS (703) 392-0111

NEWPORT NEWS (757) 240-4250

iebherr USA, Co. offers a materialhandlingequipm

n extensive line of earthm entandtechnologyinth

oving and eUSAMain c o p d c R in material handling equipment and technology in th components are developed and manufactured in-h or in close collaboration with our partners to ensu possible quality standards.These components inc drive and controltechnology, diesel engines, and a components for hydraulics, gearboxes and electro Reach out to your local Liebherr distribution partne nformation.

e USA Main ouse by Liebherr re the highest lude the entire variety of nic systems. rfor more

The National Demolition Association (NDA) recently held its annual conference and event in New Orleans, attracting more than 1,300 demolition professionals. Attendees engaged in informative meetings with industry vendors and had the opportunity to test their equipment operating skills in the live demolition area.

Mecalac, a manufacturer of construction equipment headquartered in France, capitalized on the show’s demolition

area to introduce its new Revotruck Series dumpers to the U.S. market.

The Revotruck Series dumpers feature a unique new design that combines the revolution of the cab with off-road truck capabilities. For the first time, operators can rotate the entire cab of the site dumpers at the touch of a button, allowing them to maintain their vision and focus on the job while avoiding obstacles on the construction site, according to Mecalac.

The exclusive chassis, which features central oscillation and four-wheel steering, provides stability and traction even under the most severe ground conditions. With Revotruck, material transport is smarter and safer than ever, said Mecalac. The trucks are available in six-ton and nine-ton payload capacities.

According to the U.S. general manager of Mecalac North America, Peter Bigwood, the introduction of the Revotruck Series at the National Demolition Show marks a significant milestone in the company’s expansion into the U.S. market.

This is not the first time that Mecalac has showcased its equipment at the NDA show. At previous expos and this year’s NDA show, Mecalac has demonstrated the Mecalac 6MCR, a skid steer excavator hybrid. The boom of the 6MCR features a unique configuration, allowing the excavator skid steer hybrid to access low clearance areas that would have been impossible with traditional machines. Demolition contractors have noted Mecalac’s ability to handle tasks that

larger machines could not, such as material removal in confined spaces.

Bigwood said that attendees of the show were “very impressed with the rotating cab feature of the Revotruck. Attendees commented that the improved safety, visibility and ease of operation were unique to anything they had seen in the market previously and offered significant advantages to demolition contractors.”

CEG

(All photos courtesy of Mecalac.)

Pages 39-55

JCB continues to invest in American infrastructure and innovation with the introduction of the CT380 and CT430 vibratory tandem rollers at Pave-X 2025.

Designed to meet the demands of U.S. paving professionals, these high-performance machines represent JCB’s dedication to delivering robust, dependable solutions for asphalt paving and site preparation, the company said.

“Our new rollers underscore JCB’s long-term investment in North America,” said James Gill, JCB product manager. “From our new manufacturing facility going up in San Antonio to the launch of products like the CT380 and CT430, we are laser-focused on meeting the needs of U.S. contractors with machines that are reliable, easy to operate and built to perform.”

With the addition of the CT380 and CT430, JCB has expanded its tandem roller lineup to four models, providing versatile options to match the diverse needs of American job sites. The lineup, which also includes the compact CT160 and mid-size CT260, ensures that contractors have the right tools for any paving or compaction task, whether working on tight urban spaces or large-scale infrastructure projects.

The CT380 and CT430 are equipped with features to tackle the toughest jobs, offering reliable compaction and operator-focused design, with:

• Versatile Compaction Power: Dual-drum widths of 51 in. (CT380) and 55 in. (CT430) deliver centrifugal forces of up to 13,800 lbs. and 14,600 lbs. per drum, ensuring superior com-

With the addition of the CT380 and CT430, JCB has expanded its tandem roller lineup to four models, providing versatile options to match the diverse needs of American job sites.

paction.

• Efficient Operation: Both models feature maximum travel speeds of 6.2 mph, enabling swift, efficient movement across work sites.

• Exceptional Maneuverability:

With a ±34-degree steering angle and ±13-degree oscillation angle, the rollers navigate tight turns and uneven terrain with ease.

• Operator-Centric Design: Adjustable seats, intuitive controls and exceptional visibility reduce fatigue and enhance operator productivity.

• Low Maintenance, High Uptime: Simplified service points and reduced maintenance intervals keep machines on the job longer.

• Smart Security: JCB LiveLink telematics provides advanced

tracking and monitoring for added peace of mind.

