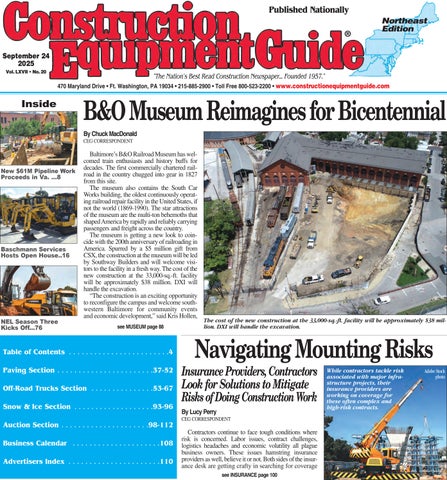

By Chuck MacDonald CEG CORRESPONDENT

Baltimore’s B&O Railroad Museum has welcomed train enthusiasts and history buffs for decades. The first commercially chartered railroad in the country chugged into gear in 1827 from this site.

The museum also contains the South Car Works building, the oldest continuously operating railroad repair facility in the United States, if not the world (1869-1990). The star attractions of the museum are the multi-ton behemoths that shaped America by rapidly and reliably carrying passengers and freight across the country.

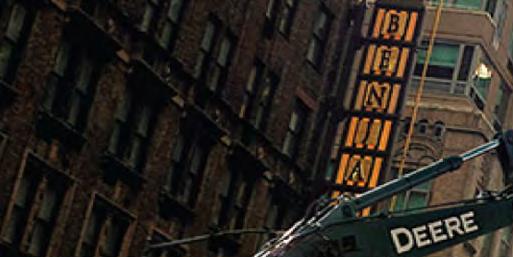

The museum is getting a new look to coincide with the 200th anniversary of railroading in America. Spurred by a $5 million gift from CSX, the construction at the museum will be led by Southway Builders and will welcome visitors to the facility in a fresh way. The cost of the new construction at the 33,000-sq.-ft. facility will be approximately $38 million. DXI will handle the excavation.

“The construction is an exciting opportunity to reconfigure the campus and welcome southwestern Baltimore for community events and economic development,” said Kris Hollen,

By Lucy Perry CEG CORRESPONDENT

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

The Rivanna Water & Sewer Authority is advancing work on a $61.5 million raw water pipeline in Charlottesville, Va., to replace two deteriorating lines between the Ragged Mountain Reservoir and the Observatory Water Treatment Plant.

Eagle Power & Equipment and Eagle Power Kubota announced a reorganization of its sales leadership and territory coverage designed to strengthen customer support, provide continuity and expand representation in new markets.

Equip Exposition announced the winner of the Equip Summer Shopping Spree: Jonathan Piper, an arborist and owner of 7 Ways Lawn & Tree. Piper and his family founded the lawn service company, based in Monroeville, Pa., in 2018.

Baschmann Services Inc., located at 1101 Maple Rd. in Elma, welcomed customers from across western New York and the Southern Tier Sept. 12, 2025, for an open house and customer appreciation day.

At Paramount Construction, family, hard work and trusted partnerships form the foundation of a business that has grown from small concrete jobs in Hartford to multimillion-dollar infrastructure projects across Connecticut.

22 MARYLAND STARTS WORK ON PAIR OF I-70 BRIDGES WEST OF HAGERSTOWN

The Maryland Department of Transportation State Highway Administration (MDOT SHA) has kicked off the replacement of two Interstate 70 bridges over Saint Paul Road near Hagerstown.

35

As a force in the development of sustainable transportation solutions, Volvo Group is celebrating 80 years of remanufacturing components for its on- road, off-road and marine applications.

68

After the structure sat virtually untouched for nearly two decades, the owner of the Fourteen Foot Bank Lighthouse in Delaware Bay is reigniting an effort to restore the historic beacon.

For more than 50 years, Liebherr has thrived in the United States as a manufacturer of mining trucks and a provider of solutions and services across 12 product segments.

76

The National Equipment League (NEL) has launched its third season with two events now available to view online, and new apps and channels launching to expand the league’s viewership.

99

Trimble announced the initiation of the Federal Risk and Authorization Management Program (FedRAMP) authorization process for its Trimble Connect, Trimble ProjectSight and Trimble Unity solutions.

104 PENNDOT SHOWS DAUPHIN BRIDGE PROJECTS AVAILABLE FOR BIDS

To give the general public a look at the Pennsylvania Department of Transportation’s plans to build three new roadway bridges in Dauphin County, the agency on Sept. 8, 2025, began displaying the project designs on its website.

DBIA will host the 2025 Design-Build Conference &

Grand in Las Vegas, uniting the nation’s leading design-build innovators for

days of powerful programming, networking and

Ten outstanding community-based nonprofits across the nation are each being awarded $25,000 in cash and $25,000 in Kubota equipment as part of this year’s Kubota Hometown Proud grant program.

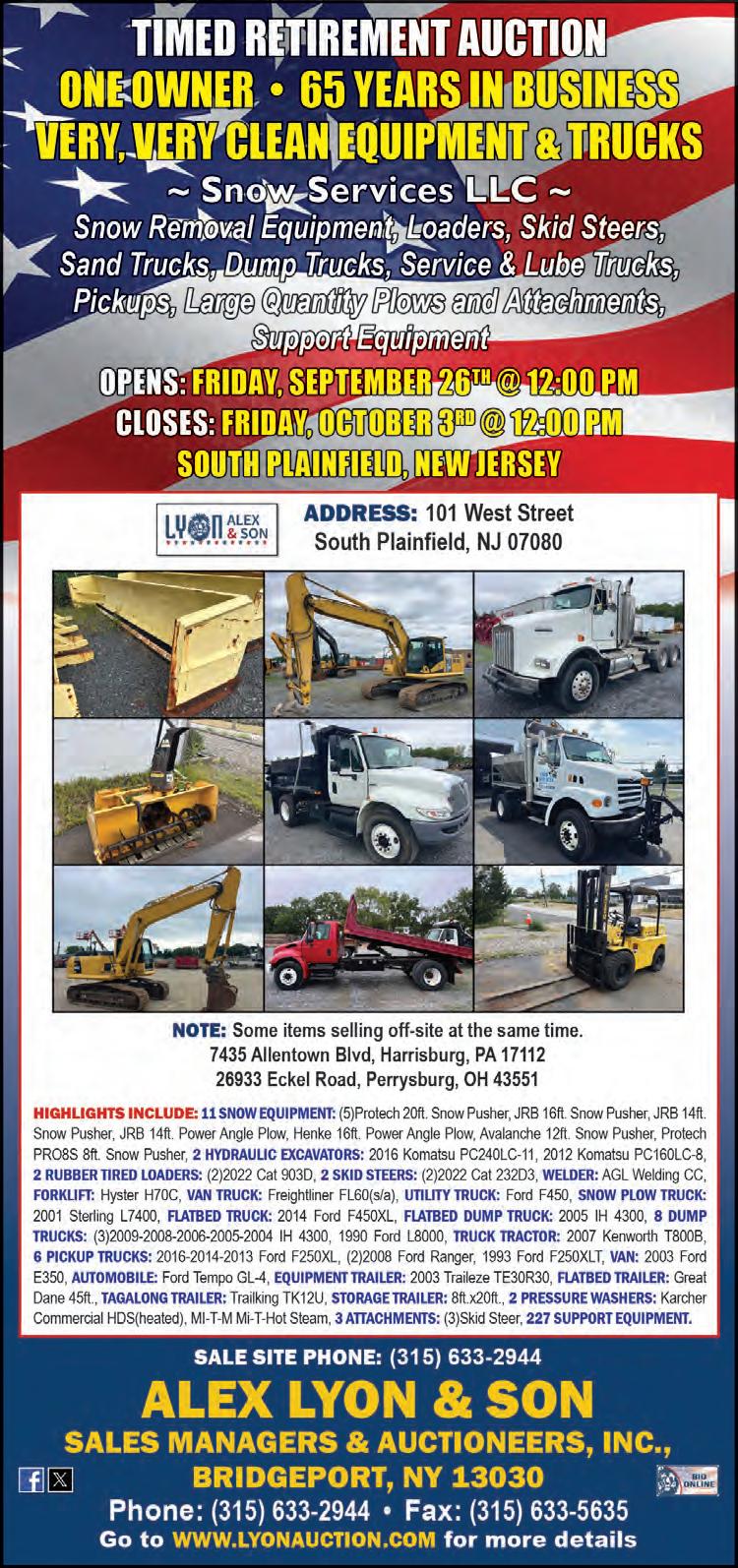

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS..$88,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXTENDAHOE, TOOL CARRIER....................................................

