MANU007 - Basic maintenance, damage prevention

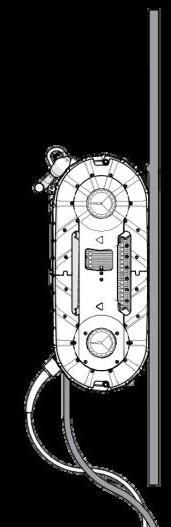

Prevent serious incidents: Always - Inspect the load arrestors before use

Prevent severe mechanical damage or personnel injuries

Inspect load arrest and supporting parts

•

Inspect the load arrest functionality by pulling the wire / rope

Inspect housing, wire, slings and ropes for damages or excessive wear.

• Do not disassemble the load arrestors

• Keep the free movement of the load arrestors

If the rope is not being kept tight between robot and load arrestor when the load bags are mounted, the load arrestor may be exposed to dust, cargo or water limiting the free movement

Grease load arrestor wheel with Würth Multi 2000

Storage and operations in sub-zero temperatures [C°]

Prevent equipment rupture and pump malfunction

Add anti-freeze to High-Pressure System

Add frost protection according to MANU011 (Highpressure System Manual) to prevent damage during storage down to –10° C (14° F).

High-Pressure system must be kept above 0 C° (32 °F) during operation at all times. - This can be bypassed in glycol cleaning.

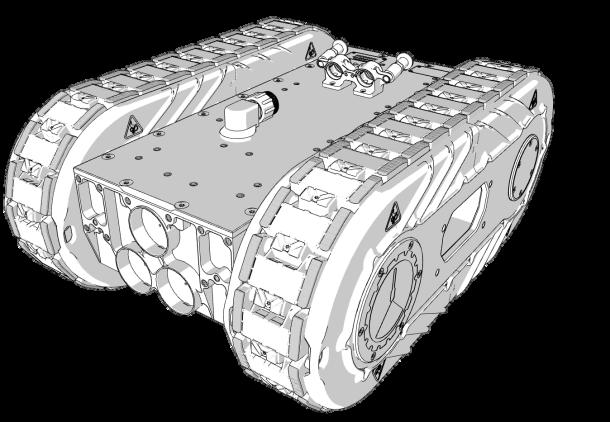

Lack of friction in robot operation

If the robot is not getting traction on the vertical sides of the vessel, follow the steps according to MANU013 (RAW0011 Manual).

Prevent downtime during operations - Inspect and replace consumables

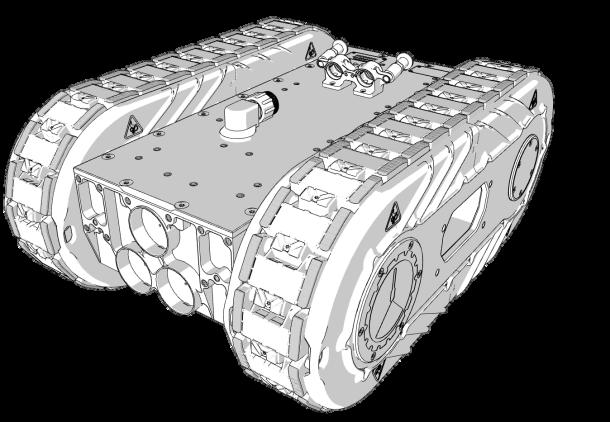

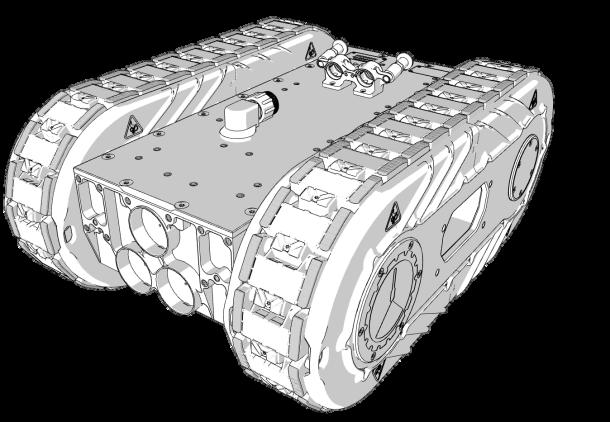

Keep the spaces between track links clean at all times

Dirt,scales, andcargo residues betweenthe links will drastically increase the risk of broken track links.

Check magnetic tracks for any damage and general wear after each cleaning and replenish lost rubber pads. Clean allmagnetsfrequently - includingbottommagnets.

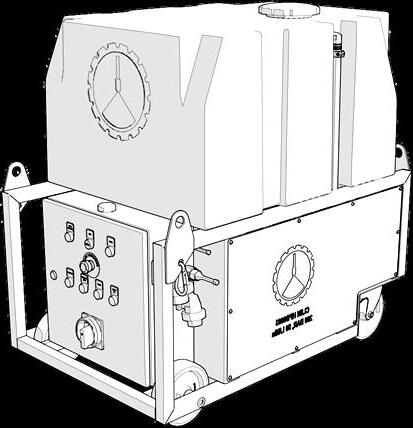

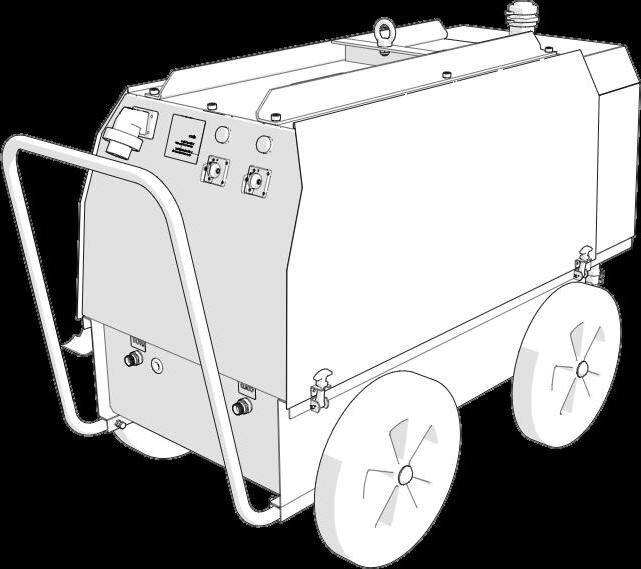

If using heater: Prevent severe failure and potential fire hazard

Prevent severe mechanical failure and potential fire hazard

Theuseofcontaminated fuelswill resultin filterclogging, damage to fuel pump, electrodes, injector nozzles and consequently lead to fuel leakage and fire.

Only use clean automotive diesel (according to EN 590) or clean marine gasoil (grade DMX or DMA according to ISO 8217).

Prevent sudden mechanical failure: Always - Keep tracks clean

Keep the spaces between track links clean at all times

Dirt,scales,andcargo residues betweenthe linkswill drasticallyincreasethe risk of brokentrack links.

Check magnetic tracks for any damage and general wear after each cleaning and replenish lost rubber pads. Clean allmagnetsfrequently - includingbottommagnets.