Powered by efficient 48.9-hp, 3-cylinder engines, the CT380 and CT430 are built to handle rigorous daily use. Their operating weights — 8,820 lbs. and 9,920 lbs. respectively — strike a balance

between easy transport and heavyduty performance.

“Our philosophy is robust simplicity,” Gill explained. “These machines are easy to operate, easy to maintain and ready to work whenever you are. That’s what makes the CT380 and CT430 invaluable on American job sites.” For more information, visit www.jcb.com.

39 Jersey Street West Babylon, NY 11704

631/643-2605 www.allislandequipment.com

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave.

S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020 www.jesco.us

1401 Hookset Rd. Hooksett, NH 03106 603/644-8787 ambroseequipment.com

1440 Route 9W Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492 203/265-6781

17 Eagle Road Danbury, CT 06810 203/775-1203

80 Pratt Rd. Plainfield, CT 06374 860/546-4808 www.wiclark.com

2350 Greystone Ct. Rockville, VA 23146 804/359-4048 www.richmondmachinery.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

8194 State Route 415 Campbell, NY 14821 607/739-8741 monroetractor.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

www.stephensonequipment.com

Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111 703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

www.traceyroad.com 6803 Manlius Center Road East Syracuse, NY 13057 315-437-1471 • 800-872-2390

Albany, NY 518-438-1100 866-740-8853 Kirkwood, NY 607-775-5010 800-370-9488

Queensbury, NY 518-793-9688 833-817-2917

Henrietta, NY 585-334-5120 866-950-6210

Utica, NY 315-765-8746 800-872-2390

Adams Center, NY 315-788-0200 888-335-0200

Wilkes-Barre Township, PA 570-410-2123 • 800-872-2390

NPK displayed its GH15 hydraulic hammer, promoting its power and efficiency for heavy-duty demolition applications. (L-R) are Scott McEver, district manager; Ben Moskowitz, pedestal boom specialist; and Ryan Crookham.

Caterpillar is celebrating its 100th anniversary. Much of the equipment and its display was adorned with the100th anniversary commemorative logo.

Cameron Calder (L) and Glen Calder of Mauldin Paving Products display the M415XT maintainer, a versatile machine equipped with a 10-ft. moldboard, loader bucket and rear scarifier designed to perform multiple tasks such as grading, loading and scarifying on construction sites.

Julie Andreas (L) and Wilm Schulz of Haver & Boecker show off the Niagara

portable plant used primarily in aggregate and mining. It offers customizable

tures and is sold directly in North America.

Thousands of paving contractors and aggregate producers were given an opportunity to get an up-close view of the latest and greatest equipment on the market.

Niel Maus, marketing manager of Okada, showcased the Okada ORV 1500 hydraulic breaker as a robust and efficient attachment designed for heavy-duty demolition and construction tasks.

Pat Maeara (L), regional sales manager of Eagle Crusher, and Jerry Freitag of Horton Supply highlighted the next-generation UltraMax 1200-CC portable crushing and screening plant. This updated model features enhancements aimed at simplifying setup, operation, and transport.

The Sakai Guardman auto brake assist system is an advanced system described as a first for the industry and offers enhanced safety on the job site.

Ian Harvey, retired director of product marketing and communications of Volvo of Shippensburg, Pa., appeared with Tony Beets, known from the TV show “Gold Rush,” to discuss mining and his favorite Volvo equipment, specifically the A50 articulated hauler.

Trail King Industries Inc. of Mitchell, S.D., is a North American manufacturer of a comprehensive range of trailers. (L-R): The team includes Cassidy Black, district sales manager; Eric Thomas, director of sales; Mark Hartman, district sales manager; Adam Risher, district sales manager; and Steve Workmeister, district sales manager.

McLanahan is celebrating its 190th anniversary and launching its rapid filter cloth changeout system. (L-R) are Alistair Forsyth, group president and managing director of Anaconda Equipment, a McLanahan Company; Mark Krause, vice president of business development of North America; Sean McLanahan, president and CEO; and Cory Jenson, executive vice president of sales and business development, all of McLanahan.

Towmaster Trailers of Litchfield, Minn., displayed its equipment trailers (L-R) with Woody Fisher, regional sales manager; Bret Taylor, North and South Central regional account manager; and Bob Keens, regional sales manager.

r No for ctedPerfe

caAmeri th r e p x E f o deliveringthe -our machines are ing and milling, ground, in every NSTRUCTION smartsafeandsu to paving, compac climate, condition, , th TECHNOLOGY AS THE GLOBAL L stainableconsistently ction and rehabilitation and terrain. From min e world is our proving EADER IN ROAD CO highest quality and lowest total cost of ownership.

