This page intentionally left blank.

This page intentionally left blank.

Organisation: Connectus

Document Title: Erosion and Sediment Control Plan

Fulcrum Document Number: CRL-PAT-ENV-CON-PLN-000897

Document based on MMS No: n/a

Client: Auckland Transport

Project: CRL Enabling Works: Contract Two

Location: Auckland CBD Project No: 2665

This document remains the property of Connectus. Its contents are confidential and shall not be reproduced, destroyed or given away without the express, written permission of Connects. The electronic version of this document in MMS Database on designated server(s) is the Master Copy and is a controlled document. Unless specifically noted thereon, other copies of this document are uncontrolled.

This page intentionally left blank.

Term Definition

ACZ Active Construction Zone

AC Auckland Council

AT Auckland Transport

CEMP Construction Environmental Management Plan

CFA Continuous Flight Auger

CR City Rail Link

CSA Construction Support Area

CTMP Chemical Treatment Management Plan

EMP Environmental Management Plan

ESCP Erosion and Sediment Control Plan

ISCA Infrastructure Sustainability Council of Australia

pH Numerical measure of the acidity or alkalinity of a solution measured on a logarithmic scale on which 7 is neutral

TP90 Auckland Council Technical Publication 90 (TP90) “Erosion and sediment control guidelines for land disturbing activities in the Auckland Region”.

TSS Total Suspended Solids

WTP Water Treatment Plant

This page intentionally left blank.

4.4.3

Connectus

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

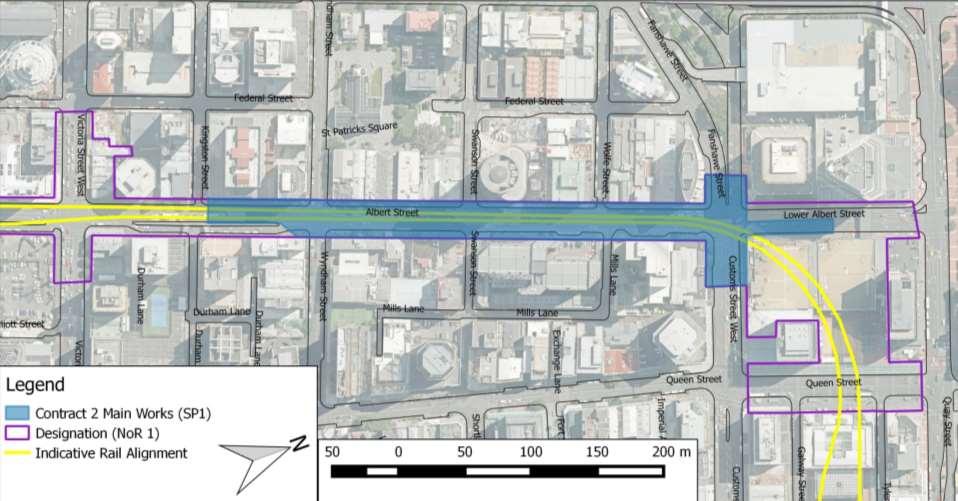

The City Rail Link (CRL) project comprises the construction, operation and maintenance of a 3.4 km underground passenger railway, running between Britomart Station and the North Auckland Rail Line in the vicinity of Mt Eden station. The works relating to this Erosion and Sediment Control Plan (ESCP) constitute part of the enabling works for the CRL. The works (the Project) involve the construction of twin rail tunnels within the Albert Street road corridor from Customs Street West to Wyndham Street. The tunnels will be constructed using a staged cut and cover method and are expected to take 33 months to complete. Figure 1 outlines the extent of works for the Project.

This ESCP (including a Chemical Treatment Management Plan (CTMP) – refer Appendix D) has been prepared by AECOM New Zealand Limited (AECOM) and forms part of the Construction Environmental Management Plan (CEMP) for the Project.

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

and Sediment Control Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000897

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

The objective of this ESCP is to provide for the management of all bulk earthworks to minimise any discharge of debris, soil, sediment or sediment-laden water beyond the site to land and stormwater drainage systems. The objective of the CTMP is to confirm the measures that will be taken to ensure that construction of the Project will be generally consistent with the Water Quality Assessment and the Industrial and Trade Activities Assessment prepared by Golder Associates (NZ) Limited, both dated December 2014

This ESCP and the CTMP will be implemented throughout the entire construction period and will be the primary tool for erosion and sediment control for the Project. They are ‘living documents’ which may undergo expansion and updates as the Project progresses and working conditions become clearer. Draft versions of the Plans were discussed with the AC monitoring team on Wednesday 2nd March 2016. Agreement on the general approach to sediment control was made during this meeting. It was also noted during the meeting that the choice of specific water treatment equipment may evolve from what is specified in this ESCP. However any change to the ESCP or CTMP will be submitted to Auckland Council (AC) (Team Leader Central Monitoring) for certification. No construction activity will commence until certification from AC is provided and no activity reliant upon a change to the ESCP or CTMP will be undertaken until the change has been certified.

This ESCP has been prepared in consultation with a Community Liaison Group (CLG) prior to submission to Auckland Council (as per condition 19 of the Britomart to Wyndham consent conditions). A record of these consultation outcomes is included in Appendix F.

Table 1 outlines the relevant conditions from land use consent R/REG/2014/5430 and how these are addressed within the ESCP.

Connectus

Project #: 2665

Client: Auckland Transport

Table 1 ESCP conditions from land use consent R/REG/2014/5430 and the relevant sections of this document

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

44 This resource consent shall expire 15 years after the consent commences unless it has been surrendered or been cancelled at an earlier date pursuant to the RMA.

45 At least 20 working days prior to the commencement of construction, a finalised ESCP which provides for the management of all bulk earthworks to minimise any discharge of debris, soil, sediment or sediment-laden water beyond the site to either land and/ or stormwater drainage systems shall be prepared and submitted to the Council (Team Leader Central Monitoring) for certification

46 No construction activity shall commence until certification from Council is provided.

47 The Consent Holder shall request the Council’s (Team Leader Central Monitoring) determination as to whether the ESCP can be certified, in writing, within 10 working days of receipt of the ESCP.

48 The ESCP shall include, but not be limited to, the following matters:

a. identification of construction zones and construction support areas;

b. specific erosion and sediment control works for each Active Construction Zone (location, dimensions, capacity supporting calculations and design drawings), which should be in line with Industry Best Practice that will meet or exceed the performance of measures detailed in Auckland Council Technical Publication No. 90, Erosion & Sediment Control: Guidelines for Land Disturbing Activities in the Auckland Region (TP90);

c. catchment boundaries; 2.2

d. the timing and duration of construction and operation of control works (in relation to the staging and sequencing of bulk earthworks); 4

e. details relating to the management of exposed areas; 4

f. reference to the Chemical Treatment Management Plan and confirmation of ESC measures necessary to give effect to that plan; 4.4.3.3

g. reference to the Contaminated Soils Management Plan and confirmation of ESC measures necessary to give effect to that plan; and. 3.4.1

Project #: 2665

Client: Auckland Transport

h. monitoring and maintenance requirements, including information on complaint investigation and response procedures, training, and roles and responsibilities

49 Any change to the ESCP shall be submitted to the Council (Team Leader Central Monitoring) for certification. No activity reliant upon a change to the ESCP can be undertaken until the change has been certified. The Consent Holder shall request the Council’s (Team Leader Central Monitoring) determination as to whether the proposed change can be certified, in writing, within 10 working days of submission of the change.

50 At least 20 working days prior to the commencement of construction, a CTMP which confirms the measures that will be taken to ensure that construction of the Project or Project Stage will be generally consistent with the Water Quality Assessment and the Industrial and Trade Activities Assessment prepared by Golder Associates (NZ) Limited, both dated December 2014 shall be submitted to Council (Team Leader Central Monitoring) for certification.

51 The Consent Holder shall request the Council’s (Team Leader Central Monitoring) determination as to whether the CTMP can be certified, in writing, within 10 working days of receipt of the CTMP.

52 The CTMP shall include, but not be limited to, the following matters:

a. Specific design details of the chemical treatment system based on a batch dosing methodology for the site’s settlement tanks, including the potential for use of nonchemical flocculants (e.g. chitin based flocculants such as Haloklear);

b. Monitoring, maintenance (including post-storm) and contingency programme (including a record sheet);

c. Details of optimum dosage (including assumptions);

d. Results of initial chemical treatment trial;

e. A spill contingency plan; and

f. Details of the person or bodies that will hold responsibility for the long term operation and maintenance of the chemical treatment system and the organisational structure which will support this system.

04, Date: 21 March 2016

Appendix D

Appendix D

Appendix D

Appendix T of the Project CEMP (Emergency Spill Response Plan)

53 Any change to the CTMP shall be submitted to the Council (Team Leader Central Monitoring) for certification. No activity reliant upon a change to the CTMP can be undertaken until the change has been certified. The Consent Holder shall request the Council’s (Team Leader Central Monitoring) determination as to whether the proposed change can be certified, in writing, within 10 working days of 1.1

Project #: 2665

Client: Auckland Transport Revision: 04, Date: 21 March 2016

submission of the change.

54 Prior to construction (bulk earthworks) commencing, a certificate signed by a senior qualified person shall be submitted to the Council (Team Leader Central Monitoring) to certify that the erosion and sediment controls have been constructed in accordance with the certified ESCP(s) as required by Condition 45 of this consent.

55 Certified controls shall include diversion bunds, silt fences, and sumps. The certification for these subsequent measures shall be supplied immediately upon completion of construction of those measures. Information supplied, if applicable, shall include:

a. contributing catchment area;

b. shape of structure (dimensions of structure);

c. position of inlets/outlets; and

d. stabilisation of the structure.

56 The Consent Holder shall ensure that there shall be no deposition of earth, mud, dirt or other debris on any road or footpath resulting from bulk earthworks on the subject site. In the event that such deposition does occur, it shall immediately be removed. In no instance shall roads or footpaths be washed down with water without appropriate erosion and sediment control measures in place to prevent contamination of the stormwater drainage system, watercourses or receiving waters.

57 The operational effectiveness and efficiency of all erosion and sediment control measures specifically required as a condition of resource consent, including the certified ESCP referred to in Condition 45, shall be maintained throughout the duration of bulk earthworks, or until the Project site is permanently stabilised against erosion.

58 The site shall be progressively stabilised against erosion at all stages of earthworks activity, and shall be sequenced to minimise the discharge of contaminants to groundwater or surface water.

59 The Consent Holder shall ensure that the erosion and sediment control measures shall be constructed and maintained in accordance with Auckland Council’s Technical Publication 90: Erosion and Sediment Control Guidelines for Soil Disturbing Activities in the Auckland Region, and any amendments to this document, except where a higher standard is detailed in the documents referred to in conditions above, in which case the higher standard shall apply.

60 Sediment control measures shall be inspected on a weekly basis and after a significant storm event to ensure effective operation. In the event that a discharge of debris, soil, silt, sediment or sediment-laden water occurs, the activity which resulted in the discharge shall cease immediately and the discharge shall be mitigated and/or rectified to the satisfaction of the Council (Team Leader Central Monitoring).

Project #: 2665

Client: Auckland Transport Revision: 04, Date: 21 March 2016

61 The Consent Holder shall ensure that all material removed from or delivered to the Project site shall be covered during transportation. 3.3

62 Upon completion or abandonment of bulk earthworks on the Project site all areas of bare earth shall be permanently stabilised against erosion to the satisfaction of the Council (Team Leader Central Monitoring).

63 Pursuant to section 128 of the RMA the conditions of this consent may be reviewed by the Council (Team Leader Central Monitoring) at the Consent Holder’s cost, by giving notice pursuant to section 129 of the Act, within six months after commencement of bulk earthworks and subsequently at intervals of not less than one year thereafter in order to achieve the following:

a. To deal with any adverse effects on the environment which may arise or potentially arise from the exercise of this consent and which it is appropriate to deal with at a later stage;

b. To alter erosion and sediment control requirements as a result of previous monitoring outcomes, and/or in response to changes to the environment and/or hydro-geological knowledge, and/or changes to industry best practice;

c. If, at any time, it is found that the information made available to the Council in the application contained inaccuracies which materially influenced the decision and the effects of the exercise of the consent are such that it is necessary to apply more appropriate conditions; and

d. If, at any time, CRL-related works being undertaken under a designation providing for aspects of the Project, or a separate resource consent, leads to an inconsistent approach to the management of effects.

99

The Consent Holder shall ensure that the following structural controls are constructed for the following catchment areas and design requirements and they are completed prior to discharges commencing from the site.

3.1, 4.4, Appendix K of the CEMP (Industrial Trade Activities Environmental Management Plan)

Project #: 2665

Client: Auckland Transport Revision: 04, Date: 21 March 2016

100 In the event that any minor modifications to the structural controls system are required, the following information shall be provided to Council:

a. Plans and drawings outlining the details of the modifications; and

b. Supporting information that details how the proposal does not affect the capacity or performance of stormwater management system. All information shall be submitted to, and the proposed modifications certified by the Council (Team Leader Central Monitoring), prior to implementation.

101 Within 30 days of the installation of the water treatment system, and prior to operation, a discharge monitoring programme, to assess the ongoing adequacy of all management practices, shall be developed and submitted to the Council (Team Leader Central Monitoring) for certification. The monitoring programme shall include, but not be limited to:

a. sampling location for final discharge from the site(s);

b. sampling locations on site (i.e. swale inlets, outlets etc);

c. methods and procedures for discharge sampling on a quarterly basis;

d. monitoring parameters for analysis, which shall include:

Daily

· Turbidity (NTU)

· pH

Weekly

· Total Suspended Solids mg/L

· Copper (total) mg/L

· Zinc (total) mg/L

· Lead (total) mg/L

· Total Petroleum Hydrocarbons mg/L

e. identified trigger levels for each of the above parameters. These trigger levels shall be developed with reference to the ANZECC Guidelines for water quality where applicable; and

f. the methods and procedures for investigating and reporting stormwater discharge monitoring results to the Council (Team Leader Central Monitoring).

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

AT is seeking an Infrastructure Sustainability Council of Australia (ISCA) Infrastructure Sustainability (IS) rating for the Project. Full details are included in the Project’s Sustainability Management Plan. Project sustainability requirements that relate directly to the ESCP are included in Appendix E.

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

This section presents a summary of the Project in relation to the matters required to be addressed by the ESCP and CTMP. A detailed description of the construction works is provided in the CEMP.

Connectus will use a cut and cover method to construct two parallel rail tunnels within the Albert Street road corridor between Customs Street and Wyndham Street. The total length of the tunnel for the Project will be 340m. A number of utilities are required to be removed, relocated, or supported during construction.

Generally, the Project works will consist of:

1. Utilities relocation and exposure

2. Piling and capping beam construction within Albert Street (including relocating of any relevant services)

3. Piling and road deck construction within the Customs Street Intersection

4. Trench Excavation, including using shotcrete and rock-dowelling

5. Construction and waterproofing of the rail tunnels

6. Backfilling of the trench, including construction of the new road pavement.

2.1.1 Utilities relocation and exposure

The location of utility service cables/pipes/ducts (gas, electricity, phone, wastewater, stormwater) (herein collectively referred to as utilities) within the Project footprint have been identified through site inspections and liaison with Network Utility Operators, including Vector Electricity, Vector Gas, Vector Communications, Chorus, Auckland Council and Vodafone. It is not feasible to completely avoid all utilities, although wherever possible piling locations and other construction activities have been selected to avoid conflict with services. This CNV DWP covers only those utility works within the designation footprint and separate provision has been made for utility works required outside of the designation footprint.

Utility relocation works required for Project construction includes works both inside and outside of the trench alignment. All works outside of the trench will be completed prior to excavation works, while the works within the trench will be completed during trench excavation or as the trench is being backfilled on completion of tunnel construction.

Further detail on utilities relocation can be found in the Project CEMP.

2.1.2 Piling and capping beam construction within Albert Street

Piling is required as the initial stage of construction for the Project. It includes the installation of cased continuous flight auger (CFA) piles and the construction of pile caps. Figure 2 shows the location and staging of the piling (the sequence will be confirmed closer to construction). The asphalt surface of the road reserve will be removed and the utilities relocated. Piling will then occur, and a Pile-Cap constructed to connect the piles along the western side of Albert Street. Reinforcing will be installed and concrete placed.

2.1.2.1

Continuous steel traffic decks will be installed along each side of the main trench along Albert Street during the piling and capping stage of construction. The traffic deck along the western side of the

Project #: 2665

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

trench will extend between Swanson Street and Customs Street, and will be used by general traffic along Albert Street. The traffic deck along the eastern side of the trench will extend between Wyndham Street and Customs Street and will be limited to use by construction traffic only. The eastern deck (construction traffic deck) will provide continuous access into the excavation along the length of the trench and additional construction site set down and plant space to supplement the southern and northern compounds. In addition to the continuous traffic decks, two pedestrian bridges will span the trench, located on the north side of the Wyndham Street and Swanson Street intersections.