$32,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXT HOE, TOOL CARRIER, TURF TIRES, BHOT SET TO CAT....$29,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE............................................................................$99,995

CHIPPERS:

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS

DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..............$29,995

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH........................................$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP........................................................................$64,995

SCREENERS:

2021 VIBROSCREEN SCM40

2021 VIBROSCREEN SCM27

$79,995

$62,995

NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE......................................................................SOLD

NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF $179,995

EXCAVATORS:

SKID STEER LOADERS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................

$149,995

$105,000 2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER..........................................................................

2016 KUBOTA SVL95-2 TRACK SKID STEER, 936 HRS, CAB HVAC, HIGH FLOW, RADIO............................................................$49,995

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS........$45,000

$169,995

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB ..........................................................................................

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED........................................................................$295,000

2019 KUBOTA KX033-4, 2421 HRS, CAB, HVAC, 3 BUCKETS, HYD THUMB, COUPLER..............................................................$33,995

WHEEL LOADERS:

2022 AVANT 528LX, 40 HRS, CAB W/HEAT, 51” BUCKET, 43” ROTARY BROOM, LIKE NEW CONDITION..........................$46,995

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER..................................................................................$39,995

TRACTOR:

2012 CASE MAX110, CAB, HVAC, 6380 HRS, 4WD, LOADER, 3PT HITCH, 3 SETS REAR REMOTS, AG TIRES........................$42,000

DOZER:

20212 CASE 850M, 850 HRS, WIDE TRACK, CAB, HVAC, COLD

WEATHER START KIT, DRAW BAR, 24” TRACKS, 112”DOZER BLADE, HYD PUMP W/PTO..............................................$159,995

2021 NEW HOLLAND L320, 360 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS, BLOCK HEATER..............................................$32,995

2018 NEW HOLLAND L234, 540 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS........................................................................$36,995

2013 NEW HOLLAND L230, 2303 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS, BLOCK HEATER..................................$26,500

MISCELLANEOUS:

AFE

The Rivanna Water & Sewer Authority (RWSA) is advancing work on a $61.5 million raw water pipeline in Charlottesville, Va., that will replace two deteriorating lines between the Ragged Mountain Reservoir and the Observatory Water Treatment Plant.

The 36-in. pipeline is designed to take the place of a pair of smaller 18-in. pipes that are between 70-100 years old. Once completed, the new line will strengthen long-term reliability and expand capacity in the region’s water system, the utility noted in an update on its website.

According to RWSA, the project is a critical component of its Community Water Supply Plan, which includes more than $300 million in investments over the next five years to upgrade its reservoirs, treatment plants, raw water transmission pipelines and pipelines for treated drinking water across Charlottesville and Albemarle County.

A detailed routing study for the project was completed in 2021, and easement acquisitions were completed in 2024. Shortly after that, Thalle Construction Co., based in Hillsborough, N.C., began working on the pipeline and will continue to do so through 2029.

Extending the water line between the reservoir and the water treatment plant has involved a series of steps since the contracting firm received its notice to proceed on the replacement effort in December.

Those milestones have included:

• a public information meeting on Jan. 29 to inform Charlottesville residents and UVA students about the upcoming project;

• Thalle and its crews began clearing trees along the pipeline’s future path on March 4;

• Hereford Drive was closed between McCormick Road and Stadium Road on May 27 to install the new 36-in. pipe under the road;

• Hereford Drive was repaved and reopened to traffic on Aug. 8;

• controlled blasting took place Aug. 18 to excavate rock more efficiently in a wooded area on UVA property between Hereford Drive and Fontaine Avenue; and

• in the first week of September, the contractors perform more blasting on the site, just north of Fontaine Avenue.

That part of the work has been carefully and conservatively designed by RWSA’s consultant engineer to protect property, the utility said, while noting that its blasting permits are obtained from the Virginia State Fire Marshall.

The process involves drilling into rock and setting small charges before heavy mats are laid across the surface to prevent loose debris from leaving the site. Before each blast, a localized siren will go off to signal the impending detonation. RWSA added that each blast generates a sound level up to 120

Progress continues on RWSA's replacement raw water line from the Ragged Mountain Reservoir to the Observatory Water Treatment Plant.

decibels and can cause minor localized ground vibrations.

Due to Fontaine Avenue’s proximity to the blasting site, the road was closed five minutes before each detonation. The roadway was reopened once safety personnel issued the all-clear. Temporary recreational trail closures also occurred on the O-Hill Long Downhill, Fontaine Multi-Use Path and Gravel Doubletrack trails.

Beginning the week of September 8, Thalle Construction began working on extending the pipeline across Fontaine Avenue, a procedure that required nighttime construction between the hours of 8 p.m. and 5 a.m. The pipeline will cross Fontaine

between the U.S. Highway 29 Bypass and Ray C. Hunt Drive.

Thru traffic is allowed during this period; however, RWSA said that lane closures are expected. All lanes will reopen each morning and remain so throughout the day.

In addition, the pipeline construction has been coordinated with UVA to minimize potential impacts on staff and patients who work or receive care in the Fontaine Research Park, adjacent to the construction site.

The work on this section of the pipeline is expected to continue through the end of October.

“This infrastructure project represents a

major milestone for long-term water reliability in Charlottesville,” said Krista Shurtz, RWSA’s vice president of natural gas and water operations.

When the project is fully completed, according to RWSA, the Ragged Mountain Reservoir to Observatory Water Treatment Plant Raw Water Line will span approximately 4 mi., including a spur-piece of piping that will be installed on the Foxhaven Farm property, connecting the Ragged Mountain Raw Water Pump Station (RMRWPS) to the southern end of the previously installed raw water line under the Birdwood Golf Course in Charlottesville.

The pump station will have the capacity to initially transfer up to 10 million gal. per day of raw water from the reservoir to the treatment plant.

Once the nearby South Fork Rivanna Reservoir to Ragged Mountain Reservoir pipeline is finished and additional pumps are installed, the RMRWPS will also be capable of transferring 16 million gal. of water daily from the Ragged Mountain Reservoir to the South Rivanna Water Treatment Plant, as well as assist with the transfer of 25 million gal. from South Fork Rivanna Reservoir to the Ragged Mountain Reservoir and/or the Observatory Water Treatment Plant.

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

New Rogers 35 ton CR35GR Gentle Risers In Stock, No-Foot Neck w/ tool box, Gooseneck work lights, 24' deck, 16* slope, adj. width bi-fold ramps, side reinforcing full length, chain boxes, outriggers, 275's on alum. outers, Air Ride, Air Dump, Aux. Night Light Battery, Extra Markers & Turns, Rear Strobes. Side Strobes Viper Red and Black................In Stock!

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN STOCK!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

New Rogers TAG25's, 24' or 26' deck. Wood or Ladderbar Style 6' Tail. Wood or Ladderbar Style 8' Air Ramps Full floor or Custom Bucket Pocket in the deck. Safety Lighting Package........ In Stock and In Production!

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

Rogers TAG25-32, 26' deck, 6' tail, 8' air ramps, dual gear, side steps, broom/ shovel chutes, Safety Lighting package, 235's on aluminum outers, Viper Red Paint........IN STOCK

Rogers TAG21XXL, 24' deck, 6' tail, 235's on aluminum outers, 8' Air Ramps. Safety Lighting Package. Red Paint.. IN

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

Eagle Power & Equipment and Eagle Power Kubota announced a reorganization of its sales leadership and territory coverage designed to strengthen customer support, provide continuity for key accounts and expand representation in new markets. The company said these changes position the company for long-term success.

As part of the reorganization, David Boe has been named sales manager of Eagle Power & Equipment. Boe joined Eagle Power in August 2014 as operations manager of the company’s former Uwchlan, Pa., store. In 2017, he was promoted to equipment manager of Eagle Power’s Montgomeryville headquarters, a role previously held by nowPresident Matt McDonald. With nearly a decade of management experience inside the company, Boe brings a deep understanding of Eagle Power’s operations and customer base to his new role.

“Eagle Power has always been about relationships — with our employees, our manufacturers, and most importantly, our customers,” said Boe. “My focus as sales manager will be to strengthen those connections and continue delivering the level of service people expect from us.”

In a related move, Jim Lutz will return to the field as senior account executive. He has been an important member of the Eagle Power team since 2007, serving most recently as sales manager. In his new role, he will focus on managing Eagle Power’s relationships with several key organizations. The company said “these relationships have been built over decades, developed through the tireless efforts of Eagle Power’s sales professionals past and present. That legacy of responsibilities and responsiveness will now be stewarded by Jim Lutz, who is uniquely positioned to maintain and grow these partnerships.”

Jim Lutz also will resume additional sales responsibilities in western Bucks and Montgomery Counties, Pa. for Case, Kubota Construction, Wacker Neuson, Eager Beaver Trailers and other

Eagle Power offerings. He will work in close coordination with his brother, Mike Lutz, who has served customers in the same area since joining Eagle Power in 2021. This collaboration ensures that customers in these core territories continue to receive the high level of attention and support they expect, while also opening opportunities for further growth, the company said.

The most significant expansion for the Lutz brothers comes with their shared responsibility for Somerset County, N.J., a new territory for Eagle Power Kubota supported through the company’s recently acquired Pennington location. In addition to representing Kubota Construction and Wacker Neuson equipment, Jim and Mike Lutz will now also represent Kubota tractors, Exmark mowers and a full line of turf equipment. This expanded portfolio will allow them to serve residential, commercial and municipal customers with industry-leading solutions.

“What I enjoy most about this business is working side by side with customers to solve challenges,” said Jim Lutz. “Taking on these key accounts, along with expanded responsibilities in Bucks, Montgomery and now Somerset County, gives me the opportunity to do just that every day.”

Mike Lutz added: “Over the past few years, I’ve been fortunate to work with a great group of contractors, municipalities and business owners in Bucks and Montgomery counties, and I’m looking forward to continuing to grow these relationships. I intend to do the same with the folks in Somerset County. I can’t wait to meet them and help their operations expand.”

Eagle Power & Equipment and Eagle Power Kubota said with these changes it reaffirms both companies’ commitment to customers while positioning the company to pursue new opportunities in both established and newly added territories.

(All photos courtesy of Eagle Power & Equipment.)

Equip Exposition announced the winner of the Equip Summer Shopping Spree: Jonathan Piper, an arborist and owner of 7 Ways Lawn & Tree. Piper and his family founded the lawn service company, based in Monroeville, Pa., in 2018.

Piper will be awarded a $5,000 shopping spree to purchase the newest gear, tools and outdoor power equipment technology attendees see at the award-winning trade show.

Piper said attending Equip and its tree care education transformed his business and grew his connections within the industry.

“After a decade serving my community as a first responder, I started 7 Ways Lawn & Tree with the goal of providing the highest quality landscaping services,” said Piper.

“I started with only homeowner grade equipment and no knowledge of Equip or the community around it.

“During winter 2022, I attended a get together with some of the local landscapers who have become great friends, mentors and collaborators. They talked about Equip and suggested I also attend. Later that fall, I came to Equip for the first time.

Katie

“I just started upgrading equipment and trying to find software, tools and classes to help me streamline and grow my business. I found all of that and more and was welcomed into an incredible community that I now look forward to meeting up with every year in October.

“From conversations with members of Davey Tree and The Davey Institute about techniques and best practices to discussions with engineering and product development teams from around the world, Equip has been an incredibly significant contributor to my success over the past three years.

“I look forward to meeting new faces at the show, live events and small meetups hosted by influencers during the week. I encourage everyone to use this time to ask questions, look for solutions and network with their fellow professionals in the greater landscaping community.”

For more information, visit equipexposition.com.

Baschmann Services Inc., located at 1101 Maple Rd. in Elma, welcomed customers from across western New York and the Southern Tier Sept. 12, 2025, for an open house and customer appreciation day.

With support from its vendors, Baschmann put on an educational and hands-on event that highlighted its wide range of equipment lines. Factory representatives were on site to answer questions directly, while demonstrations gave attendees the chance to see the machines in action.

A featured operational crushing spread showcased primarily Anaconda crushing equipment. Another crowd favorite was an excavator operators’ rodeo, which used a KOBELCO excavator to test participants’ skill behind the controls.

Guests enjoyed a variety of food throughout the day, while taking advantage of special promotional dis-

counts on parts, service and rentals. Baschmann offered event-only equipment pricing and awarded a large selection of door prizes to attendees.

Manufacturers represented at the event included ASV, Paladin, Virnig Attachments, ROKBAK off-road trucks, Hitachi loaders, Soosan hammers, Pitbull portable crushing machines, Cummins engines, Toku/Stryker breakers, Loftness, Ammann compaction equipment, KOBELCO excavators, Erskine attachments, Eager Beaver trailers, Felling trailers, Pequea trailers, McLanahan, Carlton stump grinders, Weigh Shark conveyor belt scales, TCI Manufacturing, FRD hammers and Anaconda.

Visitors praised the event for its mix of product education, food and familyfriendly activities, noting it was an effective way to learn more about the company’s offerings while connecting

with Baschmann’s staff and partners. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

see BASCHMANN page 80

An Anaconda conveyor makes the perfect flagpole to welcome guests to the

Zach Manz (L) and Peter Baschmann of Baschmann Services have worked diligently to make sure that the company provides their customers with an array of products from a wide variety of companies to meet all contractors’ earthmoving, recycling and aggregate equipment needs.

At Paramount Construction, family, hard work and trusted partnerships form the foundation of a business that has grown from small concrete jobs in Hartford to multimillion-dollar infrastructure projects across Connecticut.

Owned today by Steve Reilly, Executive Vice President, Chez-Christopher Pace (aka Chez Jr.), Vice President, and Alex Pace, Vice President of Field Operations, the company operates with more than 30 employees, a full equipment fleet and annual revenues of up to $20 million plus.

But the story of Paramount is much more than numbers. It is the journey of an immigrant family, the lessons of three generations and the value of strong relationships with suppliers.

Marzolino Pace, father of Concezio Pace (aka “Chez Sr.”), was born in 1929 in a small Abruzzo town north of Rome. Raised amid the devastation of World War II, Marzolino left Italy as a young man in search of opportunity, first heading to Venezuela before securing sponsorship to enter the United States. He arrived in Hartford in 1955, where relatives had already established a small construction firm, G Pace & Son Construction.

Starting in concrete work, Marzolino spent a decade honing his skills before joining the local cement finishers' union in Hartford. Known for his natural engineering mind despite having only an eighthgrade education, he was able to envision and build concrete forms with precision and creativity.

In 1976, Marzolino partnered with Bruno Santilli to form P&S Concrete Contractors. By 1978, his teenage son, Concezio “Chez Sr.” was working full-time at his side, and together they created Pace & Son, focused on foundations, slabs, and residential flatwork. Their small Hartford shop on Benton Street was the launchpad for a business built on long days pouring concrete by hand and wheelbarrow.

By 1984, Pace & Son won its first city contract — a $284,000 reconstruction job in Hartford's Bellevue Street. Despite a crew of just five, the company delivered the project successfully, earning credibility with municipal customers. The firm soon shifted from residential driveways and patios to road reconstruction, sidewalks and storm drain work across the city.

As the 1980s progressed, Chez Sr. became a full partner in the business, formalizing the father-son relationship legally to avoid the pitfalls common in family

operations. By the 1990s, the firm's municipal workload was steadily growing. In 1997, Chez Sr. made the difficult decision to retire his father, who by then was 68, to allow for the company's continued growth.

“I give my father credit every single day,” Chez Sr. said. “For the sacrifices he made, the work ethic he instilled and for giving me the foundation to build on.”

The next chapter came in 2000 with the formation of Paramount Construction. Recognizing that infrastructure work was increasingly complex, Chez Sr. brought in Steve Reilly, a civil engineer by trade, who excelled at matching the evolving construction project requirements. Steve became a partner, and together they positioned Paramount as a general contractor capable of managing full public works contracts — excavation, underground utilities, road prep and traffic systems.

Paramount's first major step up came with the Park Road Interchange project in West Hartford, a DOT-funded reconstruction of Exit 43 that included extensive utilities, roadwork and site improvements.

Though initially questioned as an unknown bidder, Paramount quickly established credibility when DOT staff realized they were dealing with the Pace family name.

“That was a game changer for us,” Chez Sr. said. “It showed we could handle projects of that magnitude.”

Today, Paramount regularly delivers multimillion-dollar contracts for the Connecticut DOT, the Metropolitan District Commission and various municipalities across the state. Recent work includes the Stafford Springs Roundabout, Downtown Plantsville Corridor Improvements, Capitol Ave Water Main Replacement and major

see PARAMOUNT page 84

six-year capital budget for transportation projects, the two I-70 bridges were built in 1965 and “are nearing the end of their useful service lives.”

The Maryland Department of Transportation State Highway Administration (MDOT SHA) has kicked off the replacement of two Interstate 70 bridges over Saint Paul Road near Hagerstown.

