1 Auckland City Rail Link

Contract 6 – Nikau

St Stormwater Main

Realignment

Construction

Environmental Management Plan

March 2018

Contract 6 – Nikau

St Stormwater Main

Realignment

Construction

Environmental Management Plan

March 2018

Document

Graeme Inglis - PM Martin Hughes – NR Manager

Document Approval

Andy March

Project Document Version

Original CEMP (lodged with reference design Outline Plan and resource consents) prepared by Aurecon

CEMP updated (non-material changes) to reflect demolition and extension of CSA at 28 Mt Eden Road, prepared by Aurecon

Signature

Date

Rev 5, 12 December 2016

Rev 8, 8th August 2017 CEMP updated (non-material changes) to reflect MBJV revised construction design and methodology, prepared by Beca

Rev 9, 8th March 2018

Appendix A: Designation Conditions

Appendix B: Site Layout Plans

Appendix C: Erosion and Sediment Control Plans

Appendix D: Transport, Access and Parking Delivery Work Plan

Appendix E: Construction Noise and Vibration Delivery Work Plan

Appendix F: Historic Character Delivery Work Plan

Appendix G: Trees and Vegetation Delivery Work Plan

Appendix H: Contaminated Delivery Work Plan / Contaminated Soils Management Plan

Appendix I: Air Quality Delivery Work Plan / Air Quality Management Plan

Appendix J: Communication and Consultation Plan

Appendix K: Record of CLG and IPRP feedback on the CEMP

Appendix L: Addendum to Delivery Work Plans

Figures

The following terms have been used throughout the document and are listed below for reference.

Term Meaning

Alignment

Bored Pile

Consolidation

Consolidation settlement

Construction Contractor

Designation conditions

Enabling works

Engineer

Gravity Diversion

Ground anchors

The horizontal and vertical position of the pipe or the CRL tunnels.

A reinforced concrete pile which is constructed by excavating a vertical column of soil or rock, and cast in the ground using a casing or slurry for ground support.

A process by which water saturated soil reduces in volume due to load application or lowering of groundwater level that causes the water to be squeezed/ removed out and the soil settles.

Space deformation induced by consolidation (see ‘consolidation’ above).

The contractor who is awarded the construction contract for the Project. This is yet to be confirmed.

The set of condition applied to the CRL designation which outline the compliance framework for the project (see Appendix A)

Works carried out in advance to facilitate ease of permanent works construction.

The owner or an entity acting on behalf of the owners to approve and review the works.

Where water flows are controlled by changes in elevation (gravity).

Steel tendons installed in the ground to provide support to ground retaining structures.

Groundwater Water located in pore spaces within the soil mass.

Mined tunnel

Pipe jacking

Principal Technical Adviser

Project criteria

Sensitive structures

Shafts

Slurry

Slurry system

Sub-Plans

Spoil

Tunnel boring machine

Water table

Tunnelling method utilising a road header, by hand (for small excavations), or similar technology to create open underground space combined with steel and concrete lining systems and rock bolting installed in a predetermined sequence.

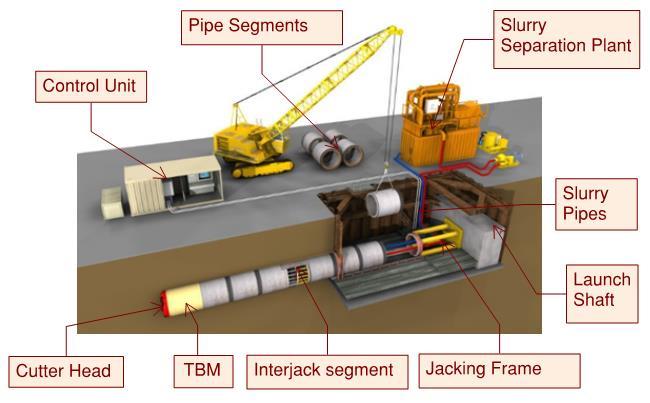

A trenchless installation method where pipes are horizontally driven between two vertical shafts.

The Principal Technical Adviser to CRLL for this Project is Aurecon New Zealand Limited.

The performance standards, both national and international that are recommended for use in the Project.

Structures susceptible to ground movements due to tunnel excavations and other construction activities. For the purpose of this assessment, this has been defined as all buildings constructed with unreinforced masonry.

Underground structures excavated from the surface for permanent or temporary access.

Water-based fluid containing suspended solids used to provide fluid pressure and spoil transport in slurry tunnelling machines, and lubrication and soil conditioning in pipe jacking.

A type of TBM in which the earth and groundwater pressures are counterbalanced by pressurised slurry to prevent heave or settlement.

The suite of Management Plans, Delivery Works Plans and Site Specific Plans which outline how the effects of the Project will be managed.

Excavated material.

A mechanically operated machine used to excavate a tunnel with a circular cross section through a variety of ground strata.

The level below which the ground is saturated with water.

The following terms have been used throughout the document and are listed below for reference.

Acronym Meaning

AC Auckland Council

AEE Assessment of Environmental Effects

AT Auckland Transport (applicant and requiring authority for CRL)

CAR Corridor Access Request

CBD Central Business District

CCP Communication and Consultation Plan

CDWP Contaminated Delivery Work Plan

CEMP Construction Environmental Management Plan

CLG Community Liaison Group

CNVDWP Construction Noise and Vibration Delivery Work Plan

CRL City Rail Link

DCR Design and Construction Report

DSI Detailed Site Investigation

DWP Delivery Work Plan

ECBF East Coast Bays Formation

ECBF ER Residual soil/ completely weathered ECBF

ECBF EU Unweathered ECBF

ECBF EW Weathered ECBF

EFC East Facing Connection

EHS Environmentally Hazardous Substances

ERP Emergency Response Plan

ESA Environmental Site Assessment

ESCP Erosion and Sediment Control Plan

ESM Environment and Sustainability Manager

GIS Global Information System

Ha Hectare

HAIL Hazardous Activities and Industries List

HC DWP Historic Character Delivery Work Plan

Heritage NZ Heritage New Zealand

HNZPT Act Heritage New Zealand Pouhere Taonga Act 2014

HSMP Hazardous Substances Management Plan

HVAC Heating Ventilation and Air Conditioning

MP Management Plan

N/A Not Applicable

NAL North Auckland Rail Line

NESAQ Resource Management (National Environmental Standards for Air Quality) Regulations 2004

NESsoil Resource Management (National Environmental Standard for Assessing and Managing Contaminants in Soil to Protect Human Health) Regulations 2011

NoR Notice of Requirement

OHLE Over Head Lines Equipment

RMA Resource Management Act 1991

SSMP Site Specific Management Plan

TA Tauranga Group

TAPDWP Traffic Access and Parking Delivery Work Plan

TBM Tunnel Boring Machine

TP90 Auckland Council Technical Publication No. 90 - Erosion and Sediment Control

Guidelines for Land Disturbing Activities in the Auckland Region 1999

TVDWP Trees and Vegetation Delivery Work Plan

This Construction Environmental Management Plan (CEMP) is submitted in support of the Outline Plan and Resource Consent application to Auckland Council (AC) for the realignment of a stormwater main which currently runs along Nikau Street in the suburb of Mount Eden in Auckland.

City Rail Link Ltd, as the requiring authority, currently holds a designation for the construction of the City Rail Link (CRL) project (and the relocation of utilities) for these works. Some work areas required for this stormwater realignment sit outside the designation. This CEMP covers all works both inside and outside the existing CRL designation.

The Nikau Street Stormwater Main Realignment (the Project) involves the construction of a replacement stormwater main to move it westward towards the existing railway line. The current alignment of the stormwater main conflicts with the proposed alignment for the CRL rail tunnels and needs to be relocated to enable construction of the tunnels.