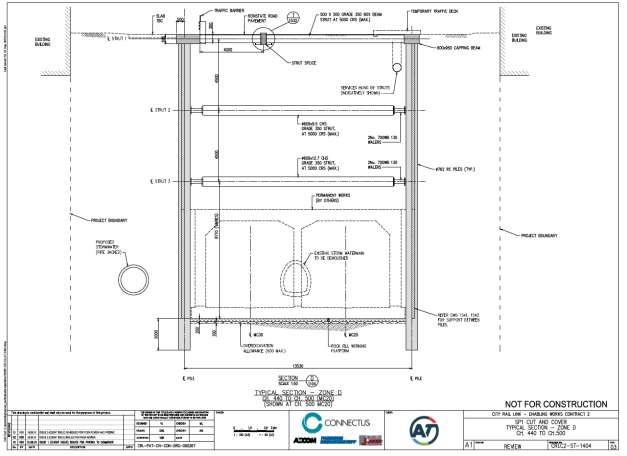

Piling and construction of a deck structure at the Customs Street/Albert Street intersection will permit traffic to cross over, while tunnel construction occurs underneath. The deck will be constructed in four stages as shown in Figure 3. This will enable traffic to utilise the intersection during construction and avoids closing the intersection completely.

Each stage requires pile installation and jet-grouting followed by excavation to approx. 2m depth to allow the construction of the concrete deck. Once all four piling and deck sections are complete, excavation and tunnel construction can commence beneath the live intersection.

In addition to supporting the traffic deck, the piles and jet-grout columns hold back the soil during excavation beneath the deck and stop water from entering the excavation site. After tunnel construction the area under the deck will be backfilled, and the deck structure ‘buried’ (i.e. the deck will no longer be a separate deck structure and will be incorporated in the area immediately below the intersection pavement).

Erosion and Sediment Control Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000897

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Figure 3 Staged construction of road deck - – sections of the deck will be constructed in 4 stages (sequentially)

Trench excavation will be carried out in layers (starting at the southern end) with installation of temporary struts and ground anchors as the depth increases.

As excavation progresses, steel waler beams and struts will be installed in combination with ground anchors to support the piled trench walls. In addition, shotcrete and/or rockfall mesh with pins will be applied to the sides of the trench to stabilise the excavation face. Shotcrete will be spray applied, Rockall mesh is installed by driving short pins into the soil and attaching the mesh to the pins.

As the trench becomes deeper, excavators and loaders will be located inside the trench to break material from the natural face of the trench and transport material to stockpiles. On the construction deck above, cranes and excavators will reach down to remove material from the trench to load onto trucks for offsite disposal.

The construction of the rail tunnels will be a rolling process with multiple work faces progressing simultaneously. The tunnel works will start at the southern end of Albert Street when the excavation plant is clear of the base of the tunnel.

Tunnel construction will be broken into 12m lengths, and comprises the following tasks:

- Base drainage and blinding

- Waterproofing

- Base foundation and construction

- Wall construction

- Roof construction

- Roof waterproofing

Figure 4 shows a typical cross section for the cut and cover tunnels.

Project #: 2665

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Concrete will be pumped to the works by pump machinery that is initially located at the compound on the southern side of Albert Street. The pump machinery is moved onto the construction deck as the works proceed further north.

Figure 4 Typical cross section for the Albert Street Cut and Cover Tunnels

As the construction of the tunnels progresses, back filling of the cut and cover excavation in the Custom Street Intersection and Albert Street trench will occur. The trench backfill will be placed on top of the tunnel structure after construction has been completed for a sufficient length (approximately 50m), including the installation of the waterproofing membrane, and will continue to follow the tunnel construction as it progresses. A layer of concrete blinding (or similar) will be placed over the roof membrane for protection from the trench backfill works. Material will be delivered to site by trucks on the construction deck. Trucks will deposit the fill material onto the floor of the deck structure and it will be collected and tipped into the trench by a loader.

Works to complete new utility routes or reinstate existing utilities will be co-ordinated with the filling operation as it reaches the upper layers. Finally, the construction of the new permanent road pavement will occur in stages after the trench backfill has been completed.

Where required in order to maintain traffic movements, it will be necessary to put down a temporary pavement. Temporary pavements will consist of unbound granular material with a bituminous seal, concrete panels or steel plates on the surface.

Erosion and Sediment Control Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000897

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

The Project works are comprised of Active Construction Zones (ACZ) D and E, which were identified during the consenting process for the CRL enabling works. These zones are described in more detail below and have been used to delineate the proposed construction methodology for different areas of work Table 2 describes the location of each ACZ:

*refer Appendix A for location of ACZ

ACZ D is the area where the Customs Street intersection piling and road deck construction is located while ACZ E is the length of Albert street where the piling and tunnel construction is located.

The Project makes use of the Construction Support Areas (CSA) identified during the consenting process, although the exact boundaries have been modified (Table 3). CSAs 4 and 6 are located at the northern and southern extent of the works respectively and will be used for the duration of the works. CSA 5 is located on the approaches to the Customs Street West/Albert Street intersection and will be used during the customs street piling and road deck construction CSA 5 will move during the four stages of road deck construction (refer Section 2.1.3 and Figure 3 of this ESCP). Once the road deck has been constructed, it will be opened to traffic and only parts of CSA 5 will be used as a CSA

Table 3 Construction Support Areas

6

*refer Appendix A for location of CSA

Details of each CSA are provided below.

CSA 6 – at the Southern end will provide for:

A small site office

A laydown area for materials and equipment

A small toilet and lunchroom facility

A generator

A load-in area for backfill material.

Concrete pumping equipment and concrete load-in.

Skip bins / rubbish and recycling bins

Provision for 150m³ of stockpiled material during the tunnel backfilling.

An earthworks storage area used for storing spoil during excavation and storing backfill material during backfilling

Project #: 2665

Client: Auckland Transport

CSA 4 – at the Northern end will provide for:

General and hazardous goods storage

Piling and deck equipment laydown

Skip bins / rubbish and recycling bins

Spill kits

Jet grouting equipment storage

A more substantial lunchroom and toilet facility

Site offices

A generator

Vehicle and Equipment Parking

Materials delivery and handling

Settling tanks

CSA 5 – On Customs Street:

Revision: 04, Date: 21 March 2016

CSA 5 will be a relatively fluid construction support area as the intention is to keep traffic lanes open through staged construction of a traffic deck. During deck piling and deck construction CSA 5 will be used for:

Piling equipment laydown

Jet grouting equipment

A Generator

Concrete delivery and pumping.

Portable toilet facilities

Skip bins / rubbish and recycling bins

Parking for the spoil removal truck

A bunded stockpiling area.

Once the bridge deck is complete, most of the area identified as CSA 5 during consenting will be open to traffic as works are carried out beneath the bridge.

Stormwater runoff from adjacent catchments will be controlled and managed throughout all construction works. Stormwater inflow rate into the trench excavation has been estimated based on the catchment area of the trench, which is calculated to be 3,700m2 (refer Appendix B of this ESCP).

Further detail regarding stormwater runoff management is provided in Section 4 of this ESCP.

The excavation work for trench construction will be located through fill material underlain by Tauranga Group sediments and East Coast Bays Formation residual soil and rock of various weathering grades

The Aurecon/PDP (2013) report highlighted key aspects of the hydrogeological regime including the following:

Groundwater within the reclamation fill (encountered at the northern end of the proposed trench excavation) occurs between 2m and 3 m below ground level with maximum tidal fluctuations in excess of 1 m.

Connectus

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Regional groundwater beneath Albert Street occurs at depths greater than 18 m below ground level, which is shallower than the proposed rail tunnel alignment.

Perched groundwater beneath Albert Street is present in a series of interbedded sandstone/siltstone layers with relatively low permeability and limited lateral and vertical extent. Groundwater levels were measured at approximately 6 m below ground level (Golder 2014b).

Preliminary assessments have indicated maximum inflows into the trench of 16.4m3/day (refer to the Project Groundwater and Settlement Monitoring and Contingency Plan (GSMCP) in Appendix J of the Project CEMP). This number has been used for the purposes of sizing the treatment devices.

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Erosion and sediment control measures will be set up to minimise the extent of soil erosion and sediment yield from the Project site during construction and will be implemented and monitored in accordance with Auckland Council Technical Publication 90 (TP90) “Erosion and sediment control guidelines for land disturbing activities in the Auckland Region”. Sediment laden water from the Project construction works during the trenching and rail tunnel construction phases will be treated to achieve the effluent quality goal was established in the Water Quality Assessment prepared by Golder Associates (NZ) Limited, dated December 2014. This identifies minimum water clarity for all discharges of 10cm or greater measured with a black disk, pH between 5 and 9, and no visible TPH. In some circumstances, and where appropriate, measures exceeding the requirements of TP90 will be used in order to meet the effluent quality goal. While Condition 99 of the Resource Consent specifies the use of structural controls as 2x 12,000L settlement tanks, developed design has resulted in a different approach to sediment control. For some work phases, the controls used will include the use of settlement tanks but other phases will apply different sediment controls as detailed below. General agreement on this approach was reached with the AC monitoring team in a meeting held on Wednesday 2nd March 2016. As per condition number 100, the following information will be provided for any minor modifications to the structural controls prior to implementation:

Plans and drawings outlining the details of the modifications; and

Supporting information that details how the proposal does not affect the capacity or performance of stormwater management system.

All sediment control measures will be fully established within each construction area before physical works commence in that area. Removal of the sediment control devices and reinstatement of the surrounding ground on completion of the works will also form part of the civil component of the project and will be managed by Connectus.

All efforts will be taken to ensure that there will be no deposition of earth, mud, dirt or other debris on any road or footpath resulting from bulk earthworks on the subject site. In the event that such deposition does occur, it shall immediately be removed. If it is necessary to wash down roads or footpaths, measures will be in place to prevent contamination of the stormwater drainage system, or receiving waters. Dirty water treatment for the different work phases will vary based on construction techniques, site constraints and weather conditions. The overarching aim will be to use the appropriate level of treatment to meet the effluent quality objective (see above) This will involve using the following levels of controls as required:

Level 1 controls consist of sediment socks and catchpit filters;

Level 2 controls involve level 1 controls with the addition of a settlement tank(s) eg Siltbuster HB50;

Level 3 controls will involve level 1 controls and settlement tank(s) with flocculation (manual or automated); and

Level 4 controls consist of a specifically designed water treatment plant located within the trench (refer Section 4.4.3.2)

Project #: 2665

Client: Auckland Transport

Table 4 summarises the hierarchy of approaches to be used.

Table 4: Overview of dirty water treatment by phase

Phase

Utilities

Piling and customs street deck construction

Albert Street piling and capping beam construction

Trench excavation phase 1

Trench excavation phase 2

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Dirty Water Treatment approach

Level 1 controls

Level 2 controls may be required for some of the larger utilities works

Level 2 or 3 controls

Level 2 or 3 controls

Level 3 controls

Level 4 control as detailed in 4.4.3

Specific sediment control measures for each work phase are discussed in Section 4 of this ESCP

Due to the limited foot print available for the Project, it is anticipated that all material excavated will be loaded directly onto trucks and disposed of off-site. During the backfilling stage, provision for 150m³ of stockpiled material has been made at CSA 6 (southern-most CSA) to allow for temporary storage

The estimated total volume of material that needs to be removed from site is approximately 85,000m³. Fill volume will be less than this, due to the construction of the tunnels, and has been estimated as 48,000m3

The following points illustrate the general approaches intended for managing runoff and sediment from the work areas (CSAs and ACZs):

Soils that are identified for off-site disposal will be loaded directly for removal

All material removed from or delivered to the Project site shall be covered during transportation.

Where temporary stockpiling of spoil materials is required above ground, cover and/or bunding shall be provided as necessary to mitigate the generation of sediment laden surface water.

Where possible, surface water will be diverted away from the construction zones.

Dirty surface runoff within the construction areas will be collected within cut-off channels, barriers and bunds/filtersocks - and removed off-site or pumped to a treatment device appropriate for the present scale of works for treatment (refer to section 4)

Protecting the stormwater system - using filter cloth over inlets or alternative inlet protection measures.

Any machine oil and fuels stored on site will be contained within a separate bunded area to avoid contamination with other surface run off. In the event of a spill any outlets from this bunded area will be closed until such time as the spill is dealt with.

Ensuring all clean surface site runoff within the construction area is kept separate from dirty water. Clean water will discharge to the existing stormwater system.

Connectus

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Road sweeping as required if any tracking of material occurs on adjacent streets.

Regular visual observations of sediment conditions will be completed by Connectus, as the Principal Contractor.

If a sediment release occurs, the time, duration, location and cause will be recorded in the daily report as well as remedial actions performed. Any sediment complaints will be recorded on Environmental Incident / Event (MMS # 020-F053-100) form and entered into the Enquiry and Complaints Register as per the procedures outlined in the CEMP.

Upon completion or abandonment of bulk earthworks on the Project site all areas of bare earth shall be permanently stabilised against erosion to the satisfaction of the Council (Team Leader Central Monitoring).

3.4.1

The majority of spoil material generated as part of the land disturbance works will likely meet clean fill classification (refer Contamination Delivery Work Plan in Appendix G of the CEMP)

During all land disturbance activities site workers will actively monitor active construction zones for the conditions/materials specified in the Contamination Delivery Work Plan (CDWP) The CDWP, which addresses the requirement for a Contaminated Soils Management Plan under the resource consent conditions for the CRL Britomart to Wyndham enabling works, contains a set of contingency measures to be undertaken if suspected contaminated material is discovered.

3.4.2

The majority of the works are taking place below ground and therefore dust generation will be largely contained. Above ground works areas will be kept free from spoil through regular sweeping. In the event dust becomes a problem the relevant areas will be dampened with either treated water from site (preference) or from the local mains water supply.

Dust control is further outlined in Section 6.3 of the Project Air Quality Delivery Work Plan (AQ DWP) (Appendix H to the Project CEMP). The AQ DWP identifies management approaches relevant to stockpiles, sealed surfaces and vehicles.

3.4.3

During any concrete or asphalt works, adjacent stormwater drains will be completely isolated with drain plugs and a submersible pump or vacuum truck will be used to remove any contaminated run-off that enters the catchpit. If this is not practicable then careful sandbagging or bunding around the catch pit grate will be used as an alternative.

Other controls that will be used include:

Minimising the amount of water used on site (e.g. in dust suppression, concrete cutting, cement mixing) so there is less run-off to control.

Dust is also created during dry concrete or asphalt cutting. Using saws that can have a vacuum attached will minimise the amount of dust.

Using a wet/dry vacuum, or vacuum truck for larger jobs, to collect all concrete or asphalt contaminated material (slurry) to be disposed off-site.

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Washing all equipment and tools in a designated wash area, well away from stormwater drains.

Using tarpaulin sheets under concrete pumps and delivery chutes to capture any spills.

Not allowing concrete trucks or concrete pumps to wash out on site.

A number of utilities will be relocated prior to and during the piling phase. These include power, telecommunications, gas, water mains and stormwater. With the exception of the Customs street stormwater works (which is being undertaken using trenchless techniques), and the combined services trench - which will take approximately 60 days, the relocations will take be relatively shortduration. Works will generally involve narrow, shallow trenching within the roadway or designation footprint as outlined in Section 2.1.1 Table 5 shows the utilities works (outside of main trench) duration and earthworks volumes.

Table 5 Utilities works (outside of trench) duration and earthworks volumes

Combined Service Trench – Western Footpath including crossings

Approximately 350m of 1.5m wide by 1.2m deep trench on western footpath between Customs St and Wyndham St

Install ducting for services

Service Providers to Connect onto existing network at Customs St and Wyndham St

3

Vector Electricity from Swanson St west across Albert St down Swanson St East

Vector Gas and Communications trench –Eastern Footpath

Install 4x150mm ducts from SW corner of Swanson St and Albert St across Albert St into Swanson St east.

Install 6 x 100mm ducts down Swanson St

Excavate 4 x joint bays down Swanson St to connect new cables to existing cables.

Construct a 1.0m wide by 1.2m deep trench on eastern footpath.

Vector Gas duct to be installed for approximately 200m between Customs St and Swanson St. Includes the installation of approximately 50m of PE Gas pipe down Swanson St to a connection point onto the existing network. (Exact location currently unknown)

Vector Communications ducts to be installed for approximately 200m between Customs St and Mills Lane, and also Swanson St and Wyndham St.

Customs St Stormwater Works

Installation of three permanent manholes.

Connection to existing Albert St Stormwater Semi-elliptical Main and connection to existing stormwater system at new SWMH 1/3.

Installation of est.40m of 600mm permanent concrete pipe via trenchless construction.

Installation of est. 10m of 525mm permanent polypropylene pipe via trenching. 50 days 150m3

Erosion and Sediment Control Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000897

Client: Auckland Transport

Swanson St East Stormwater Works –Surface Works

Swanson St East Stormwater Works -ANZ Connection

Kingston-Wyndham St Stormwater Works

Demolition of existing services pit

Installation of 1.5m internal base manhole via open excavation.

