A GREENER FUTURE

Sustainability in design, cabinet making and production: 2025 and beyond

Trade Show Reports

• LIGNA 2025

• interzum 2025

What it means to steal like a designer

Beyond the downlight grid: lighting design for interiors

Creating a sustainable business Plus!

Building living spaces.

From the editor

Welcome to issue 4 of Connect magazine! We’re diving into the huge (and I mean huuuuuge) issue of sustainability as our major theme this issue and it’s been quite the eye-opening experience talking to so many passionate and driven people in our industry. I’m so very grateful to all who shared their expertise for our main story.

Along the way I’ve discovered brilliant projects, amazing products and manufacturing processes, new ways of looking at the issue, programs and business principles and so much more. I hope you find this story both informative and inspiring — I know I did.

As always, we’re lucky to have a stellar line-up of contributing writers who always pitch such interesting and engaging stories. Pam Kershaw looks at how we can tackle the furniture and cabinetry waste crisis, Ben Fewtrell walks us through how to create a sustainable business, and Rob Ditessa brings us the remarkable story of JahRoc Furniture.

Selina Zwolsman shares her insights into lighting design for interior spaces and takes us beyond the downlight grid. Our friends at KBDi help us work through international design trends and how to use trends to inform and inspire our own work.

Plus, we’ve included a wrap-up from two extremely important international trade shows — interzum and LIGNA. Both held in Germany last May, interzum focuses on hardware and materials while LIGNA showcases the latest in machinery and technology.

I was also lucky enough to speak to Lewis Blair, one of ACFA’s longestserving trainers, who celebrated 15 years with the organisation in July. Lewis shares the story of his career and it was fascinating to see how far the industry has come in that time.

The ACFA Workplace Advice Team keeps us up to date with the new Furniture Safety Standards, and the team from HIA Economics brings us some good news for the second half of the decade.

If you have been working in the cabinet making, furniture or timber industry for years but don’t hold formal qualifications, you won’t want to miss information about how to use ACFA’s Recognition of Prior Learning (RPL) Program to have your skills recognised.

To cap off another incredible issue, don’t forget to check out the industry updates from our wonderful advertisers. These businesses help us do what we do best and we are incredibly grateful for their continued support, so please show them all some love.

Enjoy!

Connect magazine is published by the Australian Cabinet & Furniture Association.

ABN 80 000 071 787

Publisher: Dean Brakell, CEO, ACFA

Editor: Melanie Gardener

Advertising Sales: Fiona Joynes

Art Director: Liza Jane Smith, liza@monava.com.au

Contributing Writers: Rob Ditessa, Pam Kershaw, Selina Zwolsman, Ben Fewtrell, Dean Brakell, Glen Qi (HIA)

Printer: Neo Pty Ltd

Correspondence to: PO Box 157, Gosford NSW 2250

Front cover: Nina Di Marco, YDM Design Studio

Subscriptions: Connect magazine is produced as a hard-copy print publication as well as an online digital magazine. If you wish to subscribe please visit connectmagazine.com.au/

@connectmagazineaus @connect-magazine-aus

Copyright © Connect magazine (Property of the Australian Cabinet and Furniture Association). All rights reserved. The magazine or any part thereof may not be copied or reproduced without written permission from the publisher. Any specifications and/or claims here within are those of the manufacturer and/or supplier. Disclaimer: Statements by advertisers, expressed editorial opinion and/or contributors’ comments are not necessarily representative of those of ACFA Ltd or its members unless expressly stated. The publisher and editor assume no responsibility for errors or omissions or any consequence of reliance on this publication.

The Australian Cabinet and Furniture Association Ltd is a trade association that represents the interests of the cabinet making, kitchen, design, joinery, furniture, fit-out, and other wood, timber, stone and panel processing industries. Membership and advertising enquiries are welcome.

FEATURES

6 Design and Craftsmanship for a Greener Future

Sustainability in design, cabinet making and production: 2025 and beyond. By Melanie Gardener.

20 Sustainable Product Update

Give your next project a lift with our editor’s pick of the latest sustainable products.

30 Turning the Tables

Tackling Australia’s furniture and cabinetry waste crisis. By Pam Kershaw.

34 Creative Drive

Multi award-winning, WA-based, JahRoc Furniture thrives on creativity and a drive for quality, underpinned by artistic collaboration. By Rob Ditessa.

38 Visit Milan in 2026

Join us on an ACFA-hosted tour to visit Salone del Mobile.Milano and Milan’s renowned Design Districts.

40 Sustainable, Ef ficient, and Profitable What sustainability really looks like in business. By Ben Fewtrell.

42 Beyond the Downlight Grid

Smarter lighting design for kitchens and bathrooms. By Selina Zwolsman.

81 The Last Word: Making sense out of licensing for kitchens

Why ACFA continues to lobby for a uniform licensing system for cabinet making throughout the country. By Dean Brakell.

TRADE SHOWS

22 LIGNA 2025

This year LIGNA celebrated its 50th anniversary with an innovative trade show that brought the global wood industry together.

26 interzum 2025

This year’s interzum set a path for the future firmly focused on sustainable transformation.

ASSOCIATION UPDATES

46 Celebrating 15 Years

Lewis Blair celebrated 15 years with ACFA in July 2025 — we take a look at his illustrious career.

49 Inspiration v Imitation: stealing like a designer

The KBDi team helps us navigate the increasingly blurred line between influence and imitation.

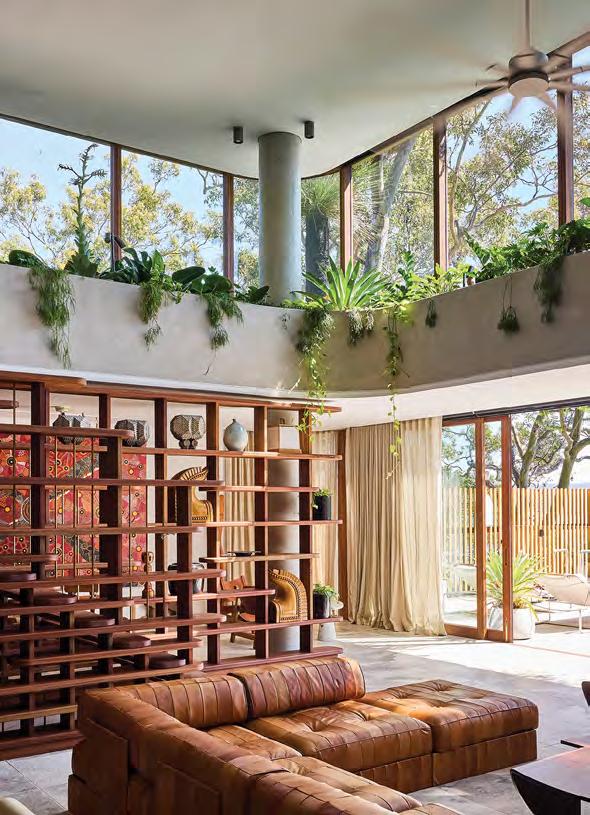

54 Housing to pick up in second half of decade

Detached housing continues to lead the way for home building this decade. By Glen Qi, HIA economist.

65 Recognise your skills and get qualified today

Gain your MSF30322 Certificate III in Cabinet Making and Timber Technology through Recognition of Prior Learning (RPL).

76 New Furniture Safety Standards

The Australian Government has introduced the Consumer Goods (Toppling Furniture) Information Standard 2024, which came into effect on 4 May 2025.

INDUSTRY NEWS

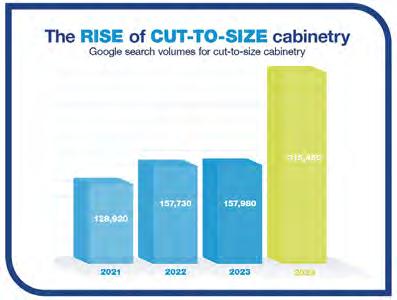

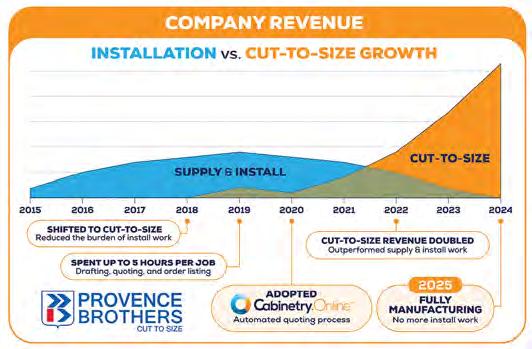

56 The Cut-to-Size Boom

How our fastest-growing cabinet makers are scaling smarter.

58 NAV ECO

Since its inception, New Age Veneers has prioritised the responsible sourcing and manufacturing of its products.

60 HOMAG at LIGNA 2025

Under the new global campaign ‘Building Living Spaces’, the entire portfolio — from HOMAG, SYSTEM TM, KALLESOE, WEINMANN, SCHULER Consulting, tapio and BENZ — came together in Hall 14.

62 LEGRABOX Special Edition

Elevate any interior space with stunning drawer side designs.

64 Storage Space Organised the Smart Way

Introducing Hettich’s interior fittings range.

66 CABINET VISION Success Story

Planit Australia customer Anertex has been using CABINET VISION for more than 25 years.

68 Finista® Edge

New Finista® Edge drawer system, available from Lincoln Sentry from 1 September.

70 Häfele Déco Collection 2025 Elegant, contemporary and deliberately versatile.

72 Faster Installs, Fewer Callbacks

Hideaway Compact redefines installation standards.

74 Grass by Häfele Bringing furniture to life!

78 Solving the Industry’s Hidden Struggles

Enter Ayrmont ARMS™, an intelligent CRM and ERP system tailored to meet the unique needs of the cabinetry and renovation industry.

79 Fenix NTM Bloom FENIX NTM introduces Bloom, a new core technology made of paper and thermosetting resins based on phenol, available from Nover Australia.

82 Index

Sustainability Design and Craftsmanship for a Greener Future

Sustainability in design, cabinet making and production: 2025 and beyond

By Melanie Gardener

In 2025, sustainability has become a cornerstone of the building and renovation industry in Australia, reflecting an ongoing global shift towards environmental responsibility and conscious living.

Australian designers and cabinet makers are embracing eco-friendly materials, energy-efficient technologies, and innovative design principles to create spaces that are both aesthetically pleasing and environmentally sustainable. Beyond just materials and energy efficiency, the design and layout of a home play a crucial role in enhancing sustainability and ensuring the space is future-proofed for long-term living.

Eco-friendly materials

The use of sustainable materials is at the forefront of global design trends in 2025. Natural materials such as reclaimed and recycled timber products, recycled metal and glass, and organic fabrics and surfaces are gaining popularity, offering both durability and

a reduced environmental footprint. These materials not only add a touch of nature to interior spaces but also promote sustainability by minimising the demand for new resources.

Biggest shifts in sustainable design and manufacturing principles

One of the most significant shifts in sustainable building and renovation is the move towards circular design principles. Rather than creating spaces that require regular updates and replacements, there is a growing emphasis on creating interiors that can evolve over time without contributing to excessive waste. This means incorporating modular furniture, moveable elements, adaptable layouts, and timeless materials that ensure longevity while reducing landfill contributions.

Another major shift is the integration of smart, datadriven sustainability. Homes are now being designed with smart sensors that monitor energy and water consumption in real time, allowing homeowners to make informed decisions about their resource use. This technological advancement has made sustainable living more intuitive, with systems that automatically adjust lighting, temperature, and appliance usage based on efficiency goals.

Energy efficiency and smart technology

Energy efficiency is a critical aspect of sustainable interior spaces. Designers are integrating energyefficient lighting, appliances, and climate control systems to reduce energy consumption. Smart home technologies, such as automated lighting and temperature controls, allow for optimised energy use, contributing to lower utility bills and a reduced carbon footprint.

Water conservation

Water conservation remains a priority in Australia’s sustainability practices. The implementation of waterefficient fixtures, rainwater harvesting systems, and greywater recycling contributes to significant water savings. Today’s innovative projects demonstrate how urban homes can achieve self-sufficiency in water management through off-grid water systems and sustainable design.

Design and layout for sustainability

Beyond materials and technology, the overall design and layout of a home can significantly impact its sustainability.

Sustainability

Passive design principles

Passive design focuses on optimising a building’s orientation, insulation, and ventilation to maximise energy efficiency. This includes:

• Positioning windows and living areas to take advantage of natural light and heat from the sun (northern orientation in Australia).

• Incorporating cross-ventilation through window placement to reduce the need for air conditioning.

• Using ther mal mass materials, such as concrete or brick, to regulate indoor temperatures naturally.

Passive design reduces reliance on artificial heating and cooling, making homes more energy-efficient and comfortable year-round.

Sustainability

Flexible and multi-use spaces

Sustainable design also involves future-proofing a home by creating adaptable spaces that can evolve with changing needs in both the short- and long-term. This includes:

• Open-plan layouts that allow for reconfiguration without major renovations.

• Multi-functional rooms that can serve different purposes, such as a home office doubling as a guest room.

• Modular fur niture that can be repurposed or expanded as a family’s needs change.

By designing with flexibility in mind, homeowners can extend the longevity of their interior spaces without frequent remodelling, which reduces material waste and construction-related emissions.

Ania Forster, director of interior design business Zephyr & Stone, is passionate about changing our approach to home building and design to focus on longevity and long-term planning, rather than shortterm outcomes or following trends too closely.

“I’ve seen too often where people have spent significant amounts of money but they don’t even enjoy

where they are living,” she says. “If the layout is wrong, or not suited to their lifestyle, it will always feel off.”

While Ania makes conscious choices about the products she specifies to ensure she is making sustainable decisions, she sees this as only one part of the eco-conscious approach to design and renovation. “I prefer to focus on maximising the beauty of the home with a particular emphasis on the floor plan, the layout in each room and the room sizes as the most valuable decisions made aren’t always the most visible,” she says. “The decisions you make before you make any selections can often determine the success of a project."

Ania adds that she sees a flow-on effect if these basic elements aren’t addressed correctly. “What happens when you sell your home?” she wonders.

“If the next person comes along and the layout isn’t functional then they are forced to renovate again to try to fix the problem, which leads to more wastage and a lost opportunity."

Ania prefers to focus on the grassroots foundation of a home and that normally necessitates taking a hard look at the floor plan. She likes to emphasise a good flow between rooms, logical layouts and spaces that work for the way her client likes to live.

“This philosophy really started for me when I began renovating and flipping houses. Very quickly I had to work out my property strategy and I realised I had to really think about the longevity of not only the products I was specifying but also the changes I was making to the interiors to ensure they were not only flexible and adaptable but that they would last well into the future,” she says.

Ania’s travels overseas, particularly to the UK and Peru, made her realise how differently we approach home construction in Australia. “Some of those buildings are 400 or 500 years old and, no, they aren’t perfect but they are still standing and they have a majesty and beauty that we just don’t see here at home,” she says.

One of her “non-negotiables” is multifunctional spaces within a home that can transform and be adapted as the needs of the homeowners changes over time. “What’s needed a decade from now can’t always be clearly seen so the most sustainable approach is to design rooms that allow for future planning and can meet a range of functions,” she adds. “Sustainability is not just about building what people want right now, but also thinking about their needs in the future."

Her tips for achieving this include making the budget work hard and managing the finishes until you are

able to achieve what you need to achieve. And, also, storage. “Make sure the kitchen is loaded with storage,” she laughs. “And don’t neglect the laundry — there is so much scope for extra storage here as well." She also cites the functionality of the kitchen with clever zone planning and a practical approach to long-term needs.

“Ideally, every home would be designed so it never needs renovating, but I know that’s not realistic,” Ania says. “But the next person to own your home shouldn’t want to immediately rip out what you’ve done. It’s a false economy to do a ‘cheap’ renovation as it will just end up in the skip bin."

She adds that her starting point with any renovation is to look at functionality and flow, to make sure that every room is optimised. “When something is well designed you often don’t notice it,” she says. “As soon as something is awkward or not functional it will stand out immediately and it will become something that annoys you every day.”

Sustainable storage and decluttering solutions

Minimalism and conscious consumption play a significant role in sustainable living. Well-designed storage solutions encourage organisation and reduce the tendency for excessive consumption. Built-in storage, modular shelving, and concealed

Sustainability

compartments can help homeowners maintain a clutter-free environment while reducing the need for additional furniture.

Sustainable cabinet manufacturing

Cabinet makers play a pivotal role in the transition to sustainable interiors. In 2025, cabinet manufacturing in Australia is increasingly guided by environmentally responsible practices, from material selection to production methods and installation.

Sustainable materials and finishes

Eco-certified timber products, such as those accredited by the Forest Stewardship Council (FSC) or PEFC, are now the preferred choice among conscientious cabinet makers. Low-formaldehyde and non-toxic engineered boards are also replacing traditional MDF and particle boards, which have higher VOC emissions. Water-based and low-VOC finishes are now standard practice, promoting healthier indoor environments.

Efficient production and waste reduction

Advanced CNC machinery and digital fabrication tools allow for more precise cutting and efficient use of materials, reducing offcuts and waste. Many workshops now implement closed-loop recycling systems, where leftover materials are reused or sent for responsible processing.

Cabinet makers are also adopting lean manufacturing principles to streamline workflows, reduce energy use, and improve overall sustainability.

Durability and design for disassembly

Sustainably made cabinetry focuses on longevity. Components are designed to be durable and repairable, with modular construction that allows for easy disassembly and reuse. This makes it possible to replace worn parts without scrapping entire units, aligning with circular economy goals.

By incorporating these practices, cabinet makers contribute not just to the visual and functional quality of interiors, but also to the environmental performance of the entire space.

reDirect Recycling Wood Recovery Initiative

The polytec reDirect Wood Recovery Initiative commenced in 2020 and is designed to service customers by collecting raw and melaminecoated particleboard offcuts for reuse. The materials are repurposed into new particleboard within a closed-loop manufacturing process which reduces waste and preserves valuable plantation resources. By participating, customers contribute to a circular economy and build more sustainable manufacturing practices.

To date, more than 1000 customers have participated in the reDirect program, with more than 7000 annual truck trips transporting urban wood residue to the facility in Oberon where it is used to produce recycled-content particleboard.

Mathew Dwyer, head of reDirect Recycling, says “we have a lot of demand for our Wood Recovery Initiative. The team and I are working with our partners on how we can expand services ensuring the urban wood residue is economically diverted from landfill. My only regret is our program reach isn’t yet across every postcode for every polytec customer in Australia. We concentrated collections near our transfer and sorting centres. We are excited about future expansion across metropolitan areas of Victoria and South Australia.”

reDirect has an extensive wood recovery program for other market segments, offering a range of services including recycling of particleboard and timber offcuts, frame and truss timber, and pallets.

redirectrecycling.com.au/

Sustainability

Indoor-outdoor integration

Blurring the lines between indoor and outdoor spaces is a prominent trend in 2025. Large windows, natural materials, and seamless transitions between interior and exterior areas create a harmonious connection with nature. This design approach not only enhances the aesthetic appeal of a space but also promotes natural ventilation and lighting, reducing reliance on artificial climate control and lighting systems.

Future planning for sustainable homes

Sustainability in interior design extends beyond the present and into long-term planning for future generations.

Durability and timeless design

Investing in high-quality, durable materials and timeless design elements ensures that interiors remain relevant for decades. Rather than following fleeting trends, sustainable interior design focuses on classic styles, neutral colour palettes, and well-crafted furniture that can withstand wear and tear. This reduces waste and the need for frequent renovations.

Sustainability

Upcycling and circular economy practices

A key aspect of future-proofing homes is embracing the circular economy where materials and products are reused, refurbished, or repurposed rather than discarded. Upcycling old furniture, sourcing secondhand materials, and incorporating reclaimed elements reduce the environmental impact of building and renovation works.

Integration of renewable energy sources

As Australia continues to embrace renewable energy, sustainable homes are incorporating solar panels, battery storage, and smart grid technology. Homeowners are designing their spaces to accommodate future energy innovations, such as vehicle-to-grid (V2G) charging, which allows electric vehicles to feed energy back into the home’s power system.

Product specification and sustainable impact

The effectiveness of sustainable design is heavily influenced by the products specified during the interior design process. Choosing the right products for the correct purpose can significantly enhance a home’s sustainability profile.

Low-impact materials and certifications

Specifying products that have been certified by recognised environmental standards (such as GECA, FSC, or GreenTag) ensures that they meet strict criteria for sustainability. These certifications assess lifecycle impacts, from raw material sourcing to manufacturing and disposal, giving designers and homeowners peace of mind about their environmental impact.

Non-toxic and health-conscious products

Volatile organic compounds (VOCs) from paints, finishes, and adhesives can negatively affect indoor air quality. Specifying low- or zero-VOC products supports healthier indoor environments. Similarly, selecting hypoallergenic and biodegradable textiles contributes to better overall wellbeing for occupants.

Locally sourced and durable products

Choosing locally manufactured products not only supports the local economy but also reduces the carbon footprint associated with transportation. Additionally, specifying durable, long-lasting products minimises the need for frequent replacements and maintenance, aligning with sustainable and economic design goals. ■

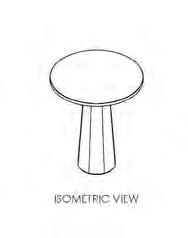

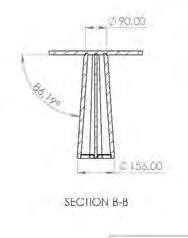

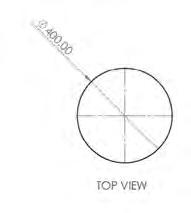

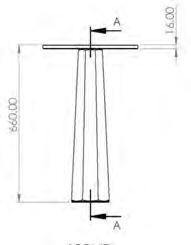

Salt & pepper side tables

“The Salt & Pepper side tables represent an exploration into combining post-consumer HDPE (High-Density Polyethylene) with traditional fabrication techniques to create sustainable furniture. The raw material is sourced in sheet format from Defy Design, a Sydney-based company that specialises in transforming plastic waste destined for landfill into impactful design products.

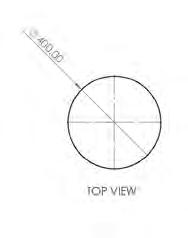

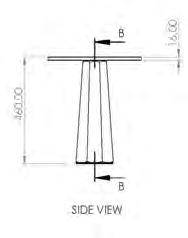

The manufacturing process employs traditional techniques of kerf bending and jig making through several distinct steps: routing, folding, welding, trimming, and assembly.

Routing The process begins with a custom timber jig that guides a trim router along nine tapered paths. The jig is clamped onto a flat sheet of HDPE, and a 60-degree router bit carves V-shaped grooves to a specific depth. A separate circular jig is used to carve out the tabletop, which includes a rebated ring on the underside. The overall shape is then cut out using a jigsaw, preparing it for the next stage.

Folding The base section is clamped into another jig while a heat gun is run along the outside edge until the plastic becomes soft enough to manipulate and fold. This

process is repeated for all seven edges, and the resulting shape forms the distinctive geometric taper and speckled swirls characteristic of the Salt & Pepper side tables.

Welding The final edge is plastic welded together internally using additional heat and a specialised tool that melts the HDPE, forming a strong bond.

Trimming The tapered hexagonal base is then fitted into a timber lathe, where the top and bottom edges are trimmed and shaped to match the rebated top and create a flat base.

Assembly The components come together by fitting a metal truss rod to the underside of the tabletop, which runs through the centre of the base where an oversized hexagonal washer and Nylock nut pulls the base and top together securely.

Although a CNC machine could handle much of the routing, the use of jigs offers a more crafted and honest approach. This method allows the recycled HDPE to emulate the aesthetic qualities of marble without the environmental impact of mining natural stone, while also serving as a deliberate contrast to the industrialised manufacturing processes of injection and blow moulding that the plastic had previously undergone.”

Carl Broeson — Carl Broeson Studio carlbroesenstudio.com/

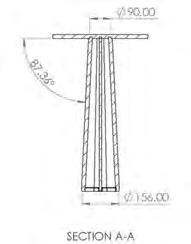

Belah House Sustainability Case Study

Belah House is an exemplary blend of innovation, beauty, and sustainability

Designed by architecture and interior design studio Silvester Fuller in collaboration with owner Jamie Durie, renowned for his expertise in landscape design and sustainable living, this ecoconscious home redefines luxury while honouring environmental principles. Named after the Wiradjuri word for "Sun," Belah House reflects a profound connection to nature, embodying a vision where every aspect is designed for sustainability and longevity.

The three-year project led by Jamie Durie and his partner Ameka showcases a meticulous integration of advanced eco-friendly technologies and sustainable materials. Throughout the home, Neolith surfaces not only enhance aesthetics but also contribute to its sustainable footprint, offering a blend of functionality and elegance.

Belah House sets a new standard for sustainable luxury living with its innovative geothermal heating,

cooling systems, and renewable energy solutions. These technologies not only ensure energy efficiency but also promote grid independence, resulting in substantial savings and reduced environmental impact. The home's commitment to sustainability extends to its construction materials, including a groundbreaking Australian concrete that significantly reduces carbon emissions.

Situated on a challenging site characterised by a steep slope and protected vegetation, the design of Belah House deliberately integrates with its natural surroundings. Each architectural decision was informed by the landscape, respecting existing trees and terrain contours. This approach not only preserves the environment but also enhances the home's stunning organic appeal.

Inside, Belah House exemplifies luxury and functionality with its meticulously designed interiors. Neolith's surfaces feature prominently, from the sleek Calacatta countertops in the kitchen to the sophisticated Black Obsession in the bar area. These surfaces not only elevate the aesthetic but also ensure practicality and ease of maintenance, reflecting Neolith's commitment to sustainable design.

The bathrooms exemplify tranquillity with a mix of Neolith Colorado Dunes and Calacatta Luxe, adding a refined yet natural touch to the space. The

interplay of textures and tones enhances natural light, reinforcing the home's seamless connection to its environment.

By integrating sustainable practices without compromising on luxury, the project aims to inspire others towards more environmentally conscious living. Through initiatives such as the ZIP tap for instant water and recycled ocean plastic flooring, Belah House embodies a holistic approach to sustainable living, promoting both environmental stewardship and modern comfort.

With this ambitious project, Belah House not only redefines residential architecture but also sets a precedent for sustainable luxury. With its blend of cutting-edge technology, eco-friendly materials, and respect for nature, this home stands as a beacon of innovation and environmental responsibility in the architectural landscape.■

Neolith neolith.com/au/neolith-projects/belah-house-asustainable-sanctuary-by-jamie-durie/

Sustainability Case Study

Nudie Jeans Repair Shop Brisbane

Sydney-based sustainable design studio X+O redefines the future of bricks-and-mortar retail

The Nudie Jeans Repair Shop in Brisbane, designed by Sydney-based sustainable design studio X+O, showcases excellence in merging sustainability with retail innovation.

At just 33m², the store’s intention was to epitomise circular design principles, repurposing and integrating sustainable elements throughout its space. X+O's brief focused on retaining and repurposing existing materials while enhancing storage capacity and integrating circular design solutions. This approach not only minimised environmental impact but also created a physical embodiment of Nudie Jeans' commitment to sustainability.

Central to the store's design is its role as a repair hub, prominently featuring a sewing machine at the shopfront. This unique setup encourages customers to engage in "forever repairs," diverting clothing from landfills and fostering lasting relationships with the brand. The strategic placement of the repair station transforms the traditional retail experience into a

community-driven repair service, where sustainability meets consumer engagement.

Key design elements include custom-made sustainable denim tile finishes crafted from recycled Nudie Jeans and construction waste. These tiles adorn the denim bar and wall fixtures, symbolising the brand's journey from purchase to return and recycle.

Locally sourced DesignerPly Hoop Pine, known for its low carbon footprint and FSC certification, was utilised for shelving and fitting rooms, further enhancing the store's sustainable profile.

The innovative use of materials extends to the floor, facade, and light tracks, all repurposed to reduce

environmental impact. Full-height denim cubbies with integrated storage cupboards optimise space efficiency while maintaining aesthetic appeal. Each design choice reflects a meticulous consideration of materiality within a circular economy framework, reinforcing Nudie Jeans' brand values at every touchpoint.

Beyond functionality, the store's design prioritises customer experience by blending sustainability with service excellence. By reimagining the retail space as a repair store, X+O and Nudie Jeans have created a destination where sustainable practices and consumer interaction converge harmoniously.

The Nudie Jeans Repair Shop in Brisbane stands as a beacon of sustainable retail innovation, demonstrating how thoughtful design can redefine traditional brick-and-mortar experiences. It embodies a future where sustainability, circularity, and consumer engagement converge seamlessly, setting a new standard for retail spaces worldwide.

“We don’t believe sustainability should be an afterthought. For us, it’s a design standard,” says Rebecca Vulic, X+O director. “Our approach proves that resourcefulness, storytelling, and environmental responsibility can coexist beautifully in retail environments.”

As global brands face mounting pressure to reduce their environmental impact, X+O’s model offers an actionable template — one that blends aesthetics, sustainability, and scalability without compromising commercial outcomes.

• Better Future World Design Awards Silver Winner, Environmental Design

• Better Future Australian Design Awards Gold Winner, Environmental Design

• Better Future Sydney Design Awards Gold Winner, Environmental Design

• Dezeen Awards 2024 Sustainability Longlist, Sustainable Interior

• INDESIGNLIVE and shortlisted for the INDE. Awards, ‘The Influencer’

• Australian Design Review Interior Design Excellence Awards (idea.) Retail and Sustainability ■

Sustainability Case Study

Arup’s new workplace is a bold, tangible expression of the global consultancy’s mission of shaping a better world. To translate this ethos into space, Arup partnered with design business Hames Sharley and Noongar artist Peter Farmer, and his family from Peter Farmer Designs to co-create a workplace that nurtures deep connections between people, place, and culture.

Occupying three levels of WS2 — Perth’s first hybrid-timber office tower — the fitout embodies regenerative design from structure to storytelling. A central void was carved from CLT slabs to increase natural light and create visual connectivity; the removed panels were repurposed into raised platforms that can be reintegrated if needed.

Arup Workplace

Perth/Boorloo

Sustainable systems and cultural integration shine in Arup’s new workplace, located on Whadjuk Noongar Country

Sustainability was not a tick-box exercise, but a rigorous, multi-layered strategy. Arup is pursuing the Living Building Challenge (LBC) and has already achieved WELL Platinum certification. The fitout is all-electric to enable Arup to draw 100 per cent of its operational energy from local renewables. More than

99 per cent of construction waste was diverted from landfill, while salvaged materials — from storm-felled timber to second-life furniture — are woven throughout.

Material choices were equally considered. All timber was responsibly sourced with full provenance, while 27 per cent of materials were procured locally in and around Perth and 55 per cent within Australia — exceeding LBC minimums. More than 640 materials and products were individually vetted, and air-quality sensors are monitoring indoor health now the space is occupied.

Cultural and ecological narratives shape every level, with Noongar artist Peter Farmer, cultural adviser Miranda Farmer and family from Peter Farmer Designs collaborating to embed meaning and memory. Backgrounded by charred jarrah wall panelling (symbolising the regenerative power of fire), a welcome sculpture greets visitors. Elsewhere, riverline engravings on lockers and pod-like sculptures reference ancient stories and creator spirits.

The workplace promotes health and connection at every scale. 95 per cent of regularly occupied spaces have access to daylight and views, and lush indoor plantings support biophilic design principles. A sculptural three-storey staircase serves as a visual centrepiece, while the tensegrity principles of its construction reduce steel consumption.

Smart building systems and digital monitoring further enhance the sustainability outcomes. Arup has committed to an energy performance 30 per cent improved upon business-as-usual benchmarks, representing an ambitious 5.5-star NABERS tenancy rating, and intends to offset all the upfront carbon to achieve a carbon-neutral fitout.

Beyond its technical achievements, this workplace is a catalyst for collaboration, cultural dialogue, and environmental leadership. As Arup describes, it is a place “resonant with our commitment to sustainable development and creating an inclusive, inspiring environment for our people.” It is a testament to what can be achieved when sustainability, storytelling and design move forward together. ■

• Australian Interior Design Awards — Sustainability Advancement Award — 2025

• Australian Interior Design Awards — Workplace Design Award — 2025

• Australian Interior Design Awards — Best of State Commercial Design WA — 2025

• AIA WA Architecture Awards — The Julius Elischer Award for Interior Architecture — 2025

• AIA WA Architecture Awards — Commendation for Sustainable Architecture — 2025

• Property Council of Australia WA Property Awards — Best Commercial Fit Out or Redevelopment — 2025

• Sustainability Awards — Interior Design Award — 2024

Kalasin from Bathco is a pedestal sink made from bamboo, a natural, durable and highly sustainable material. Unveiled at ISH earlier this year and designed by Lucio Traficante, Kalasin embodies the living structure of trees with its cylindrical shape evoking a tree trunk, growing outward in concentric rings. Crisscrossed with delicate longitudinal grooves, the surface reproduces the upward pattern of the tree’s natural growth. thebathcollection.com

Designed by Roberto Gobbo for Euromobil, Free Steel makes use of brushed AISI 304 stainless steel to create an elegant island bench for the kitchen. Stainless steel is known for its durability, hygiene and eco-sustainability, guaranteeing a recyclable solution that withstands the challenges of everyday life. Stainless steel is used for the frontal base units, grooves, plinths, top and welded sink. euromobil.com/en

Sustainable Product Update

Give your next project a lift with our editor’s pick of the latest sustainable products

MaxiWall from Big River Group is an Autoclaved Aerated Concrete that offers an alternative to traditional brick and block building materials. Its sustainable design prioritises energy efficiency and environmental responsibility, using 60 per cent less embodied energy than traditional masonry and producing 55 per cent less greenhouse emissions than concrete and brick. It also provides superior insulation qualities compared to other masonry products. bigrivergroup.com.au/

From Brisbane-based industrial designer Angus Armstrong Guy, this is the Repeat Chair — an innovative design handcrafted from more than 2000 recycled HDPE plastic bottle caps sourced from the Brisbane community. Using a simple, repeatable process of shredding and melting, the caps are transformed into plastic beams with the help of an electric oven and a hand-built timber mould. These beams are then cut, heated, and bent before being fixed into place, forming a comfortable and ergonomic seating design. alwaysgooddesign.com/

The Pipeflute Wall Hooks are a collection of sculptural wall hooks made from reclaimed stainless-steel offcuts from Naarm-based designer and maker, Carl Broesen. Carl describes the units as “referencing the rhythm of pan flutes” to take the humble hook and elevate it to a piece of architecture while focusing on the circularity of materials and sculptural intent. carlbroesenstudio.com/

The Sorbet Acoustic Panels were designed by Sze Tjin Yek as part of an Honours project which looked at ways to better manage commercial and household waste, particularly textile waste. The Sorbet acoustic panels are made from 100 per cent laundered and upcycled household textile waste and bonded together with a starch-based glue. Sorbet acoustic panels can be collected and reused to close the loop for a circular economy. sorbetacoustics.com/

Kaynemaile RE/8 mesh from Austaron Surfaces has adopted the use of Makrolon® RE by Covestro as its base material. It is produced using the same chemical infrastructure as traditional fossil-fuel based polycarbonates but sources bio-based raw materials (also known as ‘feedstocks’) from existing commercial bio-waste supply chains. All mesh is made from a single-chain polymer so the material can be cleaned back to its original state including the colours used.

austaronsurfaces.com/

The natural surfaces from the Organoid® collection use natural raw materials such as real Alpine hay from the Tyrolean region (where the company is based), moss from upcycling, flower petals, lichen and herbs are carefully applied by hand, mixed with an ecological binding agent and pressed into a thin layer. The natural properties of the raw materials are preserved for unique visual, tactile and olfactory experience.

austaronsurfaces.com/

Crafted from timber offcuts collected from the wood-working industry, TreeAzzo from Havwoods combines these reclaimed wood chips with a high-quality, VOCfree epoxy resin to form unique, design-led panels. Every panel is handmade, ensuring one-of-a-kind visual composition. TreeAzzo is available in two core panel constructions — 11mm fibre cement backing for flooring or 23mm plywood backing perfect for cabinetry, furniture, splashbacks and worktops. havwoods.com/au/

Eco Surfaces produces benchtops and other surfaces using washed and recycled glass. The surfaces are scratch and stain resistant, heat resistant and easy to clean utilising approximately 450 standard glass bottles per benchtop. Slab sizes are 3050mm x 1550mm x 20mm, with each slab weighing around 195kg. Containing less than 1 per cent crystalline silica, the slabs are safe for manufacture and installation in a range of interior environments. ecosurfacesaustralia.com.au/

LIGNA 2025

This year LIGNA celebrated its 50th anniversary with an innovative trade show that brought the global timber industry together

LIGNA was established in 1975 as a spin-off from Hannover Messe. Today, it is the leading trade show for products and services for primary and secondary industries — tools, machines and systems for custom and mass production, surface technology, timber-based panel production, sawmill technology, energy from timber, machine components and automation technology, as well as machines and systems for forestry.

2025 saw 1433 exhibitors from 49 countries, located across 10 exhibition halls, two pavilions and an impressive open-air site covering 114,078sqm in total. Close to 78,000 visitors from 156 countries attended over the four days of the trade fair.

This year’s focus was on digitalisation, automation, artificial intelligence, smart production, sustainable

and climate-friendly construction using timber and timber-based materials, and the responsible, futureoriented use of timber as a resource.

Dr. Jochen Köckler, CEO at Deutsche Messe AG, said, “despite all the benefits of digitalisation, nothing can replace the experience of seeing machines in live operation at a trade fair. I would like to thank all LIGNA exhibitors who demonstrated this so clearly here. The combination of innovation, technological progress, and passion is the best foundation for renewed investment.”

Whether in forestry, sawmilling, production, manufacturing, or craft industries, exhibitors presented solutions spanning the entire value chain, showing how current challenges can be addressed and turned into opportunities.

Trade Shows

LIGNA’s three focus topics were Connectivity, Sustainable Production and Engineered Wood to address key areas of concern for the industry as well as highlight solutions for sustainable development. Exhibitors embraced these topics with a wide variety of smart solutions, groundbreaking developments, and high-tech innovations.

Two new exhibition segments, LIGNA.Circular and LIGNA.TruckStop were popular with visitors. LIGNA. Circular in Hall 12 focused on the circular economy and sustainable material use. LIGNA.TruckStop was a hands-on way for carpenters, joiners and craftsmen from all trades to investigate the latest power tools for workshops and business management.

Felder Group was among the exhibitors at this year’s show and one of the highlights of its stand was the new Felder 700 Series with PCS safety technology. Con Badenhorst from Felder Group Australia says this will be a game changer for the industry with a full cabinet maker’s version, including the PCS safety technology, retailing from around $60,000 (ex-GST) with a smaller version available from around $28,000 (ex-GST). He adds that this is comparable to similar machines without any safety system.

The PCS (Preventative Contact System) is designed to recognise potential accidents before contact is made with the blade saw, only taking milliseconds to defuse a hazardous situation and reducing the result from catastrophic to minor at worst. The huge benefit to all is there is very little need for additional training. The system works with the blade as the sensor, so it has no cameras, no light curtains and remains functional with the saw guard swung away. It also conveniently activates when in contact with screws and nails to save blades. PCS is available in almost all series now.

This means the new technology is more accessible for all, creating safer practices and workspaces.

All Felder saws and those with PCS will still be produced in Austria and carry Felder's warranty with local extended warranty available up to five years. Sliding table X-Roll system will still carry the 10-year warranty.

Wood Tech sent representatives from QLD, NSW, SA and WA to LIGNA to explore exciting new opportunities for the Australian market and support existing suppliers. Jon Chamberlain from Wood Tech said “LIGNA is more than just a tradeshow — it’s the global benchmark for where the woodworking industry is heading. For Wood Tech, attending LIGNA 2025 as a full national sales team wasn’t just about discovering the latest in automation, smart factory tech, and CNC innovation — it was about reaffirming our commitment to bringing world-class solutions back to Australian manufacturers.

"What we saw in Germany will help shape the next chapter of our product line-up and service offering. Our customers rely on us for forward-thinking, reliable equipment and support — and our presence at LIGNA ensures we’re always ahead of the curve. As the local industry evolves, Wood Tech remains focused on delivering smarter, more sustainable, and more connected machinery solutions to workshops across the country.”

SCM Australia CEO Boris Chernyshev attended the show and said, “a clear trend was the growing interest from companies looking for highly automated, technologically advanced solutions — not only in traditional wood-working applications. This is precisely

the area where SCM has always excelled, and our goal is to deliver these cutting-edge technologies to the Oceania market.”

SCM Group represented across three stands totalling 3300sqm and the clear trend was the growing interest in highly automated, technologically advanced solutions. The Tecno Logica stand (a company that joined SCM Group in 2024) showcased a conceptual edgebanding machine that drew inspiration from automotive industry technologies. In the CNC machining centre category, SCM Group introduced two new models — Morbidelli x50 and Accord 500. In the solid timber processing segment, the topset xxl four-sided moulder drew significant attention.

Leitz Tooling Systems ANZ managing director, Sam Czyczelis, said “Spending time with our global Leitz colleagues was invaluable. The camaraderie, the exchange of technical knowledge, and the shared vision for our industry is something you simply can’t put a price on.”

Leitz released a number of new products at LIGNA 2025 including a new compact hogger with a universal tooth design and consistent cutting width, a new PolyCut circular sawblade which is designed to handle materials prone to melting and chipping, an expansion of the ProfilCut Q Diamond system with Plug&Play functionality, and the new WhisperCut PLUS which is an advanced evolution of the Diamaster WhisperCut system.

Ross Campbell from HOMAG was at the show and shares his perspective: “HOMAG’s 5000sqm presence dominated the panel processing arena at the LIGNA

featuring many new innovations both machine and digital in a dynamic display. 114 semi loads of equipment installed, operating and connected by more than 300km of electrical cable laid demonstrated HOMAG’s leading commitment to the industry. It was a visual and moving feast of technology and processes with most visitors commenting ‘it was easily the busiest booth at the LIGNA. Just what you would expect from the industry leader’.”

With its new digital platform HOMAG INTELLIGENCE, the company presented a new milestone for the industry; a cloud-based solution that creates consistent and seamless networking of furniture sales and production processes. Highlights on the stand included the new SAWTEQ S-200 flex Tec and the STORETEQ P-310 second-level storage system, the DRILLTEQ V-310 smart robot system, the new CNC programming software woodWOP 9, the latest generation of the CENTATEQ N-210 high-performance entry-level solution for nesting processing, and the EDGETEQ P-200 and woodCommander 6 digital edgeband technology.■ Next LIGNA: 10–14 May 2027 LIGNA.de/en/

interzum 2025

This year’s interzum set a path for the future firmly focused on sustainable transformation

The central theme of this year’s show was “Rethinking Resources: Circular and Bio-based Solutions” which saw exhibitors and attendees focus on playing an active role in creating a resource-efficient, sustainable future. This was an extension of the theme from the 2023 show which was the concept of “Neo-Ecology”.

Close to 60,000 visitors from 148 countries visited 1616 exhibitors from 57 countries encompassing 176,000 sqm of exhibition space over the four days of the trade fair. On display were a wide variety of innovative materials, intelligent components and smart technologies that are sure to shape the homes and workplaces of the future.

Maik Fischer, the director of interzum, said “By bringing together the two approaches — the circular economy and bio-based materials — the world’s leading trade fair for furniture production and interior design advances the development of product

innovations that are both long-lasting and produced from sustainable sources.”

With its new central theme, the trade fair highlighted two fundamental concepts in the stewardship of resources. Transitioning to a circular economy means keeping materials and products in the economic cycle for as long as possible by extending the duration of their use through reuse, repair, refurbishment and recycling. By contrast, bio-based solutions use materials produced from regrowing sources, making them environmentally friendly alternatives to petroleum-based products. Both approaches aim to minimise a product’s ecological footprint and promote sustainability.

interzum is divided into three exhibition segments — Function & Components, Materials & Nature, and Textile & Machinery. The first two segments are most relevant for our industry. The Function & Components segment includes fittings, lighting systems and semi-

Trade Shows

finished products for furniture and built-in parts with a focus on energy efficiency, comfort and convenience. Materials & Nature features timbers, veneers, parquet flooring, decorative surfaces, decor papers, timber-based materials, laminates, edging products and surface treatments, among other products with a focus on sustainable materials and environmentally sound raw materials.

Function & Components

As we often see in Europe, all major manufacturers have a focus on space utilisation and space maximisation, with the development of functional components that seek to create multi-dimensional and multi-functional space a high priority. Collaboration is a major theme with all major suppliers seeking to create co-operative and collaborative partnerships with the specification community. It’s no longer a simple sales transaction — these businesses want to play an active role in supporting their customers.

Materials & Nature

We are seeing emphasis on noise management and noise reduction/absorption with clever application.

In terms of colour palettes far fewer “whites” were on display — this is often the case in Europe where there seems to be a greater capacity for risk-taking when it comes to the use of colour.

There was a significant focus on creating hyperrealistic surface finishes with plenty of options to provide the designer and cabinet maker with a world of choice to mix-and-match either within a colour palette or provide contrast.

Matte surfaces were still dominant, with some, but not many, gloss options on display. There was very much a focus on technology and how far can the boundaries of technology be pushed in terms of material application.

Sustainability

Every major manufacturer has a focus on sustainability and most stands made a point of emphasising not only the materials that go into creating the products, but also the eco-friendly principles applied throughout the production and transportation process, as well as end-of-life recycling efforts. It’s an area that is of significant importance throughout the European manufacturing industry.

Trade Shows

Chef’s Table is an innovative swivel system from Kesseboehmer that allows bulky appliances to appear when needed then disappear back into the base unit after use. Suitable for appliances such as air fryers, food processors or bread-cutting machines, the parallel swivel mechanism has a load capacity of up to 19kg.

Hettich’s theme for the fair was “Transforming Spaces with innovative motion”. The Hettich FurnSpin, originally released in 2023, is a versatile furniture solution with broad applications in interior environments for managing space utilisation.

Blum’s AVENTOS HKi fully integrates into the cabinet side thanks to its extremely slim construction. This lift system fits perfectly into cabinet sides with a thickness of 16mm or more, making it virtually invisible from the outside. The integrated lift system remains invisible when closed, even with glass fronts.

Salice Air is a fully integrated and completely concealed hinge with three-directional adjustability. The hinge is available in three functional variations — unsprung, integrated soft-close, and push for handlefree applications.

The Vauth-Sagel VS ADD Frame is a solution for modern storage that balances aesthetics and functionality. Suitable for cabinet widths of 600mm, the frame is in black anodised aluminium with smokey glass elements. Accessories include wire frame for bottle storage, wine glass holder and shelf.

Nubo from Domus Line is a 100 per cent polycarbonate luminaire for glass shelf lighting. Designed for both 6mm and 8mm shelves the models can be configured with the light projection on either the front or rear side. A four-sided opal light chamber ensures even light distribution.

Raukantex pigmento from Rehau is a new timber-look edgeband that faithfully reproduces timber grain and streaks within the milling radius for a seamless natural look without visible transitions. The edge boasts outstanding quality, is impact-resistant and won’t chip.

Zenit 3.0 from Alvic is the new generation of silk-touch, antifingerprint, super-matte lacquered surfaces with increased surface scratch resistance, high abrasion resistance and maximum colour stability. Its microscopic surface structure provides low light reflection to create the super matte finish.

Master Oak by Unilin Panels is an innovative decorative surface that realistically mimics oak timber with a deep brushed finish and extreme matte surface. It offers superior scratch resistance, UV stability, and easy maintenance. Made from 95 per cent recycled timber, Master Oak is a sustainable and high-performance alternative.

Egger’s PerfectSense Ambiance is a velvety super-matte surface with a partial gloss effect that sparkles in the light. An elegant, expressive stone effect that is both hard wearing and easy to clean.

Häfele OneCable is a versatile and straightforward solution comprising a single profile with corner connectors into which a flat ribbon cable is inserted. Luminaires can be specified as needed for both diffused and focused lighting and controlled via the Connect Mesh app.

The latest premium walnut collection from Decospan, Walnut has a deep, intricate grain with warm hues making it very popular for application in any sophisticated space. Available as panels, sheets and edge banding, the collection is versatile, responsibly sourced and produced with minimal environmental impact.

Next interzum 11–14 May 2027 interzum.com/en/

Turning the Tables

Tackling Australia’s furniture & cabinetry waste crisis

The figures are confronting. Up to 95 per cent of commercial furniture and fittings go to landfill at the end of a typical five-year office lease. In Australian households, the tradition of passing down treasured furniture has given way to the mass disposal of “fast furniture”, with an estimated 85 per cent sent to landfill.

This is contributing to a looming environmental issue: Sydney landfills are predicted to reach capacity by 2030, with Melbourne close behind. Aside from the greenhouse gases released, imported furniture may contain PFAS (forever chemicals) which are not only extremely toxic but do not degrade in the environment.

Many organisations, including the Green Building Council of Australia, Good Environmental Choice Australia, the Product Stewardship Centre of Excellence and numerous recycling initiatives, are working to reverse this trend and promote a more circular economy. Recent Federal government action requires many large organisations to prepare annual sustainability reports containing mandatory climaterelated financial disclosures.

By Pam Kershaw

However, Australia's tax structure creates a disincentive for sustainable practices, according to Sasha Titchkosky, co-founder of Koskela, a leader in sustainable Australian furniture.

“Depreciation schemes encourage businesses to buy new, write off assets and replace them,” she says.

“A sustainable approach would reward repair, refurbishment and leasing models,” she adds. “Tax credits would be available for extending a product’s life, using recycled materials and returning assets for remanufacture."

Founded in 2000, Koskela became Australia’s first furniture B Corp (Certified B Corporation) in 2017, meeting rigorous standards of social and environmental performance.

Rethink and redesign

All its furniture is Australian made, reducing import emissions. The company works with sustainable materials and ethical suppliers, and its repair, maintenance and repurposing initiatives keep its products in the marketplace. It aims to eliminate company waste and be fully circular by 2027.

Koskela designs for longevity. Its sofas, for example, feature removable covers and replaceable panels, while mechanical fixings — rather than glue — make furniture repairs and disassembly easier. Solid timber is used sparingly: 5–8mm of hardwood on a substrate provides the benefits of solid timber with far less material.

Sasha points to the untapped potential of innovative materials. While MDF and chipboard dominate the Australian market, international alternatives now use substrates such as cardboard, hemp, coconut waste and even olive pips from the olive oil industry. Australia’s own olive and sugar cane industries could support similar developments.

Product stewardship

As a GECA-(Good Environmental Choice Australia) certified company, Koskela is committed to product stewardship, which means taking back products at the end of life.

But when commercial tenancies conclude, Koskela is never asked to collect furniture, thus losing the opportunity to refurbish for another customer, or dismantle and reuse in manufacturing, or recycle.

Koskela supports the “digital product passport” concept — a unique QR code that reveals the product origin, materials, construction and repair/rehome instructions. If government-mandated, this system

Sustainability

could hold all manufacturers accountable for their products’ lifecycle and make it easier for businesses to manage end-of-life processes responsibly.

To honour its product stewardship obligations, Koskela has introduced a commercial subscription service where it retains product ownership. Clients gain tax-deductible benefits, and Koskela retains control to refurbish or rehome items efficiently.

Its Rehoming program, introduced first for domestic clients and now extended to the commercial market, enables customers to trade in old Koskela furniture for store credits. Returned items, some more than 20 years old, are repaired, refreshed and resold.

Opportunities for cabinet makers

Sasha believes cabinet makers can play a valuable role in this circular economy, particularly in remanufacturing and repair.

“Those elements can’t be easily off-shored — they need to be done locally, and almost hyper locally. If there’s a project in Sydney, the refurbishment needs to happen in Sydney because the carbon that’s embodied in transporting furniture is quite high,” she says.

She believes cabinet makers could consider shifting from one-off transactions to ongoing relationships in retail and domestic projects. “Instead of being a buy/sell transaction, they could think about systems to contact those customers over time and provide a service to spruce up or refurbish cabinetry,” she adds.

During a complete renovation of spaces, some cabinetry could be disassembled and repurposed rather than going to landfill. Such sustainable practices can also serve as a powerful marketing point to environmentally aware clients.

Sustainability

Learning from Europe

While interest in sustainable design is growing in Australia, Karie Soehardi, founder of Circular Design Thinking (CDT), says the industry still lags behind Europe.

“The biggest issue I find from a sustainability perspective in joinery is that custom joinery usually ends up in landfill because it’s site-specific. If we could look at joinery in modular or standard sizes, and ways to dismantle easily after a fitout expires, we would have a lot of reclaimed material that could be reused locally,” she says.

“If there are ways to join without glue and understand what type of finishes we are placing into joinery and cabinetry, then we would have healthy and circular materials to disassemble and reuse.

“But the theory of this needs to be backed up with strategic infrastructure to get those materials back into the hands of cabinet and furniture makers. That is where the digital product passports can come in,” she adds.

An environmental consultancy specialising in textiles, interiors and fitouts, CDT offers practical tools to help transition to circular economy models and meet Environmental, Social and Governance (ESG) reporting standards.

It works across the supply chain — from manufacturers to recyclers — and also collaborates with universities to commercialise innovative materials.

Pressure to make the interiors industry more sustainable is now coming from large organisations that must report their carbon emissions, as well as sustainability advocates within a business.

“Many manufacturers have been waiting for years for this to happen,” Karie says. “The major barrier is that the government is still only requesting voluntary information when it comes to sustainability for the FF&E (furniture, fixtures and equipment). We need legislation to create impact: look at Sweden where

those manufacturers are making money as they have to design out waste."

According to Britain’s Ellen MacArthur Foundation (a charity committed to the circular economy), 80 per cent of environmental impact can be designed out at the product concept stage. Therefore, opportunities exist for designers, cabinet and furniture makers to improve sustainability.

When CDT works with an organisation, it examines the entire makeup of prospective products, including packaging, and questions whether it can create a better version.

“We look at innovative and natural materials, and we value what we are redesigning with. So, if we were to take back the product, we would value the material enough to reuse, repurpose or remanufacture,” Karie says.

Sustainable textiles

Sustainability is a major selling point for Sustainable Living Textiles, which achieved GECA certification in 2005 and carbon-neutral certification by Climate Active (an Australian government initiative) in 2010. It manufactures furnishing textiles in Australia, using wool from meat sheep that is unsuitable for apparel but ideal for upholstery fabrics. Textiles can be recycled through Upparel, an Australian company that recycles through partners in Australia rather than sending waste offshore.

Managing director Liz Miles says the company's third-party sustainability certification is its strongest selling point.

“Most designers see us because we’re sustainable, and they’re specifying for clients that require sustainable products or are designing for Green Star projects. Manufacturers of furniture in Australia also like to recommend our fabrics, so we become part of their story,” Liz says.

Sustainable Living Fabrics is listed on the Products Declare website of Australian Architects Declare, part of an international network of architectural practices committed to addressing climate change and biodiversity.

The company has about 22 ranges and nearly 400 different colours. The high-quality textiles are made to last, as are the classic designs, therefore ranges are rarely discontinued.

“A lot of architects and designers are trying to create less waste. When fitouts need refurbishment, hopefully they will refurbish in the fabric that was originally specified and maybe introduce a pop or highlight of a new colour. Reuse and refurbish whatever exists — this is another way designers are starting to design with a more sustainable outlook,” she adds. ■

The future of sustainable fitouts

Sustainability in interiors is increasingly supported by industry frameworks such as:

Green Building Council of Australia (GBCA): Its Green Star rating tools certify buildings and fitouts for environmental performance. The new Green Star Fitouts program will simplify certification for projects, focusing specifically on aspects the fitout owner can control. gbca.au

GECA (Good Environmental Choice Australia): Provides independent certification for products and services with reduced environmental and human health impacts. More than 2500 products are certified. geca.eco

Product Stewardship Centre of Excellence:

A not-for-profit helping brands, governments, and manufacturers design products for longer life, maximise reuse of materials and improve environmental outcomes. stewardshipexcellence.com.au

Responsible Wood & Forest Stewardship Council (FSC): Promote sustainable forest management through certification, ensuring that timber products are responsibly sourced. responsiblewood.org.au anz.fsc.org

Creative Drive

Multi award-winning, WA-based, JahRoc Furniture thrives on creativity and a drive for quality, underpinned by artistic collaboration

By Rob Ditessa

“I think it’s just about being different, and obviously quality is really important to us, making sure it’s really built well,” says Gary Bennett. Gary established JahRoc Furniture, a bespoke fine furniture business in partnership with his friend, and subsequently brother-in-law, and cabinet maker David Paris.

“We offered — pretty much from day one — a lifetime guarantee on our work,” he continues. “I don’t even know if anyone still does that. All the old guys in the industry just said ‘you guys are crazy, that’s going to bite you’. But we’ve had it all the time. We do get the odd claim, but we fix it or re-build it. I’ve even brought back a piece from Sydney, fixed it, and sent it back. We’ve found that type of commitment to our product for our clients builds a lifetime bond that keeps them coming back.”

From the start Gary wanted his work to be different, something that hadn’t been seen before. In his design work, he “wasn’t going to be led by any one influence, and just wanted to come up with new work, and to keep it fresh,” he says. He learned the art of design, he muses, through a sort of osmosis, by absorbing the shapes and colours of the world around him.

Gary’s collaborations with a variety of artists helped him learn how to see through an artist’s eye. “One particular guy, Shaun Atkinson, taught me how to see things I’d been looking at all my life but had not noticed,” he says. Shaun, the internationally acclaimed Western Australian artist, was noted for his pared-back silhouettes of the landscape and seascapes he painted using evocative shapes and colours.

Shaun’s studio and Gary’s workshop had a similar view, overlooking a beach, which eventually motivated both to collaborate on an exhibition of work inspired by the landscape surrounding their respective studios, only a few kilometres apart.

It was through this collaboration that Gary developed a deeper understanding of how to capture and reflect the colours, lines, and shapes, in the vista and geography around him. Shaun would point out a feature of the landscape or seascape in the way Gary was drawing a design. “I’d look up and there it was in the light or the scene in front of the workshop. I was sort of doing it unwittingly, I guess,” he says.

Their collaborative exhibition also included work by leading Australian poet John Kinsella. It was one of several artistic co-operations JahRoc accomplished, and this one took them to Italy.

“The [exhibition] in Italy was pretty cool because we were invited by the state government to go. They obviously saw the value of the project that we did as we were reflecting a real ‘sense of place’ in that

work. In Italy, we were really just showing our work, so we didn’t have to go there and sell furniture, which was great,” Gary explains.

“Schools wanted me to talk to their students all about design, and timber. It was ironic really as I’d never really done that well at school. Yet here they were inviting me back to talk to their students. I was even asked to talk to the Business students at the University of Western Australia. Crazy really,” he laughs.

One of the awards won by JahRoc was the Wesfi Noel Hearn Fellowship Award for ‘Outstanding Contribution to the Development of an Export Market for WA Furniture’. The award, says the WA government’s heritage website, “is given to an outstanding individual whose further personal development will benefit the growth of the furniture industry in WA”.

Gary reflects, “The Fellowship was really cool to win. The Hearn family were an integral part of the West Australian furniture industry so I felt very honoured to be the inaugural recipient of the that award. The study tour of the Japanese timber and furniture industry had a profound and long-lasting effect on me personally and on our business.”

He adds, “The FIAA [now ACFA] Best of the Best awards also felt extremely rewarding to win. In the context of the Australian furniture industry, JahRoc was a very small player. So, when we were announced as the recipient of that award for the first time in 2003, I just couldn’t believe it. We went on to back it up with wins in that category again in 2005 and 2009.”

As they rode the wave to success, Gary and David, who are both keen surfers, embarked on a collaboration with Jim Banks, the surfing identity and surfboard shaper. JahRoc made pieces and furniture, and surfboards, with a surfboard theme that showed off the rich colours and grain textures of local timber. The project was aptly titled “Always Offshore”.

Another project, a commission from Sue Ulrich and painter Bill Anderson, put Gary to the test but also showcased his design and making skills, and his fortitude. The commission was for a chaise lounge, but Gary had never designed or made any soft furnishings. With imagination and his innate skills, and the determination of the client, he accomplished the work, and won the Excellence in Lounge Furniture in the National Furniture Industry of Australia Awards. He tells Connect, “’Sue’s Chaise’, as it was named, went on to take out the Best of the Best over all categories in 2002, which we felt was an amazing achievement to be recognised by our peers in that way.”

JahRoc’s creativity and drive for quality has been sustained by artistic collaborations as well as clients attracted from related businesses. In their previous location in York, an historic town located 100km east of Perth, where they renovated an old mill building, they eventually were sought out by 11 small concerns to share the building; one purpose was a music venue. The musicians, he remembers, came and walked through to see what they were doing and put in orders. They crafted a bed for singer Marcia Hines, and other furniture for folk singer John Williamson.

“People think we moved to Margaret River because it was good business down here,” Gary continues with a laugh, “but that wasn’t the case. I moved here because I liked to go surfing, and there just happened to be a market here for what we did. We were extremely lucky in that there are people from

all over the world who come and stay here. Some of them would purchase a special piece to get shipped back home. In some years, 30 to 40 per cent of our work was being shipped around the globe.”

Gary’s wife Lara, and David’s wife Joanne, ran the art and craft gallery, and Gary says that “certainly for the past 15 years they drove sales to levels we never thought possible. Our gallery in the main street of Margaret River became a must-see destination as one of the largest most diverse regional galleries in WA, so Lara and Joanne’s role in our business can’t be overstated.” David took on production, and administration of the business while Gary was in charge of sales, marketing, and designing and custom studio work.

Humans in general want nice things but, Gary acknowledges, some people can afford them, and some cannot. He recollects suggesting to one customer that he start a payment plan. “So, he started putting $50 a week in our bank, and that went on for about 12 years, and he accumulated a house full of the most beautiful furniture,” he says.

Despite expectations that the business would grow, Gary says one of the reasons JahRoc did not expand is the challenge of finding workers when, in the WA mining industry, young people can go up north and make three times what JahRoc can pay.

In addition, the price of timber has increased. “In my early days, I used to get it for almost nothing, pretty much off old buildings. They’d say ‘if you can pick it up and put it in the skip bin you can have it’, but it’s got more and more expensive. That will keep going because of supply and demand due to scarcity which has largely been brought on by poor government policy,” says Gary.

All of our native hardwoods are wonderful to work with, he enthuses, listing jarrah, marri, sheoak and blackbutt, noting their diversity in colour and grain. He says, “They cut well and because they are hard, joints stay really strong with minimal glue. Generally, we source material from local farmers, salvaging fallen logs or in some cases where roads and developments are happening. So, it is mostly salvaged material.”

He adds, “I love Japanese hand tools because they are beautifully made and function really well. Most of my big machines are Felder. Again, they are very well made in Austria and function well while lasting a long time.”

Looking back on his working life, Gary says, “I love being creative and, while timber can be very challenging with all its nuisances, it just feels good to work with. Nature is so astounding and I never cease to be amazed by the colours and grain patterns it offers. It sounds corny but it is one of nature’s great art forms.”

When asked about skills development, Gary says it is the construction sector that gets all the attention. “They shortened apprenticeships [and] it’s a bit sad they don’t get the training they should. You can’t learn to be a tradesman in three years, it’s

Favourites in the factory

Barker 1450 wide belt sander: An older machine, originally built in the 1960s in Melbourne, it ran for the first 25 years at the Wesfi plywood plant in Welshpool, WA. We acquired it in the late 1990s.

Balestrini mortice and tenoning machines: Invaluable for our chair-making process. Big solid beasts that, once set up, will spit out beautiful tight-fitting mortice and tenons all day long.

Griggio 3800 panel saw: The sheer size of this saw along with the tilting arbour make this machine a table maker’s best friend.

Casadei 520 buzzer with a combined 3000 mm bed: I call it the air craft carrier and when I need to flatten a side board top, or I’m doing a twin slab dining table or desk, I head out to the big workshop, and this one.

Leda 630 thicknesser: Another workhorse for fast efficient gauging of large-width timber slabs. Keep the blades nice and sharp, and it’s a dream to use.

Meber 900 band saw: This is a massive band saw that can also be used for milling veneers which is very handy in our furnituremaking process.

Linde H25T fork lift: It would be hard to operate handling the large timber stacks and slabs that we do without this machine.

Caterpillar 232B skid steer: Because we operate on a bush block there are places that the forklift won’t go due to the rough terrain, and that’s when this puppy comes into her own.

pretty much impossible. I don’t know what’s going to happen in the future in that regard and I don’t know how they can fix that without some targeted government policy in that direction,” he adds.

After 40 years, David has decided to retire, and the business is up for sale. Says Gary, “I’d love to find someone who would pick it up and run with it, because I still think there’s a future in studio, small-

Rocking Chair

scale high-end, hand-crafted furniture. The further we go into the future, there’ll be fewer skilled crafts people and native hardwoods available. I think that makes people revere it even more now. The smart people can see that coming.”

That’s why, he suggests, anyone who chooses this type of work can make an incredible life from fine furniture making. “I can’t think of a better way, for me anyway, a better way to make a living,” he concludes.■

JahRoc jahroc.com.au

Visit Milan in 2026

Join ACFA on an international tour to visit Salone del Mobile.Milano and Milan’s renowned Design Districts