Wall

Rob

Geordie

Thomas McAnally

Stamm

20th

are the property of their respective owner or creator unless otherwise noted

Disclaimer: We reserve the right to refuse any advertisement or

that we deem not in the interest of the industry or the Advertiser. Permission to use content is the responsibility of the contributor including permissions to use any likeness of persons.

The

typographical

unintentional.

32043

November is a time when we can reflect and be thankful for many things in our lives. But the truth is – anytime of year gives us reasons to be thankful for little things, even when those things are silly or trivial.

For reasons unknown, when I attempted to wash dishes one Wednesday in October, I discovered that I had no hot water. Checking the water heater, I could see the little green light had stopped flashing, so I knew the pilot light was out. I knew to turn the knob to off, then turn it to pilot, then push and hold it, use the clicker, and wait. But, here’s what I didn’t know. Did I need to hold it longer? Did I need to click it again? What secret part of the sequence was I missing when it didn’t fire back up?

I remember very well playing assistant when my father was lighting the pilot on our water heater… but that was decades before all of today’s fancy controls. He used the old-fashioned match attached to the end of a wire, because lighting the pilot meant working for it. So, because I can no longer simply pick up the phone and call him, I decided to consult the internet. Nearly instantaneously, many options appeared and I chose a YouTube video by a friendly looking man who promised to cover all of the details.

If you’ve been conjecturing as to what my problem was, the answer is – when they say you may have to hold it for longer than a minute, they mean it. Plus, if you try more than once, the safety features may reset and you’ll have to give it 10 minutes rest before trying again. On my next attempt, I held that button down for an eternity and was rewarded with the flashing green light!

So yes, when I heard that gas fire up, I was very thankful. I was thankful for the internet. I was thankful I would soon have hot water. I smiled remembering that time with my father. And I was reminded once again not to take the little things for granted too.

•

• 3 Operating Modes: Auto, SemiAuto & Manual

• All 20 Axes of Movements are Computer & PLC Controlled

• Comprehensive Setup Screens Display Each Piece with Setup Data

• Anti-Collision & Optimizing Programming

• Auto Calibration Productivity & Time Tracking

• Maintenance Diagnostics

• Variable Speed Conveyor (0-50 Flights per Minute)with Powered Hold Downs

• (1) 30” x 80 Tooth Blade (27 3/4” Scarf on PAE)

• (4) 16” x 40 Tooth Blades (13 1/2” Scarf on Centerline)

• Pneumatic Blade Brakes on all 5 Blades

• 16 1/2”

By Joe Kannapell

By Joe Kannapell

Cal Jureit’s impressive debut at the 1958 NAHB Show, lumberyards and builders across America were anxious to start trussing, but they encountered several obstacles. Their deluge of inquiries couldn’t all be answered, and most were far away from the South Florida source of supply. If they saw an opportunity to enter the plate business, they faced the formidable obstacles of Jureit’s and Sanford’s patents. And for those who were able to obtain plates, they had to seek out or develop their own machinery. Of the several manufacturers who answered this call, one individual would have the most long-lasting impact, namely, Walter Moehlenpah in St. Louis, Missouri.

AfterMoehlenpah’s mechanical engineering expertise enabled him to gain a Vickers franchise, supplying parts and servicing hydraulic equipment in the Midwest. In the late 1950s, his Moehlenpah Engineering business was called in to fix a truss machine at Boise Cascade’s lumberyard outside St. Louis. After addressing the problem onsite, Moehlenpah’s technician brought back news of the chance to service machinery in a brand-new industry.

Moehlenpah was quick to capitalize on this opportunity, commissioning a veteran mechanical engineer, George Pallme, who had retired from one of his nearby customers, McDonnell Aircraft Corporation. Pallme’s first iteration, the Mark 6 Mono-Press, consisted of a C-shaped frame suspended from an overhead power unit. The key to this design was the counterbalancing of the weight of the press by the weight of the hydraulic motor and fluid reservoir, a straightforward task for Pallme, an aircraft designer. The press itself was a relatively lightweight aluminum casting, aimed at trusses with 2x6 or smaller chords. In 1961, Moehlenpah applied for a patent, which he received a year later. The Mono-Press became the entry point into the truss business for hundreds of lumber yards because it readily fit into a typical 50-foot-wide lumber shed, taking up minimal floor space. Despite the immediate success of the Mark 6, Moehlenpah didn’t stop there – he kept expanding the reach of the Mono-Press (literally and figuratively) and at the same time stretching his reach into the truss plate business.

Moehlenpah would often say, using a razor and blade analogy, that he “could make a thousand dollars selling a machine (the razor), but he would make much more if he got a nickel every time it pressed (the blades).” During the early development of his Mono-Press, Moehlenpah also searched for a source of truss plates. He first attempted to buy them from Jureit but balked at the hefty premium over steel prices that Jureit had proposed. That encouraged Moehlenpah to begin working on his own design with a local machine shop. Then Moehlenpah gained access to a plate very similar to one developed by Bill Black Sr., father of Bill Black Jr., who later founded Tee-Lok. Moehlenpah licensed it from W.B. Atkins of Timber Truss Connectors, Inc. in January of 1961, but he didn’t produce it because he had already applied for his own patent. In October 1962, Moehlenpah was awarded a patent on his own design, but he was promptly sued by Gang-Nail, as Atkins had been, in what would become the court case of the century for the plate business.

During the time Moehlenpah was getting into the business, at least a dozen other companies were also seeking entry. While South Florida was the hotbed, players in Detroit, Chicago, Pittsburgh, and Colorado Springs joined the fray. All would eventually have to surmount patent barriers, but their most immediate challenges were brought by building inspectors, who found no guidance on plated trusses in their Codes. The most vocal of these were officials of the Federal Housing Administration (FHA, which is now HUD), the only Code body that had national oversight. FHA had requested that the industry develop and submit a uniform design criterion for plated trusses. After receiving only sporadic individual responses, FHA placed a moratorium on plated truss use after July 31, 1960, unless acceptable design standards were submitted. Since FHA-backed mortgages constituted a large share of new home construction, this decree threatened an entire budding business, then in its infancy.

Next Month: Frenetic First Get-Together

Since 1970, Joe Kannapell has worked as programmer, Chief Engineer, Marketing Manager, and Sales VP for MiTek, plus 7 years at truss plants, retiring at the end of 2020.

1995 Koskovich Auto Omni Component Saw

1995 Koskovich Auto Omni saw, S/N AO950056 4-blade automated saw includes [1] 29 inch blade and [3] 19 inch blades. Includes scrap incline. Fully automated setup with full power length and all axis angulation, single sided setup from operator console, 2×3 through 2×12, 12 degree minimum angle to -71.6 maximum angle. 20’ to 2′-4” @ 90°/90°, includes owner’s manual and any available spare parts including [6] spare blades. 208/240/480 volt, 3 phase, 100 Amp, and 120 volt, 1 phase electrical, 100 Amp electrical required, 90 psi air.

$14,990 FOB SD Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Safety Speed Manufacturing Model 7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical

horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

$13,149 Base, FOB MN. Wood Tech Systems 765-751-9990

www.woodtechsystems.com

not cost

Group as

any of

more with

contact. In

advantage of our Partner Relationships

will receive the

Services

offered elsewhere.

www.FitzGroup.com

As a truss component manufacturer, you already know Simpson Strong-Tie as a reliable partner in the construction industry. But our connections go beyond the products we make. Our people can help reinforce your network of builders, engineers, contractors, equipment manufacturers and suppliers, strengthening your existing relationships. Also, our open-platform software is integrated with the most widely-used systems, and can be customized to work with the machinery you choose. Backed by our expert service and support, you’ve got all the resources to succeed.

Grow your business ecosystem with a well-connected partner. To learn more, visit our website at go.strongtie.com/componentsolutions or call (800) 999-5099.

By Wendy Boyd Chief Customer Officer –Sales, Service & Marketing

By Wendy Boyd Chief Customer Officer –Sales, Service & Marketing

From the BCMC 2022 event, in which we displayed our Framing Line and several other pieces of machinery, it became apparent that our customers are hunting for ways to save labor and costs – which includes producing wall frames for their markets. We were overwhelmed in the Spida booth with questions on how our customers can introduce a frame line into their factory and start production on their new wall line with a minimum of fuss, and then of course start reaping the rewards.

