It’s never good to waste an opportunity … even when it comes to waste.

A1 Organics, a fourth-generation family firm, has built a highly successful business turning waste into revenue. The Colorado-based company started out decades ago as a lamb-feeding operation and the inevitable consequence of that was a lot of manure. Dealing with that waste was the company’s first foray into compost, and the rest, as they say, is history.

Today, A1 is the largest producer of compost in the Rocky Mountain region, taking in more than 500,000 tons of organic waste annually, processing it and returning it to market in the form of high-quality composts, mulches and other recycled landscape materials.

than

A1

6382 West 2100 South, Salt Lake City, Utah 84128 • (801) 972-8939 • www.utahtrackandwelding.com • sam@utahtrackandwelding.com Specializing in New, Used & Rebuilt Replacement Parts • Undercarriage Parts • Attachments • New and Used Parts • Field Service • Full Service Shop • Track Repair • Equipment Sales • Hydraulic Cylinder Repair • Teeth & Edges We Buy Salvage Equipment Alternative to the dealer for all makes & models Utah Track & Welding Service & Sales

Supplies Muscle for Recycling Operation see

Liebherr

OPERATION page 6

Liebherr loaders are a critical component of A1 Organics’ operation in Commerce City, Colo., where the company recycles green waste into colored mulch, according to Kent Pendley, A1’s chief operating officer.

January 15 Vol. I • No. FOUR CORNERS STATES EDITION ® “The Nation’s Best Read Construction Newspaper… Founded in 1957.” A1 Organics photo CEG photo Your Four Corners Connection • Dennis Hogeboom • 1-877-877-4997 • dennishogeboom@cegltd.com

Turning waste into compost and landscaping materials is big business for

Organics of Colorado. The company recycles more

500,000 tons of organic waste annually at its four facilities in the Denver area. The company is led by the management team of (L-R) Chief Operating Officer Kent Pendley, Owner Dannette Wilson, Chief Financial Officer Travis Bahnsen and CEO Bob Yost.

LOGAN, UT

453 North 1000 West Logan, UT 84321 435-752-1533

SALT LAKE CITY, UT

4343 Century Dr. Salt Lake City, UT 84123 801-262-5761

CEDAR CITY, UT 482 North Main Street Cedar City, UT 84720 435-586-4406 Email: del.maxedon@centuryeq.com

