A

Th e

Component Manufacturing dverti$er

Adverti$er

Don’t Forget! You Saw it in the

May 2018 #10226 Page #6

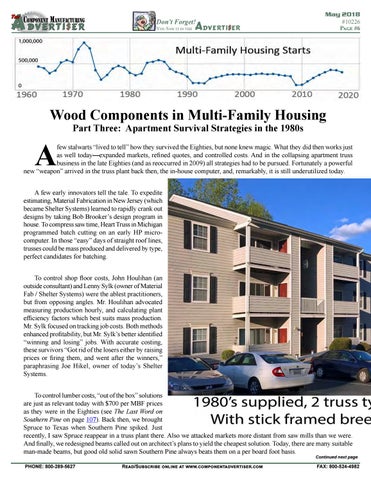

Wood Components in Multi-Family Housing Part Three: Apartment Survival Strategies in the 1980s

A

few stalwarts “lived to tell” how they survived the Eighties, but none knew magic. What they did then works just as well today—expanded markets, refined quotes, and controlled costs. And in the collapsing apartment truss business in the late Eighties (and as reoccurred in 2009) all strategies had to be pursued. Fortunately a powerful new “weapon” arrived in the truss plant back then, the in-house computer, and, remarkably, it is still underutilized today. A few early innovators tell the tale. To expedite estimating, Material Fabrication in New Jersey (which became Shelter Systems) learned to rapidly crank out designs by taking Bob Brooker’s design program in house. To compress saw time, Heart Truss in Michigan programmed batch cutting on an early HP microcomputer. In those “easy” days of straight roof lines, trusses could be mass produced and delivered by type, perfect candidates for batching. To control shop floor costs, John Houlihan (an outside consultant) and Lenny Sylk (owner of Material Fab / Shelter Systems) were the ablest practitioners, but from opposing angles. Mr. Houlihan advocated measuring production hourly, and calculating plant efficiency factors which best suits mass production. Mr. Sylk focused on tracking job costs. Both methods enhanced profitability, but Mr. Sylk’s better identified “winning and losing” jobs. With accurate costing, these survivors “Got rid of the losers either by raising prices or firing them, and went after the winners,” paraphrasing Joe Hikel, owner of today’s Shelter Systems. To control lumber costs, “out of the box” solutions are just as relevant today with $700 per MBF prices as they were in the Eighties (see The Last Word on Southern Pine on page 107). Back then, we brought Spruce to Texas when Southern Pine spiked. Just recently, I saw Spruce reappear in a truss plant there. Also we attacked markets more distant from saw mills than we were. And finally, we redesigned beams called out on architect’s plans to yield the cheapest solution. Today, there are many suitable man-made beams, but good old solid sawn Southern Pine always beats them on a per board foot basis. Continued next page

PHONE: 800-289-5627

Read/Subscribe online at www.componentadvertiser.com

FAX: 800-524-4982