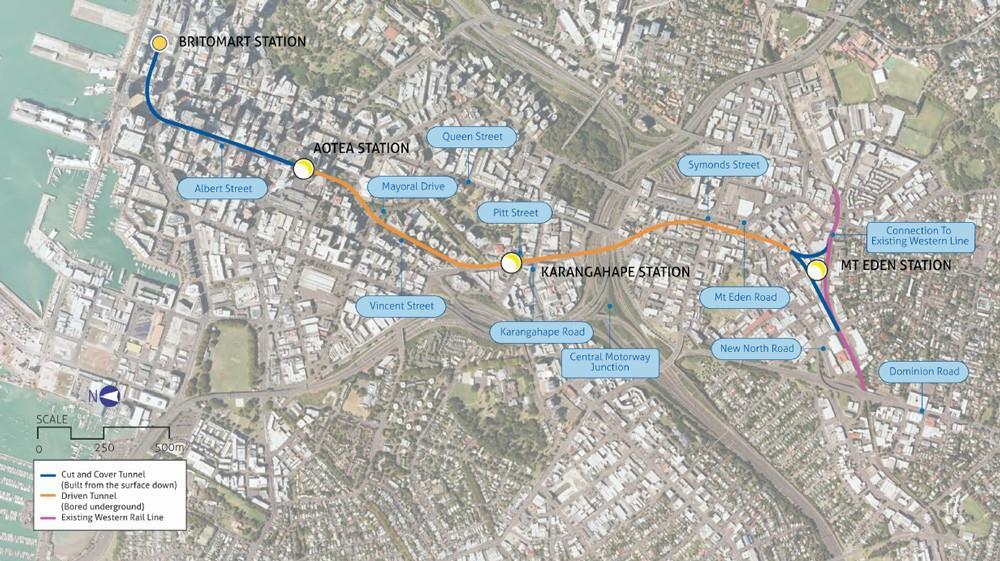

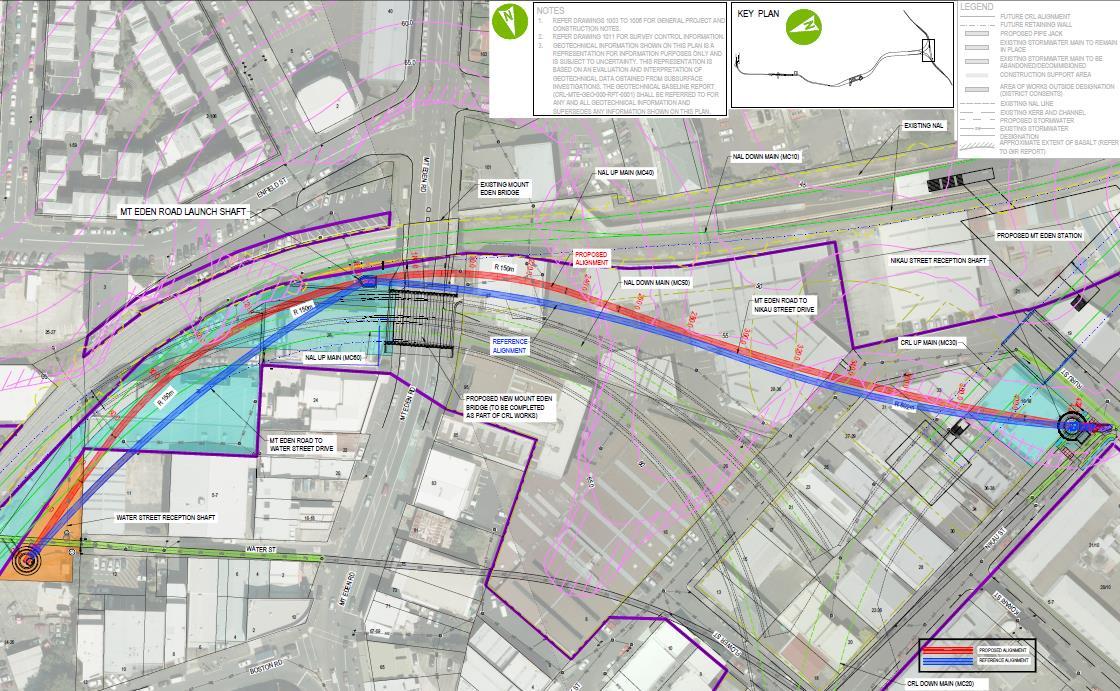

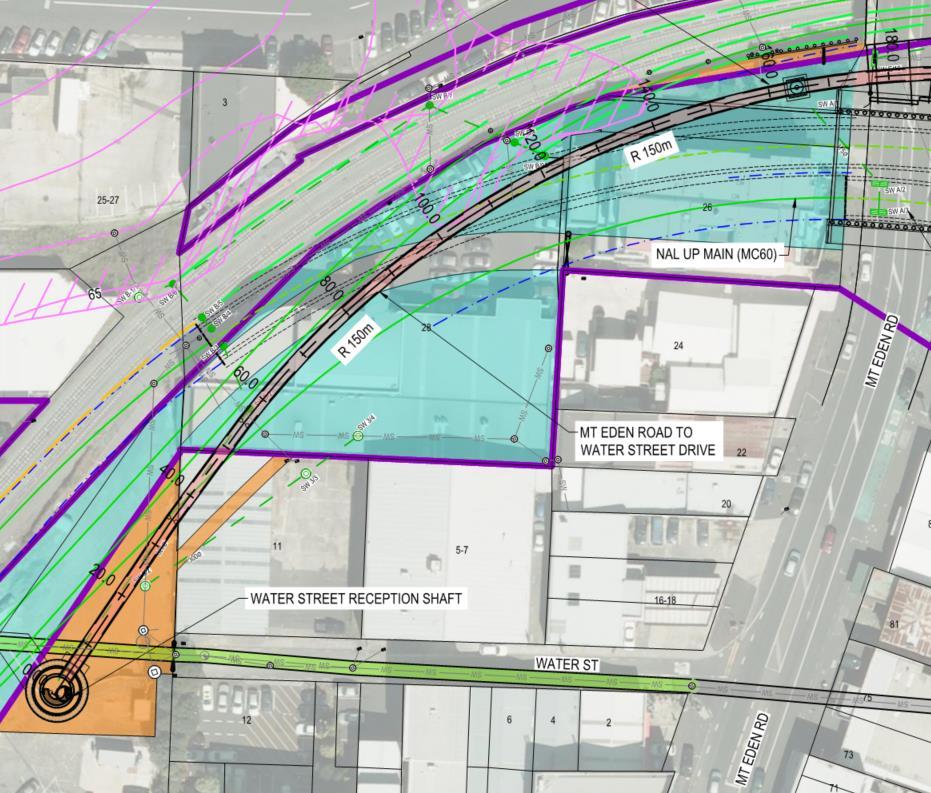

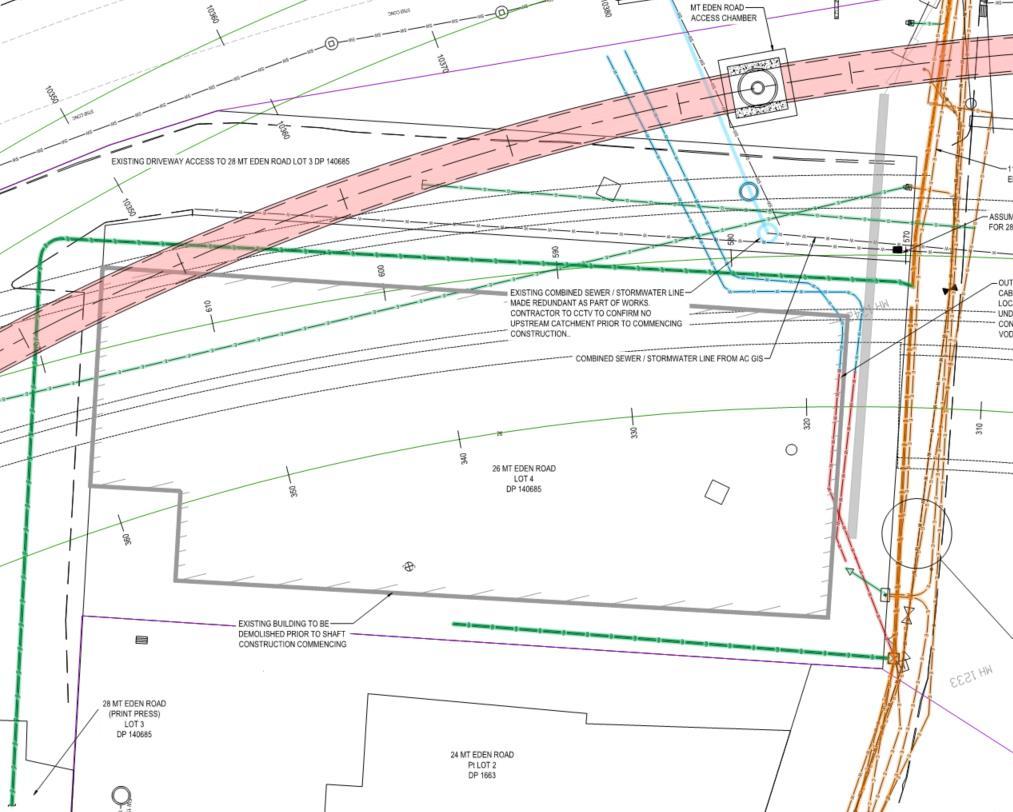

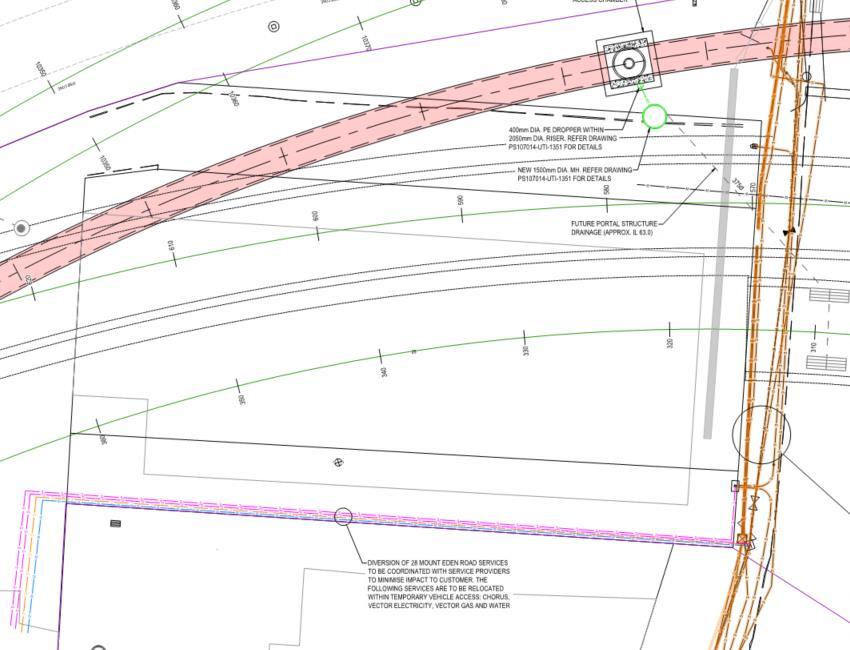

The realigned stormwater main will be constructed using the pipe jacking method, where pipes are horizontally driven between vertical shafts Figure 1 shows the proposed route for the CRL, and Figure 2 shows the extent of the Nikau Street Stormwater Main Realignment works.

The Project also requires the installation of three Gross Pollutant Traps (GPT’s). These GPTs will be located within the road reserve, with two GPT’s being located on Boston Road and one on Normanby Road (Figure 3).

The development and implementation of this CEMP and Sub-Plans is required by the CRL designation conditions. AC will certify this CEMP prior to the commencement of construction, at which point compliance with the CEMP is mandatory. Construction will not commence on site until certification of this CEMP is obtained from AC.

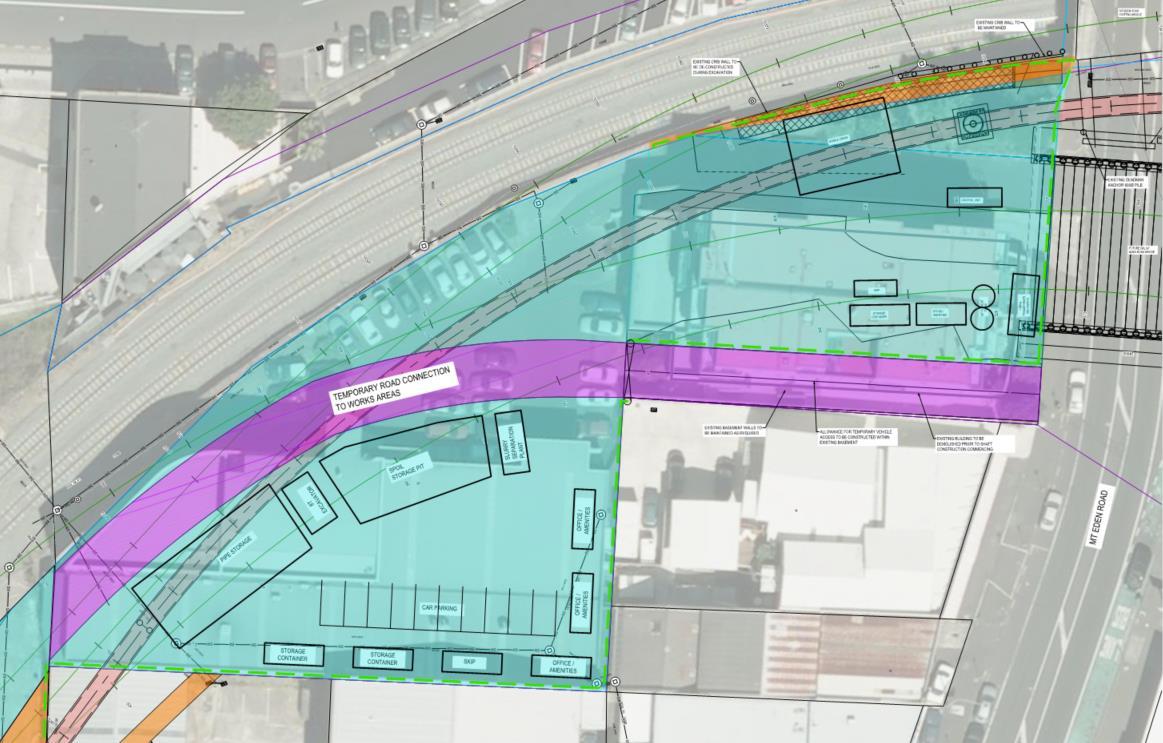

This CEMP was prepared by Aurecon for CRLL in early 2017 for the reference design stage and was approved by AC as part of the original resource consent and outline plan process. The reference design stormwater alignment that the original CEMP was based on is shown in blue at Figure 2 below.

The CEMP has now been updated by the Contractor, March Bessac Joint Venture (MBJV), as its operational document to reflect the revised construction design and methodology. The MBJV amended alignment is shown in red in Figure 2 below. A revised project description incorporating the updates to the design and construction methodology is provided for in Appendix L to replace all project descriptions in the various delivery work plans.

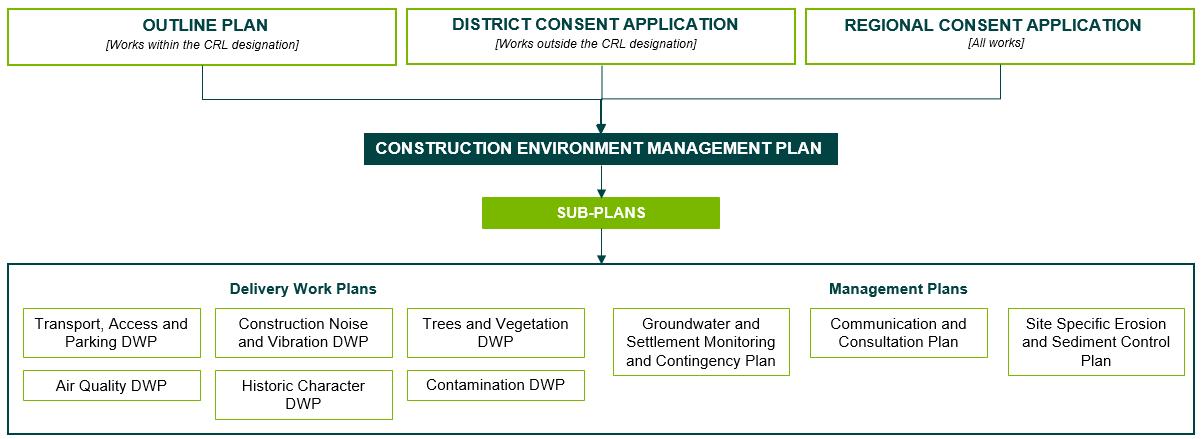

The CEMP provides the overarching framework for the management of construction effects associated with the Project. Further Sub-Plans are included as appendices to the CEMP. These Sub-Plans detail the specific environmental management controls for particular aspects of the Project.

2 Nikau Street

Main Realignment. The reference design is shaded blue and the Construction Support Areas (CSA’s) are shaded in blue and orange. The MBJV amended (26/2/18) alignment is in red.

The purpose of the CEMP is to confirm the Project construction details and staging of works and to set out how construction activities will be carried out and managed as far as is reasonably practical to avoid, remedy or mitigate adverse effects on the environment

This CEMP demonstrates that the works remain within the limits of the CRL designation and associated resource consents (for which, and application has been submitted along with this CEMP)

The CEMP will ensure that appropriate environmental management practices are followed during the Project’s construction phase. The CEMP will be implemented throughout the entire construction period (approximately 13 months) for the Project, and updated as necessary.

Overall, implementation of this CEMP willensure:

Appropriate management of adverse environmental effects associated with construction of the Project;

Compliance with the relevant designation conditions of the CRL designation and any resource consents;

Compliance with environmental legislation; and

Achievement of the Project’s environmental and sustainability objectives.

The CEMP and Sub-Plans will be reviewed at least annually or as a result of a material change to the Project, or to address unforeseen adverse effects arising from construction or unresolved complaints 1 The CEMP and Sub-Plans are required to be prepared in consultation with the Community Liaison Group (CLG) for the Project. Additionally, the CEMP and Delivery Work Plans (DWP) have undergone independent peer review prior to submission to AC. Comments received from the CLG and independent peer review process have been (where applicable and appropriate) incorporated in the CEMP and Sub-Plans, with an explanation being provided where any comments have not been incorporated. A record of consultation outcomes (CLG and independent peer review) for this CEMP is provided in Appendix J; a record of specific consultation outcomes is included in each relevant sub plan.

The CEMP has been updated (revision 9) by MBJV following Contract 6 award to reflect the revised construction design and methodology. The updates are considered non-material for the purposes of the CRL Designation conditions. As a result, the updates do not require further CLG, Mana Whenua or independent peer review input

The updated CEMP (revision 9) supersedes the existing CEMP, revision 8, for the C6 works and will support the section 127 resource consent application process and outline plan waiver request

The CEMP is an overarching document and provides the framework for managing adverse environmental effects during construction of the Project. The principles and general approach to managing the environmental effects are set out in the CEMP. The CEMP includes details of personnel responsible for the implementation of environmental management and mitigation measures. The CEMP identifies the proposed construction methodology for each component of the works and presents a framework of principles, environmental policy, objectives and performance standards as well as processes for implementing appropriate environmental management.

The CRL designation requires that a CEMP be submitted to AC with the Outline Plan, along with the Communication and Consultation Plan (CCP), Delivery Works Plans (DWP) and Site Specific Construction Noise and Vibration Management Plans (if required) 2

Where specific requirements and objectives are not addressed by the Sub-Plans, the CEMP includes measures to give effect to these.

The extent of works outside the designation are limited to:

The Water Street shaft, Water Street Construction Support Area (CSA) and approximately 55m of underground pipe (refer Figure 4); and

A small section of the Mt Eden Access Shaft and CSA sits outside the designation and within the adjacent KiwiRail designation (refer Figure 4).

Two GPT’s to be installed on Boundary Road (within the road reserve) (Figure 5)

The original proposed works have been consented. A section 127 variation to these resource consents is sought for the revised MBJV construction design and methodology (see section 2 for further detail)

1 Designation condition 22

2 Designation condition 10

In addition to managing environment effects within the designation, this CEMP also describes how effects will be managed in areas of the Project that fall outside the designation. A comprehensive approach to the management of actual or potential construction effects, irrespective of the location of the Designation boundary, is appropriate as it enables consistent environmental performance across the Project.

The management of specific environmental effects during construction is addressed through the development and implementation of a suite of Delivery Works Plans (DWP), Management Plans (MP) and Site Specific Management Plans (SSMP) required by the CRL designation

The DWP’s, MP’s and SSMP’s are collectively referred to as ‘Sub-Plans’ throughout this CEMP. The Sub-Plans relevant to these works are identified in Figure 6 and Table 1 and form appendices to the CEMP

These Sub-Plans cover all works associated with the Project including those which fall outside the designation.

A number of Sub-Plans have been updated following Contract 6 award to reflect the MBJV construction design and methodology.

Table 1 Sub-Plans attached to the CEMP

Sub-Plan

Erosion and Sediment Control Plan

Transport Access and Parking DWP

ESCP 21.1(b) and (c) Outline the methods for managing and controlling silt and sediment within the construction area.

TAPDWP 25, 30 To manage the adverse effects of construction on the transport network (including parking and access)

Construction Noise and Vibration DWP CNVDWP 36 To provide for the development and implementation of identified best practicable options to avoid, remedy or mitigate adverse effects on receivers of noise and vibration resulting from construction effects.

Historic Character DWP (Archaeology Section) HCDWP 42 To manage the adverse archaeological effects that may result during construction.

Trees and Vegetation DWP TVDWP 55 To manage the adverse effects from the removal of trees and vegetation during construction

Contamination DWP (also a Contaminated Soils Management Plan) CDWP 57 To manage the adverse effects relating to contaminated land during construction

Air Quality DWP (also a Air Quality Management Plan)

Communication and Consultation Plan

AQDWP 59 To avoid, remedy or mitigate the adverse effects on air quality during construction

CCP 15 To set out set out the framework to ensure appropriate communication and consultation is undertaken with the community, stakeholders, affected parties and affected in proximity parties during constriction

Section of CEMP

Section 4.3.2 & Appendix C

Section 4.3.3 & Appendix D

Section 4.3.5 & Appendix E

Section 4.3.7 & Appendix F

Section 4.3.8 & Appendix G

Section 4.3.10 & Appendix H

Section 4.3.11 & Appendix I

Section 4.5 & Appendix J

This CEMP and the Sub-Plans have been developed by experts and subjected to range of reviews to ensure that they are commensurate to the scale of the effects associated with the Project. This ensures that the measures proposed in the CEMP and its Sub-Plans are appropriate for managing the adverse environment effects of these construction works.

The CEMP, CCP and all the DWP’s have been presented to the Mt Eden CLG for feedback in accordance with designation condition 7.5. Where appropriate, this feedback has been incorporated into the CEMP, CCP and DWP’s. Where feedback has not been incorporated, reasons why have been provided in each document.

The CEMP and DWP’s and the feedback from the CLG on these plans has been reviewed by CRL’s Independent Peers Review Panel (IPRP). The IPRP have provided a number of recommendations to ensure the CEMP and DWP’s meet the objectives and other requirements of the designation conditions (as required by Condition 11). These inputs, along with the feedback from the CLG, are attached in Appendix K

A mana whenua workshop for this project was held in November 2016. During this workshop the mana whenua forum provided feedback and input to the CEMP, DWP’s and GSMCP. This feedback and input is summarised in Appendix K

The CEMP has been updated (revision 9) by MBJV following Contract 6 award to reflect the revised construction design and methodology. The updates are considered non-material for the purposes of the CRL Designation conditions. As a result, the updates do not require further CLG, Mana Whenua or independent peer review input.

The updated CEMP (revision 9) supersedes the existing CEMP, revision 9, for the C6 works and will support the section 127 resource consent application process and outline plan waiver request

We are all descended from Ranginui, our Father Sky and Papatuanuku, our Mother Earth. Ngā mana whenua o Tāmaki Makaurau have a special relationship with Ranginui, Papatuanuku, and their resources. Acting as kaitiaki, they endeavour to protect their whānau, hapū and Iwi and encourage all people to act as protectors of the earth.

Kaitiakitanga includes:

protecting, restoring, enhancing the mauri (life supporting capacity) of resources;

fulfilling spiritual, emotional and inherited responsibilities to the environment;

maintaining mana over resources; and

ensuring the welfare of the people those resources support.

In Tamaki Makaurau it is mana whenua who are Kaitiaki.

The aspiration of the CRL project to be exemplary in the practice of sustainability – encompassing the four well-beings (environmental, cultural, social and economic) – aligns and supports kaitiakitanga. In meeting their sustainability commitments CRL staff, contractors and others involved in the project are also supporting kaitiakitanga and mana whenua as kaitiaki. Furthermore, they are also improving the state of the environment that we pass on for future generations.

The CRL sustainability framework is informed by tikanga tiaki and mātauranga. A CRL mana whenua forum has been established for the purposes of undertaking kaitiakitanga responsibilities associated with the project. The forum comprises those mana whenua groups who expressed an interest in being involved in the CRL project and its related activities. Eight mana whenua self-identified their interest in CRL and are currently part of the forum:

Ngāti Maru

Ngāti Paoa

Ngāi Tai Ki Tāmaki

Ngāti Te Ata Waiohua

Ngāti Whātua o Ōrākei

Te Akitai Waiohua

Te Kawerau a Maki

Ngāti Tamaoho

CRLL continues to work collaboratively with the mana whenua forum on all aspects of the CRL project. With the commencement of construction for the CRL enabling works, the forum’s role will include cultural induction for contractors, assistance with discovery procedures, monitoring, and ongoing provision of mātauranga Māori input.

These Project works relate to the designation confirmed under Notice of Requirement (NoR) 6. This CEMP and its Sub-Plans are consistent with and complement the Assessment of Environmental Effects (AEE) for the Project. All works will be carried out in accordance with the CEMP and the SubPlans required by the designation.

The designation conditions are included in Appendix A. Designation conditions 19 – 24 outline what is required for the CEMP. Table 2 below identifies the relevant sections of the CEMP that address each condition.

13.1 The Requiring Authority, its contractor team, and the AucklandCouncil Consent Monitoring officer(s) shall establish and implement a collaborative working process for dealing with day to day constructionprocesses, including monitoring compliance with thedesignation conditions and with the CEMP and DWPs (including SSCNVMPs,SSCNMPs and SSCVMPs) and any material changes to these plans associated with construction of the City Rail Link.

13.2 This collaborative working process shall:

(a) Operate for the duration of the construction works and for 6 months following completion of construction works where monitoringof designation conditions is still required, unless a different timeframe ismutually agreed between the Requiring Authority and the AucklandCouncil;

(b) Have a “key contact” person representing the RequiringAuthority and a “key contact” person representing the contractor team to work with the Auckland Council Consent Monitoring officer(s);

(c) The “key contacts” shall be identified in the CEMP and shall meet at least monthly unless a different timeframe is agreed with the Auckland Council Consent Monitoring officer(s). The purpose of the meeting is to report on compliance with the designation conditions and withthe CEMP, DWPs and material changes to these plans and on any matters of non-compliance and how they have been addressed;

(d) Once construction has commenced, the Requiring Authority and / or the contractor shall provide an update to the Community Liaison Groups (Condition 7 of this designation) at least once every 3 months,or if in accordance with Condition 7 these groups meet more regularly,at least once every two months.

13.3 The purpose and function of the collaborative working process is to:

(a) Assist as necessary the Auckland Council Consent Monitoring officer(s) to confirm that:

(i) The works authorised under these designations are being carried out in compliance with the designation conditions, the CEMP, DWPs (including SSCNVMPs, SSCNMPs and SSCVMPs) and any material changes to these plans;

(ii) The Requiring Authority and its contractor are undertakingall monitoring and the recording of monitoring results in compliance with the requirements of the CEMP and DWPs (including SSCNVMPs,SSCNMPs and SSCVMPs) and any material changes to these plans;

(b) Subsequent to a confirmed Outline Plan, provide a mechanism through which any changes to the design, CEMP or DWPs, which arenot material changes requiring approval under Condition 10 triggering the requirement for a new Outline Plan, can be required, reviewed andconfirmed;

(c) Advise where changes to construction works following aconfirmed Outline Plan require a new CEMP or DWP (including SSCNVMPs,SSCNMPs and SSCVMPs);

(d) Review and identify any concerns or complaints received from, or related to, the construction works monthly (unless a different timeframe is mutually agreed with the Auckland Council Consent Monitoringofficer) and adequacy of the measures adopted to respond to these.

17.1

Upon receiving a concern or complaint during construction, the Requiring Authority shall instigate a process to address concernsor complaints received about adverse effects. Thisshall:

(a) Identify of the nature of the concern or complaint, and thelocation, date and time of the alleged event(s);

(b) Acknowledge receipt of the concern or complaint within 24 hours of receipt;

(c) Respond to the concern or complaint in accordance with the relevant management plan , which may include monitoring of theactivity by a suitably qualified expert, implementation of mitigationmeasures, and, in the case of noise and / or vibration, preparation ofa site specific noise and / or vibration management plan (in accordance with Conditions

17.2 A record of all concerns and / or complaints received shall be kept by the Requiring Authority. This record shallinclude:

(a) The name and address of the person(s) who raised the concern or complaint (unless they elect not to provide this) and details of theconcern or complaint;

(b) Where practicable, weather conditions at the time of the concern or complaint, including wind direction and cloud cover if the complaint relates to noise or air quality;

(c) Known City Rail Link construction activities at the time and in the vicinity of the concern or complaint;

(d) Any other activities in the area unrelated to the City Rail Linkconstruction that may have contributed to the concern or complaint such as non-City Rail Link construction, fires, traffic accidents or unusually dusty conditions generally;

(e) Remedial actions undertaken (if any) and the outcome ofthese, including monitoring of the activity.

17.3 This record shall be maintained on site, be available for inspection upon request, and shall be provided every two months (or as otherwise agreed) to the Auckland Council Consent Monitoring officer, and to the “key contacts” (see Condition 13).

17.4 Where a complaint remains unresolved or a dispute arises, the Auckland Council Compliance Monitoring Officer will be provided with all records of the complaint and how it has been dealt with andaddressed and whether the Requiring Authority considers that any other steps to resolve the complaint are required. Upon receivingrecords of the complaint the Auckland Council ComplianceMonitoring Officer must determine whether a review of the CEMP and/or DWPs isrequired under Condition 22 to address this complaint. TheAuckland Council Compliance Monitoring Officer shall advise the Requiring Authority of its recommendation within 10 working days of receivingthe records of complaint.

19.1 The objective of the CEMP and DWPs is to so far as is reasonablypracticable, avoid, remedy or mitigate any adverse effects (including cumulative effects) associated with the City Rail Linkconstruction.

and Appendix J

and Appendix J

and Appendix J

and Appendix J

and Appendix J

and Appendix J

and Appendix J

and Appendix J

and Appendix J

and Appendix J

and Appendix J

and Appendix J

19.2 All works must be carried out in accordance with the CEMP, the DWPs required by these conditions and in accordance with any changes to plans made under Condition 23.

19.3 The CEMP and DWPs shall be prepared, complied with and monitoredby the Requiring Authority throughout the duration of construction of the City Rail Link.

19.4 The DWPs shall give effect to the specific requirements andobjectives set out in these designation conditions.

19.5 The CEMP shall include measures to give effect to any specificrequirements and objectives set out in these designation conditions that are not addressed by the DWPs.

20.1 In order to give effect to the objective in Condition 19.1, the CEMP must provide for the following:

(b) Notice boards that clearly identify the Requiring Authority andthe Project name, together with the name, telephone number and emailaddress of the Site or Project Manager and the Communication andConsultation Manager;

(c) Training requirements for employees, sub-contractors and visitorson construction procedures, environment management and monitoring;

(d) A Travel Management Plan for each construction site outliningonsite car parking management and methods for encouraging travelto the site using forms of transport other than private vehicle to assistin mitigating localised traffic effects; and

(e) Where a complaint is received, the complaint must be recorded and responded to as provided for in Conditions 13, 15 and 17.

20.2 The CEMP shall include details of:

(a) The site or Project Manager and the Communication andConsultation Manager (who will implement and monitor the Communication and Consultation Plan), including their contact details (phone, email and physical address);

(b) The Document management system for administering the CEMP,including review and Requiring Authority / Constructor / Auckland Council requirements;

(c) Environmental incident and emergency management procedures;

(d) Environmental complaint's management procedures (seealso Condition 17);

(e) An outline of the construction programme of the work, includingconstruction hours of operation, indicating linkages to the DWPs which address the management of adverse effects duringconstruction;

(f) Specific details on demolition to be undertaken during the construction period;

(g) Means of ensuring the safety of the general public; and

(h) Methods to assess and monitor potential cumulative adverse effects.

J

D

J

21.1 In order to give effect to the objective in Condition 19.1, the CEMP shall include the following details and requirements in relation to allareas within the surface designation footprint where construction works areto occur, and / or where materials and construction machinery are to beused or stored:

(a) Where access points are to be located and proceduresfor managing construction vehicle ingress and egress to construction support and storage areas;

(b) Methods for managing the control of silt and sediment within the construction area;

Appendix D

Appendix C

(c) Methods for earthworks management (including depth and extent of earthworks and temporary, permanent stabilisation measures and monitoring of ground movement) for earthworks adjacent tobuildings and structures; Appendix C

(d) Measures to adopt to keep the construction area in a tidy conditionin terms of disposal / storage of rubbish and storage unloading ofconstruction materials (including equipment). All storage of materialsand equipment associated with the construction works shall take place within the boundaries of the designation;

(e) Measures to ensure all temporary boundary / security fencesassociated with the construction of the City Rail Link are maintainedin good order with any graffiti removed as soon as possible;

(g) The location and specification of any temporary acoustic fences and visual barriers, and where practicable, opportunities for manawhenua (see Condition 8) and community art or other decorativemeasures along with viewing screens to be incorporated into these withoutcompromising the purpose for which these are erected; 2.6.1 and Appendix J

(h) How the construction areas are to be fenced and kept secure from the public and, where practicable and without compromising theirpurpose how opportunities for public viewing, including provisionof viewing screens and display of information about the project andopportunities for mana whenua and community art or other decorative measures can be incorporated to enhance public amenity and connection to the project;

(i) The location of any temporary buildings (including workers officesand portaloos) and vehicle parking (which should be located withinthe construction area and not on adjacent streets);

(j) Methods to control the intensity, location and direction ofartificial construction lighting to avoid light spill and glare onto sites adjacent construction areas;

(k) Methods to ensure the prevention and mitigation of adverse effects associated with the storage, use, disposal, or transportation of hazardous substances;

(l) That onsite stockpiling of spoil or fill at Downtown and Lower Albert Street construction yards be minimised where practicable; N/A

(m) That site offices and less noisy construction activities be located at the edge of the construction yards where practicable; and 2.6

(n) Methods for management of vacant areas once construction is completed in accordance with the Urban Design DWP.

21.2 Subject to any alternative arrangement with the landowner of theDowntown Shopping Centre, the Downtown construction yard, including QEII Square, Downtown Shopping Centre and Lower AlbertStreet, shall be progressively released from occupation for construction purposes where the area or any part of the area is no longer required for construction.

22.1 The CEMP and DWPs shall be reviewed at least annually or as a result of a material change to the City Rail Link project or to addressunforeseen adverse effects arising from construction or unresolved complaints. Such a review may be initiated by either Auckland Council or the Requiring Authority. The review shall take intoconsideration:

(a) Compliance with designation conditions, the CEMP, DWPs (including SSCNVMPs, SSCNMPs and SSCVMPs) and material changes to these plans;

(b) Any changes to construction methods;

(c) Key changes to roles and responsibilities within the City Rail Link project;

(d) Changes in industry best practicestandards;

(e) Changes in legal or other requirements;

(f) Results of monitoring and reporting procedures associated with the management of adverse effects duringconstruction;

(g) Any comments or recommendations received fromAuckland Council regarding the CEMP and DWPs (including SSCNVMPs, SSCNMPs and SSCVMPs); and

(h) Any unresolved complaints and any response to the complaints and remedial action taken to address the complaint as required under Condition 17.

22.2 A summary of the review process shall be kept by the Requiring Authority, provided annually to the Auckland Council, and madeavailable to the Auckland Council upon request.

23.1 Following the CEMP and DWPs review process described in Condition 22, the CEMP may requireupdating.

23.2 Any material change to the CEMP and DWP must be consistent with the purpose and objective of the relevant condition. 5.7

23.3 Affected parties will be notified of the review and any material change proposed to the CEMP and DWPs (including SSCNVMPs, SSCNMPsand SSCVMPs).

23.4 The CEMP and DWPs must clearly document the comments andinputs received by the Requiring Authority from affected parties about the material change, along with a clear explanation of where anycomments have not been incorporated, and the reasons why not.

23.5 Any material change proposed to the CEMP and DWPs shall besubject to an independent peer review as required by Condition 11.

23.6 Following that review any material change proposed to the CEMPand DWPs relating to an adverse effect shall be submitted for approvalto Auckland Council Compliance and Monitoring Officer, at least 10 working days prior to the proposed changes taking effect. If anychanges are not agreed, the relevant provisions of the RMA relating to approval of outline plans shall apply.

24.1 To manage the adverse effects on Network Utilities Operationsduring the construction of the City Rail Link, the following shall be included in the CEMP.

24.2 The purpose of this section of the CEMP shall be to ensure that theenabling works and construction of the City Rail Link adequatelytake account of, and include measures to address the safety, integrity, protection or, where necessary, relocation of existing networkutilities that traverse, or are in close proximity to, the designation duringthe construction of the City Rail Link.

24.3 For the avoidance of doubt and for the purposes of this conditionan “existing Network Utility” includes infrastructure operated by a Network Utility Operator which was:

(a) In place at the time the notice of requirement for the City RailLink was served on Auckland Council (23 August 2012); or

(b) Undertaken in accordance with condition 6 of this designation or the section 176(1)(b) RMA process.

24.4 The CEMP shall be prepared in consultation with NetworkUtility Operators who have existing Network Utilities that traverse, or are in close proximity to, the designation and shall be adhered to andimplemented during the construction of the City Rail Link. The CEMP shall include as a minimum:

(a) Cross references to the Communication and Consultation Plan forthe methods that will be used to liaise with all Network Utility Operators who have existing network utilities that traverse, or are inclose proximity to, the designation;

(b) Measures to be used to accurately identify the location of existingNetwork Utilities, and the measures for the protection, support, relocation and/or reinstatement of existing Network Utilities;

(c) Methods to be used to ensure that all construction personnel, including contractors, are aware of the presence and location of thevarious existing Network Utilities (and their priority designations) which traverse, or are in close proximity to, the designation, and therestrictions in place in relation to those existing Network Utilities. Thisshall include:

(i) Measures to provide for the safe operation of plant and equipment, and the safety of workers, in proximity to existing Network Utilities;

(ii) Plans identifying the locations of the existing Network Utilities(and their designations) and appropriate physical indicators on the groundshowing specific surveyed locations;

(d) Measures to be used to ensure the continued operation of Network Utility Operations and the security of supply of the utilities by NetworkUtility Operators at all times;

(e) Measures to be used to enable Network Utility Operators to accessexisting Network Utilities for maintenance at all reasonable times on an ongoing basis during construction, and to access existing Network Utilities for emergency and urgent repair works at all times during theconstruction of the City Rail Link

and Appendix J

(f) Contingency management plans for reasonably foreseeablecircumstances in respect of the relocation and rebuild of existing Network Utilities during the construction of the City Rail Link;

(g) A risk analysis for the relocation and rebuild of existing Network Utilities during the construction of the City Rail Link; 4.3.1

(h) Earthworks management (including depth and extent of earthworks and temporary and permanent stabilisation measures), for earthworksin close proximity to existing Network Utilities;

and Appendix C

(i) Vibration management and monitoring for works in close proximityto existing Network Utilities; 4.3.1 and Appendix E

(j) Emergency management procedures in the event of any emergencyinvolving existing Network Utilities;

(k) The process for providing as-built drawings showing therelationship of the relocated Network Utilities to the City Rail Link to Network Utility Operators and the timing for providing thesedrawings;

(l) Measures to ensure that network utilities are not interrupted to the Mt Eden Corrections Facility as a result of City Rail Link works. The requiring authority shall advise the Department of Corrections andthe entity contracted by Department of Corrections to administer and runthe Mt Eden Corrections facility at 1 Lauder Road, of any works onnetwork utilities in the vicinity of the Mt Eden Corrections Facility which may impact on utility service provision to the Mt Eden CorrectionsFacility at least 14 days prior to those works occurring to allow theDepartment of Corrections (and the entity contracted to administerand run the facility at 1 Lauder Road) to arrange suitable contingencies.Communication and consultation with the Department of Corrections, and the entity contracted to administer and run the facility at 1 Lauder Road, shall be recorded in accordance with condition 15) of thisdesignation. The Requiring Authority shall be responsible for ensuring that construction works do not interrupt network utilities to the Mt Eden Corrections Facility, unless by prior arrangement with Department of Corrections and the entity contracted by Department of Correctionsto administer and run the Mt Eden Corrections facility at 1 Lauder Road.

(m) A summary of the consultation (including any methods or measures in dispute and the Requiring Authorities response to them) undertaken between the Requiring Authority and any Network UtilityOperators during the preparation of the CEMP. 4.3.1 and Appendix J

24.5 If the Requiring Authority and a Network Utility Operator cannot agree on the methods proposed under the CEMP to manage the construction effects on the Operator’s network utility operation, unless otherwise agreed, each party will appoint a suitably qualified and independentexpert, who shall jointly appoint a third such expert to advise the parties and make a recommendation. That recommendation will beprovided by the Requiring Authority as part of the CEMP along withreasons if the recommendation is not accepted.

Not applicable

The CRL project comprises the construction, operation and maintenance of a 3.4 km underground passenger railway, running between Britomart Station and the North Auckland Rail Line (NAL) in the vicinity of Mt Eden station. The proposed works include the construction of twin underground rail tunnels and two underground stations using cut and cover methods, and tunnel boring methods, up to 42 m below ground.

The CRL enabling works form a separate package to the main CRL project. The size of this project means that the various packages of enabling works have been separated into a number of construction contracts. The Nikau Street Stormwater Main Realignment package is referred to as Contract 6 (C6).

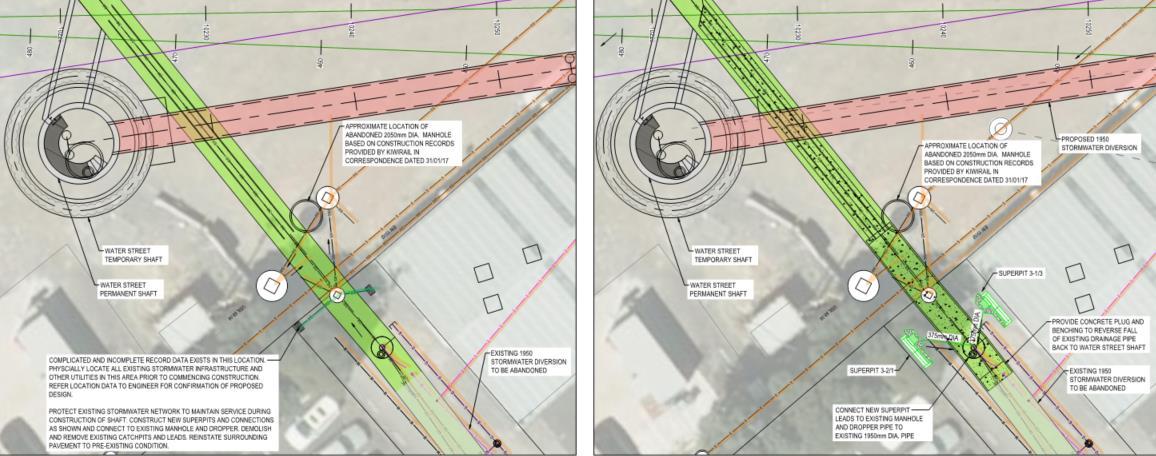

The purpose of the Project is to enable the construction of the future CRL tunnels by realigning the Nikau Street Stormwater Main which currently represents a critical CRL project constraint. The Project works involve the construction of a replacement stormwater main from the eastern end of Water Street, where it then passes beneath the CRL East Facing Connection (EFC) east of Mount Eden Road, it then continues west to connect into the existing main at the corner of Nikau Street and Ruru Street. The Project includes the construction of a central shaft at Mt Eden Road and shafts at Water Street (Drive) and Nikau Street (Retrieval)

The realigned pipeline will be 2,000mm (internal diameter) and is proposed to be constructed along a horizontally curved (R150m and 802m) alignment which is required to reach the proposed shaft locations. The realigned pipeline and shaft locations have been positioned to avoid the proposed rail alignment, basalt extents and existing properties.

One tunnel drive is proposed from the Water Street shaft. Due to the depth of the upstream and downstream connection points as well as the requirement to pass beneath the proposed CRL alignment (approximately 15-20m), pipe jacking is the proposed construction methodology. Pipejacking is a trenchless construction technique where a Tunnel Boring Machine (TBM) with a pressurised slurry system excavates material. Pipes are then horizontally driven using a hydraulic ram from a series of vertical shafts. Therefore, it is proposed to install the following shafts, along with associated CSA’s, at the following locations:

An access shaft adjacent to Mount Eden Road (approximately 2.7m in diameter), known as the “Mount Eden Road Shaft” is located between Mount Eden Road and the North Auckland Line (NAL). The construction activities shall be supported by a CSA of approximately 3928m2 (plus an additional 350m2 for a temporary vehicle access ramp) surrounding the shaft (Appendix B).

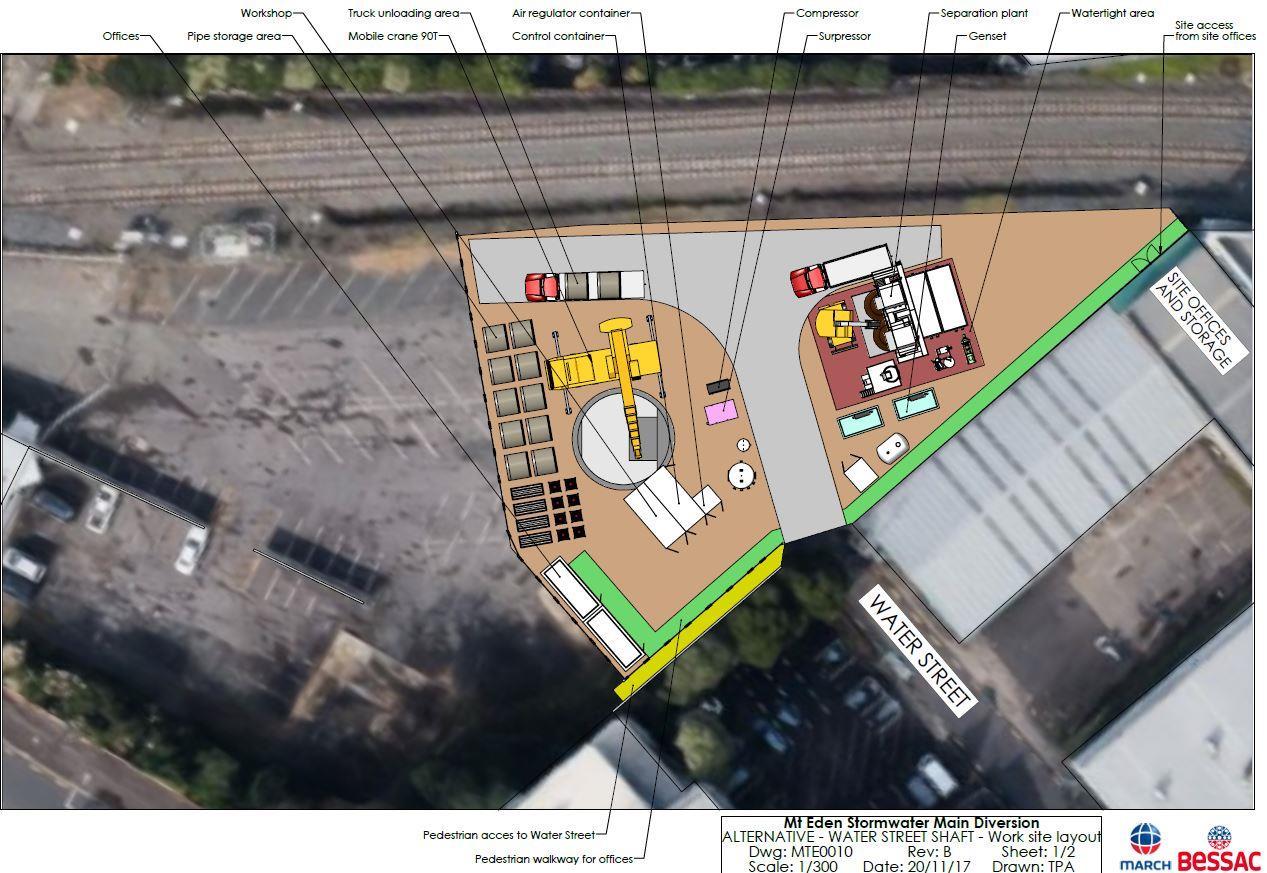

A launch shaft at Water Street (approximately 9.25m diameter and 16.7m deep), known as the “Water Street Shaft” is located within an CRLL owned vacant site which is currently used as a carpark. The shaft is to be positioned between the end of Water Street and the existing NAL lines. It is proposed to be supported by a CSA of approximately 1500m2 surrounding the shaft (Appendix B).

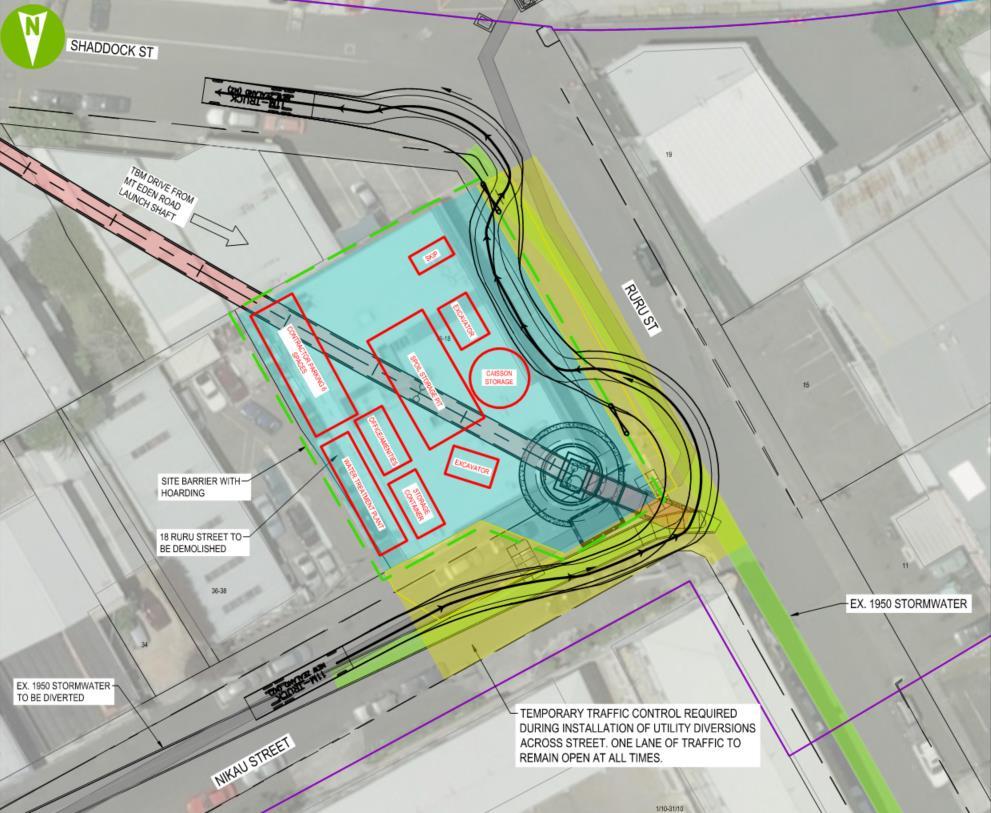

A reception shaft at Nikau Street (varies from approximately 6.1m to 10.9m in diameter and 15.4m deep) known as the “Nikau Street Shaft” is located within the footpath at the corner of Nikau Street and Ruru Street. It is proposed to be serviced by a CSA of approximately 900m2 at 16-18 Ruru Street (Appendix B).

An additional construction support area of 2728m2 will be located at 28 Mt Eden Road. The demolition of the existing building at 28 Mt Eden Road and the establishment of the additional construction support area was authorised via a further outline plan (Council reference: OPW60306133) on 13 September 2017.

The shaft locations have been strategically selected to avoid clusters of utilities. However, it is expected that some utilities will not be able to be avoided and therefore will need to be protected or relocated before piling and shaft excavation. AT is currently engaging with relevant utility stakeholders as part of this work and it is anticipated that existing services will either be relocated or protected as part of the access shaft formation.

Other ancillary works are required to enable the construction of the Project and include:

Relocation and protection of various minor utilities which clash with, or are in close proximity to, the shafts.

Temporary protection of the Huia No. 2 watermain adjacent to the Nikau Street shaft.

A section of mined tunnel of approximately 7m will extend under Nikau Street to connect the realigned section of pipe from the Nikau Street shaft into the existing stormwater main at Ruru Street.

A open cut connection to the existing pipe at Water Street.

The demolition of 26 Mount Eden Road to enable the construction of the Mount Eden shaft.

The demolition of 16-18 Ruru Street to enable the property to be used as a worksite and reduce disruption to the adjacent roads and properties. The Nikau Street shaft cannot be fully located within this property as a permanent manhole and riser is required by AC for maintenance access at this location.

The demolition of 28 Mount Eden Road to enable the use of the site as a construction support area. The floor slab and external impervious surfaces will remain in place. No excavation is proposed on this site.

Three new connections are required to connect the realigned Nikau Street Stormwater Main to the existing stormwater mains within Ruru Street at the corner of Nikau Street and Ruru Street.

In addition, three permanent access shafts are proposed within the reception and launch shafts during reinstatement at Water Street, Mount Eden Road and Nikau Street to accommodate access associated with the ongoing operation and maintenance of the realigned Nikau Street Stormwater Main.

Three new Gross Pollutant Traps (GPT’s) on Boston Road (two) and Normanby Road (one). These works will require excavating pits of approximately 6 m wide, 6 m long and 7.9 m deep to install new 2.5 m wide GPTs and manholes (Figure 3).

The Project works are anticipated to take up to 13 months depending on the methodology chosen by the Construction Contractor. Subject to obtaining the section 127 variation to resource consent, works are expected to commence in March 2018

Whether the existing abandoned alignment is backfilled or used for stormwater storage is still to be agreed with Council.

2.3.1

Generally, the Project works will consist of the following key activities. These have been described in detail in the following sections.

4. Building demolition

5. Locate/protect/relocate minor conflicting services at Mt Eden Road

6. Excavate and construct new Mount Eden Road access shaft

7. Locate and protect existing Water Street shaft (which serves the existing stormwater pipe – this shaft will not be used during construction)

8. Locate/protect/relocate other minor conflicting services at Water Street

9. Excavate and construct new Water Street launch shaft

10. Launch pipe jack from Water Street driving towards the Nikau Street Shaft

11. Put in place temporary traffic control measures at Nikau Street/Ruru Street

12. Locate/protect/relocate other minor conflicting services at Nikau Street

13. Excavate and construct new Nikau Street reception shaft

14. Retrieve the pipe jacking machine at the Nikau Street reception shaft

15. Complete mined connection works to existing 2,000mm dia. stormwater main at Water Street shaft and Nikau Street shaft

16. Install GPT’s

17. Divert flow to new stormwater main

18. Seal connections to existing stormwater main

2.3.2

In order to construct the Project, the buildings at 26 Mt Eden Road, 28 Mt Eden Road and 16-18 Ruru Street need to be demolished. This work will be completed by a sub-contractor. The demolition methodology for the two buildings will generally be conducted as follows:

1. Construct a 2.5m high mesh panel fence (with dust net or similar) around the perimeter to secure the site.

2. Establish traffic management, site entry and divert pedestrians (as outlined in the TAPDWP in Appendix D).

3. Disconnect services to the perimeter of the site.

4. Conduct an asbestos check. If asbestos is identified it will be removed by an appropriately experienced, qualified and certified contractor.

5. Remove of cabling, pipework, HVAC units, aluminium joinery and other items for reuse and recycling.

6. Structural demolition will be carried out using concrete saws, an excavator and/or a hydraulic excavator mounted pincers and breakers. The roof will be removed and the steel removed from site for recycling.

7. Blockwork walls will be demolished using a hydraulic breaker to separate the steel from the blockwork.

8. Where required to make way for the shaft, concrete floor slabs will be broken out and removed.

9. Final sweep off of the existing concrete ground floor slab to facilitate site establishment.

In addition to relocating the Nikau Street stormwater main, other network utilities also need to be relocated to make room for the construction of the pipe jack shafts.

Relocation of utilities will occur prior to commencement of shaft construction. Whilst shaft locations have been strategically located to avoid clusters of utilities, some are unable to be avoided. Prior to piling and shaft excavation protection or relocation of utilities will occur. Network Utility Operators (NUO) that will be affected by the works include Vector Electricity, Vector Gas, Vector Communications, Chorus, Vodafone, AC and Watercare Services. The following sections outline the utilities relocations that are expected to occur in relation to each shaft. The Communication and Consultation Plan in Appendix J provides further detail around the consultation and communication that has been and will continue to be undertaken with network utility providers affected by the Project. All existing network utilities in the vicinity of the three shafts have been located using Before You Dig Records, AC GIS information and as built plans provided by the network utility providers (where available). All network utilities in close proximity to the works will be physically located and marked out on site by a suitably experienced services locator prior to works commencing. Network utilities that clash with (or are in close proximity to) the shafts will be relocated or protected in advance of the main construction works.

The location, protection and/or relocation of utilities that clash with the shaft locations enables to ensure that all personnel working on site are able to conduct the works safely. Relocating or protecting all utilities that clash with the Project will ensure the continuous operation of those network utilities, with the shortest possible outage only during the changeover to the newly installed diversion. Any site access for required by network utility providers will be coordinated as required with the Project Engineer.

All earthworks in close proximity to utilities will be conducted using methods which minimise the risk of damage to these utilities. Such methods include hand excavating and hydro-excavation. Vibration effects on utilities will be managed through the protection or relocation of at risk utilities. As built drawings will be provided to the relevant NUOs for any relocated utilities. The utilities requiring protection and/or relocation for the Project are identified below.

The utilities identified at or around the Mt Eden Road Access shaft and their associated actions are summarised in Table 3 and Figure 9 below. Utilities shown in orange are likely to be protected, while utilities shown in blue are likely to require removal or diversion around the excavation works.

The services supplying electricity, water and communications to 28 Mt Eden Road will need to be relocated to ensure the continuous operation of the site office occupying 28 Mt Eden Road There may be a short period of time during the relocation of these utilities where temporary disconnection is required. The timing of this will be coordinated to ensure business continuity.

Table 3 Utilities - Mt Eden Road shaft

Asset

Details

Stormwater New stormwater connections at shaft

Action

New Ex. 375mm dia. sw to be removed

Wastewater Not identified at this stage

Potable Water 310mm and 470mm out of service (may contain Vodafone cables, refer below)

175mm CLCI (in Mt Eden Rd)

Gas 75mm 0kPa duct

Vector electricity Not identified at this stage

Chorus 1/100mm P

Minor Communications Potential Vodafone Network Cables housed in out of service water mains. Details still to be confirmed by Vodafone.

Remove/divert

N/A

Remove/divert

Protect during shaft construction, replace with bridge works as part of Main CRL project at a later date.

Protect/remove

N/A

Protect

Divert

The utilities identified at or around the Water Street shaft and their associated actions are summarised in Table 4 and Figure 10 below. Utilities shown in orange are likely to be protected, while utilities shown in blue are likely to require removal or diversion around the excavation works. Proposed stormwater assets are shown in green.

Table 4 Utilities – Water Street shaft

Asset

Details

Stormwater New and diverted stormwater connections to shaft

Wastewater Future wastewater diversion to coordinate location with shaft

Existing 150mm dia. wastewater line

Potable Water Appears to terminate at end of Water Street 10m+ clearance

Gas Appears to terminate at end of Water Street 10m+ clearance

Action

New, diversion

Future, diversion (Not part of the Project) 3

Protect

Protect

Protect

3 Diversion of this wastewater asset will be conducted during the main CRL construction phase and in not required for the Project.

Vector electricity Appears to terminate at end of Water Street 10m+ clearance

Chorus Not identified at this stage

Minor communications Not identified at this stage

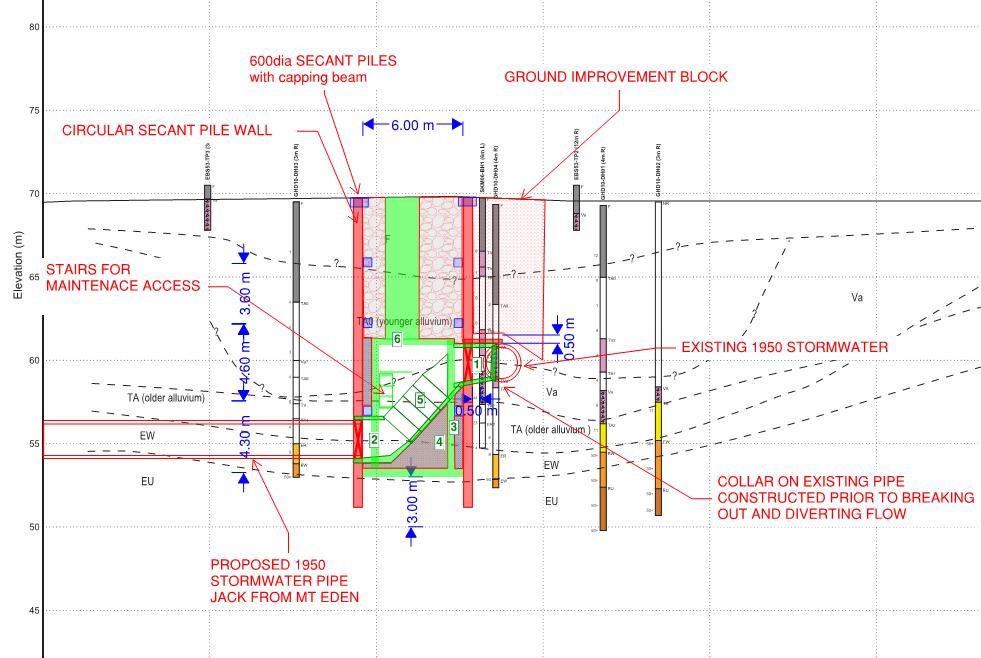

The construction of the Water Street shaft occurs immediately adjacent to the existing Nikau Street stormwater main which is being diverted by the Project. The shaft is located as close as possible to the existing stormwater main to enable a safe and effecting mining operation to connect to the existing main at completion. The piling operation is planned to be located with a minimum of 500mm clearance from the existing stormwater main to allow for construction tolerances associated with the piling. AC Stormwater has indicated that there is relatively low risk to the existing stormwater main as a result of construction, as the existing asset is being decommissioned at the completion of the project. Piling shall continue beyond the depth of the existing stormwater main to ensure loads are transferred to the ground below the pipe rather than the pipe itself. Figure 7 illustrates the indicative piling details

2.3.3.3

The utilities identified at or around the Nikau Street shaft and their associated actions are summarised in Table 5 and Figure 11 below. Utilities shown in orange are likely to be protected, while utilities shown in blue are likely to require removal or diversion around the excavation works. Proposed stormwater assets are shown in green. For further information refer to the detailed design report and drawings.

The utility relocation across Nikau Street will be separated into two parts which will be completed at different times to ensure that there is at least one lane open on Nikau Street at all times. All traffic effects from these works are (including any temporarily lane closures/reductions) are addressed within the TAPDWP (Appendix D). Any noise effects from these works will be addressed in the CNVDWP (Appendix E).

Asset

Stormwater Possible stormwater connections at shaft New/diversion

Wastewater 600mm dia combined system

150mm dia. wastewater

Potable Water Huia No. 2

150mm dia. cast iron

Gas

300mm dia. 0kPa steel duct (identified in Minor Utilities Assessment, not identified on BeforeYouDig)

MP4 32mm PE through 75mm CI duct

Vector electricity Not identified at this stage

Chorus 2/100mm P

Minor communications Not identified at this stage

2.3.3.3.1 Protection of Huia No. 2

Protect

Protect

Protect

Divert around shaft within Nikau Street

Protect

Divert around shaft within Nikau Street

N/A

Divert around shaft within Nikau Street

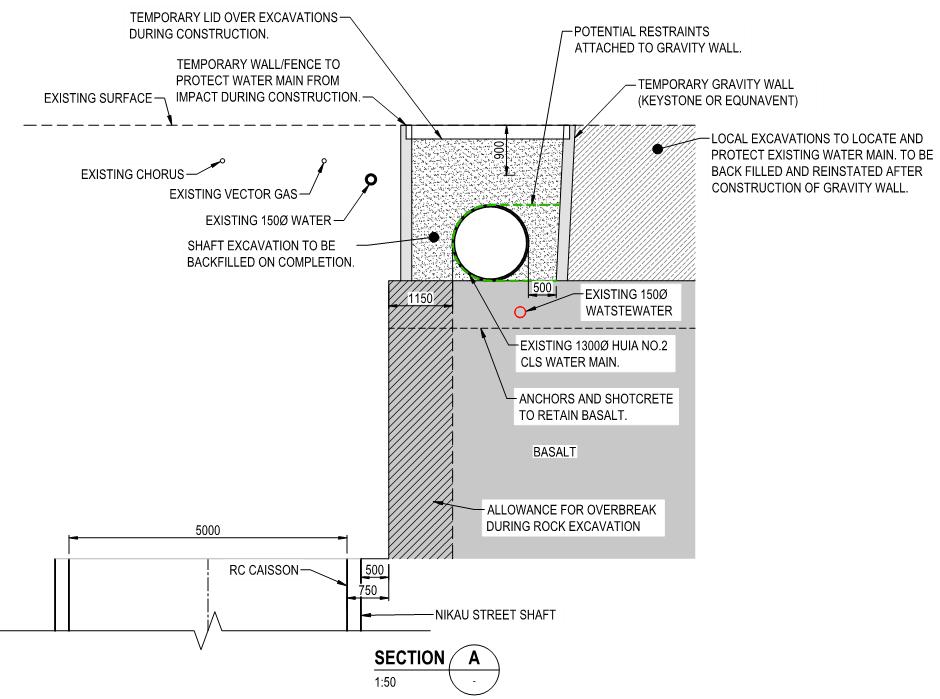

N/A

The Huia No. 2 water main is a 1300mm diameter Concrete Lined Steel (CLS) trunk water main which is a critical piece of infrastructure in Watercare’s trunk supply network. It is proposed to physically locate the existing Huia No. 2 Water main on site prior to commencing construction. Once located, the existing pipe will be carefully exposed over a length of 4-5 metres using hand digging and hydro excavations to prevent any damage. Once exposed it is proposed to construct a temporary gravity retaining wall (keystone block or equivalent) on the street side of the existing main, and reinstate the existing berm and carriageway to the back of the retaining wall.

A temporary fence (or similar) will be erected on the shaft side of the water main, with a solid cover placed over the main supported by the two walls to protect it from disturbance during shaft excavations and from the lowering of equipment into the shaft. Temporary restraints may be attached from the existing main to the new gravity wall to restrict any unintended movement of the main during construction. These protection details are illustrated in Figure 8 below.

Once the protection works outlined above have been completed the remainder of the shaft excavations will commence. Rock breaking will be undertaken to the basalt below and adjacent the existing water main. Rock breaking is likely to involve chemical fracturing and rock picking and will not involve blasting. A 1.15m allowance from the face of the excavations to the edge of the existing main has been conservatively allowed for any overbreak that might occur during excavations.

Early engagement with Watercare regarding the Huia No.2 Water Main and the protection details outlined above have indicated that the protection methodology outlined above is acceptable in principle. A Works Over Application will be submitted to Watercare along with the final design details for approval. Inspections of the water main pre, during and post construction (if required) will be agreed with Watercare as part of the Works Over Application.

Damage during construction must be prevented due to the critical nature of this asset. It is considered that the protection methodology outlined above along with ongoing consultation with Watercare is sufficient to manage the risk of damage to this asset during construction.

Left - Existing situation with services to be protected and/or removed Right - Ultimate situation showing the existing services to remain and the new services

Each shaft has individual set up requirements and layouts Shaft construction methodology for each of the three sites is outlined below.

The Mt Eden site is a sloping site An alternative site access for construction of the Mt Eden Road shaft and 28 Mt Eden Road will be established. The site needs to be excavated to make it sufficiently level for the construction of the shaft to commence. This requires lowering the ground level to the top of the access shaft level The indicative site layout is illustrated in Figure 13.

The site establishment and shaft construction at the Mt Eden Road site will generally follow the below sequencing:

1. Establish environment controls (as outlined in Sub-Plans), traffic management and site fencing.

2. Construction of a vehicle access ramp from Mt Eden Road down to the rear of 28 Mt Eden Road. This may include the relocation of services to 28 Mt Eden Road along this temporary access ramp.

3. Excavation of the site down to a level platform at the height of the finished access chamber.

4. Installation of fencing between the railway and the site once the top of the shaft has been reached.

5. Installation of the casing for the access shaft.

6. Excavation of the shaft and installation of supports as the appropriate. Once the base level of the shaft is reached the base slab will be installed.

7. Construct the permanent works including a mined link to the new stormwater main.

8. Once complete the shaft will be backfilled

9. Complete the access chamber internally

10. Complete the associated stormwater manhole and connection including cut in and dropper.

Once the building at 16–18 Ruru Street is removed the CSA can be established on top of the building foundations. The site establishment and shaft construction at the Nikau Street site will generally follow the below sequencing:

1. Establish environment controls (as outlined in Sub-Plans), traffic management and site fencing.

2. Connecting to services (water and power) to facilitate construction. Establishing site offices, toilet and Smoko facilities for staff.

3. Locate and protect Huia no.2 water supply main (refer to Section 2.3.3.3.1 for further details).

4. Excavate down to basalt level and install fill retention gravity walls

5. Pre-split and excavate basalt layer.

6. Install ground support rock bolts and shotcrete as required to stabilise basalt.

7. Install reinforced concrete ring beam to support jacks. Excavate down and push caisson down as excavation progresses to rock level.

8. Excavate remaining section of shaft below rock level installing ground support rock bolts and shotcrete as required.

9. Install base slab.

10. Carry out any strengthening to shaft wall for TBM reception

11. Receive the TBM driven from the Water St Shaft and remove from shaft

12. Install canopy tubes for mined tunnel connection.

13. Mine tunnel from base of shaft to existing pipe/shaft installing ground support ground support as mining progresses.

14. Construct permanent concrete chamber at base of shaft to connect the mined pipe to the driven pipe including a riser and dropper.

The Water Street CSA is relatively flat and requires little re-contouring to make it suitable for the construction of the Water Street shaft. The Water Street site is to be used to store the construction materials, pipe and provide some contractor parking.

The site establishment and shaft construction at the Water Street site will generally follow the below sequencing:

1. Establish environment controls (as outlined in Sub-Plans), traffic management and site fencing.

2. Connecting to services (water and power) to facilitate construction. Establishing site offices, toilet and smoko facilities for staff.

3. Locate and protect existing stormwater main (refer to Section 2.3.32.3.3.2.1 for further details).

4. Install ground improvement/soft piles around stormwater main and mined section.

5. Installation of the secant pile wall.

6. Excavate shaft to the existing stormwater main invert level, installing walers as required.

7. Install canopy tubes and necessary strengthening to the mined tunnel portal within the shaft.

8. Recommence excavation of the shaft and installation of supports as the appropriate levels are reached. Once the base level of the shaft is reached the base slab will be installed.

9. Install jacking frame in shaft and surface equipment in preparation for the tunnel boring phase.

10. Launch TBM and carry out drive to Nikau Street shaft (see Section 2.3.4.2).

11 Construct permanent concrete chamber, access stair and chute within the shaft and permanent lining for the connecting tunnel up to the mined connection level.

12 Break through secant pile wall and mine tunnel to expose existing stormwater main, installing ground support as mining progresses

11. Complete permanent lining of the mined connection to the existing main and make final connection

12. Complete construction of the permanent concrete chamber, access stair and chute within shaft.

Due to the depth of the existing stormwater main it is proposed to install the realigned main using pipe jacking, a trenchless installation method where pipes are driven horizontally between two vertical shafts using a tunnel boring machine (TBM) (Figure 12). Pipe jacking operations will be powered from a fixed electrical power supply from Vector or using diesel powered generators

Pipe jacking has a number of environmental benefits over open cut construction due to the reduced surface interaction required for this method.

The TBM has a rotating cutting head to excavate the ground and is pushed into the ground with a hydraulic jacking frame set up in the launch shaft ( Water St Shaft). As the TBM progresses forward sequential sections of pipe are lowered into the jacking frame and pushed forward behind the TBM. Intermediate jacking stations will be used on the drive to assist with overcoming friction forces on the pipe.

At the front face of the TBM cutter head is a chamber filled with slurry which combines with the excavated material and is pumped out of the tunnel. This slurry mix is primarily bentonite, water and a small amount of additives. These additives are dependent on the ground condition discovered at the site and are yet to be confirmed.

The slurry mix is pumped out through the tunnel to a separation plant located at the top of the launch shaft. The separation plant removes the excavated material from the slurry. The slurry is then pumped back into the tunnel and reused.

The TBM excavates an area slightly larger than the stormwater pipe (creating approximately 25mm gap) to allow enough space for pipe installation. This gap will either be closed by the ground or filled with grout.

2.3.6 The Project involves a single drive which starts at the launch shaft (Water Street Shaft) and ends at the Nikau Street shaft. Mined

A short section of mined tunnel is required at each of the Water Street, Mt Eden Rd and Nikau Street shafts to connect the new section of pipe into the existing pipe network. This involves excavating the mined tunnel from within the shaft and installing ground support as the excavation progresses. Ground support includes canopy tubes installed above the tunnel crown to reinforce the ground and prevent collapse and rock bolts/steel sets and lagging and/or shotcrete to support the tunnel excavation. A permanent tunnel lining is constructed from cast insitu reinforced concrete.

2.3.6.1

For this section the material encountered is likely to be predominately sandstone/mudstone rock (unweathered East Coast Bays Formation (ECBF)) with a short section of softer ground consisting of residual/weather ECBF, Tauranga Group (TG) alluvium and volcanic ash at Water Street shaft location.

Based on the ground investigations the ground conditions at Water Street Shaft are very soft and susceptible to high consolidation settlement during shaft construction. The shaft has therefore been designed as undrained using a secant pile wall to limit settlement and ground water drawdown.

For the mined connecter tunnel ground improvement in the form of deep soil mixing and/or jet grouting is proposed to replace the soft ground with a cement filled pile (soft pile). This stiffens the ground allowing for less settlement and more favourable conditions for mining the tunnel. This also helps to reduce the permeability of the ground around the opening with the shaft further reducing the groundwater drawdown.

2.3.6.2

From Mt Eden to the Nikau Street shaft. The material encountered is likely to be predominately sandstone/mudstone rock (unweathered and weathered ECBF) at either ends of the drive with a short section of softer ground in the middle of the drive consisting of residual ECBF and TG alluvium. A section of hard rock (basalt) is expected to be encountered in the middle section of the drive.

The mined connector tunnel will be constructed to join the pipe into the existing stormwater main at Nikau Street. This is to avoid placement of the shaft in the road corridor.

The new pipe will then be joined to the existing stormwater main by cast insitu concrete connection.

2.3.7

Three GPT’s are required to be installed on Normanby Road (one) and Boston Road (two). These works will occur within the road corridor. All sites are relatively flat. Traffic management around these small work areas is outlined in the TAPDWP. The GPT installation will generally be carried out as follows:

1. Excavate around existing stormwater manholes, expose and protect utilities

2. Install shoring (sheet pile or similar)

3. Remove existing man hole

4. Install GPT, new manhole and connect with existing stormwater network

5. Backfill excavation and reinstate pavement

The approximate earthworks volumes for the three shafts and two tunnels are summarised in Table 6 below. All material will be stockpiled on site for a short period of time before removal off-site. All volumes are estimated in-situ with no allowance for bulking.

For further details around erosion and sediment control refer to the ESCP in Appendix C

Once the new stormwater pipe is complete, the new alignment can be livened. This occurs by breaking through into existing pipe to complete remaining permanent works. This final connection to the new alignment will be scheduled to occur during a period of low flows and when little rain is forecast. The retired pipe section can then be decommissioned. The three shafts can then be backfilled and the permanent CRL works constructed.

The Project is anticipated to take approximately 13 months to construct. To ensure construction works are undertaken as quickly and efficiently as possible, the construction sequence activities are performed in parallel, i.e. each shaft will be constructed simultaneously. The approximate timing of these main activities and how the different work fronts may progress within the construction period is shown in Table 7

Work Stages

Mt Eden Road Access Shaft

Nikau Street Shaft

Water Street Shaft

Pipe Jacking to Nikau Street Shaft

Demolition

Key

Site setup

(including utility diversion/protection)

Piling

(Mt Eden shaft and Water Street shaft only)

Demolition

Rockbreaking

(Nikau Street shaft only)

Shaft construction

Pipe Jacking

Permanent works and backfilling

The designation conditions require that a number of noise and vibration limits are adhered to which restrict noise and vibration generating activity to between 0700 and 2200 (designation conditions 31 to 35)

Works will generally be undertaken between 0700 and 1900 Monday to Saturday. Twenty-four hour working is proposed for all pipe-jacking works. If tunnelling was to stop overnight there is a risk that the TBM may become stuck before its end destination. This would require additional works to complete the Project and recover the stuck TBM. Twenty four hour continuous construction also provides benefits to the pipe jacking operation by reducing the effects of ground water loss and settlement. The twenty-four hour working during tunnelling is also required to reduce the overall duration of the works, which allows the CRL rail tunnel construction works to commence earlier.

The Project has three small Construction Support Areas (CSA) located around each of the three shafts at 26 Mt Eden Road and 28 Mt Eden Road (Mt Eden Road site), the corner of Nikau Street and Ruru Street (Nikau Street site) and at the end of Water Street in the Wilson carpark area (Water Street site).

Where possible in the CSAs, quieter site activities such as the site offices and storage areas are located on the periphery of the CSA which are closest to surrounding buildings and face externally to the rest of the construction site.

Sufficient space has been provided for at the Water St site for the stockpiling of spoil and pipe overnight. This will limit the need for vehicle access to the site during night works.

Mt Eden Road site 26 and 28 Mt Eden Road 3928m²

Nikau Street site Corner of Nikau Street and Ruru Street 900m² Water Street site End of Water Street in existing carpark 1500m²

Once all demolition, utility relocation and utility protection works are complete the Water Street, Nikau Street and Mt Eden Road sites can be established as CSAs. For all three sites this involves setting up the traffic management and site access (as described in the TAPDWP in Appendix D), erosion and sediment controls (as described in the ESCP in Appendix C) and fencing of the site. The CSA layouts are shown in Figure 13 - Figure 15 below.

Generally site security will be maintained by establishing temporary fences at the perimeter of the works. These may be anchored to or fixed into the ground where their location is critical (e.g. to eliminate fall risks). Gates will be provided at construction entry and exit points and these will be locked shut when the site is unattended. Site security will be located at each site entrance to prevent unauthorised persons from entering the site.

Fences and hoardings may become spaces for project information, decoration or artworks on the public facing sides while still shielding drivers from distraction. Where appropriate, opportunities for public views over the works through Perspex windows will be incorporated into hoardings and fences.

Security fences and hoardings will be inspected for integrity and graffiti as part of a weekly environmental inspection. A small quantity of paint will be kept on site to paint over graffiti rapidly. Construction Contractor will target painting over graffiti within 48 hours of identifying the problem (although this may take longer if it requires working at height).

The site will be inspected for litter via the weekly inspection form.

The Construction Contractor and AT will discourage graffiti by putting murals and project information on hoardings (where practicable) to avoid providing a blank canvas for graffiti.

This will be detailed in the Urban Design DWP which will be prepared as part of a subsequent Outline Plan of Works process for the CRL Main works The works on the three sites are programmed to be completed in February 2019. The sites will then be tidied and fenced. They will be made available for the main CRL construction works which will commence shortly after the Project is complete in early 2019. As such, the site will not be left vacant for sufficiently long to warrant them being made available for any other purpose.

The Water Street site will be returned to its original use as an informal parking area prior to the CRL construction works commencing. Manholes will be installed at Water Street and in the road corridor at Nikau Street to facilitate shaft access for operations maintenance purposes. Access to the Mt Eden Shaft will be via access to 28 Mt Eden Road.

This CEMP presents a framework of principles, environmental policy and performance standards as well as processes for implementing appropriate environmental management. The methods for achieving this are presented in detail in the sections below.

Key construction activities associated with the Project include the construction of shafts and support areas and installation of the new stormwater main using pipe jacking

These activities have the potential to affect different aspects of the environment (e.g. traffic, noise). The Sub-Plans attached to this CEMP detail mitigation measures specific to the environmental aspect and detail further the construction activity which causes the potential effect.

Table 9 summarises key activities which occur in each stage of the project and possible sensitive receivers.

Table 9 Construction activities and receiving environment

Stage Main activity

Mt Eden Road shaft

Water Street shaft

Construction of site access

Earthworks to create CSA

Access shaft construction

Concrete base slab

Backfilling and installation of riser and dropper

Protect existing stormwater main

Installation of piles

Shaft construction

Backfilling and installation of riser and dropper

Receiving environment

Stormwater

Buildings (Settlement/Vibration)

Residents/Businesses (noise/vibration)

Traffic network

KiwiRail corridor

Stormwater

Buildings (Settlement/Vibration)