Core connection between SWMH 3/1 and Swanson St shaft

Install dropper

Wyndham St Stormwater Works

Swanson St West Stormwater Works

Customs St 110kv Breakout and Reinstatement

Swanson St & Wyndham St Chorus Works

Swanson St 200m water main upgrade

Revision: 04, Date: 21 March 2016

Installation of approx. 2m of permanent 600mm reinforced concrete pipe via open excavation from SWMH 3/1 past the pile line 20 Days 30m3

Installation of approx. 5m of permanent 300mm polypropylene pipe via trenchless construction from within the Swanson St shaft for the ANZ Tower connection.

Installation and connection of two permanent manholes.

Installation of approx. 80m of permanent 375mm polypropylene pipe.

Installation of approx. 26m of temporary 225mm polypropylene pipe via trenching.

15 Days 5m3

Connection to existing stormwater system at one location 35 Days 300m3

Installation and connection of one permanent manhole.

Installation of approx. 12m of permanent 450mm reinforced concrete pipe via trenchless construction.

Connection to existing stormwater system at new SWMH 9/1.

Connect to existing SWMH 7/1 via deep (3m) open excavation

Install approximately 12m of deep (3m) permanent 375mm pipe from SWMH 7/1 to within pile wall alignment.

Excavate to underside of concrete encased ducts between existing chamber on Lower Albert St and approximately 4m west of Piles (toward Fanshawe)

Saw cut concrete encasement in sections for removal

Remove encasement

Install new ducts over top of customs St traffic deck

Encase ducts in Vector approved thermal concrete

Connect/weld new ducts to existing ducting at either end

Days 75m3

3

Reinstate 20 days (3 separate Visits) 300m3

Install 8 x 100m ducts for a length of approximately 50m down Swanson St east.

Install 100mm ducting across Wyndham St and Albert St.

Locate existing water main

Isolate existing water main

Remove existing water main and replace with

15 Days –Swanson St

15 Days –(Wyndham St) 150m3

3

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

200mm PE pipe as per approved drawings

Install 3 way valve systems including thrust blocks on both tee sections on SE and SW corners of customs St

Backfill

Turn water back on

During the utilities work, sediment will be controlled by:

a) Concrete/asphalt cutting controls as outlined in section 3.4.3

b) Storing excavated material upslope of trenches, away from overland flowpaths, kerb and channels and stormwater catchpits

c) Providing filter socks around the trench area to keep clean water out, and any dirty water within the trench.

d) Providing catchpit protection for adjacent catchpits in accordance with Auckland Council Best Management Practice – Catchpit protection, July 2011

e) Covering any temporary stockpiles with tarpaulins should rain be forecast.

f) If dewatering of the trenches is required this will be undertaken by pumping water through a geotextile or filter bag and discharging to the nearest stormwater catchpit. Alternatively a sucker truck may be used to remove dirty water from the trench and dispose off site.

g) Trenches will be backfilled and permanently stabilised as soon as possible and asphalt / concrete road or footpath reinstated. Given the generally short length of work, no temporary stabilisation is proposed.

h) Regularly inspecting and cleaning out sediment controls and secondary catchpit protection.

i) Regularly sweeping up of sediment or dust and disposing appropriately so that it will not become airborne or enter surface water.

j) Once works are complete removing environmental controls and inspecting stormwater catchpits and removing any contamination associated with site works.

During the utilities work where trenchless techniques are being used, the following controls will be used:

a) Cleanwater will be diverted around the active work site using bunds. Any batching plant will be located within bunded area.

b) Sandbag/sediment socks will contain any dirty water.

c) Install catchpit protection measures such as filters.

d) Drill slurry will be contained in manholes and removed as required by sucker trucks located on/near the site for the period of the works. Sucker trucks will dispose of slurry to an authorised facility.

e) A sucker truck will be available on site for the duration of the works in the event of a spill.

For utilities works within the main trench, sediment will be managed as per the mitigation outlined for the main trench excavation outlined in Section 4.4 of the ESCP.

If cleanwater cannot be diverted it will be necessary to remove overland flow from the utilities work area by ‘overpumping’. This involves installing temporary barriers at each end of the working space and installing pumps on the upstream side of the barriers so overland flow can be bypassed around the work area and discharged on the downstream side.

Erosion and Sediment Control Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000897

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Work within ACZ E (refer Section 2.1.8 and Appendix A of this ESCP) will begin on the western side of Albert Street. Following piling in each area, pile caps will be constructed to connect the piles together. Steel beams are then installed that span between the capping beams. These support a traffic deck on the western side of Albert St between Swanson Street and Customs Street, and a construction deck on the eastern side from the southern compound to near the intersection with Customs Street.

The piling and capping beam construction on Albert Street is expected to take approximately 7 months and will take place in a number of stages so that active construction zones are restricted to the specific areas undergoing work. The zones will be responsive to the rate of progress and traffic requirements. The physical boundaries of the active construction zones may vary from week to week

Drilling will be carried out at a rate of approximately 4 piles per day. The spoil from each pile will be approximately 6m3 and deposited adjacent to each pile in a position where it can be loaded to a truck and disposed of to landfill.

Following installation of a group of piles, a section of pile capping beam will be constructed. Prior to pouring the concrete, the capping beam trench will act as a ‘sump’ to collect dirty water.

Table 6 summarises the construction activities relevant to erosion and sediment control and the control approach for each type of activity. Specific methods are discussed further below

Table 6: Piling and capping bean construction activities, duration and related sediment control approach: Construction Activity Duration Control approach

Asphalt and underlying concrete removed

Vacuum extraction system used to remove granular pavement material at each pile location and check for services

Piling drill rig used to install Continuous Flight Auger pile, depositing spoil within work zone adjacent to pile hole

1-2 weeks for each stage

4 piles/day

1-3 weeks for each stage

Off-site disposal

Collection off all concrete or asphalt contaminated material (slurry) using a wet/dry vacuum, or vacuum truck for off-site disposal

Immediate transfer of spoil to truck for off-site disposal

If temporary stockpile required and rain forecast/occurring cover stockpile, divert clean water to stormwater system and contain dirty water within bunds and pump to settlement tank for treatment. Flocculants added to settling tank if necessary to meet effluent quality goal.

Excavate below surface around and between pile, breaking back or splitting off concrete at top of pile to allow for capping beam.

1-2 weeks for each stage

Construct concrete pile Cap 2-4 weeks for each stage

Once pile cap is in place for a section of piles a width of the roadway will be excavated to 600mm so steel beams can be installed

2-4 weeks for each stage

Off-site disposal

Collection off all concrete or asphalt contaminated material (slurry) using an excavator, a wet/dry vacuum, or vacuum truck for off-site disposal

Collection off all concrete washings / spillage during pouring - for off-site disposal

Concrete/asphalt works to be managed according to best practice as detailed in Section 3.4.3 of this ESCP.

Project #: 2665

Client: Auckland Transport

These support traffic/construction decks

Road surface reinstated Varies

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Immediate transfer of spoil to truck for off-site disposal

If temporary stockpile required and rain forecast/occurring cover stockpile, divert clean water to stormwater system and contain dirty water for treatment.

Asphalt works to be managed according to best practice as detailed in Section 3.4.3 of this ESCP

Typical erosion and sediment control methods that will be used at each active work site are provided below for the western and eastern sides of Albert Street.

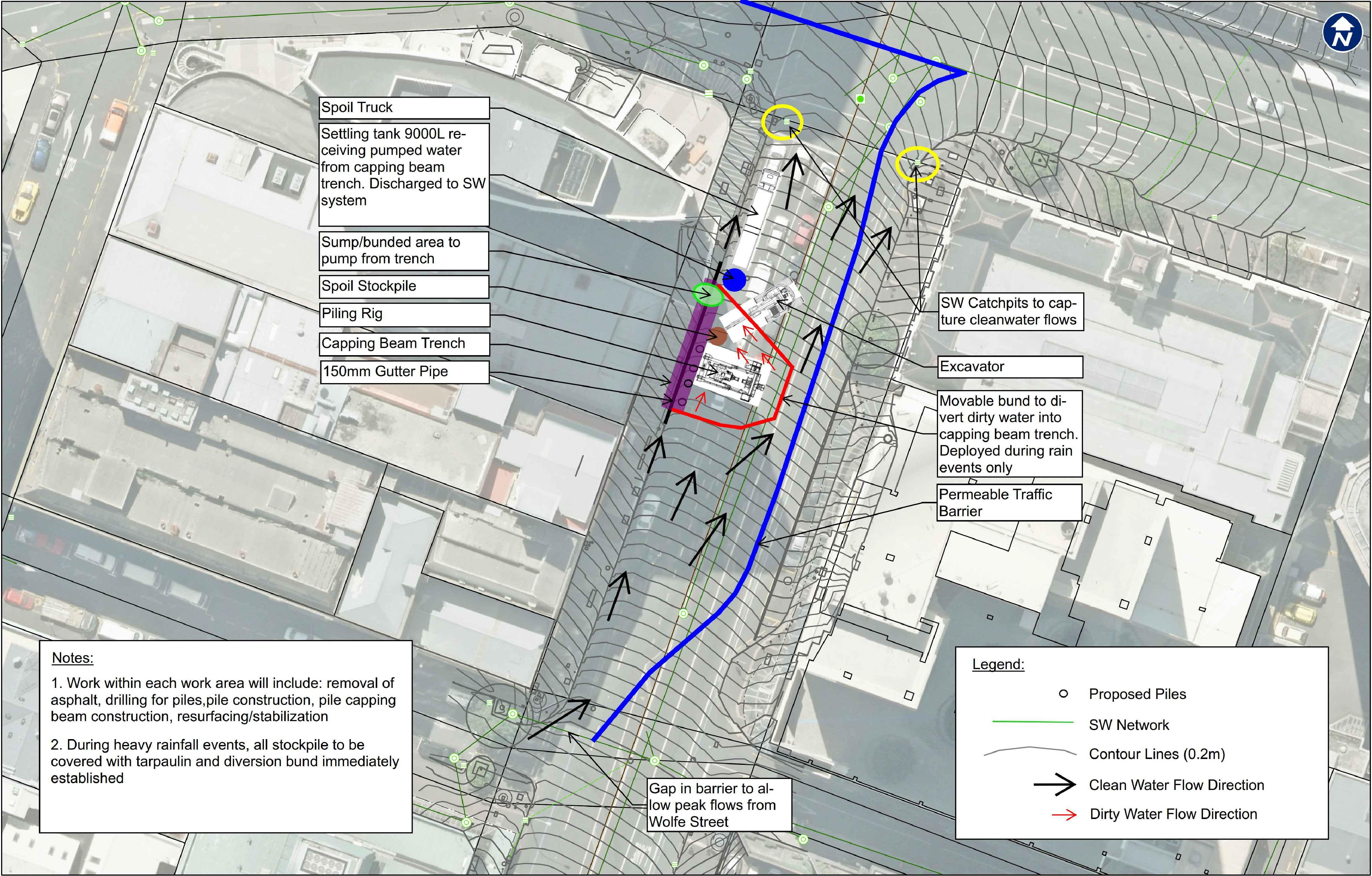

On the Western side of Albert Street, piling work is taking place in close proximity to the kerb and channel. A clean water flow path will be maintained using a temporary 150mm diameter PVC pipe in the gutter. During rain events, clean water will flow through the gutter pipe or will be diverted around the stockpile and work area downstream to the curb and channel. This is depicted in Appendix A of this ESCP, Drawing 0357

During rain events, the stockpile will be covered with a tarpaulin, and a bund around the piling area will contain and divert dirty water flow into the capping beam trench or sump so it can be pumped out to a settlement tank.

The volume of sediment laden water that could be generated during a ‘water quality storm’ design event is summarised below. This is used to determine an appropriate settlement tank size.

Work area (dirty water catchment): 140m2

Water quality storm depth (1/2 of 2 year ARI event): 27mm

Runoff volume: 4m3

Provision of a 9m3 tank is proposed which will be more than sufficient.

In summary, during a rain event the following measures will be employed:

A sandbag / sediment sock bund will be established around the work zone to capture all internal site runoff which is potentially contaminated with sediment and pumped into a 9m3 settling tank located on site.

Where water enters the pile trench (prior to the beam construction) it will need to be dewatered and pumped to the settling tank.

Clean water will be decanted off the settlement tank and discharged to the stormwater system. Flocculants will be used only if required to meet effluent quality goal

At all times, downstream catchpits will be protected using catchpit filters.

Refer to Appendix A of this ESCP, Drawing 0357 for details of clean water and dirty water management during rainfall.

The physical boundaries of the active construction zones may vary from day to day. For this reason it is not practical to establish semi-permeant clean water diversion around work areas. The preferred approach is to ensure this water can pass around the work zone without contact with any stockpiles.

Erosion and Sediment Control Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000897

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

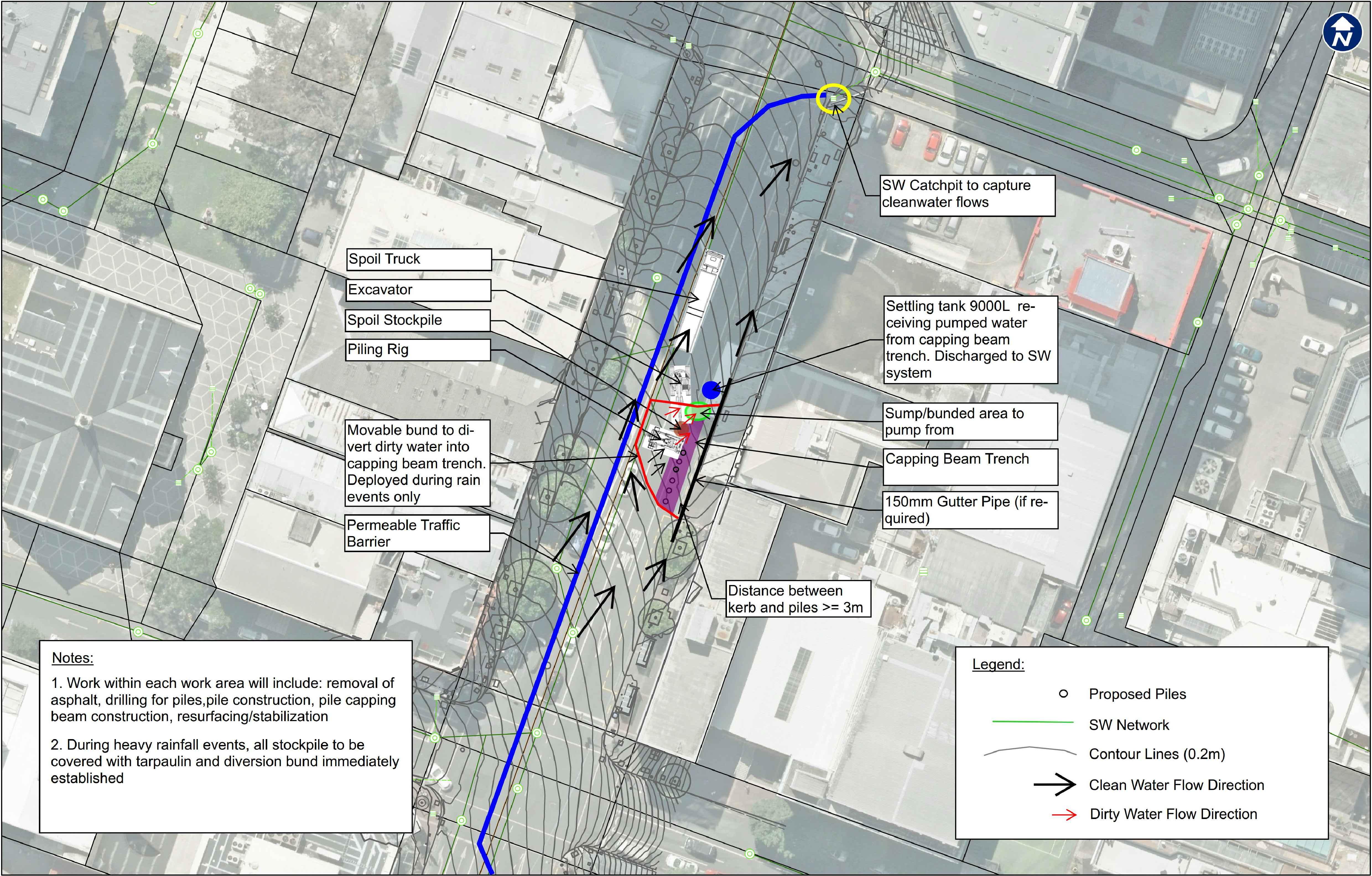

The distance between the kerb to pile face on the eastern side of Albert Street will be greater than 3 metres. Therefore a clean water flow path will be maintained around the eastern side of the work area utilising the existing roadway curb and channel systems.

During rain events, clean water will flow along the kerb and channel or be diverted around the stockpile and work area downstream to the existing stormwater system. This is depicted in Appendix A of this ESCP, Drawing 0358.

During rain, the stockpile will be covered with a tarpaulin, and a bund around the piling area will contain and divert dirty water flow into the capping beam trench or sump so it can be pumped out to a settlement tank.

The volume of sediment laden water that could be generated during a ‘water quality storm’ design event is summarised below. This is used to determine an appropriate settlement tank size.

Work area (dirty water catchment): 150m2

Water quality storm depth (1/2 of 2 year ARI event): 27mm

Runoff volume: 4m3

Provision of a 9m3 tank is proposed which will be more than sufficient. In summary, during a rain event the following measures will be employed:

A sandbag / sediment sock bund established around the work zone to capture all internal site runoff which is potentially contaminated with sediment, and pumped into a 9m3 settling tank located on site.

Where water enters the pile trench (prior to the beam construction) it will need to be dewatered and pumped to the settling tank. Flocculants will be used only if required to meet effluent quality goal.

Clean water will be decanted off the settlement tank and discharged to the stormwater system. At all times downstream catchpits will be protected using catchpit filters.

Refer to Appendix A of this ESCP for details of clean water and dirty water management during rainfall.

The spoil from each pile excavation will be approximately 6m3 and deposited adjacent to each pile in a position where it can be loaded to a truck and disposed of to landfill. It is expected that spoil will be removed off site within 24 hours. However in the event that that a stock pile remains on site beyond this time period and if rain is forecast, the stockpiles will be covered with tarpaulin, and the perimeter bunded with sediment filter socks and sand bags as described above.

Truck access will be on hard surfaces. At the end of each day, or as required, the site will be swept to keep the truck access area clean as it will not be possible to utilise a wheel wash due to space restrictions. Sweepings will be directed into the capping trench or stockpile. If the truck area cannot be kept clean via sweeping, the area will be cleaned using a wet-vac vacuum cleaner. If water is used to clean the area the dirty water will be washed into the capping beam trench. The dirty water will be removed from the trench using either a:

a) pump to a sediment tank (9,000L)

b) wet vac or a hydrovac sucker truck (for emergency / unforeseen circumstances)

It is noted that work will be halted when heavy rain is forecast, and the site protected

Erosion and Sediment Control Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000897

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Work within ACZ D (refer to 2.1.8 and Appendix A of this ESCP) consists of piling and construction of a temporary deck structure at the Customs Street/Albert Street intersection to permit live traffic to cross over, and tunnel construction beneath the road deck

The construction will take place in four phases as described in Section 2.1.3 and Figure 3 of this ESCP CSA 5 will be used during construction of the road deck. This CSA moves depending on which of the 4 stages of deck construction is being undertaken. It is noted that each stage will be completed (piling through to deck construction) prior to moving to the subsequent stage. Refer to Appendix A of this ESCP, Drawing 0355 for further detail on the erosion and sediment control methods during each of the stages Table 7 summarises the construction activities relevant to erosion and sediment control and the control approach for each type of activity. Specific methods are discussed in the following sections.

Remove existing road surface. Remove 762mm wide strip of asphalt and concrete up to a few piles width at a time.

Vacuum extraction system used to remove granular pavement material at each pile location and check for services

Piling drill rig used to install Continuous Flight Auger pile, depositing spoil within work zone adjacent to pile hole.

Jet grouting installed to bridge the gaps between the piles.

Excavation of footprint area of stage (1.5-2m)

Off-site disposal to approved landfill

Collection off all concrete or asphalt contaminated material (slurry) using a wet/dry vacuum, or vacuum truck for offsite disposal.

Immediate transfer of spoil to truck for offsite disposal

If temporary stockpile required divert clean water and contain dirty water for treatment. Flocculants added to settling tank if necessary to meet effluent quality goal.

Immediate transfer of spoil to truck for offsite disposal

If temporary stockpile required divert clean water and contain dirty water for treatment in settling tank

Deck construction, concreting, backfilling and stabilisation

Appropriate management of concrete pouring operations and backfilling.

4.3.1

Similarly to the piling work on Albert Street, the spoil from the custom street intersection piling work will be regularly loaded onto trucks for disposal off-site. Where temporary stockpiles of spoil are required these will be located within CSA 4 or CSA 5, clear of overland flow paths. In the event of rain, the spoil will be covered and a sandbag and sediment sock bund established around the work zone to capture all internal site runoff which is potentially contaminated with sediment and pumped into a 9m3 settling tank or skip located on site. Clean water will be decanted off the settlement tank and discharged to the stormwater system.

Erosion and Sediment Control Plan

Project #: 2665 Doc. No. CRL-PAT-ENV-CON-PLN-000897

Client: Auckland Transport

Revision: 04, Date: 21 March 2016

Drawing 0355 (Appendix A of this ESCP) shows each stage of works and the temporary stockpile areas which will be used during the excavation process at the Customs Street Intersection

Excavators will be used to load the material onto trucks as soon as possible following excavation. If a temporary stockpile is required and rain is forecast: cover stockpile, divert clean water and contain dirty water for treatment.

At all times downstream catchpits will be protected using catchpit filters. Refer Drawing 0355 (Appendix A of this ESCP) for details of clean water and dirty water management during rainfall.

Trucks collecting spoil will be accessing the site on hard surfaces (stabilised) minimising the spread of construction debris via truck movements. Regular road sweeping will be carried out along the adjacent roadway where trucks leave the site. Sweeping will be directed either into the work zone or to the spoil stockpile in the CSA. If areas require washing with water, dirty water will be collected within bunded areas and pumped to the 9000L settling tank located on site. Flocculants will only be used if required to meet the effluent quality goal.

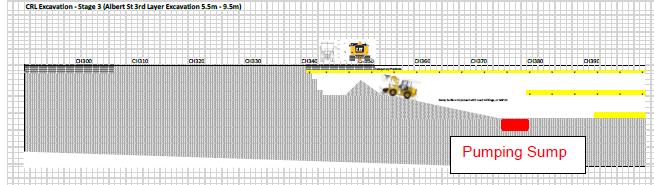

The trench excavation will begin adjacent to the southern compound and proceed from south to north down to the Customs Street intersection. Spoil will be loaded onto trucks located on the construction deck for off-site disposal during this phase (Refer Drawing 0351, Appendix A for trench overview). When excavators can no longer remove material while sitting at surface level, excavation of material will progress down to the underside of the struts in a north to south direction. Excavation will then proceed in layers from Customs Street. The estimated total amount of material that will be removed from site during the trench excavation works is approximately 85,000m3

Cranes and excavators fitted with clamshell buckets will reach down into the trench and remove the material that has been loosened. The surface cranes and excavators, located on the construction deck will load the material into 10T trucks for disposal of material offsite

The construction deck will be kept clean by regular sweeping therefore preventing spread of loose sediment or debris as the trucks leave the site. Trucks will enter the construction site from gates located along the southbound lane of Albert Street. They will reverse up to the excavation plant to be loaded, and then exit the site through the same gates, back into the Albert Street southbound lane. The construction deck, which will maintain a small crossfall towards the trench (refer SKE 0354, Appendix A) will be swept and or washed clean when necessary, in order to prevent spoil material being tracked out onto the public road. The dirty water from washing the deck will discharge directly into the trench.

For each subsequent layer of excavation, all stockpiles will be located within the trench footprint. Swale drains will be created and maintained adjacent to the pile walls to convey dirty water to the trench sump. Trench dewatering is discussed in the following sections.

Table 8 summarises the main construction activities relevant to erosion and sediment control and the control approach taken. Specific methods are discussed in Sections 4.4.1 to 4.4.3.3 of this ESCP.

Table 8: Trench Excavation activities, duration and related sediment control approach

Project #: 2665

Client: Auckland Transport

Trench Excavation from

Remove existing road surface Up to 1 week per street block (intersection to intersection)

Trench Excavation Phase 1

3 Months

Trench Excavation phase 2.

Medium sized excavator supported by wheel loader transports material from excavation face to loading area

Large excavator (20-30T) or when depth increases a crane and clamshell bucket to load material directly onto trucks.

Stabilisation using shotcrete

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Dispose of spoil to an appropriately consented fill site, in accordance with Connectus’ sustainability goals for the Project

Locate water treatment equipment at road level adjacent to excavation loading point

Excavator loading directly to waiting trucks for disposal.,

Swale drains and pump sump installed

Dirty water from the trench will be pumped to an appropriate treatment device. Early in the program while catchment areas are small and disjointed, this may be a settlement tank(s) or lamella plate clarifier (s) (e,g. Siltbuster HB50). As the excavation progresses, increasing catchment area and connectivity, dirty water will be pumped to a more substantial onsite water treatment plant.

17 months Clean water management

Water Treatment Plant (WTP) located within trench footprint

Swale drains and pump sump installed

Stockpiles located within trench.

Dirty water (groundwater / stormwater) collected and treated in WTP

During rain events, clean water runoff from the neighbouring streets intersecting the western side of Albert Street (includes Wolfe, Swanson and Wyndham Streets) will be directed into the kerb and channel where it can enter the stormwater system. This will be achieved as follows:

a) Ensuring no obstruction to flow paths along kerb and channel sections. Water will flow along sections of roadway, and temporary decking.

b) Ensuring a minimum 1% crossfall between the traffic barrier and the kerb on the western side of Albert Street to keep flow within the kerb area

Refer Drawings 0353, 0354 and 0356, Appendix A of this ESCP for further detail.

Once the first layer of excavation has taken place the catchment area draining to existing catchpits will be significantly reduced. Overland flow which enters the trench will be treated along with the groundwater and rainwater infiltrating into the trench (refer to Section 4.4.3.3 of this ESCP).

Project #: 2665

Client: Auckland Transport

No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

During this transitional phase excavation occurs from the construction deck and spoil is loaded onto trucks for disposal offsite. Water entering the trench will be pumped to a suitable water treatment device. In the early stages of excavation, as services are exposed and managed, sections of the excavation may be small and disjointed. The approach at this stage is to:

Maintain existing flow paths where possible to avoid clean water entering the trench

Use the open excavations as water storage area (most rainfall is expected to soak away to ground as the excavation is above the water table in this phase).

Use small water treatment devices (settlement tanks / Siltbuster HB50s or similar) to treat water pumped out of the disjointed excavations. Flocculants will be used if necessary to meet the effluent quality goal. This would involve hand dosing or the use of Haloklear manifold.

As the work progresses, and individual excavations become larger and more connected, water can be drained towards the larger water treatment plant to be established prior to phase 2.

During this phase, all stockpiles will be located within the trench. Both groundwater and rain water will enter the active construction zone along the entire length of the trench. For each layer of excavation, swale drains will be created and maintained adjacent to the pile walls. These drains will direct rain water and ground water along the trench to a pumping sump. The base of the excavation will be constructed with a camber to direct water to the trenches at the sides. The trenches will convey both ground water and any rainfall collecting within the trench to the sump. Once the trench has reached full depth a NOVACOIL drain will be established along each side to convey ground water to the pumping sumps. This drain will be buried within a base layer of drainage metal which is placed on top of geofabric to minimise sediment entrainment.

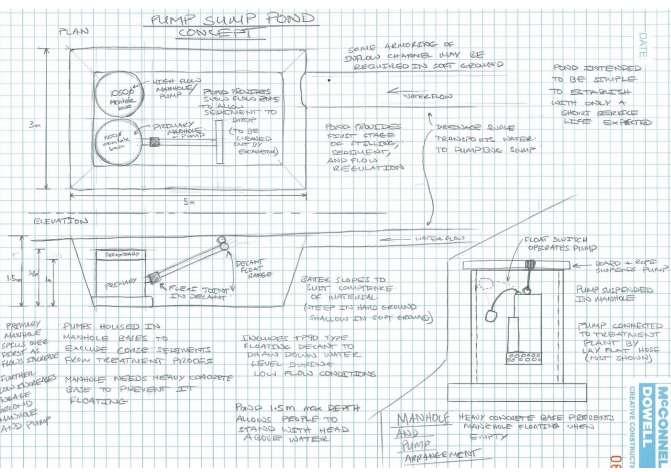

4.4.3.1

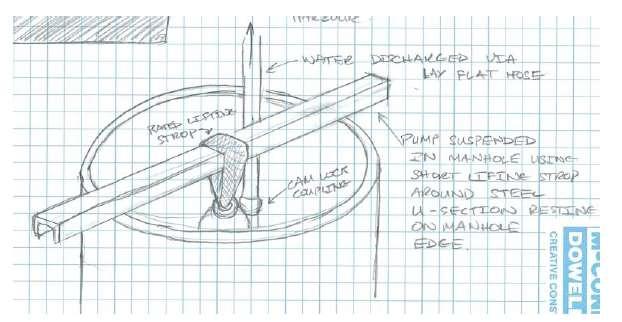

A movable pumping sump will be established for each excavation layer. The purpose of the sump is to provide some attenuation and averaging of flows as well as providing an easily maintainable space to allow sediment to drop out of suspension prior to the water being pumped to the water treatment plant (WTP) Refer Figure 5 below.

Figure 5 Schematic showing location of movable pumping sump

The sump will be moved within the trench as excavation progresses due to the confined space within the trench and co-located construction activities.

The pumping sump will consist of a hole excavated below the invert of the current lift and will contain (Figure 6):

Concrete manhole risers to house pumps and set water levels. Base and high flow submersible pumps will be installed inside the manholes.

Connectus

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

A floating decant (similar to a TP90 design) included on the primary manhole to allow the pumping sump to drain down during dry conditions. This will facilitate sump clean out and restore storage capacity in the sump.

Figure 6 Schematic showing sump and pump arrangement

4.4.3.2 Trench Dewatering- Phase 2 Trench Excavation

Sediment-laden water will be pumped from the trench, through a water treatment plant), and then discharged to the stormwater network once it has reached the appropriate effluent quality standard

Project #: 2665

Client: Auckland Transport

Three pumps will be used to lift water from the base of the trench:

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

1) Base flow pump - sized to lift the expected daily average flows out of the trench to the water treatment plant. This will be an electric submersible pump operated by a float switch. The pump will be sized to avoid frequent on / off cycling. (14L/s – refer below).

2) A standby duty pump – sized to lift the maximum treatable flow to the water treatment plant. This pump is expected to operate during rainfall events and will be sized to provide the maximum allowable flow to the WTP. This pump will also be operated by a float switch. (14L/s – refer below).

3) A high volume emergency pump – sized to deal with flows from the low probability rainfall events. This pump will discharge water directly to stormwater without treatment. Its purpose is to prevent health, safety or environmental incidents that could result if substantial flooding of the trench were to occur. This pump will be operated by a float switch with manual start and stop facilities. (This is likely to be in the order of a 50L/s pump).

Electric pumps are preferred over diesel or petrol powered pumps in line with the Project’s sustainability goals (reduced carbon footprint) and because automatic controls are easier to establish than for combustion engine driven pumps. Pumps will be connected to the WTP via lay flat hoses and cam-lock fittings which are easy to set up and reconfigure.

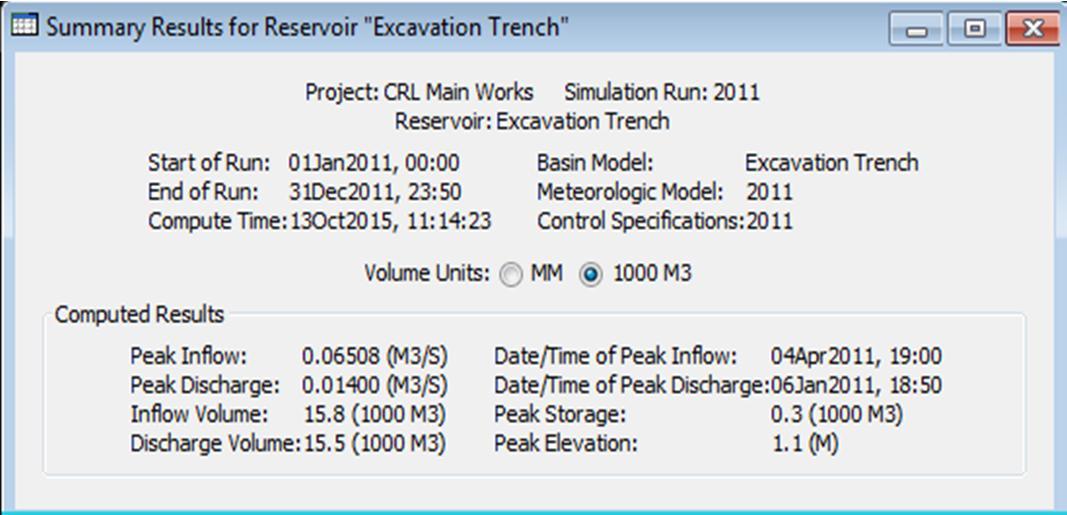

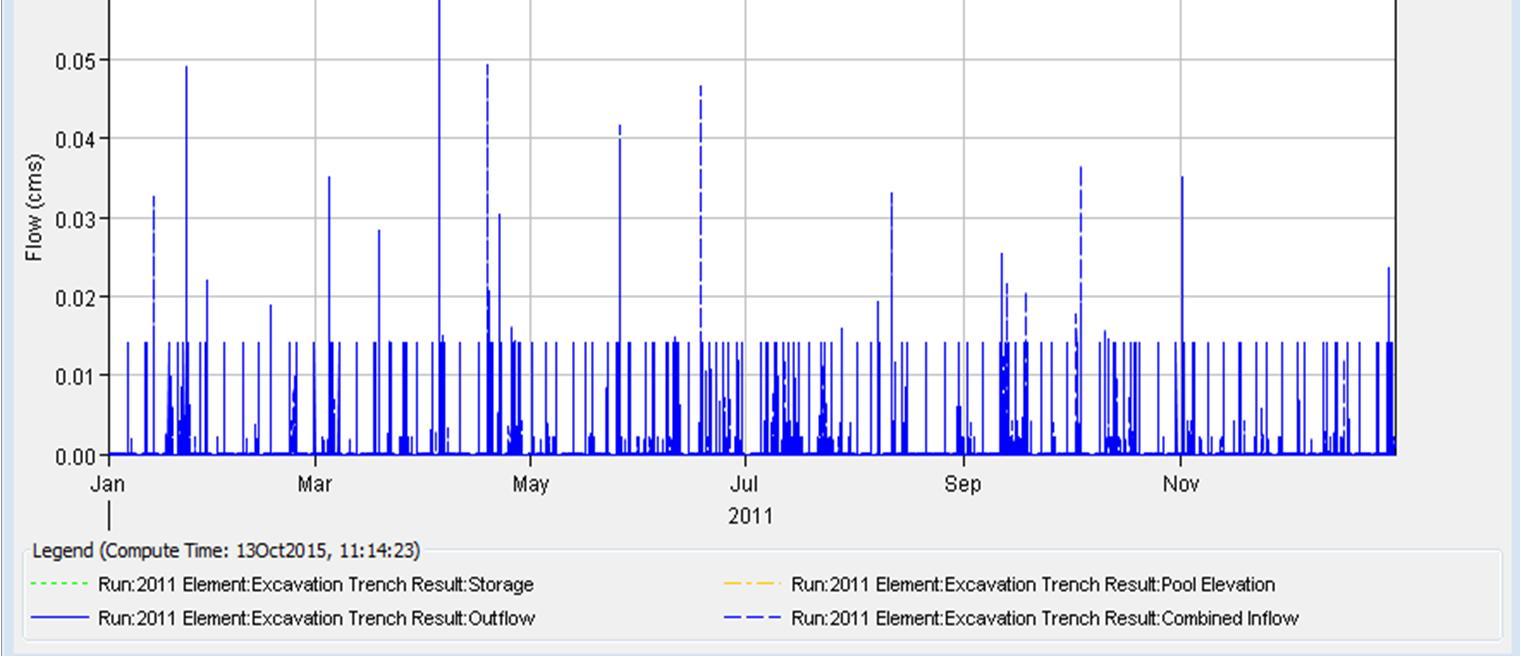

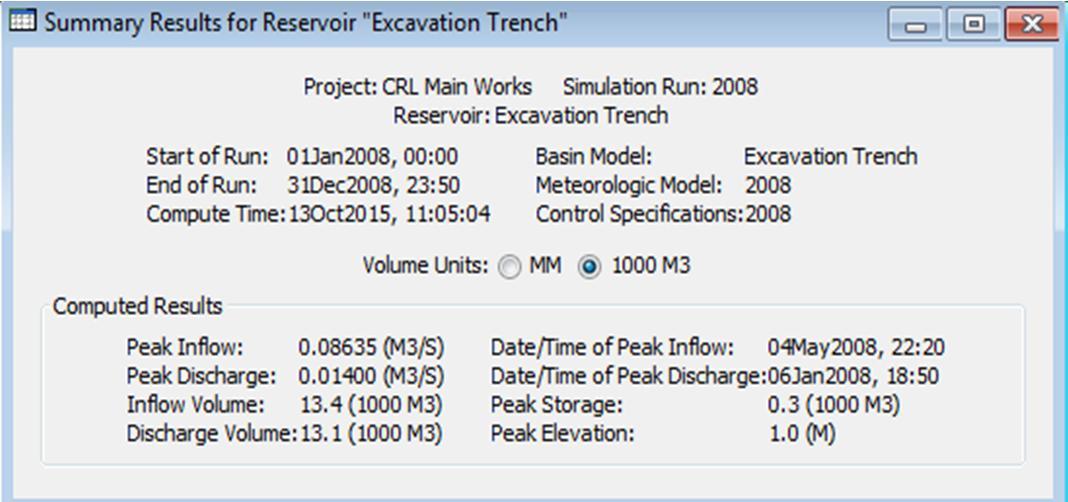

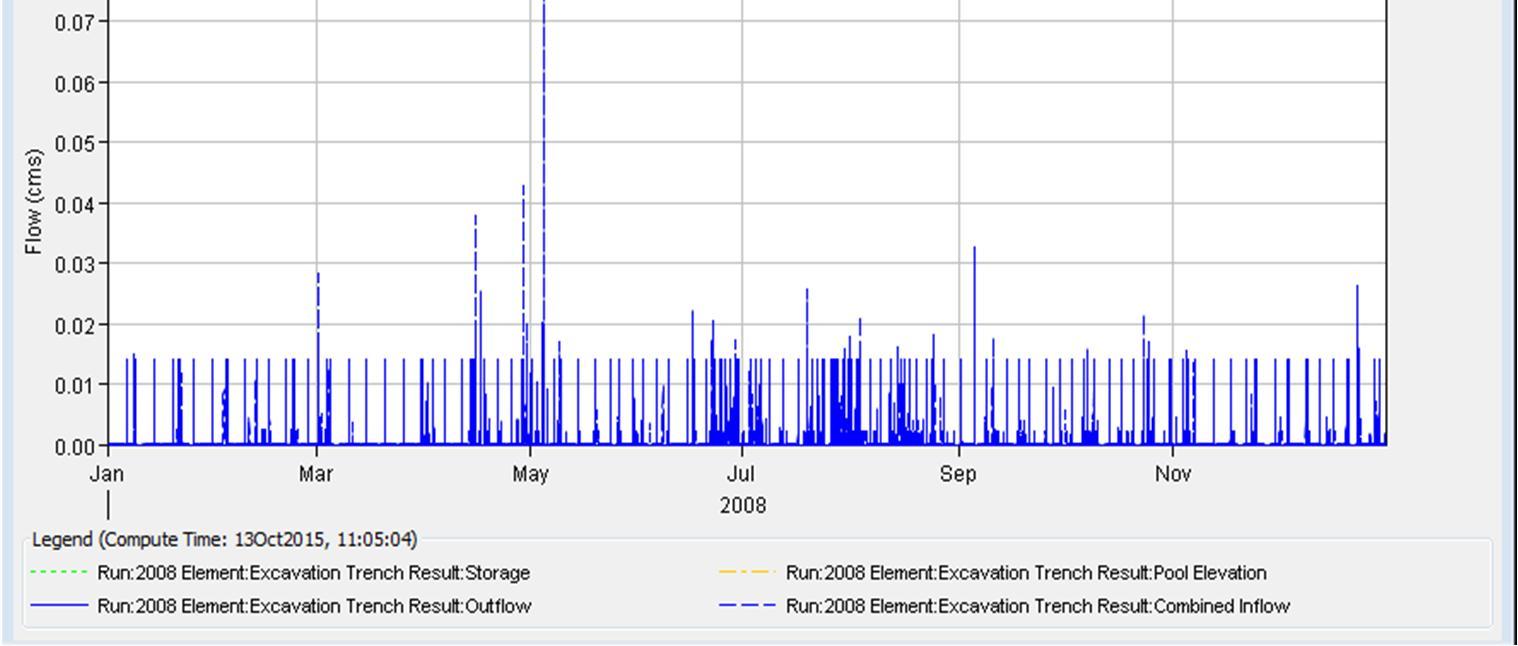

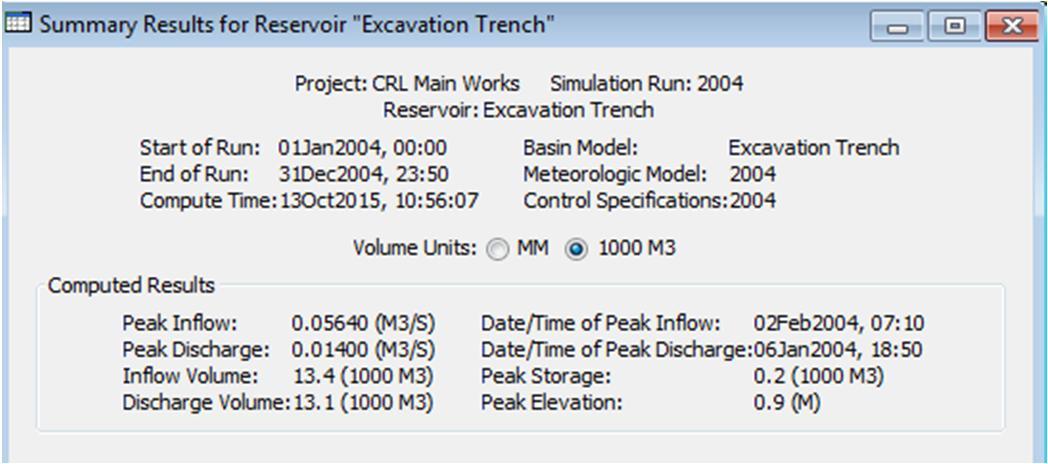

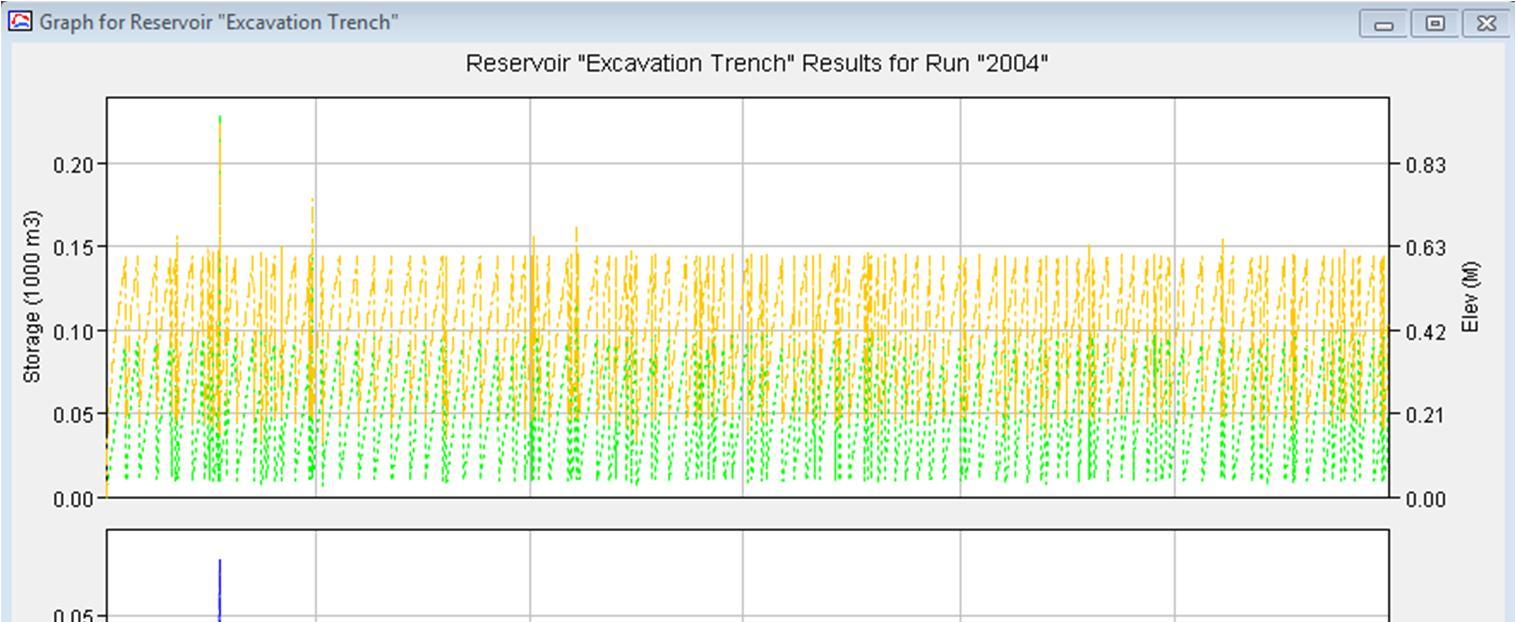

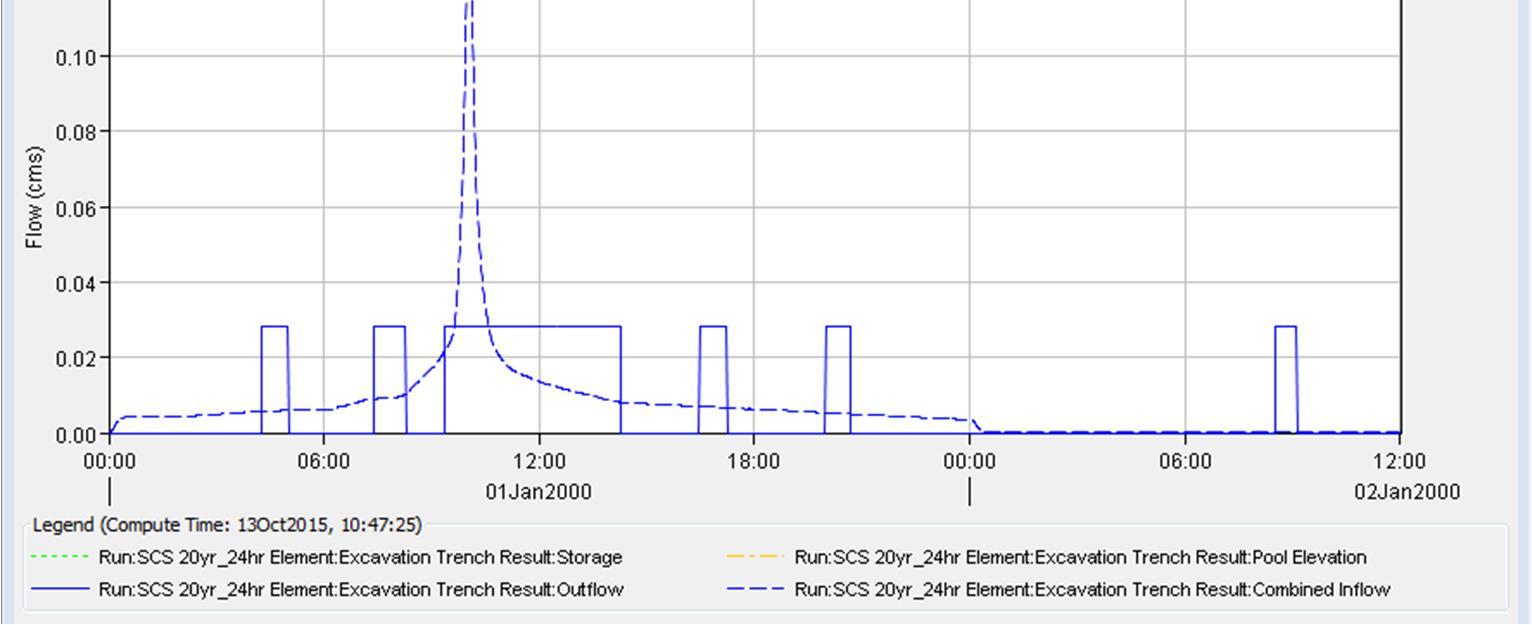

In order to predict the performance of the system, and size the pumps appropriately, modelling was undertaken using HEC-HMS – using the inputs detailed in Table 9

While the contributing catchment of the trench has been calculated at 3700m2 (refer section 2.2 of this ESCP) the modelling applied a safety factor (approximately 50%) to allow for additional flow from adjacent catchments entering the trench.

Table 9: Modelling input parameters

3/day

Rainwater catchments

Rainfall events tested

Dewatering system capacity

Pump capacity

5780m2

Time-series (2011, 2008, 2004) – taken from the Albert Park rain gauge.

1 in 20 year SCS design storm

Two units of 50m3/hr each – operated under normal conditions at half capacity (based on the siltbuster HB50).

Primary pump – 14L/s (50m3/hr) to match capacity of the siltbuster HB50

Secondary pump – 14L/s (50m3/hr) to manage peaks

Average groundwater inflow as provided

Surface area of the trench with added safety factor.

Based on manufacturers specifications

Trench dimensions

18m deep, 20m wide, 3.8% base slope.

Based on drawings provided. This provides the basis for storage which was modelled

Project #: 2665

Client: Auckland Transport

Pump settings (depth in m above trench invert)

Start 0.6m, stop 0.2m

The modelling results are summarised in Table 10.

Table 10: HEC-HMS Trench and pump modelling results

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Set based on acceptable levels of inundation within the trench

*Note: 0.8m depth equates to a flooded length of 20m; and a 1m depth equates to a length of 26m.

