A dverti $ er Component manufaCturing Serving the Structural Building componentS induStry S The Cover story on page 48 by LimTek Solutions

Anna Stamm – Advertiser Forum: The Pretext of Being Diplomatic

Joe Kannapell: Floor Truss Technology, Part V: Current Machines

Wendy Boyd – Spida Machinery: BCMC 2023—Thanks for an Amazing Show

Todd Drummond Consulting, LLC: TDC’s Educational Session on Component Manufacturing Operations

Glenn Traylor: How Do I Maintain Lumber Grade Qualifications When I Cut Off the Grade Stamp?

Tracy Roe: Eagle Metal Celebrating Success at BCMC 2023

Edmond Lim, P.Eng. –LimTek Solutions: Pick, Cut, Build—Talking Shop at BCMC 2023

Ed Serrano – Vekta: Making the Case for Automation

Eide Integrated Systems: The Best in Industry Automation at BCMC 2023

Carl Villella – Acceptance Leasing: Why Your Local Bank May Not Be Your Best Option

Landon Boucher – MiTek: What Makes a Good Salesperson?

Thomas McAnally – The JobLine: Building Your Own Home – Part VIII Moving Inside and Cash Flow

Geordie Secord – Design Connections: Make Competition About More Than Price

MiTek Staff: Wood Member-To-Wood Member Gaps

Daniel Hensington –Simpson Strong-Tie: Top Five Most Downloaded Engineering Letters

Joe Kannapell – The Last Word Can Crooked Lumber Defeat Robotics?

A dverti $ er Component manufaCturing Serving the Structural Building componentS induStry S The Inside Articles 6 10 19 27 35 43 48 55

66 77 84 92 98 113 114 134

EMBRACE THE FUTURE OF MANUFACTURING WITH SWIFT AND EFFICIENT ADOPTION OF THE NEWEST TECHNOLOGY, LED BY THE INDUSTRY EXPERTS! 4W Tomasz Cwik Automation & Robotics Specialist tomasz@4wardconsult.com 313.513.1630 Mike Ruede Jr. Automation & Robotics Specialist mike@4wardconsult.com 951.297.0085 CONNECT WITH OUR EXPERTS 4WARDSOLUTIONSGROUP.COM THE -AUTOMATIONRACE IS ON. ARE YOU READY? BOOK YOUR 4WARD AUTOMATION ASSESSMENT TODAY.

$ er

Thomas McAnally twm@componentadvertiser.org

Editor Anna L. Stamm 800-289-5627 x 3 anna@componentadvertiser.org

Distributed FREE Via e-mail subscription Download PDF or Read on line at www.componentadvertiser.com

News of Interest and Advertising inquiries can be submitted to: anna@componentadvertiser.org An Open Forum for many sources.

Deadline 20th of each month. Articles, Trade Names, and Logos are the property of their respective owner or creator unless otherwise noted

Disclaimer: We reserve the right to refuse any advertisement or material that we deem not in the interest of the industry or the Advertiser. Permission to use content is the responsibility of the contributor including permissions to use any likeness of persons.

The Advertiser is provided “As Is” including typographical errors, omissions, and mistakes both intentional and unintentional.

Advertisers Sections 4Ward Solutions Group Acceptance Leasing & Financing Acer, Inc All Points Technical Alpine Clark Industries, Inc. Eagle Metal Products Eide Integrated Systems, LLC | ProCut, LLC EstiFrame Technologies Fitzgerald Group HOLTEC USA Hundegger USA LimTek Solutions MiTek Panels Plus ROGworx Automation Simpson Strong-Tie Spida USA The Hain Company TheJobLine Timber Products Inspection Todd Drummond Consulting, LLC Triad | RUVO | Merrick Machine Vekta Automation Wasserman & Associates Wolf X Machina Wood Tech Systems ...................................................................... 4,107 ................................................. 13,51,77 ..................................................................................... 44,88,133 ............................................................................. 33,87 ..................................................................................... 21,74 .............................................................................. 8,64 ............................................................... 14,42,43 ............................... 22,66,68 ..................................................................... 40,108 .................................................................................. 71,83 .................................................................................... 15,70 ........................................................................ 9,39,83,100 ....................................................................... 1,32,48,50 ..................................................................................... 12,84,112,113 ................................................................................. 79,87,136 ....................................................................... 46,47 ................................................ 16,62,114,122,123,124 ..................................................................... 18,19,52,78,82,94 ..................................................................... 9,29,41,65 .......................................................................... 17,87,92,98,109 .......................................................... 34,104 ...................................................... 26,27 ................................................ 2,72,102 ........................................................................ 30,54,55 ............................... 7,17,33,45,51,61,69,76,79, 80,87,89,90,96,97,100,103 ..................................................................................... 83 ............................. 13,17,20,23,24,25,31,33,38,39,53, 58,59,61,63,71,73,75,79,81,87,95,103 New & Used Equipment Saws Truss Equipment Panel Equipment Trucks & Trailers Misc. Equipment Modular Manufacturing Door | Stair | Window Equipment Giggles Safety First Calendar of Events Industry News Directory Hiring Zone Published Monthly Publisher

Believe it at your own risk!

Component Manufacturing Advertiser The Advertiser 7586 Becks Grove Road

Indiana

no reproduction in whole or in part without permission

component manufacturing advertiser Archive Copies Availabl On Line www.componentadvertiser.com Inside A dverti

Component manufaCturing Serving the Structural Building componentS induStry S The ................................................................................................ 7 .............................................................................61 .............................................................................71 ............................................................................89 ............................................................................91 ..............................................................97 ................................................101 ....................................................................................................101 ............................................................................................105 ...............................................................................106 .........................................................................................118 .................................................................................................130 ............................................................................................132

Copyright 2008-2023

Freetown,

47235

from the

Anna L. Stamm Director of Communications and Marketing Component Manufacturing Advertiser.

Don’t Be Cruel

Advertiser F Forum

The Pretext of Being Diplomatic

When you are responsible for relaying a message between two parties, do you always tell the message as told to you? If not, how much do you change it, and why do you change it?

Obviously, when it comes to altering messages, we can all agree that you don’t need to be cruel and say hurtful things. So let’s just set aside that exception and focus on less obvious cases.

For Whose Convenience?

Let’s consider the cases where someone is altering a message for a reason they deem more important than simply being direct. Often, this is justified as being for the benefit of one of the parties involved. The “oh, they would have phrased it differently, but I can be more diplomatic” alteration. But, here’s the catch – altering that message is a form of lying. And, just like lying, there can be consequences. So, was the message really changed for that person’s “benefit,” or was a different dynamic in play?

White Lies or Dangerous Miscommunication?

Yes, I have an actual situation that serves as a reminder that “being diplomatic” can be a very bad thing to do. As I was sitting with my sister in her hospital room, we asked the nurse for an update on the doctor – he had promised to come that Monday but had not appeared by late afternoon. After contacting him, she returned to tell us: “oh, he agrees with your other doctors so he doesn’t need to come.” Well, because the other doctors had most definitely not agreed on the next steps, we were very upset. We asked her to contact him again and relay our shock, disappointment, and confusion at receiving that message. Some time later, she returned to tell us he would fit us in the next day.

So, what was the true message he had told her: “he was sorry he was too busy but would come the next morning.” That message made sense. That message did not leave us wondering how our oncologist could have possibly thought anything was decided without his input or ours. That message would not have led to the confrontation we had the next day, during which we all found out what the actual messages were.

