Contractors Deliver Relief in Phoenix With Tunnel Project

SSC Underground kicked off the tunneling project with a 105-ft. installation of 66-in. casing for a 48-in. waterline. The second segment included the installation of six 86-in. diameter tunnels for a total of 834 ft.

By Chuck MacDonald CEG CORRESPONDENT

National and local news have been covering the water crisis in America’s Southwest and its dependence on the dwindling resources from the Colorado River. Recent infrastructure projects in northwest Phoenix are helping to address that issue in this area of approximately 400,000 people.

The city of Phoenix recently embarked on a project that would provide an underground pipeline to supply a backup water supply from the Salt and Verde Rivers. Phoenix’s drought pipeline project included 12 mi. of new pipeline and four booster pumping stations.

SSC Underground provided the tunneling portion of the job, working with lead contractors Sundt Construction, which constructed six tunnels over 4 mi.; PCL, which constructed three tunnels in a water treatment plant; and Kiewit, which constructed one tunnel in a single location.

see PHOENIX page 12

6382 West 2100 South, Salt Lake City, Utah 84128 • (801) 972-8939 • www.utahtrackandwelding.com • sam@utahtrackandwelding.com Specializing in New, Used & Rebuilt Replacement

• Undercarriage Parts • Attachments • New and Used Parts • Field Service • Full Service Shop • Track Repair • Equipment Sales • Hydraulic Cylinder Repair • Teeth & Edges We Buy Salvage Equipment Alternative to the dealer for all makes & models Utah Track & Welding Service & Sales

Parts

March 12 Vol. I • No. FOUR CORNERS STATES EDITION ® “The

Your Four Corners Connection •

Hogeboom • 1-877-877-4997 • dennishogeboom@cegltd.com

SSC Underground provided the tunneling portion of the job, working with lead contractors Sundt Construction, which helped construct six tunnels over a 4-mi. stretch. PCL constructed three tunnels in a water treatment plant while Kiewit assisted with the construction of one tunnel in a single location.

Nation’s Best Read Construction Newspaper… Founded in 1957.”

Dennis

LOGAN, UT 453 North 1000 West Logan, UT 84321 435-752-1533

SALT LAKE CITY, UT 4343 Century Dr. Salt Lake City, UT 84123 801-262-5761

CLIFTON, CO 549 32nd Rd. Clifton, CO 81520 970-434-7363

CEDAR CITY, UT 482 North Main Street Cedar City, UT 84720 435-586-4406 Email: del.maxedon@centuryeq.com