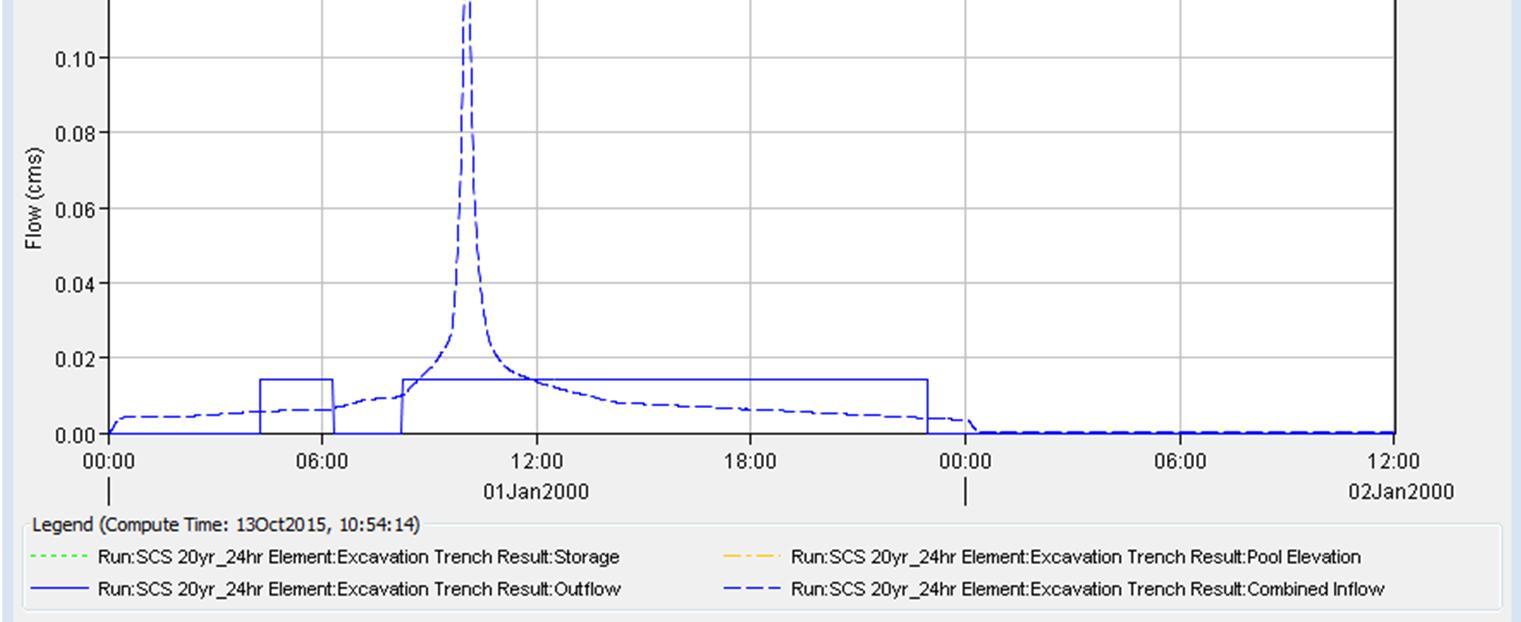

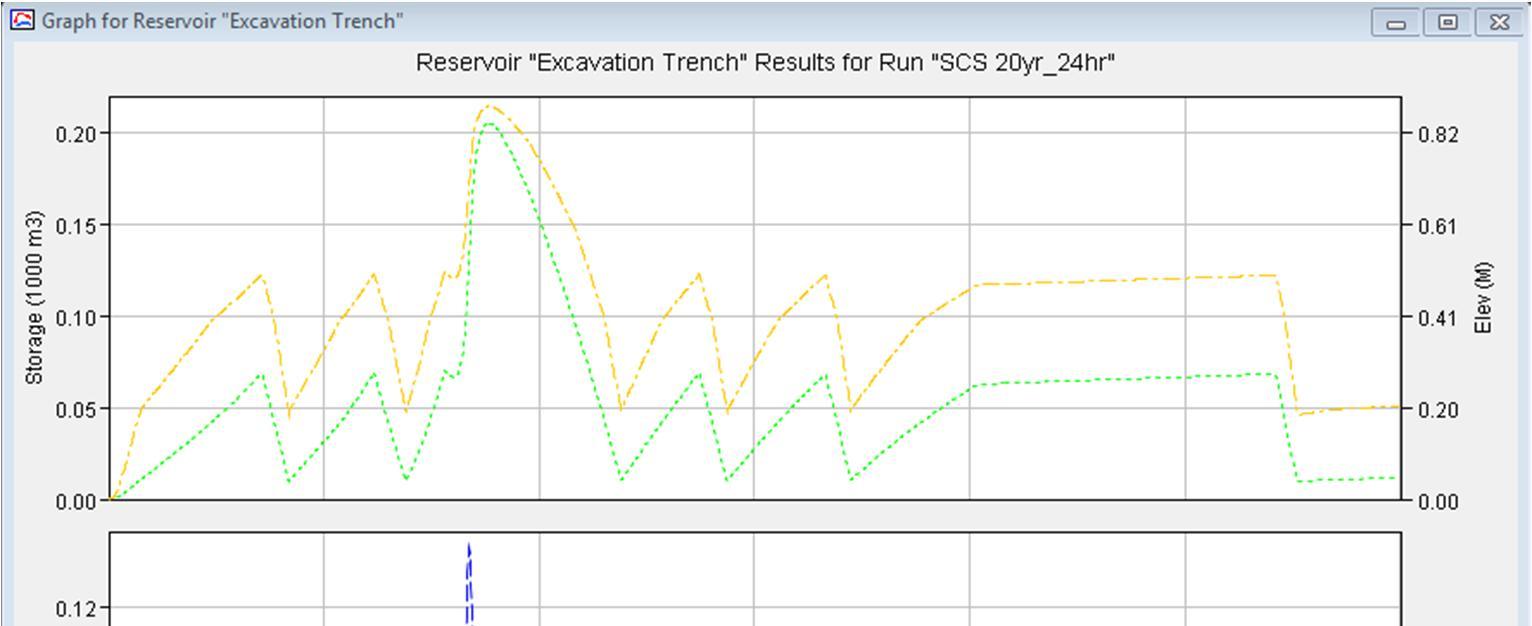

a) Time series: The results indicate that using a 14L/s pump, the maximum trench elevation achieved ranged between 0.9 and 1.1m. The worst case year was 2011, which resulted in 12 hours of the total year being above 0.8m depth, and only 2 hours above 1m. This length of time is considered acceptable, and depending on whether the working face is at the down-slope end of the trench area or not, the water level can be allowed to increase without compromising the work progress. These results confirm that all the water can be removed at a rate that can be managed by the WTP capacity.

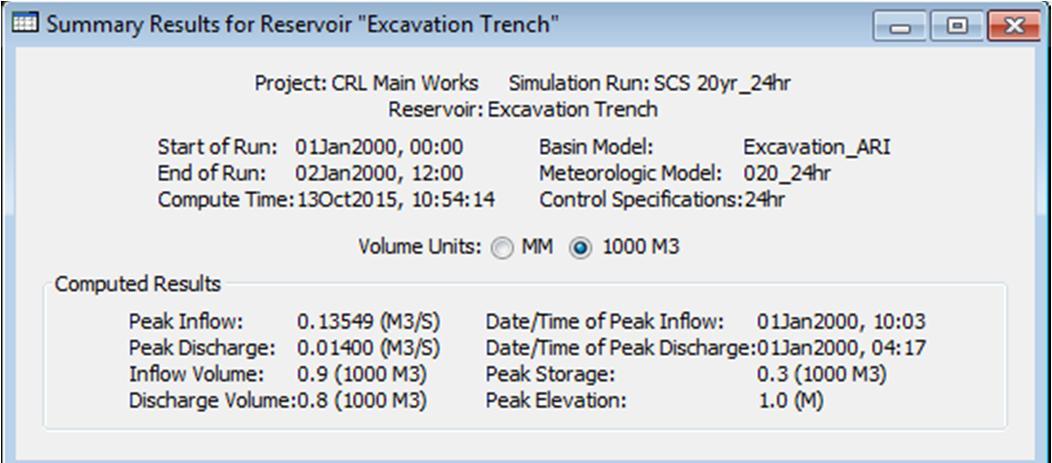

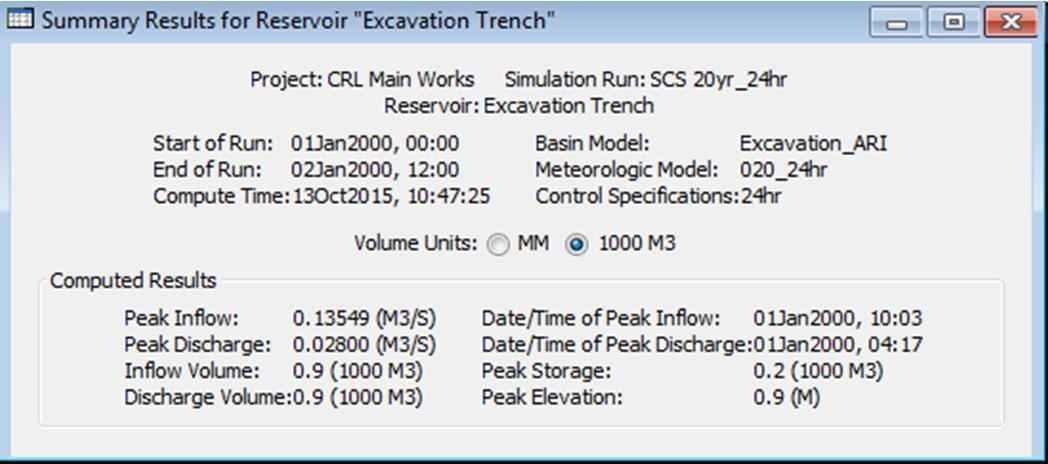

b) 1 in 20 year, 24 hour design storm: In an extreme event such as this, works will be halted, and the water level within the trench will be allowed to increase temporarily to a higher level. Modelling using a 14L/s pump (half capacity of 2 x siltbusters) – would result in a peak water level of 1.0m within the trench base, and the total volume of approximately 900m3 would take around 15 hours to pump out through the WTP (refer Appendix B of this ESCP). Using a 28L/s pump (max capacity of Siltbusters) would reduce the peak water level to 0.9m, and reduce the pumping time during the peak to around 5 hours (refer Appendix B of this ESCP). These results confirm that all the water can be removed at a rate that can be managed by the WTP capacity.

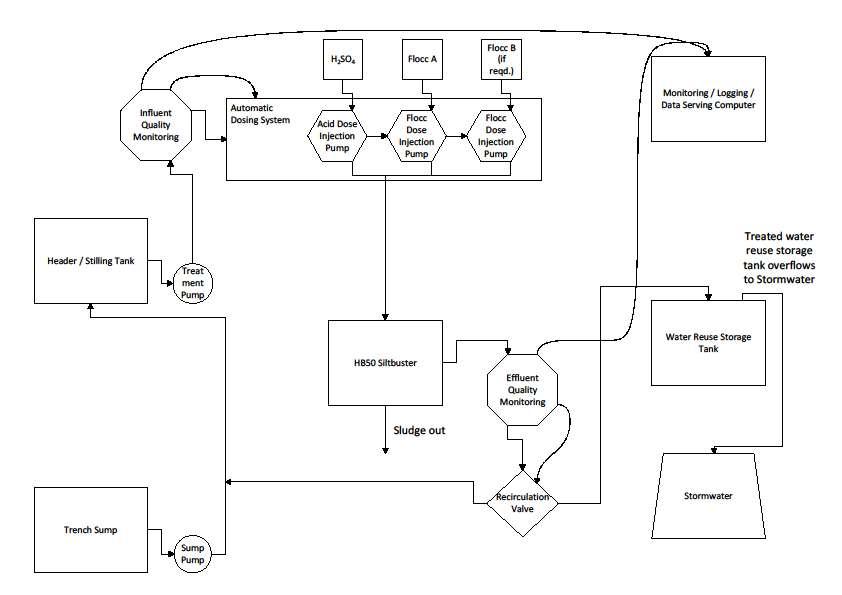

4.4.3.3 Water Treatment Plant

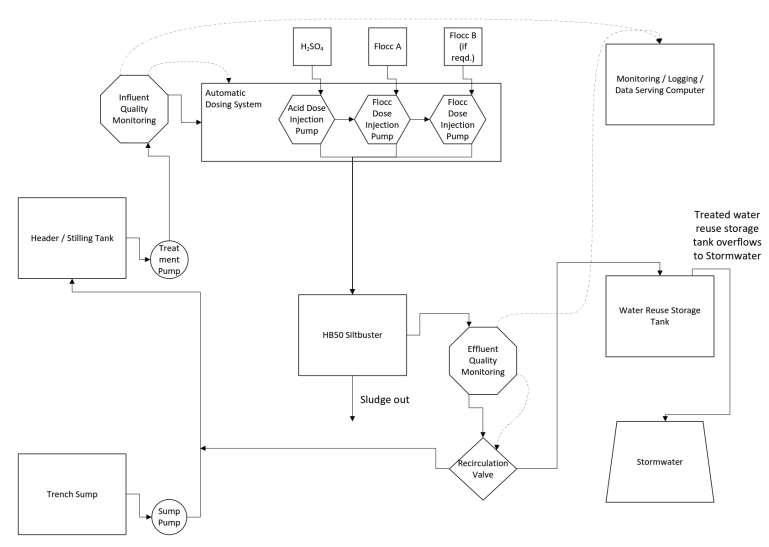

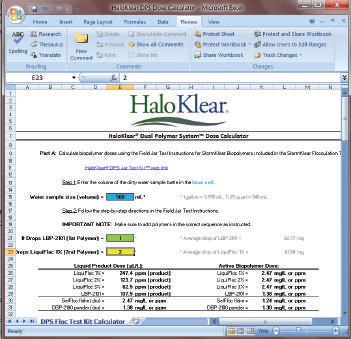

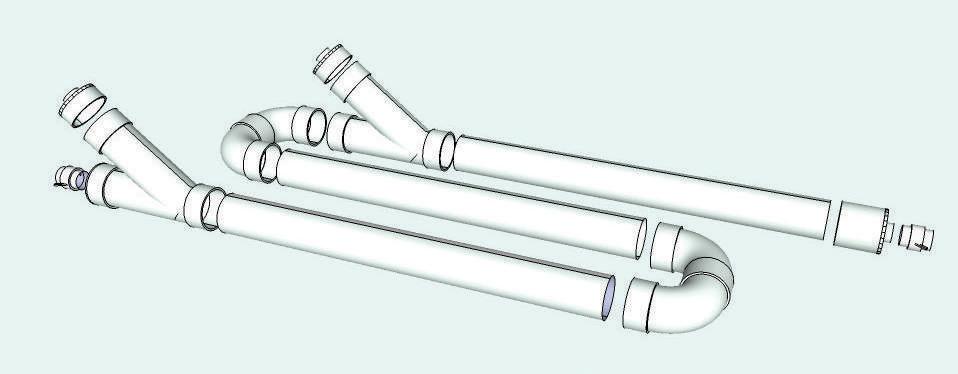

The WTP will utilise a treatment train approach consisting of the following components (Figure 7):

1. Mixing header Tank

2. Influent Quality Monitoring devices

3. Dosing system

4. Sediment settling and dewatering Tanks (eg Siltbuster Clarifiers)

5. Effluent Quality Monitoring device

6. Treated water storage/reuse

7. Discharge to stormwater network

Project #: 2665

Client: Auckland Transport

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

Project #: 2665

Client: Auckland Transport

1) Mixing Header Tank

Erosion and Sediment Control Plan

Doc. No. CRL-PAT-ENV-CON-PLN-000897

Revision: 04, Date: 21 March 2016

The first stage in the treatment train consists of a mixing/header tank. The mixing facility serves to homogenise the influent water. Rapid changes of influent water quality are evened out so that gradual changes in water quality will be fed to the rest of the treatment train. This approach reduces the frequency and magnitude of dosing adjustments. In addition, during very low flows, the tank may be used to store water for batch processing.

2) Influent Quality Monitoring

After the mixing tank, inline pH and Total Suspended Solids (TSS) meters will gather continuous influent water quality data which will be fed to the pH and flocculent dosing system

3) Dosing System

Three types of chemicals will be employed to assist the lamella clarifiers in treating water to achieve the consented water quality standard:

Coagulants

Flocculants

pH neutraliser/increase

An electronic dosing device will be used. An example of this is provided within the Chemical Treatment Management Plan (Appendix D of this ESCP)

4) Sediment Settling and Dewatering

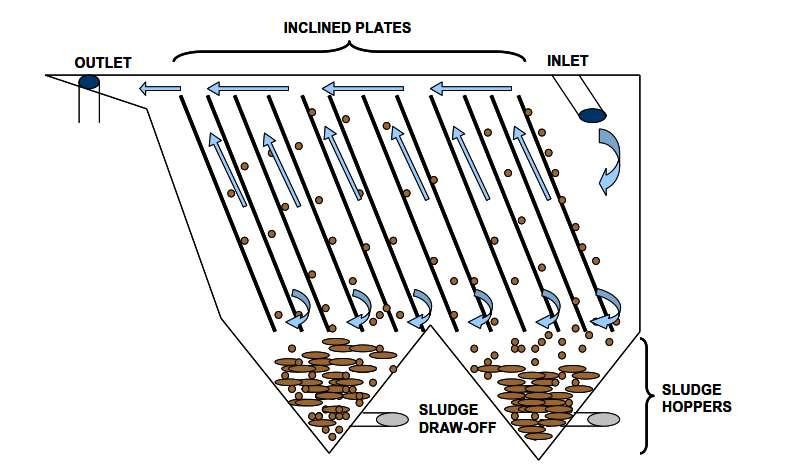

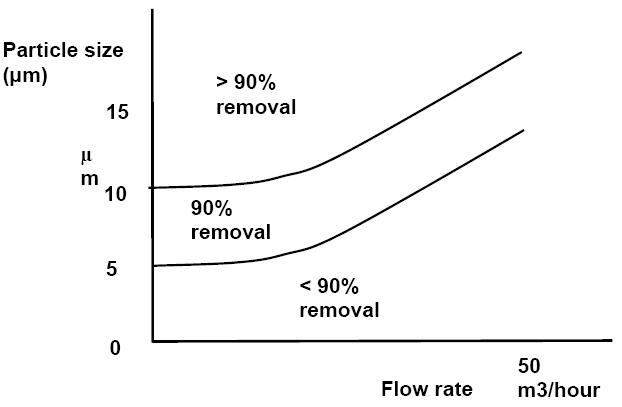

The treatment system will have a sediment settling and dewatering stage. The pump capacity calculations have been based on using two lamella clarifier tanks known as ‘Siltbusters’.

Siltbuster™ HB50 tanks have been used successfully in New Zealand and overseas, and are understood to be accepted by Auckland Council (personal communication with Malcolm Todd, Babington & Associates Ltd). Figure 8 shows a schematic of a Lamella Plate Clarifier.

The Siltbuster HB50 unit is a highly effective mobile lamella clarifier and has been specifically designed to provide water clarification for a range of applications. Process water, groundwater or site runoff can be treated either for re-use or discharge off site either to watercourse or stormwater system.

Refer to Appendix C of this ESCP for details of the clarifier unit.

Each unit has a maximum recommended hydraulic capacity of 50m3/hr (14litres/sec).

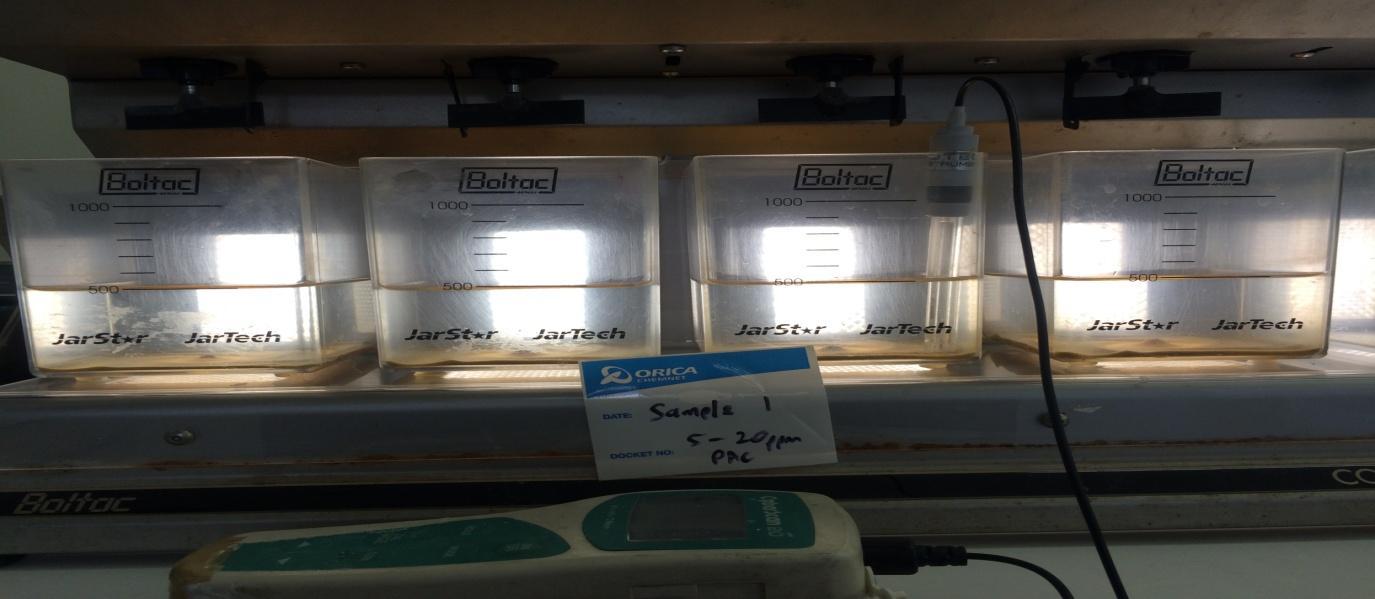

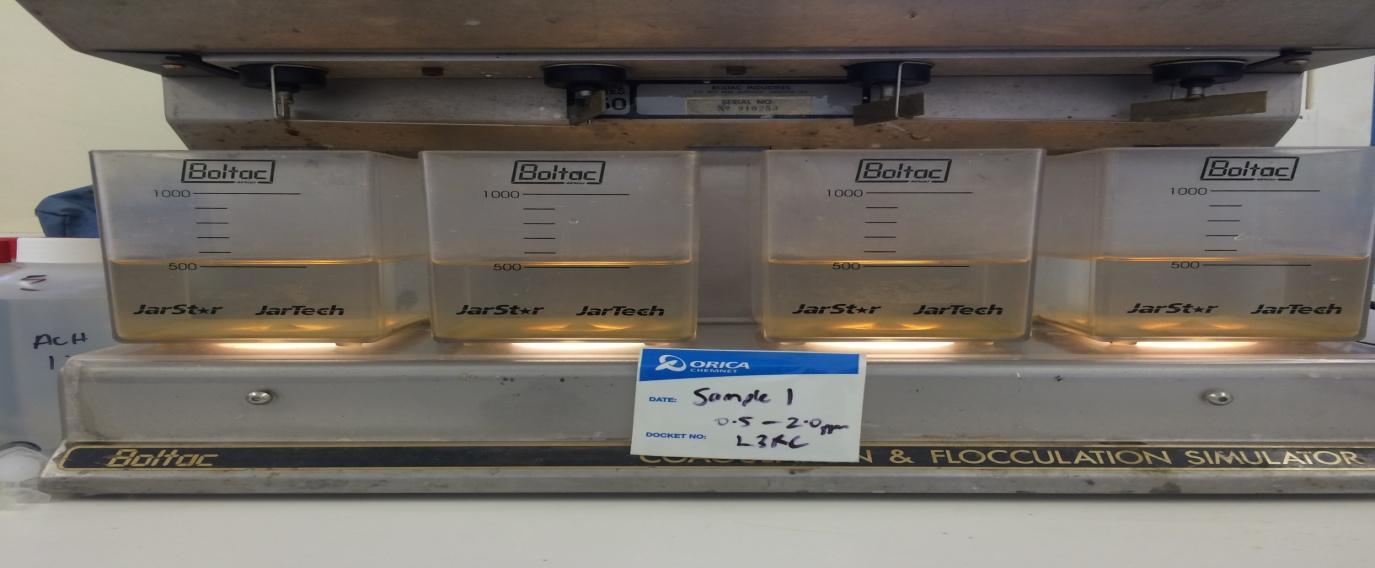

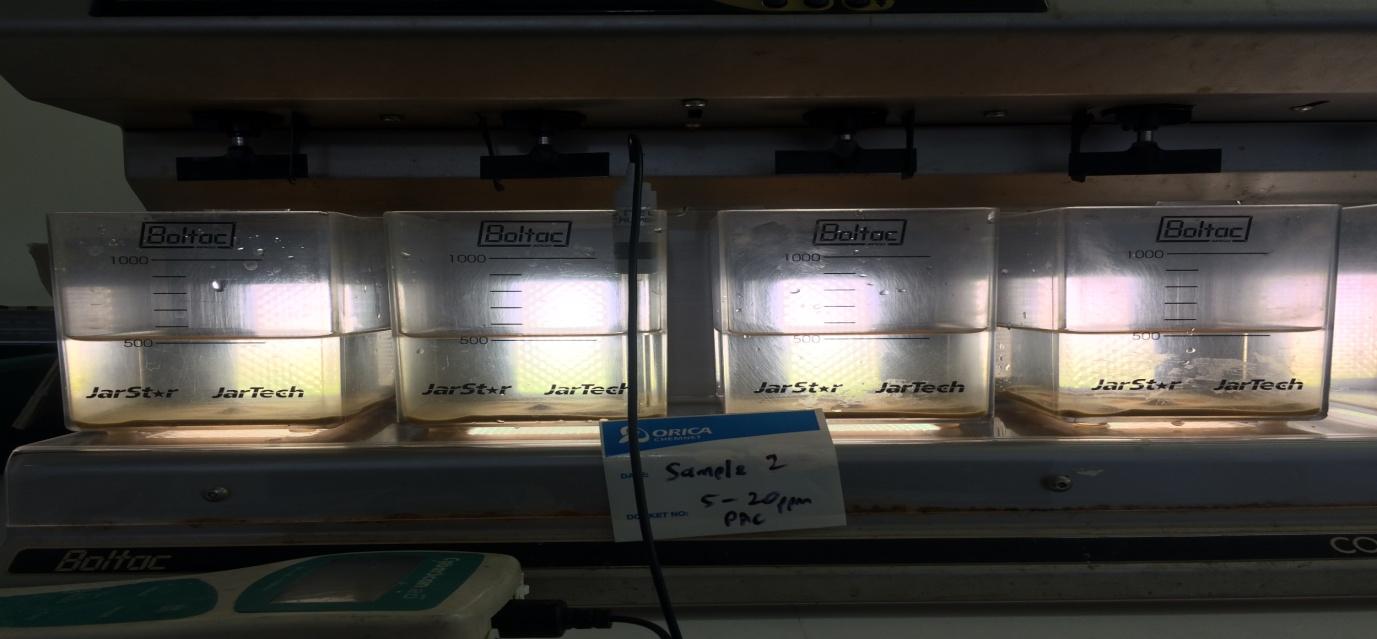

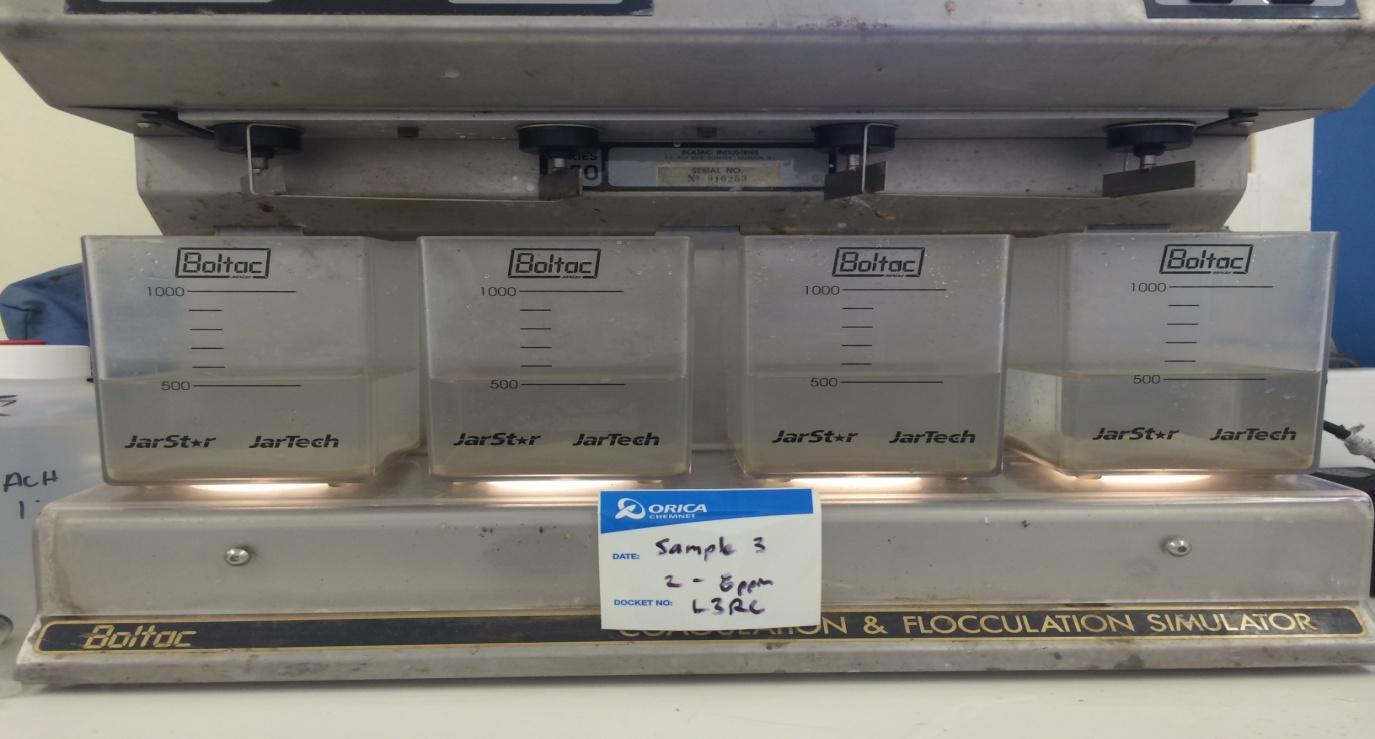

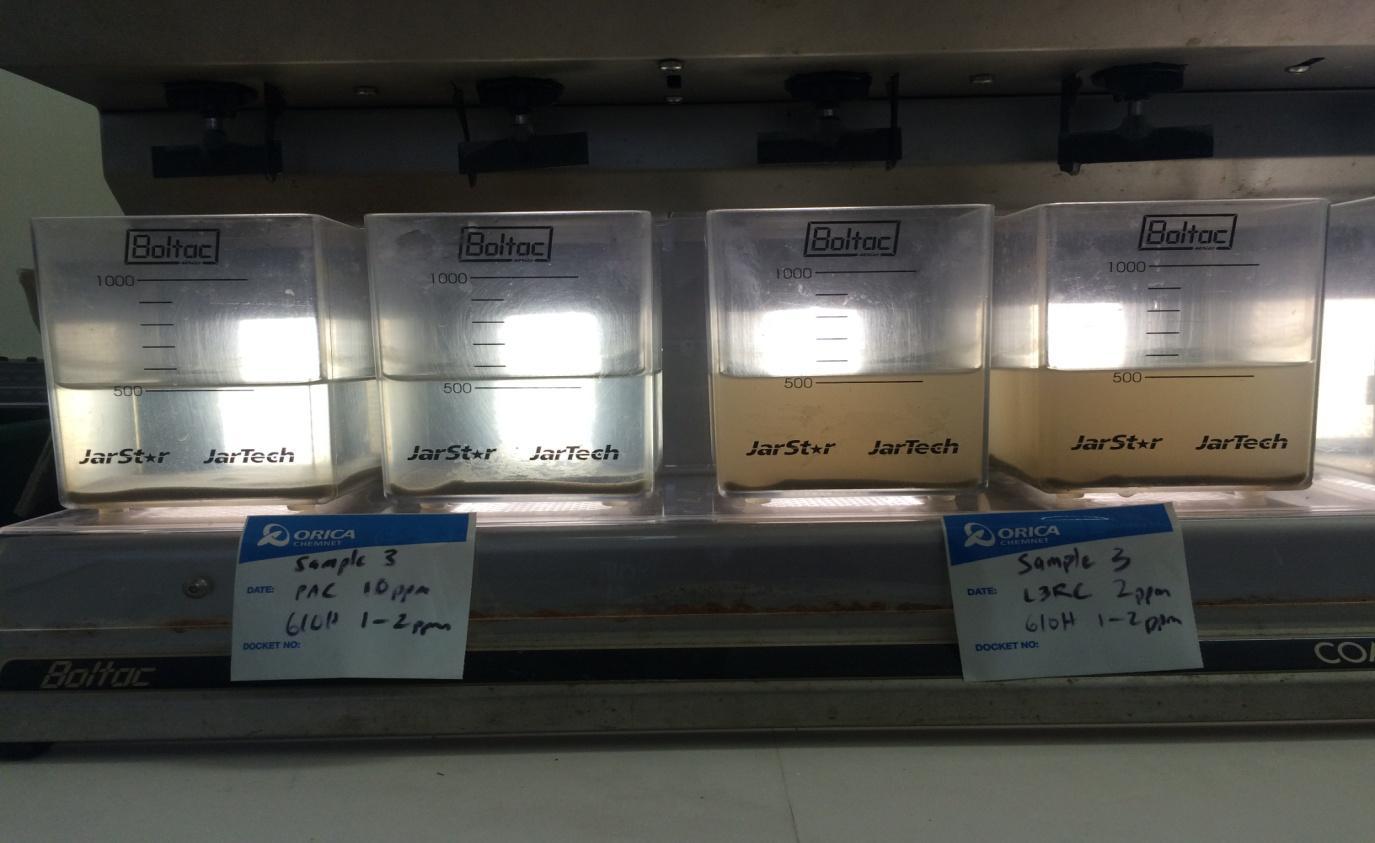

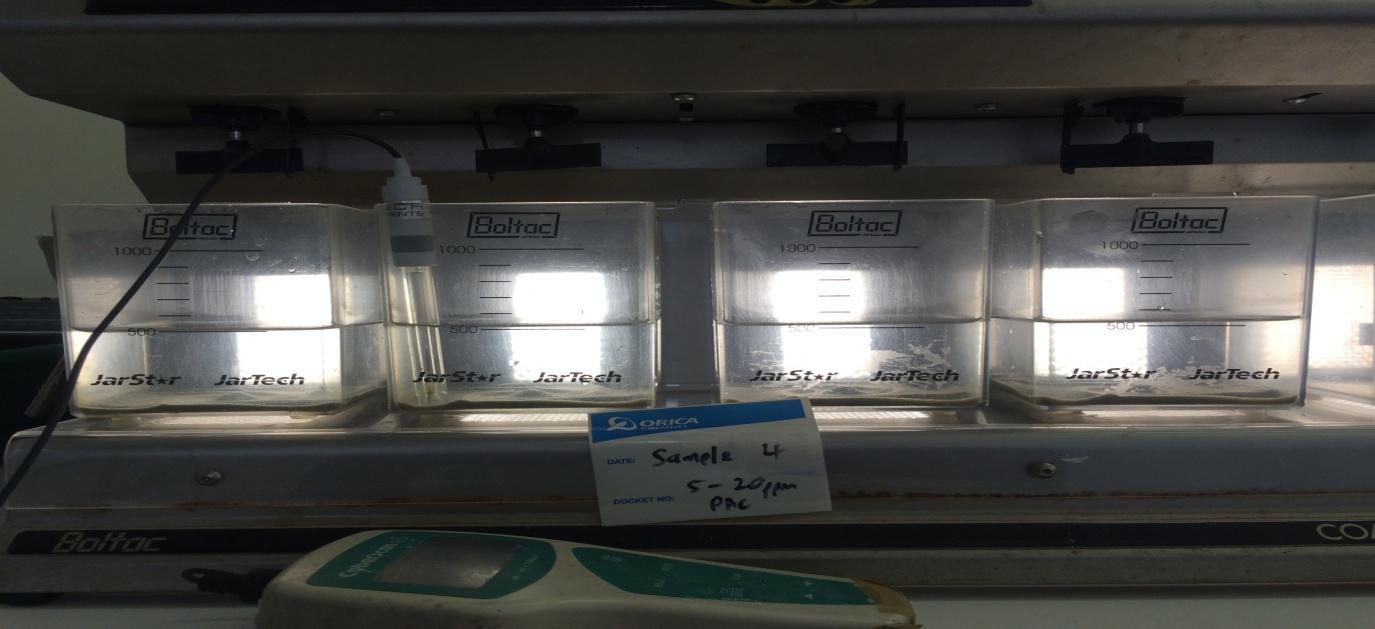

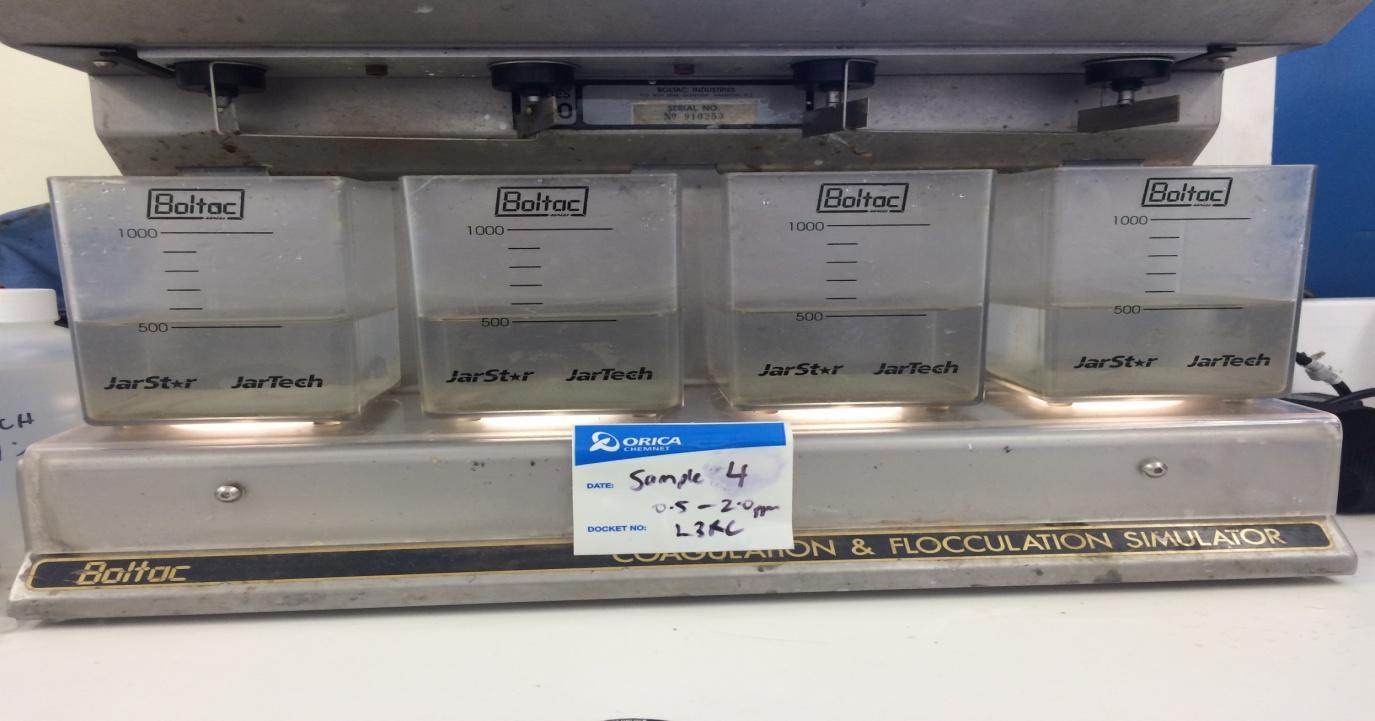

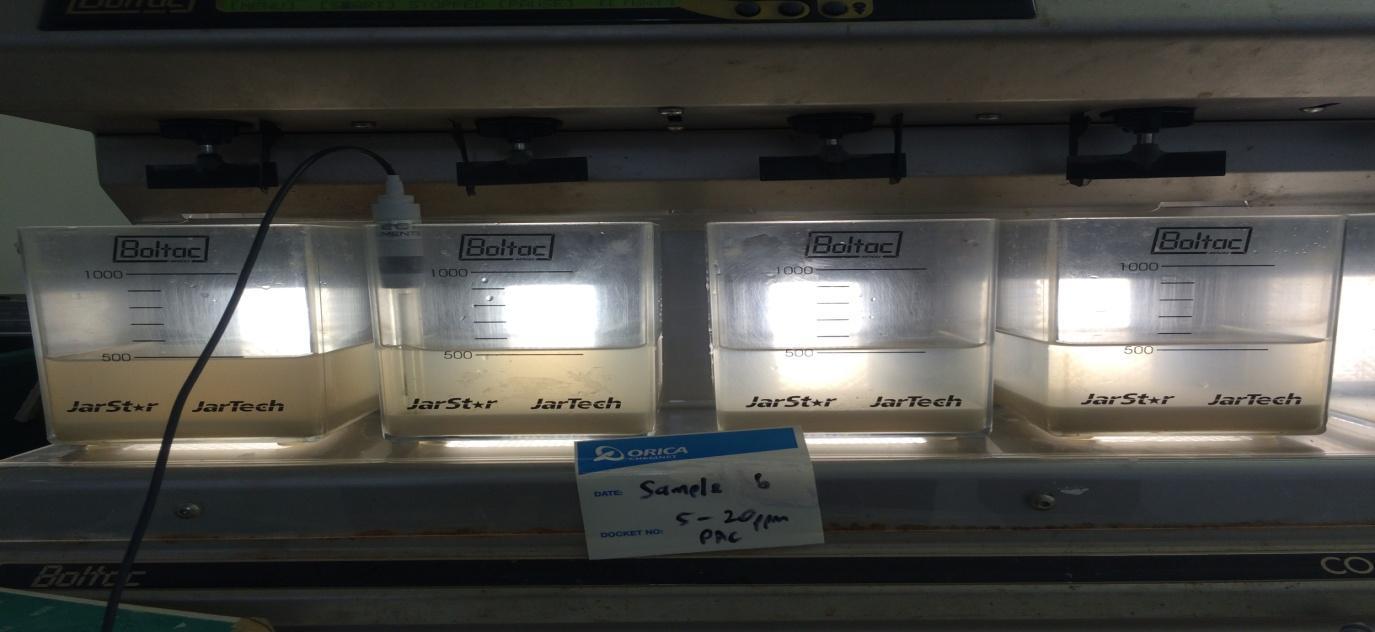

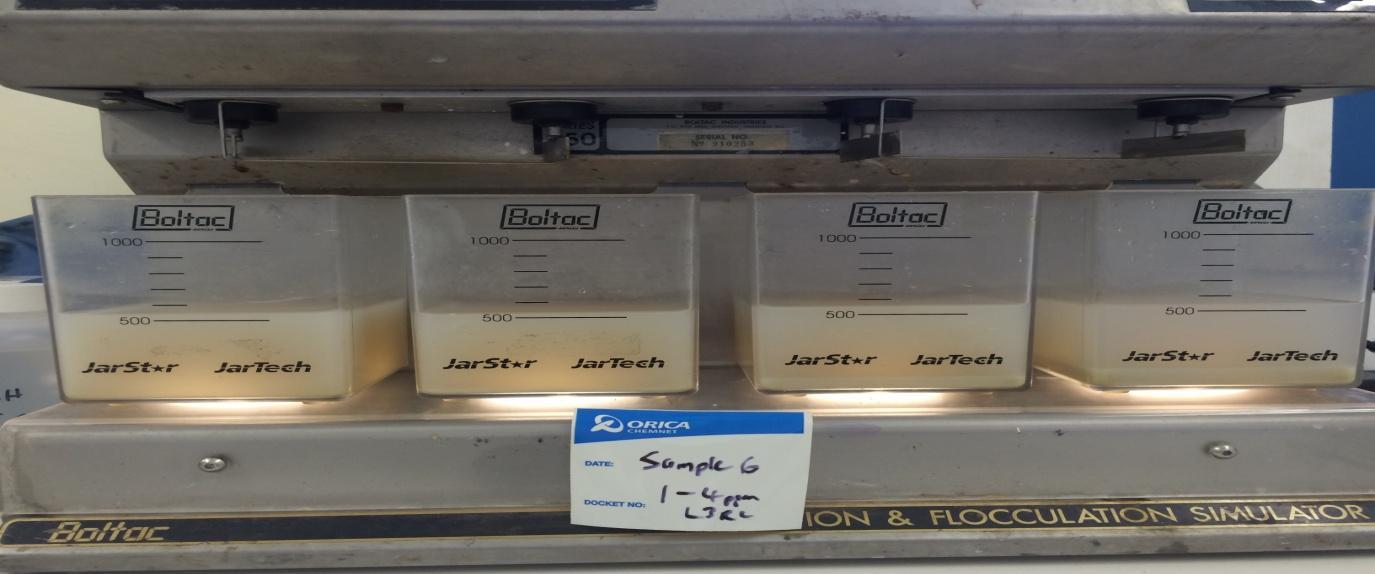

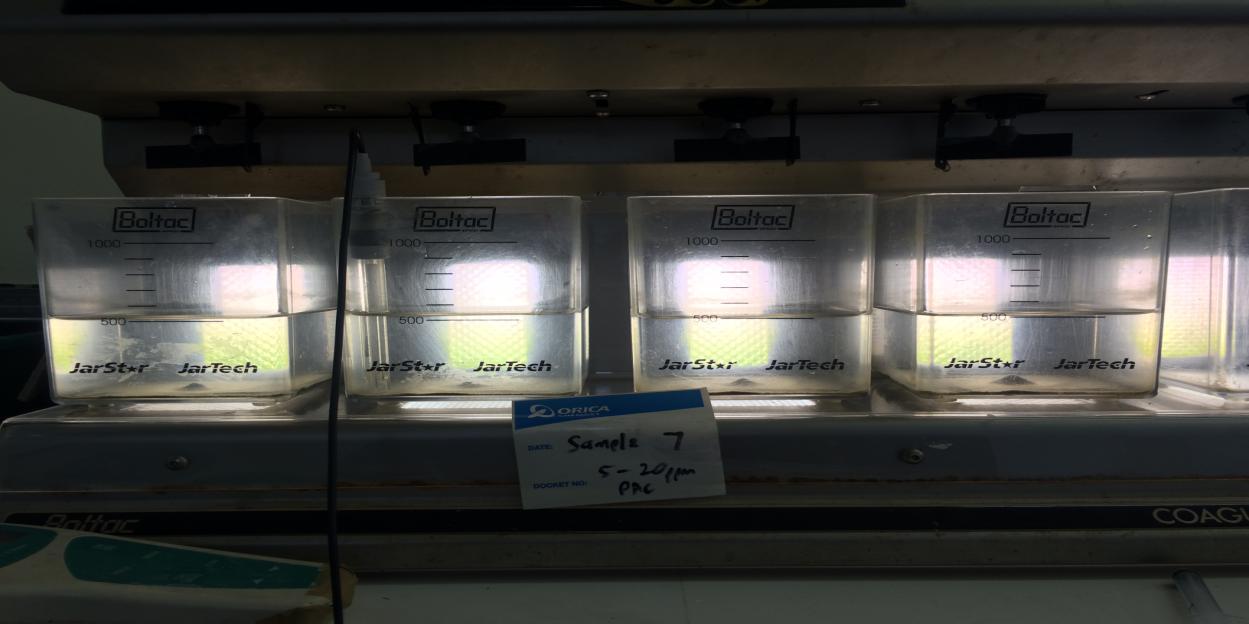

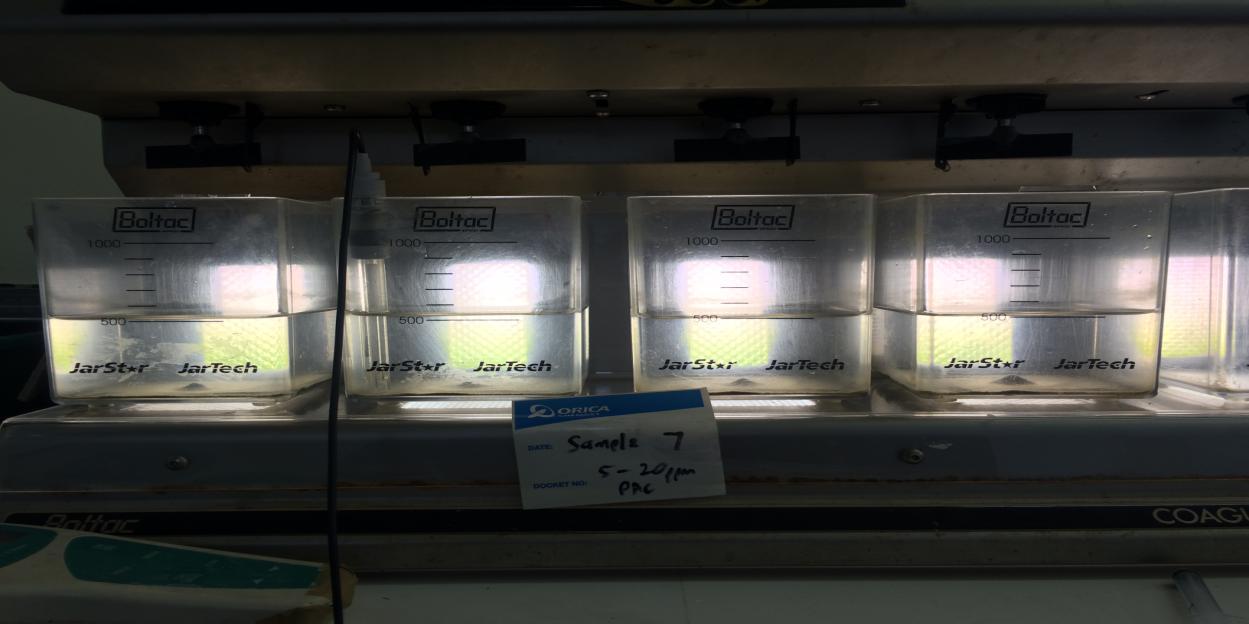

Estimates of average long term groundwater flows are in the order of 16m3/day with higher initial short term inflows of 30-60 m3/day depending on the zone and the construction methodology. A series of rainfall events (time series and design storm) have also been modelled to predict the performance of the Siltbuster unit (refer section 4.4.3.2 of this ESCP). These results show the two units proposed will have sufficient capacity to manage expected inflows. For events greater than this, water will fill up the lower reaches of the trench until such time that the WTP can process the extra volume.