By Larry Bernstein CEG CORRESPONDENT

By Lucy Perry CEG CORRESPONDENT

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

Committed to maintaining high service standards, Liebherr is building a logistics center in Tupelo, Miss., that will streamline the distribution of parts and components, ensuring timely delivery and improved availability.

Pennsylvania Gov. Josh Shapiro visited the Philadelphia Navy Yard earlier in May 2025, to highlight a $30 million investment that is planned to transform 54 acres into advanced manufacturing, life science and commercial use sites.

12 INDUSTRY LEADERS TAKE PART IN ARTBA LEADERSHIP PROGRAM

Emerging leaders in the transportation design and construction industry completed an intensive introduction to federal legislative and regulatory issues during the ARTBA Foundation’s Industry Leader Development Program.

Virginia Gov. Glenn Youngkin broke ground April 24, 2025, on the highly anticipated New River Valley Rail Project in the town of Christiansburg, located southwest of Roanoke, Va.

A trio of member-driven guidance documents to help promote the agreed-upon use of common language when representing the non-road equipment industry were issued by AEM.

The Philadelphia Phillies and NEST once again joined forces to present the second annual Skilled Trades All-Star Program to educate and inspire Philadelphia students about career opportunities in the skilled trades.

24 CHILDREN

Seven children of transportation construction workers killed on the job will receive post-high school financial assistance for the 2025-26 school year due to the ARTBA Foundation scholarship initiative.

37

Trimble announced a new integration between its B2W Track and Trimble Siteworks software systems to automate and enhance progress quantity tracking for earthwork and civil contractors.

NY CREATES, the entity that owns the Albany, N.Y. NanoTech complex on Fuller Road, said in early May 2025, that its new NanoFab Reflections building will now cost $614 million, an increase of $64 million.

38

The Steel Erectors Association of America (SEAA) announced the winners of its 2025 Safety Excellence and Craft Training Excellence Awards. These honors highlight member companies who demonstrate exceptional performance.

46

Associated Equipment Distributors (AED) announced that Nikki Haley will be the featured keynote speaker at the 2026 AED Summit in Dallas, Texas, Jan. 19-21, 2026. Haley will be joined by a lineup of additional keynote speakers.

48 GOVERNMENT REVERSES ORDER, ALLOWS N.Y.’S HUGE OFFSHORE WIND

The Trump administration on May 19, 2025, allowed construction to proceed on a massive wind farm off the coast of New York’s Long Island, a month after federal officials had issued a highly unusual stop-work order.

50 CHARLES D. STAHL HOSTS SPRING OPEN HOUSE IN LITTLE FALLS

Charles D. Stahl Sales & Service in Little Falls, N.Y., welcomed customers, contractors and industry professionals May 2, 2025, to its annual Spring Open House. The event showcased a lineup of outdoor power equipment.

The International Association of Bridge, Structural, Ornamental and Reinforcing Iron Workers (IW) and its 4,000 partner contractors have launched a partnership with CredibleMind, an innovative digital mental health platform.

ROKBAK MODEL RA30 OFF ROAD TRUCK: 30 TON CAPACITY WITH TAIL GATE, 276HP SCANIA ENGINE. AVAILABLE FOR SALE OR RENT! +N5027..........AVAILABLE FOR RENT OR PURCHASE

NEW ASV RS75 WHEEL SKID STEER: OPEN ROPS, SUSPENSION SEAT, 74" BUCKET, 21.3 GPM, ELECTRIC PLUG ON BOOM FOR ATTACHMENTS, MAX CAB, UNIT# N4200......CALL FOR PRICE

ANACONDA DF410 SCALPING SCREEN: 2 DECK TRACKED SCREENING PLANT WITH LOW HOURS, UNIT# AG1381........................................................................................CALL FOR PRICE

ANACONDA TR75 TRACKED CONVEYOR: 42” X 75’ CONVEYOR, IT ALLOWS FOR STOCKPILING OR FEEDING OF A RANGE OF APPLICATIONS. THE TR75 HAS A VARIABLE SPEED CONVEYOR IN ORDER TO FACILITATE FOR DIFFERENT APPLICATIONS SUCH AS SAND, GRAVEL, AGGREGATES, COMPOST, COAL AND WOOD CHIP. WE STOCK A FULL RANGE OF SPARE PARTS AS A DISPLAY OF OUR COMMITMENT TO PROVIDE A DEDICATED AND RESPONSIVE SERVICE TO ALL OUR CUSTOMERS, 6 UNITS IN STOCK........................................................CALL FOR PRICE

ANACONDA FTR150 UNIT AG1353: MID SIZE FEED LOADER RANGE. FULLY EQUIPPED WITH 50' STOCKPILING CONVEYORALLOWS DFOR STOCKPILING OR FEEDINGA WIDE RANGE OF APPLICATIONS. INCLUDES OPTIONAL 2 DECK VIBRATING GRID......................CALL FOR PRICE

ASV MODEL RT50: ALL WEATHER CAB WITH HEAT AND AC, SUSPENSION SEAT, 15” RUBBER TRACKS, 60” BUCKET WITH BOLT ON EDGE, UNIVERSAL SKID STEER COUPLER, YANMAR TURBO DIESEL ENGINE, BLOCK HEATER, ATTACHMENT CONTROL KIT, REAR VIEW CAMERA, APPROXIMATELY 300 HRS, UNIT# 4310............................................................CALL FOR PRICE

SIMEX PLC-24 24" WIDE COLD PLANER WITH REVERSIBLE DISCHARGE CONVEYOR: CUTTS UP TO 7" DEEP, 16 DEGREE TILT, 27-40GPM DISSCHARGE CONVEYOR HELPS LEAVE A CLEANER CUT, WINDROWS MATERIAL BEYOND THE CARRIER FOR EASIER CLEAN UP, UNIT# AT4540...... $25,400

2020 BOBCAT T740: WITH CAB, HEAT & AIR EXCELLENT CONDITION, 1600 HOURS, HYDRAULIC COUPLER, 2 SPEED, UNIT# U5863................................................................$39,000

KOBELCO SK350LC-10, APPPROXIMATELY 2400 HOURS, 31.5” TRACK SHOES, 10’10” ARM, 2 WAY AUXILLIARY HYDRAULICS, HAND CONTROL PATTERN CHANGER, HEATED AIR RIDE SEAT, VERY GOOD CONDITION, UNIT# N3651................................................................$183,000

AG1359, ANACONDA J12 JAW CRUSHER: IS AN AGGRESSIVE & POWERFUL MOBILE JAW CRUSHER. WITH THE PROVEN ABILITY OF THE UNIVERSAL CRUSHERS JAW CHAMBER 28" X 44" WITHIN AN INNOVATIVE ANACONDA TRACKED SOLUTION........................CALL FOR PRICE

30”X50’ ELECTRIC RADIAL STACKERS: 5 IN STOCK..........................................CALL FOR PRICE

2020 KOBELCO SK210LC-10: 2 WAY AUX HYDRAULICS, 31.5” SHOES, PATTERN CHANGER, 850 HOURS, 1 OPERATOR. UNIT# U5865............................................................CALL FOR PRICE

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS........................................$88,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXTENDAHOE, TOOL CARRIER..................................................................................$32,995

EXCAVATORS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER......................................................

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER........................................................................................

$105,000

$149,995

SKID STEER LOADERS:

2021 KUBOTA SVL97-2 TRACK SKID STEER, CAB, HVAC, 905 HRS, STD FLOW HYD, HYD COUPLER, 78” BKT, BACKUP CAMERA................$69,000

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS..................................$45,000

$29,995

2008 NEW HOLLAND B95B, 5805 HRS, CAB, HVAC, 4WD, EXT HOE, TOOL CARRIER, TURF TIRES, BHOT SET TO CAT......................................

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE.... $99,995

CHIPPERS:

2019 KOBELCO SK140RLC, 2192 HRS, CAB, HVAC, HYD THUMB, FRONT BLADE, RUBBER TRACK PADS..............................................................SOLD

2023 KOBELCO SK140RLC-7, 288 HRS, CAB, HVAC, BLADE, THUMB, COUPLER........................................................................................

$169,995

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB $169,995

TRACTORS:

2012 CASE MAX110, CAB, HVAC, 6380 HRS, 4WD, LOADER, 3PT HITCH, 3 SETS REAR REMOTS, AG TIRES......................................................$42,000

$29,995

2013 BANDIT 1390XP CHIPPER, 15” CAPACITY, 142 HP PERKINS DIESEL ENGINE, 2511 HRS, AUTOFEED, WINCH..........................................