Each customer’s requirements are different – but we have the solutions to suit almost any situation. Is your business dominated by raking frames or are these “one-offs” that clutter up the production floor? Our Raking Wall Extruder will provide your solution with its ability to do raking frames and also produce all of your common walls, fast and accurately, with a minimum of labor. Do you only get asked for common walls? That’s no problem, and a Wall Extruder is what you need. You can increase your production capabilities with this piece of machinery, then bring your sub-components in at the start of the line or further down the line, whichever you require.

How it is able to meet all of your needs? You simply load the top and bottom plates on the Wall Extruder, receive the first components of the wall from the conveyor, then place at the locator pins, the operator holds the fire buttons so that the nails are fired automatically through the plates into the component, then the wall advances automatically –repeat until the wall is complete. Of course, this seems simple, but there is a lot going on under the hood! Spida technology and software does the heavy lifting here to know placement and keep things running smoothly.

But the Wall Extruder is not our only machinery that delivers labor savings and technology. Nailing C Corners and L Studs can be time-consuming and cumbersome for operators, so the Stud Extruder is your go-to machine for these. This machine nails together a variety of combinations including C and L Studs, double and triple studs, fire and cabinet blocking. Computercontrolled and driven by the same file as the Extruder, the component is made, popped onto the curved conveyor, and delivered to the Extruder for placement, all with an accuracy for both construction and staging that couldn’t be simpler.

Prebuild your window and door openings on a Spida Sub-Assembly Table, then simply place them on the chain conveyor to be loaded over the side of the Extruder via a driven and pneumatically lifted roller bench, so that the operator places them into the wall ready to be nailed. At all times the system is controlled by the extruder computer software – get ready to increase your production, just with these machines.

Looking at this system as a whole, and as always depending on complexity, we see our customers building 100–170 l/f of walls per hour.

And, when it comes to sheathing, Spida has a machine for this in our arsenal as well. With one touch, the now produced wall continues through the Sheather to be nailed off with the studs clamped and straightened to reduce shiners. This set-and-forget function, after the sheathing has been tacked in place, is one of a kind and means your labor costs are set to zero. This cost savings cannot be ignored.

Spida Wall Lines are innovative, fast, and accurate, delivering a true labor-saving exercise for your bottom line. Explore the opportunities by talking to one of our team to find the system for you. Don’t forget that the Spida innovation doesn’t stop there – Floor Truss equipment, Automated Roof Truss lines, and amazing Cutting solutions are part of the whole truss and frame supply package solutions that we specialize in at Spida Machinery. Don’t wait any longer to find your factory solution.

Don’t just do it, nail it. It’s a brand new day in wall-panel production, with a whole new way of doing things better.

Terminailer®, a revolutionary, event-driven, nailing machine that completely defies any preconceived notions about sub-component assembly.

Terminailer all but shatters the stereotypical myth that subcomponent equipment is essentially peripheral – unimportant. And it does so by quickly and accurately driving far more framing nails in your wall panel jobs than ever before. Whether in your shop or in the field, one operator sets the pace for production and quality. And that reduces labor costs and other aspects of overhead.

Terminailer is an event-driven, sub-component assembler that will quickly and accurately drive 30% to 70% of the framing nails in any wall panel job. In your shop or in the field, one operator sets the pace for production and quality. The Terminailer functions independent of design software, requires zero set-up time when switching between any configuration, and requires no special operator training.

The Terminailer is easy to move around the shop so it’s location can evolve as your shop evolves. With all of the nailing occurring in the closed main chamber, nail injuries and nail location miss-fires are eliminated, making your plant that much safer.

With nearly ten years of development from people that know

it is assembled to exacting standards, well supported, and it is easily maintained with shelf-item parts. Terminailer: vetted, tested, and ready to drive maximum productivity for you. Be sure to check out our videos below for a quick review of this revolutionary

2002 Koskovich Auto Omni 5-Blade Component Saw

2002 Koskovich Auto Omni component saw, 5-blade automated saw includes [3] 20 inch blades, [1] 30 inch blade, [1] 12 inch blade and shaker waste conveyor with factory side pans. Fully automated setup with full power length and all axis angulation, single-sided setup from operator console, 2×3 through 2×12 and 4×2, 20’ to 9” @ 90°/90°, Exair cabinet coolers, remote monitor, no spares. In operation until Aug. ’21. 208/240/480 volt, 3 phase, 100 Amp saw electrical required. 120 volt, 1 phase PC electrical required.

$13,970 NOW $9,997 FOB OH Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Safety Speed Manufacturing model 7000, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00). $9,332 Base, FOB MN.

765-751-9990

www.woodtechsystems.com

The L-M Verticut 2000 is a true Precision End Trim (PET) saw that is capable of holding a 1/16th accuracy all day long. Made in the USA, the V2k comes equipped with a 15 HP 460/230 volt High-E three phase TEFC motor driving a Double ended Premium “Stellite” inlaid saw bar with a spring loaded chain tensioner and an automatic oiler to lubricate the .404 pitch custom profile semi chisel saw chain.

Rather than a single pivot-point, the saw assembly is mounted on a mandrel box that is guided by cam followers on a steel frame that is raised and lowered by a hydraulic cylinder. A console with the saw controls moves with the saw assembly along a track positioned using a manual “V” wheel geared drive or optional Hydraulic drive

The V2k is unlike other imported systems that are basically a Portable Yard Saw on a cutting rack with a best cutting accuracy of +/- 1/8″ (meaning up to ¼” accuracy variance between units of lumber). The V2k from L-M provides +/- 40 thousands, assuring consistent PET precision from unit to unit.

with unlimited phone assistance and technical help. Their team has traveled the country working on crosscut saws for many years and they know their equipment inside and out. L-M is a familyowned business that prides themselves in doing the job right and building long term

Another advantage L-M has over the competition is their commitment to personal

that is vital to their business: “Built to last as long as our customers since 1946”.

Time and again, executives state they are having problems finding enough qualified people to staff all the needed positions within their company. The truth is that this problem will get much worse, and you need to understand why to fix it.

TDC has found that companies with the best employee practices, low turnover, and very few unfilled positions have the highest profit percentages of sales among their peers, regardless of their automation within their manufacturing. I have seen their P/L statements, and it is not even close. On average, it is 5 to 10 points better. Conversely, the companies with poor employee practices have the worst net profits of their peers, and yet again, the numbers are not even close by at least 5 to 10 points below the average. (Points, not percentages.)

Why are the available labor shortages happening? There are four main reasons, but the number one problem is that 400k fewer new workers in the U.S. are coming into the labor market this year than are leaving. For the next ten years, the problem grows upward towards 900k per year with fewer workers coming than are leaving in the U.S. The problem as a percentage of the total population is even worse for Canadians. (Source for graph: Peter Zeihan Kern County Energy Summit)

The second problem is that fewer people, as a percentage of the total available, are willing to participate in the labor force for various reasons. According to the U.S. Bureau of Labor Statistics, the labor participation percentage is projected to be less, not more.

So not only do we have a shrinking labor force, fewer of the remaining are willing to be employed for various reasons.

An additional complication, the third reason, is not being openly talked about in the employment availability discussion – a large portion of the construction workforce needs to be physically healthy to perform the tasks required for the necessary work. So not only are people less willing to work, many, as much as 42%, are not able to perform the tasks needed within the construction industry. Certainly, much of the work that is in the construction industry does not need to be performed by an athlete, but let’s be honest about many of the very real physical needs within our industry.

The last reason for the labor shortage is a fun fact that most employers don’t know. The “higher education” push has been too effective for the workforce needed. Of the U.S. labor force of 140.7 million adults, approximately 69% have a college education. Of the approximately 9.2 million job openings, only 3.2 million (34.7%) needed any college education. There is a natural resistance for anyone with higher education to perform a non-college-educated job position.

The second problem concerning the participation rate needs to be further expanded upon in relation to the education level of the workforce needed.

Associate degree level has a 63.1% workforce participation rate. Those with a bachelor’s or higher education have a 72.3% participation rate.

The numbers look far worse for those without any college, which is 31% of the total workforce. Here, it’s a 55.9% participation rate for those with a high school diploma and only 44.1% for those who never graduated from high school.