SPRINGVILLE, UT

1350 South 2000 West Springville, UT 84663 801-794-1463

CLIFTON, CO

549 32nd Rd. Clifton, CO 81520 970-434-7363

DURANGO, CO

1097 Hwy 3 Durango, CO 81301 970-247-0522

ALBUQUERQUE, NM

6301 Edith Blvd. NE Albuquerque, NM 87107 505-433-2246

Page 2 • January 15, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

Corporate Office

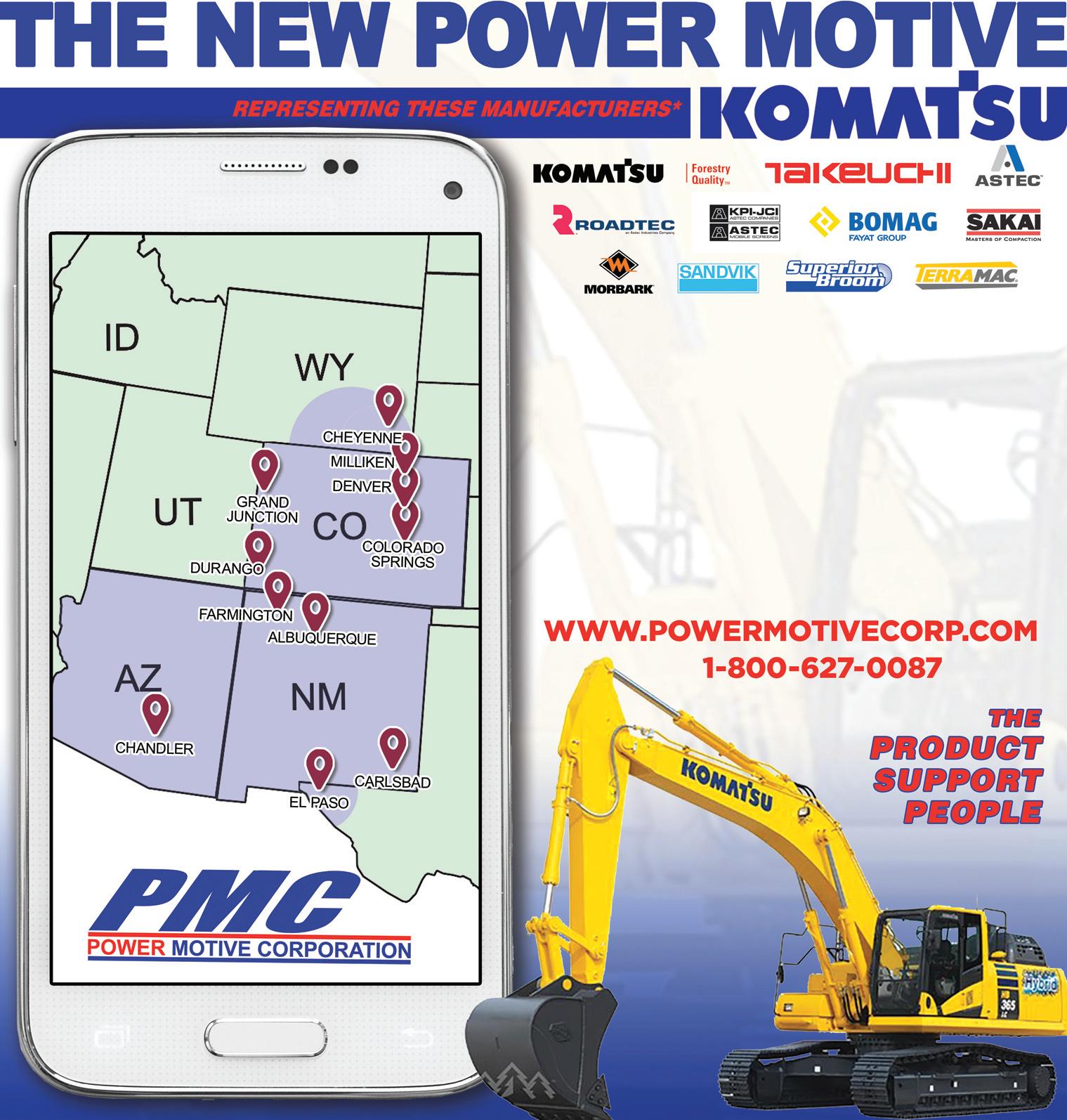

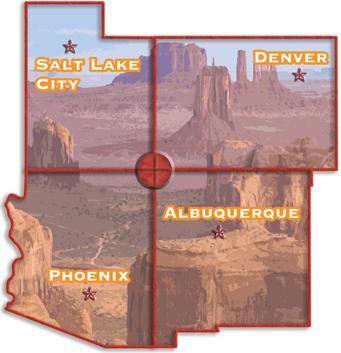

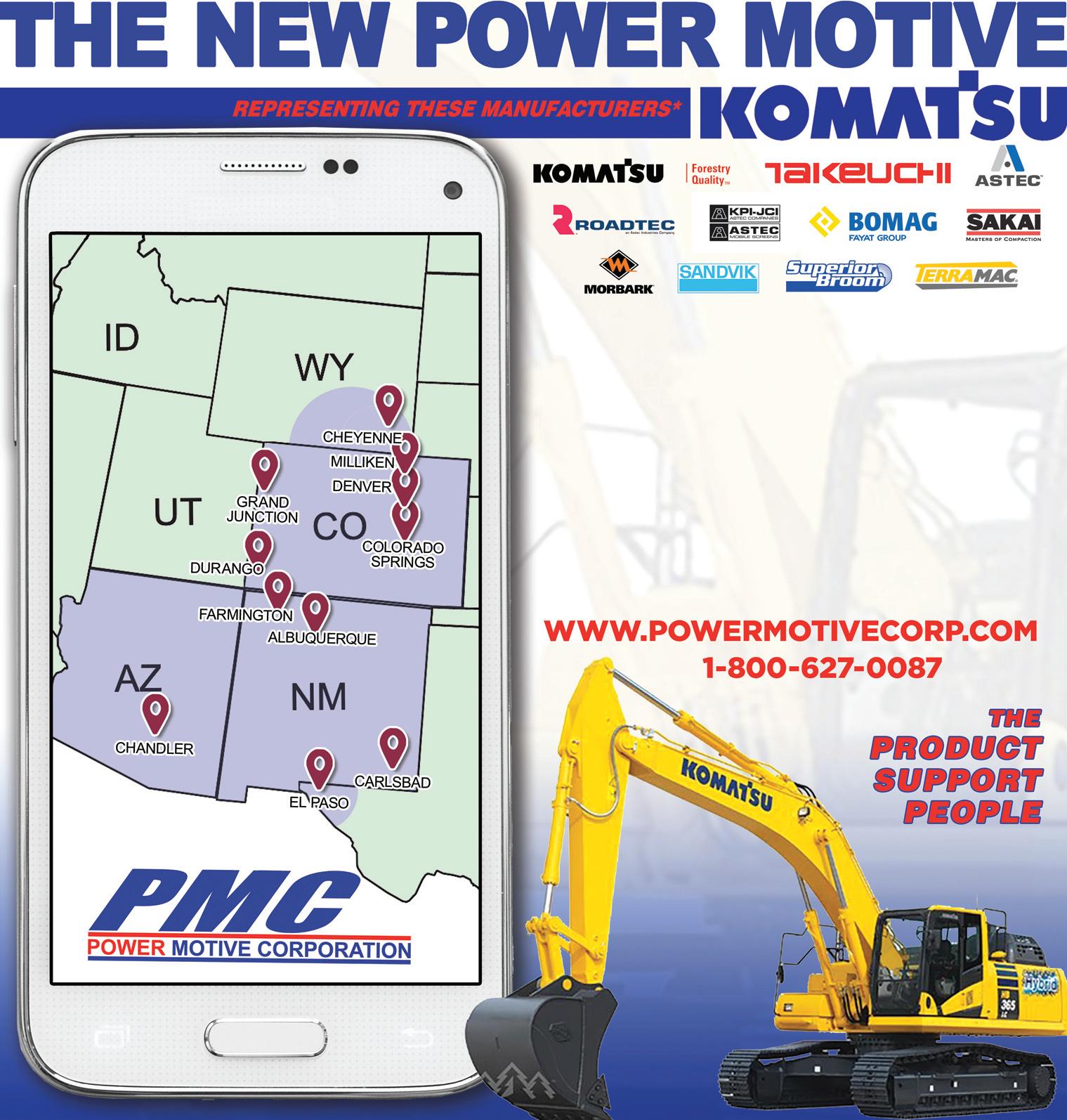

WYOMING Cheyenne 307.634.5149 NEW MEXICO

TEXAS El Paso

ARIZONA Chandler

Watch for New Branches Opening Soon! *some representation varies by state Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • January 15, 2023 • Page 3

COLORADO

5000 Vasquez Blvd. Denver, CO 80216 303.355.5900 Grand Junction 970-241-1550 Colorado Springs 719.576.5541 Milliken 970.587.1188 Durango 970.259.0455