SPRINGVILLE, UT 1350 South 2000 West Springville, UT 84663 801-794-1463

DURANGO, CO 1097 Hwy 3 Durango, CO 81301 970-247-0522

ALBUQUERQUE, NM 6301 Edith Blvd. NE Albuquerque, NM 87107 505-433-2246

Page 2 • March 12, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

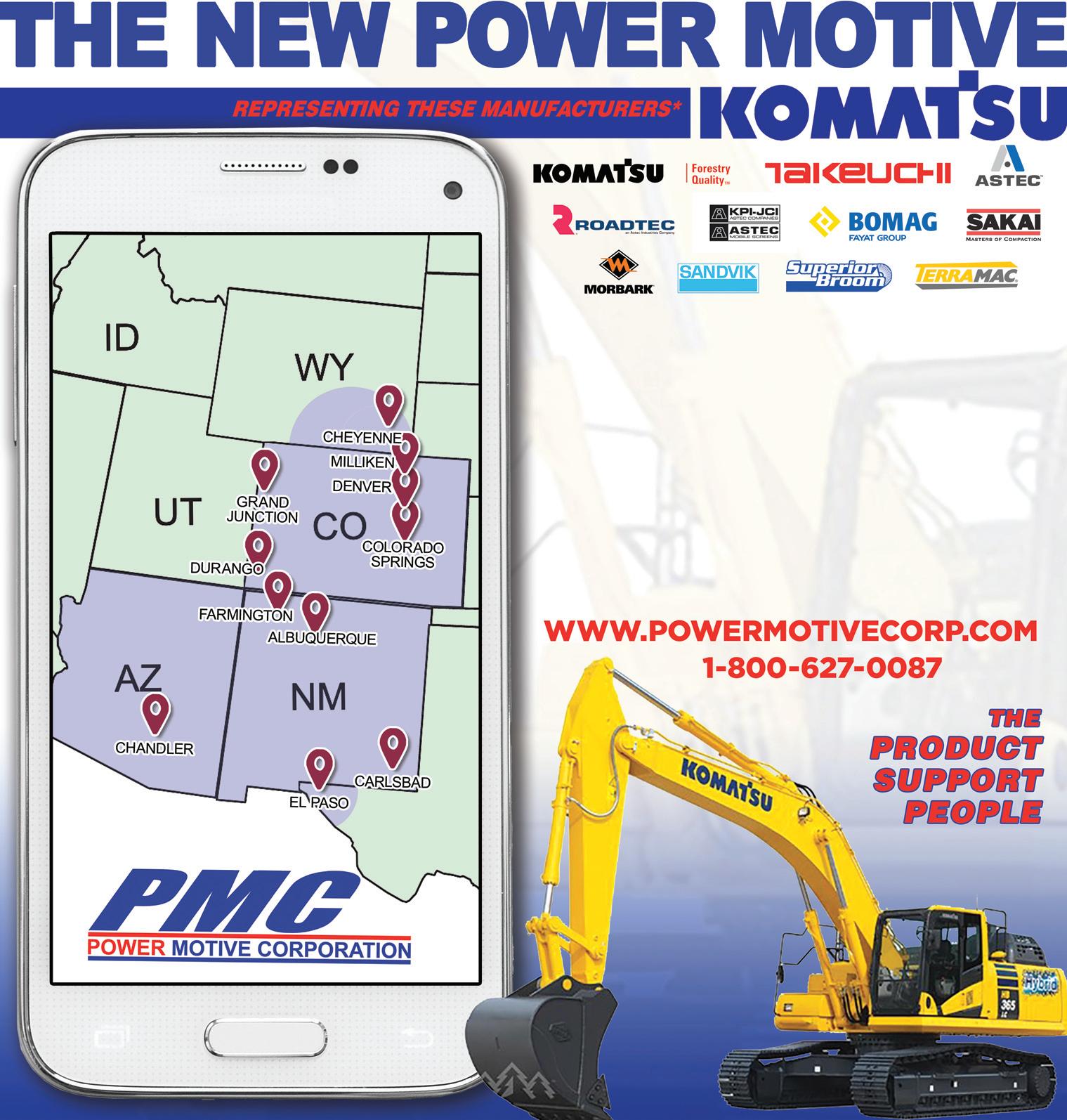

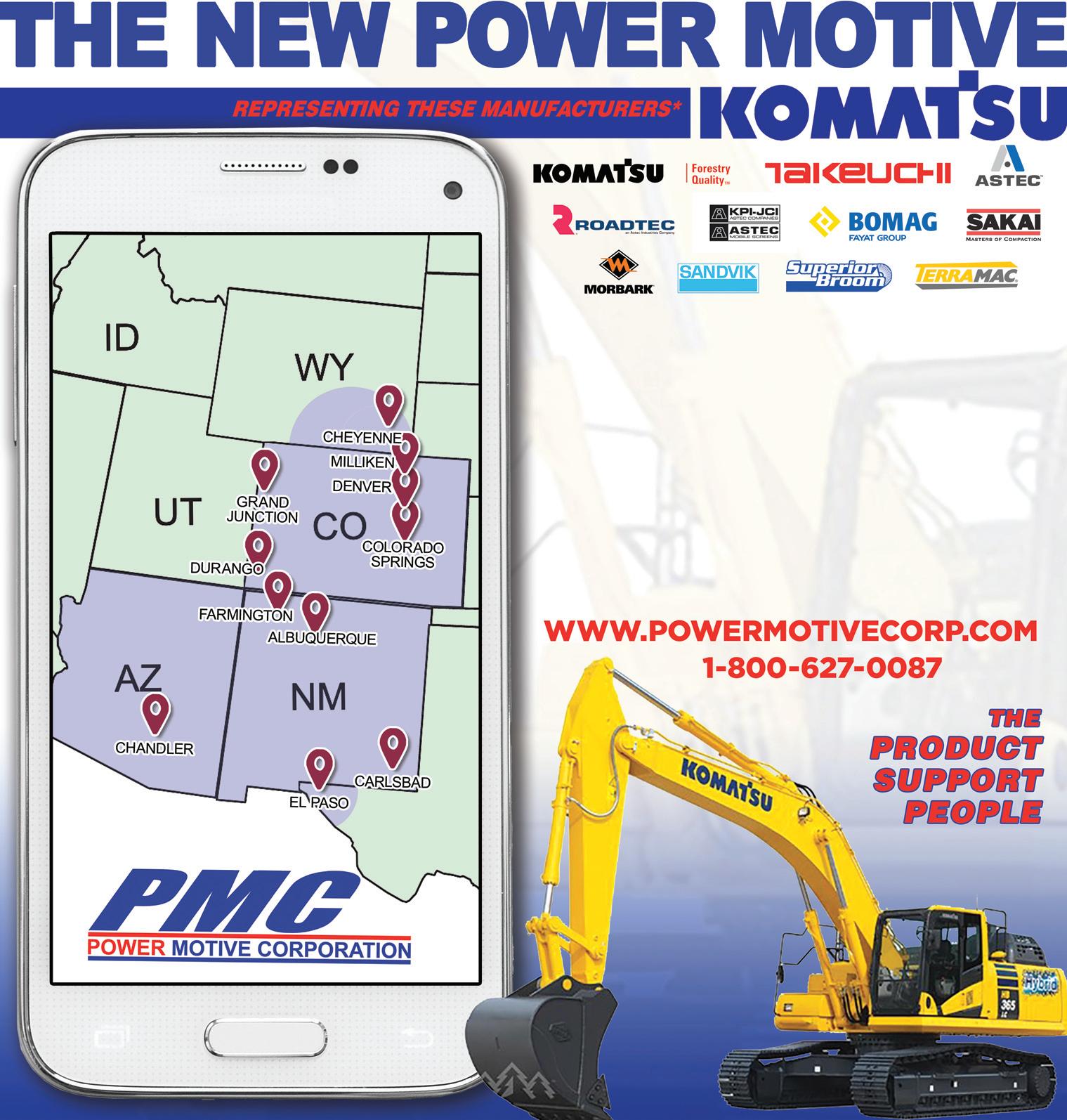

*some

COLORADO Corporate Office 5000 Vasquez Blvd. Denver, CO 80216 303.355.5900 Grand Junction 970-241-1550 Colorado Springs 719.576.5541 Milliken 970.587.1188 Durango 970.259.0455 WYOMING Cheyenne 307.634.5149 NEW MEXICO Albuquerque 505.345.8383 Carlsbad 505.485.1700 Farmington 505.324.8601 TEXAS El Paso 915.872.1001 ARIZONA Chandler 602.986.3003 Watch for New Branches Opening Soon!

representation varies by state Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • March 12, 2023 • Page 3

Colorado Dealer Takes Next Big Growth Step With XCMG

A Colorado equipment distributor is staking its future on a select line of heavy equipment as it expands in the Centennial State.

Through a calculated decision, MTC Equipment believes XCMG iron will soon be a major player, not only for contractors in Colorado, but across the country.

Founded in 2020 as a used equipment dealer in a two-bay garage, MTC now occupies 17,000 sq. ft. on eight acres just off I-76 in Hudson, approximately 30 mi. northeast of Denver. From the onset, founders Matt Fehr and son, Loren Fehr, focused on compact equipment, with skid steers representing 90 percent of all sales and rentals.

The men saw potential in what they described as “an underdeveloped market in terms of customer service,” and soon put together an ownership group that could handle the growth they envisioned for the fledgling company.