Of course, I would like to give this nurse the benefit of the doubt and chalk it up to a failed attempt to tell us a message she thought we were rather hear, as opposed to the message she was asked to relay. Even so, I wonder how much was self-interested motivation, attempting to tell us a message that would placate us, in her opinion, and keep us from asking further questions. Perhaps she was just being “diplomatic” –but unfortunately, this lie was hurtful and nearly ruined an important relationship.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #6 A dverti $ er Component manufaCturing m The

Monet DeSauw FWA 500 Floor Web Cutter

• Push Button Powered Blade Angulations

• Single Push Button Setting for 2 Blades per Side

• Electronic Digital Readouts

• Backup Mechanical Indicators

• Cuts 4 Angle Webs, Cantilever Webs (2 piece webs) & Square Blocks

• Magazine Lumber Feed for 3x2, 4x2 and 6x2 Lumber 12 1/2” to 48 1/2” Length Capacity (7” Minimum on Square Blocks)

• 60 Pieces per Minute

• (4) Internal 16” Blades & (1) External 16” Cut-Off Blade

• Pneumatic Blade Brake on External Blade

• Dust Hoods

• Belt Waste Conveyor (under saw)

• Add $4,200 for 12’ Incline Waste Conveyor (adjacent to saw)

• Add $1,900 for Extra Set of Blades

• 480 Volt / 3 Phase FOBMO

Call For Pricing

Monet DeSauw DeRobo

Linear Saw

• Automated (Truss Design Software Download) or SemiAutomated (Touch Screen Entry) Operation

• All Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup

Data

• 22” x 40 Tooth Blade on PAE Cut 1 or 2 Boards up to 20’ (2 Second Plunge Cut)

• Cut Chords, Webs, Rafters, Wedges & Stair Stringers

• Cut Long Scarfs by MultiPlunging

• Servo Positioning on Infeed, Angle & Outfeed Pusher

• Over Travel Protection

• Ink Jet Printer

• Lumber Optimization Program

• Belt Waste Conveyor

• 480 Volt / 3 Phase / 60 Amp

• Includes 5 Day Onsite Installation & Training

• Optional Monet DeSauw Live Deck, Bunk Feeder & Incline Belt Waste Conveyor FOB MO Call For Pricing

Monet DeSauw DeSawyer

2000 Automated Saw

• Touch Screen User Interface with Backup Mechanical Controls

• 3 Operating Modes: Auto, SemiAuto & Manual

• All 20 Axes of Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• Anti-Collision & Optimizing Programming

• Auto Calibration Productivity & Time Tracking

• Maintenance Diagnostics

• Variable Speed Conveyor (0-50 Flights per Minute)with Powered Hold Downs

• (1) 30” x 80 Tooth Blade (27 3/4”

Scarf on PAE)

• (4) 16” x 40 Tooth Blades (13 1/2”

Scarf on Centerline)

• Pneumatic Blade Brakes on all 5 Blades

• 16 1/2” to 20’ Length Capacity (11” Minimum on Square End Blocks)

• Vibrating Waste Conveyor Under Saw

• 480 Volt / 3 Phase

• Includes 4 Day Onsite Installation & Training

• Add $2,900 for Extra Set of Blades

• Optional Live Deck, Label Printer, Ink Jet Printer, Catcher Display & Incline Belt Waste Conveyor.

Call For Pricing FOB MO

Buy Factory Direct From Wasserman & Associates at the same price as the Manufacturer, and get the added support and care you need to be up and running FAST! WE’LL EVEN HELP SELL YOUR USED EQUIPMENT TOO!

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #7 A dverti $ er Component manufaCturing m The 800-382-0329 | www.wasserman-associates.com

NEW! NEW! NEW! NEW SAWS!

CONSIDERING EQUIPMENT? CONSIDER CLARK.

EZ-SET AUTO JIGGING EXCLUSIVE & PATENTED DESIGN

Automatic Truss Jigging System to drastically reduce setup times. Allows for 100% embedment on the table, with top & bottom chord pucks in the same slot. TopSider or standard configurations available for conventional kick-leg, walk-thru, or our new trackless 8' and 10' continuous table systems. Systems for other roller & hydraulic gantries are coming soon. Available in new machine installations or for retro-fitting your existing table. The TopSider is exclusively applicable for “kick or flip leg” style truss presses such as the Tri-Axis & Lumbermater®

FEATURES / APPLICATIONS

• Capable of 100% On-Table Nail Plate Embedment

• Two Pucks Per Slot

• 24", 26", and/or 30" Spacing

• Compatible with all current major design software

• Multiple Simultaneous Layouts

Lumbermater® is a registered trademark of Illinois Tool Works, Inc., or ITW.

EQUIPMENT FOR TRUSS & COMPONENT MANUFACTURERS WWW.CLARK-IND.COM / GENERAL@CLARK-IND.COM LOCAL 417-235-7182 • US TOLL FREE 800-743-9737

2Seconds

That'sallthetimeittakes

todrillstudsforrunningRomexorotherelectricalwireinthewallpanels

Motor: HeavyDuty5HP-3phase-220vor440v(Pleasespecifywhenordering)

MotorcarriagebearingandspindleassemblymountedonBlanchardgroundsteelplate

LinealmotionishardenedandgroundVbearingsandrails

BlockSizes: 2x4through2x12infiniteheightsettingtocenter

AirSupply: 100psi10CFM

Drills: 2wing3/4'”CarbideTippedcanaccommodatesmallerorlarger

Spindles: AlloySteelpolishedandgroundprecisionshafting

Frame: 2"SteelWithPowderCoatFinish

Covers: 10Gauge(1/8"Thick)Aluminumremovable

Dimensions: Height-60inches,Width-33inches,Depth-33inches

Shippingweight: 750lbs.-(Includingcrate)

MADEINAMERICABYAMERICANS

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #9 A dverti $ er Component manufaCturing m The 916-508-3558• ww w.thehaincompany.com SeetheStudDrillerinaction! Goto https://youtu.be/AnODX5vPesE forademonstration

Work Smar ter

Floor Truss Technology, Part V: Current Machines

By Joe Kannapell

By Joe Kannapell

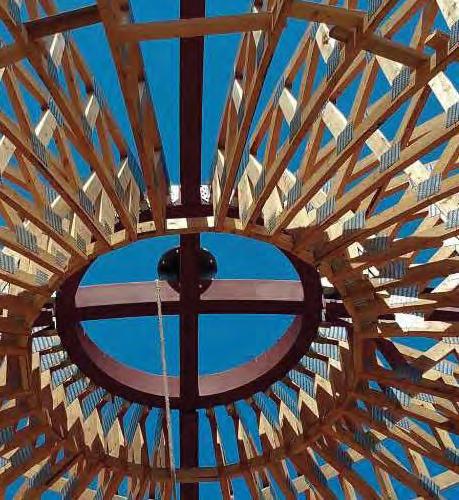

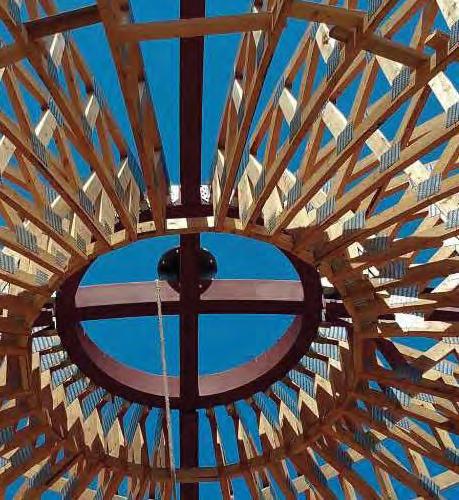

Component manufacturers learned one very painful floor truss lesson in the 1970s that needed to be remedied in the 1980s – nightmare repairs can result from plates not being fully embedded. That predicament usually resulted from insufficient tonnage to fully press the larger plates found on double chords, near off-center chases, or on special end details. Suppliers rectified this with an array of solutions, one of which broke the mold and another set the standard for the next 40 years.

Nearly all new machines in the 1980s were roller gantries, based on the 40-foot-long “flip and back plate” models of the 1970s, with one unique exception, the Structur-Span extruder machine conceived by Jim Adams, a decorated WWII pilot and TPI founder. He created the J.D. Adams Company in the 1950s, a full-service plate and machinery company that was later sold to Truswal. The Structur-Span could handle the largest and heaviest gauge truss plates, and was very labor efficient, as attested by Don Hershey and Carol Shoffner. Though it has been supplanted by other machines, the out-of-the-box design of the Structur-Span may be the best choice for floor depths greater than 24 inches and on spans up to 32 feet.

Alpine debuted its second generation floor machine, the SpeedRoll, as part of its big equipment splash at the first dedicated industry equipment show, the 1980 BCMC in Louisville. The Speed-Roll replaced Alpine’s prior offering, the System 42 Fabricator, that had a light duty vertical press head without sufficient power to seat larger plates. The very name of the new machine announced its superiority to the start-and-stop traverse of the Fabricator, or any vertical press machine. With rollers on the top and the bottom of the kick-leg table, and a larger motor than the Clary, plate embedment was much improved. And being exhibited adjacent to the venerable Roll-A-Master roof machine gave the Speed-Roll an extra degree of credibility at BCMC. At the same time, Alpine implicitly signaled its full embrace of roller technology and their intent on becoming a full-fledged machinery supplier.

