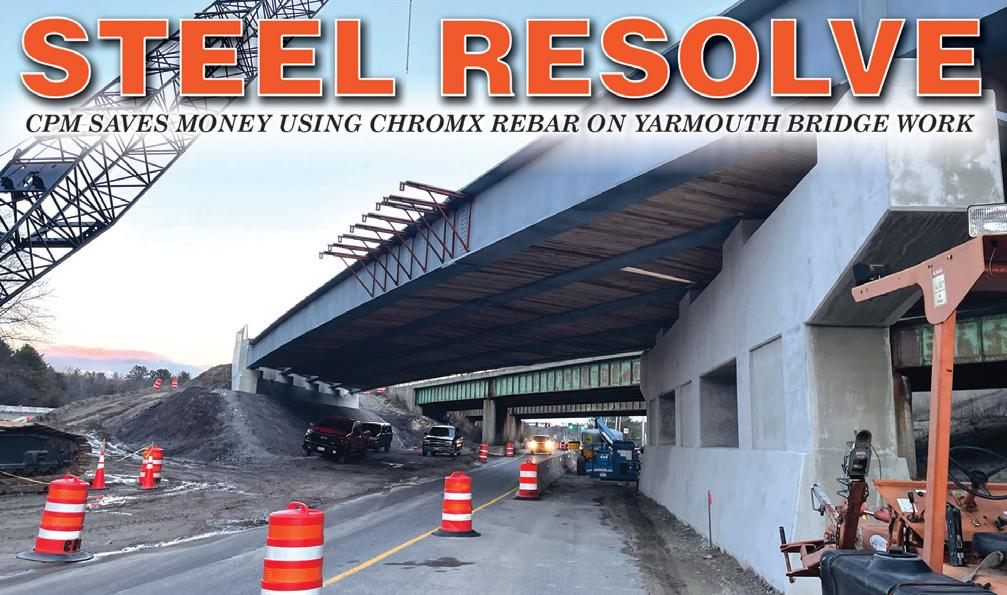

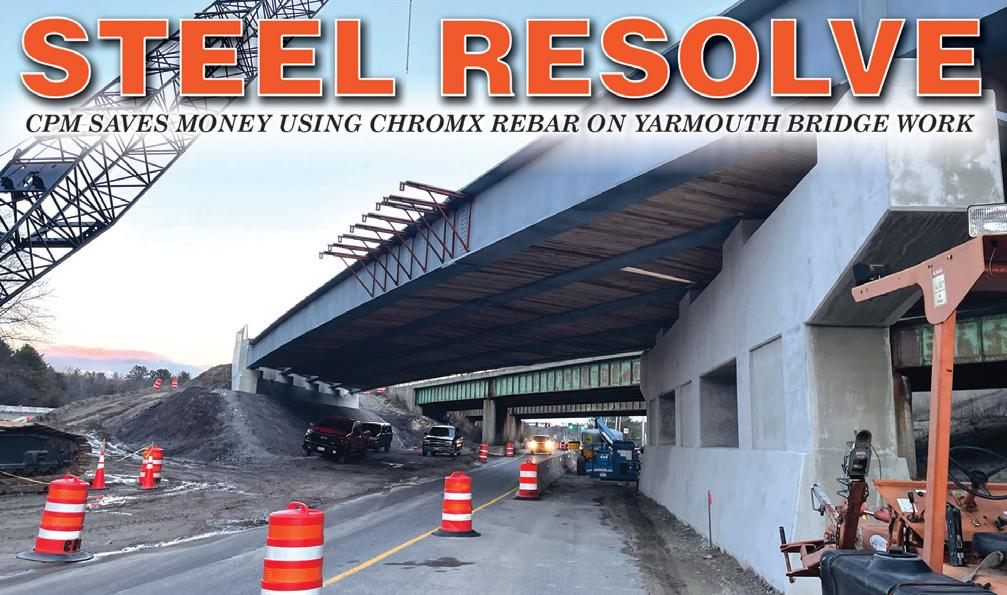

By Ken Liebeskind CEG CORRESPONDENT

The contractor of Maine Department of Transportation’s bridge replacement project in Yarmouth overcame the impact of the rise in steel prices during the Russia-Ukraine conflict by switching to ChromX rebar for the second half of

the project.

“When the war in Ukraine started, steel prices started going up because Ukraine is one of the major suppliers of nickel,” said Andrew Kittredge, president of CPM Constructors, Freeport, Maine, the lead contractor on the project. “With this project being a four-year job, the

see BRIDGES page 14

Road, Bridge Construction Season Has Begun Within Vt., N.H.’s Upper Valley

As any New England motorist who has driven over the Connecticut River on Interstate 89 or tried to get from Thetford, Vt., to Lyme, N.H., can tell you, road construction season in the two states’ shared Upper Valley began its annual ramp up in May.

In the interest of spending less time in traffic, the Valley News in West Lebanon, N.H., has provided a look at where roads and bridges are under con-

struction in the Upper Valley of Vermont and New Hampshire this summer.

River Bridge Work Linking Both States Are Ongoing

In a river valley, the biggest choke points are bridges, and three key ones are under construction this summer that connect the two New England states.

In addition to the Lyme-Thetford

bridge, which is slated to be closed until October 2024, and the I-89 bridges over the Connecticut River, slated to be built through 2025, the Ledyard Bridge linking Hanover, Vt., and Norwich, N.H., also is under construction. A $2.8 million rehabilitation of the structure includes repaving and improving the expansion joints and deck membrane. It also will replace the

THE NEW ENGLAND EDITION A Supplement to: Your New England States Connection • Kent Hogeboom 315-866-1423 ® “The Nation’s Best

Construction Newspaper…

June 21 2023 Vol. LXI • No. 13

Read

Founded in 1957.”

Andrew Kittredge, president of CPM Constructors, said, “With this project being a four-year job, the escalation on steel was going to be a problem so MDOT allowed us to switch to ChromX rebar.”

see CONSTRUCTION page 16 CALL 800-367-4937 *On approved credit Financing Available SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY 24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS State Supplement sponsored by: Affordable Price. Premium Service. Thousands in Service! CALL YOUR ONE-STOP HAMMER SHOP™ TODAY!!! CALL 888-81-GORILLA(46745) • Largest hammer repair facility in North America • Demolition tools and parts for ALL makes and models • Hammer-equipped excavator rentals • Backed by a 75 year family owned business 938G,H • 950G,H • 966G,H WANTED LOW HOUR CAT LOADERS Phil (413) 427-7171 Tibbits Equipment Services, Inc. www.tibbitseq.com 802-479-9696 Specialty Construction Equipment SALES • RENTALS • HAMMERS Since 1989 KWIK KLEET® Traction Cleats www.foleyengines.com • Exhaust Scrubbers • Perkins Engines • Deutz Engines • Twin Disc/Rockford Clutches

Page 2 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide See Our Complete Inventory at www.wiclark.com

stk# 26327, 653 Hrs, ROPS, Deutz diesel, single drum vibratory, good rubber, like

new condition................................................$64,500

2018 HAMM H7I

2014 DEERE 60G stk# 27845, 1400 hrs, hyd thumb, 24" bucket.. $64,500

2018 DEERE 50G

stk# 26377, Cat power, 6'5" 15mm drum, rigid conveyor, 60% bottoms, good belting with grade....................................................

$89,500

2010 WIRTGEN 2100

2017 JOHN DEERE 85G

stk# 27812, 3300 hrs, skid steer cplr, coupler, 1yd bucket............................................$59,500

2015 DEERE 204K

Stk# 27802, 2200 hours, C/air, hi flow, 2 speed, coupler..................................$59,500

2016 DEERE 333G

2019 LEEBOY 8500D stk# 28000, Kubota, 8-15' propane screed...... $109,500

Call Mark Doty @ 203-823-2316

Stk#27764, C/air, angle blade, hyd thumb, 24" bucket, new tracks................................$67,500

stk# 27248, 1780 hours, c/air, push blade, hyd thumb, well maintained........................$89,500

2017 JOHN DEERE 75G stk# 27856, 4216 hours, c/air, mech coupler, gp bucket..............................................$74,500

OPRROOVVEN U WITH UPTI

PTIME IME KITS

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock :kits

Easy e for (TCO) Ownership of thinki We’re equipment.

They are: rain e • T ervic ts • S Par

order and par ing • Application Special customer very to machine” the “beyond ng

stocking NEBOGENNN BOGEN SEN ctor suppor xible Financing lists • Fle

• Hydraulic service k

D T shops ols ervice owing kits system kits nance service kits its kits

trucks Choose a uptime dependable deliver througho t ttachments • A

Cost Total lower and its of life the out

And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th a more Learn

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 3

C BEYOND E H HE HIN

MA virtual I ntime losellyt

•

to

ea t d t stock asy to s l dow NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN y-t t act OGEN f tor ained technicians tr ned tec cians components and too • Ideal for

se and

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to from the follo • Central lubrication • Preventive mainte • O-Ring kits • Electrical service k Hydraulic service k

s that these kits, go, are custommachine model SENNEBOGEN 2-6351 ) 29 (800 ongmead ast L E oa er R 1 Shak 25 yle t.ww our to commitment our

nformation w bout

on he QR code. (800 Berli 1980 28 A 010 , M ow d om omers

requipment.c cust

52-4473 ) 3 0 7 in, CT 0603 urnpike 0 Berlin T sennebogeen-na.com/beyond-the--machine

Secret Ingredient to SENNEBOGEN Sales Success ... Service

According to Brooke Tyler IV, vice president of product support and Bill O’Keefe, SENNEBOGEN specialist at Tyler Equipment, “Sales is not about sales. It is about service, support and stocking inventory. That’s how one becomes the Top SENNEBOGEN Tree Care Dealer in North America.”

“We know that a SENNEBOGEN tree care handler is a purpose-built machine. Therefore, everything we have for this machine is also purpose-built,” they said.

Tyler Equipment, a 101-year-old company, understands the market and the needs of its customers.

“We now have five SENNEBOGEN factory-trained, road-service technicians on staff who are ‘purpose-built’,” O’Keefe said.

“They only work on SENNEBOGEN material and tree care handlers. Their service trucks are also ‘purpose-built’. They are stocked with UPtime Kits and all the special tools they might require on any piece of equipment, including being Wi-Fi enabled.

“Also, we have a dedicated SENNEBOGEN parts person and all warranty claims are submitted by the service technicians in the field, eliminating any hiccups or comebacks to the customer. We look after it all.”

O’Keefe then explained that after the owner has had the machine for a little bit, the SENNEBOGEN User Experience person meets with the customers and makes sure that they are maximizing the capabilities of the machine.

According to O’Keefe, “This makes our customers very happy as the tips and tricks they learn makes their machine even more productive and their operation more profitable.”

O’Keefe recounted a recent event where one of its tree care machines was on a highway job in Rhode Island. The company got a service call early in the afternoon and within three hours of the initial call, the machine was up and running.

“That’s exactly what I’m talking about,” said O’Keefe.

“The SENNEBOGEN tree care handlers are unique machines. You have to spend a lot to own one,” said O’Keefe. “But it’s a great deal easier to spend that money when you know the support is there and that if your machine is down it will be back up quickly. The other key factor is inventory. The Tyler family, who are actively involved on a dayto-day basis, have invested heavily in inventory based on their belief that if you don’t have the machine when a customer is looking for it, you are going to lose the sale.”

Small Territory But Big Rewards

Tyler Equipment has a small geographic footprint, which covers three out of the seven smallest states in the United States:

Rhode Island, Connecticut and Massachusetts. But that hasn’t stopped it from being a top SENNEBOGEN dealer, having finished as one of the top three last year and as Top Tree Care Dealer in 2022. So how do they do it?