Matt and Loren were joined by Noah Fehr, a cousin, along with Demetrius Wiegand, to form the ownership group.

Demand for used equipment was strong, as was the product support the young company offered customers. Almost immediately, the team began eyeing larger quarters.

Looking for Right Mix

With management in place, the company

set its sights on the Hudson property and an equipment partner that offered a full line — skid steers to excavators — and in sizes ranging from compact to full-size machines.

Within months, the group had moved to the new larger facilities and began exploring equipment lines.

“We were looking for a line that had the right product mix that was readily available along with a strong warranty program and the right support in terms of parts when needed,” said Wiegand. “XCMG met all of our criteria.

“We spoke to other OEMs and eventually decided to bring in three XCMG machines and do our own testing against the leading brands,” Wiegand added. “The results were very favorable toward XCMG.”

After putting the units out for rent, the group was even more convinced that XCMG was the right partner.

“We had a machine out on rent and a piece of curved glass broke while on a job,” Wiegand said. “With something like glass, we weren’t sure how quickly it could be replaced but were happy when it arrived two days later.”

Parts warehouses for XCMG are located in Las Vegas and Houston with another facility set to open in Georgia.

XCMG is the third largest construction equipment manufacturer in the world, according to Wiegand, behind just Caterpillar and Komatsu.

Loren Fehr said it was the complete range of machines offered by XCMG that really pushed him in their direction.

“With excavators ranging from minis to the 490, which is a 110,000-pound machine, and loaders from two-and-a-half-yard capacity all the way to five yards, we have what

Page 4 • March 12, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

Demetrius Wiegand, rental manager of MTC Equipment, is excited about the complete line of iron his company now offers from XCMG. According to Wiegand, XCMG is one of the largest manufacturers of heavy equipment in the world. The Hudson, Colo., distributorship offers excavators, loaders and compaction equipment and will soon add skid steers and aerial lifts.

Excavators from XCMG are visible from I-76 approximately 30 mi. north of Denver. MTC Equipment officials said the full line of excavators and loaders are ready for immediate delivery.

see MTC page 6

The company got its start selling used skid steers and still maintains a large inventory of compact equipment available for sale or rent.

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • March 12, 2023 • Page 5

MTC Plans Aggressive Expansion Within Centennial State

the market wants,” Fehr added, noting that skid steers would be available in the very near future.

All XCMG machines are powered by either Kubota or Cummins, according to Wiegand. Compaction equipment, graders and scissor lifts also are available from XCMG and will be carried by MTC.

“We’re very confident in the product,” Wiegand said. “The performance is great. The durability is great. Frankly, we want to compete with Deere and CAT, and we think we can.”

Big Plans in Big State

Part of the attraction of being located in an unincorporated area of Hudson was the lack of a local sales tax. Wiegand pointed out that customers can save as much as $10,000 in taxes on an excavator purchase when compared with neighboring counties.

Still, there is an aggressive expansion plan already in the works that will take MTC to all major population centers in Colorado.

With 23 employees in Hudson, nine of which are technicians, the foundation has been laid on the north side of the Denver Metro area.

Plans are to open branches in Grand Junction, Fort Collins, Colorado Springs and in Denver proper.

The company also sells Fecon attachments, FirstGreen and Baumalight machines, along with other attachment lines and Stihl landscaping equipment.

XCMG, though, will be the engine that powers MTC’s growth, Wiegand believes.

“We’re very comfortable with XCMG

being our identity,” he said. “MTC is XCMG and soon the entire state will know that.”

About MTC Equipment

MTC Equipment is a family-owned andoperated business that specializes in heavy equipment sales and service along with quality equipment attachments. The company is committed to honesty, transparency and a “deal done right the first time around.” In addition to the XCMG equipment line, MTC represents Fecon, Baumalight, FirstGreen,

Furukawa Rock Drill (FRD), Worksaver, Virnig, and Stihl and is located at 21323 I-76 Frontage Rd in Hudson, Colo.

For more information, visit www.mtcequipment.net.