Tee-Lok introduced its own version of a kick-leg machine, with air cylinders in the center of the table, each protected by adjacent skate rollers to preclude damage when a truss is flipped to the opposite side. Tee-Lok’s 24-inch rollers and powertrain provided better embedment than the 18-inch rollers on Alpine’s or Clary’s floor machines. However, on all machines with floating tables like these three, plating was compromised if the kick legs were damaged or if the floor was not level. In addition, over many years of use, and thousands of pressing cycles, these ½-inch thick tables are subject to bowing due to metal fatigue, which also negatively affects plate embedment.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #10 A dverti $ er Component manufaCturing m The Continued next page

In contrast to the equipment made by plate suppliers, a hulking floor machine arrived in 1980 from an independent that acquired a nick-name apropos for both the machine and the inventor. This behemoth, dubbed the Fatman and built by Ronnie Wright, towered over all the other roller gantry floor machines, and set a standard still in force today. The Fatman rode on the table itself, eliminating the risk posed by poorly maintained kick legs, or an uneven floor.

With this machine, Ronnie demonstrated both the welding prowess he had gained in his dad’s shop and that he honed in Clary’s plant building component saws. He left Clary in 1968 to start his own business, Production Equipment and Engineering, and built roller equipment for Alpine. In the late 1970s, he began working on a floor machine that would correct the shortcomings of existing machines.

The Fatman led the competition with the following features:

• Better plate embedment because the gantry head is fixed vertically between an elastic pad on top of a tube-steel section welded to the table and a V-shaped bearing angle welded to the bottom of the support structure.

• More accurate camber by providing separate adjustments at each jig.

• Easier flipping and ejection due to pop-up lifters on both infeed and outfeed sides of the table.

• Capability for end ejection via exit rollers in the table.

• E xpandability because the table has intermediate floor supports, additional sections can be readily added on in the truss plant.

• Operator riding platform

Hydro-Air also upped its game by doubling the plate pressing power of its Beaver floor machine from 40 to 80 tons. However, by the early 1990s, this would be of little consequence. Going forward the table-riding roller gantry machines would the preferred way for CMs to exploit the three fundamental advantages of floor trusses – longer spans, open webs, and easier installation.

Next Month: The Last Round of Floor Machines

Since 1970, Joe Kannapell has worked as programmer, Chief Engineer, Marketing Manager, and Sales VP for MiTek, plus 7 years at truss plants, retiring at the end of 2020.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #11 A dverti $ er Component manufaCturing m The

MII.COM/FLOOR-TRUSS Helping Builders Save Time + Reduce Costs Increase the value of the advanced component package you provide to builder customers with open web floor trusses. Builders who partner with their component manufacturer to design their builds using floor trusses can gain efficiencies in shorter cycle times and reduced waste compared to I-Joists. Are you ready to help builders design for floor trusses from the start? Talk to a MiTek Representative to get started.

2004 Omni Miser Saw

• Model RTWF (Automated Rood Truss & Wall Panel Cutting Saw)

• 5 HP Motor with 16" Blade (cuts 2x3 through 2x12 up to 16' in length)

• Ink Jet Printer (Two Faces)

• Incline Live Deck

• 6 Magazine Feeders - (3) 2x4 and

•

• Spare

•

•

•

•

Safety Speed Manufacturing Model

7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

$14,499 Base, FOB MN. Wood Tech Systems 765-751-9990

www.woodtechsystems.com

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #13 A dverti $ er Component manufaCturing m The SAWS

Start smarter... Grow faster... Achieve more... cvillella@acceptlease.com | www.acceptlease.com 894 Beaver Grade Road, Suite #304 - Moon Township, PA. 15108 Phone: 412-262-3225 Fax: 412-262-1154 Keep More of Your CASH Eliminate Yearly Financial Reporting Low Fees Fixed Payment Programs No Additional Collateral Now offering short term Working Capital Loans “Serving the Component Industry Since 1996” Start smarter... Grow faster... Achieve more...

NEW!

(3) 2x6

Feeder

• Bunk(Bulk)

with Enclosure & Stand

• Computer

Waste Conveyor

Incline

Parts

Dust Collector

Grizzly

Phase

480 Volt / 3

Feeder #1 does not work

Magazine

length/angle accuracy

10% of the cuts

Currently has

issues on about

available upon request

FOB WI

& Associates

765-751-9990 www.woodtechsystems.com Safety Speed Manufacturing Model 6400 Panel Saw Safety Speed Manufacturing model 6400 vertical panel saw, 3 HP worm drive motor, 64 inch crosscut, 1 3/4" inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 120 volt. Starting at $5,799 FOB MN. NEW! REPRESENTATIVES 765-751-9990 www.woodtechsystems.com New Monet FWA-500 AC Automated Floor Web Saw Call For Pricing FOB MO Additional Information Here NEW!

• Video

$15,000

Wasserman

800-382-0329 www.wasserman-associates.com

THE NEWEST PANEL DESIGN PLATFORM AVAILABLE

TRUEBUILD ® LAYOUT WITH PANEL DESIGN FUNCTIONALITY WAS WRITTEN FROM THE GROUND UP TO DELIVER COMPLETE MODEL CONTROL TO PANEL DESIGNERS.

Learn More About Our W all Pan e l F u nctionalit y at Ea gle

#TIMETOBUILD

EMPOWERING GREAT COMPONENT MANUFACTURERS

Plates. Hangers. Fasteners. Connect with the industry standard.

Over the years, many truss and component manufacturers have come to rely on code-listed truss connector plates from Simpson Strong-Tie. Known for strength, quality and reliability, they’re part of a total solution that can help your operation run even more efficiently. Choose from a wide selection of framing angles and straps. Specify heavy-duty girder hangers. And secure them all with speed and ease using our Strong-Drive ® structural fasteners. Backed by industry-leading product availability and service, you can take truss components — and your business — to the next level.

Find out what a total solution can do for you. To learn more, visit go.strongtie.com/componentsolutions or call (800) 999-5099.

Integrated Component Solutions | Products, Software and Service for Smarter Building

© 2023 Simpson Strong-Tie Company Inc. TRUSS23-HARD

Equipment Wanted!

Saws

Automated Component & Linear Saws (2010 & Newer)

Monet DeSauw or TimberMill

Manual Component Saws

Floor Web Saws

Spida (Apollo) Saws with Truss Automation

Bunk Cutters

Truss Equipment

Roller Gantry & Hydraulic

Press Systems

Finish Rollers

Truss Stackers

Floor Truss Machines

Lumber Splicers

Jack Tables C-Clamp Presses

Trucks &

• Stretch Roll-Off Trailers

• Go oseneck Roll-Off Trailers

Modular

• Pacific Automation or MiTek Mobile Home Press Contact

Terminailer XP

Price: $224,000

FOB: MN

800-382-0329 | www.wasserman-associates.com

Don’t just do it, nail it. It’s a brand new day in wall-panel production, with a whole new way of doing things better.

Terminailer®, a revolutionary, event-driven, nailing machine that completely defies any preconceived notions about sub-component assembly.

Terminailer all but shatters the stereotypical myth that subcomponent equipment is essentially peripheral – unimportant. And it does so by quickly and accurately driving far more framing nails in your wall panel jobs than ever before. Whether in your shop or in the field, one operator sets the pace for production and quality. And that reduces labor costs and other aspects of overhead.

Terminailer is an event-driven, sub-component assembler that will quickly and accurately drive 30% to 70% of the framing nails in any wall panel job. In your shop or in the field, one operator sets the pace for production and quality. The Terminailer functions independent of design software, requires zero set-up time when switching between any configuration, and requires no special operator training.

The Terminailer is easy to move around the shop so it’s location can evolve as your shop evolves. With all of the nailing occurring in the closed main chamber, nail injuries and nail location miss-fires are eliminated, making your plant that much safer.

With nearly ten years of development from people that know machinery it is assembled to exacting standards, well supported, and it is easily maintained with shelf-item parts. Terminailer: vetted, tested, and ready to drive maximum productivity for you. Be sure to check out our videos below for a quick review of this revolutionary machine!

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #17 A dverti $ er Component manufaCturing m 800-289-JOBSJobLine.com, inc. Time To Hire? We’re here when you need help! visit: www.thejobline.com email: twm@thejobline.com STRICTLY CONFIDENTIAL! 765-751-9990 www.woodtechsystems.com NEW!

Trailers

Equipment

for a Fair Market Value Assessment of your Used Equipment Operational, Needs Work, and Parts Only equipment will be considered! SAWS Whirlwind Model 1000 Cut-Off Saw

5 HP Motor with 14" Blade • 2 3/16" x 8 1/4" Capacity • Pneumatic Blade Guard/Lumber Clamp • Foot Pedal Control

Dust Collection Outlet

460 Volt / 3 Phase

1 Left Hand & 1 Right Hand Model Available $3,500 Each FOB NC Wasserman & Associates 800-382-0329

Wasserman & Associates

•

•

•

•

www.wasserman-associates.com

The PieceMaker

Fast, accurate cutting for your manufacturing centre.

THE AUTOMATED LINEAR SAW EVERY TRUSS PLANT NEEDS

US fabricators agree they are loving the PieceMaker in their production facility. Full optimisation with the ability to look ahead panel by panel or job by job. Cuts standard and custom mitres, birdsmouths, raking plates and studs, low angles, long cuts, large timber sections and all your normal standard cutting.

With a short lead time to have installed in your factory, enquire about the PieceMaker today!

spida.com E sales@spida.com T +1 866 647 7771

By Wendy Boyd Chief Customer Officer Machinery Group Spida Machinery

BCMC 2023—Thanks for an Amazing Show

The word I used to describe BCMC 2022 in Columbus last fall was “awesome,” so choosing a single word for 2023 I have to pick “amazing.” From start to finish, everyone participating in this year’s Building Component Manufacturers Conference in Indianapolis, from attendees and exhibitors, did an amazing job making this one of the best shows yet!

As promised, we featured our Raked Wall Extruder and Frame Line, demonstrating how we can speed up any manufacturer’s wall line for both raking walls and common walls. Our new machinery is designed to improve efficiency and increase productivity, and it will streamline processes, reduce setup times, automate tasks, and enhance workflow integration.

We were pleased to introduce our new Automated Roller Plant Truss manufacturing line that will reduce operational costs and save on maintenance. In single or multiple truss set-up, this new technology will handle the intricacies needed to get your jobs done.

And of course, we showcased the PieceMaker, the most cost-effective and intuitive Linear Saw on the market. Thank you to everyone who visited the booth to talk about our machinery and attend our live sessions!

I couldn’t have asked for a better show—it truly was amazing. On behalf of our entire Spida team, thank you to everyone for making it possible!

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #19 A dverti $ er Component manufaCturing m The

4,001,398

That’s the total trigger count from all six nail guns combined on an installed Terminailer.® For a machine that was a little over two years old, that is a big number; a real tribute to the durability of the machine’s components and engineering.

Yes, that number represents a pretty darn impressive mechanical milestone to be sure, but what is really impressive is that human hands were saved from millions of repetitive motions and potentially costly nailing accidents.

With just a sole operator, Terminailer drives a whole lot of improvement in efficiency and output. This amazing sub-component assembler quickly and precisely drives 30% to 70% of the framing nails in any wall panel job—be it batch, or just–in–time production. All with no complicated training, software or set-up time required when switching configurations. Add increased safety and easy maintenance with off-the-shelf parts, and you can see why Terminailer should be driving greater productivity in your plant.

Put things together like never before.

www.TERMINAILER.com 765-751-9990 Terminailer ® is a registered trademark of Construction Industry Innovations, LLC Copyright 2023 All Rights Reserved

Terminailer® and

Terminailer XP

IntelliVIEW Suite Manage. Design. Build.

The industry’s most powerful integrated component design, engineering, and management software for steel and wood-framed structures.

iCommand

Manage projects, customers, materials, pricing & inventory

iModel Design truss layout & profiles

iDesign Optimize material usage & engineer trusses

iPanel

Design wall layouts, panelize, bundle, break & stack

eShop

Maximize crew productivity & improve manufacturing efficiency

The IntelliVIEW Suite is a fully integrated software solution for the layout and design of a building’s rough framing elements—including roof and floor trusses, wall panels, solid sawn, EWP, sheathing and various ancillaries.

The IntelliVIEW Suite provides the industry’s most complete analysis of the design, cost information and bill of materials—promoting increased profits by reducing plate and lumber use.

Ask those who know. They’ll tell you about the people at Alpine who make a difference.

BUILD MORE. alpineITW.com | 800.521.9790

ProCut™ UC Linear Saw Series ~ Safe. Accurate. Clean.

Precise cutting up to 4-boards high! The ProCut™ UC Linear Saw Series is configurable to any assembly line; providing a safe, accurate way to cut your lumber, while keeping your materials moving on your line.

Maximize your output with ProCut™ Material Handling Systems

Load the ProCut™ with a stockpile of lumber strategically positioned near the Linear Infeed Conveyors. Select and arrange the materials according to their processing sequence. The lumber is then supplied to the ProDeck™ Lumber Infeed, where it gathers and is delivered to the sawyer for processing.

After being cut by the ProCut™, the material is transported to an accumulator where it is assembled and combined with all the other components required for the job. From there, the material is conveyed to the staging area at each truss assembly workstation. The staging areas at the table provide an uninterrupted supply of perfectly cut and organized material.

Enhance the efficiency of your plant by removing carts and reducing congestion in staging areas. By utilizing the ProCut™ saw along with the ProDeck™ and our Custom Material Handling Systems, you can customize a setup that optimizes the flow of precisely cut parts and materials, delivering them directly to your assembly stations.

The ProCut™ UC Linear Saw Series offers many variations to suit your plant and assembly line. Let us design a system for you.

UC LINEAR SAW SERIES ™ UC LINEAR SAW SERIES ™

Cut materials at the staging area of each truss assembly workstation.

Cut materials organized and staged with all components for the job.

ProCut UC - 4 Linear Saw

ProCut LLC (612) 521-9193 www.eidemachinery.com/emsi-procut/

2006 Alpine AutoMill SC

Automated Component Saw

• Model 348B

• Automated Setup via Download or Semi-Automated Setup via Touch

Screen Input

• 23 Axes of Automation

• Sets up in 2 to 15 Seconds

• Five Blades cut 2x3 thru 2x12 up to 20'

• Waste Conveyor (under saw)

• Excludes Incline Waste Conveyor (adjacent to saw) and Live Deck (in fronnt of saw)

• 480 Volt / 3 Phase

• Video available upon request

$38,900 NOW $32,900 FOB TX

Wasserman & Associates

800-382-0329

www.wasserman-associates.com

2001 Alpine AutoMill RS Component Saw

2001 Alpine AutoMill RS component saw, model 343H. Computer controlled saw sets up in 2 to 19 seconds and downloads from a network or by using a touch screen for ease of operation. Windows 98 operating system. Five-head automated component saw works in both automated (downloading files) and semi-automated control via touchscreen input. It has [23] axes of automated movement, enhanced diagnostics, auto management reporting. Cuts from 13″ to 20′ long material in size range from 2×3″ through 2×12″. Includes [3] 18″, [1] 22″ and [1] 32″ blades with air brakes and belt under-saw scrap conveyor. 480v/60Hz/3Ph power.

$28,997 FOB FL

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Safety Speed Cut Model 7000 Panel Saw

Safety Speed Manufacturing model 7000, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00). $10,199 Base, FOB MN.

New L-M Equipment Verticut 2000 PET / Bunk Saw Station

The L-M Verticut 2000 is a true Precision End Trim (PET) saw that is capable of holding a 1/16th accuracy all day long. Made in the USA, the V2k comes equipped with a 15 HP 460/230 volt High-E three phase TEFC motor driving a Double ended Premium “Stellite” inlaid saw bar with a spring loaded chain tensioner and an automatic oiler to lubricate the .404 pitch custom profile semi chisel saw chain.

Rather than a single pivot-point, the saw assembly is mounted on a mandrel box that is guided by cam followers on a steel frame that is raised and lowered by a hydraulic cylinder. A console with the saw controls moves with the saw assembly along a track positioned using a manual “V” wheel geared drive or optional Hydraulic drive

The V2k is unlike other imported systems that are basically a Portable Yard Saw on a cutting rack with a best cutting accuracy of +/- 1/8″ (meaning up to ¼” accuracy variance between units of lumber). The V2k from L-M provides +/- 40 thousands, assuring consistent PET precision from unit to unit.

Another advantage L-M has over the competition is their commitment to personal service with unlimited phone assistance and technical help. Their team has traveled the country working on crosscut saws for many years and they know their equipment inside and out. L-M is a familyowned business that prides themselves in doing the job right and building long term relationship that is vital to their business: “Built to last as long as our customers since 1946”.

Price based on configuration

FOB OR

765-751-9990

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #23 A dverti $ er Component manufaCturing m The SAWS 765-751-9990 www.woodtechsystems.com

NEW!

www.woodtechsystems.com

NEW!

Call

Condition: New Location: MO

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #25 A dverti $ er Component manufaCturing m The 765-751-9990 www.woodtechsystems.com NEW!

New Monet DeSawyer 2000 Component Saw

New, Monet DeSawyer 2000, computerized, five-bladed component saw, sets up in 15 to 17 seconds, can run in manual mode, downloads projects from a network or manually using display screen controls. Features all powered movements, cuts from 15" 90/90 cuts to 20 foot length, 2 x 3" to 2 x 12" lumber depths and internal brakes are standard. Options include enhanced servo controls featuring autocalibration, catcher's display and either shaker or belt scrap conveyor and incline. 440 volt, 3 phase electrical. for Pricing

All Things Being Equal, a Gain of Three Net Profit Points is a Low Bar for TDC. A Gain of Only One Point Would Easily be 10x the TDC Investment for Most Companies

All Departments Sales, Design, Manufacturing, and Admin

✓ Proven and Practical Process Improvement with Lean Manufacturing based on Refined Industrial Engineering.

✓ Increase Overall Productivity in all Departments. Not Just the Manufacturing Area.

✓ Achieve Real Labor Reduction Costs Per Sales Dollar.

✓ Reduce Mistakes and Improve Quality.

Equipment and Building Design Recommendations

✓ Material flow, Equipment, and Building Design.

✓ Unbiased with Absolutely No Referral Fees.

✓ Too Many Vendors have Suggested Costly Facilities and Equipment Choices with Significant Constraints that Could have been Avoided with TDC.

Time Standards Development

✓ Productivity Scheduling, Efficiencies Measurement, Productivity Incentive Programs, and Labor Cost Estimations.

✓ Units based on Work Minutes, R.E., or S.U

✓ See Article: A 1 Industries – Leader in Wood Truss Industries

Proper Productivity Incentive Programs for All Departments

✓ Based on Proven Industrial Engineering Practices

“…. Todd’s services included plant efficiency, design efficiency, better organization, man minutes per truss type, and more.

Just implementing a few of Todd’s suggestions will more than pay for his services in a short amount of time. …”

“….It was an investment well spent because I not only learned a completely different way to view labor metrics, but I came out of it with a completely different mindset on pricing, scheduling, and staffing. ….”

www.todd drummond.com todd@todd drummond.com (603) 748 1051

Brad Emmert—President Brazil, IN

Shane Soule President Bremen, IN

Read Dozens of Client Testimonials (Link) Referrals for Well Established Expert Services Lumber Purchasing Streamlined and Simplified Expert Recruiting Services for Mid to Executive Level Personnel Quote Roof, Floor or Panels 10x Faster than Using the Design Programs AppWright—Seamless Project Communications For Every Department

TDC’s Educational Session on Component Manufacturing Operations

If you were unable to attend my educational session at BCMC, Component Manufacturing Should Not Be Operated as an LBM Supplier by TDC, or if you attended and still have questions, I invite you to download the presentation, now available as a PDF.

During the presentation, we discussed what should be industry norms but are not. If your group is open to exploring this new information, you may gain a fresh perspective on your business.

Key Topics Covered:

• Work Minutes: Learn why work minutes offer better pricing, scheduling, and effective incentive programs, making them a superior measurement for wood trusses.

• Employee Demographics: Understand the differences in employee issues and explore what can be done differently.

• Potential Net Profit Gains: When implementing better practices, learn what are the potential net profit gains.

• Additional Considerations: Explore related topics, including why Just-In-Time is the number one lean tool, often misunderstood and misapplied.

Highlights from the educational presentation,

“Component Manufacturing Should Not Be Operated as an LBM Supplier by TDC,” include the following:

1. The Fallacy of Using Board Foot Units vs Work Minutes (R.E., S.U., Man-Minutes)

• Component Manufacturers (CMs) are in the business of creating manufactured products, not simply reselling lumber units. This approach is based on proven methods from Ph.D. Industrial Engineers.

• It’s crucial to explore the significance of using work minutes as a much more accurate measure for pricing, scheduling, and assessing productivity.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #27 A dverti $ er Component manufaCturing m The

Continued next page

Todd Drummond

• Discover the typical gains that can be achieved when employing proper work minutes based on Industrial Engineering practices.

2. Two vs. Three Assembly Crew Labor and Productivity

• Consider the economic aspects of employing two assembly crew members vs. three for labor savings and potential gains.

• Reflect on why your group might be led astray in terms of equipment recommendations and the design of new facilities.

3. In dependently Owned CM Locations vs. LBM-Owned CM Locations

• Gain an understanding of the net profits typically achieved by independently owned CM locations in comparison to their LBMowned counterparts.

• Challenge the misconception that LBM operators can afford to sacrifice a few net profit points in exchange for gaining additional sales.

4. Challenges in LBM-Owned CM Operations

• Approximately 50% of CM operations owned by LBM companies face significant challenges in their relationship between LBM sales personnel and CM operations, even after years of operation.

5. Impact of High Employee Turnover

• High turnover results in a workforce divided into thirds: 1/3 with three or more years of experience, 1/3 with 1 to 3 years, and 1/3 with continuous turnover.

• Understand that high turnover leads to sales and net profit losses and that addressing personnel issues is more effective than simply investing in additional equipment.

6. Employee Practices and Profit Margins

• Find out how much CM operations with poor employee practices lose in potential net profits.

You can download the complete 20-page educational presentation, which contains easily comprehensible information, by accessing this link to TDC’s SugarSync PDF file: Component Manufacturing Should Not Be Operated as an LBM Supplier by TDC.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #28 A dverti $ er Component manufaCturing m The

Continued next page

If you and your team aspire to achieve more in less time, consider TDC’s proven results in process improvement of employee practices, pricing, truss labor estimation, and other best-in-class practices. Tailored solutions are designed to meet your specific needs, going beyond typical software and equipment vendor recommendations.

Embrace the Drummond Method, and your company can realize cost savings and net profit gains that typically take months or years to accomplish, all within weeks or months, resulting in an average of 3 to 6-point net profit gains for CMs. All areas are addressed, not just manufacturing.

Don’t just take my word for it—read testimonials from satisfied clients with decades of expertise and experience: TDC Testimonials.

Website: www.todd-drummond.com

E-mail: todd@todd-drummond.com

• Phone (USA): 603-748-1051

• Copyrights © 2023

HSF Hain Systems Framer

Electrical Supply: 110 VAC

Motor: 1/4 HP, 110 VAC, Linear Actuator

Highly Accurate: +/- .010 Inches

Stop Rail: 2 x 4 x 1/4 Aluminum Extrusion

The Hain Systems Framer (HSF) will help you build square and accurate wall panels for residential or commercial construction applications. It will help you cut building costs by saving time and improving your quality. It’s a reliable, efficient and proven system that features a ruggedly simple design. The HSF is based on a proven design with over 20 years of actual production use and maintenance experience. It comes fully assembled and is designed for portable job site framing or in-plant permanent installation. The table has many optional attachments and will support Mylar Tape wall layout or any other type of layout. The optional gun rails can also be retro-fit to any table.

Stops: Jig Bored Steel

Stop Blocks: Machine Billet Aluminum

Details:

Internal Components: Hardened, Ground and Polished Steel and Billet Aluminum

Dimensions:

Length: 5 feet (60”) to 60 feet (720”)

Table Construction: Thick-wall Structural Steel Tubing, Jig Welded for Accuracy

Height: 12 inches

Depth: 12 inches

Air Supply: 90 psi (10 CFM Air Flow Recommended)

Electrical Supply: 120 VAC

Powder Coat: Industrial Gray

Dimensions: Height: 43”

Length: 16’ or 20’

Width: Adjustable 8’ to 10’ or 8’ to 12’

Shipping Weight: 3000 lbs

If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing setup. The MEA is versatile allowing “left” or “right” handed operation and measurement in “feet and inches” or “inches” depending on your preference. The MEA is also available in a “Skid Mounted” version.

theHAINCOMPANY 6125 Enterprise Drive, Unit 9 | Diamond Springs, CA 95619 530.295.8068 | sales@thehaincompany.com

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #29 A dverti $ er Component manufaCturing m The

Electrical Supply: 110 VAC Motor: 1/4 HP, 110 VAC, Linear Actuator Highly Accurate: +/- .010 Inches Stop Rail: 2 x 4 x 1/4 Aluminum Extrusion Stops: Jig Bored Steel Stop Blocks: Machine Billet Aluminum Internal Components: Hardened, Ground and Polished Steel and Billet Aluminum Dimensions: Length: 5 feet (60”) to 60 feet (720”) Height: 12 inches Depth: 12 inches If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing

IT’S ONE THING IN LIFE TO MAKE THE CUT. IT’S ANOTHER TO MAKE IT BETTER.

Designed for high-volume floor truss web output with even greater safety, the Monet DeSauw FWA-500 AC (for “automated controls”) offers the very latest in operator-friendly saw technology. Perfect for manufacturers running floor trusses in large volumes with variable web design, the 500 AC features automation for all blades, including the fixed cut-off blade for minimal waste. And without any need to open the saw motor cabinets, except for periodic service, you’ll benefit from enhanced safety as well. You might say that with the fully automated FWA-500 AC, Monet DeSauw has set a new standard. Again. Contact us today to discuss how this exceptional machine can positively impact your production goals.

765-751-9990 www.woodtechsystems.com

Wood Tech Systems is a registered trade name of Wood Truss Systems, Inc.

One month after installing a Double Lumber PickLine to feed two TCT Linear Saws:

"We are getting 3,000 to 5,000 bdft more each saw, than we were getting before the install.

We have shut down one Cybersaw and one TCT chord saw.

This equals about 3 less people 10 hours, and 2 less forklifts 10 hours.

Overall, it is a major improvement to our operation. We hope to have the chance to run it two shifts to further accelerate the payback.”

Tom Hollinshed, Owner

LimTek Solu�ons Inc.

6021 Yonge St., Unit 1019

Toronto, ON M2M 3W2

Tel: (416) 888-4457

Edmond.Lim@LimTekSolutions.com

Edmond.Lim@LimTekSolu�ons.com

LimTekSolu�ons.com

2004 Mitek Cyber A/T Component Saw

• Frame #433 - December 2004

• Fully Automated 5 Blade Component Saw

• 1-32" and 4-20" Blades cut 2x4 through 2x12 up to 16' in Length

• Touch Screen Computer with Computer Upgrade in 2014 (Windows 10)

• Catcher Display Screen

• Belt Waste Conveyor (under saw)

• Spare Blades & Parts

• 240 Volt / 3 Phase

• Electrical Transformer available at addition expense

• Excludes Incline Waste Conveyor (adjacent to saw)

• Videos available upon request $63,500 NOW $59,900

MA

New, DeRobo linear saw by Monet organizes "fill" boards to increase optimization of each board, can produce unlimited scarf cuts, cuts 1 or 2 boards at a time and cuts webs, chords, wedges, rafters and open-stair stringers. Works with all major connector plate manufacturer's software. Features include 22 inch blade, left-to-right feed direction standard, lumber push and pull grippers for more accuracy, ink marking on the 1 1/2" face of the incoming boards and small piece capture and delivery to the front of the saw for easy access. Infeed deck and bunk feed are shown as options only. 480 volt, 3phase. Call for pricing, FOB MO.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #33 A dverti $ er Component manufaCturing m The Your Solution for Lack of Technical Staff ● PlanSwift Lumber and Building Material Takeoffs ● Truss and Wall Panel Design Experienced Staff ● EWP Layouts and much more! Eliminate your lack of technical resources to grow sales and increase the clock speed of your company Dave.AllPoints@gmail.com • www.AllPoints.Tech The Gold Standard in Technical Support Teams 800-382-0329 | www.wasserman-associates.com REPRESENTATIVES 765-751-9990 www.woodtechsystems.com

Monet DeRobo Linear Saw

New

NEW!

FOB

The truss industry relies on 3rd party quality assurance services to provide random visits to review the plants Quality Assurance program along with their operations. If your plant needs to comply with the IRC, IBC and to those who depend on solid, experienced QA expertise, we ask you to consider selecting Timber Products Inspection, Inc. (TP) as your choice for 3rd party inspections.

Proudly serving the forest products industry for over 50 years, TP brings the expertise you need to ensure your business is successful. As a responsible partner, TP delivers to clients, employees, and the industries we serve the confidence to drive value through the effective use of our diverse professional team.

TP would like to welcome the following authorized agents to our inspection team, each of whom have many years of experience in the truss industry!

• Al Coffman

• Jean Hart

• Curt Holler

• Chuck Ray

• Glenn Traylor

• Elliot Wilson

If you have questions about how you can make this selection, please contact your authorized agent above or Glenn Traylor at 919-280-5905 or trusguy@gmail.com.

https://www.tpinspection.com/ https://www.tpinspection.com/auditing-services/truss

Read/Subscribe online at www.componentadvertiser.com

By Glenn Traylor

How Do I Maintain

Lumber Grade Qualifications When

I Cut Off the Grade Stamp?

The past twenty years have brought many changes to the Metal Plate Connected Wood Truss Industry. These changes require manufacturing to change too, as the entire process continues to evolve and mature. Here is one situation where changes in manufacturing are necessary

Not too long ago, component manufacturers were required to maintain lumber stamps and markings throughout the manufacturing process to provide validation that the lumber they were using met design requirements. Back in the day, fabricators would purchase specific lengths from lumber manufacturers in increments that made sense for their operation with this need in mind. This lumber would be cut on component saws and the boards were designed to maintain their grade stamps.

Importantly, the component manufacturer (CM) has been allowed to crosscut lumber without impacting the lumber grade if the lumber was marked as that grade. (A “marking” exception can be short lumber, but that’s another article.)

Examination of the process

Today, with the advent of linear cutting, maintaining a lumber stamp is impractical if not virtually impossible. While this might be a disadvantage to grade traceability, the value the linear saw brings regarding higher yield and reduced labor makes the new problem worth the extra work.

To maintain compliance with the ANSI/TPI 1 standards, lumber must be selected that meets or exceeds all eight properties that define the grade. (For more on this topic, see my December 2021 article, “Can I Substitute Lumber of Another Grade or Species?”) When weekly in-house inspections are made, inspectors should verify lumber grades.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #35 A dverti $ er Component manufaCturing m The

Continued next page

A generic lumber grade stamp

Linear saws use longer lumber to increase yield but cut off grade marks in the process

When 3rd party inspectors review the CM, this process should be repeated. So, with all the cutting up of lumber and the fact that lumber manufacturers normally stamp their products in one place, what should the CMs be doing to provide traceability of the lumber? How can CMs maintain the lumber’s pedigree? The following procedures and processes can be implemented in part or in total to help ensure compliance.

Receiving Lumber

1. When receiving lumber, transfer grade indicators by painting the end of lumber in the unit. Some lumber manufacturers already do this with a stamp. Caution, sometimes the wrong piece gets bundled with another grade at the lumber manufacturer, so be sure to watch for this situation.

2. Segregate lumber species and grades, and keep them segregated when storing lumber.

3. Limit the number of lumber grades inventoried at the plant.

4. For the typical CM, consider stocking limited grades of wide lumber. This would not be practical for high snow load regions or agricultural trusses.

5. Document your receiving process and keep records.

Processing Lumber

6. When rejecting lumber or reclaiming drops at the saw, make sure to segregate and tag unmarked lumber using your plant’s marking system or a manual process.

7. Although the linear saw’s batch program is very reliable, verify its process on occasion, at least monthly.

8. Mark process lumber with wax markers, using different colors for different lumber grades when grades become mixed (usually during the picking process).

9. Use the linear saw’s printing capabilities to mark components. A batch number printed on the cut material can provide an investigator the link to follow.

10. Be familiar with lumber grade requirements so problems can be spotted.

11. Document your lumber process and keep records.

The Bottom Line

The changes in cutting processes dictate a different approach to lumber traceability. In the old days, following grade marks worked well. Today, establishing a precise process is much more effective and provides the “paper trail” for audit. This process should be documented in your quality assurance program manual (QAP) and will become a review element during your 3rd party audit.

An ANSI/TPI 1 3rd Party Quality Assurance Authorized Agent covering the Southeastern United States, Glenn Traylor is an independent consultant with almost four decades of experience in the structural building components industry. Glenn serves as a trainer-evaluator-auditor covering sales, design, PM, QA, customer service, and production elements of the truss industry. He also provides project management specifically pertaining to structural building components, including on-site inspections and ANSI/TPI 1 compliance assessments. Glenn provides new plant and retrofit designs, equipment evaluations, ROI, capacity analysis, and CPM analysis.

Glenn Traylor Structural Building Components Industry Consultant http://www.linkedin.com/in/glenntraylor

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #36 A dverti $ er Component manufaCturing m The

“The Workshop is unique from other events because it’s specific to MSR. Having all of the content focused on a product that I know I’m using and I need to learn more about makes it a really valuable use of my time. Plus, I knew that everyone I talked to would be someone I could potentially do business with in the future.”

—Doug Ready, Wick Buildings, Mazomanie, WI

“I would encourage other component manufacturers to attend the workshop because it is an opportunity to gain a better understanding of MSR and how it can be used. That makes you a more responsible customer because you know how to maximize its use in the design of your product.”

—Porter Clark, Hiwassee Builders Supply Inc., Athens, TN

Fairfield Inn & Suites Charlotte Uptown 201 S. McDowell Street Charlotte, NC 28204 Hotel Deadline: April 3 Save the Date! Wednesday, 4/17 Golf Outing Social Hour Independent Dinner Thursday, 4/18 Educational Sessions Tour Hosted Dinner Friday, 4/19 Educational Sessions A PRIL 17-19 CHARLOTTE, North Carolina Learn more at msrlumber.org/workshop 2024 WORKSHOP

IF ONLY YOU COULD NAIL EVERYTHING IN LIFE THIS EASILY.

With a Terminailer XP, it takes only one person to drive between 30% and 70% of the framing nails in any given job . And all this nailing is done within a secure enclosure, so your people are protected from costly nailing injuries while eliminating literally millions of repetitive motions ( 4,001,398 repetitive motions to be exact , judging from the total nail count tallied recently on a two year-old Terminailer XP).

That’s a lot of nails successfully installed to be sure, and a lot of debilitating repetition your workers’ hands are spared, without any complicated training, software or lengthy setup time required.

Developed by people who know wall panel production, Terminailer XP boasts multiple repeat buyers, 20-plus machines performing exceptionally in the field and tens of millions of nails installed. Thoroughly field-proven, Terminailer is ready to drive greater productivity for you. Contact us today for more information.

765-751-9990 www.woodtechsystems.com

Wood Tech Systems is a registered trade name of Wood Truss Systems, Inc.

Used Hain Quick Rafter Cutter

• Reconditioned in December 2020

• Board Sizes: 2x4 and 2x6

• Motors: Two 1 HP / 220 Volt or 440 Volt / 3 Phase

• Saw Blades: 7 1/4" Carbide Tipped (set at 45 degrees)

• Angle Adjustment: Manual Rotation with Air Brake

• Air Supply: 90 PSI

• Carriage: Steel Rails with Steel Dual V Rollers

• Pedestal: 3/16" Formed Steel

• Saw Housing: 1/2" Billet Aluminum

• Covers: 10 Gauge (1/8" thick) Steel

• Fully Enclosed for Safety

$12,500 FOB AZ

Wasserman & Associates 800-382-0329

www.wasserman-associates.com

NEW!

2000 Automill 5-Blade Component Saw

2000 Timbermill model 343H, five (5) blade component saw cuts lumber from 2″ x 3″ through 2″ x 12″, lengths from 18 inches to 20 feet, including 4″ x 2″ four-angle floor webs from 18 inches. All powered movements, includes computer controls, (1) 30″, (1) 20″ and (3) 14″ blades, analog scales, shaker scrap conveyor, scrap incline and extra set of blades. 480 volt, 3 phase electrical required. 90 PSI air required.

$24,997 FOB ON

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

REPRESENTATIVES

Monet FWA 500 Floor Web Saw

New, Monet five-head, floor truss web saw, cuts 4-angle, 4x2 floor truss webs from 16 inches and 90-90 blocks from 12 inches to four foot long maximum length. Features 10-board magazine feed, powered, fixed-quadrant angulation, manual carriage standard, shaker-pan scrap conveyor with short incline conveyor and cut-off blade. Option for longer carriage length, single-sided setup (shown in pictures, but not standard), dust hood and horizontal scrap conveyor. 480 volt, 3 phase. Call for pricing, FOB MO.

765-751-9990

www.woodtechsystems.com

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #39 A dverti $ er Component manufaCturing m The SAWS

2008 Alpine PF90 Wall Panel Saw 2008 Alpine PF 90 wall panel cutting and marking system. 3.5″ x 12″ maximum cutting profile, Inkjet option, cuts to 16 ft long. From the OEM’s literature, “Effortlessly handles two of the most critical and difficult processes in any wall panel operation – plate cutting and panel layout. At the rate of 1,000 linear feet per hour or more, uses data from the design software and accurately marks stud, cripple and jack locations, job and panel number, subcomponent and window/door locations, and even sheathing locations on both top and bottom plates simultaneously with ink-jet printing.

$8,499 FOB NY Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Electrical Supply: 110 VAC

Motor: 1/4 HP, 110 VAC, Linear Actuator

Highly Accurate: +/- .010 Inches

Stop Rail: 2 x 4 x 1/4 Aluminum Extrusion

Stops: Jig Bored Steel

Stop Blocks: Machine Billet Aluminum

Internal Components: Hardened, Ground and Polished Steel and Billet Aluminum

Dimensions:

Length: 5 feet (60”) to 60 feet (720”)

Height: 12 inches

Depth: 12 inches

If you are looking for the fastest, most consistent way to measure and cut your product, then the Hain Measuring System (MEA) is your answer. The MEA changes from one length t any length instantly, up to 60’, without changing the operator’s position on the line. It is also highly accurate (+/- .010) and quickly moves from one length to the next in seconds. The MEA is designed for quick and easy setup and is simple to use. Even a first time user will be productive with little or no training required. It can adapt to any saw and can be mounted to any surface so that you can integrate the MEA with your existing setup. The MEA is versatile allowing “left” or “right” handed operation and measurement in “feet and inches” or “inches” depending on your preference. The MEA is also available in a “Skid Mounted” version.

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #41 A dverti $ er Component manufaCturing m The theHAINCOMPANY 6125 Enterprise Drive, Unit 9 | Diamond Springs, CA 95619 530.295.8068 | sales@thehaincompany.com

SAWS

A dverti$er Component manufaCturing S erving the S tructural B uilding c omponent S i ndu S try The Hiring Zone Building Component Industry's Job Board Employer to Candidate Direct Hiring No Recruiting Fees! Post your Opportunity... Candidates respond directly to you! For Additional Information Contact: twm@componentadvertiser.org or Call: 800-289-5627 x1 Visit our website: www.componentadvertiser.com/Hiring-Zone MORE INFORMATION HERE 2021

16' TigerStop • Oliver Model 5025.002 Upcut Saw • 7.5 HP / 230 Volt - 3 Phase • 18" Blade (4" x 9", 2" x 12" Capacity) • Foot Pedal Control • Open Interface to TigerStop (SET) • 16' TigerStop (TS16) with 18' Roller Table (TABR16) • Saw Attachment Plate (SAP) $19,900 FOB TX Wasserman & Associates 800-382-0329 www.wasserman-associates.com

dverti$er Component manufaCturing S erving the S tructural B uilding c omponent S i ndu S try The

Oliver Upcut Saw with

A

Design

to walls, to panels, and everything

Introducing a new level of design tools,

from the ground up.