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH..........................................................................$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP......................................................................................................$64,995

SCREENERS:

2021 VIBROSCREEN SCM40

2021 VIBROSCREEN SCM27

NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE................................................................................

$79,995

$62,995

$195,000

NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF........$179,995

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED........................................................................................

$295,000

2003 TEREX HR16 MINI EXCAVATOR, CAB, HEAT, 3253 HRS, HYD THUMB, RUBBER TRACKS, 4 TON..................................................................$19,995

2018 YANMAR VI080-1A, CAB, HVAC, 1351 HRS, THUMB, RUBBER TRACKS................................................................................................SOLD

WHEEL LOADERS:

2022 AVANT 528LX, 40 HRS, CAB W/HEAT, 51” BUCKET, 43” ROTARY BROOM, LIKE NEW CONDITION........................................................

$46,995

2002 DAEWOO MEGA200V, 2YD 4IN1 BKT, 2283 HRS, HYD COUPLER........ $39,995

MISCELLANEOUS:

AFE ROTARY FORESTRY HEAD, SKID STEER MOUNT $17,995 HLA 96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT.

By Cindy Riley CEG CORRESPONDENT

Committed to maintaining high service standards, Liebherr is building a logistics center in Tupelo, Miss., that will streamline the distribution of parts and components, ensuring timely delivery and improved availability. The new facility will incorporate the latest technologies and sustainable design elements, in an effort to meet changing customer requirements.

The planned investment sum for the whole campus development is up to $230 million. In the long term, Liebherr is planning to create more than 300 new jobs on the campus. These expansions and services will enable Liebherr to make long-term partnerships.

A project of this scale not only represents a major investment in Mississippi’s economic future but also positions the Tupelo region as a critical logistics hub in the southeastern United States. Based on Liebherr’s groundbreaking press release, this project will generate hundreds of construction and longterm operational jobs, strengthen regional supply chain capabilities and attract further industrial development. This kind of strategic infrastructure sets the stage for sustained growth, increased tax revenues and enhanced competitiveness for both the local community and the state.

The first phase involves an investment of $176 million. The facility will initially support the distribution of products from the multinational equipment manufacturer’s earthmoving, tower cranes, concrete technology, mobile and crawler cranes and maritime cranes, as well as components. Additional product segments are expected to

The planned investment sum for the whole campus development

create more than 300 new jobs on the campus.

be integrated shortly after operations commence.

Hive Business Park is considered an ideal setting for Liebherr's new facility, as it combines strategic location, robust infrastructure and strong community backing. The central location facilitates efficient distribution and reduces transit times. The park is equipped with modern infrastructure that supports

large-scale logistics operations, including warehousing, distribution, pre-assembly, packaging and customs services.

Noted in Liebherr’s press release, this facility will greatly enhance Liebherr's operational efficiency across the Americas and the United States by streamlining the distribution of parts and components, reducing delivery times and improving the availability

of critical supplies. This strategic investment will bolster Liebherr's supply chain infrastructure, ensuring that customers receive timely support and parts availability. According to Liebherr’s recent news release regarding updated information on this large scale project, it is expected to create numerous job opportunities, with an see LIEBHERR page 20

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

New

55

3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN

pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK! Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

Rogers TAG21XXL, 24' deck, 6' tail, 235's on aluminum outers, 8' Air Ramps. Safety Lighting Package. Red Paint.. IN STOCK!

Pennsylvania Gov. Josh Shapiro visited the Philadelphia Navy Yard earlier in May 2025, to highlight a $30 million investment that is planned to transform 54 acres into advanced manufacturing, life science and commercial use sites.

The funds were awarded through the Pennsylvania Strategic Investments to Enhance Sites (PA SITES) program and aims to create jobs and grow the state’s economy by developing the Navy Yard’s Greenway District.

The local investment is part of Shapiro’s first round of PA SITES funding of $64 million awarded to 11 sites across the state.

Navy Yard Philadelphia photo

Ensemble / Mosaic Team with Gov. Shapiro (L-R) are Barnin Mitra, Leslie Smallwood-Lewis, Jasmine Childress, Alex Schon, Riley Balitsaris, Kate Vivaldo, Brian Cohen, Gigi Umstead, Michael Ianni, Gov. Josh Shapiro, Mark Seltzer, Nelson Way and Michael McColgan

“When I took office, I made clear that my administration would be focused on making Pennsylvania more competitive and making us a leader in economic development, job creation and innovation,” he said. “We’ve heard loud and clear: Pennsylvania needs more shovel-ready sites to compete for businesses and good-paying jobs. These investments lay the groundwork to attract companies, strengthen communities and make sure our commonwealth is ready to compete and win in today’s economy.” Shapiro was joined by Rick Siger, secretary of the state’s Department of Community and Economic Development, at the Navy Yard, currently home to more than 150 employers and 15,000 jobs, South Philly Review reported May 18, 2025.

“When we were developing the Economic Development Strategy, we took feedback from site selector experts who told us Pennsylvania needs more readily available sites for growing businesses to see [the state] as a viable option,” Siger said. “These projects will create new jobs, expand opportunity for Pennsylvanians and strengthen the commonwealth’s economic future for years to come because when it comes to delivering real economic development results, Pennsylvania gets it done.”

A $30 million grant awarded to Ensemble/Mosaic Navy Yard LLC will fund utility infrastructure, soil excavation, grading and stormwater management to develop the Greenway District. The construction will prepare six lots for up to 700,000-sq.-ft. of advanced manufacturing and commercial space and complements a $6 billion redevelopment effort that is expected to generate 12,000 new jobs.

Five years ago, the Philadelphia Industrial Development Corp. (PIDC) awarded the partnership development rights to 109 acres at the Navy Yard, which is being transformed into a mixed-use district. The master plan includes 9 million sq. ft. of new development, including lab and manufacturing space for life sciences companies, 4,000 apartments, and 235,000 sq. ft. of retail.

In addition, in 2024, the state’s Housing Finance Agency awarded a $500,000 Pennsylvania Housing Affordability and Rehabilitation Enhancement Fund grant to develop mixed-income residential apartments and the New Africa Cultural Center and Museum in Philadelphia.

“This transformative investment from the commonwealth’s innovative new PA SITES program strengthens the Navy Yard’s role as a powerful engine of job creation and

economic growth throughout Philadelphia and Pennsylvania,” said Jodie Harris, PIDC’s president, who stood alongside Shapiro at the Navy Yard. “It will help attract new businesses, support the expansion of our life sciences and advanced manufacturing industries and create hundreds of good-paying jobs across a wide range of skill and educational levels.

“This is about building opportunity for workers, for small businesses and for the long-term prosperity of Philadelphia and the region.”

The Philadelphia Navy Yard site was chosen among 66 applications requesting more than $377 million during the first round of PA SITES funding. The state continues to accept and review applications on a rolling basis, with additional grant and loan awards expected later this year.

State Sen. Nikal Saval, who represents the citizens of South Philadelphia and also was on hand for Shapiro’s announcement, said, “Pennsylvania thrives when we invest in the brilliance and capacity of our people and communities. The work here at our Navy Yard shows the successful reclamation of a heavily industrialized space. This endeavor demonstrates the importance of — and demand for — development that fosters density, honors accessibility through walkable streets and public transit and embraces design and infrastructure that enables communities to thrive for the long-term, even as our region faces extreme weather and rising sea levels.”

PA SITES funding can be used for grants to conduct plans or feasibility studies for prospective sites as well as construction grants and loans to help finance strategic investments to enhance properties across the state.

Award amounts are determined based on a competitive analysis that includes the applicant’s need, the marketability of the fully developed site and the project’s alignment with the key industries in Pennsylvania’s 10-year Economic Development Strategy, in addition to local and regional priorities.

“With LEED-certified buildings, improvement of state roads like Broad Street and a focus on stormwater management, the Navy Yard is paving the way nationally as a leader in green development,” said Pennsylvania House Rep. Elizabeth Fiedler, whose constituents live in near the Navy Yard. “They’re bringing jobs and revenue to South Philadelphia responsibly, and I’m eager to see this new neighborhood bloom.”