About XCMG

Founded in 1943, XCMG is the third largest construction machinery company in the world. It is ranked 65th in the list of China’s Top 500 Companies, 44th in the list of China’s Top 100 Manufacturing

Enterprises, and second in the list of China’s Top 100 Machinery Manufacturers. XCMG is dedicated to its core value of “Taking Great Responsibilities, Acting With Great Morals, and Making Great Achievements” and its corporate spirit of being “Rigorous, Practical, Progressive and Creative” to keep moving toward its ultimate goal of becoming a leading world-class enterprise capable of creating real value, according to the manufacturer.

(All photos courtesy of MTC Equipment.)

Page 6 • March 12, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

MTC from page 4

MTC sells a wide range of attachments for compact and full size equipment including Fecon mulchers.

It’s a family a “Fehr” at MTC Equipment with Matt Fehr (R), president; nephew Noah Fehr (L); and son, Kyle. All are active in the business as is Matt’s other son, Loren (not pictured).

MTC’s reputation grew from its service department, where they are known for providing support for all brands of equipment.

Two Rokbak RA30s Work On Utah Mega Pipeline Project

When Utah-based contractor BHI was awarded low bid on a 3-mi. stretch of canal essential to the irrigation around the largest city in Uintah County, in the north-eastern part of the state, it knew that extensive excavation and backfill would be on the cards and that it would require the most robust and reliable equipment.

Hive of Activity in Beehive State

BHI has been tasked by Uintah Water Conservancy District to enclose a 78 in. high-density polyethylene (HDPE) pipe across a vast portion of the Steinaker Service Canal near the city of Vernal.

Owing to a water shortage over the past several years, the Uintah Water Conservancy District has been working to improve provision to the surrounding area, with the Steinaker Service Canal Enclosure Project. The existing channel is being converted into a pressurized pipeline to provide a firm water supply to land in the surrounding Ashley Valley, with the aim to minimize and even eliminate loss of water through seepage and evaporation, maximizing the amount of water available for irrigation purposes.

Upon completion, the canal enclosure will be the largest diameter HDPE pipe installation in the United States of America.

BHI is self-performing the entire scope of the project, which includes site preparations, excavation, pipe installation, back-fill and restoration of the canal. To handle the largescale earth-moving, BHI needed articulated haulers that would be up to the challenge, day after day, in an intense six-month timeline.

Operating With Ease

Rokbak dealer Rasmussen Equipment, of Salt Lake City, supplied two RA30s to BHI on a rental-purchase option in September 2022. The haulers were received so positively on site that the purchase was completed before the end of the year.

The RA30s are tasked with transporting rock and rubble to excavate the area in order to install the pipe, later they will support with the subsequent backfill. With the capacity to transport a payload of up to 30.9 t, a maximum engine power of 276 kW (370 hp), a heaped capacity of 22.9 cu. yd., and a maximum torque of 1880 Nm @ 1,400 rpm, the

Rokbak RA30 can be relied upon to allweather-operate, transporting loads effectively and efficiently, with optimal traction in difficult terrain and combating steep inclines with ease.

“The RA30 is a top-performing machine,” said BHI operator Reese Shultz, who has already clocked up more than 2,000 hours alongside colleague Dustin Gardner in the two RA30s since work commenced in September.

“It’s fuel efficient, powerful and with features like the tailgate helping to maximize load retainage as well as multiple reverse gears enabling quick cycle times, it’s been

designed for productivity. It also has excellent mobility, it’s relatively narrow [10 ft. 6 in. at its maximum width] which is hugely beneficial in confined job site spaces.”

“One of the first things I noticed when I started using the RA30 was that it has proper visibility, from a comfy seat, in a quiet cab and the HVAC system works really well,” said Gardner. “It’s a real solid ride and it’s comfortable to operate over various ground conditions.”

Cushioned bump stops on the steering cylinders reduce strain on the operator over an extensive shift and a 45-degree steering angle at either side creates a turning radius of

just 27 ft. 9 in., resulting in enhanced maneuverability. There is a spacious, ROPS/FOPScompliant, pressurized cab. Smoother gear shifting accentuates these levels of comfort, alongside other benefits like faster cycle times, lower fuel consumption and reduced carbon emissions.