Kenworth, Con-Tech Manufacturing and Rihm Kenworth recently partnered to donate a special Kenworth T880S 11-yd. Con-Tech BridgeKing mixer to raise money for charity. The mixer truck was recently shown at World of Concrete in Las Vegas.

smart, safe, and sustainable, consistently delivering the

During a live auction, the T880S mixer was sold to New London, Minn.-based Crow River Construction for $260,000. All proceeds of the sale were given to ConTech-designated charities, including Ronald McDonald House of Rochester, Minn.; Make-A-Wish Foundation of Minnesota; St. Jude’s Children’s Research Hospital; Child Liberation Foundation, among others.

For Crow River Construction, the Kenworth T880S mixer presented an excellent opportunity for the company to add a new truck to its growing fleet. The T880S, with a set-forward front axle, helps mixer customers comply with federal bridge formulas. A PACCAR MX-11 engine powers the truck.

Crow River Construction launched its ready-mix division in 2021 and has built an all-Kenworth ready-mix fleet consists of 14 Kenworth T880 and W900 trucks.

“The timing was perfect,” said Kraig Hanson, Crow River Construction owner “We were looking to add another T880 mixer to our fleet when our contacts at Rihm Kenworth and Con-Tech reached out about the auction. It was awesome to purchase a new truck that’s a good fit for our operation

and to see that money was donated to some incredible charity organizations that are making a difference in our local communities in Minnesota and beyond.

“This auction is a significant fundraising initiative that resulted in a remarkable donation to charity organizations that all of us at Con-Tech deeply value,” said Dan Welsh, president of Con-Tech Manufacturing in Dodge Center, Minn. “We greatly appreciate Crow River Construction for purchasing this truck to help make this happen.”

“It was great to team up with Con-Tech, Rihm Kenworth and other contributing suppliers to build this truck and help raise money for some incredible charity organizations,” said Kyle Kimball, Kenworth director of marketing.

Crow River Construction, founded in 2013, specializes in sewer and water and utility construction work in addition to its ready-mix services and aggregate material sales. Company-wide, the firm operates 28 Kenworth trucks, including T880, W990 and W900 models. Crow River Construction works with Rihm Kenworth — Sauk Centre, Minn. its local Kenworth dealer.

“Kenworth trucks make up the majority of our fleet, and they are very reliable for us,” said Hanson. “We have a great relationship with Rihm. They’ve done a great job supporting our company by equipping us with trucks that match our operational needs.”

ALL ISLAND EQUIPMENT

39 Jersey Street West Babylon, NY 11704

631/643-2605

allislandequipment.com

AMBROSE EQUIPMENT / ALTA EQUIPMENT

1401 Hooksett Rd. Hooksett, NH 03106

603/644-8787 ambroseequipment.com

HOFFMAN EQUIPMENT COMPANY

1440 Route 9W Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020 www.jesco.us

MONROE TRACTOR

1001 Lehigh Station Rd. Henrietta, NY 14467

585/334-3867

5035 Genesee Street Buffalo, NY 14225

716/681-7100

8194 State Route 415 Campbell, NY 14821

607/739-8741

www.monroetractor.com

RICHMOND MACHINERY

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

W.I. CLARK COMPANY

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492

203/265-6781 17 Eagle Road Danbury, CT 06810

203/775-1203

80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA

600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA

135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057

800/692-7600

Ebensburg, PA

2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY

3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY

6018 Drott Drive East Syracuse, NY 13057 800/368-6455

Northern, VA (DC)

8192 Euclid Court Manassas Park, VA 20111

703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742

301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

The LeeBoy Rosco NV55 self-propelled broom is designed for heavy sweeping applications including milling, paving, airport and construction site cleanup. The NV55 is the go-to for contractors looking for simple operation and superior sweeping, according to the company.

The NV55 is equipped with a 74 hp (55 kW) Hatz Tier IV diesel 4H50TIC engine, 30-gal. fuel tank, 7-ft., 6-in. HD brush head (with optional 8-ft. head), quick change brush system, variable down pressure and brush speed controls, suspension seat and tilt column, joystick control for travel and broom functions, options include HD side shift brush head and foot pedal transmission.