Albuquerque 505.345.8383 Carlsbad 505.485.1700 Farmington 505.324.8601

915.872.1001

602.986.3003

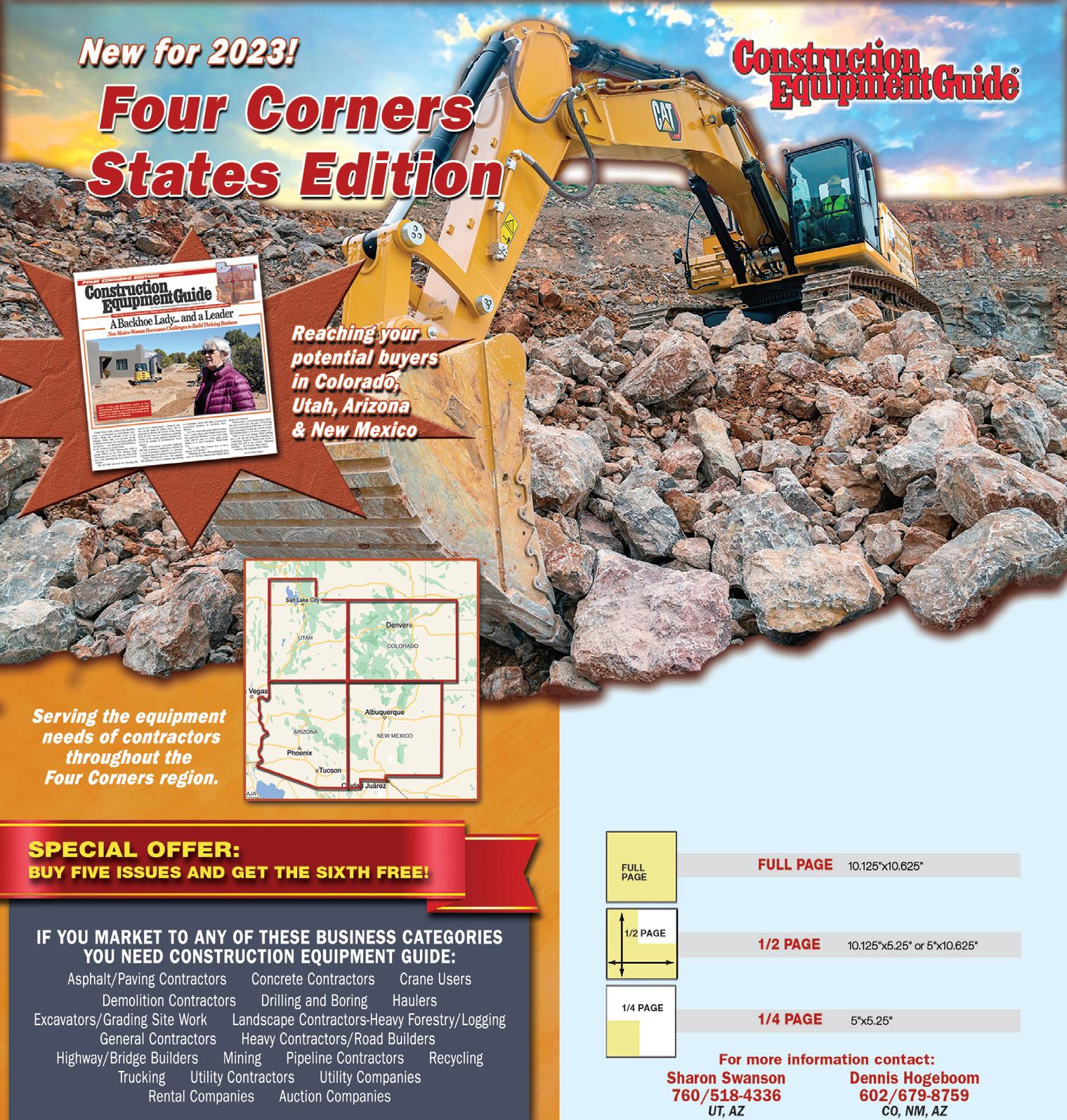

Case Minotaur Groundbreaker Roadshow Comes to Salt Lake

The Case Minotaur Groundbreaker Roadshow, making its way across the United States, made a stop at Century Equipment located in Salt Lake City on Nov. 10, 2022.

To introduce the Minotaur at Century Equipment, customers were invited to get in the cab and see the capabilities and versatility that the Minotaur offers. Customers were able to use the Leica guided system for moving rock and rough grading. Century also provided an area where customers could operate the Minotaur in the mud. Customers noted that “this cut, it doesn’t just push material — it truly acts like a dozer.”

What makes the Minotaur unique is its first in its class performance, as it operates like a full-size dozer, but in a compact design. And the name, Minotaur — part man/part beast — applies in the name of this piece of equipment: part dozer, part loader, part beast.

This is a whole new product category, not just in the world of Case, but across the board with all manufacturers. It is one of the most versatile compact machines ever built, according to Case, out-pushing and outloading machines of its size, while providing the precision and productivity the industry craves. It is incredibly versatile and offers the best of both worlds.

Another unique addition on the Minotaur is the ripper system that comes with the machine. The Minotaur also comes Leica ready for its guidance system.

Mitch Blake, territory sales manager of Case, has “never been more excited about a product in his 25 years with Case. The Minotaur is perfect for someone wanting the versatility of two different machines but doesn’t want to be hauling both. So, for instance, you can put this and a bucket on a trailer and off you go. This is still a big machine and requires at least a 1- ton truck with a deck over trailer.”

The Minotaur comes in at 18,000 lbs. (9 tons).

“It would be perfect for the contractor that did landscaping or dug basements; it’s perfect for grading,

heavy pushing or fine grading,” said Blake.

Minotaur is unique because it looks like a compact track loader or a skid steer with tracks.

“It was built first and foremost to be a dozer, the ripper provides easier dozing and earth-moving,” said Blake. “This takes the components of a true dozer that has a C frame and it couples up underneath the pan and hydraulically locks it in to place where it should be. The dozer blade is the same dozer blade used on the 650 M.”

This Minotaur has 29 patents and has been in development for six years. According to Blake, “This frame was never intended to have wheels; it was always going to have a track. It lends itself to the Case 2050 size dozer and it has Case dozer DNA throughout the entire machine. Someone will get in it and say, yes, this is a Case.”

If you look inside the cab, the set-up is traditional paddle controls, different from a normal CTL. The Minotaur runs the same as other dozers. Users can change ISO pattern to dozer mode, where it remaps the entire hydraulic, electrical and engine specs to be just like a dozer. It is incredibly versatile — as it can be used for road and bridge cleanup or dozing in very small intricate areas, it would also be great for slope work, a farm cleaning out ponds or trimming up roads, according to Case.

Blake is proud of the work that Case has done on creating the Minotaur.

“Roughly 10,000 hours of testing in the field have gone into its development which is mostly unheard of today,” he said. “This created a new class; it is unique and new to everyone.”

Doug Buddell, Salt Lake City branch manager of Century Equipment, knows the perfect customer and the niche this will provide.

Page 4 • January 15, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

Century Equipment’s New Arrival...

see

13

Contractors were able to get in the cab and test the dozer ability in the mud at the recent Minotaur Roadshow at Century Equipment in Salt Lake City. Century Equipment has been in business since 1969 and a Case dealer since 1970.

MINOTAUR page

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • January 15, 2023 • Page 5 FOUR CORNERS PUBLISHING 2023 Issue Closing Publishing 4 February 1 February 12 6 March 1 March 12 8 March 29 April 9 10 April 26 May 7 12 May 24 June 4 14 June 21 July 2 Issue Closing Publishing 16 July 19 July 30 18 August 16 August 27 20 September 13 September 24 22 October 11 October 22 24 November 8 November 19 26 December 6 December 17

A1 Organics, Power Screening LLC Tackle Colorado Waste

That all translates to a lot of material handling as it is received, stockpiled and fed into the appropriate processing machines and, ultimately, loaded for delivery.

Kent Pendley, A1 vice-president of operations, said choosing the right equipment is crucial to the success of the business.