Thirty-one emerging leaders in the transportation design and construction industry completed an intensive introduction to federal legislative and regulatory issues May 6-8, 2025, during the American Road & Transportation Builders Association (ARTBA) Foundation’s Industry Leader Development Program (ILDP).

The ILDP, held in conjunction with the association’s Federal Issues program and the Transportation Construction Coalition Fly-In, provided participants with a solid understanding of industry economics, how transportation work in the United States is funded and financed, how actions by the federal government impact the industry, and how they — and their company or agency — can become politically engaged. ILDP attendees also met with their members of Congress to discuss opportunities to continue to grow investments in surface transportation.

The 2025 class includes:

• Eduardo Luis Acosta Jr., Texas Department of Transportation;

• Kevin Allen, Zachry Construction Corp.; Richard Barrett, RK&K LLP;

• Len Becker, HNTB Corp.;

• Allison Scott Berkheimer, RK&K LLP;

• Thomas Boals, Vulcan Materials Co.;

• Jenna Brose, AECOM;

• Skye Gentile Bush, Parsons Corp.;

• Joseph Cole Denney, J&D Specialized Equipment Hauling;

• Eric Dues, GFT;

• Raymond Farcas, Parsons Corp.;

• Jay Gabrielson, Parsons Corp.;

• Wilson Gebhart, SIMON, A Colas Co.;

• Isabel George, ARTBA;

• Todd Hubbard, Idaho Transportation Department;

• Jad Kabbani, ARTBA;

• Brian Kelso, Delta Cos. Inc.;

• Andy Kowske, HNTB Corp.;

• Aldo Madrid, Texas Department of Transportation;

• Casey Potts, RS&H, Inc.;

• Andre Guzman Rocha, Duit Holdings Inc.;

• Rajeev Shah, Parsons Corp.;

• Gregory Siebers, Parsons Corp.;

• Sarah Silberstein, AGC of Texas;

• Jessica Smith, GFT;

• Cheryl Ashley Spatz, Psomas;

• Rodney Paul Svec, Texas Department of Transportation;

• Timothy Adam White, Terracon Consultants Inc.;

• Alexis Williams, STV Inc.;

• Heather Wills, STV Inc.; and

• Jennifer Wood, Parsons Corp.

Approximately 900 graduates from more than 200 industry firms and public agencies have completed the ILDP since 1996. HNTB, one of the world’s leading infrastructure firms, is the program’s exclusive sponsor.

For more information, visit artbafoundation.org

MANASSAS, VA

6918 Wellington Rd. Manassas, VA 20109 703/257-2381

JESSUP, MD 10421 Guilford Road, Jessup, MD 20794 410/792-9134 from Washington D.C. 301/725-7394

DELMAR, DE

38420 Sussex Highway Delmar, DE 19940 302/846-3033

HARRISBURG, PA 6680 Allentown Blvd., Harrisburg, PA 17112 717/652-5430

KING OF PRUSSIA, PA 450 E. Church Road, King of Prussia, PA 19406 610/279-5200

Virginia Gov. Glenn Youngkin broke ground April 24, 2025, on the highly anticipated New River Valley Rail Project in the town of Christiansburg, located southwest of Roanoke, Va.

As part of the Virginia Passenger Rail Authority’s (VPRA) Transforming Rail in Virginia (TRV) initiative, the construction encompasses railroad infrastructure upgrades that will allow VPRA to extend its Amtrak Virginia service from Roanoke to Christiansburg and return passenger rail service to the New River Valley for the first time since 1979.

“Today’s groundbreaking represents a lot of hard work, determination and collaboration,” Youngkin told the event’s guests. “We are here today because people came to the table and worked together to execute a new and dramatically better deal — one that accelerates the return of passenger rail service to the New River Valley years earlier, on a better line, and at a much lower cost to Virginia’s taxpayers — than the one I inherited. I look forward to all that this station will do to support and grow such an important region of the Commonwealth.”

Amtrak Media noted that the new passenger rail effort in Christiansburg will include:

• a new station platform with a canopy;

a parking lot and access roads;

• track improvements and an updated signaling system; and

• an Amtrak layover facility in the nearby community of Radford, Va.

The estimated cost of the entire VPRA project is $264.5 million. Preliminary construction began in late February 2025, with the bulk of the work set to commence in May 2025.

The extension of service to Christiansburg will be via Norfolk Southern’s main line (N-Line), the result of an agreement between VPRA and Norfolk Southern completed last September through which VPRA purchased the Manassas Line and gained access to the N-Line, according to Amtrak.

By expanding service from Roanoke to Christiansburg on the N-Line, VPRA will use existing infrastructure with a focus on developing a station stop at the Cambria site, which previously served the community from 1904 to 1979.

The project also will enhance Norfolk Southern’s freight service through the area.

“I want to thank VPRA and Norfolk Southern for coming together last year to reach an all-around better deal for Virginians,” said Virginia Secretary of Transportation W. Sheppard Miller III. “The new agreement between VPRA and Norfolk Southern is the reason we are here breaking ground on a project that will provide additional connectivity and promote economic growth in the New River Valley.”

Created by the Virginia General Assembly in 2021, the New River Valley Passenger Rail Station Authority has the lead in renovating the historic Christiansburg station build-

ing at Cambria — to be called the New River Valley Station. Construction is expected to begin in 2027.

“Extending passenger rail from Roanoke to Christiansburg will provide a much-needed transportation alternative along the increasingly busy I-81 Corridor,” said Virginia State Sen. Travis Hackworth. “I’m excited to see this region of Virginia benefit from the Transforming Rail in Virginia initiative. I want to thank all those involved for making this project a reality.”

Amtrak Virginia service is expected to begin in 2027 with two daily roundtrips between Christiansburg and Washington, D.C., with stops in Roanoke, Lynchburg, Charlottesville, Culpeper, Manassas, Burke Centre and Alexandria. Travel times are estimated to be 50 minutes between Christiansburg and Roanoke and just under six hours between Christiansburg and Washington.

From the nation’s capital, the service will continue north onto Amtrak’s Northeast Corridor to Philadelphia, New York, Boston and points in-between.

One of VPRA’s four corridors of service, the Roanoke corridor began with one daily roundtrip between Lynchburg and Washington in 2009. Since that time, the service was extended from Lynchburg to Roanoke and increased from one daily roundtrip to two.

Ridership along the corridor also has grown — from a little more than 100,000 between Lynchburg and Washington during its first year, to more than 343,000 passengers between Roanoke and Washington in 2024.

Since its formation, VPRA’s service has grown to include eight roundtrips daily along four corridors with stops at 17 stations in Virginia and one in Washington, D.C.

“Passenger rail creates greater potential for sustained economic growth, facilitates job creation and provides an efficient, affordable travel alternative to riding on the crowded interstate highway system,” noted Virginia’s U.S. Rep. Morgan Griffith. “Today’s groundbreaking announcement means that the New River Valley will reap tremendous benefits and more. Extension of passenger rail to the New River Valley is an encouraging sign of things to come.”

VPRA was established in 2020 to promote, sustain and expand the availability of passenger and commuter rail service across the state of Virginia. The agency is committed to delivering and expanding its state-supported Amtrak Virginia passenger rail service.

A trio of member-driven guidance documents to help promote the agreed-upon use of common language when representing the non-road equipment industry and discussing the topics of autonomy, cybersecurity and data were issued by AEM this week.

The guidance documents, which are available to view and download on AEM.org, were released in conjunction with AEM’s Celebration of Construction on the National Mall in Washington, D.C. They serve as consensus resources for association staff, members and industry peers to drive conversations and communications related to autonomy, cybersecurity and data.

“When it comes to aligning our members and our industry on ever-evolving issues and topics of importance, words matter,” said AEM Senior Vice President Curt Blades. “It’s why we leveraged the collective knowledge expertise of our membership to develop these guidance documents. Autonomy, cybersecurity and data impact our industry and our world in so many ways, and AEM is committed to helping ensure conversations and communications surrounding these topics are conveyed clearly, consistently and accurately.”

The three guidance documents were the direct result of months of collaboration between AEM member company representatives serving on the association’s Ag and CE Technology Leadership Groups. While they are not intended to be comprehensive or all-encompassing viewpoints on autonomy, cybersecurity and data, the documents do contain both industry use cases and everyday examples. Ultimately, they help guide information sharing inside and outside of the industry, with lawmakers and regulators, with customers and equipment end users, and with the general public regarding:

• the implementation of autonomy in the non-road equipment industry;

• the levels of cybersecurity for machine data today; and

• how data moves among different layers.