Brooke Tyler and Bill O’Keefe explained it very simply: “Our customers are not only our friends, but our partners too. Today, we’re proud of our business reputation and

the overwhelming majority of our deals with our ongoing customers are done with a handshake. We also encourage prospective customers to ask one of our existing customers about Tyler Equipment. We are confident that they will give us a five-star review and then go on to tell them about our service. It’s that simple.”

“Many of our customers help us with demos. They believe in the product as much

as we do and they feel that growing the industry is going to make the industry stronger,” O’Keefe added.

Additionally, with regards to the tree care industry, Tyler Equipment has taken the time to listen to their customers and identify the type of work they do. This means segmenting the tree care market into several smaller markets with DOT contractors as one segment.

Another segment breaks down into residential, university, parks & recreation, commercial, and municipal contractors. Then there are the rail/utility right-of-way contractors. One contractor even mounted his 718 with rail trucks like a modern-day self-propelled handcar.

Other segments that Tyler has identified include those specializing in storm cleanup and biomass operations.

“To continue to be number one we are constantly beating the bushes and guess what? New opportunities arise. Tyler didn’t get to celebrate over 100 years in business by waiting for the phone to ring,” O’Keefe said.

“The key reason we are successful at selling SENNEBOGEN tree care and material handlers is because our service just knocks it out of the park. Granted, the SENNEBOGEN tree care machines are in their own category without a lot of competition. However, before a customer spends that kind of money they want to know that they have Tyler Equipment behind them. That’s exactly what we do.”

For more information, visit www.sennebogen-na.com.

Page 4 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

(L-R) are Constantino Lannes, president SENNEBOGEN LLC; Brooke Tyler, VP of Tyler Equipment; Erich Sennebogen, managing director of SENNEBOGEN GmbH; Colleen Miller, national sales manager of SENNEBOGEN; Bill O’Keefe, Tyler Equipment; and Greg Roberts, SENNEBOGEN tree care specialist.

SENNEBOGEN tree care handlers are everywhere, and this one from Distinctive Tree Care was on the job.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 5

Page 6 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide The Nice Company, Inc Equipment Sales and Rentals 9 Rosenfeld Drive, Hopedale, MA Toll Free# 508-381-3939 • www.theniceco.com We sell NICE machines! 2016 Hyundai HL980, 7000 Hours, 371HP Scania motor, 7.3 Yd Bucket, AC/Rear Camera, Load scale system, Powershift trans., 29.5 R25 tires 75% or better, Well maintained $159,000 2014 CAT 730 Truck, 9400 hours, 6x6, Tires 65% or Better, Rear Tailgate, Work Ready............ $199,000 2016 CASE CX145CSR, 3300 hours, JRB Coupler, Hydraulic thumb, Auxiliary hydraulics, Road liner pads, Great condition, Work ready .... $109,000 2018 Deere 410L, 2600 Hrs, Ride Control, Backhoe Pilot Controls, Powershift Trans., 2017 US EPA Label, QC, Diesel Exhaust Fluid Req., Hyd. Cplr, 93" Loader Bkt, 24" Backhoe Digging Bkt, Rear Aux. Hyd REDUCED $99,000 $94,500 2007 Metso/Nordberg CV50, 832 hours, Duetz Motor, 3" Top Screens, 1" Bottom Screens, Newer rear tires, Pintle hook, 1-3 yd loader capacity $49,000

2019 Hyundai HX160L, 350 hours, 36" Bucket, Aux. Hydraulics, AC/Rear Camera, 2 Speed, Work Ready $129,000

2012 Volvo L70G, 8100 hours, 3 Yard Bucket, QC, Aux. Hydraulics, Heat/AC, New Rear Tires, Runs Good! $72,500

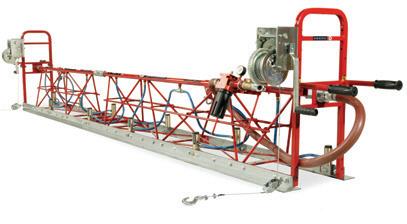

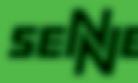

CONNECTICUT 410 Burnham St., South Windsor, CT 06074 860-289-2020 MASSACHUSETTS 120 Interstate Dr, W. Springfield, MA 01089 413-363-0780 WHY CHOOSE ABLE TOOL and EQUIPMENT... • Local Ownership with flexible approach • Trained staff for repairs and maintenance • Dedicated Parts personnel on site • Focused on the Heavy Construction Industry • Providing the BEST support equipment available • Experienced outside sales staff Sales • Service • Parts • Rentals abletool.net Screeds and Trowel Allen Razorback screeds have been used through four decades in all corners of the world! SA12 Truss Screed Allen Engineering products are USA engineered & manufactured. HD7070 Magic Screed Pouring, Placing, Finishing Concrete? We Can Help! Made in the USA PRO446 Walk-Behind Trowel Proud to be your Full Service Dealer NEW Inventory In Stock!

2020 Hitachi ZX210 LC-6, 2400 hours, Aux. Hydraulics, QC, 36" Digging Bucket, Rear & Side Cameras, Ready to Work $159,000

Experience the Progress.

The Liebherr Generation 8 Excavators – A glimpse into the future

Liebherr completely redesigned its basic concept to offer customers more comfortable and intuitive products with even higher performance. The new Generation 8 crawler excavators feature more powerful engines for shorter load cycles and higher productivity, heavier counterweight for higher digging power and bucket capacities, all this while maintaining reduced fuel consumption.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 7

www.heavymachinesinc.com PORTLAND, ME 2401 Broadway, Bldg #3 S. Portland, ME 04106 877-202-1275 | 207-550-0014 SKOWHEGAN, ME 159 North Ave. Skowhegan, ME 04976 888-875-3954 | 207-858-0051

Museum Picks Designer of Native American Art Center

Vermont’s Shelburne Museum, the largest art and history museum in northern New England, announced May 8 that it had chosen Adjaye Associates, an internationally acclaimed architecture studio to design the museum’s new Perry Center for Native American Art.