“We’re pretty adept at finding the right equipment for the right job,” Pendley said. “For moving the amount of material we move, the Liebherr L550 and L580 loaders have proven to be the right choice.”

The company’s four facilities — two producing compost and two producing colored mulch — utilize Liebherr wheel loaders exclusively on new purchases. It has nine Liebherr loaders in operation, with another 550 loader being delivered to them in 2023.

But that hasn’t always been the case.

“In 2016, we made the decision to investigate other loader options as we were not entirely happy with the equipment that we were using at the time,” Pendley said.

“We were customers of Power Screening LLC, using their Komptech Hurrikan plastic separator/screeners,” he added. “So, we mentioned our need for loaders to Ryan Puckett, our rep at the time, and he suggested we look at Liebherr. Frankly, I had never heard of a Liebherr loader.”

Pendley noted, though, that for composting and recycling equipment, A1 had started looking to Europe years earlier.

“They are light years ahead of the U.S.,” he said.

“We sent out spec sheets to all the major equipment distributors and included Power Screening’s Liebherr product,” Pendley said. “Everyone came back in with their proposals and Liebherr was the clear winner.

“First, they were the clear winner on price,” Pendley went on. “Not because Liebherr was less expensive, but because Ryan sized it properly. Others were clearly overselling us based on our needs.”

Pendley said that based on the proper sizing in Power Screening LLC’s proposal, they could buy their first two

loaders for the price of a single loader with some other brands.

“Still, we didn’t know much about the machines, so we did a lot of research,” he said. “After doing our due diligence and having a Liebherr factory rep visit our site to help evaluate our needs, we made the decision to purchase two of their loaders. We have never regretted the decision.”

Game Changing

First and foremost, “the reliability of their machines is unmatched in our opinion,” Pendley said.

“A case in point is that on the first two machines we bought, we purchased the full 10,000-hour maintenance warranty,” he said. “We laugh now that we probably way overspent on the maintenance plan based on how much service was required. The next loaders we bought, we respectively declined the maintenance plan,” he chuckled.

A1 said it has had no unexpected problems with any of its Liebherr loaders, even the oldest unit, which has more than 10,000 hours of service.

In addition to the reliability of the Austrian-made machines, Pendley points out three other factors that will contribute to A1 buying more Liebherr loaders going forward.

1. Fuel consumption. Pendley maintains that they are achieving fuel use as low as 3.2 gal. per hour in its compost facilities operating the 580, compared to consumption as high as 7-to-8 gal. per hour with loaders from other manufacturers. “That’s a huge difference over the course of the year,” he said.

2. In the dirty environment of the A1 facilities, clean air filters are very important to the continued operation of the machine. Pendley said the location of the air intake system — directly behind the cab rather than at the rear of the machine — helps prolong the life of the filter.

“With the well-placed location of the intake, we’re not having to replace the air filter nearly as often,” he said. “We would previously replace the filter twice in a 250-hour service cycle. Now we see filters that really do not need to be replaced even after 250 hours.”

3. The Liebherr loaders, unlike other manufacturers, do

Page 6 • January 15, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

A1 Organics COO Kent Pendley (L) and Power Screening LLC’s Dustin Sweeney with a Liebherr 550 wheel loader at A1’s facility in Keenesburg, Colo. Pendley credits Sweeney and Power Screening Vice President Ryan Puckett with being valuable equipment partners.

see OPERATION page 14

While the residential waste brought in to A1 facilities is supposed to be free of plastics, that’s not always the case. The Komptech Hurrikan S wind sifter was the solution provided by the Power Screening team. The machine sorts and removes plastics and light metals from the finished compost product. The plastic is blown into a trailer for removal.