From plans,

above.

built

and

ever. Learn more a t EagleMetal.com Continued next page

build faster than

By Tracy Roe

Celebrating Success at BCMC 2023

This year’s Building Component Manufacturers Conference and Framers Summit (BCMC | FS) in Indianapolis will be remembered as one for the record books. Attendance was great and you would be hard pressed to find someone who didn’t have a good time. My key takeaway from this show is the word BUZZ. There is certainly a buzz in the air!

Even before the show floor opened, the party got started, literally, with the SBCA 40th anniversary industry celebration. Whether or not you’ve been a part of our group since the founding of the Wood Truss Council of America in 1983, or journeyed with us through our years as WTCA – Representing the Structural Building Components Industry, everyone was welcome to enjoy this birthday bash for SBCA.

This year’s award recipients were celebrated at the party. Earning accolades were these outstanding SBCA members. Dave Brakeman of Alpine won SBCA’s 2023 Industry Leadership Award. Kevin Kraft of Alpine won SBCA’s Dick Bowman Industry Enthusiast Award. The Dwight Hikel Humanitarian Award was given to Tom Whatley of Eagle Metal. And, inducted into SBCA’s Hall of Fame was Norm McKenna of MiTek. The commitment and expertise of these fine individuals has helped all of us in this industry.

The party continued after the show floor opened, with 121 exhibitors across 65,000 sq ft. You name it and you could probably find it on display, and you could definitely find plenty of individuals ready to talk about the industry and all we have to offer.

To everyone who stopped by the Eagle Metal Products booth, thank you so much for taking the time to introduce yourself. If we missed you at the show, please reach out – we’d love to hear from you. In either case, be sure to mark your calendar for next year when we take BCMC to Milwaukee, October 7–11. Let’s keep the party going!

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #43

system is protected under U.S Patent #8,960 ,244 and other patents Acer Inc. 301 Industrial Drive Rushford, MN 55971 507-864-2220 www.acerinc.com Adaptable Efficiency With the Ranger Retrieval System The Ranger helps you wring maximum production from your saw investment . An automated saw deserves an automated feed system .

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #45 A dverti $ er Component manufaCturing m The 800-382-0329 www.wasserman-associates.com 2013 Monet DeSauw Finger Jointing Line • Monet DeSauw Cut-Off/Shaper Unit • Rook Metering Equipment Glue Machine ($22,900 New in 2021) • Monet DeSauw Finger Joint Press • Excludes Dust Collection System $52,900 NOW $42,500 FOB MO

Pick, Cut, Build—Talking Shop at BCMC 2023

We had non-stop traffic in the Enventek booth at BCMC 2023 in Indianapolis. Enventek (Dave and Larry Dalson, Michael Bell) and LimTek (Ed Lim) are the only turnkey in-line automation suppliers

for existing truss plants. We are gaining installed base momentum as word is spreading about our proven solutions that are robust and flexible. Yes, everyone knows about the amazing auto-feeding RetroC component saw, which is the only one of its kind in the component industry. We would love to sell you a standalone auto-feeding RetroC to replace your existing saws or add additional sawing capacity, but we would rather upsell you to our complete system – A Fully Loaded RetroC. That is really how to Feed the Beast!

We take great pride in every one of our installations. Every installation is different and we figure out how to get the right fit as every component plant is different and each plant has their own unique set of constraints whether it is yard layout, plant configuration, and/or people. A Fully Loaded RetroC standardizes how lumber is picked, cut, and presented to the truss builders. The component industry is actually a simple business – pick the lumber, cut the lumber, build the trusses. We have a proven robust complete system for that!

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #48 A dverti $ er Component manufaCturing m The

Continued next page

Edmond Lim, P.Eng. LimTek Solutions Inc.

The quiet before the storm, ready to talk shop at the booth. Thank you to all who spent time to sit down and talk shop with us.

Pick the Lumber

No forklifts running around all day. Bad lumber stays away from the saw and build tables. The picker is the first line of quality control. The picker follows the pick list on the WiFi tablet and the PickLine checks each board length, board width and the quantity against the pick list. We can install a standalone Lumber PickLine to feed any automated saw including all the major brand linear saws and any automated component saw whether the sawyer is on the fixed end or the movable carriage end.

Cut the Lumber

Less wear and tear on the sawyer gives the sawyer the opportunity and time to be the seond line of quality control. SpeedCatch is all software driven. The sawyer just cuts the lumber and SpeedCatch will fill the cart slots and eject the filled cart. All the sawyer has to do is make sure there is an empty set of carts queued behind the saw to be automatically pulled into the saw.

Build the Trusses

Lumber is collated and presented standardized in front of each truss build table from left to right of table by following the cart map as shown on the color-coded big screen. Boards are simply dragged/pulled onto the tables. The boards are oriented the right way. There is no helicoptering of boards. Because the carts are perpendicular to the tables and located closer to where they need to be, the wear and tear on the truss builders is reduced significantly.

When you’re ready to Feed Your Beast and see these efficient and effective systems for yourself, let us know! Inside and out, LimTek Process Organization Technology will help you squeeze out more truss production and deliver quality trusses with shorter lead times to better service your customers by organizing your truss fabrication processes to maximize your investment in automation. https://limteksolutions.com/#solutions

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #49 A dverti $ er Component manufaCturing m The

· Simplified Re-Design · Robust low maintenance · No upper hold downs · Electronic braking · Auto feeding lumber · Holds calibration · Out cuts any linear saw · Cut-by-Truss or Batch cut 6021 Yonge St., Unit 1019 Toronto, ON M2M 3W2 Tel: (416) 888 -4457 Edmond.Lim@LimTekSolu�ons.com LimTekSolu�ons.com

Twin Axis sheathing saw: Cuts X and Y axis simultaneously in one pass through the saw. Cuts up to 1″ thick, wood sheathing material, minimum width 3″. Fully enclosed to reduce noise, dust, and improve operator safety; automated via downloaded sheathing cutting files from wall design software. Includes 8 foot long idler infeed conveyor and outfeed conveyor with pop-up skate wheels, (1) spare blade and all available spare parts. 220v/440v, 3phase electrical saw, 120v, 1 phase electrical PC. 100 PSI at 14 CFM air required.

$17,991 NOW $11,950 FOB VA

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

PHONE: 800-289-5627 FAX: 800-524-4982 Read/Subscribe online at www.componentadvertiser.com Don’t Forget! You Saw it in the Adverti$$er October 2023 #15291 Page #51 A dverti $ er Component manufaCturing m The A dverti$er Component manufaCturing S erving the S tructural B uilding c omponent S i ndu S try The SAWS EKSTROM-CARLSON MODEL E STRAIGHT LINE RIP SAW • 10 HP Arbor Motor • 3 HP Variable Speed Feed • 4" Maximum Thickness (when using 18" Blade) • 48" Throat • Adjustable Rip Fence • Overhead Holddown • Automatic Chain Oiler • Dust Outlets $10,500 FOB MI Wasserman & Associates 800-382-0329 www.wasserman-associates.com DANCO

• 3 3/8" Maximum Thickness • 13 1/2" Maximum Distance from Rip Fence to Outer Saw • 100 HP Arbor Motor • 2 HP Feed Motor • 7 1/2 HP Dust Collector • 480 Volt / 3 Phase • Waste Conveyor with Short Incline $35,000 NOW $27,900 FOB MN Wasserman & Associates 800-382-0329 www.wasserman-associates.com 2005 PCS / MiTek Twin Axis Sheathing Saw 2005

GANG-RIP SAW

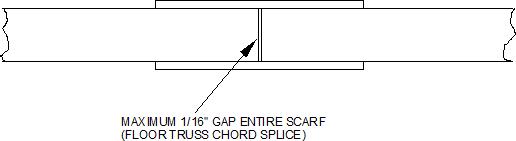

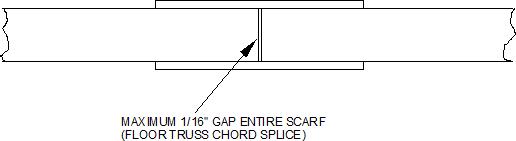

PCS/MiTek