At the same time, the museum also said it would be the stewards of the Perry Collection of Native American Art, which includes items from Plains, Prairie and Southwest peoples, and “forms the core of a museum initiative to collaborate with Indigenous nations, scholars, and culture bearers to present a model of stewardship for Indigenous creative culture and presentation to a broad audience.”

The proposed gallery space will be within a sustainable building surrounded by integrated landscaping and created in collaboration with Indigenous voices whose cultures and people are represented in the works to be cared for at the Shelburne.

Adjaye Associates has studios in Accra, London and New York, with its work found across the globe. The studio’s most wellknown commission to date, the Smithsonian

National Museum of African American History and Culture, opened in 2016 on the National Mall in Washington, D.C.

“Shelburne Museum is honored to be partnering with David Adjaye and his team to create a welcoming space where Tribal members and scholars can study and engage with Indigenous art, and all visitors — the local community, schoolchildren and tourists — can experience the museum,” said Thomas Denenberg, director and CEO of the Shelburne, located on the east bank of Lake Champlain, south of Burlington, Vt.

“David and his colleagues are in absolute

alignment with the museum’s goal to serve as a culturally competent steward of a nationally important collection.”

Indigenous Designers to Collaborate With Adjaye

The Perry Center for Native American Art at Shelburne Museum is planned to be a 9,750-sq.-ft., highly sustainable pavilion, according to the museum. Crucially, the $12.6 million Perry Center will be designed from the ground up in partnership with Indigenous peoples to support the culturally appropriate interpretation and care of Indigenous material culture.

“Our team is inspired by the potential of the Perry Center to not only enhance Shelburne Museum as a destination for education, but also to amplify and empower the Indigenous communities represented by the collection and to reconceptualize the role of a 21st century museum facility,” noted Adjaye. “As the design architect for the new Perry Center, Adjaye Associates intends to cultivate opportunities for transformation, storytelling, and cross-cultural dialogue, ensuring the Perry Center contributes to the

unique eclecticism and mission of Shelburne Museum.”

The New York City office of Adjaye’s firm will work closely with Indigenous partners in the design of the building. Two Row Architect has been named the Indigenous consultant on the project, while a Native American Advisory Committee and a Native American Collections Stewardship Advisory Committee, respectively, will advise on the Perry Collection’s care, and host a series of cultural competency seminars. These committees include academics, museum professionals (including those of Indigenous heritage), and members of the Abenaki nation.

Groundbreaking for the new building is planned for the fall of 2024, with the pavilion’s tentative opening likely in 2026.

Shelburne Houses Range of Beautiful Objects

The Shelburne Museum is Vermont’s foremost public resource for programming in the arts and humanities. Incorporated in 1947, the museum complex is made up of 39 buildings and 22 gardens on a 45-acre campus.

see MUSEUM page 14

New Balance Begins Work On $65M Factory Addition

Boston-based New Balance broke ground June 5 on the expansion of its current athletic footwear manufacturing facility in Skowhegan, Maine.

The company’s $65 million investment will add 200 new jobs and double the factory’s production capabilities through a 120,000-sq.-ft., single-story addition to the existing five-story facility, which is itself seeing a 20,000-sq.-ft. renovation.

All the work is slated to be complete by the end of 2024, according to New Balance.

Current manufacturing operations at the factory will continue during the construction phase. The company’s expansion design, engineering and construction is being managed by Green Leaf Construction in Leominster, Mass.

New Balance Dedicated to American Craftsmanship

New Balance Skowhegan’s expansion reflects the company’s strong commitment to domestic manufacturing and highlights its longstanding pride in the American craftsmanship and innovation of its Maine associates, according to Joe Preston, its president and CEO.

“Manufacturing has always been at the

core of our company culture,” he said at the kickoff of the factory’s newest construction.

“Our Maine associates have proven that high-quality athletic footwear can be produced in the U.S., [and the] Skowhegan factory expansion ensures their skilled craftsmanship and dedication to continuous improvement will help us meet our significant [domestic] and global consumer demand and drive future business growth.”

In a joint statement, Maine’s top three political leaders — Gov. Janet Mills, and U.S. Senators Susan Collins and Angus King — praised New Balance for its continued commitment to the state, in addition to calling the state “the best place in the world to run a business, raise a family or base a manufacturing plant.”

“Our people’s legendary work ethic and legacy of craftsmanship produces highquality products that are sought out around the globe,” the statement continued. “We’re excited by New Balance’s significant, jobcreating investment in the Skowhegan community and look forward to seeing its lasting impact for years to come.”

New Balance Skowhegan currently employs approximately 270 associates producing the brand’s popular MADE 996,

997, 998 and 1300 shoe models.

When the expanded space is operational, the Skowhegan facility will see a significant increase in its production capacity, turning out about 1.3 million pairs of shoes a year, added John Campbell, New Balance’s vice president for corporate services.

The original Skowhegan site was purchased by New Balance in 1981.

“We are proud to be part of the Maine business community for more than 40 years and excited to add 200 new jobs as part of our Skowhegan factory expansion,” Dave Wheeler, New Balance’s COO, told the groundbreaking’s audience.

He added that the shoemaker is proactively working to innovate and expand its domestic supplier network for its MADE U.S. footwear as well as drive new automation and robotics opportunities to enhance associate safety and ergonomics, as well as increase productivity.

At the ceremony, New Balance also announced a $250,000 gift to the Kennebec Valley Community Action Program (KVCAP) in support of the Skowhegan Area Early Childhood Education Center that will be built as part of the new MSAD 54 Margaret Chase Smith Community

School.

“New Balance has always been strongly committed to the communities where our associates live and work,” explained Raye Wentworth, the company’s director of domestic manufacturing. “We’re thrilled to be able to support this important opportunity to add quality, affordable education and childcare resources for local families.”

New Balance is the only major athletic shoe manufacturer that has continued to maintain factories in the United States. Including the Skowhegan facility, the company owns five plants in Maine and Massachusetts where approximately 1,300 workers prepare, cut and mold athletic shoe materials and components before sewing, pressing and assembling them into the final product.

Just last year, the company opened its fifth athletic shoe factory in Methuen, Mass. New Balance has been producing footwear in the United States for more than 75 years. Besides its factories in New England, the company owns another in the United Kingdom. In total, the company employs 8,000 associates around the world, and, in 2022, reported global sales of $5.3 billion.

Page 8 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

The Perry Center for Native American Art at Shelburne Museum is planned to be a 9,750-sq.-ft., highly sustainable pavilion.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 9

providing

100 YEARS STRO

celebr ork and Co New Y

H.O. Penn nnecticut strong, ed to keeping

Since 1923 dhidkfC All Rights Reserv © 2023 Caterpillar (845) 733-640 783 Bloomingburg Bloomingburg, NY illdbdihii TERPILLAR, LET’S DO THE WORK, their re T T, ved. CA , CA (718) 863-3 v Bronx, NY 1 0 Road 12721 699 Brush A 844-CAT ill ellow , the “P spective logos, “Caterpillar Corporate Y (631) 758-7 LIE (Exit 660 Union A NY Holtsville, 800 venue 0465 -1923Power Edge” and Cat “Modern 500 62) venue 11742 Y 1 Poughkhkeeps 122 Nox (845) 4 rn Hex” trade dress as we sie, NY12603 xon Road 52-1200 Newin 225 R (86 ell as corporate and product identity ngton, CT 06111 Richard Street 0) 666-8401 used herein, are trademarks of Caterpillar and may not be used without perm ss on. www .com.caterpillar .cat.com / www

equipment and s with the highest forged a legacy i of our local comm Since 1923, H.O. upport we provide ensu level of uptime and prod n

Contractors unities. The people of H Penn has been building res the bridges are .Theuctivity within the region .O. Penn have the very foundation

while we

e are committe W scheduleandsk schedule, and sk completed on tim NG. ate

kyscrapersreachnewhe kyscrapers reach new he e, new roadways are op eights ened ahead of

Page 10 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide NH 03106 Hooksett, 1401 Hooksett Rd AmbroseEquipmen 603-644-8787 t.com and in 35 years of p ving Equ a Astec P New England’s PR wledge y kno dustr ving experience pa ipment with over EMIER dealer for

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 11

and Mobile Scr

vailable ommels a Tr eens

ent or own. to r

aggregates and more soils, capable of screening – Scalper 77C

– double deck, yder 516T Sp product separation.

sand and gravel. soils, designed to separate rock,

– ideal for skid steers to Might II

mulch and compost. process topsoil,

– separates topsoil, rommel 612T Tr

compost and green waste

American Made Grade 80 steel for

Complete exceptional durability

– perfect for two Scapler 107D technical support.

®

Page 12 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

AlbanyBinghamtonB NY: BuffaloCampbellRochesterSy Worceste Woburn MA: yracuse s Bus Women’ e are a Certified W 585.202. See what we can do Hartford CT: er com monroetractor iness. 2067 for your job-site! TION SINCE 1966 T AMERICAN-MADE INNOVA Albany Binghamton B Buffalo Campbell Rochester Sy

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 13

CPM Constructors Leads Interstate Bridges Project in Yarmouth, Maine

BRIDGES from page 1

escalation on steel was going to be a problem so MDOT allowed us to switch to ChromX rebar. The southbound structure was completed with stainless steel and we made the switch when we started the superstructure. The northbound will be all ChromX.”

A Cascade Steel product page noted, “ChromX is a high-strength corrosion resistant concrete reinforcing steel and two ChromX rebar grades can allow less steel to be used and provide varying amounts of elevated corrosion resistance.”

“When the price of stainless steel skyrocketed, it introduced a lot of uncertainty as to whether or not there would be a sufficient quantity available to satisfy demand,” said Paul Merrill, MDOT spokesman. “We responded by specifying less stainless steel reinforcement and using more high chromium ChromX steel reinforcement in new contracts. For existing contracts like Yarmouth, where a high quantity of stainless steel reinforcement was required, we allowed the contractors to propose an alternate reinforcement type [typically ChromX].”

“The Maine Department of Transportation is replacing two interstate bridges that carry the northbound and southbound sides of I-295 over Route 1 near Exit 17 in Yarmouth,” said MDOT. “This project also involves extending the Beth Condon Memorial Pathway to the Yarmouth Visitor Center. The southbound interstate bridge will be built on a new alignment.”

Yarmouth’s Bridge Advisory Committee identified two major goals for the project: create a bridge that reinforces the traditional look and feel of the historic village and connect vehicular, bicycle and pedestrian linkages to reflect the town’s Complete Street policy, and improve the continuity of the Beth Condon Memorial Pathway.

For the Beth Condon Memorial Pathway, a recreation path in Yarmouth, the town’s website noted that the town “recently received a Planning Partnership Initiative matching grant from Maine Department of Transportation to develop a plan to extend the Beth Condon Memorial Pathway along Route 1 from Exit 17 to the Cousins River Bridge.

“The Parkway currently ends on Route 1 south of Exit 17, at the Citgo station. In 2023, the Beth Condon Pathway will be extended to Exit 17, where it will cross from the west side of Route 1 to the east side at the recently installed traffic signal. This extension will be constructed in conjunction with the planned replacement of the I-295 bridge over Route 1, and the bridge and path projects will be bid together by MaineDOT. The proposed path is a 12-feet wide multiuse path beginning 0.06 of a mile southwest of Spring Street and extending northerly 0.50 of a mile to the State of Maine Visitor Information Center building along Route 1 as well as crossing Route 1 at the Exit 17 traffic signal and heading to the Delorme/Garmin entrance.”

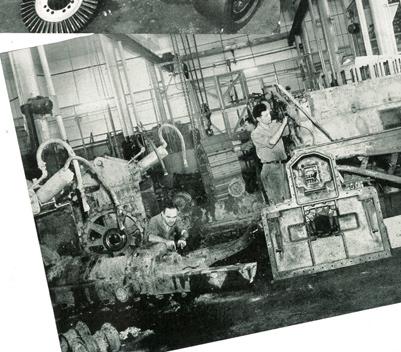

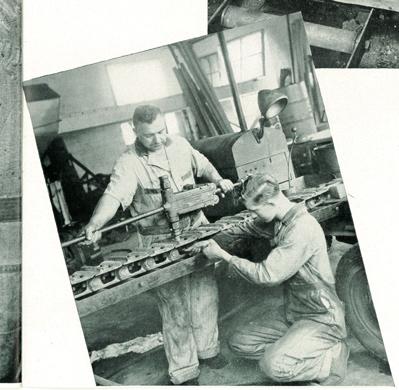

Kittredge said CPM Constructors started work on the

Vermont’s Shelburne Museum Chooses Designer of Native American Art Center

One of Shelburne’s more prominent structures is the Round Barn, a three-story building measuring 80-ft. in diameter.

MUSEUM from page 8

In its collection are more than 100,000 objects in unique and unparalleled installations of American art and material culture. It also houses many beautiful, fascinating and whimsical objects such as the Ticonderoga, a restored 220-ft. steamboat, the last walking beam side-wheel passenger steamer in existence. Built in Shelburne in 1906, the vessel once plied the waters of Lake Champlain as a day boat, serving ports along the New York and Vermont shores until 1953.

Another of the Shelburne’s more prominent structures is the Round Barn, a three-story building measuring 80-ft. in diameter. At 122 years old, the structure is an example of the Shaker-designed round barns first built almost 200 years ago in Massachusetts.

bridge project in fall 2021 and began work on the southbound side.

“We’ve completed the substructure for both abutments and the pier with structural steel for the southbound side, formed the deck and placed rebar for the deck,” he said. “We built both the approach, drainage, on and off ramp work and started the temporary median crossover.”

When asked what CPM Constructors needs to do to complete the project, Kittredge said, “We have to finish the southbound bridge, demo the existing northbound bridge, build the new northbound bridge and demo the existing southbound bridge.”

Work will begin on the northbound bridge in July and August, he said, adding that the company has not started on the Beth Condon Memorial Pathway, and it will probably be completed at the tail end of the project.

The contract amount is $27,566,210. This project is the recipient of federal grant funding from the U.S. Department of Transportation’s Competitive Highway Bridge Program. The project is scheduled to be completed by the end of 2025.

(All photos courtesy of CPM Constructors.)

The museum’s trailblazing founder, Electra Havemeyer Webb (1888–1960), repeatedly called for expanding scholarly and popular understanding of American material life as one of the principal collectors who defined the field in the decades that bracketed World War II. A critical example of this impulse was Webb’s deep interest in, and engagement with, Indigenous art and culture, an aspect of the Shelburne’s program not fully realized in her lifetime and of singular importance to the institution today.

Adjaye Recognized Internationally for His Work

In addition to the National Museum of African American History and Culture, among many other of Adjaye Associates' completed works are the new George Street Plaza & Community Building with Indigenous artwork in Sydney, Australia’s central business district; the Sugar Hill Mixed-Use Development and Children’s Museum of Art and Storytelling in Harlem, N.Y.; the Nobel Peace Centre in Oslo, Norway; and the Idea Stores — two pioneering community libraries in London’s Tower Hamlets.

In 2017, Adjaye was knighted by Queen Elizabeth II and was included in TIME Magazine’s 100 Most Influential People List. He also is a recipient of the 2021 RIBA Royal Gold Medal, considered one of the highest honors in British architecture for significant contributions to the field internationally, and has received the World Economic Forum’s 27th Annual Crystal Award, which recognizes his “leadership in serving communities, cities and the environment.”

Page 14 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

CEG

CPM Constructors started work on the bridge project in fall 2021 and began work on the southbound side.

This project is the recipient of federal grant funding from the U.S. Department of Transportation’s Competitive Highway Bridge Program.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 15 316 Market Street Fort Kent Mills, ME 04744 207-834-3171 491 Lakewood Road Madison, ME 04950 207-858-4748 Frank Martin Sons, Inc. fms-equipment.com NOW YOUR AUTHORIZED HITACHI DEALER FOR MAINE Toll Free 844-307-2596

Slew of Road, Bridge Construction Projects On Busy Summer Schedule for Vt., N.H.

raised median with a painted one.

As the job progresses, the dedicated turn lane onto Tuck Drive in Hanover will be closed.

With the Lyme-Thetford bridge closed, the Ledyard Bridge also is likely to see more traffic. Vehicles leaving Hanover over the bridge occasionally back up to the town’s Dartmouth Green.

Further south on the I-89 bridges over the river at West Lebanon, traffic will shift to new temporary lanes under construction between the two spans, enabling work on the northbound structure. That bridge work often causes backups as well, but transportation officials in both states said contractors clear out early on holiday weekends to allow

for the heavier flow of traffic.

“Our construction bureau tells [contractors] to wrap it up and get out of the way,” Richard Arcand, a spokesperson of the New Hampshire Department of Transportation (NHDOT), said in a phone interview with Valley News.

Just east of the river bridges, some work remains to be done on the nearby spans over U.S. Highway 4 and the Mascoma River at I-89 Exit 19, Arcand noted.

On the west side of the river, the Vermont Agency of Transportation (VTrans) will begin work on the I-89 southbound bridge over the White River in West Hartford sometime in July. Jeremy Salvatori, a project manager at VTrans, told Valley News that the six- to eight-week project will entail closing one lane at a time while workers repair expansion joints.

Crews also are under way on several bridges along I91 from Fairlee through St. Johnsbury, with traffic down to one lane on most of them and the speed limit reduced to 55 mph. VTrans regards the work as “preventative maintenance.”

In addition, the replacement of a railroad bridge on Vt. 14 in Royalton means the underpass is still only one-way, though now it has traffic lights during construction. The project is due to last into 2024, and Vt. 14 will be closed for up to 21 days next summer when the bridge is finally rebuilt, and the narrow road is realigned into a two-lane highway.