Non-road equipment is designed to execute specific functions relative to its intended applications and tasks in nonroad environments in agriculture and construction. Construction worksites, farm fields, dairies and feedlots, areas of animal husbandry, etc., are dynamic environments defined by fences or other boundaries with some level of restriction for access or entry.

These do not apply to on-road operation of non-road equipment.

For more information, visit AEM.org/Insights.

initial 180 jobs and plans to expand further, potentially creating more than 300 jobs in the long term. This influx of employment will drive economic growth in the region, providing stable incomes and fostering community development. Additionally, the construction and operation of the facility will stimulate local businesses and services, contributing to the overall economic vitality of the area.

Evans General Contractors has been selected as the contractor for the project. According to Arturo Garcia, project executive of Evans General Contractors, the construction of a distribution and logistics center is a multi-phase process. It involves site selection, design, permitting, site preparation, building construction and final systems installation that includes earth work, concrete work, building envelope, steel installation, joist and deck, electrical installation, plumbing, roofing, HVAC and other trades.

“In Mississippi, this process has evolved alongside the state’s growing importance as a logistics hub, due to its strategic location along the Gulf Coast, major interstate highways such as I-55 and I-20, rail connections and proximity to major ports such as the Port of Gulfport and the Port of Pascagoula. Mississippi has increasingly attracted logistics investments due to its strategic geography, improving infrastructure and incentives offered by state economic development programs. The state’s experience in supporting major distribution centers means that while the construction process follows general industry standards, it also includes local adaptations for climate, soil conditions and storm resilience.”

Garcia said work has been progressing steadily and largely uninterrupted.

“We’ve maintained strong momentum across all phases, thanks to proactive scheduling and constant coordination between subcontractors. While we experienced a few weather-related delays due to heavy rain and even some unexpected snow in the area, these impacts were minimal and quickly mitigated through revised daily work plans.

“We’ve also been conducting weekly coordination meetings, particularly focusing on ongoing design developments from systems integrator vendor, SSI Schafer. SSI Schaefer will manage the complete delivery of warehouse and conveyor technology and oversee all involved trades. This collaboration has been crucial in aligning design updates with field conditions and installation sequencing, ensuring there are no bottlenecks during critical path activities.”

Construction currently taking place includes site clearing, mass grade cut /fill,

underground utilities installation, underground electrical duct banks, placing concrete in foundations and slab on grade and soil testing. Garcia noted that Tupelo, like much of northeastern Mississippi, has clayheavy soil that can expand and contract with moisture.

“This creates challenges for laying stable foundations and can lead to long-term structural issues if not properly addressed. Soil testing and appropriate foundation systems, like pier and beam or deep footings, are often necessary. In addition, Mississippi weather has a considerable impact on construction due to its highly variable and often severe climate.

“The state experiences frequent thunderstorms, heavy rainfall, high humidity and extreme heat, especially during the summer months. These conditions can delay project timelines, increase labor and material costs

and pose significant safety risks on site. Rain can also create muddy job sites that are difficult to work on without proper drainage or gravel access roads.”

Liebherr heavy equipment being used on the job includes the L 550 and L 546 wheel loaders for earth work, moving dirt, loading material into trucks and site cleanup; the R 945, R 930 and R 920 crawler excavators for earth work and digging foundations and trenches for utilities; the PR 756, PR 736 and PR 726 crawler dozers for earth work, pushing large volumes of earth and site clearing; a PR 716 crawler dozer; and a TA 230 articulated dump truck.

Liebherr 250-ton and 350-ton cranes also are needed for lifting and placing steel beams, roof and other large structural components, while the Liebherr 38XXT and 47XXT truck-mounted concrete pumps deliver concrete to hard-to-reach areas like

deep footings, slab pours or upper floors.

Other heavy machinery on site includes graders to prepare a smooth, level base for foundations or paved surfaces such as parking lots and loading docks; skid steers for moving material and cleanup; and forklifts for unloading and transporting materials and boom lifts to provide access to high elevations for steel erection, electrical installation and roofing,

Approximately 250,000 cu. yds. of dirt will be moved on the project. Crews are working with roughly 35,000 cu. yds. of concrete and about 180,000 sq. ft. of concrete tilt wall panels.

For an effective construction outcome, Garcia said ensuring effective collaboration among all the various stakeholders is essential and calls for early and consistent engagement.

“It starts with clear communication and shared expectations. This includes owners, architects, engineers, subcontractors, vendors and inspectors to align goals and identify potential conflicts before they impact the schedule or budget.

“We also have weekly design meetings with all stakeholders and weekly meetings with Liebherr vendors to keep everyone informed and accountable. These include agenda-driven updates, milestone tracking and open forums for identifying and resolving issues early.”

The logistics center, a major milestone for the company, is expected to be completed in late 2026. For Joerg Stroebele, managing director at Liebherr-Logistics GmbH, carefully planned design and construction of the facility underscores the company’s dedication to excellence.

“By establishing this facility, Liebherr aims to provide faster and more efficient services to its customers, reinforcing its position as a leader in the industry.” CEG

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

The Philadelphia Phillies and NEST once again joined forces to present the second annual Skilled Trades All-Star Program — an immersive, hands-on event designed to educate and inspire Philadelphia middle school students about career opportunities in the skilled trades.

On June 3, 2025, at Citizens Bank Park, the program welcomed approximately 50 students from Mayfair School. The event serves as a cornerstone experience for students enrolled in a one-of-a-kind trades curriculum led by their teacher, Evin Jarrett, a former contractor who now teaches the only middle school trades program in the district. Throughout the day, students will explore the inner workings of a major league stadium while engaging directly with professionals who operate and maintain it.

“The ballpark may be the backdrop, but the real focus is on building the future,” said Carolyn DiGiuseppe, general manager of facilities of Citizens Bank Park for

Oak View Group. “These students are stepping into a world that is often hidden behind the scenes — but vital to everything around us. We’re showing them that these careers in the skilled trades are not just accessible, they’re essential and filled with opportunity.”

The agenda included behind-the-scenes access to key operational areas within Citizens Bank Park, including the HVAC controls room, carpenter shop, mechanical room and the grounds crew facility. Each station featured interactive discussions led by the Phillies’ facilities team and trade foremen, offering students insight into the systems and teamwork required to maintain the ballpark’s infrastructure.

In addition to the technical

exploration, students received a guided tour of the stadium, a visit from the Phillie Phanatic and lunch at Pass and Stow to round out a day that blends education, mentorship

Seven children of transportation construction workers killed on the job will receive post-high school financial assistance for the 2025-26 school year due to the American Road & Transportation Builders Association (ARTBA) Foundation scholarship initiative.

The program was established with a major gift from two Roanoke, Va., highway contractors and their companies — Stan Lanford (1999 ARTBA chairman) of Lanford Brothers and Jack Lanford (1991 ARTBA chairman) of Adams Construction Company. Scholarships have a value of up to $10,000 annually.

More than 225 “Lanford Family Transportation Construction Worker Memorial” scholarships have been awarded to worthy students from 33 states to pursue undergraduate and graduate courses, as well as technical training.

The 2025 class includes:

Amy McNeil Stepan, Lumberton, Texas

The Philadelphia Phillies and NEST joined forces to present the second annual Skilled Trades All-Star Program.

and inspiration.

Based in South Jersey, NEST helped establish the Skilled Trades Advisory Council (STAC) in 2023, uniting industry experts across the country to champion skilled trades as viable and rewarding career choices. The Skilled Trades All-Star Program is a direct extension of STAC’s mission, seeking to illuminate the path for youth toward these essential roles.

“Programs like this create momentum,” said Rob Almond, CEO of NEST. “By working with schools, communities and forward-thinking partners like the Phillies, we’re helping to change

Amy’s father, Jeffrey McNeil, was killed in 2005 while working for the Texas Department of Transportation. Amy is a graduate student at Texas Woman’s University pursuing her master’s degree to become an acute care gerontology nurse practitioner.

Breana Jones, Gaston, S.C.

Breana’s father, Stan Jones Sr., died in 2007 after being struck by a vehicle while at work for the South Carolina Department of Transportation. Breana will be a senior at Winthrop University studying graphic design.

Katie & Christopher Hutt, Cleveland, Tenn.