Exceeding Expectations

Rasmussen Equipment has provided Utah contractors with equipment solutions for more than 75 years. That wealth of experience combined with the RA30’s capabilities for taking on the toughest tasks and terrain has proven to be an ideal combination.

“It’s always easy to work with BHI because of the professionalism and knowledge throughout the organization,” said Rasmussen Equipment’s Sales Representative Brandon Dorney, who has worked closely with BHI for many years and facilitates the equipment support provided by Rasmussen Equipment.

“We enjoy keeping up with the demands of BHI and coming up with solutions to individual projects. When BHI outlined this particular job with its challenging earthmoving aspects, we knew they needed Rokbak haulers.”

With the Steinaker Service Canal Enclosure Project due to run until April 2023 and a huge amount of groundwork still to be done, BHI expects to put the RA30s through their paces for a good while yet.

For more information, visit www.rokbak.com.

Two Rokbak RA30s are busy transporting rock and rubble in Utah.

BHI likes the fuel efficiency, quick cycle times, mobility and operator comfort that the RA30 provides.

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • March 12, 2023 • Page 7

The RA30s have been efficiently transporting loads on site since September last year.

Page 8 • March 12, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • March 12, 2023 • Page 9

Rocky Mountain Asphalt Conference and Equipment Show

(L-R): Steve Harry, Jeff Schwankl and Nick Busicchia, all of Power Motive Corporation, said the Takeuchi skid steers are becoming increasingly popular on paving jobs, both with municipalities and contractors. Power Motive is the Komatsu dealer for a large portion of the Southwest and represents Astec paving and aggregate equipment as well.

The Rocky Mountain Asphalt Conference and Equipment Show held its 50th annual trade show and conference at the National Western Complex in Denver from Febr. 7 to 8.

Forty-two education sessions were offered on innovation, new technology and other industry related topics along with the popular equipment show.

RMACES also offered a tour of a working asphalt plant and a day-long “Asphalt Plant Academy.”

Tom Peterson, show chairman, announced next year’s event will be held at the same venue on Feb. 6 to 7, 2024. CEG

Page 10 • March 12, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

Marketing used construction, ag and transportation equipment is the specialty of Steffes Auction Group, an Iowa-based company that holds auctions throughout the Midwest and eastern Rockies. Its impressive display inside the National Western Complex was manned by (LR) Chris Gellner, Travis O’Leary, Colin O’Leary and Josh Ryken.

Jason Kelley (L) and Rollie McDaniel, territory managers of Bobcat of the Rockies, were on hand to talk about Bobcat’s T86 compact track loader.

Honnen Equipment represents the Wirtgen Group of products in parts of four states — Colorado, Utah, Wyoming and Idaho. Its booth at RMACES featured Vogele paving machines and Hamm compaction equipment.

The Powerscreen line of aggregate equipment was represented at the show by its dealer, Powerscreening LLC, which also sells Terex washing systems. (L-R): Powerscreening LLC customer Jerry Whaley of Kiewit, Craig Rautiola of Terex and Powerscreening’s Patrick Malfitano.

Hosts Its 50th Annual Event

specializes in new and used heavy equipment for construction and municipalities with branch locations in Denver, Colorado Springs

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • March 12, 2023 • Page 11

Anthony Cataldo of MTC Equipment displayed XCMG compaction equipment at RMACES. The full line of XCMG equipment was recently taken on by MTC in Hudson, Colo. The XMR303S is a double-drum vibratory road roller.

Ray Webb (C), an employee of Faris Machinery Co. for the past 52 years, is flanked by company President Giles Poulson (L) and Bill Smith, sales manager. Faris

and Fort Collins.

Wirtgen’s W 35 Ri small milling machine was one of many machines on display from 4Rivers Equipment. On hand (L-R) were Bret Bollmeier, Wirtgen Group product specialist; Greg Hart, customer service representative; and Jeremy Griebel, territory manager.