Although not a bridge project, VTrans also plans to replace a culvert on Vt. 113 at the Thetford-West Fairlee line. The project will close the state highway on June 24-25 to remove the aging

metal drainage tunnel and install a much larger concrete box culvert. Before and after the replacement, the road will be down to one lane while work is taking place.

Many paving projects are so small, lasting only a day or two, that NHDOT does not post information about them, but the repaving of 4 mi. of N.H. 11 between Claremont and Newport, one of the busiest roads in the area, is an important effort, according to Valley News. Work started May 22, Arcand said, and was expected to last three weeks.

Additionally, parts of N.H. 120 and N.H. 12A, from Claremont north to Cornish, are slated for repaving and guardrail work. Much of U.S. 4A, from Lebanon to Andover, also is due to be repaved in August and early September.

In Hanover, the town’s public works department will resurface Lyme Road from Park Street to the roundabout at Reservoir Road, as well as South Street, Currier Place, Dorrance Place, and Sanborn Road. Town officials have not yet decided on a start date for both projects.

In early September, NHDOT also plans to repave part of Etna Road in Hanover.

The city of Lebanon will soon perform its $1.7 million replacement of the 1958 cast iron water main on Miracle Mile, a project expected to wrap up in 2024, Valley News learned.

The roadwork extends about a mile from the Terry Dudley Bridge east on U.S. 4 to the area around Buckingham Place.

The construction will mostly be done through twolane alternating traffic, with a single lane restriction in

use “as little as possible, and mostly at night,” explained Lebanon Public Works Director Jay Cairelli.

In addition, the city also will continue its repaving of 1.3 mi. of Poverty Lane, a rural road.

The biggest state paving project on the Vermont side of the Upper Valley appears to be the resurfacing of Vt. 107 from the intersection of Vt. 12 in Bethel to the intersection of Vt. 100 in Stockbridge.

This job is a shallow repaving designed to extend the life of 10 mi. of roadway, big chunks of which were rebuilt after heavy damage from 2011’s Tropical Storm Irene. A surprisingly busy highway in a rural area of central Vermont, it connects the state’s Upper Valley to Rutland and points west.

It seems reasonable to expect that there will be more construction projects coming online this summer, Valley News reported, what with federal funding from the American Rescue Plan Act (ARPA) and the Infrastructure Investment and Jobs Act (IIJA) pouring into Vermont’s and New Hampshire’s coffers.

But the funding cannot create construction workers out of thin air, so the number of projects and the amount of money spent is roughly constant, VTrans officials told the news source.

It is possible to assign numbers to specific materials, though.

For instance, Bradford, Vt., held off on paving last year because the cost of asphalt was around $90 per ton, explained Phil Page, the town’s longtime road supervisor. Now that the current quoted price is just shy of $80 per ton, he said Bradford will pave parts of Goshen and South roads this summer.

Page 16 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

CONSTRUCTION from page 1 PORTABLE ROCK CRUSHING Onsite or Quarry • Making aggregates since 1983 Call us today ROCK CRUSHING • (860) 491-2283 GOSHEN, CT www.FAYWRIGHTINC.com

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 17 Barry Equipment Co., Inc.F&W Equipment 164 Boston Post Road Orange, CT 06477 203-795-0591 www.fwequip.com Central Equipment Company 45 Dempsey-Greaves Lane Stillwater, ME 04489 207-827-6193 www.centralequipmentco.com www.barryequipment.com 30 Birch Island Road Webster, MA 01570 508-949-0005 7 Harry’s Way Webster, MA 01570 508-949-0005 1608 John Fitch Blvd South Windsor, CT 06074 860-288-4600 Equipment East, LLC www.equipmenteast.com 61 Silva Lane Dracut, MA 01826 978-454-3320 196 Manley Street Brockton, MA 02301 508-484-5567 1474 Route 3A Bow, NH 03304 603-410-5540

NEW ENGLAND SUPPLEMENT ADVERTISER INDEX

R.I. Sens. Help Land $9M for Upgrades at Warwick’s Airport

More than $9 million in federal funding for operational upgrades and planning at T.F. Green International Airport in Warwick, R.I., has been awarded to the Rhode Island Airport Corporation (RIAC), due to the efforts of the state’s top two elected officials in Washington.

U.S. Senators Jack Reed and Sheldon Whitehouse announced May 24 that two federal U.S. Department of Transportation grants, totaling $9,015,250, will be administered through the Federal Aviation Administration’s (FAA) Airport Improvement Program (AIP).

The monies designated for use at T.F. Green International will be used for the realignment of Warwick’s Taxiway C, and to conduct an environmental assessment on the facility’s proposed South Cargo project.

“On behalf of all at the [RIAC], we are extremely grateful for the tireless work of our congressional delegation to secure federal infrastructure funding to help ensure that Rhode Island T. F. Green International Airport can support our state’s economy for decades to come,” said Iftikhar Ahmad, RIAC’s president and CEO.

Taxiway C Realignment

The largest chunk of the federal funding, $8.5 million, will go to support the reconfiguration of Taxiway C (also known as “Taxiway Charlie”) to meet FAA standards, Newport Buzz reported.

The airplane connector between Runway 5-23 and Runway 34 has been in service for more than 30 years and has not been rehabilitated or rebuilt during this period. It also connects the T.F. Green International terminal to Runway 23.

Due to the taxiway’s wear and tear over the last three decades, its pavement is in significant need of repair.

The realigned portion of Taxiway C will be constructed to the required 400-ft. runway-to-taxiway separation as per FAA design standards and have a 20-year design life, according to RIAC. Additionally, Taxiway C between Taxiway C1 and Runway 34 will be rehabilitated in its current alignment with a 10-year design life.

The entire $12 million project is expected to be complete by the fall of 2024.

South Cargo Project

Reed and Whitehouse also helped secure $500,500 to support the prerequisite study for a proposed cargo development at Warwick’s busy airport, which would enable greater volume to be processed through the facility, bolster economic activity, and increase efficiency for cargo tenants.

“Rhode Island T.F. Green Airport has several taxiways, but [Taxiway C] is vital to the airport’s layout and is overdue for an upgrade,” said Reed, a senior member of the U.S. Senate Appropriations Committee. “These federal funds will help improve the taxiway and make it safer, more efficient and resilient for years to come.”

In his statement, Whitehouse remarked, “The Infrastructure Investment and Jobs Act [IIJA] continues to deliver for Rhode Island by providing much-needed funding to improve taxiway safety and take steps toward increasing cargo capacity at T.F. Green. I am pleased to help secure investments that will boost the Ocean State’s economy for years to come.”

The federal funds will flow to the state through the IIJA, which was signed into law by President Biden in November 2021. It will direct an estimated $45 million to the state’s airports over five years.

Under FAA guidelines, AIP awards may cover up to 90 percent of the cost of its projects, with the rest coming from state or local funds.

RIAC is a quasi-public corporation empowered to undertake the planning, development, management, acquisition, ownership, operations, repair, construction, improvement, maintenance, sale, lease or other disposition of Rhode Island’s primary airports.

Besides T.F. Green International, that list includes North Central Airport in Smithfield, Quonset Airport in North Kingstown, Westerly Airport in the town of Westerly, Middletown’s Newport Airport, and the Block Island Airport, located off the south coast of the state.

Page 18 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

“These federal funds will help improve the taxiway and make it safer, more efficient and resilient for years to come.”

U.S. Senator Jack Reed Rhode Island

JOIN OUR TEA Management, sales, service the field), parts, administrati .monr Apply today at: www ro o 18 locations across N M! (in-shop or in on, and more. oetratorr..com/career/ A, MA, CT , P NYY, PA T, , RI and VT – monroetractor.com

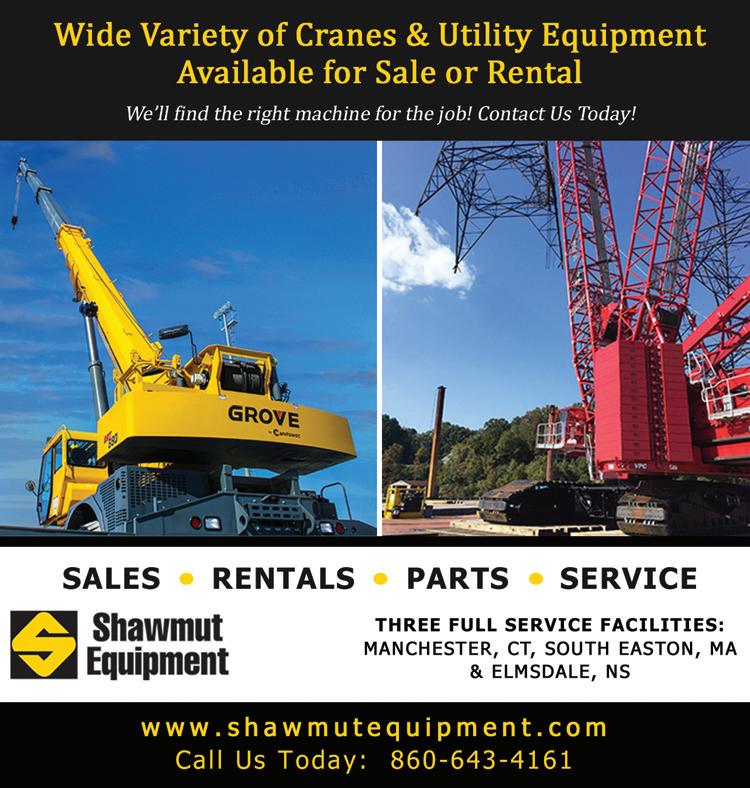

The Advertisers Index is printed as a free editorial service to our advertisers and readership. Construction Equipment Guide is not responsible for errors or omissions. ABLE TOOL & EQUIPMENT..................................................................................6 ALTA EQUIPMENT COMPANY/NITCO LLC..............................................1,10,11 BARRY EQUIPMENT CO. INC...........................................................................20 CHADWICK-BAROSS INC..................................................................................13 DEVELON NORTHERN NEW..............................................................................17 EQUIPMENT EAST............................................................................................1,5 FAY & WRIGHT EXCAVATING INC....................................................................16 FOLEY INC - WORCESTER..................................................................................1 FRANK MARTIN & SONS INC............................................................................15 GORILLA HAMMERS............................................................................................1 H O PENN MACHINERY CO INC..........................................................................9 HEAVY MACHINES INC........................................................................................7 J R VINAGRO CORPORATION............................................................................1 M G EQUIPMENT..................................................................................................1 MONROE TRACTOR............................................................................................18 MONROE TRACTOR & IMPLEMENT..................................................................12 ROGERS BROTHERS CORPORATION............................................................19 SHAWMUT EQUIPMENT CO INC......................................................................16 T-QUIP SALES & RENTAL INC..........................................................................12 THE N.I.C.E. COMPANY........................................................................................6 THE W. I. CLARK COMPANY................................................................................2 TIBBITS EQUIPMENT SERVICES INC................................................................1 TYLER EQUIPMENT CORPORATION..................................................................3

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • June 21, 2023 • Page 19 The Ultimate in Trailers® ROGERS BROTHERS CORPORATION ALBION, PA Over a CENTURY of building the very best heavy-duty trailers for your hauling needs! Contact your local dealer for a quote today. TRAILERS TO MEET EVERY HAULING CHALLENGE! Committed to building superior quality, reliability and durability into every trailer. Tyler Equipment www.cn-wood.com 200 Merrimac St. Woburn, MA 01801 (781) 935-1919 140 Wales Ave. Avon, MA 02322 (508) 584-8484 3 Rocky Hill Road Smithfield, RI 02917 (401) 942-9191 C.N. Wood Co., Inc. www.tylerequipment.com 251 Shaker Road East Longmeadow, MA 01028 (413) 525-6351 • (800) 292-6351 Parts: (877) 255-6351 1980 Berlin Turnpike Berlin, CT 06037 (860) 356-0840 • (800) 352-4473 Parts: (860) 356-0848

Page 20 • June 21, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide