Mt Eden Main Works

CRL-MTE-RME-LKA-PLN-800042

Revision: 001

Date: 29 June 2020

CRL-MTE-RME-LKA-PLN-800042

Revision: 001

Date: 29 June 2020

CRL-MTE-RME-LKA-PLN-800042

This document is uncontrolled when printed. This document should be printed in colour

Revision Status

Revision Date Version details

Rev A00 16 April 2020 Draft for Auckland Council and Independent Peer Review

Rev 000 16 June 2020 Final for Pre-lodgement

Rev 001 29 June 2020 Final for submission

Approval Status

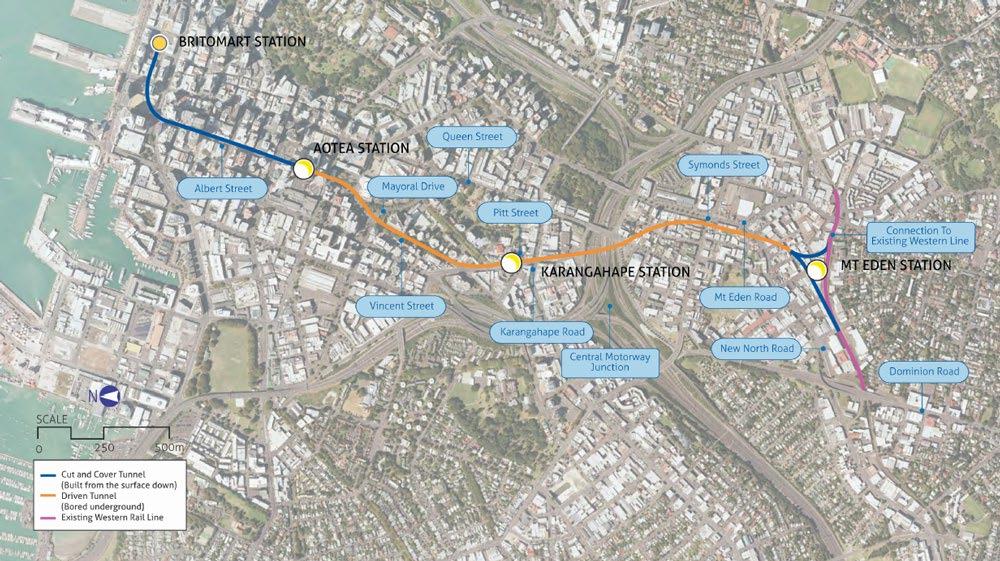

The City Rail Link (CRL) project comprises the construction, operation and maintenance of a 3.4 km underground passenger railway, running between Britomart Station and the North Auckland Rail Line (NAL) near Mt Eden Station. The CRL also involves the construction of two new underground stations at Aotea and Karangahape and a redeveloped Mt Eden Station (refer to Figure 1-1). The design and construction of the CRL infrastructure between the Aotea and Mt Eden Stations is being delivered by the Link Alliance.

This Contamination Delivery Work Plan (CDWP) has been prepared in relation to the Mt Eden Main Works (“main works”).

CRL works in the Mt Eden area involve the construction of the southern section of the tunnel structures and the tie-in of the CRL railway to the existing NAL, including the construction of the redeveloped Mt Eden Station. The Mt Eden Active Construction Zone (ACZ) and Construction Support Areas (CSAs) are generally located between Nikau Street to the north, State Highway 1 (SH1) to the east, Dominion Road to the west and the existing NAL to the south.

The works in this area include:

• Operational activity required to support the tunnel boring machine (TBM) drive, including control room and plant, storage and spoil handling;

• Construction of a new Mt Eden Station building, incorporating passenger linkages between the new CRL platform and the modified existing NAL platform;

• Road over rail bridges at Mt Eden Road, Normanby Road and Ruru Street with sections of road realignment;

• Grade separation structures for the existing and new rail lines to pass-over and connect with each other, including the Newton Junction Grade Separation Structure, the Eastern Facing Connection and the Western Facing Connection;

• Construction of a portal vent house building structure;

• Installation of retaining walls and utilities;

• Pedestrian and cyclist bridge structures at Fenton Street and Porters Avenue; and

• New road linkages within the reinstated area post-construction

Given the nature and scale of CRL construction works in Mt Eden, works are being undertaken in a staged manner, involving:

• Enabling and early works (demolition, network utility relocation and site establishment work) – early works have commenced and will continue to end of 2020;

• Main construction works (construction of the underground CRL cut and cover tunnels, grade separation structures and trenches, station building and platforms, and tie-ins to the NAL) to be undertaken from mid-2020 through to mid-2023; and

• Public realm reinstatement – likely to be undertaken from 2021 to early 2024.

To reflect the staged construction approach for the CRL in the Mt Eden area, a series of CDWPs are being prepared.

This CDWP addresses the main works, which are detailed in the Construction Environmental Management Plan (CEMP) and summarised in Section 2 of this CDWP.

If required, a CDWP will also be prepared for the future public realm reinstatement.

This CDWP has been prepared to outline measures that will be implemented to mitigate and manage the potential human health and environmental effects associated with potentially contaminated soil encountered during the main works

The objectives of the CDWP are:

• To avoid, remedy or mitigate the adverse effects of construction on human health which may result from the disturbance of contaminated materials during construction; and

• To minimise discharges to land or water from any contaminated material encountered during the main works.

CRL Designation 2500-6 (conditions 57 and 58) requires the preparation of a CDWP while conditions 131-150 of the discharge permit (R/REG/2016/1895) and land use consent (R/LUC/2016/1890) require a Contaminated Soils Management Plan. These two separate requirements have been combined and are addressed in this single CDWP.

This CDWP has been prepared in consultation with the CRL Mana Whenua Forum, Mt Eden Community and Business Liaison Group (CLG), and has been reviewed by the Independent Peer Reviewer (IPR) prior to submission to Auckland Council (as per designation conditions 7 and 11, and resource consent condition 19). A record of the consultation and review outcomes, including the Link Alliance’s response to matters raised, is included in Appendix A.

This CDWP has been prepared in general accordance with Ministry for the Environment (MfE) ‘Contaminated Land Management Guideline No. 1: Reporting on Contaminated Sites in New Zealand’ (revised 2011) (MfE, Contaminated Land Management Guidelines No. 1: Reporting on Contaminated Sites in New Zealand (CLMG), 2011a), and forms part of the CEMP for the main works.

This CDWP has been prepared by Daniel Ware and reviewed by Stephen Thomson, both being Contaminated Land Professionals (CLP).

Daniel Ware is a Contaminated Land Scientist at WSP. Daniel has a Bachelor of Science Degree and Post Graduate Honours Degree in Chemistry.

Stephen Thomson is a Principal Contaminated Land Scientist at WSP. Stephen has a Bachelor of Science Degree and Post Graduate Diploma in Physical Geography. Stephen has over 23 years’ experience in the contaminated land industry, including considerable experience in undertaking investigations, managing, and reporting on contaminated land for public and private sector clients. Stephen prepares and reviews technical reports and is considered a Suitably Qualified and Experienced Practitioner (SQEP) under the Resource Management (National Environmental Standard for Assessing and Managing Contaminants in Soil to Protect Human Health) Regulations 2011 (NES Soil).

Table 1-1 outlines the CRL designation and Regional Resource Consent conditions relevant to the CDWP.

Table 1-1 Designation and Regional Resource Consent conditions for CDWP and where addressed in this document

57.1

57.2

57.3

A Contamination DWP shall be prepared to manage the adverse effects relating to contaminated land during the construction of the City Rail Link or any part of it.

The objective of the Contamination DWP is to avoid, remedy or mitigate the adverse effects of construction on human health which may result from the disturbance of contaminated materials during construction.

To achieve the above objective the following shall be included in the Contamination DWP and implemented as required:

(a) A health and safety plan that addresses:

(i) Worker safety in relation to hazardous substances; and

(ii) Worker training with regard to handling hazardous substances, identifying potentially contaminated soil / material, and notification procedures for discovery of contamination;

(b) Procedures for how erosion and sediment control, stormwater, dust, and odour control measures will manage the removal of contaminated soil / material;

(c) Procedures for contaminated soil classification, management and disposal of contaminated soil / material;

(d) Where any trenches/excavations during civil works are to be sealed as a result of contamination and how this is to be recorded;

(e) How and which work areas are to be restricted to authorised personnel only and procedures to limit the presence of ignition sources in these areas (e.g. no smoking within or adjacent to construction area, no welding or open flames near areas with high concentrations of hydrocarbon contamination);

(f) Procedures for the monitoring and management of the removal of contaminated soil / material by a suitably qualified environmental specialist;

(g) How the placement of re-used contaminated soil / material will be recorded and tracked;

This Document

This Document

Section 6.2, 6.4 and 6.8

Section 5.6, 5.7 and 5.8

Section 5.3 and 5.4

Section 5.14

Section 6

Section 5.4.3

Section 8

(h) Where areas for stockpiling and storing contaminated soil / material will be established on the construction site and the procedures for managing the containment of the contaminated soil / material in these areas;

(i) Cross references to the specific sections in the Communications and Consultation Plan which detail how the general public will be communicated with on the management of the adverse effects relating to the removal of contaminated soil / material.

At the completion of construction works a validation report will be prepared in accordance with any Ministry for the Environment guidelines and submitted to the Auckland Council Consent Monitoring officer documenting the management of soil and evidence of appropriate disposal.

Resource Consent Conditions

131

132

At least 20 working days prior to the commencement of construction (earthworks), the Consent Holder shall provide a Contaminated Soils Management Plan (CSMP) to the Council (Team Leader Central Monitoring) for certification. The CSMP shall be prepared by a Contaminated Land Professional in accordance with the Contaminated Land Management Guidelines, No. 1 –Reporting on Contaminated Sites in New Zealand, Ministry for the Environment (revised 2011).

The Consent Holder shall request that Council (Team Leader Central Monitoring) provide a determination to the Consent Holder, in writing, within 10 working days of receipt of the CSMP, whether the CSMP can be certified as per the requirements of the Condition 134.

Document

Document

Noted

133

134

No earthworks shall commence until a. certification is provided Council (Team Leader Central Monitoring) that the CSMP satisfactorily meets the requirements of Schedule 13(A4) of the ACRP: ALW and b. all measures identified in the plan as being required to be established prior to commencement of earthworks have been established.

The CSMP shall address the following matters:

a. The areas within the project site designated for excavation works, and an updated map/s showing the land disturbance activity areas,

b. Excavation management, and disposal procedures for soil, sediment, dust, surface run-off water, perched groundwater, and groundwater if encountered.

c. Temporary containment, treatment, and testing procedures for any water getting in contact with contaminated material if the disposal option is to the stormwater system or the marine environment is considered.

d. Contingency measures for unexpected discovery of contamination.

e. Proposed sampling and analysis, if applicable.

Noted

f. Any proposed works summary reporting. (a) – Figures 1 to 4, Appendix D

136

138

139

140

141

142

143

The Consent Holder shall notify the Council (Team Leader Central Monitoring) at least two working days prior to any earthworks activity on the site and provide the following details: a. Name and telephone number of the project manager and site owner, b. Site address to which the consents relate, c. Activity to which the consents relate, and d. Expected duration of works.

All disturbance of contaminated and potentially contaminated soil shall be carried out in accordance with the certified CSMP required by Condition 131 and any changes to the plan shall be submitted to the Council (Team Leader Central Monitoring) for certification prior to the change being implemented.

The Consent Holder shall ensure that all disturbance of contaminated soil shall be supervised by a suitably qualified and experienced Contaminated Land Professional whose responsibilities shall include making sure that the soil management and disposal practices, the contingency measures outlined in the certified CSMP required by Condition 131, and all relevant consent conditions are adhered to. Section 3.0

The Consent holder shall ensure that regular inspections of the works area shall be carried out by a suitably qualified and experienced Contaminated Land Professional. These inspections shall be documented, and the relevant records retained and provided to Council Team Leader Central Monitoring) in the Site Validation Report (SVR) required by Condition 149. Section 5.10

The Consent Holder shall manage soil disturbance works to minimise any discharge of debris, soil, silt, sediment, or sedimentladen water from the site to either land, stormwater systems or the receiving marine environment. The implementation of erosion and sediment controls shall be in accordance with the ESCP required by Condition 53.

The Consent Holder shall manage all soil disturbance works to avoid the potential for cross-contamination of materials to occur, in particular, movement of contaminated soil around the site or deposition of contaminated soil on other parts of the site shall be avoided. Where soils are identified for off-site disposal, they shall be loaded directed for removal, where possible, and all material shall be covered during transportation off site.

To minimise the spread of contaminated material, any temporary stockpiles of excavated contaminated materials shall be located within the catchment of erosion and sediment controls for the site. All stockpiles shall be covered with either polythene or an equivalent impermeable material when the site is not being worked and during periods of heavy rain.

At all times, dust shall be controlled in accordance with the publication titled Good Practice Guide for Assessing and Managing the Environmental Effects of Dust Emissions, Ministry for the Environment 2001.

Excess soil or waste materials removed from the subject site shall be deposited at the disposal site which holds a consent to accept the relevant type of contamination.

This document

Section 5.5

Section 5.6

Section 5.8

Section 5.4

147

148

149

The Consent Holder shall implement the procedures for the management, treatment, temporary containment, testing, and disposal of groundwater and surface run-off water via the stormwater system in accordance with the report titled Auckland City Rail Link: Resource Consent Package 2: Aotea Station to North Auckland Line Construction and CRL Operation: Draft Erosion and Sediment Control Management Plan, dated 13 May 2016, prepared by Aurecon New Zealand Limited, and provided with the application.

Any perched groundwater or surface run-off water encountered within the excavation area requiring removal shall be considered potentially contaminated, and shall either: a. be disposed of by a licensed liquid waste contractor; or b. pumped to sewer, providing relevant permits are obtained; or c. discharged to the stormwater system, provided testing demonstrates compliance with 50 times the Australian and New Zealand Environment Conservation Council (ANZECC) Guidelines for Fresh and Marine Water Quality (2000) for the protection of 95 percent of marine water species, and is free from petroleum hydrocarbons.

Where contaminants which have not been anticipated by the application are identified, works in the area containing the unexpected contamination shall cease until the contingency measures outlined in the certified CSMP required by Condition 131 have been implemented, and have been notified to the Council (Team Leader Central Monitoring). Any unexpected contamination encountered during the works and contingency measures implemented shall be documented in Site Validation Report required by Condition 149.

Section 7.1 and 8

All imported fill shall: a. comply with the definition of clean fill material Section J1 of the Auckland Unitary Plan (Operative in Part); and b. be solid material of an inert nature; and c. not contain hazardous substances or contaminants above recorded natural background levels of the receiving site. Noted

All sampling and testing of contamination on the site shall be overseen by a suitably qualified and experienced Contaminated Land Professional. All sampling shall be undertaken in accordance with Contaminated Land Management Guidelines, No. 5 – Site Investigation and Analysis of Soil, Ministry for the Environment (revised 2011) (MfE, 2011b)

Within three months of the completion of earthworks on the site, the Consent Holder shall provide a Site Validation Report to the Council (Team Leader Central Monitoring). The SVR shall be prepared by a suitably qualified and experienced Contaminated Land Professional in accordance with the Contaminated Land Management Guidelines, No. 1 – Reporting on Contaminated Sites in New Zealand, Ministry for the Environment (revised 2011).

Section 5.10

Section 8

The SVR required by Condition 149 shall address the following matters:

a. A summary of the works undertaken, including a statement confirming whether the excavation of the site has been completed in accordance with the certified CSMP required by Condition 131;

b. The location and dimensions of the excavations carried out, including the relevant site plan;

c. A summary of soil, groundwater, and surface run-off water testing undertaken, if applicable, including tabulated analytical results, and interpretation of the results in the context of the Contaminated Land Rules of the Auckland Unitary Plan (Operative in Part);

d. Copies of the disposal dockets for the contaminated soil and ‘clean fill’ material removed from the site;

e. Records of any unexpected contamination encountered during the works and contingency measures undertaken, if applicable;

f. Details regarding any complaints and/or breaches of the procedures set out in the certified CSMP required by Condition 131 and the conditions of this consent;

g. Results of testing, if required, of any spoil disposed offsite; and

h. Results of testing of any imported fill material to ensure compliance with the definition of clean fill material in Section J1 of the Auckland Unitary Plan (Operative in Part).

The Link Alliance is seeking an Infrastructure Sustainability Council of Australia (ISCA) Infrastructure Sustainability (IS) rating for the CRL project. Further details can be found in the main works CEMP and Sustainability Management Plan. Sustainability requirements that relate directly to this CDWP are included in Appendix B These requirements are imbedded within the Delivery Work Plans and Management Plans for the main works to ensure that sustainability is a key focus and ‘the way we do things’.

In some cases, the IS requirements and sustainability goals enhance the designation and resource consent requirements.

This CDWP is a live document that will be reviewed at least annually, or as a result of a material change to the main works, or to address unforeseen adverse contamination effects arising from construction, or unresolved complaints. Refer to the CEMP for further detail on the review and updating process.

The main works involve construction along several active work fronts concurrently within the Mt Eden area at any one time, to enable the redevelopment of Mt Eden Station and establish the CRL tie-ins to the NAL. Works will be carried out in a staged fashion. The construction staging and methodologies are described in greater detail in the CEMP.

Within the main works area, there are already other works occurring in accordance with the Mt Eden Enabling Works (OPW60350039) and Normanby Road Early Works (OPW60351423) outline plan packages.

In summary, the main works involves:

• Ground improvements, in the form of deep soil mixing (contiguous piling and grout injection), within the NAL corridor between Mt Eden Road Bridge and Normanby Road;

• Bulk excavations and construction of retaining walls along the NAL to provide for the rail trenches and installation of new tracks. The excavation will encounter basalt, which will be removed via rock-breaking and blasting. In places, softer ground conditions are anticipated to be encountered, which may require the use of sheet piles;

• Construction of the eastern and western crossover structures that enable the CRL rail lines to tie-in to the NAL;

• Construction of the Porters Avenue and Fenton Street pedestrian and cyclist bridges;

• Construction of the Normanby Road grade separation bridge, including regrading of Normanby Road and realigning the Boston Road roundabout;

• Redevelopment of the existing NAL platform;

• Construction of the CRL platform and the foundations and building structures for the Mt Eden Station building and the ventilation building; and

• Operation of the TBM, including the conveying of spoil material from the tunnels and the refuelling and general maintenance of the TBM within CSA 4.

The main works will be divided into several stages within the various work areas.

Generally, the works along the NAL are divided into two stages to allow works on the northern (down main) and southern (up main) sections to correspond with the ‘Single Line Running’ of train services through the construction area.

Works within the Mt Eden station area are divided into 12 stages. Stages 1-4 have already been addressed in the Mt Eden Enabling Works outline plan package, and stages 5-12 will be undertaken as part of the main works For the new Mt Eden Station building and ventilation building, construction of the foundations and building structures will be undertaken as part of stages 5 – 12, while the finishing of the buildings, including internal and external fittings, will be completed as part of the future public realm reinstatement.

The construction staging, and methodologies are described in Sections 2.3 and 2.4 of the CEMP.

The main works will be undertaken near the existing Mt Eden Station and along the NAL, in an existing urban environment. The main works area is generally bounded by the NAL (south), State Highway 1 (east), Dominion Road (west), and Nikau Street (north) (refer Figure 2-1). The main works will include construction activity along Nikau Street, Ruru Street, Porters Avenue, Fenton Street, Haultain Street, Ngahura Street, Flower Street, Shaddock Street, Mt Eden Road, Normanby Road, Boston Road and Nugent Street.

Designation 2500-6 KiwiRail Designation 6300

Confirmation of this CDWP is required as part of the main works Outline Plan process and the CDWP must also be certified by the Council (Team Leader Central Monitoring) prior to the commencement of earthworks. The certified CDWP shall be readily available on site at all times. The provisions of the CDWP shall be outlined to all parties undertaking works during the main works, during the site inductions (refer Section 6.2).

Each person involved in the works has equal responsibility to avoid, remedy or mitigate adverse environmental and human health effects. The Construction Manager(s) and environmental personnel for the main works are responsible for the implementation of the CEMP and associated management plans/DWPs (including this CDWP).

The key personnel responsible for implementation of this CDWP are identified in Table 3-1. However, all site personnel are responsible for following the requirements of the CDWP. Refer to the CEMP for further detail on roles and responsibilities.

Table 3-1: Key Personnel and Contact details

Title

Project Managers Glen Kirk glen.kirk@linkalliance.co.nz

Francois Pageron francois.pageron@linkalliance.co.nz

Thibaut L’Hopital

Deputy Construction Manager – NAL

Communications and Engagement Manager

Link Alliance Senior Communications and Engagement Advisor – Mt Eden

Environment and Sustainability Manager (ESM)

Mt Eden Main Works Contaminated

Land Professional (CLP)

Mt Eden Enabling Works Contaminated

Land Professional (CLP)

Thibaut.lhopital@linkalliance.co.nz

Nick Adams nick.adams@linkalliance.co.nz

500 1744

547 9013

564 5756

022 645 1637

Rachel Blundell rachel.blundell@linkalliance.co.nz 027 306 9156

Sonya Leahy

Sonya.Leahy@linkalliance.co.nz

021 223 5204

Helen Jansen helen.jansen@linkalliance.co.nz 027 355 5270

Sarah Sutherland sarah.sutherland@linkalliance.co.nz

Stephen Thomson

Stephen.thomson@wsp.com

021 956 397

029 355 1425

Shane Moore SMoore@tonkintaylor.co.nz

027 445 7324

Intrusive investigations have been undertaken within the CRL Designation 2500-6 and existing NAL railway corridor (KiwiRail Designation 6300) - referred to in this section as the main works area.

This summary includes data from the following sources:

• City Rail Link: Contaminated Land Assessment, 2012, prepared by AECOM New Zealand Limited, (AECOM 2012);

• Auckland City Rail Link: Contaminated Land Assessment – Aotea Station to North Auckland Line, 2016, prepared by Golder Associates (NZ) Limited (Golder 2016a);

• Auckland City Rail Link: Contaminated Land Assessment – South Pacific Timber, 2016, prepared by Golder Associates (NZ) Limited (Golder 2016b); and

• Data collected for this CDWP along the rail corridor and surrounding public land, displayed within Appendix C, collected 2019/2020 by WSP New Zealand Limited (WSP).

For accessibility and logistical reasons, some of the soil investigations were unable to target specific locations and instead were undertaken in locations that provide a general indication of the potential for ground contamination.

The geology in the main works area comprises the following:

• Ballast – within the NAL corridor, surficial ballast comprised of cobbles and gravels typically up to 1-2 m below ground level (bgl).

• Fill – fill variably comprised of clays, silts, sands and rubble. Fill is typically up to approximately 4 m bgl. The composition and thickness vary irregularly across the main works area.

• Tauranga Group (TA) – alluvium, typically composed of clayey to sandy silts. These sediments are derived predominantly from erosion of East Coast Bays Formation (ECBF). Some areas of very soft TA and high organic content TA have been encountered (TA0)

• ECBF – a sequence of sandstone beds with interbedded mudstone and siltstone layers

• Auckland Volcanic Field (AVF) – three distinct lithologies present; ash, tuff and basalt lava.

Fill is typically underlain by TA/ECBF but within the works area there are areas underlain by AVF

For ease of interpretation and based on the risk profile (refer Section 4.3) the geology has been split into three groups: ballast, unnatural soils (engineered and non-engineered fill) and natural soils (TA, ECBF and AVF) A fourth type of material will be encountered during excavation following ground improvement which will comprise stabilised soft Tauranga Group sediments. This is discussed further in Section 4.3.4.

The regional water table generally occurs near the top of the ECBF along the topographic high of Newton Ridge. Piezometer data along the top of the Newton Ridge indicates the presence of zones of perched groundwater, with water levels typically varying between 0.5 – 2 m bgl, similar to that found in other areas of the CRL project in Mt Eden (refer to the Groundwater and Settlement Monitoring and Contingency Plan for the main works).

Soil quality testing undertaken within the main works area has focused on potential contaminants from a wide range of commercial and industrial processes. Due to the area’s history with ammunition manufacturing, timber storage, historic rail marshalling yard and infilling activities, soil analysis focused of the following contaminants of concern:

• Heavy metals and metalloids – arsenic, cadmium, chromium, copper, lead, mercury, nickel and zinc.

• Polycyclic aromatic hydrocarbons (PAH).

• Total petroleum hydrocarbons (TPH).

• Asbestos.

It should be noted that not all samples were analysed for every contaminant of concern. The following discusses the contaminant condition of the three generic soil types: ballast, unnatural soils (fill), and natural soils. All sample locations used in this assessment are indicated on Figure 1, Appendix D.

Ballast was observed along the existing NAL railway corridor, both under and between the tracks. Ballast was generally found to be between 0.5 – 2.0 m deep across the track areas. Ballast consisted of gravel and cobbles with very minor silt/sand fines. The potential contaminants of concern within the ballast would be petroleum hydrocarbons and asbestos from the operation of the trains. However due to the coarse nature (coarse gravel) of the ballast it was not able to be sampled.

Any asbestos from the wear of train brake pads would be small fibres, likely friable, that would not bind to the ballast but migrate through the ballast and bind to the underlying fill. Collection of 17 samples from the surface of the underlying fill, immediately below the ballast, between Mt Eden Road bridge and the western end of the existing Mt Eden Station platform, did not identify any asbestos present. Asbestos in brake pads has not been permitted in New Zealand since 2016 and the ballast in this part of the NAL corridor was replaced in 2007, when double tracking was installed. Taking this into account, the risk of asbestos being present within the ballast is low.

Additional to the sampling and testing of the shallow fill for the presence of asbestos, the surface of the ballast was visually inspected by an asbestos assessor for the presence of Asbestos Containing Material (ACM). The presence of visible ACM is unlikely to be from the train brake pads, but from offsite sources; i.e. nearby buildings, demolition rubbish etc. Three small pieces of chrysotile ACM (white asbestos) were identified on the ground surface between Mt Eden Road bridge and the western end of the existing Mt Eden Station platform. All pieces of ACM identified were found to be broken pieces of asbestos containing cement board, which was a product used widely in the construction of buildings prior to the 1990s It is recommended that a further inspection is undertaken again prior to disturbance of the ballast and any ACM identified is reported and removed by a licensed specialist

The sources of petroleum hydrocarbons within the ballast is assumed to originate from the hydraulic brake fluids of the engines and carriages, with some small amounts of diesel due to the use of the tracks by freight trains. Some areas of petroleum hydrocarbon staining of the ballast were observed, however this was limited in extent. The ballast affected by this staining would be suitable for reuse, however because of the staining the ballast cannot be disposed off-site as cleanfill. The condition of the underlying soils is discussed in Section 4.3.2.

Previous investigations conducted by Golder Associates on the South Pacific Timber site at Ruru Street included 16 samples that were analysed for asbestos. Of these, two samples were reported as having asbestos present at depths of 0.2 and 1.5 m respectively. Further quantitative analysis identified one sample as having a weight/weight (w/w) of <0.001% for both ACM and combined Asbestos Fines/Fibrous Asbestos (AF/FA). The other sample was unavailable for quantitative analysis, due to sample degradation during initial analysis.

Soil quality data collected from the main works area (refer Table 1, Appendix C and Figure 2, Appendix D), indicates that fill material contains concentrations of heavy metals above both the Auckland Region Background Values for volcanic soils and the Auckland Unitary Plan – Operative in part E30.6.1.4.1 Permitted Activity soil acceptance criteria. Additionally, concentrations of PAHs and TPHs were detected above the laboratory level of reporting (LOR). These soils would be classified as either managed or contaminated fill and as such, require disposal to a suitably qualified managed landfill.

Samples collected from two locations (Test Pit 107 and Borehole 167, AECOM July 2012) contained concentrations of arsenic and benzo(a)pyrene equivalence (BaPeq), respectively, exceeding the NES Soil guideline values for Commercial and Industrial activities.

4.3.3.

The natural soils have been tested and analysed (refer Table 2, Appendix C and Figure 3, Appendix D), for a range of contaminants, including heavy metals, TPHs and PAHs. The results indicate the following:

• Heavy metal concentrations are below the Auckland regional background concentrations for volcanic soils. Note: The nickel concentration in a number of soil samples, whilst below the regional background concentrations, exceeds the Auckland Unitary Plan – Operative in part E30.6.1.4.1 Permitted activity soil acceptance criteria (AUP, 2016)

• Concentrations of TPH are generally below laboratory LOR in most samples. However, concentrations above the LOR of TPH carbon range C15 to C36 were detected in four samples. Due to the depth of these samples (up to 8 m bgl), the low solubility of hydrocarbons and the absence of the more soluble petroleum hydrocarbons in the samples, it is extremely unlikely the petroleum hydrocarbons detected are from wider contamination. The likely source of these hydrocarbons is from grease added to the drill rig auger flights during the investigations. Note: the soil samples were collected during the geotechnical investigations. Locations where TPHs were detected in natural soils are indicated on Figure 4, Appendix D.

• The concentrations of PAHs in soil samples along the NAL corridor are predominantly below the laboratory LOR. However, eight samples contain concentrations of perlyene slightly above the LOR, in addition one of these samples also contained trace concentrations of fluoranthene and pyrene and a second containing just fluoranthene and perylene. Due to the depth of the perylene detection (up to 8 m bgl), the geology it was detected in (Auckland Volcanic Field) and the absence of other PAHs in the samples, it is expected that the presence of perylene reflects naturally occurring concentrations. The PAHs detected in the other two samples are not reflective of widespread contamination of natural soil in the NAL.

• PAH compounds were however detected in soil samples collected from locations outside of the NAL (i.e. AECOM and Golder Investigations). It is likely that PAHs are more widespread in these natural soils.

Even though there was detection of TPH and PAHs within the soil samples collected from the NAL, these soils can be classified as cleanfill for the reasons discussed above. The natural soil outside of the NAL cannot be considered cleanfill due to the presence of PAH compounds.

Certain areas of Tauranga Group sediment were found to be geotechnically unsuitable for excavation and construction (i.e. very soft) and requires stabilisation through soil mixing with cement prior to construction. The stabilisation activities are to take place along the NAL corridor between Normanby Road, Boston Road and Mt Eden Road on the northern side of the existing NAL tracks. A diagram of the area to be stabilised can be found in the Industrial and CEMP.

The soil mixing methodology is also outlined in the CEMP. In summary it involves the mixing of a cement grout in a mixing tank and then injecting and mixing the grout with the soft Tauranga Group sediments in-situ. To mix the grout with the sediment either a hydraulic piling rig or excavator fitting with the appropriate mixing tool will be used,

During the works, it is anticipated that approximately 15,000 m3 of stabilised Tauranga Group sediment will later be excavated and removed from site as part of construction No current soil quality data exists for the stabilised material; however as described in Section 4.3.3, the original soft sediment soils are classified as cleanfill. During the stabilisation works, it is anticipated that the soil and any associated water will have an increase in pH. Prior to removal from site the stabilised sediment will require sampling and analysis to confirm it meets cleanfill requirements. This is outlined further in Section 5.4.4.

This section details the procedures for the management of contaminated media (soil, groundwater and surface water) during the main works. It includes control measures for reducing human exposure to contaminated soils and water while minimising contaminated discharges to air, land and/or water. These measures must be established prior to commencing and maintained during earthworks associated with the main works. The Council (Team Leader Central Monitoring) is to be notified at least two working days prior to commencement of any earthwork activities.

• Erosion and sediment controls shall be implemented in accordance with the Erosion and Sediment Control Plan (ESCP) prepared for the main works before earthworks commence;

• Excavated spoil shall be placed directly into a truck for immediate off-site disposal, where practicable;

• Excavated spoil classified as contaminated fill (refer Section 5.3) retained on site as part of contingency storage shall be placed within erosion and sediment controlled areas and covered when not being worked and as weather conditions dictate, so as to minimise dust and runoff (additional details for management of stockpiles are provided in the Air Quality DWP (AQ DWP) prepared for the main works);

• Spillages of soil during placement in trucks shall be cleaned up as soon as practicable. Spillages shall not be left unattended as contaminated soil could be trafficked by trucks and transported off-site; and

• The earthworks shall be periodically observed by the CLS. If unexpected contamination is encountered during works, the works shall cease in the immediate vicinity and the procedures documented in Section 7 of this CDWP shall be followed.

The management of asbestos in soils is regulated under the Health and Safety at Work (Asbestos) Regulations 2016 (Asbestos Regulations). In order to help achieve compliance with the Asbestos Regulations, WorkSafe New Zealand has prepared an Approved Code of Practice (ACoP): Management and Removal of Asbestos (September 2016). The ACoP refers readers to the BRANZ Asbestos in Soil Guidelines.

The key requirements of the Asbestos Regulations and ACoP are that works involving asbestos contaminated soils must be undertaken with appropriate asbestos controls in place and that contaminated soil removed from site must be taken to an approved disposal site.

Table 5-1 provides a summary of the controls indicated in the NZ Asbestos in Soil Guidelines for different concentrations of AF/FA and ACM. The results of the limited asbestos in soil investigations undertaken specifically within the South Pacific Timber site indicate the presence of trace asbestos in fill soils. Disturbance of surficial fill material on the South Pacific Timber site shall be undertaken, as a minimum, as Unlicensed Asbestos Works as defined in ‘NZ Asbestos in Soil Guidelines’, unless further testing is undertaken to justify that the controls are not required. In regards to the ballast along the NAL corridor again, it is recommended that a further inspection is undertaken again prior

to disturbance of the ballast and any ACM identified is reported and removed by a licensed specialist

If a higher concentration of asbestos fibres is detected as part of any additional testing, then the relevant level of controls outlined in Table 5-1 shall be implemented. This CDWP is to be reviewed and updated to confirm the controls to be implemented on receipt and review of any additional soil results.

Table 5-1: Summary of asbestos requirements as detailed in the NZ Asbestos in Soil Guidelines

Additional documentation/ notification requirements

removal control plan and WorkSafe notification for asbestos removal

Oversight by a licensed removalist

Personal protective equipment (PPE)

removal control plan and WorkSafe notification for asbestos removal

Minimum respiratory protective equipment

Dust/asbestos fibre suppression

Disposable coveralls rated type 5, category 3, nitrile gloves, steel toe capped gumboots or safety footwear with disposable overshoes.

Full-face P3 respirator with particulate filter.

Water and polymer spray via localised points before and during works.

Air monitoring Air monitoring required

Disposable coveralls rated type 5, category 3, nitrile gloves, steel toe capped gumboots or safety footwear with disposable overshoes.

Half-face P3 respirator with particulate filter.

Water and polymer spray via localised points before and during works.

Air monitoring not required but can be undertaken depending on the site setting and to confirm that

Disposable coveralls rated type 5, category 3, nitrile gloves, steel toe capped gumboots or safety footwear with disposable overshoes.

Disposable P2 dust mask

No asbestos-specific PPE as concentrations are unlikely to exceed trace levels in air.

Water spray via localised points.

No asbestos-specific requirements as concentrations are unlikely to exceed trace levels in air

Water spray via localised points.

Air monitoring not required but can be undertaken depending on site setting to confirm

Air monitoring not required

Scenario

Class A works –non-friable

>0.1% w/w AF+FA in soil

Decontamination facilities

Vehicle (truck) protection

Dedicated wet decontaminatio n area or trailer. Consider powered and plumbed unit

200 µm heavygauge polythene wrapped soil/lined trays and truck covered.

HEPA filter system fitted for all occupied vehicles filter replaced or clean down with HEPA vacuum cleaner post work

Vehicle Washing Facilities

Class B works –non-friable

>0.01% w/w AF+FA in soil

>1% ACM

Asbestos-related works

>0.001% w/w AF+FA in soil

>0.01 % w/w ACM

concentrations are below 0.01 f/ml that concentrations are below 0.01 f/ml

Dedicated decontamination area and foot wash

Dedicated decontamination area and foot wash

Unlicensed asbestos work

≤0.001% w/w AF+FA in soil

<0.01% w/w ACM

Finishing surfacing/cap

Ongoing management

Visual assessment plus swab and air sampling inside the cab by an independent assessor

200 µm heavygauge polythene wrapped soil/lined trays and truck covered.

HEPA filter system fitted for all occupied vehicles where friable ACM on site (lagging, insulation, etc).

Truck lining/soil wrapping depends on the receiving landfill. All trucks will be covered.

Standard air conditioning.

Foot wash and used PPE collection area.

Truck lining/soil wrapping depends on the receiving landfill. All trucks will be covered.

Standard air conditioning.

Visual assessment plus swab (if friable) by an independent assessor or independent competent person* or SQEP following brush and or wash down

Visual assessment by a competent person* or SQEP following brush and or wash down

Visual assessment by a competent person* or SQEP following brush and or wash down

No special finishing/cover requirements if soils are confirmed to meet health criterion (0.001% w/w). Otherwise:

Hard cap - No depth limitation, no controls.

Soft cap – at least 0.2 m and should be delineated by a permeable geotextile marker layers between the cap and underlying asbestos/contaminated material.

If validation testing shows any soil at the base of any excavation contains asbestos, even at <0.001% w/w, the Asbestos Regulations require the location of these to be recorded in an asbestos management plan.

The spoil generated as a result of the main works will require off-site disposal. In the context of this CDWP, spoil generated shall be classified as per the following three categories to define disposal requirements:

Cleanfill material is defined in the Auckland Unitary Plan – Operative in Part (AUP) as:

Means natural material such as clay, gravel, sand, soil and rock which has been excavated or quarried from areas that are not contaminated with manufactured chemicals or chemical residues as a result of industrial, commercial, mining or agricultural activities. Excludes:

• Hazardous substances and material (such as municipal solid waste) likely to create leachate by means of biological breakdown;

• Product and materials derived from hazardous waste treatment, stabilisation and disposal practices;

• Materials such as medical and veterinary waste, asbestos, and radioactive substances;

• Soil and fill material which contain any trace element specified in Table E30.6.1.4.2 at concentration greater than the background concentration in Auckland soils specified;

• Sulfidic ores and soils;

• Combustible components;

• More than 5 % by volume of inert manufactured materials (e.g. concrete, brick, titles); and

• More than 2 % by volume of attached biodegradable material (e.g. vegetation).

Managed fill comprises:

• Soil containing metal contaminants above the published background concentrations for volcanic soils outlined in the AC Technical Publication TP153: Background Concentrations of Inorganic Elements in Soils in the Auckland Region (ARC 2002)

• Soil containing any concentrations of petroleum hydrocarbons or polyaromatic hydrocarbons.

• Soil containing low level asbestos in soil concentrations (depending on disposal facility).

• Note: there are currently no managed fill tip sites within the Auckland Region that can accept asbestos.

• Soil that does not contain hazardous substances or materials in the form of household and industrial waste or organic waste.

5.3.3.

Contaminated fill comprises:

• Soil with concentrations of contaminants exceeding managed fill acceptance criteria.

• Household and industrial waste.

• Asbestos in soil and/or ACM.

Surplus spoil requiring offsite disposal shall be managed according to the location and nature of the material, as follows:

Ballast is considered to be free of contaminants if no odours or staining are present and may be reused as part of construction. If removed from site and if no odours or staining are present it can be disposed as cleanfill, subject to landfill acceptance.

Any ballast that has odours or staining, particularly within the current Mt Eden Station area, will require disposal to a suitable disposal location. Ballast is suitable for permanent or temporary reuse during construction.

Fill is present across the site varying in depth but typically present between the surface and approximately 4.0 m bgl. Based on the available results, fill materials cannot be disposed as cleanfill and will require disposal to either a managed or licenced landfill. Disposal to managed fill is subject to compliance with the spoil meeting the acceptance criterial of the disposal location

Transport of spoil for disposal offsite must follow the measures outline in Section 5.5.

5.4.3.

Following removal of all fill material, the underlying natural material, if free from staining or odour, is suitable for disposal as cleanfill. The receiving facility may require confirmatory testing, and this can be addressed by providing the data in Appendix D or undertaking further sampling for the specific area to be excavated. Any sampling should be undertaken in accordance with the soil sampling procedures detailed in Section 5.10. Where practical, fill materials will be kept separate from natural material. These will be stored in separate bunds if stockpiling is to take place. Where mixing occurs of these materials, all material will be considered as managed fill.

In all cases:

• Trucks transporting spoil for disposal offsite will be covered as outlined below in Section 5.5;

• The necessary permits from the disposal site operator will be obtained to confirm that the facility can receive the materials prior to off-site transportation; and

• All weighbridge dockets and/or a summary sheets will be retained for inclusion in validation reporting at completion of the works (refer Section 8).

There is limited opportunity for reuse of spoil. If spoil is to be re-used the appropriate environmental controls (if any) are to be advised by the CLS. Such controls may include encapsulating the soil (refer finishing surface/cap requirements in Table 5-1).

There is very little soil quality data for the soft Tauranga Group Sediment (TA0) and with the addition of a cement grout during stabilisation it is unknow whether the material will meet cleanfill standards. Therefore prior to removal from site the excavated stabilised material will be sampled, with samples analysed for heavy metals (arsenic, cadmium, chromium, copper, lead, mercury, nickel and zinc), TPH, PAH (at a rate 50% of the other analysis) and pH. If the early sampling indicates that the heavy metal, TPH and PAH concentrations are below expected background concentrations the

amount of sampling or analysis may be reduced, however sampling rates will need to be undertaken at a rate that satisfies the respective landfill requirements.

During excavation of the stabilisation material, all practical steps must be undertaken to prevent any mixing with other materials (specifically contaminated fill) as outlined in the Industrial and Trade Activities Environmental Management Plan prepared for the Link Alliance for the Normanby Road Early Works.

The following measures shall be implemented to prevent spoil from being dispersed onto roads or transported to another site (excluding transport to a disposal facility) as well as to minimise generation of dust:

• Any excess soil on vehicle tyres shall be removed before vehicles leave the works area. A wheel wash will be established on site and vehicles that have tracked over exposed soils will be required to exit the works area via the wheel wash;

• Excess soil shall be removed from vehicles and plant before they leave the works area;

• All trucks transporting excavated spoil to the selected disposal facility shall be covered to prevent the spillage of spoil and dust emissions; and

• Additional controls (refer vehicle protection and vehicle washing facilities in Table 5-1) are required for the disturbance of asbestos contaminated fill material on the South Pacific Timber site and any future site found to have asbestos, unless further testing is undertaken to justify that the controls are not required. Such controls include:

• Visual assessment by a competent person following cleaning of vehicle before leaving the works area.

• Depending on the requirements of the receiving site, truck lining/soil wrapping of fill material during transport may be required.

If a higher concentration of asbestos fibres is detected as part of any additional testing or discovery of unexpected contamination, then the relevant level of controls outlined in Table 5-1 shall be implemented.

Any material deemed to be contaminated (fill and any material discovered unexpectedly (refer Section 7.1)) should only be stockpiled where no practical alternative is available. Stockpiles of contaminated soil must follow the following protocols where established:

• All stockpiles shall be properly bunded and covered as described in the ESCP and AQ DWP

• Stockpiles must be placed on impermeable surfaces, if this is not practical at the time, consultation must be sought from the CLS prior.

• All water that comes into contact with contaminated soil stockpiles must be captured and managed, refer to Section 5.7.

5.7.1. Stormwater

All practical steps must be taken to keep stormwater and surface run off separated from ground and perched water. Separation and diversion of clean stormwater away from areas of ground disturbance is standard practice for any earthworks activity but becomes more important where contaminants are present. To minimise the potential for clean stormwater to encounter contaminated soil, the stormwater and sediment controls detailed in the ESCP for the main works shall be implemented.

All water that has interacted with exposed spoil including groundwater, perched and surface run off water will be manged and disposed of via the following methodology outlined in the ESCP and summarised below:

• Piped or pumped to a sediment control system or settlement tank(s);

• Further treatment (i.e. flocculent additives, pH adjustment) in accordance with the procedures detailed in the Flocculent Treatment Management Plan (FTMP, attached as Appendix C to ESCP) for the works; and

• Testing in accordance with the Water Quality Discharge Monitoring Programme (WQDMP) included in the FTMP to confirm compliance with the criteria for discharge to stormwater.

• Regular testing will be undertaken on a daily and weekly basis of water being disposed of to the stormwater system. This testing includes the following:

Dissolved zinc g/m3

Total petroleum hydrocarbons g/m3

Ammoniacal nitrogen* g/m3

Nitrate nitrogen* g/m3

* only in discharge from treatment systems in CSA 3 and CSA 4.

Discharge into the stormwater network is viable; providing the previously mentioned testing complies with 50 times the Australian and New Zealand Environmental Conservation Council (ANZECC) Guidelines for Fresh and Marine Water Quality (2000) as stated in condition 145 of discharge permit R/REG/2016/1895. If these conditions are not met, refer to Section 7.2.

To minimise the generation of dust during earthworks (particularly during earthworks within fill), the following controls taken from the AQ DWP shall be implemented:

• Weather forecasts shall be obtained each day during work to check for predicted high wind conditions and any such predictions shall be notified to relevant construction staff so that dust management procedures are adequately prepared and implemented;

• In windy conditions, if soils are dry and friable during excavation then they shall be dampened with water;

• Limit drop heights of soil from the excavator bucket into trucks;

• Immediately clean up spilled soil from truck loading areas prior to loading additional trucks;

• Ensure vehicles do not leave site with excess soils between the tyre tread as this will be distributed on public roads and will generate dust;

• If dust cannot be controlled during excessively windy conditions, then earthworks shall cease until dust can be managed; and

• If a dust release occurs, the time, duration, location and cause is to be recorded in the daily report as well as remedial action performed.

Further detailed dust management and monitoring requirements are set out in the AQ DWP prepared for the main works.

The contaminants in soil and groundwater, particularly during excavation in the fill, are unlikely to generate odours and vapours. If odorous soil is encountered, then the actions outlined below shall be implemented:

• Limit the time that the excavation of odorous materials is exposed and occurs;

• Removing excavated odorous material from site as quickly as possible in covered trucks;

• The odorous material shall be covered to suppress odour emissions, and work in that area suspended until suitable mitigation measures can be put in place if the odorous material cannot be removed quickly;

• Install an odour suppressant system if appropriate; and

• Install a ducted fan or additional mechanical ventilation to reduce vapour concentrations in the area if required.

If odorous material is encounter, the time, duration, location and cause is to be recorded in the daily report as well as remedial action performed, including notifying the CLP.

Further detailed dust management and monitoring requirements are set out in the AQ DWP prepared for the main works.

The CLP will undertake regular inspection and/or supervise soil disturbance activities during construction. This will be a minimum of one inspection per fortnight by the CLP or a delegated person approved by the CLP.

Any sampling and testing of soils shall be undertaken by the CLP according to the requirements of the NES Soil Regulations and the MfE Contaminated Land Management Guidelines No.5. Site

Investigation and Sampling (revised 2011). Samples for asbestos testing shall be collected in accordance with the NZ Asbestos in Soil Guidelines.

Soil samples shall be collected according to the following procedure:

• The materials encountered shall be described in accordance with the NZ Geotechnical Society Guidelines for the classification and field description of soils and rocks for engineering purposes;

• Hands shall be freshly gloved to collect soil and the samples shall be placed immediately into the appropriate laboratory supplied sample containers;

• Any equipment used to collect the samples shall be decontaminated between sample locations using clean water, Decon-90 (a phosphate-free detergent) and deionised water rinses; and

• Samples shall be shipped in chilled container to an IANZ certified laboratory under chain of custody documentation.

The CLP shall evaluate any analytical results against the relevant human health and environmental discharge regulatory standards/acceptance criteria as appropriate.

It is not anticipated that soil materials will be imported as part of the main works. In the event that soil materials are imported these shall originate from:

• A site which has been determined by a suitably qualified contaminated land professional to have had no known history of potentially contaminating activities, as detailed on MfE’s Hazardous Activities and Industries List (HAIL) (MfE, 2011c); or

• A site which has been adequately investigated by a suitably qualified contaminated land professional, in accordance with MfE 2011b Contaminated Land Management Guidelines No. 5 Site Investigation and Analysis of Soils, to meet the ‘cleanfill material’ definition as prescribed in the AUP (refer Section 5.3.1).

Soil materials imported will typically be tested at a rate of 1 in 1000 m3 for metals and PAH and any evidence of the presence of asbestos shall trigger testing for asbestos content in soil. The CLP will determine the required rate and analysis based on the source site. It is preferable that the fill is tested at source prior to its transport to the site. However, if not, then the imported soil materials shall be stockpiled and bunded on site with appropriate controls until test results are available.

Additional, engineering materials may be used including clean quarry materials and recycled crushed concrete aggregate that is site won or sourced from a quarry or supplier. The supplier of these materials is to provide documentation to confirm suitability for use.

For crushed concrete aggregate the additional information is required:

• Sourced from the site: address of the source site, copies of pre-demolition asbestos surveys, copies of asbestos clearance certificates prepared prior to demolition and asbestos testing at a rate of 1 in 500 m3.

• Sourced from a supplier: confirmation of processing procedures and asbestos testing at a rate of 1 in 500 m3 of product is to be provided by the supplier. The CLP shall review the supplied information prior to acceptance or the material stockpiled on site until available.

The following reuse, off-site soil disposal management and record keeping measures will be implemented by the Link Alliance:

• A record of the works undertaken, soil location, depth, and volume of the material removed, and results of tests shall be kept for the purpose of being included in the Site Validation Report (SVR) to be prepared by the CLP, refer to Section 8. Records will also indicate whether the material was removed as cleanfill, managed fill or contaminated fill, refer to Section 5.3

• Irrespective of the disposal facility nominated, all vehicle movements including registration, estimated weight, and disposal location will be recorded.

• Tracking documentation is to be signed prior to leaving the works area and checked at the waste disposal facility.

• Transportation subcontractors are required to cover loads and take appropriate measures to control dust, refer to Section 5.8.

• Trucks will be inspected prior to departing the site to ensure the load is adequately covered and any spillage is contained.

• A record of any contaminated soil left in-situ including the soil location, depth and estimated volume shall also be recorded for the purpose of being included in the SVR. This includes the re-use of soil to back fill or make good any ground within the main works area

Receipts summarising soil disposal will be collated and provided to the CLP at the completion of the land disturbance activities for the works

If mobile contaminants (light non-aqueous phase liquid, contaminated perched water) are encountered, sealing of excavation service trenches is required to prevent them from acting as a conduit for migration of contaminated groundwater away from the site, a pipe dam shall be installed at the site boundary. The pipe dam shall be either concrete or another impervious material to be specified by the drainage design engineer. The dam shall encase the pipe and extend up the trench to just below the paved surface.

The locations of pipe dams will be recorded on as-built drainage drawings and included in the validation reporting at completion of the works (refer Section 8).

This CDWP provides procedures for site personnel working in and around contaminated and/or potentially contaminated soil and water during the excavation works. The following is designed to dovetail with the Construction Health and Safety Management Plan.

The procedures have been developed to provide a framework for managing contamination related effects at the site. However, these procedures are not intended to relieve the owner or controller of the place of work of either their responsibility for the health and safety of their workers, contractors and the public, or their responsibility for the protection of the environment.

All parties working on the main works shall comply with:

• Applicable parts of the Health and Safety Policy;

• Construction Health and Safety Management Plan;

• Any requirements of WorkSafe New Zealand;

• The Health and Safety at Work Act 2016 and Regulations; and

• Any other applicable legislation, regulations, codes and guidelines.

Sub-contractors engaged on the main works are required to provide their own Health and Safety Plan for their equipment and workers.

Daily toolbox meetings are to be undertaken and documented by the Health and Safety Officer (HSO) or delegate.

All personnel shall be required to participate in a site induction that includes a review of procedures with respect to contamination. The induction shall be provided such that all relevant personnel understand, prior to commencing work, what procedures are to be implemented and why. The purpose of the induction is to educate the workers with respect to the hazards associated with contaminated soil and water, safe working procedures, safety equipment and requirements, and the response plan in the event of an emergency.

An appropriately qualified HSO as listed in Table 3-1 (or anyone with delegated authority) , or similar, shall be appointed for the duration of the works so that where contamination is being managed, there is a designated person responsible for the implementation of and adherence to contamination related health and safety procedures, in addition to the other site specific health and safety requirements.

The HSO shall ensure that all relevant personnel are familiar with the application and use of required PPE and procedures specified in this CDWP and other site-specific documentation prior to the commencement of work.

The following general safety procedures shall be followed by all personnel entering and/or working in the construction zone:

• Hazards encountered and not identified during the site induction/toolbox shall be reported to the designated HSO;

• Any incidents shall be reported to the HSO;

• Site personnel shall avoid unnecessary contact with documented and potentially contaminated soil and groundwater; and

• Site personnel who may come into contact with contaminated soil shall be provided with the minimum level of PPE as defined in Section 6.7 of this CDWP.

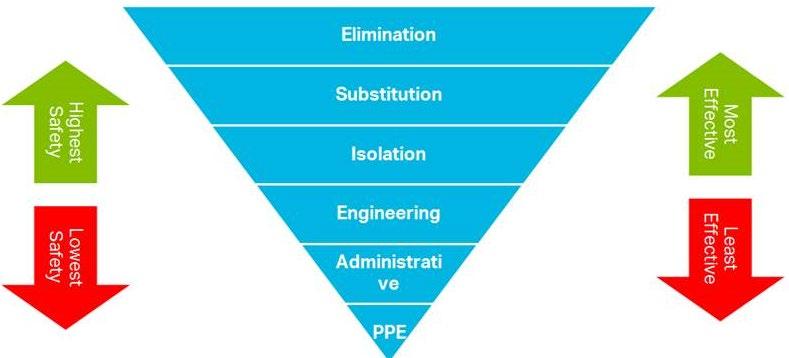

When considering hazard and risk controls, the hierarchy listed below should be followed, in preference from one to five. Example questions are provided to illustrate each step (refer Figure 61).

• ELIMINATION – does the task that creates the hazard need to be performed?

• SUBSTITUTION – can a different tool be used?

• ENGINEERING – can the hazard be guarded to protect people?

• ADMINISTRATION – are there warning signs and a procedure to address the hazard? Administrative controls include procedures to reduce the risks associated with identified hazards. These controls include:

• Job Safety Analysis (JSA) or Task Analysis.

• Work plans.

• Training.

• Warning signs.

• Communication with the Site Manager/HSO.

• PERSONAL PROTECTIVE EQUIPMENT – is the appropriate PPE being used? The following is noted:

• PPE is considered the lowest level of protection against a hazard.

• No single combination of protective equipment and clothing can provide protection against all hazards; PPE should be used in conjunction with other protective methods.

• The types of PPE will depend on the specific task undertaken. However, certain PPE is required in all work areas.

Investigations indicate contamination within fill material and natural soils were found to be above Auckland Background Values (refer Sections 4.3).

Potential exposure routes for contaminants include:

• Inhalation of dust (potentially contaminated and uncontaminated);

• Ingestion of potentially contaminated soil, dust or groundwater;

• Dermal absorption of potentially contaminated soil or dust; and

• Skin and eye contact with potentially contaminated soil or dust.

Recommended procedures to mitigate the risk associated with these hazards are provided in Section 6.6

Other hazards that may be identified if unexpected contamination is encountered (refer Section 7).

There is the potential for additional hazards to be identified and encountered during the main works. The HSO is responsible for reviewing any new work element and assessing whether there are any new associated hazards and associated elimination, isolation and minimisation measures. The HSO shall seek review by the CLP if necessary. The HSO shall then instruct all personnel on the health and safety procedures associated with the new hazard.

6.6.1.

Inhalation of dust (whether it is contaminated or not) can pose a health risk and therefore the dust control measures shall be implemented for the duration of the earthworks as detailed in the AQ DWP and outlined in Section 5.7 of this CDWP. The following additional measures shall be considered to minimise inhalation of dust:

• Monitor wind speed and direction, and where practicable, stand up wind of excavations and vehicle loading areas;

• Water spray via localised points; and

• Boot wash available for personnel leaving excavation areas to prevent the tracking of soil around and off-site.

Additional controls are required if a higher concentration of asbestos fibres is detected as part of any additional testing or if unexpected contamination is encountered. The controls to be implemented are outlined in Table 5-1

The investigations to date indicate there is a low potential for the presence of volatile contaminants or gases that are likely to represent a human health risk with respect to the inhalation exposure route. However, mitigation of vapour or risk can be achieved as follows:

• If there are olfactory indications for vapours or vapours are suspected, the volatile organic compound (VOC) content of the area shall be checked with a calibrated photo-ionisation detector (PID) with a 10.6 electron volt (eV) lamp. If readings are above 50 ppm, work shall stop, the area vacated and the CLP and/or HSO shall be informed. A respirator shall be worn when re-entering the area to re-test the atmosphere;

• At the same time, and if an area or excavation is to be accessed with limited air flow (i.e. excavations below existing floor slabs) air quality shall be monitored prior to entry using a calibrated gas meter(s) able to measure lower explosive limit (LEL), oxygen (O2), methane (CH4), carbon monoxide (CO) and hydrogen sulphide (H2S); and

• Work shall not resume unless approved by the HSO in consultation with the CLP

The following precautionary measures shall be implemented to ensure skin contact with, and ingestion of contaminants is minimised:

• Disposable nitrile gloves shall be worn by personnel who need to have contact with contaminated soil during the excavation works.

• Overalls shall be worn if there is the potential for contaminated soil to contact other parts of the body (legs, arms etc.);

• Boot covers shall be worn by personnel who need to traverse contaminated soils during excavation works or washable boots worn with a boot wash in place and utilised; and

• There shall be no eating, drinking or smoking in the works area to prevent contaminated soil contacting food or being ingested directly via soiled hands.

A key factor in controlling dermal contact and ingestion of contaminated soil is through maintaining good personal hygiene. The following shall be observed for works involving contaminated soils:

• Hand to mouth and hand to face contact shall be avoided during work;

• Hands shall be washed before eating, drinking and smoking;

• Eating, drinking and smoking shall only be permitted in designated areas;

• Overalls worn within the works area shall be removed before leaving the works area; and

• Disposable coveralls may be worn and disposed of at the end of each working day.

All workers handling or coming into contact with contaminated or potentially contaminated so il shall wear the following PPE to protect against the above risks:

• Overalls or disposable coveralls; and

• Impermeable gloves (tear resistant if appropriate).

Additional PPE (refer PPE and minimum respiratory protective equipment in Table 5-1) are required if a higher concentration of asbestos fibres is detected as part of any additional testing or if unexpected contamination is encountered. Such controls include the use of disposable coveralls (rated type 5, category 3), disposable overshoes (or similar) and specific respiratory protective equipment depending on the type and concentration of asbestos present (as a minimum disposable P2 dust mask shall be available on site).

Changes to site specific PPE requirements shall be reflected in all health and safety documentation and all parties notified. The PPE specified above is in addition to that required for non-contamination related health and safety.

Details of communication and consultation procedures are set out within the Mt Eden Main Works Communication and Consultation Plan (CCP). The CCP outlines the way in which the general public are to be communicated with on CRL project matters, including the management of adverse effects relating to the contamination and the process for public and affected parties to register a complaint.

Procedures relating to environmental emergencies and incidents are detailed within the CEMP. The CEMP and/or Industrial Trade Activity EMP (ITA EMP) should be referenced for further information on environmental incidents including spill response, incident recording and reporting.

If during earthworks, contaminated soils or hazardous material in addition to those described in Section 4.3 is encountered, cease all work in the area of concern until the CLP has assessed and identified the material.

Evidence of additional contamination likely to trigger a stop work procedure may include:

• Visual (buried refuse, metal objects, building material, soil or water staining/bleaching or discolouration);

• Chemical odours (fuel, sulphurous, rotting vegetation or sewage);

• Separate phase liquids or ‘rainbow effect’ films on groundwater;

• Auditory (gas leaks, flowing or dripping liquid); and

• Fibrous cement based board materials that may contain asbestos.

If any such indicator is observed during earthworks, the following steps should be taken:

• Cease all work within a 10 m radius and make the work area safe and restrict access to all workers until instructed by the ESM (refer Table 3-1) or approved delegate;

• Shut off all ignition sources and, if possible, contain any contaminant discharge and close/divert any water flow;

• Advise the ESM;

• Work shall not resume until the ‘all clear’ is given by the ESM;

• The ESM (in consultation with the CLP) shall assess the site. If the assessment concludes that confirmation of contamination is required, the following actions shall be implemented:

• Control the site: install temporary fencing, temporary cover, silt traps and bunding as required around the area of potential contamination

• Small volumes of excavated soil shall be contained in covered skips to minimise contaminated discharges from rainfall runoff and dust

• If this is not possible, larger volumes shall be covered and bunded to manage dust and stormwater runoff

• Potentially contaminated water shall be collected and disposed of to an appropriately licensed treatment facility. It must not be discharged to the construction stormwater system

• Samples of the suspect material shall be collected (by the CLP or delegate) for laboratory analyses using appropriate procedures (refer Section 5.10)

• The results of the laboratory analysis shall be assessed against the relevant human health and environmental discharge regulatory standards/acceptance criteria as appropriate;

• The CLP should be consulted on the handling and management of contaminated soil and/or water, and any specific health and safety precautions that may need to be taken to minimise risk to construction workers/and or the general public;

• Any soils or material requiring off-site disposal must be disposed of at facilities consented to accept the material; and

• Maintain a register of any additional contaminated material discovered, including location, type, quantity and disposal record (disposal receipts). This information will be documented in the Site Validation Report (refer Section 8).

Where unexpected contamination is significantly different in extent and concentration from that anticipated, the Council (Team Leader Central Monitoring) will be advised prior to carrying out any further work in the area of the unexpected contamination.

As described in Section 5.7, where the quality of water being discharged from the site cannot meet the standards required for discharge to stormwater, or unexpected contamination conditions are encountered (refer Section 7.1), additional controls will be required.

If unexpected contamination conditions are encountered the area in which unexpected contamination conditions have been encountered shall be isolated so that site water from this area can be separated from that generated across the wider site.

A number of options could be employed if the quality of water being discharged from the site cannot meet the standards required for discharge to stormwater on an ongoing basis, including, but not limited to:

• Improving effluent quality through additional treatment; and/or

• Collection (for example by tanker trucks) for off-site disposal to an appropriately licensed facility; and/or

• Discharge to sewer, subject to removal of sediment and issue of any necessary temporary trade waste permits.

The CLP shall be consulted to assist with defining appropriate control measures in the event that the standards required for discharge to stormwater cannot be met.

On completion of the soil disturbance works associated with the main works, a Site Validation Report (SVR) (refer conditions 149 and 150 of discharge permit R/REG/2016/1895) will be prepared and provided to Auckland Council. The purpose of the SVR is to confirm that the objectives of the works have been achieved, and that the works were undertaken according to agreed procedures and reporting on any incidents. The SVR is required to be prepared by the CLP and shall comply with the MfE 2011a.

The SVR shall include, as a minimum:

• A summary of the works undertaken, including a site plan and a statement confirming whether the excavation of the site has been completed in accordance with the certified CDWP;

• The location and dimensions of the excavations carried out, including relevant site plan and location of contaminated soil reused (if any);

• A summary of soil, groundwater, and surface run-off water testing undertaken, if applicable, including tabulated analytical results, and interpretation of the results in the context of the Contaminated Land Rules of the Auckland Unitary Plan (Operative in Part);

• Summary of the disposal dockets for the spoil disposed off-site;

• Summary of the inspections undertaken by the CLP during disturbance of contaminated soil;

• Records of any unexpected contamination encountered during the works and contingency measures undertaken (if applicable);

• Details regarding any complaints and/or breaches of the procedures related to contamination;

• Results of any testing undertaken;

• Documentation and results of testing of any imported fill; and

• Any long-term monitoring/management requirements.

This SVR shall be provided to Auckland Council within three months of completion of the soil disturbance works associated with the main works.

AECOM 2012: Contaminated Land Assessment: City Rail Link (Rev 4). Prepared by AECOM New Zealand Limited for City Rail Link dated 25 July 2012 (Revision 4).

ARC 2002: AC Technical Publication TP153: Background Concentrations of Inorganic Elements in Soils in the Auckland Region.

AUP 2016: Auckland Unitary Plan – Operative in part E30.6.1.4.1 Permitted activity soil acceptance criteria. Auckland.