OPERATION from page

1 A1

Organics photo

CEG photo

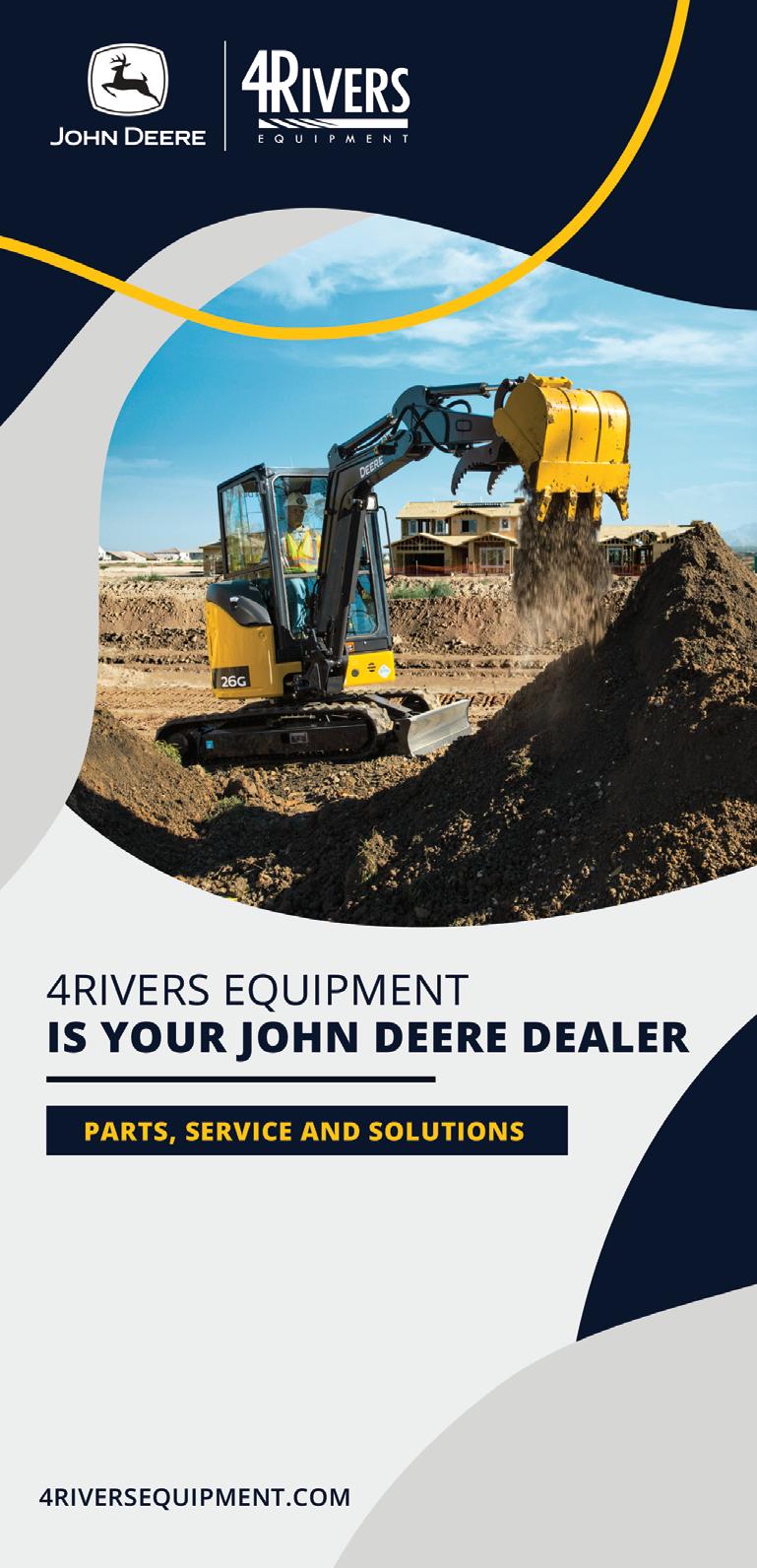

4Rivers’ First Machine Rebuild Takes Place at Fort Collins

A project three years in the making, the 4Rivers Equipment location at Fort Collins, Colo., performed the company’s first machine rebuild though John Deere’s Powertrain ReLife Plus Program. Upon the project’s completion, 4Rivers Equipment will have its first Certified Machine Rebuild Center.

The John Deere Powertrain ReLife Plus Program extends the life of a machine through its comprehensive and flexible machine rebuild solution. This process optimizes total owning and operating costs by getting a machine through its second life.

“Starting with a fresh set of remanufactured major powertrain components, the Powertrain ReLife Plus Program allows you to build on that strong foundation to create a customized repair plan unique to that particular machine,” the John Deere website states. “Certified technicians conduct a thorough inspection of your machine to help you identify where investments are needed to give it new life while still giving you the flexibility to consider work to the less critical areas of the machine.”

Additionally, the main goal of machine rebuilds is to provide the customer with as many options as possible to extend the life of their machine without compromising its expected performance and reliability.

“The biggest focus from [John] Deere’s perspective is to offer the customer options. Whether that’s a new tractor, a ReLife or something in-between, we want to do more business with them and give them choices on how they do business with us,” Territory Customer Support Manager of John Deere Ryan Engelman said.

4Rivers Equipment has been searching for the right opportunity to introduce

Starting with a fresh set of remanufactured major powertrain components, the Powertrain ReLife Plus Program allows you to build on that strong foundation to create a customized repair plan unique to that particular machine.

machine rebuilds for the past three years. The process is not quick and simple, though, as there is a list of qualifications to meet to become a certified rebuild center.

Engelman described the lengthy certification process as a massive spreadsheet where the dealership is scored on various areas from standard operating procedures to cleanliness and how they plan on exceeding a customer’s expectations.

“We had to take a good, close look at ourselves, our processes and procedures,” Director of Customer Support Braid Reid

John Deere’s Machine Rebuild Program

“The cost of a rebuild is a fraction of a full replacement and can lengthen the life of John Deere articulated dump trucks, dozers, excavators, wheel loaders and scraper tractors,” the John Deere website states.

John Deere breaks the Machine Rebuild Program down into six simple steps:

Step 1: Replace required major powertrain components like the transmission engine and axels;

Step 2: Review the results of the machine with dealer;

Step 3: Specify any additional parts to replace;

Step 4: Select ReLife warranty terms;

Step 5: Work is performed on your machine by certified John Deere technicians;

Step 6: Let you ReLife Machine help manage owning and operating costs.

For more information, visit https://www.deere.com/en/construction/machine-rebuild-program/

said. “Deere representatives came out and we sat down for four hours. We went through the whole thing, walked through the facility and explained our reason for picking the location. The next thing we know, we were off and running.”

The final qualification to become a certified rebuild center is to successfully complete a full machine rebuild. After performing quotes for eight potential projects, the circumstances aligned for 4Rivers to finally begin a machine rebuild for the Pueblo County Fleet on their 772D motor grader.

“It’s exciting to watch the professionalism and expertise of our dealership,” Reid said when asked about the project finally coming to fruition. “It’s exciting to see all of that in motion now.”

The first milestone of the project took place on Dec. 21, where the customer came to the Fort Collins location and reviewed the process. The estimated completion date for the rebuild is the second week of February.

For more information, visit the 4Rivers social and blog channels as it documents the project.

(All photos courtesy of John Deere.)

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • January 15, 2023 • Page 7

Gary Medill (L), service technician, working on the relife, and service writer Lois Hilbrands, both from the Fort Collins location. The engine and motor grader are currently undergoing a rebuild. The project is still in process and will be finished in February.

Page 8 • January 15, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • January 15, 2023 • Page 9

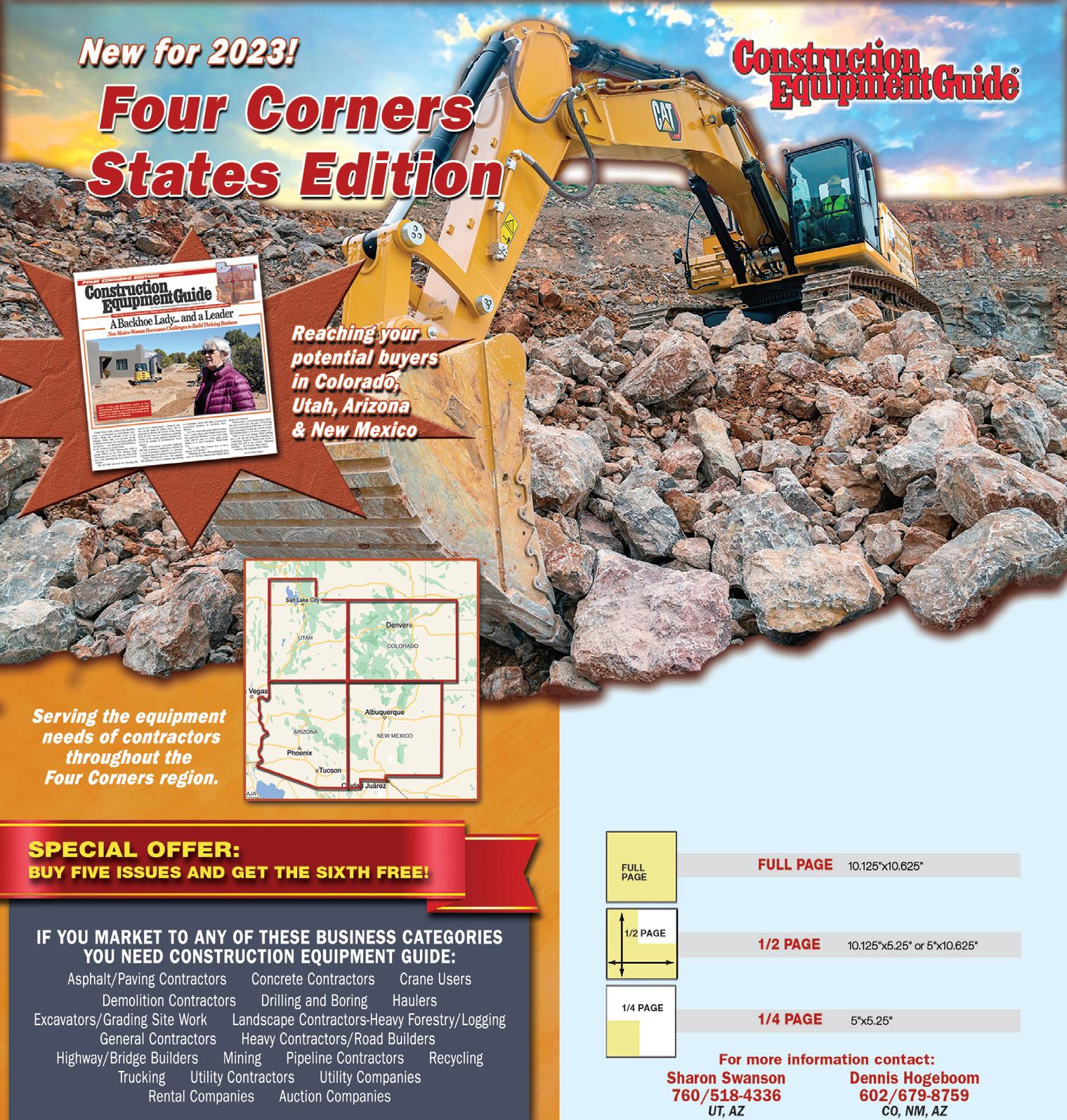

Recycling Key Part of Arizona’s Broadway Curve Project

Reduce, reuse and recycle: They’re key to protecting natural resources and lessening the amount of trash in local landfills. They’re also an important part of the Interstate 10 Broadway Curve Improvement Project.

“We reuse as much as we can so nothing goes to waste,’ said Kole Dea, senior resident engineer of the Arizona Department of Transportation. “If something can’t go back into the project, then it’s recycled.”

Asphalt millings, concrete, metal and steel are the most common types of waste, but the project team has future plans for all of them.

Asphalt Millings

When construction began in summer 2021, crews removed the rubberized asphalt from the surfaces of

Asphalt millings, concrete, metal and steel are the most common types of waste, but the project team has future plans for all of them for the Broadway Curve.

I-10 and U.S. 60 in the project area. That work created 1.3 million sq. yds. of millings, which are being used as the base layer for temporary haul roads in the project area. Millings provide a strong base for trucks and equipment to drive on, and they reduce dust — another plus for the environment. Millings also can be mixed in with dirt to build embankments that will support the roadway. Outside of the project area, ADOT uses millings on its maintenance roads in unpaved areas.

Concrete

As walls and other concrete structures are taken down to make way for new construction, they’re broken up so they can serve a new purpose. Crews are using equipment to break each piece into sizes no larger than 24 in.Those pieces are used as fill to build up approaches for new bridges and can be used to fill in holes or otherwise supplement unstable

materials in the project area.

Metal, Steel

Metal and steel products are major components of highway infrastructure, inside and out. In addition to what locals can see, they’re also being used to reinforce concrete girders and other structures and strengthen walls on the highway. Steel rebar and other materials are broken down and taken to a recycling facility. Reusable construction debris recycled steel is as strong and durable as new steel made from iron ore.

ADOT works in compliance with state and federal regulations to ensure reused materials do not pose a threat to the environment. Careful testing confirms that the paint stripes on milled asphalt don’t contain lead, and that old pipes or bridge structures are free from asbestos.

As new roadways, ramps and bridges take shape throughout the Broadway Curve work zone, construction crews are taking into account how important the infrastructure from the past is to building for the future.

(All photos courtesy of ADOT.)

In summer 2021, crews removed the rubberized asphalt from the surfaces of I-10 and U.S. 60 in the project area. That work created 1.3 million sq. yds. of millings, which are being used as the base layer for temporary haul roads in the project area.

Page 10 • January 15, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

“We reuse as much as we can so nothing goes to waste,’ said

Kole Dea, senior res-

ident

engineer of the Arizona Department of Transportation.

The I-10 Broadway Curve Improvement Project runs along 11 mi. of I-10 between Loop 202 and I-17 near Phoenix Sky Harbor International Airport.

Crews use equipment to break each piece into sizes no larger than 24 in. Those pieces are used as fill to build up approaches for new bridges.

John Deere Names Jason Connel Territory Champion

When Jason Connel learned he was Territory Champion of the John Deere Technician of the Year Award Program, he was overwhelmed with gratitude and humbled to receive the prestigious honor.

The John Deere Technicians Award Program recognizes those who epitomize what it means to be “John Deere” and honors extraordinary commitment to the brand. Connel, a service technician at Hobbs, was chosen out of a territory-wide pool of nominees.

“To know that somebody thought enough of my work to nominate me was very humbling,” Connel said. “I like to be a part of the team, so to stand out in the crowd is not always my strong front. Just to know that I’ve worked hard, and people recognize that, I think is a great accomplishment.”

4Rivers CEO John Shearer said Connel exemplifies the company’s core values of integrity, respect, commitment and innovation.

“I’m very proud to have one of our technicians named the Territory Champion, especially coming from our location in Hobbs, New Mexico, where it’s not always easy to stand out nationally,” Shearer said. “Jason fits the model for what our vision of an engaged employee is. He volunteers with the community, develops new technicians and is very talented. I don’t think we could have gotten a better candidate and John Deere obviously thought the same thing.”

Connel, who has a reputation for positivity and a knack for customer service, is one of the top technicians at his shop. Hobbs Service Manager Dewayne Spears and Parts Manager Justin Crowder, who nominated Connel for the award, said he is one of the most integral pieces of their aftermarket support.

“Jason has retained his top-notch attitude and ability to focus on what the customer truly wants, needs and expects out of our dealership and the John Deere brand,” the team at Hobbs said in a statement to John Deere. “Jason is always willing to give valuable face time to a customer experiencing a problem. He is an active listener when the customer explains an issue they are having. He has also been willing to go out to a customer’s shop and diagnose a problem when a field technician is not nearby.”

Driven by a passion for the trade and the thrill of a challenge, Connel approaches difficult tasks without forfeiting his signature positive attitude. Amid a technician shortage, he has successfully juggled a stacked jobboard without compromising quality of service, something he takes great pride in.

The John Deere Technicians Award Program recognizes those who epitomize what it means to be “John Deere” and honors extraordinary commitment to the brand. Connel, a service technician at Hobbs, was chosen out of a territory-wide pool of nominees.

“Customer service motivates me,” Connel said. “I really enjoy knowing the customer is happy, visiting and talking with them and making sure they’re happy with what we are doing. That’s something I think my dad instilled in me — a work ethic to put out good product and to be productive.”

Connel’s passion for the trade was sparked by his father. Growing up, they spent countless hours together at home in the shop working on cars. When it came time to choose a career, Connel’s path was clear as he already knew what he loved to do.

Connel graduated from New Mexico Junior College’s two-year Automotive Technology program. Early in his career, he spent 10 years as an automotive mechanist. He later worked in a scrapyard where he got into heavy equipment — leading him to 4Rivers where he’s spent the past eight years.

Throughout his career, Connel has noticed a recurring life lesson that can be learned from the industry.

“You never stop learning new things,” Connel said. “I think that is really important because the industry changes so rapidly. The desire to strive and learn is so important. Keeping up with this industry is a challenge and I enjoy that challenge.”

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • January 15, 2023 • Page 11

4Rivers photo

Construction Crews Demolish Towers at Utah Tech Univ.

Out with the old and in with the new, Utah Tech University is tearing down Nisson Towers, the school’s oldest student housing building, to make room for the brand new Campus View Suites III.

According to the university’s strategic plan, student

enrollment is predicted to increase from 12,556 students this year to 16,000 students by 2025.

With this drastic increase in enrollment, Utah Tech began implementing the third phase of its student housing project. The first two phases consisted of the completion of Campus View Suites I and II located near the corner of 100 South and 1000 East in downtown St. George.

The Campus View Suites III building has a total budget of approximately $65 million, with around $55 million allocated to the construction. It is funded through a bond that will be paid back using the rent from its future residents.

Seth Gubler, director of housing and student life of Utah Tech University, told St. George News that this new addition to on-campus housing is projected to be complete and ready for student use by the fall semester of 2024.

“Students are excited anytime we add a new building,” Gubler said. “There’s an enthusiasm that floats around in the air, and we do try to make each facility a little bit better than the last one.”

The layout will be similar to the previous Campus View Suites and Gubler added that they are planning to include additional study rooms as per feedback from students and possibly a small market for residents to get groceries.

Jon Gibb, director of facility planning and construction,

told St. George News that all of the Campus View Suites buildings have been contracted through Layton Construction Company.

Work is currently under way as the northeast corner of the campus is fenced off by the contractor. Gibb said the company has been working on hazardous materials abatement and plans to have the Nisson Towers completely taken down by mid-February.

Campus View Suites III are planned to be completed in June 2024 in time for incoming students to have access for the fall semester. The existing Campus View Suites buildings were successfully finished by their target dates and allowed a sufficient transition time for students coming to the school.

“Even if we’re a few weeks late, it’s really catastrophic,” Gibb said. “It hurts, because the students don’t have anywhere to go if it’s not done. So we definitely really want to forecast, look ahead and make sure we hit that target date.”

With the increase of enrollment, parking has reportedly become an issue among students at the university. In an attempt to remedy that issue, Utah Tech is planning the removal of the Edith Whitehead Education building and eventually the removal of the North Plaza building.

(Photo courtesy of St. George News.)

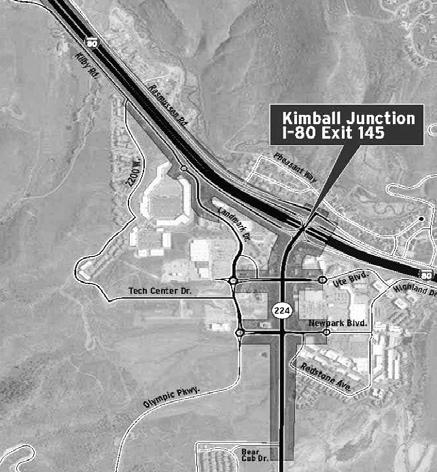

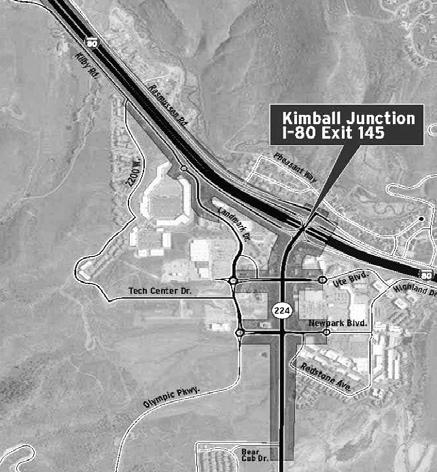

Utah Dept. of Transportation Asks for Input On Project

The Utah Department of Transportation is conducting an environmental study in the Kimball Junction area and is seeking public input on the scope of the project. UDOT is asking for input on the proposed alternatives, purpose and need of the project, alternative screening criteria, potential impacts to the community and natural environment and identification of significant issues or potential new alternatives. The public comment period is open now through Jan. 27, 2023.

(Jan. 11) to review the current project details and answered any questions. Additional information on the upcoming meetings and the environmental study can be found on the project website. The public is encouraged to review the project documents, attend the public meetings and submit comments at udot.utah.gov

solutions to meet those needs;

• Minimizes and avoids environmental impacts where possible; and

• Engages the public and stakeholders through an open and transparent process.

UDOT is preparing this study to evaluate improvements at the I-80 and SR 224 interchange at Kimball Junction and on SR 224 from Kimball Junction through the Olympic Parkway intersection in Summit County.

“This study is focused on long term transportation solutions for all modes of travel in the Kimball Junction area while balancing the environmental objectives,” said Grant Farnsworth, UDOT Region 2 project manager of the EIS. “We look forward to continuing our partnership with the Summit County and Park City communities to better understand the transportation needs throughout the area.”

With the public comment period, UDOT also hosted an in-person open house (Jan. 10) and a virtual meeting

UDOT is preparing this study to evaluate improvements at the I-80 and SR 224 interchange at Kimball Junction and on SR 224 from Kimball Junction through the Olympic Parkway intersection in Summit County. This study builds on and uses information from the Kimball Junction and SR 224 Area Plan.

UDOT’s goal for the project is to develop a comprehensive, technically sound EIS which accomplishes the following:

• Builds on and uses information from the Kimball Junction and SR 224 Area Plan;

• Addresses the transportation needs in the area;

• Identifies and screens alternative

UDOT will further evaluate the alternatives proposed in the Area Plan, along with any new alternatives proposed during the study and will take into consideration all public feedback. The proposed alternatives currently include:

1. Taking no action;

2. A split-diamond interchange and intersection improvements;

3. Grade-separated intersections with one-way frontage roads to the I-80 interchange;

4. Intersection improvements with pedestrian enhancements; and

5. Other reasonable alternatives that may be identified during the EIS process.

For more information, visit https://kimballjunctioneis.udot.utah.gov/

Page 12 • January 15, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

(Photo courtesy of UDOT.)

Layton Construction has already begun work at the northeast corner of campus.

Century Equipment Invites Guests to See New Machine

from page 4

“It’s perfect for the contractor that does grading and especially fine grading,” Buddell said. He expects that the laser guide is “ideal for this type of work as it can get within 1/16 of an inch, which makes it perfect to level out gravel for final grade. Also, by simply dropping the blade and the lasers, it can be used as a track loader, so they have multiple applications with one machine. The versatility is what really sets the Minotaur apart from other classes of equipment.”

Century Equipment has nine locations including Salt Lake City, Utah; Springville, Utah; Logan, Utah; Cedar City, Utah; Durango, Colo.; Grand Junction, Colo.; Rock Springs, Wyo.; Albuquerque, N.M.; and Dyersburg, Tenn.

For more information, visit https://www.centuryequipment.com.

For the full Groundbreaker Roadshow tour schedule, visit CaseCE.com/Roadshow.

(All photos courtesy of Construction Equipment Guide.)

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • January 15, 2023 • Page 13

Mitch Blake, territory sales manager of Case, talks to a representative from Hughes General Contractors about this all-new, industry-first equipment category, the compact dozer loader. Doug Buddell, Salt Lake City branch manager; and Dallen Rozema, Springville branch manager, look on.

MINOTAUR

Fourth-Generation Family Firm Turns Waste Into Success

not have DPF filters on the units. They are able to bypass the use of the filter within their own Liebherr engines, which is a huge benefit and results in cost savings. This has been a major factor for the uptime we see in our operational use. This is the case for their excavators and crawler dozers as well.

Ergonomics, visibility and ease of operation are all exceptional, Pendley said of Liebherr.

“Our operators love the ergonomics of the Liebherr to the point that they protest if they have to operate another brand,” he laughed. They want their machine back.”

A1’s work force is “tenured” in Pendley’s words and that makes both visibility and ease of control important. “Most of our guys did not grow up playing with joysticks, but they have no problem with the Liebherr controls.”

Valuable Partner

While Pendley and others at A1 said they have not experienced significant downtime with Liebherr, service is still critical.

“Response time with Power Screening is outstanding,” Pendley said.

When A1 had a machine go down, Power Screening had a guy on my site the next morning, after a call to Dustin [current Power Screening LLC Rep Dustin Sweeney]. It wasn’t even their piece of equipment.”

The current challenge of getting parts on a timely basis is a sore point with Pendley.

“This whole supply chain thing is ridiculous,” he said. “We as an industry cannot accept four-five week or more availability on parts.

“In today’s business climate, we must find the most reliable equipment, the most available parts, and the best response time,” he added. “When we do that, we come back to Liebherr as a manufacturer and back to Power Screening as a dealer.”

Power Screening’s Sweeney agreed.

“The customer just cannot be told to wait,” he said. “As part of the solution, we’ve added warehouse space to accommodate for more parts, so that we can bring in parts we would not normally keep

in stock.”

“More than anything,” Pendley said of A1’s relationship with Power Screening, “these guys have done a great job of learning our industry. That understanding of

CEG photo

what we do means they give me better information.”

Sustainability

A1 Organics is proud to be a leading organics recycling solution

for a sustainable Colorado. But sustainability has always been in the company’s DNA.

Duane Wilson founded the lamb feeding operation back in the 1970s. His three children contin-

ued running the company when he and his wife retired. One of the siblings (Chuck) eventually bought out his brother and sister and owned A1 until his untimely passing in 2016. Chuck’s wife, Dannette, is now sole owner.

The various generations of the Wilson family successfully navigated the transition from selling compost to the ag community to taking in the bile salts coming out of the waster water treatment facility of nearby Coors Brewing Company and turning residential yard waste and lumber into decorative landscape material.

Today, they are a major recycler of manure, bio solids, green waste and food waste and producer of colored mulch for the landscape industry. In addition to the hundreds of thousands of tons of compost handled annually, the company also sells 140,000 cu. yds. of mulch.

While ownership remains with the Wilson family, the company is currently run by the management team of Travis Bahnsen; president and CEO, Bob Yost, vice president, chief technology officer, and Pendley.

From its humble beginnings in lamb waste, the company now boasts diverting more than seven million tons of organic material from Colorado landfills.

A1 sees both opportunity and responsibility in the growing waste recycling industry. If its history is any indication, it’ll seize both.

About Power Screening LLC

Headquartered in Henderson, Colo., outside of Denver, with additional locations in Albuquerque, N.M., and Salt Lake City, Utah, it serves the crushing, screening, composting, shredding, stockpiling, material handling, washing, earthmoving, construction and aggregate equipment industries. Each of its branches offer full-service sales, rental, parts and service support for customers.

Established in 1984, it now offers one of the largest stock of new and used crushing, dry screening and composting equipment in the Rocky Mountain region.

Additionally, it is the Rocky Mountain dealer of Liebherr’s line of excavators, wheel loaders and crawler tractors.

Page 14 • January 15, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

CEG

CEG photo

The Komptech Hurrikan S wind sifter was part of a package of equipment provided by Power Screening LLC for A1 Organics’ waste recycling operation, one of the largest in the western states.

are

to

the use of the filter

their

and

cost savings.

achieves fuel use as low as 3.2 gal. per hour in its

facilities

OPERATION

page 6

The Liebherr loaders

able

bypass

within

own Liebherr engines, which is a huge benefit

results in

A1

compost

operating the 580.

from

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • January 15, 2023 • Page 15

Page 16 • January 15, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide