THE BUSINESS OF COLLABORATION

Bridging craft and vision between cabinet makers and interior designers

HANDLE RANGE

EXPRESS YOUR STYLE IN ANY SPACE WITH OUR DESIGNER, EVERYDAY, TRADITIONAL AND PROFILE RANGES.

Engineered with meticulous attention to detail, the comprehensive Modar ® handles selection offers unique choices for residential, commercial, retail and custom furniture applications.

From modernising an existing room right through to a new build, Modar ® has the solutions that will suit your space beautifully.

EXCLUSIVELY BY LINCOLN SENTRY

From the editor

Welcome to issue 3 of Connect magazine! I have truly been humbled by the amazing feedback from our industry this magazine is such a passion project for me and it’s wonderful to have that enthusiasm and joy mirrored in our readers.

Get comfortable and grab a cuppa as this is a feature-packed issue!

As the weather turns chilly, we focus on the business of business as our major theme this issue. With the majority of our industry made up of sole traders and small-to-medium businesses, it’s common for the busy-ness of running a business to be a hot topic among members.

I had the pleasure of speaking with a pretty fantastic group of tradesmenturned-designers for a story on collaboration between the design and cabinet making sectors. Their insights are fascinating and they were able to bring their experience on both sides of the fence to provide some very interesting commentary.

Our contributing writers also turned their attention to a range of business issues Selina Zwolsman breaks down the essential skill of business writing and how to craft words that work; Ben Fewtrell takes us on a journey through business financials; and Pam Kershaw looks at how to maximise your business branding.

Our incredibly diverse industry comprises a wide range of different types of business, so we wanted to know more. Rob Ditessa spoke to Gareth Krost from Krost Business Furniture about this successful family business. And I was privileged to speak to four completely different individuals and businesses to look at their origin stories and celebrate the different ways they contribute to our industry.

Plus, catch up on progress with the ACFA/KBDi merger, enjoy the ISH Design Plus Award winners from the show earlier this year, and soak up the Vivid Emerging Designer winners from 2024 (ahead of the 2025 awards later this year). The ACFA Workplace Advice Team has an update on Casual Employment Law changes, and our friends at KBDi look at the range of pathways into our industry and explore how we can encourage more participation from school leavers. The HIA Economics team has provided a very interesting update on market confidence in the kitchen and bathroom sector.

And, you won’t want to miss all the fabulous updates from our advertisers please support these wonderful businesses who support our organisations and make it possible for us to continue to do what we do best. Enjoy!

Connect magazine is published by the Australian Cabinet & Furniture Association.

ABN 80 000 071 787

Publisher: Dean Brakell, CEO, ACFA

Editor: Melanie Gardener

Advertising Sales: Fiona Joynes

Art Director: Liza Jane Smith, liza@monava.com.au

Contributing Writers: Rob Ditessa, Pam Kershaw, Selina Zwolsman, Ben Fewtrell, Dean Brakell, Monique Penton, Tom Devitt (HIA)

Printer: Neo Pty Ltd

Correspondence to: PO Box 157, Gosford NSW 2250

Front cover: Minosa (Nicole England Photography)

Subscriptions: Connect magazine is produced as a hard-copy print publication as well as an online digital magazine. If you wish to subscribe please visit connectmagazine.com.au/

@connectmagazineaus @connect-magazine-aus

Copyright © Connect magazine (Property of the Australian Cabinet and Furniture Association). All rights reserved. The magazine or any part thereof may not be copied or reproduced without written permission from the publisher. Any specifications and/or claims here within are those of the manufacturer and/or supplier. Disclaimer: Statements by advertisers, expressed editorial opinion and/or contributors’ comments are not necessarily representative of those of ACFA Ltd or its members unless expressly stated. The publisher and editor assume no responsibility for errors or omissions or any consequence of reliance on this publication.

The Australian Cabinet and Furniture Association Ltd is a trade association that represents the interests of the cabinet making, kitchen, design, joinery, furniture, fit-out, and other wood, timber, stone and panel processing industries. Membership and advertising enquiries are welcome.

FEATURES

6 The Business of Collaboration

The power of collaboration to bridge craft and vision between cabinet makers and interior designers. By Melanie Gardener.

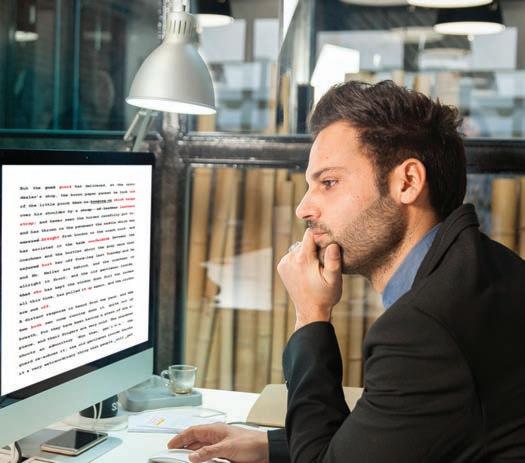

14 Words that Work

The art of business writing for cabinet makers and designers. By Selina Zwolsman.

18 Know Your Numbers

The five financial foundations every business owner should master. By Ben Fewtrell.

22 Business Branding

Your brand is the heart of your business, but is it driving business growth? By Pam Kershaw.

26 Brothers at Work

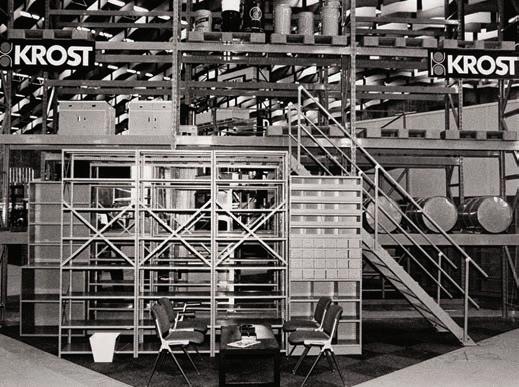

When brothers Colin and Steve Krost immigrated to Australia, they found that their family’s expertise and passion for designing and making office furniture had “stuck”. By Rob Ditessa.

32 Crafting Success

Stories of entrepreneurs in the cabinet making and furniture industries. By Melanie Gardener.

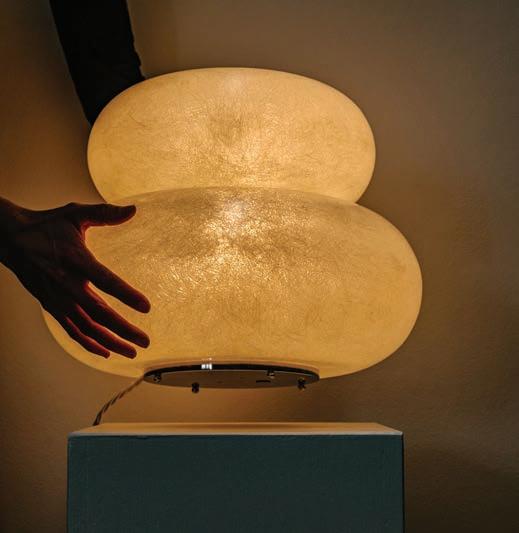

50 2024 Vivid Emerging Designer Awards

Held as part of Décor + Design, the Vivid Emerging Designer Awards celebrate the future of Australian design.

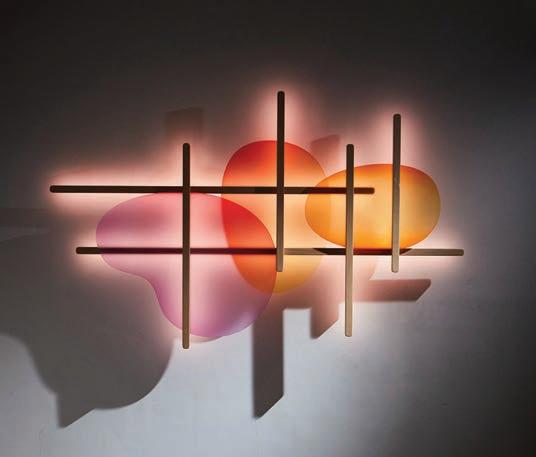

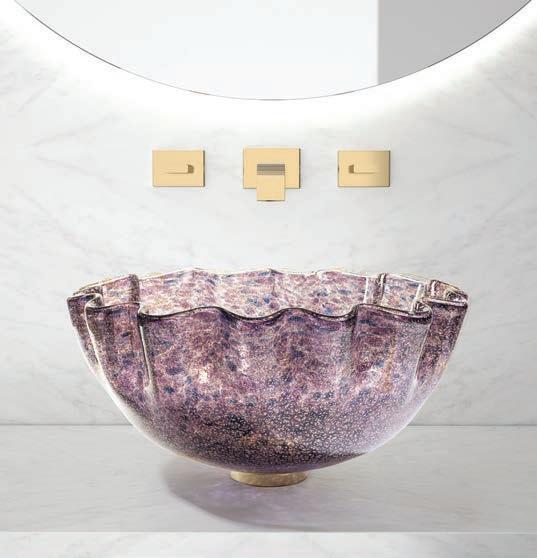

52 Product Update

Give your next project a lift with our editor’s pick of the latest kitchen, bathroom and interior products.

56 ISH 2025 Designplus Awards

From more than 160 entries, 13 outstanding solutions have been selected.

63 Kitchen+Bath Show is coming to Melbourne in June 2025

As the premier event dedicated to the kitchen and bathroom industry, Kitchen+Bath Show brings together the best brands for three days of inspiration, innovation and networking.

81 The Last Word: Sharpening Your Personal Saw — Part 2

Creating better business owners by establishing good habits and routines and asking for help when you need it. By Dean Brakell.

ASSOCIATION UPDATES

42 Pathways to a Productive Future with KBDi Building a career in the kitchen and bathroom industry

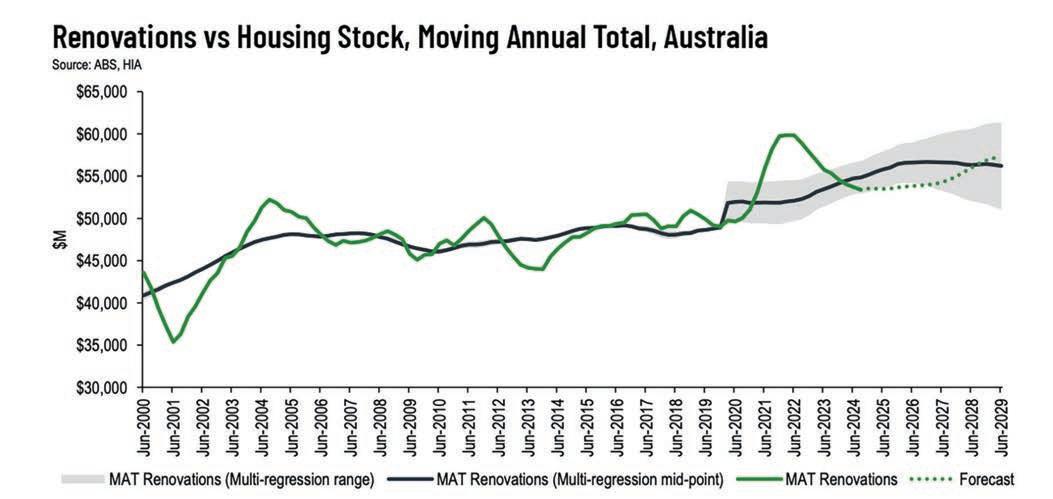

46 Improving Market Confidence to Drive Kitchen and Bathroom Activity

HIA has just released its annual Kitchens & Bathrooms Report for 2024/25, providing insight into this important sector, as well as the broader housing and renovations markets and economy. By Tom Devitt, HIA senior economist.

48 ACFA + KBDi Merger Update

With KBDi members voting in May, the merger is moving ahead with confidence.

54 School-Based Apprenticeships & Traineeships

Educational Pathways Program for MSF30322 — Certificate III Cabinet Making (Kitchens & Bathrooms).

62 NCVER 2024 R TO Outcomes Explorer

A summary of ACFA’s results in the recent NCVER 2024 training survey.

64 AFRDI Green Tick Update

ACFA has received an update from the Australasian Furnishing Research and Development Institute (AFRDI) regarding its Green Tick certification program.

68

Casual

Employment Law Changes

With the upcoming changes to casual employment laws, it’s important that employers understand their obligations.

INDUSTRY NEWS

60 Hideaway Floor Mount Range

Striking the balance between premium design and great value.

65 Salice Exedra Pocket Door System

The Salice Exedra Pocket Door System from Nover Australia features a cam-assisted sliding mechanism complemented by a linear damping system.

66 WingLine L — The Folding Door you Love, UPGRADED!

Hettich is proud to announce the latest enhancements to its most popular folding door system, WingLine L.

69 Modar® Handles at Lincoln Sentry

Styles and finishes for all types of projects; Modar® Handles are exclusive to Lincoln Sentry.

70 The Home of Beautiful Natural Stone CAV’ART Designer Stone has established a reputation as a leading supplier of natural stone with an incredible range.

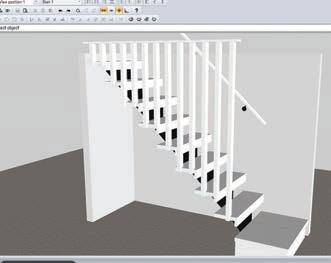

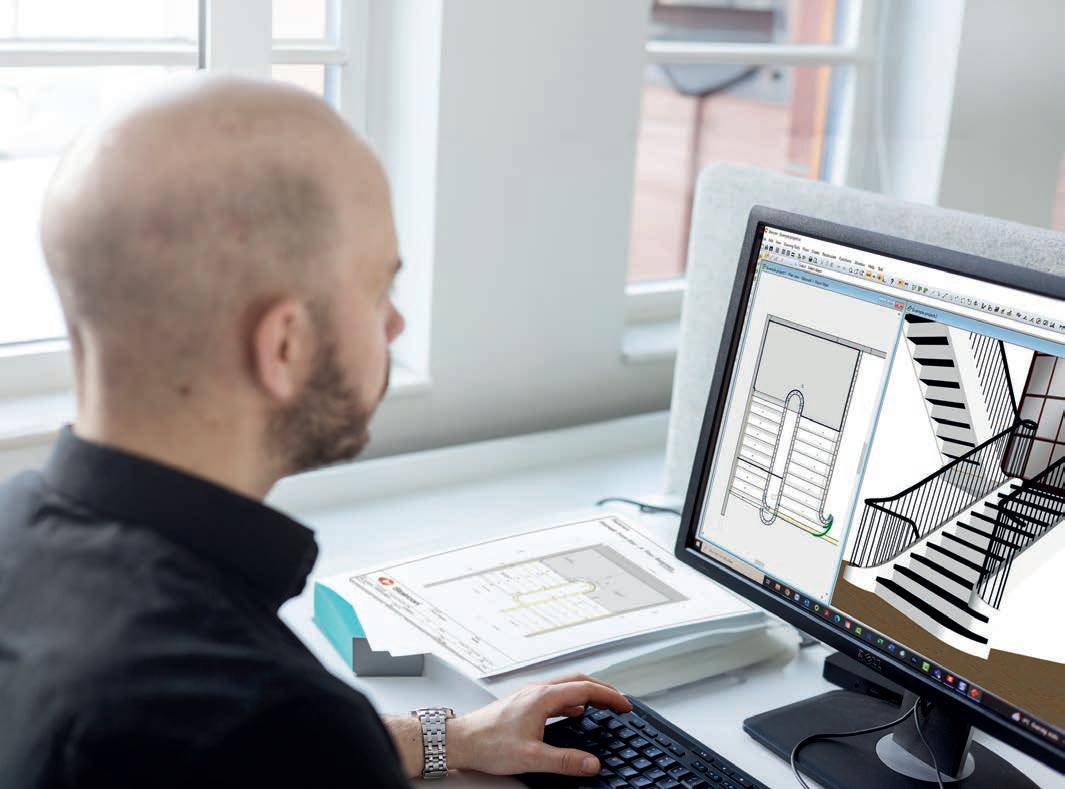

72 Transforming the Joinery Industry with VORTEK Spaces and CABINET VISION

In the ever-evolving world of joinery and interior design, staying ahead of the curve is crucial.

74 Reimagine the Possibilities for Dynamic, Multifunctional Spaces with REVEGO REVEGO by Blum is designed to optimise room functionality while maintaining a sleek, contemporary aesthetic.

76 Stair Innovations Reaches New Heights with Staircon Digitalisation is transforming how stairs are designed and built — thanks to Staircon.

77 What are the Most Profitable Cabinetry Businesses Doing Differently?

Join the Cutting Edge Expo — an event connecting close to 100 of Australia’s most innovative cabinet makers and manufacturers.

78 Saving Cabinetry with Removable Labels

Say goodbye to sticky residue and leftbehind bits of label with industry-tested removable labels, reducing labour costs and damage for cabinet makers.

79 Want to Be the Go-To Manufacturer for Cabinets?

Cabinetry.Online’s new 3D Room Planner lets cabinet makers and tradies create cabinetry designs directly from their website — without needing to purchase or install software themselves.

80 Owning vs Renting a Factory: What’s Right for Your Business

Deciding whether to own or rent your factory can have a major impact on your long-term finances and business flexibility.

82 Index

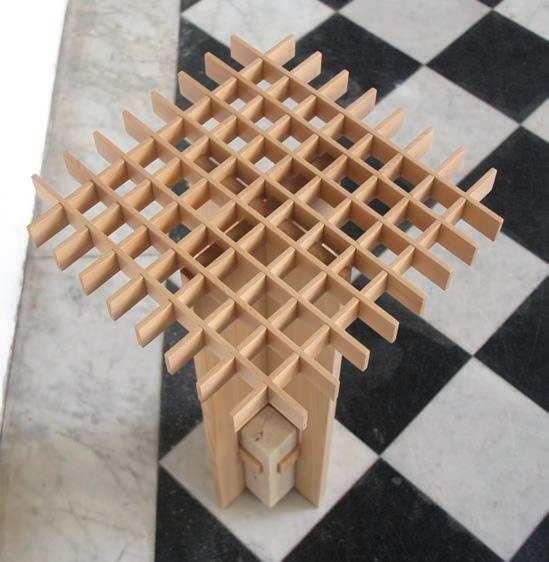

The Business of Collaboration

The power of collaboration to bridge craft and vision between cabinet makers and interior designers

By Melanie Gardener

The partnership between cabinet makers/ joiners and interior/kitchen/bathroom designers should extend far beyond the mere assembly of timber components and the arrangement of spaces. In an ideal world, this synergy should embody the seamless integration of creative vision with meticulous craftsmanship. Although we don’t always live in a perfect world, it’s worth reiterating the benefits of collaboration

Andrew Wright

between these two essential sectors of our industry, as this will ultimately benefit both professionals as well as elevate the final outcome for clients.

To get a broad view of how these relationships can best be established, we spoke to a range of professionals who have been both tradespeople and lauded designers. These wonderful people gave their time freely to examine the best of each sector and give their opinions on how we can foster communication and collaboration more broadly in the future.

Our expert contributors

Andrew Wright from Wright Designed undertook his apprenticeship as a furniture craftsman majoring in Cabinet Making in the late 1970s. He progressed from tradesman to foreman and installation supervisor and is now a Certified Kitchen Designer (Au) and Certified Bathroom Designer (Au). He is a self-employed feefor-design kitchen and bathroom designer and is a multi-award winner across a range of industryjudged competitions.

Darren Genner from Studio Minosa started his apprenticeship as a wood machinist in the late 1980s then became a leading hand and worked his way up to production manager, contracts administrator and briefing designers. He made the transition to full-time

design following exposure to exciting new design software. Studio Minosa was established in 2001 as a fee-for-design interior studio, breaking away from the commission-based model that dominated the kitchen and bathroom landscape at the time. Studio Minosa is one of the most highly awarded design studios in Australia with a multitude of accolades — currently HIA NSW Kitchen Project of the Year and a finalist in the HIA Australian Kitchen & Bathroom Awards 2025.

Gavin Hepper from Concepts by Gavin Hepper completed his apprenticeship in Shopfitting and Detailed Joinery in the mid 1990s and a move to a large kitchen company opened his eyes to the complexity of quality joinery work. He moved into joinery installation and discovered the beauty of quality joinery that was backed by good design. Gavin went on to establish a design and construct business, which has today become a full-service interior design

Business & Finance

business. Highly awarded, Gavin is currently HIA Australian Bathroom Designer of the Year 2024.

Mal Corboy from Mal Corboy Design undertook his apprenticeship in Cabinet Making in Perth from the late 1970s through to the early 1980s. Following a move to New Zealand, he started labouring in contract manufacturing roles before setting up his own feefor-service design company specialising in kitchens, bathrooms and full interiors as well as freestanding furniture pieces. Mal is a Certified Kitchen Designer (Au) and a multi-award winner in industry-judged competitions across Australia and New Zealand, as well as a finalist and winner in many significant international awards programs. He is also a professional member of the Designers Institute of New Zealand.

Nathan Wundersitz from SpaceCraft Joinery started his Certificate III in Furnishing in the mid-1990s. Today, he enjoys success with his wife and business partner, Ellen, in their business which provides full design, manufacture and renovation services from their own factory. Nathan’s love for craftsmanship started in high school with a Year 12 woodworking project and, although offered a university place, deferred that offer and took on an apprenticeship instead. Nathan is the current KBDi Certified Designer of the Year and 2024 Design Spaces Commercial winner.

Image: Minosa (Nicole England Photography)

Darren Genner & Simona Castagna Image: Nicole England Photography

Business & Finance

Enhanced Design Aesthetics and Functionality

When cabinet makers and joiners collaborate closely with interior designers from the inception of a project, the results speak for themselves. Interior designers bring their expertise in spatial planning, colour theory, and overall aesthetics, while cabinet makers/joiners contribute their technical proficiency in woodworking, material selection, and structural integrity.

Darren Genner feels that it’s imperative that designers understand the technical background of what they are designing. “You don’t want to design something that can’t be built,” he says. “We are deliberately a very technical studio so we always aim to design from knowledge while being open to learning as well."

This synergy allows for the creation of custom freestanding and built-in pieces of furniture and joinery that not only complement but enhance the overall design scheme of a space. Collaborative efforts ensure that each piece of furniture not only

Gavin Hepper

looks stunning but also functions optimally within the space.

“The whole industry benefits when we collaborate more,” says Mal Corboy. “We need to show that we’re more professional and we offer a better solution than an imported option. For me, the best products are designed locally and made locally with an understanding of the environment in which they will be installed."

Technical Expertise: Harnessing the Best of Both Worlds

One of the greatest strengths of collaboration between cabinet makers/joiners and interior designers is the merging of technical expertise. While interior designers excel in conceptualising layouts, ensuring aesthetic cohesion, and optimising spatial dynamics, cabinet makers and joiners bring in-depth knowledge of materials, joinery techniques, and structural feasibility.

Andrew Wright feels that cabinet makers should be more actively helping designers by making themselves available for consultations and providing feedback to the designer, so the designer can help the homeowner make good decisions. “It all comes down to the quality of the plans and the specifications,” he says. “Cabinet makers shouldn’t have to guess at what the designers mean if it’s not on the plans or the specifications, then it doesn’t exist."

A cabinet maker’s expertise ensures that design ambitions do not exceed practical limitations, resulting in a finished product that is both beautiful and structurally sound.

“My background has taught me to simplify things,” explains Gavin Hepper. “From a design perspective, I concentrate on the function and the form first to

Image: Concepts by Gavin Hepper (Louise Wellington Photography)

ensure it’s fit for purpose for the clients. Then we’ll add layers of materials to make it right for the look and style the clients want to achieve."

Similarly, new materials and techniques emerge regularly in the industry, from sustainable timber options to advanced joinery methods such as CNC machining and laser cutting. Cabinet makers/joiners keep abreast of these developments, advising designers on what’s possible and helping to push the boundaries of innovation.

“When I’m conceptualising something I intuitively know if it’s achievable,” says Darren. “Anything can be drawn in CAD but ultimately it has to be buildable and it’s always about the client we design for people and places so we’re focused on the outcome."

Conversely, interior designers introduce cabinet makers to emerging trends in finishes, textures, and overall styling, ensuring their craftsmanship remains in line with modern design demands.

“Designers need to specify carefully and be very clear when drawing their plans but be open to suggestions from the cabinet maker,” says Andrew. “Cabinet makers should be adventurous and open to new ideas and new materials consult with the designer and work towards a solution."

By combining these skill sets, projects benefit from both creative ingenuity and technical excellence, resulting in a harmonious fusion of form and function.

Mal says having a technical background and an understanding of how items can be built is a huge advantage when it comes to designing spaces.

“Every time I’m designing, I’m actually building it in my head,” he adds. “It’s so much more than just drawing lines on a page and if there is a stumbling block I have a good chance of being able to solve it."

Tailored Solutions for Client Needs

Every client is unique, with specific preferences, lifestyles, and functional requirements for their spaces. By collaborating, cabinet makers/joiners and interior designers can tailor their creations to meet these individual needs effectively. This customisation extends beyond aesthetics to include ergonomic considerations, storage solutions, and even sustainability preferences.

“Designers should be asking questions of their joiners — how can I make this better? Will this work? How will this function?” Darren advises. “Cabinet makers need to be open minded ask leading questions to understand the design intention and be open to exploring all avenues towards a solution."

Image: Mal Corboy Design

Mal Corboy

Business & Finance

The ability to offer bespoke solutions not only enhances client satisfaction but also sets a benchmark for quality and exclusivity in the industry.

“The benefit of all those years in the trade is the understanding of materials and what they can do and how much they cost,” adds Gavin. “This means we make better use of the budget and we know how to push boundaries when we need to."

Seamless Project Management and Execution

Successful interior design projects require meticulous planning and seamless execution. Collaboration between cabinet makers/joiners and interior designers streamlines this process significantly. Each side brings distinct strengths that contribute to a smoother workflow, ensuring deadlines are met and costly mistakes are avoided.

Mal chooses to work with a small handful of manufacturers with whom he has built a relationship over time. “It’s important to match the project with the manufacturer as everyone has different capabilities,”

he explains. “And we need to be talking all the time and working to the mutual benefit of the client."

Darren says that it all comes down to trust. “If you want to be able to push the envelope you really have to have the marriage of designer and joiner correct there has to be a synergy,” he says. “And that means making sure everyone on the project is aligned to a common goal or outcome."

Andrew agrees that the benefit of enhanced communication is a smoother and more managed installation process which ultimately benefits the client. “We will have a more efficient industry if everyone understands the products they are using so both designers and cabinet makers should be reaching out to the product suppliers to stay up to date with the latest technical updates,” he says.

The Interior Designer’s Strengths

Concept development and client liaison: Translating a client’s vision into a coherent design plan that aligns with technical feasibility.

Material and finish coordination: Ensuring aesthetic harmony while balancing functionality and durability.

Space planning and integration: Ensuring cabinetry and joinery elements fit seamlessly into the overall design.

Project oversight and communication: Managing timelines and keeping all trades aligned for smooth execution.

Nathan Wundersitz

Image: SpaceCraft Joinery (Jonathan VDK Photography; Styling by Swell Studios)

Mal adds that it’s part of his job as a designer to ensure a seamless and smooth process. “I’m working with and talking to the manufacturer all the time through a project, collaborating with them to make sure everyone is going to be happy with the end result."

The Cabinet Maker/Joiner’s Strengths

Precision and craftsmanship: Translating technical drawings into real-world applications.

Structural integrity and engineering know-how: Ensuring furniture and fittings are safe, durable, and practical.

Problem-solving and on-site adjustments: Adapting designs to real-world conditions without compromising quality.

Installation and final touches: Ensuring a flawless finish, from alignments to integrated mechanisms.

Working together on the project avoids costly revisions, prevents miscommunication, and results in a finished space that is both visually stunning and technically sound.

Nathan Wundersitz says his background in cabinet making gives him an intrinsic insight into the element he’s designing. “I can visually see it in my head as I’m designing it,” he says. “I always know if it will work or it won’t and I can usually pick up issues at an early stage and that avoids unwanted issues down the track."

Expertise Exchange and Professional Growth

Collaboration between cabinet makers/joiners and interior designers is a continuous learning experience, benefiting both parties in numerous ways.

“Find people who are like minded,” advises Gavin. “As a designer, understand the complexities of the project and pick your joiner carefully. Joiners should be emboldened to ask questions of their designers and actively be a part of the solution be confident in your own expertise to collaborate on the project."

How Interior Designers Benefit from Collaborating with Cabinet Makers/Joiners

Deeper understanding of craftsmanship: Working with skilled cabinet makers gives designers a richer appreciation for joinery techniques, material characteristics, and finishing processes. This

Image: Concepts by Gavin Hepper

Image: Wright Designed

Business & Finance

knowledge helps them create more practical and achievable designs.

Innovative material insights: Cabinet makers often work with cutting-edge materials, from engineered timbers to composite panels as well as the latest hardware innovations, and can introduce designers to new possibilities for sustainability, durability, and aesthetic appeal.

Structural feasibility awareness: By collaborating, designers gain a better grasp of weight loads, fixing methods, and construction constraints, allowing them to push boundaries without risking structural failure.

Practical cost considerations: Cabinet makers provide real-world cost implications of different materials and designs, helping designers create stunning interiors while staying respectful of budget constraints.

Problem-solving on site: Seeing how cabinet makers and joiners troubleshoot unexpected challenges gives designers insights into more flexible and adaptable design approaches.

Nathan adds that collaboration puts everyone on the same page and allows each party to contribute their expertise. “Building trust and respecting everyone’s time is important,” he says. “We all come away with a better understanding of the finer details and we can ensure a seamless and smooth transition to the finished product."

How Cabinet Makers/Joiners Benefit from Collaborating with Interior Designers

Exposure to new design trends: Interior designers keep a pulse on emerging trends, from minimalist aesthetics to bold statement pieces, inspiring cabinet makers to expand their style repertoire.

Refined finishing techniques: Working with designers often encourages cabinet makers to refine their finishes, incorporating high-end lacquers, specialty veneers, and detailing techniques that elevate their craft.

Understanding of spatial design and client needs: Exposure to the bigger picture of interior design helps cabinet makers see beyond individual pieces to appreciate how their work integrates into an entire space.

Business growth and market expansion:

Collaborations with designers often lead to more projects, as designers bring cabinet makers into highend residential and commercial jobs. This expands their client base and portfolio.

New business opportunities: Many cabinet makers establish long-term working relationships with designers, leading to repeat work, referrals, and co-branded marketing opportunities.

“It’s really about respect,” says Gavin. “The broader building industry is segmented down into micro specialists and respect should always go both ways. No one is on a higher pedestal than anyone else respect each other’s expertise."

By sharing knowledge and expertise, both cabinet makers/joiners and interior designers elevate their craft, expand their professional capabilities, and ultimately enhance the quality of the interiors they create.

Image: Minosa (Nicole England Photography)

Image: Mal Corboy Design

Nathan says clear communication goes both ways. “Cabinet makers and designers talking in the early stages of any project will ensure the ideas on the table are achievable and practical and we can avoid any costly reworks that might come up,” he adds.

Andrew feels suppliers can play a role in ensuring both sectors are adequately educated on the products available and, most importantly, on their proper application. “There are a lot of technical aspects with some products and new materials are coming out all the time,” he says. “It can be hard to keep up with everything but we won’t see successful application of products unless the designers and manufacturers fully understand how they should be used."

Competitive Advantage in the Market

In a competitive market where differentiation is key, the ability to offer integrated design and craftsmanship solutions provides a distinct competitive advantage. Clients increasingly seek personalised, high-quality interiors that reflect their tastes and lifestyle preferences.

Gavin says that both sectors have an extraordinary amount of knowledge and passion that can be applied for the greater good of the client. “If both parties can be willing to share and collaborate, be open and transparent, and tap into learnings along the way, that will build both portfolios as one,” he says.

“The end result for everyone is a better outcome for the clients, for the joiners and for the designers,” adds Darren. “If there is a synergy between the designer and the joiner that leads to transparency and honesty, and both businesses win through a more professional reputation and increased referrals and leads."

By showcasing a portfolio enriched by collaborative projects, both cabinet makers/joiners and interior designers can position themselves as trusted partners capable of delivering superior outcomes. This reputation not only attracts discerning clients but also strengthens brand credibility and fosters long-term client relationships.

“Pricing and quoting a job is where the relationship can start to unravel so it’s really important that there is a clear understanding of the client’s budget — even if it’s a range — so we can make sure we’re focused on solutions,” says Nathan.

“If you are specifying well and you understand the products you are specifying, plus how they are made

and applied then there are efficiencies through the manufacturing process which can reduce mistakes or costly remakes, leading to cost savings and increased profitability,” adds Andrew.

The collaboration between cabinet makers/ joiners and interior designers transcends traditional boundaries to create synergistic partnerships that elevate the art of interior design. Through enhanced aesthetics, tailored solutions, technical expertise, efficient project management, and continuous professional growth, this partnership not only meets but exceeds client expectations.

“I’ve seen a range of manufacturing premises around the world and the Australian/New Zealand industry is up there with the best,” Mal says. “And that’s thanks to designers stretching what can be done and cabinet makers being open to go there with them."

As the demand for bespoke craftsmanship and personalised interiors continues to rise, embracing collaboration becomes not just a strategy but a cornerstone of success in the dynamic world of interior design and woodworking.

“If you have a good relationship between designer and cabinet maker there is no resistance as all parties have been involved right from the start,” says Nathan. “The long-term impact from this collaboration is a harmonious working relationship that doesn’t step on anyone’s toes."

In essence, when craft meets vision, the possibilities are limitless, and the results are nothing short of extraordinary. ■

Image: SpaceCraft Joinery (Jonathan VDK Photography; Styling by Swell Studios)

The art of business writing for cabinet makers and designers

Words that Work

By Selina Zwolsman

In the world of kitchen design and manufacturing, it’s easy to think that the most essential tools in your belt are your CAD software, your colour samples, or your tape measure. But there’s another tool that quietly shapes your business every single day your words.

Business writing is often overlooked in trades or visually driven industries. However, clear and professional communication can be the difference between a seamless project and a stressful one. It can mean landing a dream client or losing them to someone else. Whether you’re drafting a client email, preparing a proposal, or sending specifications to a supplier, how you write matters.

In this article, we’ll unpack how business writing can enhance your design or cabinetry business, saving you time, elevating your brand, and helping you

create better experiences for your clients, teams, and trade partners.

Why Writing Matters in Manufacturing and Design

Let’s face it — most people don’t enter the cabinet making or design industries because they love paperwork. But writing is everywhere in your business: emails, quotes, design briefs, social media captions, invoices, installation notes, warranty information, award entries and more.

Good writing helps people trust you. It shows you’re organised, detail-oriented, and professional and is especially helpful to clients who may not understand what goes into a build or fitout. If you can explain your process clearly and confidently in writing, you instantly set yourself apart.

Poor communication, on the other hand, creates confusion, and vague instructions can lead to expensive mistakes. Overly technical language can overwhelm a client, and a rushed or sloppy email can make your business look careless.

Strong writing doesn’t mean flowery or corporate, robotic language; it means clarity, empathy, and getting to the point.

Step 1

Know Your Audience — Clients, Suppliers, and Teams

Writing well starts with knowing who you’re writing for. In this industry, you’re often switching between very different types of readers:

Clients

Clients are emotionally invested in their projects, and often unfamiliar with technical jargon. They need reassurance, transparency, and straightforward explanations. They also need to feel included and confident in their decisions.

Suppliers and Trades

These readers are detail-driven and need precision. Use technical terms and straightforward instructions. Where possible, set out your requirements in table format (to keep the details aligned and perfectly clear). Most importantly, avoid ambiguity.

Team Members and Subcontractors

This writing needs to be instructional and time-aware (i.e. get to the point assume the reader has 30 seconds to understand what you want). Use bullet points or numbered lists and clear formatting to avoid misinterpretation.

Adjusting your tone and detail level to suit each audience is a genuine business skill that will pay off with fewer mistakes and better working relationships.

Apply Order and Structure

Step 2

Applying structure to your writing is as essential as having processes for your manufacturing. With a set order, you’ll make sure your written task includes all the important details and is seamless from beginning to end. This is especially important in emails.

Client emails are a daily reality, and they’re often sent on the fly. However, a well-written email can set expectations, correct misinterpretations, and prevent bigger issues down the track.

The Structure of a Clear Email

• Send List: Let’s start with who you’re sending your email to. The ‘to’ field is for people who are directly affected by the contents they’ll need to understand the information, respond to a query or take action. The ‘CC’ (carbon copy) field is for people who simply need to be kept in the loop. It’s more of an ‘FYI’ email. Finally, the ‘BCC’ (blind carbon copy) should be used when you want certain people to receive the message but don’t want other recipients to know. Keep in mind that someone who has been bcc’d in an email may reply to join in the conversation, and this could offend other recipients who were unaware someone was effectively eavesdropping on the conversation. BCC should be used with care.

• Subject Line: To reflect the goal of the email e.g. Response Required: Colour Selections

• Heading: A very brief summary of what your email is about. (Remember, the first line of your email often appears directly under the subject line in your reader’s inbox.)

e.g. Colour Selections: Rubble Project (to be determined by 30 June)

Business & Finance

• Salutation: Friendly but professional.

e.g. Dear Betty (formal) or Hi Betty (less formal) Jumping straight into the body of an email without a basic greeting can come across as abrupt or a little ‘gruff’.

• Body: This is the update, question, or next step.

• Close: This usually depends on the intent of your email — is it formal or less formal/casual?

Formal: if you’ve started your email with a ‘Dear Betty’, you may wish to close your email with ‘Yours sincerely’ (very formal and a little oldschool), ‘Best regards’ or ‘Kind regards’. Or just plain old ‘Regards’ for a neutral and professional option.

Less Formal/Casual: if your greeting was of the ‘Hi Betty’ kind, you can close your email with the very popular ‘Cheers’ or ‘Warm regards’.

Step 3

Proofread Your Writing

Always, always, always proofread what you’ve written before you hit send. Use tools such as Grammarly to help with spelling and structure, and use your computer’s text-to-speech function to hear your words read aloud. If you’re a fan of ChatGPT, check technical references and ask for sources AI has a tendency to fabricate facts.

Strong business writing doesn’t mean sounding like a corporate robot — it means being clear, consistent, and kind in how you communicate. In our industry, well-worded writing can help you:

• Win more clients

• Avoid costly mistakes

• Build trust across every touchpoint

Remember, you don’t need to be a writer to write well. You just need to consider your reader, be mindful of your mission (what you hope to achieve) and be willing to improve.

Challenge: Select an email or document you’ve recently sent and quickly rewrite it using the tips above. A small adjustment in how you communicate can result in significant shifts in how your business is perceived and how smoothly your projects run.

Our Most Important Writing: Estimates, Quotes and Fee Proposals

An estimate, quote, or fee proposal is often the first document we share with new clients and is potentially the most important. This piece of writing could be the foundation of a significant business relationship, so it is essential to get it right.

While the terms estimate, quote, and proposal are often used interchangeably, they have important technical differences. Understanding these terms is valuable for establishing or refining your business processes. Regardless of what you call it, this document may serve as your initial point of professional contact with a potential client, so you will want to make a positive impression.

Estimates

An estimate can be viewed as a ballpark figure. As the name suggests, it’s simply an ‘estimation’ of how much a job will cost. Do you have limited information about the scope of work needed for a new project? Are you uncertain about the client’s commitment to moving forward with the job? In both cases, an estimate may serve as a practical way to avoid wasting time for both you and the client. Your estimate might outline a defined scope of work and allow for extras or upgrades to accommodate the extended scope. Alternatively, it could provide a range of fees to address various scenarios. Always clarify that your submission is merely an estimate and may be subject to change.

Quotations

While not always legally binding, a quotation is often seen as a more accurate representation of the costs associated with your services than an estimate. Quotes are ideal for easily quantifiable projects with few variables; if you have a clearly defined scope of work, a quote may be your best option. Since the cost of your services or related products can increase, be sure to include an expiry date for any quoted work.

(For instance, a quote issued in June this year might be inaccurate by next January, so ensure your quote isn’t open-ended.)

Fee Proposals

If you suspect you’re competing with others, consider preparing a structured and detailed proposal. A proposal might include a quotation or estimate, along with comprehensive information about the project and the services you provide. Your proposal should feature a work schedule, indicating how long you’ll need for the different stages of the project. If your schedule includes any assumptions — such as receiving prompt responses from your client — you’ll want to ensure this is clearly communicated. Additionally, if your project timeline relies on a specific start date, ensure your client understands precisely when you’ll need an official ‘go-ahead’ to secure the time frame.

Regardless of the option you present to your client, it’s essential to include the following in quotes, proposals, and any subsequent contracts:

• Business details: Providing your A.B.N. and contact information is a legal requirement.

• Costs: Detail the specifics of your services and outline inclusions and exclusions. If your business is registered for GST, you cannot exclude this tax from your estimate, quote or fee proposal. Business-toconsumer (B2C) prices must include GST.

• Variations: Explain how different scenarios or variations may influence the price and how they will be addressed contractually.

• Payment terms and conditions: Specify when you will require payments and the terms under which you operate (e.g., seven-day payment terms).

• Quote expiry date: Clearly note the date by which the quotation must be accepted,

especially if you need advance notice to fit the project into your schedule.

• Payment methods: Specify your preferred payment method if you require a deposit upon acceptance of the quotation.

• Customer acceptance signature: Include a ‘sign here’ statement to confirm the agreement.

Words may not build cabinets or install kitchens, but they do build trust, clarity, and confidence, and these are the foundations of any successful project. Whether you’re briefing a supplier, sharing instructions with your team or preparing a proposal for a new client, taking the time to communicate clearly is an investment in your business. Like any skill, good writing becomes easier (and better) with practice. So keep refining your words; they might become one of your kit’s most powerful tools. ■

Selina Zwolsman CKD Au, CBD Au is a qualified interior designer and experienced writer specialising in design and building-related content. She produces technical and editorial content for industry and training organisations, and assists small to medium business owners with web and media copy, email marketing campaigns and more. Selina has shared many design-related presentations with trade and consumer audiences and loves to promote the work of Australia’s best designers and manufacturers. Contact Selina via her website at nicelysaid.com.au.

Know Your Numbers

The five financial foundations every business owner should master

By Ben Fewtrell

Running a business without knowing your numbers is like building a kitchen without a plan. You might get the job done, but chances are you’ll waste time, money and materials, and possibly end up redoing things down the track.

The good news is, you don’t need to be an accountant to stay in control of your business finances. With a few simple tools and a shift in mindset, you can take charge of your numbers and make faster, smarter decisions.

This article covers the five most important financial foundations every business owner should understand. Master these and you’ll build a stronger, more sustainable business.

1. Budgeting — Build Your Profit In, Don’t Hope for It

Most business owners treat profit like leftovers. They pay the bills, cover wages, buy materials, and if there’s anything left in the bank, that’s their “profit.” But that’s a risky and reactive way to run a business. Profit should be planned for, not hoped for.

The better approach is to budget for profit up front. That means deciding how much profit you want to

earn, ideally as a percentage of sales, and then building your budget around that number.

For example, if your target is a 10 per cent net profit margin, then for every $100 in sales, $10 should be left over as profit. You then work backwards: What are your fixed costs? What’s your cost of goods sold? What gross profit margin do you need to hit your profit goal?

Your budget should cover:

• Sales (realistic based on past performance)

• Cost of Goods Sold (COGS): direct materials, subcontractors, and production labour

• Fixed Expenses: wages, rent, insurance, power, subscriptions

• Net Profit: what you want to keep after everything is paid

Tip: There are only three ways to improve your net profit, and your budget helps you spot where to focus:

• Increase sales

• Improve your gross profit margin (e.g. by increasing prices or selling highermargin services)

• Reduce your fixed or operating expenses

Budgeting isn’t about restriction. It’s about control. It gives you a framework to make confident decisions all month long.

2. Break-Even — The Exact Point Where Profit Begins

Most people think of break-even as the point where sales equal expenses. That’s technically true, but the real value of knowing your break-even point is this: it tells you exactly when you start making money.

Knowing your break-even helps you plan your sales targets with precision. Once you pass that point, whether it’s a certain number of units, days worked or dollars earned, every additional sale brings in profit (after covering variable costs).

The mistake many business owners make is guessing their break-even or calculating it incorrectly. A common error is putting expenses in the wrong category — for example, including fixed costs in cost of sales or vice versa. This gives you a false break-even figure and can lead to undercharging or chasing the wrong sales targets.

To get it right, you need to understand the difference between:

• Fixed Costs: rent, salaries, insurance, admin overheads

• Variable Costs (COGS): materials, casual wages, freight, production costs

A simple formula to calculate break-even sales is: Break-Even Sales = Total Fixed Costs ÷ Gross Profit Margin (%).

Once you know your break-even, break it down further. How many jobs do you need per month or week to cover your costs? What does that look like in terms of units or sales value? This turns vague targets into clear, actionable goals.

3. Cash Flow — Your Business Fuel Gauge

If profit is the reward, cash is the fuel that keeps your business running. And just like a car, if the fuel runs out, everything stops, no matter how profitable the trip might have been.

That’s why cash flow forecasting is essential. Think of it as your business’s fuel gauge. When you can see in advance that you’re getting low, you’ve got time to do something about it — whether that’s chasing overdue invoices, delaying a purchase, or bringing in extra work.

A 90-day rolling cash flow forecast gives you a forward view of:

• What’s coming in: customer payments, grants, loans

• What’s going out: wages, rent, materials, tax

• Where any shortfalls may occur

Many business owners rely on their bank balance to tell them how they’re doing. But the balance today doesn’t show what’s coming tomorrow. A forecast helps you look ahead.

This doesn’t need to be complicated. A simple spreadsheet or accounting software can help you build and maintain your forecast. And once you get into the rhythm of updating it regularly, it becomes one of your most powerful planning tools.

Business & Finance

4. Cash Gap — The Hidden Danger Between Paying and Getting Paid

You’ve paid for your materials, paid your team and completed the work. Now you’re waiting to get paid.

That waiting period is your cash gap, and it can be a major threat to your business’s financial health, even if you’re profitable on paper. The cash gap is the time between when money goes out and when money comes in. The longer the gap, the more you need to fund that difference from your own reserves, overdraft or credit.

In businesses with long job cycles or payment terms, the cash gap can quickly become a problem. Fortunately, there are ways to shorten it.

Here’s how:

• Take a legal, fair deposit. In many states, you’re limited by law to a 10 per cent deposit for residential projects. But even that can help offset initial costs.

• Use progress payments. Don’t wait until the end of a job to issue an invoice. Instead, break the job into stages and invoice along the way.

• Invoice promptly. The sooner you invoice, the sooner you can get paid.

• Negotiate supplier terms. Try to align your outgoings with your expected incoming cash to ease the gap.

• Tracking your average “Debtor Days” (how long it takes to get paid) will help you see if your gap is growing and where you need to tighten up.

5. Profit & Loss — More Than a Tax Tool, It’s Your Monthly Report Card

Most business owners have a Profit & Loss (P&L) statement, but it’s often used just for tax time or when the bank asks for it. That’s a missed opportunity.

Your P&L should be a monthly tool you review by the 10th of the following month. With cloud accounting software, there’s no reason you can’t have up-todate, reconciled figures on time.

Once you’ve got the numbers, compare them to your budget. If your sales were lower than expected or your expenses blew out in a particular area, this is your chance to investigate and adjust for next month.

Your P&L should also be set up in a way that makes sense to you, not just your accountant. That might mean reworking your chart of accounts so income and expenses are grouped in ways that reflect how you think about your business. Avoid vague categories such as “miscellaneous” or “sundry.” They don’t help you understand where your money is going.

Used properly, your P&L becomes a monthly review tool that helps you stay accountable, spot problems early and fine-tune your business strategy.

Know Your Numbers — Monthly Checklist

Use this checklist each month to stay in control of your business finances:

Budgeting for Profit

❑ Have I set a clear monthly profit target?

❑ Is my budget built around that target?

❑ Am I reviewing actual vs budget figures each month?

Break-Even Clarity

❑ Do I know the exact point where I start making a profit?

❑ Have I correctly separated fixed and variable costs?

❑ Can I express break-even in units, days or dollars?

Cash Flow Forecasting

❑ Do I have a 90-day cash flow forecast?

❑ Am I updating it weekly?

❑ Do I check it before making major spending decisions?

Managing the Cash Gap

❑ Do I know how long it takes to get paid (Debtor Days)?

❑ Am I using fair deposits and staged payments where possible?

❑ Are my supplier and customer terms aligned?

Using My P&L

❑ Is my P&L reconciled and ready by the 10th?

❑ Do I compare it to my budget every month?

❑ Is it structured in a way that’s meaningful to me?

Know your numbers. Own your decisions. Grow your business. ■

Ben Fewtrell is the co-founder and managing partner at MaxMyProfit. With more than 20 years of experience in business growth, Ben is also the co-creator of the “Business Exceleration™ Blueprint” and co-hosts the Max Your Business Podcast. He’s known for his dynamic presentations and effective business coaching, helping companies boost their sales and efficiency.

Max My Profit maxmyprofit.com.au/

Business Branding

Your brand is the heart of your business, but is it driving business growth?

By Pam Kershaw

When people think of a brand, a logo usually springs to mind the Apple icon, the Nike swoosh, the Mercedes three-pointed star.

But behind every great logo is a branding strategy that differentiates the business and communicates its value to customers.

“Branding is not just about visibility, it’s about building recognition, trust and a competitive edge in the market,” says Liza Jane Smith, founder and creative director of Monava Design and Connect magazine’s art director.

“It’s the perception clients and customers form when they encounter the business name, products or services. It’s what transforms a business from just another service provider into a recognised name in the industry.

“A strong brand creates credibility, making potential clients feel confident in their choice even before they see the finished work. With a well-defined brand, a small business can position itself as an expert in its field, attract valued clients and build long-term

relationships rather than competing on price alone,” she says.

Helen Watts, director and art director of Watts Design, says strong branding can make even the smallest start-up look well-established.

“I’ve had businesses that are one-man bands come to us. Because we’ve made them look the part from day one, they already appear like an established business and are getting work well beyond their expectations,” she adds.

Both designers agree that amateur-looking logos and brands rarely connect with customers.

“The market is flooded with cheap designers and budget branding options that promise a quick fix but lack the strategic expertise needed to build a strong, lasting brand,” Liza Jane says. “A true brand specialist does more than create a logo — they craft an identity that positions a business for long-term success."

Every customer touchpoint — business cards, website, social media, brochures, letterheads for quotes, presentation folders, signage on buildings,

work vehicles and employee uniforms should reinforce the same quality and professionalism. Consistency is key.

The Brand Development Process

At Watts Design, branding starts with a client factfinding session. The designers need to understand the business and its customers, the company’s longterm goals and if the intention is to sell the business in the future.

“This helps clients see their business from another perspective because things arise in that session which they realise they haven’t tackled,” Helen says. “They can rectify things that might prevent them from connecting effectively with the customer."

The process also addresses problems or challenges in their sector, a competitor analysis, the global market if relevant and the business’s point of difference. If there’s no point of difference, Watts Design will create one.

For example, a rural kit home company offered generic Federation-style designs that lacked a defining feature. Watts suggested adding an indoor/ outdoor fireplace and built a brand around the strapline “Home is where the hearth is."

“We designed the company’s stand for a home expo around this feature, and a large number of customers signed up,” Helen says.

In another case, a solo furniture maker needed materials for an expo. Watts developed the brand Mood Furniture around how his individually crafted furniture affected a room’s mood and feel. The strapline was “Contemporary Concept Furniture”.

The branding used a colour palette based on timber tones, with a beautiful catalogue, website and stationery range.

The client called up after the expo and said he’d won an agent to represent him after this single business contact. “I cannot believe that everyone thinks I’m massive and they love my branding. I’ve picked up so much work,” he says.

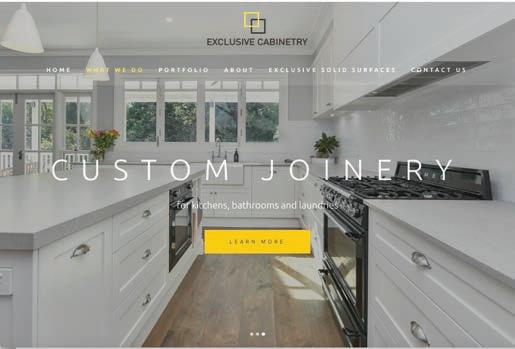

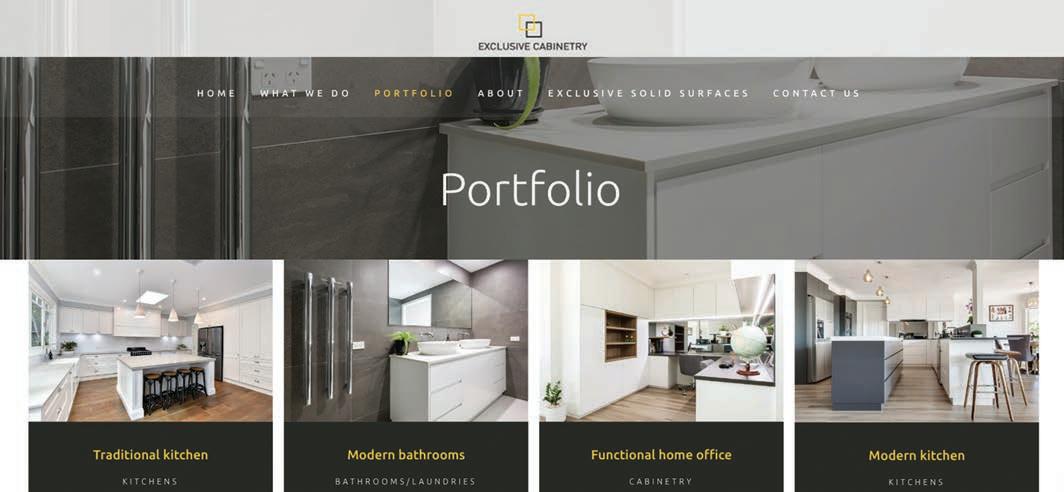

Liza Jane was involved in the rebranding of Exclusive Cabinetry, a company founded in 2014 and specialising in high-end cabinetry for kitchens, bathrooms and interiors.

“The goal of this branding project was to create a visual identity that reflected the company’s craftsmanship, professionalism and contemporary aesthetic,” she says.

The clean logo design had a minimalist aesthetic, with mustard yellow and dark grey providing a contemporary feel, strong visual contrast and good

image credit: Watts Design

image credit: Watts Design

brand recognition. The new, highly functional website layout included:

• Intuitive user interface

• Premium product images

• Easy navigation and prominent call-to-action buttons to encourage engagement

• A balance of white space and structured content

“The rebranding resonated strongly with existing and prospective clients, contributing to a noticeable increase in enquiries and new business opportunities.

“It helped open doors to new contacts who were unaware of the company’s capabilities, marking a clear step forward in the business’s growth and market presence,” she adds.

Liza Jane is offering Connect readers 25% off a corporate identity design package — ideal for launching or refreshing your brand this Winter. Email liza@monava.com.au for details.

Consistency is Crucial

Once a brand has been developed, consistency is crucial.

A branding style guide shows how the corporate colours and specific fonts should be used. It may include a style guide for social media, the tone of voice and specific wording for promotional materials and the dialogue for salespeople.

Helen cautions clients against straying from this consistent identity: “Even when they have all the tools for social media, we sometimes find they fall back into the trap of creating their own content. It looks amateurish, it’s not in line with the language we’ve created."

“Language is a huge part. It’s the emotion people can buy into, it’s where you gain trust. It’s where you can pre-empt the concerns they may have, show them you’re concerned about them and how they’re going to benefit from your product,” she adds. “Clients need to stay with the look, the colours and the dialogue because that’s the brand, that’s how they are perceived.”

Now Let’s Get Social

Social media is one of the most effective — and affordable — ways to build trust, showcase your work and reinforce your brand. Yet many small businesses struggle to use it well, says Emily Cooke, Head of Strategy at social media specialists Brandshake.

“Many don’t have the time, strategy or confidence to do it well,” she says. Common mistakes include:

• No strategy: posting randomly without a clear plan

• Content paralysis: not knowing the audience or what to say

• Overthinking: waiting for the perfect photo

• Lack of time: social media becomes an afterthought

• Focusing only on followers: not realising your next client may be watching

Emily recommends starting with a clear strategy; ask yourself these questions:

• Who are you trying to reach? (Homeowners, designers, builders?)

• What do they care about? (Style, function, timelines, trust?)

• What sets you apart?

• What are the most common FAQs from customers?

• What are the industry stereotypes you want to challenge?

• Do you have stories, testimonials or awards to share?

Choosing the Right Platform

Use demographic data (search “social media demographics”) to find out where your audience is.

Then focus on one or two platforms:

• Instagram: non-negotiable for visual businesses. Use Stories to show work in progress, Reels to show process videos, and your grid to showcase finished work.

• Facebook: still highly relevant, especially Facebook groups for local businesses and referrals.

• LinkedIn: ideal for interior designers or manufacturing businesses building B2B connections.

• Pinterest: for high-end, visual work targeting renovators and new home builders.

• TikTok: increasingly relevant — it’s not just a Gen Z playground anymore.

Brandshake offers downloadable strategy templates and a content framework at brandshake.com.au.

Use code ACFA25 for 25% off.

Essential Tools For Great Content

You’ll need:

• Good photography

• Compelling copy

• Client testimonials

• A content plan to efficiently produce batches of posts

Brandshake recommends posting at least twice a week, ideally three to five times. Tip: use Stories on Instagram to stay top-of-mind without needing polished content.

“Don’t obsess over likes — focus on what leads to business,” Emily says. Track metrics including:

• Profile views

• Link clicks

• Enquiries mentioning social media

• Saved/shared posts

• Replies to Stories

If you’re getting visibility, traffic and leads, it’s all working. If not, tweak your content type, format or message.

Business & Finance

Google reviews are powerful — prompt happy clients to leave one. A quick end-of-project survey can also generate website and social media testimonials if you ask questions about the quality of craftsmanship and materials, service delivery, ontime completion, etc.

Are Your Posts Performing?

“Consistency and showing up on social media matter more than single results and performance,” Emily says. “We want content sitting on your profiles ready for when people have had a recommendation to work with your business and are in the research and validation phase."

Tracking performance can show that your posts are working, as these real-life examples from Brandshake reports show:

Searches: eg up 575 per cent in the last seven days. This indicates people are thinking about you and have entered the 'consideration' phase. Your awareness-level marketing is working and people are moving down the sales funnel.

Impressions: eg up 12.3 per cent month to month — so more people saw your content than in the previous month. Are you being more consistent? Are you doing community engagement and outreach, where you like and comment on other people’s content? Are you posting higher-quality content that gets better engagement and is shown to more people?

Engagement rates: eg 9 per cent this month compared to an average of 2.4 per cent on LinkedIn. Indicates high-quality engagement from likes, comments, shares, saves or interaction with your content. Valuable, relatable, inspirational and entertaining content encourages higher engagement.

Is your brand on track to perform well and support your business? If not, it might be time for a brand audit and reset to drive business growth. ■

Brothers at Work

When brothers Colin and Steve Krost immigrated to Australia, they found that their family’s expertise and passion for designing and making office furniture had “stuck”

By Rob Ditessa

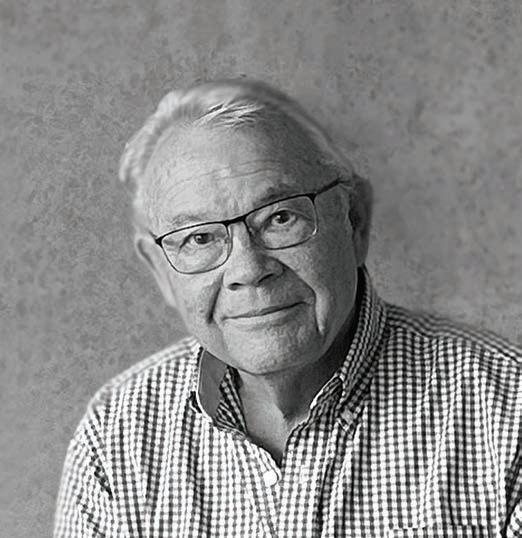

In 1989 the Krost brothers established Krost Business Furniture, totally independent from the Krost business back in South Africa, recounts Gareth Krost. He is one of Colin’s sons, and a director of the business that is headquartered in Sydney’s Mascot, with a staff of 95.

“Over the years, Krost has evolved from supplying traditional steel office furniture to designing and manufacturing products that meet the needs of a modern workplace. A shift towards locally made furniture, multifunctional designs, and solutions, that promote employee wellbeing has driven the innovations in our product range,” says Gareth.

Their success in staying profitable and relevant in an era of competition from cheap flat-pack furniture, he tells Connect, comes from maintaining a competitive edge by prioritising quality, service, adaptability, and complying with industry standards. Many products carry five- or 10-year warranties, and certifications such as AFRDI Blue, AFRDI Green, and GECA.

“We want clients to see Krost as an investment rather than a disposable purchase. We provide commercial-grade, fully assembled furniture that delivers a high return on investment by lasting longer, performs better, and that reduces the need for frequent replacements,” says Gareth. He adds that to eliminate a client’s costs associated with selfassembly, Krost offers an end-to-end “white glove” service where all products arrive fully assembled, and are installed into position, ready for immediate use.

He continues, “Our turnkey service is a core part of our business. We provide clients with a seamless service that includes consultation, design support, manufacturing, delivery, installation, and post-

Krost Family. Image supplied by Krost

installation care. It has become one of our key differentiators in the market. The demand for comprehensive project management continues to grow because businesses are looking for hassle-free, time-efficient, streamlined fit-outs. Our clients value our ability to coordinate with other trades and handle complex jobs."

He lists customisation supported by local manufacturing as another success factor. “In our state-of-the-art manufacturing facility, we can produce customised workstations, storage, and joinery, using high-quality, locally sourced materials. This guarantees that a client can achieve a bespoke look, and a tailored fit, without any compromise on lead times,” he says.

Maintaining that competitive edge requires a proactive approach to the business, stresses Gareth. “We don’t wait for the market to dictate change. We anticipate it. One of our key insights is the importance of operational agility. By investing in advanced manufacturing equipment and technology, and optimising our processes, we have significantly increased our capability to complete complex projects with short lead times. Our ability to efficiently scale up production has allowed us to win large

commercial projects where speed and precision are simply non-negotiable."

Decisions are “data-driven”. Through “real-time analytics and process automation”, Krost continuously refines operations, identifying areas for improvement in scheduling of production, use of material, and in logistics, “to maximise efficiency while maintaining high standards of quality."

But success does not come without facing then overcoming challenges.

One of the biggest challenges comes from disruptions in the supply chain, such as the ones in recent years when global logistics issues reduced availability of many materials and upset lead times across all industries, he says. With the strong relationships Krost has always fostered with suppliers, by surging local production, holding larger stock levels of key materials and components, and with a strategy of proactive stock management, Krost was able “to mitigate delays and maintain our industrybest lead times even during uncertain periods,” explains Gareth.

An ongoing challenge is balancing efficiency with customisation. “We have to retain the ability to offer

Yarra Falls Project — 452 Johnson St Photographer — Pixel Collective

Business & Finance

custom pieces at scale and at the same time remain cost-effective and efficient. To achieve this, we have invested in advanced manufacturing technology and software,” he points out.

Additionally, the shift to working from home, and the challenge of bringing people back into the office, has required a rethinking of workplace design. Businesses are now looking to create warmer, more inviting spaces that feel like an extension of home, leading to the rise of resimercial-style furniture, he explains. “We have responded by developing designs that prioritise comfort, use soft materials, and adaptable layouts, to make sure that offices remain attractive and engaging environments where employees will want to work,” he says.

Gareth sums up that these challenges have driven growth and innovation, underlain by a commitment to staff and technological development.

“We are committed to fostering a culture of learning, innovation, and professional growth,” he says. He details how the team regularly participates in certified training and professional development programs, and how they support employees to take

on specialist courses in manufacturing techniques, CAD software, project management, and workplace design. Through in-house mentoring and training, employees gain hands-on experience in different aspects of the business.

Krost contributes to the progress of the industry, says Gareth, by offering internships, and work placements for university students, to provide realworld experience in furniture manufacturing, design, and business operations. “We support apprenticeship programs, particularly in manufacturing, cabinetry, and upholstery, offering practical training and career pathways for young professionals entering the industry,” he adds.

Innovation has driven the way that Krost works, its manufacturing methods, product design, and operations, he continues. He describes how the manufacturing plant with its multi-million-dollar German-engineered equipment “has enabled us to refine our production processes to ensure consistency, accuracy, and the ability to create intricate design details that meet evolving workplace demands,” Gareth says.

Gareth is especially proud of the Remi and Casali ranges, which, he says, showcase how Krost integrated materials and methods to create a distinctive collection of tables and reception counters that are durable and elegant. He talks about the

North Sydney Project — Equifax Photographer — Phu Tang

Gareth Krost Image supplied by Krost

expanding range of height-adjustable products that cater for diverse working styles, and the latest addition to the range, two new height-adjustable workstations for collaborative work environments.

He says Krost wants employees “to customise their own work environment and promote movement to enhance workplace wellbeing”.

In the factory, among all the machinery and equipment Gareth specifically points out the recently upgraded edge banding machines which use laser edging technology, Edgetape, for “seamless, gluefree edge bonding for improved durability and aesthetics”, and the automated storage system that uses a “Kardex Remstar XP Vertical Lift Module, optimising material storage and retrieval for increased efficiency”. He adds, “We have integrated 3D CAD/ CAM software into our workflow. This allows us to design model digitally to generate machine-ready files that guarantee precise execution and minimal waste. With our advanced integrated management system, we can maintain rigorous quality assurance checks at every stage, from material inspection to final finishing."

He continues, “Beyond manufacturing, our customised ERP software has transformed the way we design, quote, and produce furniture. Our system optimises everything in the entire workflow, from order to final installation. It assures us seamless project management. And, our integration of manufacturing CAD/CAM applications for custom joinery design allows us to rapidly create prototypes, and refine products."

In the beginning the Krost brothers, Gareth points out, worked without their own manufacturing plant, instead partnering with existing local factories across Sydney to produce veneer products, partition screens, and other office furniture. As the business grew and industry trends changed, Krost recognised a shift towards more sustainable and cost-effective production methods, and that due to its cost, problems with durability and availability, the use of veneer was becoming less viable. Krost invested in its own manufacturing facilities around 2017 and moved to laminate-based production.

“This move marked a pivotal moment for Krost. It let them control quality, improve efficiency, and scale production. They could streamline operations,

Remi Table Image supplied by Krost

Image supplied by Krost

refine their products to respond more quickly to market demands. This shift laid the foundation for the advanced manufacturing capabilities that define Krost today,” says Gareth.

One of Krost’s most notable large-scale projects, he relates, was for a fit-out for the NSW Department of Communities and Justice. “We worked closely with architects, project managers, and trades to supply

commercial furniture in 66 courthouses across the state. This project required careful planning, logistics coordination, and seamless execution, to meet the complex needs of government spaces,” Gareth explains.

The project began, describes Gareth, with detailed consultations with the department to comprehend the requirements for durability, functionality, and aesthetics, of furnishings in high-traffic courthouse environments for each site, paying attention to spatial layouts, compliance considerations, and the specific needs of users. Krost provided technical drawings, product samples, and layout suggestions for each courthouse to meet the brief’s goals for sustainability and costs.

With 66 locations across NSW, logistics planning was critical, reflects Gareth. “We worked with our delivery and installation teams to develop a staggered rollout schedule, ensuring minimal disruption to courthouse operations. Our project managers liaised with contractors, IT teams, and site managers to align

Image supplied by Krost

Image supplied by Krost

furniture installation with other trades. Our installation crews handled full assembly, placement, and waste removal at each site, so that all furniture was ready for immediate use. We continue to support the department with our ongoing furniture supply and service, which showcases our commitment to longterm partnerships,” he says.

From its experience and knowledge of the industry and market, what does Krost see for the future?

Gareth says businesses are prioritising multi-functional spaces, where furniture can be easily reconfigured to support different work styles, whether for focused individual tasks, collaborative teamwork, or hybrid working setups. "The rise of hot-desking, co-working, and remote working is driving interest in foldable and stackable furniture that can be stored when not in use. The next phase of office furniture will see more built-in technology solutions, such as wireless charging, integrated power hubs, and Internet-ofThings enabled desks that adjust settings based on user preferences. Environmental Product Declarations will play a growing role in ensuring transparency and accountability in sustainable furniture production, providing verified data on a product’s environmental impact throughout its lifecycle.”

With environmental concerns in mind, Gareth sums up: “Our goal is not to just create furniture, but to design for longevity, adaptability, and minimal environmental impact." ■

Image supplied by Krost

Southern Neurology Project Photographer — Pixel Collective

Image supplied by Krost

Crafting Success

Stories of entrepreneurs in the cabinet making and furniture industries

By Melanie Gardener

The cabinet making, joinery and furniture design industries are built on a foundation of craftsmanship, creativity, and precision. But beyond the skill of the trade, running a successful business in this sector requires determination, adaptability, and a solid strategy.

Across the industry, professionals have taken different paths to establish their businesses — some following family traditions, others pivoting from unrelated careers, and some setting out with a bold vision to redefine the market.

In this article, we explore the diverse journeys of several business owners who have carved out their own space in the industry. From small bespoke workshops to larger-scale manufacturing operations, we’ll uncover how they got started, the challenges they faced, and the unique business structures they have built. Their stories offer insights and inspiration for anyone looking to turn their passion for cabinetry, joinery or furniture making into a thriving enterprise.

Colin Fardon

Colin Fardon runs a small workshop based in Lismore, NSW that focuses on custom-made furniture and antique restoration. He has studied under Geoffery Hannah for more than 20 years and has so refined his craft that he has been chosen as a recipient of a Churchill Fellowship from the Winston Churchill Memorial Trust.

Colin explains that his interest in working with timber was sparked by his grandfather whose hobby was woodworking. “I always like to work with my hands, particularly woodwork at school,” he says. “And I’d grown up with my grandfather making model cars

The Wanderer Cabinet Image by Clayton Lloyd, Flawless Imaging

Colin Fardon Image by Amy Anderson

and timber sulkies, so it felt like a natural progression." His school careers advisor suggested Colin check out a prestigious furniture maker in Lismore (Geoff Hannah) and Colin soon started taking woodworking classes on a Saturday — classes that would continue for the next 19 years.

“Before I had even finished school I’d applied for an ABN and started a side business restoring furniture,” Colin explains. “I attended my first exhibition with Geoff and some of his students when I was 16 and it really opened by eyes to what could be done."

To that end, Colin obtained a position with a local joinery business working four days per week and, on the fifth day, he continued with his woodworking classes. He also worked nights and weekends on his own projects. A trip overseas on a study tour in 2007 with Geoff and some of his students, when Colin was 19, was an extraordinary experience which allowed Colin to truly appreciate pieces of furniture he hadn’t previously known existed.

Colin’s own pieces had been starting to gain attention in the local area. A cabinet he had made for his HSC project in Queensland maple was chosen by the Board of Studies to be exhibited, and a bookcase built in mahogany and American walnut for an Exhibition of Excellence in Grafton prior to the Europe trip won him first prize.

Colin credits Geoff as a major source of inspiration and a key mentor in his development as a furniture craftsman. Geoff’s reputation as a master craftsman was well established with some of his major pieces displayed at the Sydney Opera House and Government House, Canberra, plus a key piece known as the Hannah Cabinet which is publicly owned and was displayed at the Lismore Art Gallery.

Returning after his European trip, Colin embarked on his first solo furniture exhibition which was held in Casino in 2010 and featured 15 pieces. The event was a sellout with 11 pieces sold on the opening night, some even before the exhibition opened. “That was pretty good feeling at just 22 years old,” laughs Colin. “It was also a great morale boost and, practically, it allowed me to invest in new machines." Colin’s HSC project and the first-prize bookcase both sold at this exhibition.

The success of that first exhibition meant Colin’s diary filled up quickly with commissions and restoration projects and, for the next few years, he was able to reinvest that income into new machines and updated tools.

In 2016, Colin was offered the opportunity to exhibit at the Old Art Gallery in Lismore with Geoff and some of his students. For this project, Colin wanted to push himself so he set out to create a table cabinet utilising a variety of timbers including olive, olive burl, North Queensland walnut and ebony, with 12 internal drawers behind two front doors and exquisite interior detailing created by hand. “It was small, but it was a big job,” explains Colin. “Beautifully ornate furniture has such a presence and that inspired me to make a similar cabinet but on a larger scale." When the original table cabinet sold after the exhibition, this provided the impetus for Colin to make plans for a follow-up piece, destined for another exhibition three years in the future.

“It took me a total of 1137 hours and it has 40 drawers with three secret compartments,” Colin says

The Table Cabinet