In Sept of 2021, there was a need to fill approximately 9.2 million job openings. Of the 9.2 million openings, 6 million were nondegree job openings. Yet there were only 3.39 non-college-educated potential workers available. And no, legal or illegal immigration numbers into the U.S. are not close to filling those open positions. (Source of information for Graphs A and B: The Demographic Drought, 9/2/21, Author and Sr. Labor Economist Ron Hetrick)

Automation and labor issues. Many believe that, somehow, a company can invest a lot of capital into the available automation to manufacture roof and floor trusses to markedly reduce the needed personnel within their company. The answer from the leading truss guru lean manufacturing industrial engineering expert, yours truly, is a definitive: no, you cannot. And if you cut back on the number of personnel in many areas, your company will suffer lost sales and net profits. TDC has witnessed this in more than a few companies.

Yes, some tasks of material handling may reduce the headcount by a few personnel, but as far as the manufacturing process for wood trusses, the answer is still no. Current robotic automation for wood truss automation assembly is overrated and is simply not practical. TDC has yet to witness a fully automated truss system that significantly reduces the total labor workforce needed while maintaining or improving the total output worth the capital investment.

TDC has conceptually developed a practical and workable automation assembly roof truss system that would almost double the output of most gantry tables. Yet, no one has taken up my offers to help develop the automation seriously. If your company has the means to develop robotic automation and is seriously interested, contact me.

Those who believe they can reduce the number of personnel on the assembly tables falsely believe labor savings based on board footage (B.F.) per work hour rates. For every needed assembler on a wood table, the rate is approximately $3k to $3.5k in sales per shift. Translated, this means that when there are only two roof truss assemblers when there should be three, the company loses $3 to $3.5k in additional sales per shift per workstation. For more about this subject, see How to Lose Millions of Profits with Linear Saws and Two-Person Crews.

For all the wood truss manufacturers still using B.F. or other non-work-minute estimations, such as piece count with an average setup time applied to each piece, please see Estimating Truss Labor Using Board Footage Versus Proper Man-Minute Time Standards.

How does automation investment make sense to reduce labor? Automation within the truss manufacturing process and in the design/admin process can, if done correctly, dramatically improve productivity and quality for the same amount of labor. The takt time, units per hour rate greatly enhances the amount of product being produced for the same amount of labor. It can also improve quality and the learning curve to get new workers up to speed. It is not the magic pill to reduce the total number of personnel unless your company wishes to reduce the total sales output. Reducing the number of personnel and improving the output per labor hour are not the same thing. Sometimes one must employ more personnel to enhance the units per labor hour. And just because your company may have a lot of automation does not mean you can fill those positions with warm bodies and not expect output and quality to suffer, which it seriously would. Too many highly invested companies only operate at about a 60% efficiency rate because of the labor practices.

As stated in my October article, Including Meaningful Process Improvement on Your Capital Investment Checklist, “Over the coming decade, the companies that survive and prosper will only be those with strong and healthy H.R. management practices.” This article should convince your company to take best-in-class H.R. practices seriously. Automation is not going to be good enough. And if you want to review your company’s labor management practices, TDC can help.

The team of TDC is your best source for learning about proven and practical lean manufacturing best practices combined with industrial engineering principles to keep your company at the leading edge of competitiveness. No one is better at providing your team with proven results for good employee practices, pricing, truss labor estimation, and so many other best-in-class practices. TDC’s tailored solutions are for the client’s specific needs. Go beyond the typical software and equipment vendor recommendations for your operations and do what many have dared to do. Embrace the Drummond Method, and your company can experience cost savings, and net profit gains that usually take months or years can be accomplished in weeks or months, resulting in an average of 3 to 6 point net profit gains for CMs. All areas are addressed, not just the manufacturing. Please do not take my word about TDC’s services, though. Read the public testimonials many current and past clients with decades of expertise and experience have been willing to give: https://todd-drummond.com/testimonials/.

Website: www.todd-drummond.com

Phone (USA): 603-748-1051

E-mail: todd@todd-drummond.com

Copyrights © 2022

2000 SpeedCut MetraCut

2000 SpeedCut MetraCut model SSA17 centerline radial arm saw, provides center-in cutting with turntable analog angle measurement. Includes (1) 16 inch diameter blade with 1 inch diameter arbor bore. Angular capacity 164 degrees with a maximum scarf cut of 31 inches. No conveyors included. 220/440 volt 3 phase electrical required.

$10,793 FOB TN

Wood Tech Systems

765-751-9990

www.woodtechsystems.com

Five-blade SERVO controlled saw is configured with [1] 30 inch blade, [3] 20 inch blades and [1] 12 inch blade. This saw includes shaker side-pans, and numerous OEM spare parts, several sharp blades, and Matthews Ink-jet with stand (needs reconditioning). 208/240/480 volt, 3 phase, 100 Amp, and 120 volt, 1 phase electrical, 100 Amp electrical required.ASIS, Where-IS

$44,990 FOB KY

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Complete Roof Truss cutting functions including angle cutting with auto-loading conveyor system, auto-discharge. 15KW (20HP) saw motor with a 25″ blade will cut any length lumber from 3’6″ to 24′, and in widths from 1.5″ to 17.75″. Up to 4-board stacked cutting of dimensional 2×4. Saw comes with OEM in-feed and out-feed extensions for processing longer length material (I-Joist). According to Hundegger literature: “The Hundegger Whole House Saw ™ is a computer numeric controlled (CNC) saw capable of cutting a wide range of roof, floor and wall framing components, including wood I-joists, laminated strand lumber (LSL), laminated veneer lumber (LVL) and glue-lam”. Maintenance program, and tech support available in N. America. This saw is under power and operational. OEM installation required for successful startup at buyer’s location. Printer needs to be rebuilt. Saw available to ship after 30 September 2022. 480 volt, 3 phase, 65 Amp saw electrical required, 120 volt, 1 phase, 20 Amp computer electrical supply required. 150 PSI at 27 CFM air required.

765-751-9990

www.woodtechsystems.com

truss industry relies on 3rd party quality assurance services to provide random visits to review the plants Quality Assurance program along with their operations. If your plant needs to comply with the IRC, IBC and to those who depend on solid, experienced QA expertise, we ask you to consider selecting Timber Products Inspection, Inc. (TP) as your choice for 3rd party inspections.

serving the forest products industry for over 50 years, TP brings the expertise you need to ensure your business is successful. As a responsible partner, TP delivers to clients, employees, and the industries we serve the confidence to drive value through the effective use of our diverse professional team.

would like to welcome the following authorized agents to our inspection team, each of whom have many years of experience in the truss industry!

Al Coffman

Jean Hart

Curt Holler

Chuck Ray

Glenn Traylor

Elliot Wilson

trusguy@gmail.com.

919-280-5905

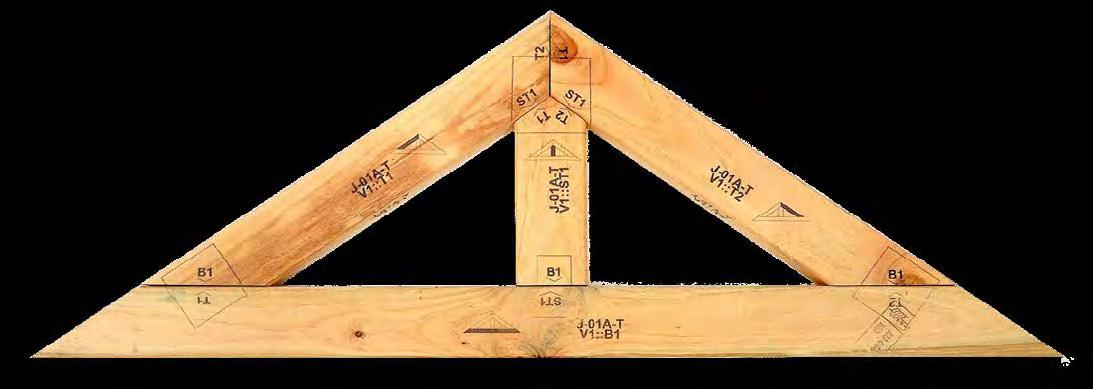

Facethe facts—occasionally, it is necessary to replace connectors. It’s part of the manufacturing process. In my May 2016 article, Is There a Reduction For Plating in a Previously Plated Area?, we discuss the limitations and considerations of removing a plate, including upsizing the plate and how to calculate the necessary upsize connector. The area of the chord and web members where holes have been made by the original plate loses 50% of its capacity, so the replacement must be done with a larger plate. Typically, smaller plates can be replaced by upsizing the connector by height and width up one size, but as the plate size increases the proportion must increase.

Witnessing a truss repair recently, I noticed a truss builder aggressively removing a connector. Although I had thought this was intuitive, it needs to be said aloud—special care must be taken when removing a plate. After removing the plate, this truss builder was planning to just replace the plate with a slightly upsized connector, but I asked him to wait until we could investigate the repair. Unfortunately, a significant amount of wood had been removed, which created a significant problem. The area that was damaged by the wood removal had become totally ineffective. That meant additional tooth count would be required in the damaged area. Bringing this to the attention of the builder and his supervisor, I realized this calculation surprised them. Per ANSI/TPI 1 section 3.9.2, when a plate is removed, the area of removed lumber becomes ineffective.

As shown in these photos, a significant amount of wood may be destroyed while removing the connector. This area must be replaced 100% by upsizing the connector accordingly.

The diagram shows how either the 50% requirement or the 100% requirement will be activated after you remove a connector.

Another requirement that may seem intuitive but also should be said aloud— remember that the upsized connector must be of the same type and gauge. That means you cannot replace a 20-gauge connector with an 18-gauge connector, for example. This also comes from ANSI/TPI 1, section 3.6.6.

The final statement that needs to be said aloud is this—taking a few extra seconds or minutes to “be careful” will be worth it, because you need to take special care not to remove wood when removing a connector. Not only will the damage make your repair more difficult and require a larger connector, it also may make your repair impossible.

An ANSI/TPI 1 3rd Party Quality Assurance Authorized Agent covering the Southeastern United States, Glenn Traylor is an independent consultant with almost four decades of experience in the structural building components industry. Glenn serves as a trainer-evaluator-auditor covering sales, design, PM, QA, customer service, and production elements of the truss industry. He also provides project management specifically pertaining to structural building components, including on-site inspections and ANSI/TPI 1 compliance assessments. Glenn provides new plant and retrofit designs, equipment evaluations, ROI, capacity analysis, and CPM analysis.

Structural Building Components Industry Consultant http://www.linkedin.com/in/glenntraylor

to Michael Bryan, Purchasing Manager at Wheeler’s located in Rome, GA for winning Timber Products Inspection’s 2022 BCMC ANSI/ TPI 1 Inspection Challenge.

had the highest score competing with fabricators from across America! Recently, Glenn Traylor presented Michael with the grand prize, a Yeti cooler provided by Timber Products Inspection, a worldwide provider of third-party certification for the truss and wood products industry.

The Spida Apollo saw with Automation is a computerized, pull-arm type saw used for cutting either wood truss components or wall panel cutting and represents the lowest-cost way to add an automated single-blade saw to your operation. Features include angle cutting from 10 to 170 degrees, 36 inch scarf cuts, patented variable stroke limiter for safety, solid frame and arm design, 17 inch industrial touch screen with enclosure, 7.5 HP motor, plug and play wiring making installations easier and includes cowls for adding a dust extraction system.

Available options include software is available for both trusses and wall panel cutting, laser guide showing exactly the path of the blade before the blade moves, Safe Grip™ Clamp for cutting smaller pieces, clamping table, Plate Marker template providing automated set up for marking joint locations (studs, sub-component locations, etc.) on top/bottom plates, Chop Saw Table for adding another saw for miter/compound or end cuts, prior to feeding the Spida Apollo saw, Portable Dust Extractor and spare blades.

Saw is available in 240 volt, 20A or 460 volt, 15A 3 phase electrical. Computer requires 110 volt, 1 phase, 20A.

765-751-9990

New, DeRobo linear saw by Monet organizes "fill" boards to increase optimization of each board, can produce unlimited scarf cuts, cuts 1 or 2 boards at a time and cuts webs, chords, wedges, rafters and open-stair stringers. Works with all major connector plate manufacturer's software. Features include 22 inch blade, left-to-right feed direction standard, lumber push and pull grippers for more accuracy, ink marking on the 1 1/2" face of the incoming boards and small piece capture and delivery to the front of the saw for easy access. Infeed deck and bunk feed are shown as options only. 480 volt, 3phase. Call for pricing, FOB MO.

765-751-9990

www.woodtechsystems.com

New Square 1 Rolsplicer, splices 2"x3", 2"x4" and 2"x6" lumber with a 3 to 4 second cycle time. Presses the lumber together prior to imbedding plates. Embeds plate lengths up to 19 inches. Features two, recessed, simultaneous-activation buttons, guarded motor and sprockets, external lubrication points, 3 HP motor and a footprint of 59" long x 42" wide. Optional 20' infeed and 10' outfeed conveyor available. 480 volt, 3 phase electrical. Other voltages available.

765-751-9990

www.woodtechsystems.com

2002 Auto Omni 5 blade automated component saw includes shaker waste conveyor with factory side pans, [3] 20 inch blades, [1] 30 inch blade and [1] 12 inch blade. Fully automated setup with full power length and all axis angulation, single sided setup from operator console, 2×3 through 2×12, 22’ to 3′ @ 90°/90°, and spare blades. 208/240/480 volt, 3 phase, 100 Amp and 120 vac, 90 Amp electrical required.

Price: $19,990 FOB PA

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

2008 Alpine PF90 Wall Panel Saw

2008 Alpine PF 90 wall panel cutting and marking system. 3.5″ x 12″ maximum cutting profile, Inkjet option, cuts to 16 ft long. From the OEM’s literature, “Effortlessly handles two of the most critical and difficult processes in any wall panel operation – plate cutting and panel layout.

At the rate of 1,000 linear feet per hour or more, uses data from the design software and accurately marks stud, cripple and jack locations, job and panel number, subcomponent and window/door locations, and even sheathing locations on both top and bottom plates simultaneously with ink-jet printing.

MORE INFORMATION HERE $8,499 FOB NY

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Safety Speed Manufacturing model 6400 vertical panel saw, 3 HP worm drive motor, 64 inch crosscut, 1 3/4" inch maximum thickness, accuracy within 1/64th of an inch, 10 foot welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include lower frame extensions, digital readouts, laser guide, stop bar, vacuum and midway fence. 120 volt. Starting at $5,169 FOB MN.

765-751-9990

www.woodtechsystems.com

By Tracy Roe

By Tracy Roe

TheGreek philosopher Heraclitus is credited with the origin of the phrase, The only constant in life is change. This couldn’t be more true in the world we live and work in today. Whether we are enduring labor shortages, a global pandemic, material shortages, input cost increases, or an unstable economy, we must remain vigilant. We have people counting on us at home and at the office to make the right decisions and to push forward. To say the past 24 months in our industry has been unprecedented is an understatement. The future shows no signs of returning to what we used to identify as normal anytime soon. Everyone must have a plan for tomorrow.

Being a truss fabricator in today’s market and economy is especially demanding. You are forced to make decisions every day based on the information you have at the time. What if things suddenly change? Are you prepared? Do you have backup plans B, C, and D ready to execute? Our TrueBuild® software suite offers the flexibility to execute your plan in your plant your way. Our TrueBuild® Job Management application contains nothing pre-determined or confining. Use it your way. It gives you the ability to assign any task to any resource you choose and also be able to operate with your own status list within each one. You have complete control of capacity and working days, all with the ease of drag-and-drop functionality. You will never “lose” a project again with our quick-look unscheduled list.

This application uses a ticket-based format instead of the traditional job folder with reporting on its contents. Instant visualization of all jobs within a project and all tickets within a job makes it efficient to track progress on those otherwise complicated multi-job or multi-delivery jobsites. TrueBuild® Job Management gives you instant reference where each piece of the puzzle lies in your operation. You have complete and customizable status and task tracking, again based on your process.

TrueBuild® Job Management will even offer you visibility into your performance. As a fabricator, especially in these times, variables are constantly changing. This makes your pricing strategy even more important. Our Labor Analysis Dashboard shows you immediately how your estimated labor stacks up against your actual labor. There are no time collection devices, and no corrupt data because someone on the floor forgot to click a button. You can enter actual data from your timeclock reports or other ledger entries, and spread that data over a day, a week, or any period you choose.

A good Job Management application should not be bulky, cumbersome, or intimidating. Instead, it should be intuitive to the user and be flexible enough to meet the needs of any size operation. It should have exactly what you need but nothing that you don’t. When we developed TrueBuild® Job Management, we wanted to achieve complete flexibility in managing jobs and scheduling your operation with a clean, easy to use interface. We are confident that we have delivered exactly that. Make the decisions you need to make for your business with precise data in a very clear and easy to read interface. Adaptability is a key to success. This software application isn’t like other job management solutions on the market. Contact us today and let us show you what you are missing.

FOB VA Wood Tech Systems 765-751-9990

www.woodtechsystems.com

• Automated Stop & Automated Saw

as directed by Truss Software

• Generation 1 - Windows 98 (highly recommend Spida $32,000 Upgrade)

• 5.5 HP Motor (3 Phase) with 17.7" Blade

• Computer with Enclosure

• Outfeed Table with Automated Stop

• Infeed Roller Conveyor $15,900 FOB KY

Wasserman & Associates 800-382-0329

www.wasserman-associates.com

MiTek Blade linear saw, model 89060-501 for processing up to 20′ length material from 2×3 through 2×12 lumber. The Blade includes a crooked lumber sensor (CLS), servo axis control including bevel cut capability, standard 16-valve face printer, and short horizontal waste conveyor. System includes a 2017 Ranger RT, 65‘, 10 bay lumber retrieval system in an optional “TEE” configuration with 9 bays in front of the Blade feed-rail and 1 bay to the rear (current configuration features (4) Full-unit carts/(6) magazine carts). The Ranger features an integrated control system, 70 feet/minute vacuum pick-head, laser material scanner, and perimeter safety system. Cut material discharges to a skewed out feed-conveyor or an optional rear-facing discharge for delivering cut truss parts to an assembly-table (both conveyor set-ups included). (1) spare blade included. Currently in operation. Installation by the OEM is suggested. 230 volt, 3 phase electrical required. 110 PSI @ 50 CFM air required.

765-751-9990

Safety Speed Manufacturing Model 7400 XL Panel Saw

Safety Speed Manufacturing, model 7400 XL*, vertical panel saw, 3 HP induction motor, 64 inch crosscut, 2 1/8" maximum thickness, accuracy within 0.005 inches, 13 foot long welded steel frame with integrated stand and linear V-guides, enclosed counterweight system, adjustable vertical and horizontal rules. Quick changes from vertical to horizontal cutting. Includes machined aluminum material rollers, hold down bar, wheels, quick stop gauges and material hold downs. Dust collection ready. Options available include digital readouts for vertical cuts, automated length measuring, laser guide, stop bar, vacuum and midway fence. 208-230/460 volt, 3 phase electrical (208-230 single phase, 2 HP power optional +$100.00).

765-751-9990

www.woodtechsystems.com

Since 2006, we've been helping businesses of all kinds build their online presence. We make websites and software for the construction industry to empower companies to reach a wider customer base and engage their audiences. Companies all around the world work with us to make websites and apps that people actually want to use. Reach out to Wolf X Machina if you're a business and you want a website that actually drives results.

Highly confidential position, Regional Manager opportunity. Experience with operations in the $20-50M range. Responsible for all areas of Truss and Wall Panel Manufacturing operations, safety, inventory control, delivery, and customer service at 3 locations producing $10-15M each. The facilities produce Roof and Floor Trusses.

Compensation $100k+ base range plus substantial bonus based on your performance. Very competitive benefits package. Relocation package is negotiable if not in the region. Please inquire to discuss details. Strictly Confidential! Let's talk to see if this is a perfect opportunity for you.

visit: www.thejobline.com email: mail@thejobline.com

Monet DeWall 90/90 wall panel marking saw is a computer numeric controlled wall panel saw with touch screen user interface. Cuts and marks up to 2 boards at a time using 2x4 through 2x8 or cuts and marks one board at a time. Call for pricing, FOB MO

765-751-9990

www.woodtechsystems.com

The majority of our machinery installs are requested to be done over a weekend, usually starting on Friday. A weekend install requires key personnel to give up their weekend in order to minimize production interruption. The weekend of September 30, 2022 in Green Bay, WI was a particularly challenging weekend installation because an existing RetroC had to be shut down in order to be upgraded with 70 ft of auto feed live deck, and concurrently a 250 ft Lumber PickLine had to be constructed — and there was a Packers home game on Sunday to boot!

For this plant, the 70 ft of “actively passive” auto feeding live deck was replacing two full-time forklifts. The biggest fear factor was the thought of implementing just-in-time material feeding. The two full-time forklifts used to pick several jobs ahead in order to keep up with the RetroC to minimize saw idle time. Just-in-time in-line material feeding is possible because the RetroC is that reliable, and that fast.

The goal for the weekend installation team was to improve material in-feed to the RetroC to utilize as much of the RetroC’s unused capacity and to finish before Sunday’s 3:25 pm kickoff time. Packers fans are some of the best and loudest in the NFL and the weekend installation team was no exception, pushing to finish early to enjoy Green Bay becoming a huge tailgate party around Lambeau Field.

The conversion of two full-time forklifts to just one part-time position of replenishing lumber bunks on the 250 ft Lumber PickLine was a big part of the ROI calculation.

Mission accomplished, and the Packers won in OT!

When you’re ready to see these efficient and effective systems for yourself, let us know! Inside and out, LimTek Process Organization Technology will help you squeeze out more truss production and deliver quality trusses with shorter lead times to better service your customers by organizing your truss fabrication pro cesses to maximize your investment in automation. https://limteksolutions. com/#solutions

2006 Alpine AutoMill SC, model 348B, five-blade component saw. Servo controlled computerized saw sets up in 2 to 19 seconds and downloads from a network or by using a touch screen for ease of operation. Five-head automated component saw works in both automated (downloading files) and semi-automated control via touchscreen input. It has 23 axes of automated movement, enhanced diagnostics, and auto management reporting. The SC cuts from 9″ 90/90 blocks to 2′-6″ to 20′-0″ long angled material, in sizes ranging from 2×3″ through 2×12″, and 4-angle floor webs from 3′-4″. Includes [3] 18″, [1] 20″ and [1] 32″ blades with air brakes, under-saw shaker conveyor and a scrap incline conveyor. Includes owner’s manual, all available spare blades and all available spare parts. 480v/ 60Hz/ 3 phase electrical required.

765-751-9990 www.woodtechsystems.com

New, Monet five-head, floor truss web saw, cuts 4-angle, 4x2 floor truss webs from 16 inches and 90-90 blocks from 12 inches to four foot long maximum length. Features 10-board magazine feed, powered, fixed-quadrant angulation, manual carriage standard, shaker-pan scrap conveyor with short incline conveyor and cut-off blade. Option for longer carriage length, single-sided setup (shown in pictures, but not standard), dust hood and horizontal scrap conveyor 480 volt, 3 phase. Call for pricing, FOB MO.

765-751-9990

www.woodtechsystems.com

The Squaring Station consists of a squaring table with various features. The squaring table is designed to hold wall panels square while sheathing is tacked in place and rough openings are cut out, ensuring quality panels every time.

This model can be stand-alone or integrated into a full production line. Various sizes and configurations are available.

•

Generation 3 Framing Table has adjustable 20’ long walls, with wall heights from 6’9” to 14’ 3”. Studs are placed between color-coded stud locators. With just a push of a button, the width adjustment clamp is activated to clamp and square all components. The Generation 3 Framer features a wider table top, designed with the framer in mind. Our new Anti-Slip Surface allows the operator to work on a comfortable and safe surface.

»

squaring lip

»

Razer S5 Linear Saw features AIT auto infeed tables and a stacking system for auto loading two stacked boards into the saw. The saw modules configure for either left-to-right cutting and/or “Z” shaped layout. The Razer S5 Linear Saw provides stack cutting and side by side cutting. The saw cuts Bevel (45 degree only), all main angles, and cut on edge (floor trusses).

track for placing window

Squaring

door

WoodRunner

WoodRunner WR-2 lumber retrieval system seeks and retrieves the exact boards needed to cut. The core of the system is a trolley with an automated picking head. The trolley moves back and forth on a runway truss positioned over lumber carts while the picking head’s laser scans below. After locating the specific piece of lumber needed, the picking head uses a powerful vacuum to hold the board while moving it to the infeed deck.

»

material length with 4 lumber carts

load magazine cart, with guide tracks.

deck holds up to 12 2x4s in queue, and

of the picking head.

system with 5 lumber stations.

2018 Clark Mini Barn Press, builds rigid frames for sheds from 8 foot to 14 foot spans, to 3′-6″ height. Builds mansard and rafter shapes. Includes (5) track mounted heads with 8″ x 10″ platens, material clamps, 10 HP hydraulic power unit with manifold for air and fluid, ball valve controls, mounting track and all available jigging. 460 volt, 3 phase electrical required.

Tech Systems 765-751-9990

2007 Clark Industries Horizontal Truss Stacker Model HVS, Two Unit, 2-Zone, 14’ Horzontal Stacking System. Two lifting units (one master and one slave) with integral electrics. A truss sensing system consisting of adjustable laser sensors mounted on slide rails. One indoor electric control enclosure & panel w/PLC and manual controls. A stacker-conveyor interface package comprised of (1) mounted 3-push button enclosure and (1) remotely mounted 2-push button enclosure (pause/ emergncy stop). Hand-held Wampfler Remote Control System. 8 stacking rails and 4 stripping posts. Stack 1 5/8” thick x 14’ tall trusses up to 30 high. Stack a truss in approximately 40 seconds (cycle time). Stack up to 55’ or longer trusses on each side of the conveyor with minor assistance for truss sag, shorter lengths can be stacked unassisted. Excludes 77’ Walk Through Conveyor System. Two systems available at $25,000 NOW $19,900 Each. FOB NE. Wasserman & Associates 800-382-0329 www.wasserman-associates.com

• 7' x 40' Table with 3/4" Steel Table Top

• Two 5' Park Sections

• Truss Depths from 12" to 26"

• Truss Flip-Over Arms

• Side or End Ejectors

• Bui lt-In Camber for Clamping on Both Sides

• Air Cylinders Under Table

• 2 Contr ol Valves for Clamping

• 1 Contr ol Valve for FlipOver Arms

• 1 Control Vlave for Ejectors

• 24" Diameter x 1" Wall Thickness Roller

• 10 HP / 3 Phase Gear Motor

• Front & Rear Emergency Shut-Off Bars

• Joystick Control

• 2' per Second Travel Speed

| www.wasserman-associates.com

98’ x 14′ side-eject system complete with (13) T&G plastic top 14’x72″, recessed-rail tables, with (12) skatewheel liftouts. 110′ dual gantry rail, and dual 7′ park stations. Table plastic is newly installed on 6 tables with material included to refinish the remaining 7 tables. Currently configured with 20″ aisles (includes aisle cover plates). System includes 120′ of conveyor @ 5′ O.C. (12-pwr, 12-idle ), no receivers. Features one (1) 24″ dia. Klaisler GR 14-24 recessed rail, gantry roller with 24″ diameter roller, riding platform, and push-button controls. 14′ Final-Roller with 20″ diameter rollers, driven by dual SEW Euro-Drive motors with a single safety-bar. includes all available air-manifold, electrical chord, jigging hardware , 230v, 3ph, 60 amp power. As-is, Where-is.

New table-guided (NO rail) gantry system by Spida, side-eject or end-eject options, with continuous production tables built to length. Available in steel, plastic or combination table top options. Can be fabricated to receive automated jigging such as “Wizard” brand. 24″ diameter gantry heads feature raised operator platform, heavy-duty steel roll with 4″ shaft, baffles and heavy-duty spherical bearings, dual 7.5 HP braking gear motors for a total of 15 HP, easy adjusting bogie wheel assemblies, safety bars, Wampfler “finger safe”, under-table-mounted electrical supply and optional soft start drive. Spida can provide the combination of powered transfer rolls, sloping ejectors, receivers, idler conveyors and powered conveyors required to meet your configuration needs. 440 volt, 3 phase electrical. Other voltages available. FOB IN.

765-751-9990

By Rob Bellian Sales and Marketing Manager

By Rob Bellian Sales and Marketing Manager

Today, linear saw technology provides unmatched efficiency with profound differences to productivity, service, and reliability. An automated linear saw can also reduce the lumber cut waste by batching and combining different cuts of various pieces known as lumber optimization. So what is the one question that’s seldom asked but has the biggest impact on a business when choosing a linear saw: how efficient and flexible are the optimization algorithms of your system?

Optimizing seems relatively straightforward – it’s largely based on the software looking at your components, mixing and matching them to work out what length of timber would be best to cut from them. Cut files can have hundreds of components, but without meaningful and efficient ways of sorting the components after cutting, the order of the cutting becomes critical and a significant optimizing constraint.

Obviously, if you’re thinking of investing in a new linear saw to improve your optimization, you’ll have lots of questions. My advice: make sure these five are on your list.

1. Is there flexibility in the cutting order? You may want to cut in a certain way now, but a good algorithm will give you efficient options to cut in a variety of manners. A good optimizing algorithm must be extremely flexible in how it can be configured if you want to get optimal results

2. How mature is the algorithm? Optimizing algorithms are a far less obvious element of a linear saw, but they have one of the single biggest impacts on the financial benefits. Look for long-standing, constantly improved and improving algorithms.

3. Are there tools to help refine your settings? Every plant will want and need to optimize differently. This means a flexible system must be configured in a custom way to best fit your business. A good software package should have specific tools that will help you work out things such as what lengths of timber you should stock and the impact of the cutting order on timber efficiency.

4. Where and how can optimizing be performed? Some businesses prefer to optimize at the saw. Others prefer for someone in the office to be responsible for minimizing waste. A good optimizing solution will provide efficient means of doing both, including the ability to lock files that have been pre-optimized. The software should also make it easy to optimize several files at once and automatically print off and/or save necessary files and documents, such as pick lists.

5. Can I run sample files and see the results? If you are looking at a new saw, it is a great idea to ask the suppliers you’re considering to run some sample files for you and analyze the results – the more, the better! It’s amazing how rarely this happens for such a crucial element of a very expensive piece of equipment.

If you have a linear saw, take the time to evaluate your optimizing systems and settings. If you are looking at purchasing a linear saw, ask the questions and take the time to ensure the optimizing system stacks up to today’s standards and your expectations. Don’t be afraid to evaluate your options against the optimizing software of the Vekta Razer Saw.

We’ve developed and continually improved our optimizing software over the past 20+ years with the focus on enhancing optimizing for both flexibility and efficiency. We’ve engaged and collaborated with Curtin University Mathematics Department to develop ground-breaking mathematically guaranteed optimizing algorithms – making a significant investment in the R&D on this endeavor alone. With the ability to do a variety of cuts between 0° to 67° at a throughput rate of 300 – 500 components per hour, it’s no wonder the Vekta Razer V5 Linear Saw is the choice of large and small plants today.

Optimization is not a trivial element in today’s linear saws, and it isn’t something that can be developed properly in just a few years. Good, proper, and efficient optimization is an extremely complicated process that can’t be rushed. Go ahead and prepare some sample results – they’ll be worth it.

2016 Triad exterior and interior wall panel lines with conveyors and terminal stations. Builds 2×4 and 2×6 walls up to 16’ in length with wall heights from 6’-9” to 10’-2” and includes Component Nailer model FTN and panel lift model XPL1000:

Exterior line includes (2) sets of Rough Opening Assembly tables model RO-CAT, framing table model Gen II with manual nail-gun tool dollies each side & stud locators at 16” and 24” o.c., squaring and sheathing table model Gen II with staple & routing combo bridge & side shift for seams @ 3” & 6” o.c. fasteners, top & bottom plate gun mounts for 6” o.c. fasteners, auto stop & tilt features, (3) 10 ft skatewheel conveyors, (4) 20 ft x 36″ roller conveyors and (4) powered infeed conveyors with chain track.

Interior line includes Rough Opening Assembly table model RO-CAT, framing table model Diamond Quad with manual nail-gun tool dollies each side, pop-up rollers & stud locators at 16” and 24” o.c., (2) 10 ft skatewheel conveyors, (4) 20 ft x 36″ roller conveyors.

System sold for over $223,000 new. Sold as one system only. 110 volt, 1 phase electrical required. 100 PSI air required.

Used Triad wall assembly equipment includes 16 ft x 12′-3″ max height framing station, model G2, with (2) two-tool dollies, squaring/ sheathing combo table, model G2 SH-SQ, with multi-tool mount nailing bridge and separate manual-drive router bridge, quantity of (6) 10 ft long x 2 ft wide idler roller conveyors with (4) legs, and Triad model FTCN component nailing station with four Hitachi NR83A nail tools.

Framer includes 16″ and 24″ color-coded stud locators, pop-up skate wheel conveyors, tool dollies have two tool mounts each (no tools) and powered height adjustment. Sheathing bridge includes joy-stick controls, tool offset, tool tilt, laser guide, power return and mounts for up to (23) Hitachi nail tools. Router and all available spare parts included. 120 volt, 1 phase, 30 Amp electrical required. 100 PSI air required.

Wall Panel Work-Station (Green)

Custom fabricated, heavy-duty table ideal for producing rough openings, rake-walls, even interior walls. Table features a squaring lip, double-row pneumatic liftouts, duplex 110v outlet for hand tools. Table dimensions: 16’ 4 1/2” long, 9’ 5” wide, 30 1/2” high.

$9,490 FOB KY Wood Tech Systems 765-751-9990 www.woodtechsystems.com

Wall Panel Work-Station (Blue)

Custom fabricated, heavy-duty table ideal for producing rough openings, rake-walls, even interior walls. Table features a squaring lip, double-row pneumatic liftouts, duplex 110v outlet for hand tools. Table dimensions: 17’ 8 3/4” long, 9’ 5” wide, 25 1/2” high.

$9,490 FOB KY

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Consider Panels Plus wall panel assembly equipment for manufacturers of wood or steel wall panels, floor-panels, and related framing components. Panels Plus is an employee owned, ISO certified, manufacturing company that builds state-of-the-art equipment featuring durable construction, with fit and finish second to none in the structural building component industry. The referenced base framing table allows you to assemble from 7-12 foot wall heights, at industry standard 16 foot lengths, at a working height of 29 to 32 inches. This framer design includes controls at each end of table, squaring stops and pneumatic clamping for consistent wall panel quality. Frames 2x4 or 2 x 6 walls, with color-coded, steel stud locators at 16 and 24 inches O.C. spacing. Includes pop-up skate wheels for easy transfer of completed wall frame. Framing table can be configured to receive wall framing light bars, other options include custom buildable wall heights, lengths and auto-indexing of optional 2 or 3 tool carriages.

Additionally from Panels Plus are sheathing tables with features that include foot pedal control at squaring end of table, with squaring stops, roller conveyors at both sides, single pendant controls for bridge, tool spacing at 6 inch centers with 3 inch bridge shift for offset nailing. Tool bridges can accommodate from 2 x 4 to 2 x 8 walls, with seam tilt being standard equipment Panels Plus Tool Bridges are available with single beam or dual beam design for two different tool mounts on one bridge. Squaring stations, sub-component tables, conveyors and panel lifts are also available to complete the configuration of the wall panel assembly line. Price includes factory installation and training. 50 CFM at 120 psi air. 120 or 230 volt, 1 phase electrical.

765-751-9990 www.woodtechsystems.com

Modern business relies on actionable data to drive decisions. That’s why truss component manufacturers rely on Simpson Strong-Tie. As a partner to the construction industry, we’re continuing to invest more resources in solutions built just for you. Our open-platform software can be integrated with your existing systems and equipment for smoother collaboration inside and outside the company. At the same time, it provides secure access to proprietary data, so customized reports can be created with greater ease and control. Use your data, your way, and drive business results.

Get the software you need to manufacture business success. To learn more, visit our website at go.strongtie.com/componentsolutions or call (800) 999-5099.

2021 Triad Router Bridge & Portion of V-Track

2021 Triad Routing Bridge with approximately (20) feet of v-track. Fits over tables that build up to 12′ nominal height wall panels. Includes powered automatic bridge return, powered vertical router movement, manual fine adjustment wheel, manual vertical router travel with chain drive and (1) Milwaukee router, catalog #5625-20 120 volt, 1 phase, 15 Amp electrical required. No table included.

$28,970 NOW $5,000 FOB BC

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

FOB: MN

IBS Tool Bridge & Router Bridge

IBS multi-tool bridge with (24) tool stations.

features auto-return, button controls and laser guide mount. Fits up to 12′ nominal rail centers. IBS router bridge features (1) router, laser guide mount and lever-switch button controls. Fits up to 12′ nominal rail centers. Sold as a pair. Includes all available floor mounted, v-rail. Both bridges missing laser sub-assembly. 120vac, 120psi air.

$15,975 FOB UT

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

New Panels Plus floor framing machine, supports the structural members creating floor sections from 2" x 6" LVL through 2" x 10" to 2" x 12" dimensional lumber, 20" deep wood floor trusses or engineered wood / I-joists. Standard footprint of floor panels (cassettes) up to 12' wide x 45' long. Table consists of a fixed section and a track-guided, moveable section controlled by either a foot switch or push-buttons.

Includes a series of color-coded locator pins at 16", 19.2 and 24" on-center spacing and clamping with squaring feature including foot pedal control. The locators individually flip down if a joist comes out on top of them. After the floor is complete and unclamped, the floor section can be raised up on skate-wheel conveyors and rolled out or lifted off the table using an overhead crane. Table height is 24.5", OAL 45.5 ft, OAW 14.5 ft. 120 volt, 1 phase, 15 Amp electrical required. 90 to 120 PSIG at 15 CFM air required.

www.wasserman-associates.com

Alpine has it all—the right equipment, user-friendly software and dependable hardware to improve your teams efficiency. Alpine delivers the complete package for success—including comprehensive support and service that sets us apart within our industry.

Ask those who know. They’ll tell you about the people at Alpine who make a difference.

“Alpine has been our partner for the 20 years we’ve been in the truss industry. Their service and product innovation are second to none!”

— Joe Nolte, Noltex Truss

2016 Triad wall assembly equipment, model Diamond Quad Framer, Panel Nailer Bridge and Flow Thru Nailer. Builds from 6′-9″ to 9′-3″ panel heights to 16′-0″ long. Framer includes power height adjustment, (4) Hitachi nail tools, squaring stops, manual dollies and parking sections. Nailing bridge includes (18) Hitachi nail tools, laser pointer, 3″ tool shift function and plate fire. Flow Thru Nailer includes (4) Hitachi nail tools. Handle bar router and all available skatewheel conveyors are included. 120 volt, 1 phase electrical required. 100 PSI at 10 CFM air required at nail bridge and Flow Thru Nailer.

765-751-9990

www.woodtechsystems.com

IT’S ONE THING IN LIFE TO MAKE THE CUT. IT’S ANOTHER TO MAKE IT BETTER.

The concept of the Spida Extruder is to bring materials to a central location as the product is extended or “extruded” to create the framed wall panel. A single operator in one central location, feeds the studs and sub-components in-between the plates, while the Extruder does the nailing. The Extruder features (4) servo-controlled, indexing, bracket-mounted tools that can be coil or stick fed, hands-free clamping of plates and is adjustable for wall heights starting from 5’-11”, with options to build walls to 12‘3”, from 2×4″ to 2×8″ lumber.

An option is available to add an intermediate tool mount, for fastening blocking between studs, a notoriously slow process in wall panelization that usually reduces production. The Extruder design makes this connection much easier for the operator, keeping your wall production high.

The support stations are adjacent to the Extruder and operators at those stations build the sub-component openings, sub-assemblies (like ladders) which are conveyed to the central operator’s station, where they are dropped and nailed into the panel in sequence.

Conveyors and transfer tables of various configurations are used to bring the parts to the Extruder. Each design takes advantage of curved or raised conveyors to efficiently bring materials to the Extruder and fit within your plant’s material flow in the most efficient way possible.

Once the wall panel is framed, it proceeds by conveyor to a squaring station and a sheathing station for completion. Here too, the sheathing is fastened as the panel passes by the sheathing bridge with its’ (4) four, high-speed tools. There are options for router bridges and automated ply loading. The Spida Sheather is a fully automated, CNC machine that features touch screen controls and tilt nailing at seams.

Over ten years in development and use in Australia and Asia, there are now several locations using the Extruder here in North America. A typical system can be installed in about (5) hours thanks to the modular, “plug-and-play” design of the Spida wall equipment. 120 volt, 1 phase, 15 Amp electrical required and 110 PSI air @ 6 CFM required for each Extruder and Sheather station.

Developed in a commercial wall panel production facility this is the remarkable ProStack, fully automated wall panel stacker. The ProStack relieves your build team from creating a stack of wall panels and keeps them building walls instead. Stacks 2×4 through 2×8 walls up to 20′ in length and up to 12 feet in height. The ProStack automatically centers each layer including multiple wall

on the same layer, and the ability to “create” fork lift pockets for ease of loading in your yard or on the build site. (Please see video for more.) 208 volt, 3 phase, 45.3 full Amp load electrical required. No air required. Footprint is 26′-5″L x 19′-3″W.

2016 Triad exterior and interior wall panel lines with conveyors and terminal stations. Builds 2×4 and 2×6 walls up to 16’ in length with wall heights from 6’-9” to 10’-2” and includes Component Nailer model FTN and panel lift model XPL1000:

Exterior line includes (2) sets of Rough Opening Assembly tables model RO-CAT, framing table model Gen II with manual nail-gun tool dollies each side & stud locators at 16” and 24” o.c., squaring and sheathing table model Gen II with staple & routing combo bridge & side shift for seams @ 3” & 6” o.c. fasteners, top & bottom plate gun mounts for 6” o.c. fasteners, auto stop & tilt features, (3) 10 ft skatewheel conveyors, (4) 20 ft x 36″ roller conveyors and (4) powered infeed conveyors with chain track.

Interior line includes Rough Opening Assembly table model RO-CAT, framing table model Diamond Quad with manual nail-gun tool dollies each side, pop-up rollers & stud locators at 16” and 24” o.c., (2) 10 ft skatewheel conveyors, (4) 20 ft x 36″ roller conveyors.

System sold for over $223,000 new. Sold as one system only. 110 volt, 1 phase electrical required. 100 PSI air required.

With a Terminailer XP, it takes only one person to drive between 30% and 70% of the framing nails in any given job . And all this nailing is done within a secure enclosure, so your people are protected from costly nailing injuries while eliminating literally millions of repetitive motions ( 4,001,398 repetitive motions to be exact , judging from the total nail count tallied recently on a two year-old Terminailer XP).

That’s a lot of nails successfully installed to be sure, and a lot of debilitating repetition your workers’ hands are spared, without any complicated training, software or lengthy setup time required.

Developed by people who know wall panel production, Terminailer XP boasts multiple repeat buyers, 20-plus machines performing exceptionally in the field and tens of millions of nails installed. Thoroughly field-proven, Terminailer is ready to drive greater productivity for you. Contact us today for more information.

765-751-9990 www.woodtechsystems.com

Wood Tech Systems is a registered trade name of Wood Truss Systems, Inc.

Withinterest rates on the rise, it’s important to consider working with funders who are not as quick to increase rates. You need a lender who will help you not squeeze you, in this economic climate or any climate. You need a company that will work with you to do the best they can for you.

Here at Acceptance Leasing and Financing, we have strong working relationships with the top funders in the business and can pass on the best rates in the industry to you, despite the rising rate environment.

New programs are being created and marketed all the time, and we would be pleased to introduce you to them so that you could take advantage of these offers.

One obvious advantage we have is to be able to lock in a rate regardless of the delivery date of the equipment. With supply chain disruptions, you want to be able to secure a lower rate now and not be exposed to the uncertainty of what rates may be like months into the future.

Of course, many programs that you may not be aware of are on-going. “Application Only” financing permits you to apply for financing with a minimum of paperwork. We also offer deferred payment programs which allow you to make minimal monthly payments during your slow season to help you with cash flow issues.

And of course, there is always the flexibility of deciding the terms of your financing, from 24 months up to 84 months in some cases.

We invite you to contact us at 412 262-3225 to learn what programs are currently in place to help you with your borrowing needs. And remember, there is no annual financial reporting required after you’ve been approved. The only collateral is the equipment being financed.

We are Acceptance Leasing and Financing Service, Inc. We’re proud to be celebrating our 30th anniversary in business this year. Established in 1992, we pride ourselves on our Certified Leasing and Financing Professional designation. We are a member of SBCA and a frequent attendee of the BCMC tradeshow. We can provide financing for any new and, regardless of age, used equipment.

We look forward to working with you.

AMI's industrial floor trucks (material carts) are designed of hardwood construction, fitted with space-age phenolic, roller-bearing wheels, and ball bearing swivel casters for strength and durability. AMI's phenolic wheels resist shock without chipping. They are non-sparking, non-marking, and can be operated continuously between -50℉ and 260℉. They are unaffected by grease, oil or debris on your shop floor.

Hain 20' Powered Measuring System

Adapts to Any Saw. Left or Right Hand Operation. Feet & Inches System (Stops at 12” Centers) or Inches System (Stops at 10” Centers). Motor: 1/4 HP Linear Actuator (110 Volt). Stop Rail: 2 x 4 x 1/4” Aluminum Extrusion. Stops: Jig Bored Steel. Stop Blocks: Machine Billet Aluminum. Optional Lengths from 5’ to 60’. Optional Gang Stop. Add $890 per 10’ Section of Heavy Duty Roller Conveyor with Stands $7,890 Wasserman & Associates 800-382-0329 www.wasserman-associates.com

Since

make websites

industry to empower companies to reach a

base and engage their audiences. Companies

around the world work with us to make websites and

that people actually want to use. Reach out to Wolf X Machina if you're a business and you want a website that actually drives results.

WOLF X MACHINA www.wolfxmachina.com info@wolfxmachina.com

MISC.

Scrap Incline

legs, side-rails,

power

Where-Is.

$1,990 FOB KY

Wood Tech Systems 765-751-9990 www.woodtechsystems.com

2017 CMF-Stealth Live Deck

2017 CMF-Stealth Live Deck, (6) rail/ pedestal design, 16′ wide x 20′ long, powered infeed for component saws. Handles lumber lengths from 3′ to 20′. Features guarded sprockets, heavy-duty construction, dual push-button controls at both ends of deck and adjustable base feet. Split-design, easily shipped and installed. Multi-voltage 3 phase motor. Steel panels between rails not included.

$28,497 FOB PA

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Quincy QT-15 splash lubricated, reciprocating compressor with 120 gallon tank.15HP motor supplies a manufacturer stated 52.5 CFM at 175 PSI. 230v, 3 phase electrical.

$2,990 FOB IN

Wood Tech Systems 765-751-9990

www.woodtechsystems.com

New SL Laser Projection System

The WoodRunner WR-2 lumber retrieval system seeks and retrieves the exact boards needed to cut. The core of the system is a trolley with an automated picking head. The trolley moves back and forth on a runway truss positioned over lumber carts while the picking head’s laser scans below. After locating the specific piece of lumber needed, the picking head uses a powerful vacuum to hold the board while moving it to the infeed deck.

Call for Price

Eide Integrated Systems, LLC 612-521-9193

www.eidemachinery.com

New, laser projection system from SL Laser. Projects roof truss, floor truss and wall panel design images accurately onto building surface, for faster setup and fabrication times. Each laser head provides 21' projection length (@15 foot ceiling heights). Includes system computer, cables, mounting hardware for attachment to customer's structure, factory installation, training and choice of green or red laser. Works with each connector plate manufacturer's design software. Modular nature of the laser heads allows for easy, future expansion of system length. 120 volt, 1 phase. FOB NC Wood Tech Systems 765-751-9990

www.woodtechsystems.com

Virtek LPS-6R, 3-Head System

2003 Virtek, 3-head system, model

includes

with

and

heads for

and

Projection area of 14′

20′ with proper

height

work area. Red laser projection. 110 volt,

phase electrical.

$9,890 FOB OK

Wood Tech Systems 765-751-9990

The Generation 3 Framing Table has adjustable 20’ long walls, with wall heights from 6’9” to 14’3”. Studs are placed between color-coded stud locators. With just a push of a button, the width adjustment clamp is activated to clamp and square all components. The Generation 3 Framer features a wider table top, designed with the framer in mind. Our new Anti-Slip Surface that allows the operator to work on a comfortable and safe surface.

Call for Price Eide Integrated Systems, LLC 612-521-9193

www.eidemachinery.com

on

It

to the next in

simple to use. Even a first

It can adapt to any saw and

with your existing

operation and

preference. The MEA is

When I think about JobLine turning 30, my first thought is: how did time go by so fast