Katie and Christopher’s father, Chris, was struck and killed in 2006 while installing signage for United Rentals in a highway work zone. Katie will be a senior studying architecture at the University of Tennessee, Knoxville, where her brother will be a sophomore.

Zoe Watts, Marshall, Ark.

Zoe’s father, James “Kirk” Watts, was killed by overturned equipment while work-

More than 225 “Lanford Family Transportation Construction Worker Memorial” scholarships have been awarded to worthy students from 33 states.

perceptions and create pipelines. The trades offer purpose, pride and prosperity — and those messages need to reach students early.”

Jarrett, whose own story from job site to classroom has drawn national recognition, created the Mayfair program to introduce students in grades 4 through 8 to foundational skills in plumbing, electrical, masonry and carpentry. He incorporates hands-on learning, industry certifications and studentled media like the Dope Student Podcast to make the trades feel tangible and empowering at an early age.

“This is how we change the narrative,” said Jarrett. “We’re not just exposing students to careers — they’re seeing themselves in these roles. When you give young people the tools, literally and figuratively, to shape their futures, they rise to the occasion.” NEST logo

ing for the Arkansas Department of Transportation in 2018. Zoe will be a sophomore majoring in nursing at the University of Central Arkansas.

Bailey Edwards, Gadsden, Ala.

Bailey’s father, Keith, was killed in 2020 when he was struck by an 18-wheeler while placing road work signs for Vulcan Materials Company. Bailey will be a freshman studying biomedical sciences at Auburn University.

Toxey Voudrie, Trussville, Ala.

Toxey’s father, Darin, was struck and killed while working for Jefferson County Roads and Transportation Department in 2015. Toxey will be a freshman studying sports and medicine at the University of Alabama at Birmingham.

Two Graduations

Multi-year Lanford Scholarship recipient Jenna Jares graduated in May 2025 with a master’s degree in occupational therapy from the University of Mary Hardin-Baylor in Belton, Texas.

Another 2024-25 awardee, LaToya Hood, will receive her bachelor’s degree in healthcare administration from Texas Southern University this summer.

For more information, visit artbafoundation.org

generator, Deutz diesel, stk#AE376.......... $27,500

2016

2,531 hours, 41 ft

2018 Peterbilt 567, 272,016 miles, 10 wheel, 15 ft steel Brandon body w/ 3 chutes, Paccar MX13, 455 hp, Allison automatic, 20k f, 46k r, spring suspension, hitch, stk#TK997 $139,500

2017 Doosan DX140LCR-5, 4,288 hours, 32" bucket, hydraulic thumb, a/c, 4 cyl Perkins turbo, 2 speed, backup camera, 33k lbs, stk#XC730....................................$77,500

2017 John Deere 410L, 5,909 hours, 4x4, x-hoe, cab w/ a/c, ride control, pilot controls, 4-in-1 bucket, 1-way rear aux hyd, new 24" digging bucket, stk#BH191..........$49,500

2016 MEC 60J, 3,037 hours, 60 ft boom lift, 8 ft basket, skypower, 4 cyl Kubota turbo, stk#AE044................$23,500

2005 Caterpillar D8T, 17,631 hours, 12'9" semi-u blade w/ tilt, cab w/ a/c, diff steer, 6 cyl Cat C15 Acert turbo, 87k lbs, stk#DZ577..................................................................$129,500

Rebuilt 3264820 transmission Fits Cat 773, 775, 773G, 775G

Just in for Teardown, TL1225D ML701857 telehandler, Machine had 3800 hours when torn down

Bucyrus Erie 22-B Dragline, 1:50 scale - $295

Bantam Lattice Truck Crane on White WC Carrier,1:50 scale..............

Bucyrus Erie 22B Dragline,1:50 scale....................................................

Bucyrus Erie 22B Cable Shovel,1:50 scale............................................$215

Bucyrus Erie 22B Cable Backhoe,1:50 scale..........................................$215

Case 580E Backhoe/Loader,1:35 scale....................................................$65

Case 580SR Backhoe/Loader,1:50 scale................................................$150

Case 850B Angle/Tilt Dozer,1:35 scale..................................................$100

Case 1845B Uni-Loader,1:35 scale..........................................................$60

Case DH4B Trencher,1:35 scale..............................................................$75

Case 9030B Excavator,1:50 scale............................................................$40

Caterpillar AP-1000 Asphalt Paver,1:50 scale......................................$100

Caterpillar C-591 Pipelayer,1:70 scale....................................................$70

Caterpillar CB534 Double Drum Roller, 1:50 scale................................$40

Caterpillar D3 Track-Type Tractor,1:50 scale........................................$110

Caterpillar D4E Track-Type Tractor, new color,1:50 scale......................$75

Caterpillar D4E Track-Type Tractor, old color,1:50 scale......................$75

Caterpillar D6H Track-Type Tractor,1:50 scale........................................$90

Caterpillar D7C Track-Type Tractor,1:50 scale......................................$110

Caterpillar D8L Track-Type Tractor,1:50 scale......................................$100

Caterpillar D8N Track-Type Tractor, 1:50 scale....................................$110

Caterpillar D9N Track-Type Tractor w/black Tracks,1:50 scale............$100

Caterpillar D9N Track-Type Tractor w/yellow Tracks,1:50 scale..........$100

Caterpillar D10 Track-Type Tractor w/ ripper,1:50 scale......................$100

Caterpillar D11R Track-Type Tractor,1:50 scale......................................$75

Caterpillar 225 Crane w/clamshell bucket,1:50 scale............................$50

416 Silver Backhoe/Loader,1:50 scale..................................

cn-wood.com

CONNECTICUT

Newington: 860-665-7470

New Haven: 203-848-6735

MASSACHUSETTS

Avon: 508-584-8484

Whately: 413-665-7009

Woburn: 781-935-1919

NEW YORK

Holmes: 845-878-4004

RHODE ISLAND

Smithfield: 401-942-9191

finkeequipment.com

NEW YORK

Selkirk: 518-767-9331

VERMONT finkevt.com

Colchester (Burlington): 802-316-3805

fosterfwineland.com

PENNSYLVANIA

Ebensburg: 814-472-4441

Martinsburg: 814-793-3734

St. Mary’s: 814-781-1365

hoff

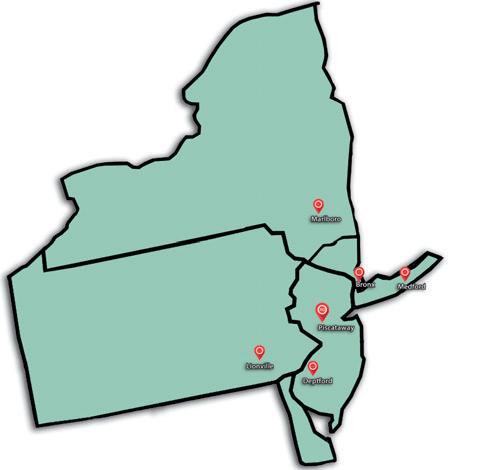

NEW JERSEY

hwyequip.com

Drums: 570-788-1127

Ephrata: 717-859-3132

Harrisburg: 717-564-3031

Lock Haven: 570-769-1070

Deptford: 856-227-6400

Piscataway: 732-752-3600

NEW YORK

Bronx: 718-822-1180

Marlboro: 845-236-3000

Medford: 631-207-2900

PENNSYLVANIA

Lionville: 610-363-9200

hwyequip.com/keystonecme

Delmont: 412-775-0051

VIRGINIA

Bealeton: 540-439-0668

Chesapeake: 757-485-2100

Chester: 804-748-6411

Fishersville: 540-887-8291

Salem: 540-380-2090

• Mounting adapters included with seat

• Seats ship within one business day

• Ship Nationwide

Exact Crane & Equipment’s Jack Swan (president), and his son, Jeff Swan, (vice president of operations), were on the international stage at bauma 2025. This isn’t the first time, as Jack has attended more than 10 bauma trade shows and Jeff is catching up at six shows.

“Over the years, bauma has continued to grow, and machines have come a long way. It’s always impressive to see what industry is working on and what’s next,” said Jeff. “As one of the world’s largest construction trade shows, bauma is instrumental in networking with colleagues and checking out the newest equipment. It provides opportunities for companies, such as Exact Crane who are a prominent name in crane sales and bare rentals in the Midwest, to invest in equipment that focus on reliability, performance and customer satisfaction.”

up time.

