Skills Spur

P&C Construction Leads

$30M Workforce Skills Training Center Project

By Cindy Riley CEG CORRESPONDENT

A $30 million, 50,000 sq.-ft. facility that will prepare students for high wage/high demand career fields is taking shape in Boaz, Ala.

Snead State Community College broke ground on its Workforce Skills Training Center in January 2023.

“There is a growing need to provide workforce training in the fields of welding, machine tool technology, heating ventilation air conditioning and refrigeration and industrial systems technology in the northeast region of Alabama,” said Greg Randall, executive project director of workforce enhancement at Snead State. “To help support the increased demand for skilled professionals in the area, we secured funding to build a modern facility that will house the training programs. These programs will not only serve Marshall County but also the surrounding counties.”

The project was primarily driven by stakeholders in local business and industry, K-12 educational partners, the Marshall County Economic Development Council and the Alabama Community College System.

“The need for this workforce skills center was so vital that the Marshall County K-12 School System donated the prop-

see SKILLS page 6

USNC Announces Construction of $232M

MMR Assembly Plant in Gadsden, Ala.

Ultra Safe Nuclear Corp. (USNC), a Seattle-based company that’s expanding microreactor technologies, plans to invest $232 million to locate a facility in Gadsden, Ala., to produce its Micro-Modular Reactor (MMR).

The announcement was made by Alabama Gov. Kay Ivey on June 21.

The highly automated MMR Assembly Plant (MAP) will manufacture, assemble, test and inspect the nonradiological modules needed to construct its advanced

microreactors, reported Alabama News Center. No radioactive material is to be used or stored at the company’s Gadsden facility.

USNC said the plant will be the nation’s first commercial scale microreactor production facility. When operational, MAP will employ 250 professional and technical workers.

Construction is to begin in 2024, with the facility operational in 2027.

page 2

ALABAMA STATE EDITION A Supplement to: Your

•

GA • 1- 800- 409 -1479 see FACTORY

Alabama Connection

Rich Olivier, Atlanta,

Located on U.S. Highway 431 near Marshall Technical School, the facility will be one of five new centers being built in the state by the Alabama Community College System.

Ultra Safe Nuclear rendering The 578,000-sq.-ft. factory will feature advanced manufacturing processes and equipment and will be capable of producing up to 10 complete MMR nuclear batteries per year. ® “The

July 26 2023 Vol. XXV • No. 15 CALL 800-367-4937 *On approved credit Financing Available SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY 24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS State Supplement sponsored by: Affordable Price. Premium Service. Thousands in Service!

Nation’s Best Read Construction Newspaper… Founded in 1957.”

AGC Welcomes New Generations in Construction Industry

Alabama AGC hosted its 39th Annual Convention on June 22 to 25 in Sandestin, Fla., at the Sandestin Hotel.

The three-day, family-friendly event allows members to network within their industry, discuss constructionrelated legislation and participate in educational offerings.

The 2023 convention brought together the younger generations of the AGC family with 180 of the 456 attendees being 17 or under.

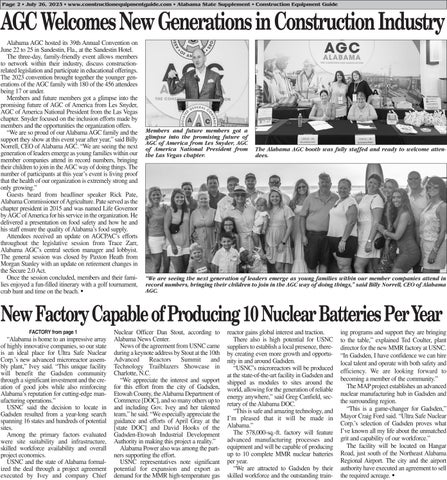

Members and future members got a glimpse into the promising future of AGC of America from Les Snyder, AGC of America National President from the Las Vegas chapter. Snyder focused on the inclusion efforts made by members and the opportunities the organization offers.

“We are so proud of our Alabama AGC family and the support they show at this event year after year,” said Billy Norrell, CEO of Alabama AGC. “We are seeing the next generation of leaders emerge as young families within our member companies attend in record numbers, bringing their children to join in the AGC way of doing things. The number of participants at this year’s event is living proof that the health of our organization is extremely strong and only growing.”

Guests heard from headliner speaker Rick Pate, Alabama Commissioner of Agriculture. Pate served as the chapter president in 2015 and was named Life Governor by AGC of America for his service in the organization. He delivered a presentation on food safety and how he and his staff ensure the quality of Alabama’s food supply.

Attendees received an update on AGCPAC’s efforts throughout the legislative session from Trace Zarr, Alabama AGC’s central section manager and lobbyist. The general session was closed by Paxton Heath from Morgan Stanley with an update on retirement changes in the Secure 2.0 Act.

Once the session concluded, members and their families enjoyed a fun-filled itinerary with a golf tournament, crab hunt and time on the beach.

New Factory Capable of Producing 10 Nuclear Batteries Per Year

“Alabama is home to an impressive array of highly innovative companies, so our state is an ideal place for Ultra Safe Nuclear Corp.’s new advanced microreactor assembly plant,” Ivey said. “This unique facility will benefit the Gadsden community through a significant investment and the creation of good jobs while also reinforcing Alabama’s reputation for cutting-edge manufacturing operations.”

USNC said the decision to locate in Gadsden resulted from a year-long search spanning 16 states and hundreds of potential sites.

Among the primary factors evaluated were site suitability and infrastructure, skilled workforce availability and overall project economics.

USNC and the state of Alabama formalized the deal through a project agreement executed by Ivey and company Chief

Nuclear Officer Dan Stout, according to Alabama News Center.

News of the agreement from USNC came during a keynote address by Stout at the 10th Advanced Reactors Summit and Technology Trailblazers Showcase in Charlotte, N.C.

“We appreciate the interest and support for this effort from the city of Gadsden, Etowah County, the Alabama Department of Commerce [DOC], and so many others up to and including Gov. Ivey and her talented team,” he said. “We especially appreciate the guidance and efforts of April Gray at the [state DOC] and David Hooks of the Gadsden-Etowah Industrial Development Authority in making this project a reality.”

Alabama Power also was among the partners supporting the effort.

USNC representatives note significant potential for expansion and export as demand for the MMR high-temperature gas

reactor gains global interest and traction.

There also is high potential for USNC suppliers to establish a local presence, thereby creating even more growth and opportunity in and around Gadsden.

“USNC’s microreactors will be produced at the state-of-the-art facility in Gadsden and shipped as modules to sites around the world, allowing for the generation of reliable energy anywhere,” said Greg Canfield, secretary of the Alabama DOC.

“This is safe and amazing technology, and I’m pleased that it will be made in Alabama.”

The 578,000-sq.-ft. factory will feature advanced manufacturing processes and equipment and will be capable of producing up to 10 complete MMR nuclear batteries per year.

“We are attracted to Gadsden by their skilled workforce and the outstanding train-

ing programs and support they are bringing to the table,” explained Ted Coulter, plant director for the new MMR factory at USNC.

“In Gadsden, I have confidence we can hire local talent and operate with both safety and efficiency. We are looking forward to becoming a member of the community.”

The MAP project establishes an advanced nuclear manufacturing hub in Gadsden and the surrounding region.

“This is a game-changer for Gadsden,” Mayor Craig Ford said. “Ultra Safe Nuclear Corp.’s selection of Gadsden proves what I’ve known all my life about the unmatched grit and capability of our workforce.”

The facility will be located on Hangar Road, just south of the Northeast Alabama Regional Airport. The city and the airport authority have executed an agreement to sell the required acreage.

Page 2 • July 26, 2023 • www.constructionequipmentguide.com • Alabama State Supplement • Construction Equipment Guide

The Alabama AGC booth was fully staffed and ready to welcome attendees.

Members and future members got a glimpse into the promising future of AGC of America from Les Snyder, AGC of America National President from the Las Vegas chapter.

“We are seeing the next generation of leaders emerge as young families within our member companies attend in record numbers, bringing their children to join in the AGC way of doing things,” said Billy Norrell, CEO of Alabama AGC.

FACTORY from page 1

Connected to Customers, from Rock to Road®

We help build the roads that connect goods to markets, people to communities and families to one other. Astec pavers, screeds, mills, stabilizers and MTVs yield innovative and reliable Rock to Road solutions that create value and connection. We are inspired to connect with our customers through innovative design for safe and reliable roads.

astecindustries.com

Construction Equipment Guide • Alabama State Supplement • www.constructionequipmentguide.com • July 26, 2023 • Page 3 COWIN.COM | 18002392694 Birmingham, AL 205.841.6666 Montgomery, AL 334.262.6642 Mobile, AL 251.633-4020 Oxford, AL 256.832.5053 Pensacola, FL 850.479.3004 Huntsville, AL 256.536.9390 Tuscaloosa, AL 205.848.4147 Atlanta, GA 404.696.7210

ROCK TO ROAD® Lawrenceville, GA COMING SOON

A t T homp s on Tr ac t or, w e ar e com m i t t ed t o o f f er i ng qual i t y ne w, us ed an d r en t al equipmen t , as w el l as s er v ice, par t s , t echnol og y, an d s a f e t y supp or t . Our ex per ienced r epr es en t a t i ves ar e r ead y t o as sis t an d ensur e y ou an d y our t eam succeeds

f r t w y t m i v n t f i t l l e t r o r t rr r .T i p y

, y is s o u r s u cce s s Th h ro o u g h o u reele n tlle s s p u rs s u i t o f oppe ra a tiio n a exxcellle n ce a n d c u s t o m e r s a tiis s faac tiio n, , we h ave e b u il l t a co mppa n th h a we e a re p ro o u d o f. . ” – Luc Thho m ps o n M ars s h , O wnner

w r y T

Tanner, A L 35671

)

(256 3 53-7721

DOTHAN 118 Vulcan Way

Dothan, AL 36303 (334 6 71-1040

)

HUNTSVILLE 3600 Governors Dr

Huntsville, AL 35805

Montgomery, AL 36117 (334 215-5000

)

Pensacola, FL 32534 (850) 471-6700

)

(256 5 32-1776

MOBILE 30950 State Hwy 181

Spanish Fort, AL 36527 (251) 626-5100

/

OPELIKA /AAUBURN 508 Columbus Pkwy

Opelika, AL 36801

(334) 749-3359

OXFORD/A A NNISTON 2300 Hwy 21 S

Oxford, AL 36203

(256) 831-4104

PANAMA CITY 4109 Cato Rd

Panama City, FL 32404

(850 7 85-4007

THOMASVILLE 2501 Joe Davis Industrial Blv Thomasville, AL 36784 (334) 636-0420

TUSCALOOSA 3550 Joe Mallisham Pkwy Tuscaloosa, AL 35401 (205) 247-2800

TUSCUMBIA 1030 AL-20

Tuscumbia, AL 35674

d

(256 3 81-2771

)

Page 4 • July 26, 2023 • www.constructionequipmentguide.com • Alabama State Supplement • Construction Equipment Guide Construction Equipment Guide • Alabama State Supplement • www.constructionequipmentguide.com • July 26, 2023 • Page 5 THOOMPS TR ON ACTOR: COOMMMI C TE T D TO Choose a partner you can count on m tT “ n. “A A Th h o mp p son T YOUR S SUCCESS. e t v r Tr Trraacto r, , we believe th h t y a yo o ur success ALABASTER (Shelby County) 2070 Corporate Woods Dr AlabasterAL35007 r DECATUR 6969 Highway 31 S Tanne A L35671 MONTGOMERY 10120 Hwy 80 E MontgomeryAL36117 PENSACOLA 2670 W 9 Mile Rd PensacolaFL32534 S com.thompsontractor. bsite: r we u o o o t r g u o o yo t t neares ocation e l tor e s h t t isi , v ep s r ale r s racto n T hompso r T u t yo ontac ) A A abas ter, A L 3 5 0 0 7 (2 0 5 6 6 4 - 483 3 AT T TA L L A /GADSDEN 121 G ber t F err y Rd SE At ta la A L 3 5 9 5 4 2 5 6) 57 0 -110 0 BIRMINGHA M 24 01 P nson H ghway B rm ngham, A L 3 5 217 (2 0 5 8 41- 860 1 CRES T V IE W 5 74 9 John G vens Rd Cres v ew, F L 3 2 5 3 9 (8 5 0) 6 8 2- 6 510 C CA T All Rights Reserved. CA © 2023 Caterpillar ATT, ATTERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. www.cat.com / www.caterpillar.com

t hompson t r ac tor.com

Snead State’s Skills Training Center Due to Complete in 2024

SKILLS from page 1

erty on which the new facility is currently being built,” Randall said. “Dr. Cindy Wigley, the superintendent of the Marshall County School System, helped bring the facility to fruition through property donation. The reaction to the new facility has been very positive, as this has been a goal of the local stakeholders for about 10 years.”

Not only will training be provided for high school students who participate in dual enrollment, but also traditional students and workers seeking to enhance their current skills for upward mobility at their place of employment.

Located on U.S. Highway 431 near Marshall Technical School, the facility will be one of five new centers being built in the state by the Alabama Community College System. Randall said the design process took almost one year.

“Snead State Community College hosted meetings with the architects on campus throughout that year to determine which programs would be housed at the new center, what the size of the laboratories would be, how the administrative areas and conference center would look and how the exterior and interior façade and fixtures will be presented.”

Construction is currently slated for completion by June 2024.

“The contract states 480 days for completion. Rain has been a major factor, because there were approximately 375 yards of dirt that had to be removed for structural soundness. As of this time, the construction completion date is expected to be met.”

The contractor is P&C Construction, based in Chattanooga, Tenn. For crews, the main challenge so far has been the weather.

“Because of the amount of dirt that had to be replaced, continuous rain in the early phase of this construction project delayed transfer and packing of the dirt,” said Randall. “Secondly, supply chain issues have caused a few delays. There is some equipment, such as electrical panels and chillers, that have long lead times.”

Currently, all footings have been poured and foundation block is currently being laid, along with required rebar. Electrical stub outs are at 70 percent completion and work has begun on a path for sanitary sewer lines. Plumbing for eyewash stations also is being installed. The concrete pad

will be poured in a matter of days.

“The property donated had a building that housed a high school cosmetology training program and a commercial driver license testing center,” Randall said. “Both programs have been relocated and the building has been demolished and cleared.”

Regarding site preparation and excavation, work includes not only removing dirt that isn’t structurally sound, but also rerouting sanitary sewer lines.

“The site has a city sewer line across the middle of the property. It was decided that a cost advantage would be to not use the existing line on the property and connect to an existing line behind the property. This solution prevented the requirement of a sewage grinder pump to be installed.”

Approximately 500 cu. yds. of dirt is expected to be moved during construction. Due to continued site prep, the main equipment on site is relegated to a combination of skid steers, backhoes, a dozer and boom lifts. The main materials used on this project to date are block, concrete, structural steel and rebar. As the facility nears completion, it will consist of a combination of brick façade and metal siding.

Speaking at the official ceremony to mark the start of con-

struction, Snead State President Joe Whitmore told the crowd the project will be worth the wait.

“When you look around here, you can see just how important and just how critical our groundbreaking today is to our community and our state. This is something we’ve been planning for about three years. It will provide very much needed training and education, and prosperity to our community.”

Gov. Kay Ivey said, “Our economy and workforce needs are evolving with every day that passes by. Projects like this one that we are celebrating today are part of the reason why we have been so successful in bringing in 73,000 new jobs and more than $40 billion in investments.”

“This project has been exciting to watch,” said Randall. “The amount of skill displayed by the workers and architects has been astounding. This will be the first facility of its kind in North Alabama that will provide the community with not only valuable training, but also a common area to meet and discuss new ideas on the future of the workforce in Alabama.” CEG

(All photos courtesy of Taylor Beck/Snead State Community College.)

Page 6 • July 26, 2023 • www.constructionequipmentguide.com • Alabama State Supplement • Construction Equipment Guide

Construction is currently slated for completion by June 2024.

The contractor is P&C Construction, based in Chattanooga, Tenn.

A $30 million, 50,000 sq.-ft. facility that will prepare students for high wage/high demand career fields is taking shape in Boaz, Ala.

Construction Equipment Guide • Alabama State Supplement • www.constructionequipmentguide.com • July 26, 2023 • Page 7

Page 8 • July 26, 2023 • www.constructionequipmentguide.com • Alabama State Supplement • Construction Equipment Guide