Intermittent single-lane closures could result, but the idea is to maintain two lanes of traffic in both directions as much as possible during the I-70 bridges construction, MDOT SHA spokesperson M. Daniel Allman said in a recent email to the Hagerstown Herald-Mail. In addition, he wrote that both bridges will be constructed simultaneously.

Still, the structures are currently rated in “fair” condition by the state.

“Replacing the bridges before they become poor rated will prevent additional disruptions to this heavily traveled roadway,” noted the CTP.

Weather permitting, the $23 million project is expected to be completed by the spring of 2027.

That could make traveling between Hagerstown and Clear Spring a bit more challenging, the newspaper reported Sept. 5.

Local drivers are already using detours to get around the U.S. Highway 40 bridge closure over Conococheague Creek to the north of I70.

The 89-year-old historic bridge along U.S. 40 is getting a much-needed rehabilitation and is not expected to reopen to traffic until August of 2026. That project could be done by July 2027.

Between now and then, I-70 is one possible detour for the U.S. 40 project.

Beginning the week of Sept. 8, crews started erecting temporary traffic signs for the interstate highway’s bridge replacement effort, which will involve a single-lane closure to perform shoulder work and install barrier walls on the right shoulders along I-70 heading both eastbound and westbound.

Once that is done, traffic will be shifted to the right and both lanes will be open, according to Allman. When the work on the left side is done, vehicles will be moved to the left so construction can be done on the right side.

The actual heavy work along I-70 is expected to get moving the week of Sept. 15.

Triton Construction, of St. Albans, W.Va., is the contractor for the I-70 bridge replacement projects, MDOT SHA noted in a news release. It also said that the work has a price tag of $19.8 million; however, in early September, Maryland’s draft Consolidated Transportation Program (CTP) listed the project’s latest estimated cost at more than $23 million.

The latter figure, Allman wrote, reflects the work’s recent bidding history and price revisions for possible tariffs.

In addition, both bridges show wear on their road surfaces and in their concrete supports. In fact, the HeraldMail reported that each bridge has at least one concrete end cap that is so badly worn that its edge is near an outside girder that holds up the road surface.

To alleviate these issues, Triton Construction will remove the three-span steel beam bridges and build new single-span steel girder structures in their place.

The current bridges, according to Allman, use two piers with one on each side of Saint Paul Road. The new spans will eliminate the need for piers and instead feature new steel that runs continuously from abutment to abutment.

In the end, the new bridges will be 17 ft. wider than the current structures, he said, and no additional lanes will be added.

Beyond that, MDOT SHA noted that plans for the I-70 bridge replacement project will include:

• widening and resurfacing parts of I-70;

• building stormwater management measures and drainage structures;

• Updating a camera used for live traffic at the state’s Coordinated Highway Action Response Team (CHART) site to one with more modern technologies such as digital and high-definition color, among others; and

• installing signs and pavement markings.

Local Emergency Services Director Cautions Motorists

Washington County Emergency Services Director R. David Hays told the Hagerstown newspaper that projects like the I-70 bridge improvements generally result in highway shoulders not being available in the work area.

Anytime that happens, along with some motorists slowing down, the frequency of crashes could increase, he said. First-responders also could be “somewhat impeded” if there are no highway shoulders for them to use to get to accident sites.

According to the Maryland CTP, the state’s

With any road construction, Hays advises motorists to use caution and reduce speeds to allow for better traffic flow and to avoid potential collisions. When drivers hear emergency vehicles approaching, he added, they should try to clear as much of the road as possible to let them through.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

MANASSAS, VA 6918 Wellington Rd. Manassas, VA 20109 703/257-2381

JESSUP, MD

10421 Guilford Road, Jessup, MD 20794 410/792-9134 from Washington D.C. 301/725-7394 DELMAR, DE

38420 Sussex Highway Delmar, DE 19940 302/846-3033

HARRISBURG, PA 6680 Allentown Blvd., Harrisburg, PA 17112 717/652-5430

KING OF PRUSSIA, PA 450 E. Church Road, King of Prussia, PA 19406 610/279-5200

2018 Cat CB24B #165-05069, 3,176 hours, ROPS folding Rollbar, hydrostatic, 47in double drum vibratory, lights, water system $22,500

2019 SUPERIOR BROOM SM74C

#175-18038, 2,952 hours, Cab, air, 74hp Cat diesel engine, 2 speed, 8ft front mounted broom, 45degree angle, water system, ST225/75R15 tires, (1) spare tires $38,800

2017 CATERPILLAR 725C2

#140-12010, 6,418 hours, 6x6, Cab, air, 25-ton capacity dump body, mechanical tailgate, 23.5R25 tires $165,500

Farmington (Rochester), New York Fax: 585-924-7624 Email: tdelany@americanequipmentllc.com 585-924-5480 ext. 520 www.americanequipmentllc.com

C.N. WOOD

cn-wood.com

CONNECTICUT

Newington: 860-665-7470

New Haven: 203-848-6735

MASSACHUSETTS

Avon: 508-584-8484

Whately: 413-665-7009

Woburn: 781-935-1919

NEW YORK

Holmes: 845-878-4004

RHODE ISLAND

Deptford: 856-227-6400

Piscataway: 732-752-3600 NEW

Bealeton: 540-439-0668

Chesapeake: 757-485-2100

Chester: 804-748-6411

Fishersville: 540-887-8291

Ebensburg: 814-472-4441

Martinsburg: 814-793-3734

St. Mary’s: 814-781-1365

Smithfield: 401-942-9191 fosterfwineland.com

Selkirk: 518-767-9331

Bronx: 718-822-1180

Marlboro: 845-236-3000

Medford: 631-207-2900

PENNSYLVANIA

Lionville: 610-363-9200 hwyequip.com

Drums: 570-788-1127

Ephrata: 717-859-3132

Harrisburg: 717-564-3031

Lock Haven: 570-769-1070

Salem: 540-380-2090

Binghamton: 607-754-6570

Buffalo: 716-681-7100

Campbell: 607-739-8741

Henrietta: 585-334-3867

N. Syracuse: 315-452-0000

As a force in the development of sustainable transportation solutions, Volvo Group is celebrating 80 years of remanufacturing components for its on- road, off-road and marine applications.

The remanufacturing program, which launched in 1945 in Ko ̈ ping, Sweden, is supported in North America today by operations in Middletown, Pa., and Charlotte, N.C.

“Remanufacturing is a cornerstone of the Volvo Group’s sustainability journey and has been since the first renovated gearboxes were produced in 1945,” said Stephen Roy, chairman of Volvo Group North America. “Not only does this initiative play a significant role in reducing our environmental impact by minimizing waste, but it also supports our customers by providing reliable Volvo-quality parts at a lower cost. We are proud to have two key U.S. facilities contributing to this important work.”

Every remanufactured component undergoes a stringent inspection, evaluation and remanufacturing process to ensure it meets exacting specifications, according to Volvo.

This includes electromagnetic crack detection, precision machining, expert recovery and welding techniques, calibration with certified gauges and dynamic testing, all completed by certified technicians.

In addition, every remanufactured compo-

nent comes with a 100 percent warranty on parts and contingent damage, as well as a 100 percent warranty on labor when installed by an authorized dealer.

Remanufacturing also supports the Volvo Group’s carbon footprint reduction effort, as remanufacturing uses up to 85 percent less raw material and 80 percent less energy than new production.

Today, Volvo maintains one of the most extensive remanufactured product inventories in the industry, covering more than a dozen key categories including engines, transmissions, coolant pumps, cylinder heads and turbochargers. In North America, remanufactured products are available for Volvo Trucks, Mack Trucks, Volvo Penta, Volvo Construction Equipment, Volvo Buses and Prevost.

“Our commitment to remanufacturing isn’t just about business — it’s about responsibility,” said Sherman Williams, Volvo Group North America’s remanufacturing product development director. “We are proud to offer our customers a solution that not only meets their needs but also aligns with their values. By investing in remanufactured parts, they are making a positive impact on the environment and supporting a more sustainable future for us all.”

For more information, visit volvogroup.com/na.

Due to its high daily output, the large milling machine from Wirtgen can handle a broad spectrum of applications, ranging from surface layer rehabilitation and fulldepth pavement removal to fine milling, according to Wirtgen.

The new large milling machine W 210 XF has been available and working on construction sites since January 2025. Currently, it is available in the United States, Europe, Australia, Japan and Taiwan. The large milling machine from Wirtgen can handle a broad spectrum of applications ranging from surface layer rehabilitation and full-depth pavement removal to fine milling.

Its Mill Assist machine control system ensures absolute efficiency on every construction site. In automatic mode, it always ensures the most favorable working balance between performance and costs, according to Wirtgen. It also allows the selection of three different working strategies that optimize the process with respect to cost, performance or quality, according to Wirtgen.

Powered by a John Deere engine with a maximum rated power output of 778 hp, the W 210 XF delivers powerful and efficient milling performance in every situation. Wirtgen and John Deere worked in close collaboration on fine-tuning the engine’s torque characteristic to meet the specific needs of cold milling applications, according to the companies.

The combination of the powerful engine and the Dual Shift two-speed powershift transmission enables an enormous range of milling drum speeds. The lower range of milling drum speeds enables significant reductions of fuel consumption, pick wear and noise emissions, according to Wirtgen.

The upper range of milling drum speeds makes it possible to achieve high area performance with a high-quality milling pattern, even at the maximum milling depth of 33 cm. This means that the W 210 XF is ideally equipped to

complete even the most demanding milling tasks with maximum sustainability, according to Wirtgen.

The requirements on construction sites often change from one day to the next. This means that outstanding flexibility is a must. An example of this in the case of the W 210 XF is that the milling drum can be exchanged for a Multiple Cutting System (MCS) drum within minutes.

The ability to rapidly change to application-specific milling drums with different tool spacings considerably increases machine productivity. At the same time, the choice of the ideal drum for a specific application also reduces wear-related costs, according to Wirtgen.

Wirtgen offers a range of milling drums for the W 210 XF to meet the requirements of any milling application.

39 Jersey Street

West Babylon, NY 11704

631/643-2605

www.allislandequipment.com

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020

www.jesco.us

1401 Hookset Rd. Hooksett, NH 03106 603/644-8787 ambroseequipment.com

1440 Route 9W Marlboro, NY 12542 845/236-3000 www.hoffmanequip.com

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492 203/265-6781

17 Eagle Road Danbury, CT 06810 203/775-1203

80 Pratt Rd. Plainfield, CT 06374 860/546-4808 www.wiclark.com

2350 Greystone Ct. Rockville, VA 23146 804/359-4048 www.richmondmachinery.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

8194 State Route 415 Campbell, NY 14821 607/739-8741 monroetractor.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Northern, VA (DC) 8192 Euclid Court Manassas Park, VA 20111 703/330-5579

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY 3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Opening This FallLancaster, PA 20 Stauffer Lane Ephrata, PA 800/325-6455 www.stephensonequipment.com

Engineered and built to exceed the demands of commercial paving, the Weiler pavers incorporate proven designs with new innovations to provide performance, reliability and outstanding mat quality in a wide range of applications.

Murrysville, PA

724-327-1300

Erie, PA

814-898-3388

Somerset, PA 814-445-7915

Clearfield, PA 814-765-1611

Mansfield, PA 570-662-7171

Kane, PA 814-778-5250

clevelandbrothers.com

Mt. Pleasant, PA 724-696-4080

Watsontown, PA 570-538-2551

Ephrata, PA 717-859-4905

State College, PA 814-237-8338

Harrisburg, PA 717-564-2121

Pittston, PA 800-922-8630

Bridgeport, WV 304-842-2222

Shinnston, WV 304-592-5855

Bellefonte, PA 814-353-2800

Blawnox, PA 412-828-7810

Camp Hill, PA 717-730-7435

Cranberry Twp, PA 724-776-7660

Ebensburg, PA 814-471-1710 Indiana, PA 724-463-8743

Barnesville, PA 570-773-1720 Howard, PA 814-355-3500

Hunker, PA 724-861-6080

Eighty Four, PA 724-325-9297

Piscataway, NJ 732-885-5555 Hammonton, NJ 609-561-0308 Bensalem, PA 215-639-4300 Whitehall, PA 610-261-4887 Bear, DE 302-328-4131

Poughkeepsie, NY 845-452-1200 Bronx, NY 718-863-3800 Bloomingburg, NY 845-733-6400

Holtsville, NY 631-758-7500 Newington, CT 860-666-8401

Milford, MA 508-634-3400

North Reading, MA 978-276-2400

Stoughton, MA 781-399-8580

Wareham, MA 508-291-1200

Cranston, RI 401-946-6350

miltoncat.com

Richmond, VT 802-434-7800

Londonderry, NH 603-665-4500

Brewer, ME 207-991-3100

Scarborough, ME 207-885-8000

Batavia, NY 585-815-6200

Binghamton, NY

607-772-6500

Clifton Park, NY 518-877-68000

Tonawanda, NY 716-799-1320 N. Syracuse, NY 315-703-7000

Vögele photo

The project involved difficult paving conditions with snow, wind and icy temperatures. A Mini 500 from Vögele was used to pave the new asphalt surface course efficiently and to a high quality standard.

Vögele photo

The lead contractor deployed a Vögele Mini 500 asphalt paver for the rehabilitation of a footpath on the summit of the Niesen mountain in Switzerland.

Due to its striking shape, the 7,750ft.-tall Niesen in the Bernese Oberland also is known as the “Pyramid of the Alps.”

To prepare the popular mountain destination south of Lake Thun for the summer season, the path between the mountain station and the mountain restaurant had to be renovated. The 558-ft. route is used for food and beverage transportation and is frequented by approximately 1,000 people every day in the high season.

As the summit of the Niesen can only be reached by funicular or helicopter, the construction site logistics were a major challenge. Due to the

high quality requirements, the surface course had to be laid by machine in a width of six to 14 ft. In addition, the weather conditions were very difficult due to the altitude and exposed location. As a result of the low temperatures, the paving team had only a narrow time window each day for the paving work.

Vögele photo

A spectacular material feeding method. A helicopter offloaded fresh, hot asphalt mix to the Mini 500 every four minutes to keep it constantly supplied with sufficient material for continuous paving.

To pave the new surface course efficiently and to a high standard, the contractor, Marti AG Bern, opted for the Mini 500 from Vögele. The manufacturer’s smallest road paver model is predestined for applications where narrow pave widths, compact dimensions,

low weight and high paving quality are required, according to Vögele. With a transport length of 8.5 ft., a width of 3 ft. and a weight of 1.54 tons, the site team was able to transport the paver to the mountain station using the Niesen cable car. The Niesenbahn is one of the longest funicular railroads in the world and climbs at a gradient of 68 percent in some places up to the mountain station.

LESLIE EQUIPMENT COMPANY www.lec1.com

6248 Webster Road Cowen, WV 26206 304/226-3299

2098 Lillian Lane Pleasant Valley, WV 26554 304/534-5454

19 Goff Crossing Drive Cross Lanes, WV 25313 304/204-1818

80 John Deere Lane Norton, WV 26285 304/636-6421

136 Clifftop Drive Beaver, WV 25813-1525 304/255-1525

www.monroetractor.com

1001 Lehigh Station Road Henrietta, NY 14467 585/334-3867

5035 Genesee Street Buffalo, NY 14225 716/681-7100

7300 Eastman Road N. Syracuse, NY 13212 315/452-0000

8194 State Route 415 Campbell, NY 14821 607/739-8741

6 Equipment Drive Binghamton, NY 13904 607/754-6570

GROFF TRACTOR & EQUIPMENT www.grofftractor.com

800-33-GROFF 800-33-(47633)

6779 Carlisle Pike Mechanicsburg, PA 17050

210 Rolling Ridge Drive Bellefonte, PA 16823

963 South Center Ave New Stanton, PA 15672

179 Perry HWY Hamony, PA 16037 2550 East Cumberland St. Lebanon, PA 17042 640 Lowther Rd. Lewisberry, PA 17339

www.unitedequip.com

80 Southbridge Rd. • Route 20 North Oxford, MA 01537 508/987-8786

2397 GAR Highway • Rte 6 & 136 North Swansea, MA 02777 508/379-9810

88 Camelot Drive • Unit 42 Plymouth, MA 02360 508/830-9997

1620 Page Blvd Springfield, MA 01104 413/543-5595

4 Sterling Road North Billerica, MA 01862 978/667-4345

34 Page Road West Hermon, ME 04401 207/947-6786

106 North Street Houlton, ME 04730

207/532-6517

1505 Caribou Road New Canada, ME 04743 207/834-6701

396 County Road Westbrook, ME 04092 207/773-3777

98 Sheep Davis Road Pembroke, NH 03275 603/225-2769

300 Clinton Street Springfield, VT 05156 802/885-6840

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

www.traceyroad.com 6803 Manlius Center Road East Syracuse, NY 13057 315-437-1471 • 800-872-2390

Albany, NY 518-438-1100 866-740-8853 Kirkwood, NY 607-775-5010 800-370-9488

Queensbury, NY 518-793-9688 833-817-2917

Henrietta, NY 585-334-5120 866-950-6210

Utica, NY 315-765-8746 800-872-2390

Adams Center, NY 315-788-0200 888-335-0200

Wilkes-Barre Township, PA 570-410-2123 • 800-872-2390

ALL ISLAND EQUIPMENT

39 Jersey Street West Babylon, NY 11704

631/643-2605 allislandequipment.com

HOFFMAN EQUIPMENT COMPANY

1440 Route 9W

Marlboro, NY 12542

845/236-3000 www.hoffmanequip.com

AMBROSE EQUIPMENT / ALTA EQUIPMENT

1401 Hooksett Rd. Hooksett, NH 03106

603/644-8787

ambroseequipment.com

JESCO, Inc.

1275 Bloomfield Ave. Fairfield, NJ 07004

973/227-2221

800/321-8080

118 St. Nicholas Ave. S. Plainfield, NJ 07080

908/753-8080

800/241-7070

1790 Route 38 Lumberton, NJ 08048

609/267-2020

www.jesco.us

MONROE TRACTOR

1001 Lehigh Station Rd. Henrietta, NY 14467

585/334-3867

5035 Genesee Street Buffalo, NY 14225

716/681-7100

8194 State Route 415 Campbell, NY 14821

607/739-8741

www.monroetractor.com

W.I. CLARK COMPANY

30 Barnes Ind. Pk. Rd. Wallingford, CT 06492

203/265-6781 17 Eagle Road Danbury, CT 06810

203/775-1203 80 Pratt Rd. Plainfield, CT 06374

860/546-4808 www.wiclark.com

RICHMOND MACHINERY

2350 Greystone Ct. Rockville, VA 23146

804/359-4048 www.richmondmachinery.com

Harrisburg, PA 7201 Paxton Street Harrisburg, PA 17111 800/325-6455

Wilkes-Barre, PA 600 Sathers Drive Pittston, PA 18640 866/667-6756

Butler, PA

796 Unionville Road Prospect, PA 16052 724/865-9221

Philadelphia, PA 135 Lincoln Avenue Prospect Park, PA 19076 800/220-4033

EQUIPMENT, INC.

Pittsburgh, PA 8181 Noblestown Road McDonald, PA 15057 800/692-7600

Ebensburg, PA 2350 Munster Road Lilly, PA 15946 814/886-5191

Albany, NY 3 Industry Drive Waterford, NY 12188 518/357-2200

Syracuse, NY 6018 Drott Drive East Syracuse, NY 13057 800/368-6455

www.stephensonequipment.com

Northern, VA (DC)

8192 Euclid Court Manassas Park, VA 20111 703/330-5579

Hagerstown, MD 20332 Leitersburg Pike Hagerstown, MD 21742 301/733-7414

Baltimore, MD

1109 Middle River Rd Middle River, MD 21220 800/633-5077

Opening This FallLancaster, PA 20 Stauffer Lane Ephrata, PA 800/325-6455

“The job was spectacular even before the actual paving,” said Iwan Hachen, paving foreman. “Transporting a road paver by cable car is not an everyday occurrence for us either. The Mini 500 is extremely compact and was extremely practical in terms of the requirements for this project.”

Another challenge was the delivery of materials. The contractor used a helicopter to transport the hot asphalt to the paver as quickly as possible. It took the mix from the Thermo trucks 2300 ft. below the construction site and transferred it directly into the material hopper of the Mini 500 at intervals of just under four minutes.

photo

The helicopter transferred the mix directly into the material hopper of the Vögele paver.

Equipped with the AB 135 extending screed, including bolt-on extensions, the Vögele paver paved the 1.6 in. thick surface course over a width of 5.9 ft. — in several

strips in some cases. The closely timed material transfer enabled a constant paving process. This enabled the construction team to complete the surfacing work, including the paving of the verge, in just two days. For more information, visit wirtgen-group.com/en-us/.

814-371-3600 McKean, PA 800-872-2390 Wilkes-Barre, PA 570-410-2123 Zelienople, PA 724-452-7800

Exchanging the milling drum assembly enables the completion of milling widths of 6.5 ft., 7.2 ft. or 8.2 ft.. With the aid of the quick-change system, the entire milling drum housing can be exchanged in less than an hour, according to Wirtgen.

Wirtgen Group Performance Tracker Milling, or WPT Milling for short, is available for the automated documentation of milling tasks. The operator is kept constantly informed about the current machine and job parameters, and when the work has been completed, the data is transmitted to the machine owner, who can then use them for fast and precise billing.

In addition to displaying construction site and machine data, the automated documentation also shows the CO₂ emissions for the entire construction site. The John Deere

Operations Center presents all information in real time.

The Level Pro Active leveling system was developed by Wirtgen specifically for cold milling machines. Clearly readable control panels provide information and measured values from all currently connected sensors and ease the machine operator’s workload, according to Wirtgen.

The system is fully integrated into the control system of the cold milling machines and, as essential machine functions are directly interconnected, enables a high level of automation and precise milling results. The system also offers numerous automatic and additional functions that make the operator’s job easier, for instance, automatic lifting for driving over manhole covers. For more information, visit wirtgen-group.com.

ADTs such as the Rokbak RA30 and RA40 are built for off-road performance, steep grades and tough terrain.

Haulers such as these feature regularly across projects you’d expect them — and some where you wouldn’t. Here’s a look at six unique, and perhaps unexpected, ways articulated haulers are working harder and smarter — beyond the pit.

One of the most versatile adaptations of ADTs is the articulated water truck. These haulers can be used for dust suppression, site cleaning and even emergency firefighting. Equipped with water tanks and pumps, ADTs can perform on the tough terrain where traditional fire trucks may struggle. Units are able to transport water, assist in earth moving and prove a stable presence in unstable conditions. Recently, through a partnership with Hydex, Rokbak haulers have been transformed into mobile water distribution units.

In the dense and often uneven landscapes of forest operations, haulers fitted with logging platforms have become forestry workhorses. Their ability to traverse slippery, muddy and steep terrain makes them ideal for hauling large quantities of logs to and from remote locations. ADTs with logging racks help maintain forestry productivity even in adverse weather conditions or undeveloped sites.

The robust engineering of articulated haulers makes them perfect for defense operations. Modified as military trucks, these vehicles can transport equipment, munitions or personnel across unpredictable terrain where conventional trucks would fail. Their high ground clearance and drivetrains are suited for rapid deployment, disaster response and logistical support in both combat zones and humanitarian missions.

Drilling and geotechnical projects can benefit from ADTs converted into mobile drilling platforms. When equipped with hydraulic drill arms and on-board compressors, these rigs can reach otherwise inaccessible sites — whether for mineral exploration, utility installation or foundation work. Their articulation and all-terrain capability mean operators can access tough areas without creating new access roads, minimizing environmental impact.

Articulated trucks can play an essential role in waste management, especially in landfills, recycling facilities, demolition sites and waste processing plants. Nearly every landfill uses one or more ADTs for tasks like cell development, hauling soil and building haul roads. Designed for rough terrain, slopes and soft or wet ground, these trucks are ideal for the challenging conditions often found in such environments.

Their versatility and durability make them a key asset in efficiently transporting waste and debris across large-scale operations.

Whether it’s a flood, landslide or wildfire aftermath, ADTs can be rapidly repurposed for emergency logistics. Their ability to transport heavy supplies, debris and water can contribute to post-disaster operations. The high articulation and ground clearance allow access to remote areas where other trucks cannot go, delivering aid or clearing paths for emergency services.

Molded in Motherwell, Scotland, Rokbak’s ADTs are built to be more than dump trucks. The RA30 and RA40 platforms serve as foundations for industry-specific solutions and can help redefine what’s possible on — and off — the road..

(This article is courtesy of Rokbak.)

MAINE Heavy Machines, Inc.

www.heavymachinesllc.com

SKOWHEGAN (207) 858-0051

MASSACHUSETTS

Quality Fleet Service

SOUTH PORTLAND (207) 550-0014

www.qualityfleetservice.com

EVERETT BROCKTON

(888) 267-3857

SOUTH HADLEY (413) 213-0632

(833) 444-6373

MARYLAND Liebherr r Equipment Source

www.liebherr.com

BALLTTIMORE (410) 379-3994

NEW JERSEY GT Mid Atlantic, LLC. wwwgtmidatlanticcom

TOTOWA (973) 785-4900

VINELAND (856) 697-1414

NEW YORK

Tracey Road Equipment, Inc.

www.traceyroad.com

ALBANY (518) 438-1100

KIRKWOOD (607)7755010 SYRACUSE (315) 437-1471 ADAMS CENTER

HENRIETTTA A (585) 334-5120

QUEENSBURY (518) 793-9688

PENNSYLVLVVAANIA RECO Equipment, Inc. www.recoequip.com

CRANBERRY TWP (724) 779-4646

(315) 788-0200

(732) 780-4600 (607) 775-5010

Tracey Road Equipment, Inc.

MARCY (315) 765 8746 www.traceyroad.com

WILKES-BARRE (607) 775-5010

VIRGINIA Liebherr r Equipment Source www.liebherr.com

MANASSAS (703) 392-0111

NEWPORT NEWS (757) 240-4250

iebherr USA, Co. offers a materialhandlingequipm

n extensive line of earthm entandtechnologyinth

oving and eUSAMain c o p d c R in material handling equipment and technology in th components are developed and manufactured in-h or in close collaboration with our partners to ensu possible quality standards.These components inc drive and controltechnology, diesel engines, and a components for hydraulics, gearboxes and electro Reach out to your local Liebherr distribution partne nformation.

e USA Main ouse by Liebherr re the highest lude the entire variety of nic systems. rfor more

see CHART page 62

Komatsu and Pronto announced a strategic collaboration to deploy Pronto’s autonomous haulage technologies to quarry operations in the North American market.

The partnership centers on the launch of Komatsu Smart Quarry Autonomous, powered by Pronto, a system that integrates Pronto’s autonomy technologies into quarrysized haul trucks and ties into Komatsu’s Smart Quarry solutions. This alliance “further positions both companies as leaders in transforming the quarry industry through cutting-edge autonomous technologies,” according to the companies.

“This collaboration with Pronto accelerates our vision of smart, automated quarry operations,” said Jason Anetsberger, Komatsu’s senior director of customer solutions. “We have decades of experience with autonomous haulage in large- scale mining. Now we’re bringing that expertise to quarries of all sizes. It’s a solution that helps drive productivity beyond what was previously possible and can support efforts to enhance safety by facilitating the removal of workers from areas of potential hazard.”

“Partnering with an industry leader like Komatsu is about more than technology, it’s about accelerating the future of heavy industry,” said Anthony Levandowski, CEO of Pronto. “Previously, the most advanced autonomy was reserved for the largest mines. Today, by combining Komatsu’s trusted hardware and vast support network

with Pronto’s scalable, intelligent autonomous platform, we are fundamentally changing the game. We’re enabling a future of enhanced safety and incredible productivity that is now accessible to quarries of all sizes.”

The new OEM-agnostic solution will allow quarry operators to retrofit existing Komatsu vehicles or purchase new trucks equipped with Pronto’s self-driving system, enabling 24/7 operation with minimal human intervention, according to the company.

The result is a step-change in operations: promoting safety by removing drivers from the immediate quarry environment, facilitating consistent cycle times with better fuel efficiency and providing data-driven insights via the Smart Quarry platform designed to optimize the overall operation of quarries.

Pronto’s autonomous technologies use artificial intelligence and an array of rugged sensors to perceive the environment and navigate haul roads. This streamlined approach is designed to significantly lower the cost and complexity of deploying autonomy for quarries of all sizes.

Combined with Komatsu’s Smart Quarry site fleet management and analytics suite, operators will be equipped with an unprecedented level of insight and real- time control over their operations.

For more information, visit komatsu.com.

A Montano Co., Inc.

www.amontanoco.com

571 Route 212 • Saugerties, NY 12477

845.247.0206

All Island Equipment

www.allislandequipment.com

39 Jersey St. • West Babylon, NY 11704

631.643.2605

Butler Equipment

www.butlerequip.com

631 New Park Avenue West Hartford, CT 06110

860.233.5439

George & Swede Sales & Service www.georgeandswede.com

7155 Big Tree Rd. Pavilion (Buffalo/Rochester), NY 14525 585.584.3425

Lorusso Heavy Equipment, LLC www.lhequip.com

Loved for the features. Trusted for the performance.

MAKE YOUR MOVE

...to greater versatility, performance, comfort, and visibility

...to more standard features

...to easier service

Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more without feeling like longtime fans.

...to excellence in earthmoving equipment

...to HiMATE telematics, for greater operational intelligence

or na.hd-hyundaice.com.

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, na.hd-hyundaice.com

Leading-edge solutions help mine owners address their most pressing concerns: operating costs, productivity, the environment and mine safety. Hitachi Construction Machinery is forging a path toward Zero Emissions, Zero Downtime and Zero Entry Mines to reduce fuel consumption and interruptions for a lower cost per ton while enhancing safety by removing employees from mining operation danger zones.

Hitachi Construction Machinery pioneered the hydraulic excavator beginning in 1965. In 1979, the company entered the mining industry in earnest. Today, the company offers a range of EX-7 wired mining electric excavators that complement conventional EX-7 excavators, helping mine operators lower their total cost of ownership (TCO) while slashing greenhouse gas emissions.

EX-7 electric excavators require less frequent servicing and experience reduced machine downtime by eliminating the diesel engine.

When paired with reliable EX5600-7 excavators, the nextgeneration EH4000AC-5 rigid dump trucks make for a sustainable and efficient mine site. EH4000AC-5 dump trucks have been designed to reduce fuel consumption while enhancing productivity, reliability and safety.

Work mode selection allows workers to choose the optimal mode based on the mining site environment and operating conditions. In ECO mode, the engine output is lower than the default setting, resulting in reduced fuel consumption. H/P mode provides higher engine output.

This model also has been designed with the potential retrofit expansion to trolley diesel and battery systems, making it nextgeneration capable for reduced emissions.

Hitachi mining haul trucks offer a retrofittable trolley configuration that allows drivers to alternate between powering the truck in diesel mode and raising the pantograph to power the truck via overhead catenary lines in Trolley Mode.

Trolley trucks simultaneously boost production, reduce operating costs and lower greenhouse gas emissions. They climb uphill slopes at approximately twice the speed of diesel trucks and reduce noise emissions while running in trolley mode.

While running in trolley mode, the diesel engine runs less extending the engine life and reducing maintenance costs, according to the manufacturer.

Hitachi Construction Machinery elevates mine site sustainability to the next level with the development of a zero-emission full battery trolley dump truck.

Drawing electric power from a dynamic charging system allows continuous operation with no stops for recharging.

This dynamic charging system minimizes the weight of the battery solution, maximizing the truck’s payload capacity.

The all-battery trolley dump truck utilizes an ABB-supplied onboard battery system and dynamic charging option via pantograph and overhead trolley lines to simultaneously charge the battery and provide energy to power the truck. Regenerative braking also adds charging capabilities to the battery management system.

The drive toward zero emissions requires a holistic approach that extends beyond the equipment. Mine sites operate 24/7 and they need management solutions to reduce environmental impact while achieving sustainable resource extraction.

Fleet management and digital mining solutions from Wenco, a wholly owned subsidiary of Hitachi Construction Machinery, and Envirosuite, an environmental intelligence

company, provide real-time data to enable responsible mining practices.

Hitachi Construction Machinery offers a full suite of digital solutions to solve environmental and greenhouse gas challenges.

Through business partnerships and startups, there is a suite of innovative solutions across the full spectrum of mining operations. One example is analyzing driver operation data and machine emissions to calculate optimal operation routes.

Safety is a primary concern when people work close to mining equipment. Limiting employee exposure is possible through mine site automation, such as driverless automated haul trucks.

The Hitachi Automated Haulage System (AHS) combines advanced digital technologies and Wenco International Mining System’s fleet management system (FMS) to enable uncrewed operation of mining trucks at open-cut mining pits. The system optimizes route navigation, acceleration and braking for decreased life-cycle costs.

AHS takes automation to the next level by allowing mixed fleet integration with manned fleets while transitioning from conventional to autonomous operations, open interoperability to optimize across your entire truck fleet and the ability to retrofit existing trucks.

On the path to a Zero Entry Mine, Hitachi Construction Machinery is developing a system for semi-autonomous and remote operation of ultra-large hydraulic excavators.

Key features of this system are the Digging Assist Function to support the excavation of ore, and the Loading Assist Function to support an optimized loading cycle.

Once complete, this system aims to improve operational performance, and mine sites will benefit from reduced operator burden and increased productivity.

Reducing downtime and extending product life helps mine sites maintain production rates while reducing greenhouse gas emissions.

Mine sites can achieve both goals by closely monitoring mining operations and machine health.

With ConSite Mine remote monitoring and remanufacturing services, users can prevent breakdowns and extend the life of their machines.

ConSite Mine remotely monitors the condition of large hydraulic shovels and rigid dump trucks, promptly generating alerts when sensors detect abnormalities.

One of the features, ConSite Oil, continuously monitors oil conditions to catch issues that occur between oil analysis intervals.

ConSite Mine Plus leverages digital platforms with ecosystem partners to enhance operational efficiency, reduce unexpected downtime and maximize equipment performance. The consolidated digital platform provides customers with a Path to Zero Downtime.

Hitachi Construction Machinery established the Technological Centers of Excellence (TCoE), which remotely monitors and supports mine operations 24 hours a day, 365 days a year from Australia, Japan and Canada.

The same information customers get in their mine control room is monitored in real-time. Advanced digital technologies will analyze data to help drive customer solutions.

For more information, visit www.hitachicm.us/industry/mining/.

Five Star Equipment, Inc.

www.fivestarequipment.com

60 Paul Rd., Rochester, NY 585-235-3011

1653 NY Route 11, Kirkwood, NY 607-775-2006

284 Ellicott Rd., Orchard Park, NY 716-662-2191

5835 East Taft Road, North Syracuse, NY 315-452-4560

1300 East Dunham Dr., Dunmore, PA 570-346-1701

46 Route 97, Waterford, PA 814-796-2663

2585 Lycoming Creek Rd, Williamsport, PA 570-494-4030

Groff Tractor & Equipment

www.grofftractor.com

6779 Carlisle Pike, Mechanicsburg, PA 717-766-7671

2550 E. Cumberland St., Lebanon, PA 717-273-2616

800-225-4001

3215 State Rd., Sellersville, PA 215-258-5700

800-523-2209

400 Stoke Park Rd., Bethlehem, PA 610-867-4657

800-587-9790

640 Lowther Rd., Lewisberry, PA 717-938-6568

866-787-0001

179 Perry Hwy, Harmony, PA 724-776-3636

963 South Center Ave., New Stanton, PA 724-755-0124

Leslie Equipment

www.lec1.com

Beaver, WV

304-255-1525

Cowen, WV

304-226-3299

Cross Lanes, WV

304-204-1818

Pleasant Valley, WV

304-534-5454

Norton, WV

304-636-6421

Marietta, OH

740-373-5255

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

JESCO, Inc.

www.jesco.us

Middletown, DE

302-376-0784

South Plainfield, NJ

908-753-8080

800-241-7070

Fairfield, NJ

973-227-2221

800-321-8080

Lumberton, NJ

609-267-2020

888-217-0600

Beacon, NY

845-831-1800

800-724-0725

Deer Park, NY

844-482-0910

JohnDeere.com/ADTs

Oxford, MA 508-987-8786

North Billerica, MA 978-667-4345

Plymouth, MA 508-830-9997 NO. Swansea, MA 508-379-9810 Springfield, MA 413-543-5595

Clifton Park, NY 518-371-5111

Gouverneur, NY 315-287-0703

Hermon, ME 207-947-6786

Houlton, ME 207-532-6517

New Canada, ME 207-834-6701

Westbrook, ME 207-773-3777

Pembroke, NH 603-225-2769

Springfield, VT 802-885-6840

Williston, VT 802-658-2121 W.I. Clark Company www.wiclark.com Wallingford, CT 203-265-6781

Danbury, CT 203-775-1203

Plainfield, CT 860-546-4808

AdClosingDate October9,2025

PublishingDate October22,2025

AdClosingDate November6,2025

PublishingDate November19,2025

AdClosingDate December4,2025

PublishingDate December17,2025

AdClosingDate TBD2026

PublishingDate TBD2026

AdClosingDate TBD2026

PublishingDate TBD2026

After the structure sat virtually untouched for nearly two decades, the owner of the Fourteen Foot Bank Lighthouse in Delaware Bay is reigniting an effort to restore the historic beacon that sits approximately 3.5 mi. off the coast of Bowers Beach, Del.

Michael Lynn Gabriel purchased the 19th century lighthouse during an online auction in 2007 for $200,000. At the time, he had big plans for the structure, but health issues at the time precluded him from pursuing any projects, the Cape Gazette in Lewes, Del. reported Sept. 9.

Gabriel, who lives on the West Coast, had a meeting with the U.S. Coast Guard in July, and the hope is that the agency can participate in restoring the lighthouse, which remains fully operational.

He said the timing works out because the Coast Guard will soon be upgrading the lighthouse’s batteries and solar component. More usable space can be created inside the structure, he added, once the agency positions the batteries closer to the lighthouse’s walls.

The most important thing to do right now, Gabriel told the Gazette, is to create a powered lift for people and equipment to access the lighthouse.

“I want people to be able to go on and off the lighthouse easily without climbing dangerous, wet ladders 30 feet in the air,” he said.

Besides bringing in the Coast Guard to help in the restoration process, the U.S. Army Corps of Engineers also will be consulted on whether it can design a dock at the base of the structure.

Gabriel’s ultimate goal is to restore what was removed from the lighthouse 50 years ago when its operation became automated.

“To this day, no one at the Coast Guard can explain why they gutted lighthouses rather than simply putting a lock on the doors,” he said.

A GoFundMe page to collect money for the Fourteen Foot Bank Light restoration efforts was established by Gabriel, but he also hopes to acquire future grants for the project.

The lighthouse is named after an oval shoal of the same name in Delaware Bay.

Prior to a lighthouse being constructed at the site, the area was monitored by a lightship. However, harsh winters often forced the lightship to abandon its post and seek refuge behind the breakwater off Lewes. In 1878, a lighthouse was finally recommended to ensure around-the-clock warnings to passing ships.

Construction of the lighthouse took place from 1885 to 1887, and it became the first such light in the nation to be constructed using the pneumatic caisson method. The wooden base and the cast-iron cylinder were made on shore and sailed to the shoal from Lewes, located approximately 20 mi. to the west.

The keeper’s house atop the caisson is a two-story, castiron dwelling, fabricated by Messrs. H.A. Ramsay & Son of Baltimore, Md. It also had a basement between the first floor and the concrete base of the caisson cylinder.

According to the website Lighthousefriends.com, the Fourteen Foot Bank Light’s original builders moored the old 200-ft.-long steamer Moro Castle at the construction site with six anchors, and its massive deck was used to store machinery, sand, broken stones, timber, a kitchen and quarters for the workers, while coal, cement and sections of the cylinder and air shaft were placed below deck.

In addition, secured amidships was a boom derrick capable of lifting 2 tons and reaching 30 ft.

In a near-disaster, shortly before work on the foundation was complete, the Moro Castle parted her moorings and started to drift toward the cylinder. To lessen the impending impact, a couple of alert workers dropped fenders over the side of the cylinder.

When the ship struck the lighthouse’s foundation, the joints between the plates of iron on which some workers were sitting opened up and latched on to a couple of the men’s trousers. Not wanting to be left behind, they decided to slip out of their pants, which held them fast to the cylinder, and leapt on board the errant ship.

When completed, the construction project came in under budget at $125,000, and the Fourteen Foot Bank Light was finally activated in April 1887.

If the new 21st century rehabilitation project comes to fruition, the Gazette noted, Gabriel plans to restore the structure’s three bedrooms and two bathrooms as well as update the kitchen with period-appropriate appliances. He also wants to power the living space with a wind generator.

In addition, Gabriel hopes to host tours and possibly offer the living space as a bed and breakfast.

www.amontanoco.com

571 Route 212, Saugerties, NY 12477 845/247-0206

www.andersonequip.com

18 Gorham Industrial Pkwy Gorham, ME 04038 207/591-5482

142 Target Industrial Circle Bangor, ME 04401 207/942-0177

4176 Route 417 Allegany, NY 14706 716/372-8822

720 E Franklin Street Endicott, NY 13760 607/748-3400

115 Middle Road Henrietta, NY 14467 585/334-6770

2140 Military Road Tonawanda, NY 14150 717/877-1992

6317 Thompson Road Syracuse, NY 13206 315/463-8673

912 Albany Shaker Road Latham, NY 12110 518/785-4500

151 Packard Road East Montpelier, VT 05651 802/223-9689

1 Andy’s Way South Charleston, WV 25309 304/756-2800

www.chappelltractor.com

454 Route 13 South Milford, NH 03055 800/698-2640

251 Route 125 Brentwood, NH 03833 603/642-5666 391 Loudon Road Concord, NH 03301 800/358-6007

www.GTMidAtlantic.com

Greenwood, DE 800/756-9433

Folcroft, PA 610/586-2710

Freehold, NJ 731/780-4600