Among the highlights at bauma this year, was the much-anticipated arrival of the Tadano AC 5.250L-2, a gamechanger in the all-terrain category. This 300-ton mobile crane offers versatility for contractors needing big capacity, without compromising set-

Some features of the AC 5.250L-2 are its reach, capacity, travel and technology. At the heart of its appeal is one of the longest booms in its class of 259.3 ft., which enables it to handle complex lifts with ease, according to the company.

Whether you’re swinging HVAC units onto tall buildings or erecting tower cranes,

this 5-axle beast stands out with its ability to get into tight areas and offer a long reach. For companies looking for capacity within a short range, the charts on this 300-ton crane are impressive and show its abilities. With maximum counterweight flexibility, variable transport configurations and good taxi crane properties, it offers an economical option for companies as well, according to the compa-

ny.

The Tadano AC5.250L-2 was quite popular at bauma, and Exact Crane is looking forward to having one arrive by year end in Solon, Ohio.

“We are excited to offer another top-performing option for customers,” said Jeff. “It will be a great advantage for companies looking for a compact crane with a big reach.”

As an official Tadano dealer and trusted equipment provider, Exact Crane is always looking ahead — whether its innovation in lifting technology or building stronger relationships across the construction world.

Recently, Exact Crane’s longtime Tadano regional manager, Bob Krause, took on a new role as director of sales. He has been an exceptional sales representative, and everyone at Exact wishes him the best in his new role. Exact also welcomes its new regional manager, Tony Hampton, and looks forward to working with him for years to come.

For more information, visit exactcrane.com and tadano.com. CEG

Visit our website for more attachments!

Trimble announced a new integration between its B2W Track and Trimble Siteworks software systems to automate and enhance progress quantity tracking for earthwork and civil contractors.

This field-to-office connection allows contractors to compare actual material production quantities achieved to planned quantities more easily and accurately. Continuous assessment of field progress can be critical for civil contractors, enabling them to make timely operational adjustments to protect profitability and to bill for accurate payments as work increments are completed, according to Trimble.

“Civil contractors must continuously evaluate how well projects are progressing against budgets, timelines and productivity goals,” said John Sheedy, director of product management of Trimble. “Relying on phone calls, forms, e-mails and other disconnected communications tools to report on production quantities limits timeliness and accuracy of that reporting. This new software integration brings automation to the process to increase efficiency, eliminate errors and pro-

Trimble announced a new integration between its B2W Track and Trimble Siteworks software systems to automate and enhance progress quantity tracking for earthwork and civil contractors.

vide an auditable progress trail for billable milestones.”

The new Trimble progress-to-plan reporting workflow allows project managers to create requests for quantity measurements — such as the amount of material added, moved or removed at a site — within the B2W Track performance tracking application. Those requests are relayed automati cally to personnel in the field who use

see B2W page 96

NY CREATES, the entity that owns the Albany, N.Y. NanoTech complex on Fuller Road, said in early May 2025, that its new NanoFab Reflections building will now cost $614 million, an increase of $64 million.

DPS/Gilbane, a joint venture between DPS Advanced Technology Group and Gilbane Building Co., was awarded the contract, which was initially set at $550 million in early 2024.

But by the end of 2024, the NY CREATES board agreed to increase the DPS/Gilbane contract to $614 million, although that forced NY CREATES to also seek additional private funding sources, according to minutes from its Dec. 16, 2024, board meeting.

“As the project has progressed, identification of project requirements has been further refined,” the records said.

Increases in the cost of large, complex construction projects are not unusual, especially in the early stages, NY CREATES said, and it is seeking a $150 million credit line with M&T Bank to cover the extra costs.

The project also includes construction of a 900-car garage at the Albany NanoTech campus, along with upgrades to the electrical substation to handle the additional power the research facility will require once it is

completed in 2026.

NY CREATES operates two legacy nonprofit entities that own real estate in Albany and in other areas like Utica, N.Y.

One, Fuller Road Management Corp. (FMRC), owns the Albany NanoTech buildings and is the entity that is seeking the loan, although NY CREATES, which is technically separate from Fuller Road Management, will serve as “a guarantor” for the loan, according to the board minutes.

“FRMC is working through the loan process to secure up to $150 million should it be needed for any unforeseen costs related to construction of NanoFab Reflection, which is being specifically designed to house the most complex High NA EUV equipment ever made,” Steve Ference, a NY CREATES spokesperson, told the Times Union in a statement.

“Commercial loans of this size generally take several months to close,” he said. “The project, which will enable development of the world’s most advanced computer chips right here in the U.S., is currently on schedule.”

A next generation lithography tool, the

High NA (an acronym for numerical aperture) EUV (extreme ultraviolet) process uses ultraviolet light waves to etch atomic-sized transistors onto the silicon wafers used to produce smaller, more powerful, and energy-efficient microchips.

NanoFab Reflection will house one of the most expensive machines ever built for computer chip manufacturing, the $400 million EXE: 5200 High NA EUV lithography

machine. Only one company, ASML of the Netherlands, manufactures the machines.

“This [NanoFab Reflection] complex is poised to play a pivotal role in shaping the future of semiconductor innovation here in New York and across the country,” said Christian Calabrese, senior project executive of Gilbane, in a statement.

The new ASML machine is so important to making next-generation chips that the United States has an agreement with the Dutch not to sell the machine to China, according to the Times-Union.

New York State is contributing $500 million for the construction of NanoFab Reflection, which will also be home to a new, $825 million national computer chip research center funded by the federal CHIPS and Science Act. It also will be home to New York’s $10 billion High NA EUV Lithography Center, first announced by Gov. Kathy Hochul in December 2023. DPS/Gilbane has been actively hiring as the project progresses. In addition, the joint venture is in the process of awarding a number subcontracts for the project.

The Steel Erectors Association of America (SEAA) announced the winners of its 2025 Safety Excellence and Craft Training Excellence Awards.

These honors highlight member companies who demonstrate exceptional performance in workplace safety and the training of ironworkers. Awards were presented at SEAA’s 2025 Convention & Trade Show in Pittsburgh, Pa.

“This year’s recipients demonstrate what’s possible when safety and training are treated as top priorities,” said Jason Farris, chairman of SEAA’s Safety and Education Committee. “Their commitment to safety and workforce development is essential for the future of our trade. These are companies that lead by example, invest in their people and prove that excellence is achievable at every level.”

Recipients are selected through a blind evaluation process led by the association’s Safety & Education Committee. Submissions are judged across multiple criteria including training investments, portability of credentials, incident rates and overall safety performance.

Fourteen SEAA member companies received Safety Excellence Awards in three categories; World Class, Premier and Gold, for their outstanding 2024 safety records. Winners were evaluated based on EMR ratings, OSHA 300A logs, and safety program practices over a three-year period.

World Class

• Cooper Steel, Shelbyville, Tenn.

• Derr & Gruenewald LLC, Brighton, Colo.

• GMF Steel Group, Lakeland, Fla.

• High Plains Steel Services LLC, Windsor, Colo.

• MAS Building & Bridge Inc., Norfolk, Mass. Premier

• Flex-Erect, Houston, Texas

• Gardner Watson Decking, Oldsmar, Fla.

• Group Steel Erectors Inc., Ridgeland, Miss.

• JPW Erectors Inc., Syracuse, N.Y.

• L.R. Willson & Sons Inc., Gambrills, Md.

• Piedmont Steel Company LLC, Winston-Salem, N.C.

• S&R Enterprises LLC, Harrisburg, Pa.

Gold

• Cubas Welding Construction Inc., Charlotte, N.C.

• Shelby Erectors Inc., Reddick, Fla.

• Craft Training Excellence Awards

Three member companies were recognized for their workforce development programs. Evaluations considered credential portability, apprenticeship programs, training content and recruitment efforts.

World Class

• GMF Steel Group, Lakeland, Fla.

• Derr & Gruenewald LLC, Henderson, Colo.

• Shelby Erectors Inc., Reddick, Fla.

“SEAA applauds all the recipients for their commitment to advancing the steel construction industry through safe practices, employee development and exceptional project performance,” said R. Pete Gum, executive director, SEAA.

For more information, visit seaa.net/safetyaward.

Metro Bobcat, Inc. Eldersburg 410-795-1500 Forestville 301-568-1104 Gaithersburg 301-840-9300 White Marsh 410-483-0600 www.metrobobcat.com

Bobcat of the Finger Lakes Fairport 585-223-4056 www.djmequipment.com

Robert H. Finke & Sons Inc. Selkirk 888-266-9821 • 518-767-9331 www.finkeequipment.com

Bobcat of Saratoga Gansevoort 877-461-5065 www.bobcatofsaratoga.com

Summit Handling Systems, Inc. Walden 845-569-8195 www.summitbobcat.com

Bobcat of Connecticut East Hartford 860-282-2648 www.bobcatct.com

Bobcat of Stratford Stratford 203-380-2300 www.bobcatct.com

Bobcat of Greater Springfield West Springfield 413-746-4647 www.bobcatct.com

Bobcat of Worcester Worcester 508-752-8844

Bobcat of Rhode Island Warwick 401-921-4300 www.bobcatct.com

www.contractorssales.com 121 Karner Road Albany, NY 12212 518-456-1445 • 888-468-5479 1283 Dolsontown Road Middletown, NY 10940 845-956-0222

Ashland, VA 866-955-6071 Chesapeake, VA 800-342-3248 Frederick, MD 833-546-5235 New Castle, DE 302-501-6900

www.chadwick-baross.com 10 Fox Hollow Road Oxford, CT 06478 860-261-0730 67 McGuire Road South Windsor, CT 06074 860-761-0381

The watershed approach will allow water to flow to the lower parts of the region and give it somewhere to go. Currently, the water is trapped during high tidal events, which leads to the flat, low-lying area being more likely to flood during wet weather and major storm surge events.

The team will build two pump stations during the project’s first phase. The East Riser Ditch pump station is being constructed in Carlstadt, and the Losen Slote/Liberty Street pump station is being constructed in Little Ferry.

The East Riser station will run on diesel, and the Losen Slote station will run on gas. The fuel selection was based on community input and fuel source availability.

Development (HUD) created the Rebuild by Design competition in response to the storm. The New Jersey Department of Environmental Protection (NJDEP) won the competition. It was awarded $150 million towards the design and construction of a solution that will reduce flooding risks and enhance resiliency in this area.

The study area includes five towns: Little Ferry, Teterboro, Moonachie, South Hackensack, and Carlstadt. The NJDEP and contractors are in various stages on multiple projects designed to make the towns more resilient to severe storms.

The NJDEP originally submitted a proposal that would have made extensive changes. Once HUD determined the grant’s value, NJDEP returned to the drawing board to reconsider how to proceed.

“The current plan includes several components of our original plan,” said Kimberly McEvoy, bureau chief, division of resilience engineering and construction of NJDEP. “It’s a regional approach, which also identifies future projects as more funding becomes available.”

“The projects we chose will address the root causes of the area floods,” added Dennis Reinknecht, director, division of resilience engineering and construction of NJDEP. “Completing them will be like unplugging the bathtub in the meadowlands as more water will move through the area more efficiently.”

Just how much water can these pump stations handle? Reinknecht said that the East Riser Ditch pump station will be able to handle 500 cu. ft. per second, equivalent to an Olympic-size swimming pool, in three minutes.

Other plan elements include constructing a riverfront park in Little Ferry on the Hackensack River. Currently, the area is home to a dilapidated waterfront that provides no access to the water from Little Ferry.

Once the public park is completed, people will be able to stroll along the water. Educational space signage and a kayak launch site will be on site. The public green infrastructure floodplain preservation project. Floodplain preservation means more green space for rainwater to infiltrate (i.e., flood storage) and is an area designed to flood, therefore, help the area be more resilient to flooding.

Finally, there will be a pocket park at the Losen Slote Pump Station property. The pocket park includes a seating area and educational signage.

The meadowlands area is home to a diverse ecosystem community in densely populated areas. Coexistence is a challenge. While the team recognized that the stormwater infrastructure in the area is aged and underperforming, they had to determine how best to use HUD funding so it could have the greatest impact.

“We used hydraulic modeling, surveying and collected flood data to model how water gets out of the region,” McEvoy said. “Our

Baschmann Services, Inc. www.baschmann.com

1101 Maple Road Elma, NY 14059

716-219-7045

Drobach Equipment Rental www.drobach.com

2240 Route 22 E Union, NJ 07083

908-686-0018

Equipment East www.equipmenteast.com

61 Silva Lane Dracut, MA 01826 978-454-3320

196 Manley Street Brockton, MA 02301 508-484-5567

250 Washington Street Auburn, MA 01501 508-635-5058

Heavy Machines, Inc. www.heavymachinesinc.com

2401 Broadway, Bldg. #3 S. Portland, ME 04106 877-202-1275 207-550-0014

159 North Avenue Skowhegan, ME 04976 888-875-3954 207-858-0051

Jersey Rents www.jerseyrents.com

252 Atlantic City Blvd. Bayville, NJ 08721

732-606-1002

Hoffman Equipment www.hoffmanequip.com

300 South Randolphville Road Piscataway, NJ 08854 732-752-3600 1330 Hurffville Road Deptford, NJ 08096 856-227-6400

22 Peconic Ave. Medford, NY 11763 631-207-2900

1144 Zerega Ave. Bronx, NY 10462

718-822-1180

1440 Route 9W Marlboro, NY 12542 845-236-3000

120 Gordon Drive Lionville, PA 19341 610-363-9200

bestlineinc.com

Allentown, PA 484-223-3814

Harrisburg, PA 717-540-7867

Lemont Furnace, PA 724-437-1578

Muncy, PA 570-546-8422

Shippensburg, PA 717-530-8400

State College, PA 814-237-9050

Towanda, PA 570-265-4440

Warminster, PA 215-675-3009

West Chester, PA 610-241-3633

Jessup, MD 410-792-4750

Keyport, NJ 732-334-6225

Equipmenteast.com Dracut, MA 978-454-3320

Brockton, MA 508-484-5567 Bow, NH 603-410-5540

barryequipment.com Webster, MA 508-949-0005

Gorham, ME 508-949-0005

South Windsor, CT 860-288-4600

Rhode Island 508-949-0005 centralequipmentco.com Stillwater, ME 207-827-6193

monticelloequipment.com Monticello, NY 845-794-0100 midisleequip.com Ronkonkoma, NY 631-317-1000

Associated Equipment Distributors (AED) announced that Nikki Haley will be the featured keynote speaker at the 2026 AED Summit in Dallas, Texas, Jan. 19-21, 2026.

Haley will be joined by a lineup of additional keynote speakers, including First Sergeant Matt Eversmann (Ret.), economist Lauren Saidel-Baker, and an expert OEM panel moderated by Marc Johnson of Pinion Global.

“We are honored to welcome Ambassador Haley to the 2026 AED Summit,” said AED President and CEO Brian P. McGuire. “Her bold leadership and global perspective, combined with the incredible lineup of speakers, will bring valuable insight to this year’s event.”

Haley’s keynote will be presented as part of “Dinner and a Conversation” — an engaging and candid onstage dialogue between Haley and McGuire. The dinner event will offer attendees a rare opportunity to hear firsthand insights from one of the most influential figures in American politics and global diplomacy.

Haley made history as the youngest governor in the country and the first minority female governor in America. Under her leadership, South Carolina became a powerhouse in economic development, earning the nickname “The Beast of the Southeast.” As U.S. ambassador to the United Nations, Haley was widely recognized for her principled leadership, commitment to U.S. interests and outspoken advocacy for human rights. She was named one of Time Magazine’s 100 Most Influential people in the world and one of Forbes’ World’s 100 Most Powerful women.

In addition to Haley, the Summit will feature First Sgt. Matt Eversmann (Ret.), whose story was portrayed in Black Hawk Down, sharing leadership lessons on resilience and strategic decision-making from his military experience. Marc Johnson of Pinion Global, a trusted advisor to equipment dealerships, will moderate the OEM Panel and economist Lauren Saidel-Baker of ITR Economics will provide essential macroeconomic analysis to help attendees make data-driven decisions for 2026 and beyond.

The AED Summit is the premier event for the equipment industry, uniting distributors, manufacturers and service providers from around the globe. The 2026 Summit will deliver world-class educational programming, unparalleled networking opportunities and invaluable strategic insights to help industry leaders drive their businesses forward.

For more information, visit aedsummit.com.

Able Tool & Equipment

410 Burnham Street • South Windsor, CT 06074 860-289-2020

120 Interstate Drive • W. Springfield, CT 01089 413-363-0780 www.abletool.net

Admar Construction Equipment & Supplies

1950 Brighton Henrietta Town Line Road • Rochester, NY 14623 585-272-9390

7800 Brewerton Road • Cicero, NY 13039 315-433-5000 449 Commerce Rd. • Vestal, NY 13850 607-798-0333

1394 Military Road • Tonawanda, NY 14217 716-873-8000

2390 Rochester Rd. • Canandaigua, NY 14424 585-396-0031

878 Old Albany Shaker Road • Latham, NY 12110 518-690-0750

3001 West 17th Street • Erie, PA 16505 814-833-7761

121 Armstrong Road • Pittston, PA 18640 570-299-5505

1990 McKees Rocks Road • McKees Rock, PA 15136 412-458-4421 16000 Brookpark Road • Cleveland, OH 44135 216-465-3737

www.admarsupply.com

Cap Rents Supply, LLC 18-25 43rd Street Astoria, NY 11105 718-932-4100 • Fax: 718-932-8971 www.caprents.com

Equipment East

61 Silva Lane • Dracut, MA 01826

978-454-3320

1474 Route 3A • Bow, NH 03304

603-410-5540

196 Manley Street • Brockton, MA 02301

508-484-5567

www.equipmenteast.com

Gamka Sales Co., Inc.

983 New Durham Rd. Edison, NJ 08817

732-248-1400

Fax: 732-248-1445 www.gamka.com

Link-Belt Mid-Atlantic Construction Equipment

5263 Agro Drive, Suite 101 Frederick, MD 21703

301-732-7800 linkbeltma.com

Skyview Tractor Repairs, LLC

133 Rothsville Station Road Lititz, PA 17543

717-665-6997

www.skyviewtractor.com

Tri-County Contractors Supply, Inc.

154 Wayside Avenue

West Springfield, MA 01089

866-925-0211 • 413-733-5189

www.tricountycontractors.com

Company Wrench

2636 S. Black Horse Pike

Williamstown, NJ 08094

856-404-9618

www.companywrench.com

The Trump administration on May 19, 2025, allowed construction to proceed on a massive wind farm off the coast of New York’s Long Island, a month after federal officials had issued a highly unusual stop-work order that had pushed the $5 billion project to the brink of collapse.

In a statement, New York Gov. Kathy Hochul said she had spent weeks pressing President Trump and Interior Secretary Doug Burgum to lift the government’s hold on the wind farm.

The project, known as Empire Wind, is being built by the Norwegian energy giant Equinor and when finished is expected to deliver enough electricity to power 500,000 New York homes.

Empire Wind photo

Equinor said work would now resume and still aims to complete the wind farm by 2027.

“After countless conversations with Equinor and White House officials, bringing labor and business to the table to emphasize the importance of this project, I’m pleased that President Trump and Secretary Burgum have agreed to lift the stop work order and allow this project to move forward,” Hochul said.

When the Trump administration halted work on Empire Wind in April 2025, it stunned observers and sent shock waves through the wind industry.

Equinor had obtained all necessary permits for the project after a four-year federal environmental review, and the company had already begun laying foundations for the project’s turbines on the ocean floor. Another 1,500 workers had begun constructing a marine terminal in Brooklyn.

Then, Burgum said that the permits had been rushed and ordered all work to stop immediately.

But the Trump administration, which has frequently criticized the wind industry, gave no indication of if or when the stop-work order might be lifted, the New York Times reported.

Faced with uncertainty, Equinor began warning that it might have to cancel the project, which was already 30 percent complete. The company said it had been losing $50 million every week that construction was halted, with nearly a dozen vessels sitting idle and workers on the sideline.

However, Equinor said work would now resume and still aimed to complete the wind farm by 2027.

“I would like to thank President Trump for finding a solution that saves thousands of American jobs and provides for continued investments in energy infrastructure in the U.S.,” said Anders Opedal, the chief executive of Equinor. “I am grateful to Governor Hochul for her constructive collaboration with the Trump administration, without which we would not have been able to advance this project and secure energy for 500,000 homes in New York.”

It was not immediately clear how Hochul persuaded the White House to lift its stop-work order.

She had emphasized to Trump that terminating the wind project would kill more than 1,000 jobs among workers from parts of New York that supported him, according to people familiar with the matter who spoke to the Times on the con-

dition of anonymity because they were not authorized to discuss the governor’s conversations.

In recent months, the president has stated several times his desire to see more natural gas exploration in the northeast as well as the completion of the Constitution Pipeline, which would carry gas from Pennsylvania to eastern New York, but faced opposition from environmental groups as well as New York state officials. It was canceled in 2020.

While there was no specific bargain related to the pipeline, Hochul said in a statement that “New York will work with the administration and private entities on new energy projects that meet the legal requirements under New York law.”

According to the Times, those new energy projects could include pipelines.

The White House and Interior Department did not respond to the newspaper’s request for comment.

The collapse of the project would have posed major challenges for New York, where grid operators had been counting on the construction of several new offshore wind farms to provide large quantities of electricity without producing any planet-warming emissions. To fight global warming, the state has set aggressive targets for using renewable energy but is not on track to meet those goals.

New York already has one offshore wind farm in operation, South Fork, which is capable of producing 132 megawatts (MW) of electricity, enough for roughly 70,000 homes.

Empire Wind is expected to have 816 MW of capacity, while Sunrise Wind, another project under construction off Montauk, N.Y., would produce 924 MW.

Without those wind farms, New York City and Long Island could face the risk of electricity shortages in the years ahead, with few ready alternatives, according to a recent study by Aurora Energy Research, an analytics firm.

Trump has been a critic of wind power for years, ever since he unsuccessfully tried to stop an offshore wind farm from being built in view of one of his Scottish golf courses.

On his first day in office in his second term, he signed an executive order that halted approvals of new offshore wind farms and directed Burgum to explore the possibility of “terminating or amending” any leases that had already been issued.

The Trump administration’s stop-work order on Empire Wind appeared to be on shaky legal ground, experts said.

“I am not aware of any instance where a project of this sort that has gotten all its permitting has been legally halted,” said Joel Eisen, a law professor at the University of Richmond. “The lack of evidence to support the decision is a strong signal that a federal court would probably find this to be an arbitrary and capricious decision.”

www.amontanoco.com

571 Route 212, Saugerties, NY 12477 845/247-0206

www.andersonequip.com

18 Gorham Industrial Pkwy Gorham, ME 04038 207/591-5482

142 Target Industrial Circle Bangor, ME 04401 207/942-0177

4176 Route 417 Allegany, NY 14706 716/372-8822

720 E Franklin Street Endicott, NY 13760 607/748-3400

115 Middle Road Henrietta, NY 14467 585/334-6770

2140 Military Road Tonawanda, NY 14150 717/877-1992

6317 Thompson Road Syracuse, NY 13206 315/463-8673

912 Albany Shaker Road Latham, NY 12110 518/785-4500

151 Packard Road East Montpelier, VT 05651 802/223-9689

1 Andy’s Way South Charleston, WV 25309 304/756-2800

www.chappelltractor.com

454 Route 13 South Milford, NH 03055 800/698-2640

251 Route 125 Brentwood, NH 03833 603/642-5666

391 Loudon Road Concord, NH 03301 800/358-6007

www.GTMidAtlantic.com

Greenwood, DE 800/756-9433

Folcroft, PA 610/586-2710 Freehold, NJ 731/780-4600

Vineland, NJ 856/697-1414

Upper Marlboro, MD

301/627-3938 Baltimore, MD 410/247-7454 Frederick, MD 301/682-4441

Charles D. Stahl Sales & Service in Little Falls, N.Y., welcomed customers, contractors and industry professionals May 2, 2025, to its annual Spring Open House.

The event showcased a lineup of outdoor power equipment from manufacturers, including Fisher, Boss, SnowEx, Husqvarna, Cub Cadet, Gravely and Yanmar.

This year’s event provided attendees with an opportunity to explore new products, discuss custom solutions and learn more about Stahl’s wide-ranging capabilities from onsite factory representatives. To round out the event, guests enjoyed a complementary lunch.

In addition to outdoor power equipment, Stahl also offers commercial truck up-fitting solutions and represents Rugby, DuraMag, Stahl Air-Flo and Tommy Gate, allowing contractors and municipalities to customize truck bodies to meet their operational needs.