SSC Underground Utilizes Trenchless Technology On Job

PHOENIX from page 1

The tunnelling portion of the job came to $4.3 million.

SSC Underground was tasked with using trenchless technology to burrow through the earth, allowing traffic and everyday life to continue overhead with minimum interruptions. This approach used small skid steers to dig through the rocks and dirt. Workers then used jackand-bore equipment to push the steel casing into the newly created hole. In the Sundt project, the enormous casings were 10-ft. long and 86 in. in diameter, tall enough that the entire Phoenix Suns professional basketball team could walk through without having to stoop.

Once the tunnel construction began, precision digging was required. On the Sundt section of the job, the workers needed to dig a tunnel so that the casings would connect the pipe being laid by Sundt in open-cut trenches with approximately 1-in. tolerance.

SSC Underground began working on the project in 2019 and wrapped it up at the end of 2022. SSC’s consulting division worked closely with design engineers and other contractors to devise an

underground road map for the work. Using its underground potholing fleet, the crew located existing utility lines so that they could be relocated or pipeline alignment could be designed around them.

“Every dollar spent on pre-construction potholing/SUE saves $7.82 in construction costs,” said Arvid Veidmark, president of SSC. “Often when tunnelling, we will find previously unknown infrastructure, even gas lines, which of course can be quite dangerous.”

The tunnel crew installed the steel casings underneath major arterial roadways and intersections, neighborhood streets and an active water treatment plants. Ground conditions ranged from caliche, cemented cobbles, alluvium and hard dirt. Each day seemed to bring its own set of challenges as workers changed strategy to fit the soil requirements. The job required more than 12 trenchless installations. Workers managed each operation to minimize disruption to the public while considering time, cost and risk.

SSC kicked off the tunnelling with a 105-ft. installation of 66-in. casing for a 48-in. waterline under Glendale Avenue at the base of Piestewa Peak Mountain, using a motorized boring unit from Robbins to perform this crossing as the ground was solid rock. Working for Kiewit, this crossing was a key connection as this section ran through neighborhoods and had a major impact to residents.

The second segment included six 86-in. diameter tunnels under intersections along the 32nd Street

alignment for a total of 834 ft. for a 66-in. waterline. These tunnels were constructed using an S70 Bobcat skid steer equipped with either a hammer attachment or a rotary head to do the digging in hard dirt conditions. Production varied between 3 ft. to 9 ft. of installation per shift. As a subcontractor to Sundt Construction, SSC worked as a partner to sequence the tunnels to minimize traffic lane closures and keep access as open as possible to the many businesses along this corridor.

Page 12 • March 12, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

The skid steer in the pipe is removing dirt and rock so the pipe can be shoved toward its connection point.

A collapsing trench can be extremely dangerous to workers who work underground. SSC Underground takes precautions to keep workers safe including soil analysis, shore box engineering and shoring pits.

Workers encountered a flooded pit on several occasions because of unusual rains. After draining the pit, workers continued digging. SSC Underground has resources to prevent flooding when workers are actively engaged in construction.

These 96-in. pipes emerge into the pit having punched through hard rock conditions. see PHOENIX page 14

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • March 12, 2023 • Page 13

CORNERS PUBLISHING

Issue Closing Publishing 8 March 29 April 9 10 April 26 May 7 12 May 24 June 4 14 June 21 July 2 16 July 19 July 30 Issue Closing Publishing 18 August 16 August 27 20 September 13 September 24 22 October 11 October 22 24 November 8 November 19 26 December 6 December 17

FOUR

2023

SSC, Sundt, PCL, Kiewit All Play Vital Role in Phoenix

“Our deepest dig was 33 feet underground,” said Veidmark. “That was inside the water treatment plant. Our work teams had to keep the equipment running yet remain vigilant while tunneling under roads and important structures. We stayed away from a reservoir and a traffic intersection. Often, they found some previously undiscovered underground structure. They had to decide whether to have it removed or tunnel deeper or go around it.”

The final segment of SSC’s installations was for PCL Construction. The digging team installed three 96-in. tunnels at the origination point of the pipeline, the 24th Street Water Treatment Plant. Using the same skid steer method as in earlier digs, the workers encountered solid rock conditions, averaging 18 in. per shift of tunnel advancement.

These three tunnels — 35 ft., 115 ft. and 101 ft. in length — connect four pits for installation of a 72-in. waterline. Three of the four pits were constructed as semi-permanent structures to allow for the angles and elevations necessary to complete the connections.

Not only did work teams have to deal with hard rock, but also surprising weather emerged.

“Several times our teams came to work and discovered that the pit had been flooded in the night,” Veidmark said. “We simply pumped out the water and went to work.”

Veidmark is proud of the work that he and his team accomplished for the general contractors in charge of the overall projects.

“Tunnelling allows life on the surface to go on in a normal manner,” he said. “It means fewer traffic backups with cars idling for long periods of time. Also, when working underneath a neighborhood we can keep the worksite clean and try to be as invisible as possible.”

With other tunneling projects coming for the future, companies like SSC Underground must consider their options.

“Workers are becoming harder to find, so we sometimes look to larger and more efficient equipment to do the job,” Viedmark said. “Large tunnel boring machines should be considered as well as improved geotechnical information. We are hoping improved technology will provide answers in our business.” CEG

photos courtesy of SSC Underground.)

Page 14 • March 12, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

(All

PHOENIX from page 12

Waterlines are being pushed into the steel casing.

The 32nd Street Greenway required an 86 in. pipeline to carry the 66-in. waterlines through to their destination.

A skid steer removes dirt and rock while the casings are pushed into the hole using jack and bore equipment.

Equipment is poised to continue pushing the tube through the dug out areas.

TI’s $11B Investment in Utah

Texas Instruments Incorporated (TI) recently announced plans to build its next 300-mm semiconductor wafer fabrication plant in Lehi, Utah.

The new fab will be located next to the company’s existing 300-mm semiconductor wafer fab, LFAB, in Lehi, Utah. Once completed, TI’s two Lehi fabs will operate as a single fab.

“This new fab is part of our long-term, 300mm manufacturing roadmap to build the capacity our customers will need for decades to come,” said Haviv Ilan, TI executive vice president, COO, incoming president and CEO. “Our decision to build a second fab in Lehi underscores our commitment to Utah and is a testament to the talented team there who will lay the groundwork for another important chapter in TI’s future. With the anticipated growth of semiconductors in electronics, particularly in industrial and automotive, and the passage of the CHIPS and Science Act, there is no better time to further invest in our internal manufacturing capacity.”

The landmark $11 billion investment marks the largest economic investment in Utah history. The Lehi expansion will create approximately 800 additional TI jobs as well as thousands of indirect jobs. TI will strengthen its partnership with the Alpine

School District and will invest $9 million to improve student opportunities and outcomes.

“Companies like Texas Instruments continue to invest in Utah because of our worldclass business climate and exceptional workforce,” said Utah Gov. Spencer Cox. “TI’s new semiconductor fab will solidify Utah as a global semiconductor manufacturing hub for generations to come.”

The fab will be designed to meet one of the Leadership in Energy and Environmental Design (LEED) building rating system’s highest levels of structural efficiency and sustainability: LEED Gold. Plans include recycling water at nearly double the rate of the existing Lehi fab. Advanced 300-mm equipment and processes in Lehi will further reduce waste, water and energy consumption per chip.

Construction of the new fab is expected to begin in the second half of 2023, with production as early as 2026. The cost of the new fab is comprehended in TI’s previously announced capital spending plan to expand manufacturing capacity and will complement TI’s existing 300-mm fabs, which include DMOS6 (Dallas), RFAB1 and RFAB2 (both in Richardson, Texas) and LFAB (Lehi, Utah). TI is also building four new 300-mm wafer fabs in Sherman, Texas.

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • March 12, 2023 • Page 15

Page 16 • March 12, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide