JUNE/JULY 2025 • JUIN/JUILLET 2025 MAGAZINE.CIM.ORG

JUNE/JULY 2025 • JUIN/JUILLET 2025 MAGAZINE.CIM.ORG

FLS ARMOUR™ Mill Liners are engineered for reliability, durability and performance, while being optimised per your milling needs and goals. We have North America based manufacturing capabilities and mill lining experts to support our customers and ensure our technology delivers.

But FLS is more than just a parts supplier, we partner with our customers throughout the lifecycle of the technology. This includes performing 3D scanning, wear reports and much more to maintain positive consistency for your mill’s throughput and product output. It is also

key to look into downstream processing after mill lining optimisation, which only a full flowsheet OEM like FLS can do.

Partner with FLS today to maximise your milling performance and efficiency.

Read our blog around considerations after optimising your mill liners

42%

consider vehicle electrification as having the greatest potential to increase efficiency and sustainability of mining operations

plan to invest in the decarbonization of their haulage fleet by 2026

68%

plan to electrify at least 25% of their fleets by 2030

More than 400 executives from mining companies globally were surveyed and agree that the time to act is now. To achieve safe and sustainable mining operations while developing a proficient and productive workforce, the shared sentiment is that automation, electrification, and digitalization are essential to future operations. Read their perspectives and how they plan to evolve their operations in our latest ESG report.

https://new.abb.com/mining/campaigns/mining-moment

Every year, CIM Magazine profiles a collection of individuals who are making a significant impact on Canada’s mining sector in different ways, whether through cutting-edge research and development, strengthening Canada’s supply chain of critical minerals or championing Indigenous engagement and participation in the industry.

By Graham Chandler, Ashley Fish-Robertson, Lynn Greiner, Sara King-Abadi, Alice Martin, Tijana Mitrovic, Kelsey Rolfe, Mehanaz Yakub

High-performing, reliable communication networks are enabling the next era of autonomously controlled machinery in mines

By Mehanaz Yakub

How a mine on a remote island off B.C.’s coast began supplying iron ore to Japan’s booming steel industry in the 1960s

By Ailbhe Goodbody

12 A powerful performance Compiled by Ashley Fish-Robertson

13 New closure guide

By Kelsey Rolfe

24 A safety shift

By Ashley Fish-Robertson

Columns

26 Only using price-weighted equivalent grade suggests that all the metals are equally recoverable, equally payable and equally marketable

By Vanessa MacLean and James Whyte

28 Why lithium needs more than hype to power the future

By Sasan Maleki

Indigenous participation in mining

29 Three Fires Group is paving the way for Indigenous involvement in Ontario’s growing battery sector

By Ashley Fish-Robertson

AI in operations

31 Computer vision is seeing new potential for safety and productivity in mining By Rosalind Stefanac

33 Mauricio Vega of Weir Group understands that mining’s adoption of artificial intelligence will not happen overnight, but he sees its potential to transform operations and create value in the processing plant

By Mehanaz Yakub

CIM news

47 CIM CONNECT 2025 wrap up

48 Maintenance, Engineering and Reliability Society of CIM scholarship honorees

48 Upcoming CIM events

49 We are profiling CIM-Bedford Canadian Young Mining Leaders Award winners to learn how they are giving shape to the future of the industry. First up, meet Hannah Lang

By Tijana Mitrovic

50 This year’s Metallurgy & Materials Society of CIM Award winners

Contenu francophone

51 Table des matières

51 Lettre de l’éditeur

52 Mot de la présidente

Article de fond

53 Les noms à connaître

Chaque année, nous dressons le profil d’une série de personnes qui ont un impact significatif sur le secteur minier canadien de différentes manières, que ce soit par la recherche et le développement de pointe, le renforcement de la chaîne d’approvisionnement du Canada en minerais essentiels ou la promotion de l’engagement et de la participation des autochtones dans l’industrie.

Par Graham Chandler, Ashley Fish-Robertson, Lynn Greiner, Sara King-Abadi, Alice Martin, Tijana Mitrovic, Kelsey Rolfe, Mehanaz Yakub

Montreal | Nov. 4-6, 2025

This Year’s Conference Chairs Register Now. Advance your next mine project.

The only global event dedicated entirely to mining projects—from concept to execution.

As much as this industry is concerned with industrial processes, we have been shown in so many ways that it is very much animated and inspired by its people.

We can see how keenly interested our network is in the photo galleries generated by the daily happenings at CIM CONNECT.

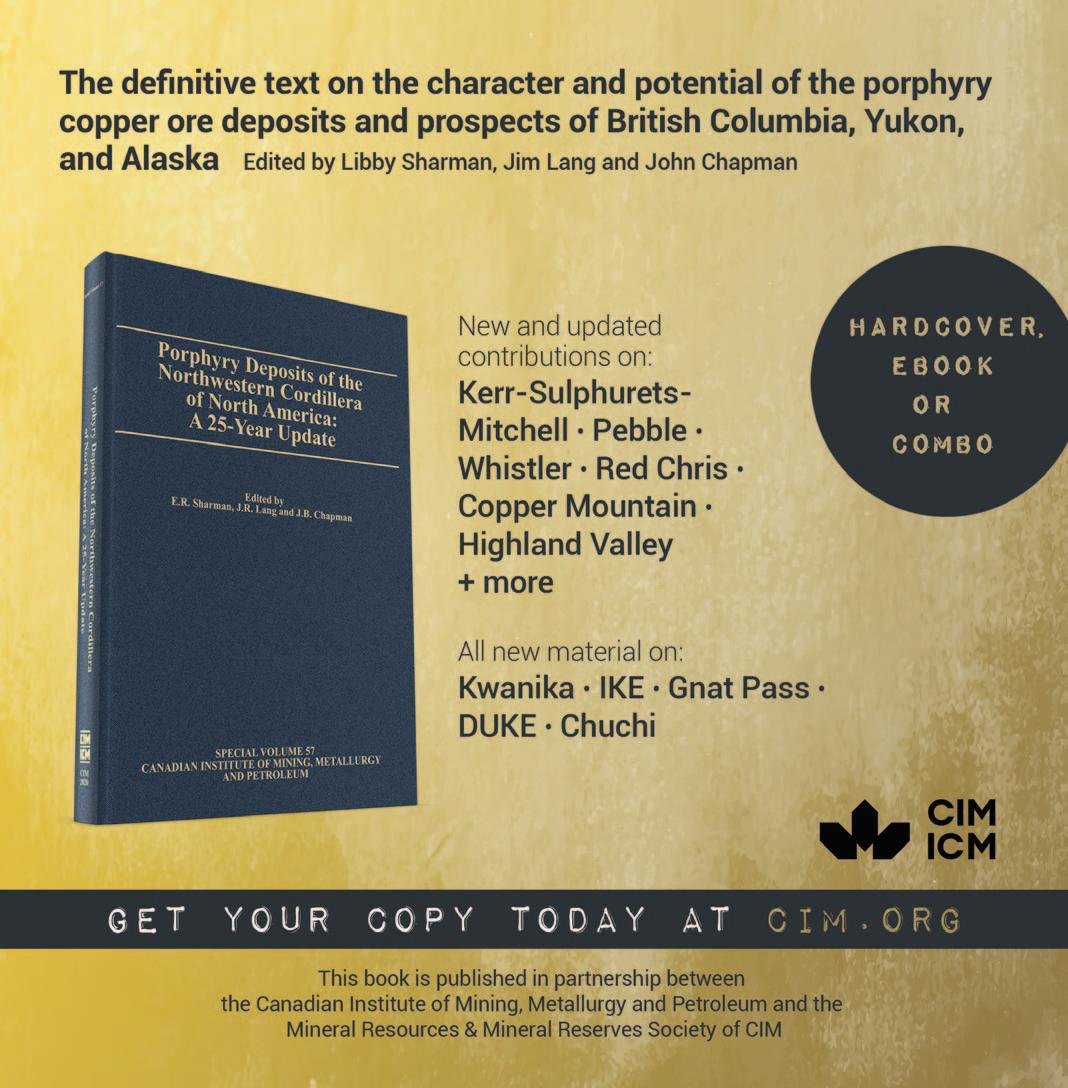

The Institute’s social media engagement also blooms when we have the opportunity to post images from branch and society events.

That data from our newsletters tells us the same: readers want to see the people behind the stories.

CIM Magazine’s annual “Names to know” feature (p. 35) gives us the opportunity to really lean into this. This year, we have profiled nine individuals whose efforts are directed at challenges from mineral exploration to policy execution to metallurgical innovation.

Those who we feature are not selected by hard and fast quantitative criteria. It is more that they rise to the surface in a flotation process determined by a combination of current events, industry trends and serendipitous discoveries. We hope that, together, these people and their stories sketch out the character of our sector at this moment, and the direction it is heading.

I would also like to bring to the surface the names of the magazine’s editorial team whose work was recently nominated for four different National Magazine Awards in the business-tobusiness category.

Congratulations to Senior Editor Ailbhe Goodbody, whose three stories by Mehanaz Yakub, Trish Saywell and Lynn Greiner that took varied lines of inquiry into the subject of environmental monitoring were considered among the best editorial series.

Special Projects Editor Silvia Pikal’s timely eight-part series “Mining and Mental Health,” which ran throughout 2024, was

Editor-in-chief Ryan Bergen, rbergen@cim.org

similarly recognized as among the best regularly featured editorial. In addition, the story she and past CIM Magazine intern Alice Martin developed on work being done to place qualified female mining engineers from Chile into Canadian operations got a nod for the best diversity, equity and inclusion reporting.

And finally, our ritual, the CIM Magazine weekly mining news recap—which our staff writer, Ashley Fish-Robertson, weaves together into a polished newsletter every Friday— earned recognition as among the best editorial newsletters.

Behind it all is Michele Beacom, our managing editor, who injects her wisdom as needed and shepherds us from one deadline to the next.

Delivering top-notch material does not come easy, both for the wrinkles that need to be smoothed out on the page and the many struggles that present themselves outside of work life.

In general, the success of an editor’s work is measured by the attention it does not draw to itself. It is the errors and oversights that generate the immediate feedback. So, congratulations to the CIM Magazine team for the richly deserved recognition.

Ryan Bergen, Editor-in-chief editor@cim.org

Managing editor Michele Beacom, mbeacom@cim.org

Senior editor Ailbhe Goodbody, agoodbody@cim.org

Special projects editor Silvia Pikal, spikal@cim.org

Staff writer Ashley Fish-Robertson, afrobertson@cim.org

Contributors Graham Chandler, Lynn Greiner, Sara King-Abadi, Vanessa MacLean, Sasan Maleki, Alice Martin, Tijana Mitrovic, Kelsey Rolfe, Rosalind Stefanac, James Whyte, Mehanaz Yakub

Editorial advisory board Mohammad Babaei Khorzhoughi, Vic Pakalnis, Steve Rusk, Nathan Stubina

Translations Karen Rolland, karen.g.rolland@gmail.com

Layout and design Clò Communications Inc., communications.clo@gmail.com

Published 8 times a year by: Canadian Institute of Mining, Metallurgy and Petroleum 1040 – 3500 de Maisonneuve Blvd. West Westmount, QC H3Z 3C1 Tel.: 514.939.2710; Fax: 514.939.2714 www.cim.org; magazine@cim.org

Advertising Senior Account Executives Marlene Mignardi, mmignardi@cim.org, 416-843-1961 Dinah Quattrin, dquattrin@cim.org, 416-993-9636

Subscriptions

Online version included in CIM Membership ($215/yr). Print version for institutions or agencies – Canada: $275/yr (AB, BC, MB, NT, NU, SK, YT add 5% GST; ON add 13% HST; QC add 5% GST + 9.975% PST; NB, NL, NS, PE add 15% HST).

Print version for institutions or agencies – USA/International: US$325/yr. Online access to single copy: $50.

Copyright©2025. All rights reserved.

ISSN 1718-4177. Publications Mail No. 09786. Postage paid at CPA Saint-Laurent, QC.

Dépôt légal: Bibliothèque nationale du Québec. The Institute, as a body, is not responsible for statements made or opinions advanced either in articles or in any discussion appearing in its publications

Printed in Canada

Explore topics like predictive maintenance, advanced automation, decarbonization strategies, and workforce innovation. Join us for 3 days of keynotes, technical sessions, and expert insights. Connect with industry leaders and shape the future of mining.

1-3,

At the CIM CONNECT conference in May, many people asked me how I ended up in the mining industry. The simple answer is that my early career opportunities were offered by Inco Ltd. However, that answer doesn’t capture why I remained in the industry, seeking further roles as my career progressed, nor why I am so passionate about Canada’s pivotal role in the energy transition.

The fulsome answer is the people. Interaction with the incredible and diverse workforce is the secret behind my rewarding career in the resource sector. The people who work at the corporate office, the people who work at the mines, the people who work supporting the supply chain, the service providers. The people who live and work in the communities we operate in and the many lives that are impacted by the materials we produce and the income those people earn. People are the face and heart of this industry, not pictures of open pits or large haul trucks.

The resource industry is facing unprecedented challenges— the regulatory breakdowns, lack of available capital, talent shortages and negative public perceptions are merely a few. However, we are also at the beginning of a renaissance opportunity, with governmental agencies and world leaders understanding that extractive industries must play a leading role in the energy transition, supplying critical minerals to build renewable energy generation, storage, transmission and carbon-free transport systems.

The industry has a role to play in identifying and addressing the issues we face. The question I have been contemplating for years is how. How do we come together to collaborate on a large scale to identify the issues and problem solve? How do we facilitate and

People are the face and heart of this industry, not pictures of open pits or large haul trucks.

support ensuring the appropriate experts are in the room together working on the right agenda?

ChatGPT told me “A great leader isn’t just someone with authority—they inspire, guide and empower others to achieve a common vision.” The industry and CIM members have a common vision to sustainably and responsibly produce the materials required as we transition to a carbon neutral future. CIM is a collection of people who are leaders, who inspire, guide and empower every day.

My question to each of our members is simple, yet incredibly complex. How do we collate and solve the issues the resource industry faces at a large scale? If we can do this effectively, we will be the leaders the world needs right now and we will attract the younger generations to this industry.

Branches and societies by their very design are set up for collaboration and to identify issues facing the industry within specific areas and across disciplines. How do you, as members, see us working together to identify and tackle broad issues?

I want to hear from you on this topic as it is my belief that this organization has the collective knowledge and experience to change the world. Please send me an email at president@cim.org if you have any thoughts on how we may effectively collaborate together across disciplines and borders. I no longer want us to run the individual 400-metre hurdle event. I want us to be in the final heat of the highly anticipated 4 x 100-metre relay event— which I will point out that Canada won at last year’s Olympics, defying all odds.

This is how we, as resource professionals, will be successful leaders in 2025: by working together.

Candace MacGibbon President, CIM president@cim.org

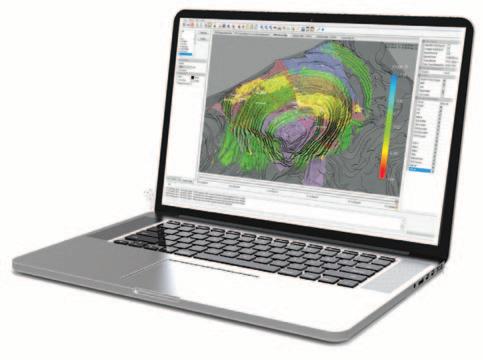

Metso recently introduced its Sustainable Flowsheet Explorer (SFX), a digital solution designed to streamline the complex assessment of mineral processing flowsheets. The SFX allows users to assess, simulate and compare various technological alternatives within a flowsheet, delivering useful insights into energy consumption, water usage, greenhouse gas emissions, operating costs and metallurgical performance. Evaluating technological options for a flowsheet, which traditionally takes weeks, can now be accomplished in minutes. The SFX brings together key performance indicators into one unified web-based platform, delivering visualizations of the results that can support informed decision-making.

HAIP Solutions recently launched its BlackIndustry 1.7 Pro Max Sensor industrial in-line scanning hyperspectral imaging camera, which features an ultra-high spatial resolution of 2,560 pixels and a short-wave infrared range of 900 to 1,730 nanometres. The ultra-narrow five micrometre slit enhances spectral resolution, enabling users to detect previously unidentifiable mineral absorption features—which the company said is an essential capability, allowing for more precise material differentiation. The camera comes bundled with HAIP’s BlackStudio software, which supports advanced spectral analysis of acquired data. Additionally, the camera features an integrated graphics processing unit for on-camera classification.

Compiled by Ashley Fish-Robertson

ABB’s recently launched GMD Co-Pilot, an artificial intelligence-powered digital solution that can improve the operation and maintenance of gearless mill drives (GMDs) by providing operators with real-time, accurate insights into operational data, which could include maintenance recommendations or interpretation of technical documentation related to GMDs. It is designed to improve decision-making, troubleshoot potential future maintenance issues and prevent equipment failures that could lead to unexpected downtime and increased maintenance costs. The solution, which can be fully integrated with the company’s GMD Connect cloud platform, features a multilingual interface that is easy to navigate, allowing users to ask questions in natural language.

Compiled by Ashley Fish-Robertson

To kick off the opening plenary at the 2025 CIM CONNECT Convention and Expo on May 5

(continued on page 13)

in Montreal, musician and dancer Samuel Ojeda took to the stage at the Palais des congrès dressed in black and gold ceremonial attire to deliver a terri-

torial acknowledgment, followed by a powerful flute and drum performance. Ojeda, born in northwest Mexico and part of the Tahue Clan of the Yoreme

Nation, now resides in Montreal. This year’s CIM CONNECT shattered previous records, with 7,601 participants in attendance. CIM

ICMM aims to provide “recipe book” for successful socio-economic transitions in mining

By Kelsey Rolfe

Last spring, migratory caribou returned to a part of Rio Tinto’s Diavik diamond mine in the Northwest Territories that the animals had previously had trouble accessing. As part of its progressive reclamation, the North Country Rock Pile was re-sloped into a shape similar to an esker, a notable landscape feature in the area; the pile’s gentle shape made it easier for caribou to navigate.

It was the recommendation of Diavik’s traditional knowledge panel, a group of representatives from each of the Indigenous communities with whom the company has participation agreements in the Lac de Gras area where the mine is located. The panel has met 15 times since 2011 and made more than 250 recommendations that have informed the company’s closure planning. Once the site ceases operations next year, the panel will transition to a post-closure traditional knowledge monitoring program.

“The focus will shift from informing our designs and our approach to postclosure monitoring, and how we’re meeting our cultural use objectives as part of our closure performance,” said Gord Stephenson, Diavik’s senior manager of surface operations and closure, in an interview with CIM Magazine.

Diavik’s traditional knowledge panel features in a new ICMM handbook, released in May, aimed at helping mining companies, communities and stakeholders plan for closure and the post-mining socio-economic transition.

Mining companies have long been seen as responsible for leading all aspects of closure, including communities’ socio-economic transitions. However, the handbook promotes a shift from company-led transition models towards multistakeholder ones that give local communities, governments, Indigenous groups and civil society far more say in their post-mining future and see miners

take non-central roles such as conveners, financiers or capacity-builders.

“You can equally find examples of where mining projects have changed the lives of communities for the better and of where that hasn’t been the case—or maybe it’s been the case for the duration of the project, but afterwards that benefit has either not been sustained or has actually resulted in a worsened situation for communities,” said Danielle Martin, ICMM’s co-chief operating officer and director of social performance.

Martin noted that particularly for rural and remote communities, mining projects have often enabled the development of, or greater access to, telecommunications, utilities, health care, schools and community-wide wealth creation. However, when transitions fail, former mining towns are left with social, economic and environmental scars.

Multistakeholder transition approaches offer several benefits, the handbook states, including greater clarity for communities about future changes in mining activity and their implications, better decision making, and giving stakeholders who “will live with post-mining legacies” more of a voice in the process.

The handbook is part of ICMM’s ongoing community resilience program, which delves into the skills and capabilities communities and other stakeholders need in order to ensure that they reserve lasting benefits from mining. Martin said that ICMM heard overwhelmingly from members that they wanted to see a focus on transitions, given the lack of existing research, case studies or guidance on the topic.

“It’s complex. It takes a long-time horizon and requires the input of a lot of actors and fundamentally needs mining companies to step out of the middle of

the circle, where they’re in control of something,” Martin said.

ICMM formed expert working groups of member companies and partnered with the Cooperative Research Centre for Transformations in Mining Economies in Australia.

The handbook presents nine multistakeholder models for socio-economic transitions. The models include more traditional and smaller-scale collaborative efforts such as mine closure consultative groups and monitoring committees. It also includes innovative approaches such as land and asset trusts that miners either set up or donate reclaimed mine lands to, or post-mining joint ventures, such as Teck Resources’ SunMine solar farm on the former Sullivan mine site in Kimberley, B.C., which ceased operations in 2001.

The report also highlighted regeneration or development coalitions, collaborative regional planning processes and social investment transition foundations as other potential partnership models.

While Martin said that ICMM had hoped to come up with something of a “recipe book” for successful socioeconomic transitions, she noted that a range of context-specific factors—such as a community’s physical proximity to, and level of economic dependence on, the mine, whether workers are predominantly locals or fly-in-fly-out, the existence of a diversified local economy—will all influence what an ideal transition looks like.

The report said communities that experience socio-economic success postmining do have a few things in common, including a clear vision for their future, an ability to harness place-specific aspects such as natural landscapes or infrastructure to their benefit, and support from external parties.

Having enough time and information to prepare in advance was also a crucial factor. The guidance recommends companies begin transition planning as early as possible and proactively share more information with stakeholders than they have typically done in the past.

“These processes do take time, but as long as the process is initiated early enough, there’s a lot of value to be gained,” said Stephenson. “Mining can’t happen in isolation. Recognizing that mining does have an end and having that early engagement allows time for different perspectives to be heard and incorporated into the outcome.”

While the handbook acknowledged some mines are in operation for decades and it is difficult to plan that far ahead, Martin said it is possible to do some initial “visioning” in the early stages and slowly add more “flesh on the bones” as the years pass.

While Martin said multistakeholder approaches were more likely to lead to successful transitions, she noted they are also far more complex.

The handbook pointed out that these approaches can be hamstrung if stakeholders are not afforded enough time or given enough information in advance, as well as by any existing trust issues or conflict among local stakeholders that makes them unwilling to participate. Mining companies themselves may struggle with their lack of control over the planning process. The report also pointed out that declining resourcing

levels towards the end of a mine’s life, and employee turnover during that time, can create additional challenges.

Tara Marchiori, Diavik’s manager of communities and social performance, noted one challenge that the company worked through was ensuring that the right community representatives, with the right level of expertise and community support, were at the table, and that there was continuity in community participation.

At Diavik, Stephenson said that the panel’s recommendations influenced how the company plans to reconnect the mine operations to Lac de Gras, revegetation plans and waste rock pile design. The multistakeholder approach, he said, “really creates a sense of ownership with communities as well, because they had an integral part in developing the plan.” CIM

B.C.-headquartered Anfield Energy announced on May 27 the approval of its Velvet-Wood uranium and vanadium project in southeastern Utah. The environmental review for the project was completed by the federal Bureau of Land Management within 14 days, as demanded by the Trump administration.

The U.S. Department of the Interior first shared on May 12 that it planned to expedite the environmental permitting process for the project, supporting U.S.

President Donald Trump’s push to increase domestic energy production. The company had submitted the plan of operation for approval in May 2024.

The project is the first uranium project to be expedited by the U.S. government under Trump’s newly established emergency permitting procedures, announced in April, to speed up the environmental review process for domestic energy projects.

“We are very pleased that the Department of the Interior has greenlit our Velvet-Wood project in an expedited manner,” said Corey Dias, chief executive officer of Anfield Energy, in the May 27 press release. “This confirms our view

that Velvet-Wood was well-suited for an accelerated review, given that it is a pastproducing uranium and vanadium mine with a small environmental footprint. The company will now pivot to advancing the project through construction and, ultimately, to production.”

Anfield Energy also owns the shuttered Shootaring Canyon uranium mill in Utah, located around 180 miles from the Velvet-Wood mine area, which the company plans to restart to convert uranium ore from the Velvet-Wood project into uranium concentrate. The mill was built in 1980, operated briefly in 1982, and has been under care and maintenance since then. According to the company, the mill is one of only three licensed, permitted and constructed conventional uranium mills in the United States.

The Velvet-Wood project was acquired by Anfield Energy from Uranium One in 2015. Prior to that, Atlas Minerals—its previous owner—mined approximately 400,000 short tons of ore from the Velvet deposit, with grades of 0.46 per cent uranium oxide and 0.64 per cent vanadium pentoxide, recovering

about four million pounds of uranium oxide and five million pounds of vanadium pentoxide between 1979 and 1984.

A 2023 preliminary economic assessment from Anfield Energy estimated the capital expenditure to bring the VelvetWood mine and Shootaring mill into production would be US$80 million.

– Ashley Fish-Robertson

The future of Barrick Mining Corporation’s Loulo-Gounkoto mine remained in doubt as of June 3 press time. In mid-April Mali’s military junta closed the company’s national office in Bamako, the country’s capital, and threatened to expropriate its Loulo-Gounkoto gold complex unless operations resumed and tax payments were made—marking the latest escalation in a long-running dispute.

The company confirmed that an agreement had been negotiated and accepted by the Malian government in

February, appearing to offer a potential resolution to a nearly two-year-long conflict over the Loulo-Gounkoto gold complex, a major earner in the country—the company said in a Dec. 16, 2024, statement that Barrick generated over US$1 billion for Mali’s economy in 2023.

However, in an April 15 press release, the company stated that while it has signed the agreement, the Malian government has failed to execute it. The company added that the agreement appears to be “obstructed by a small group of individuals placing personal or political interests above the long-term interests of Mali and its people.”

Under the terms of the deal, Barrick agreed to pay about US$438 million to Mali. In return, the company’s detained employees would be released, seized gold would be returned and operations at Loulo-Gounkoto would resume. The company noted in the April 15 press release that it paid US$85 million to the government in October 2024 as part of a framework to resolve the dispute.

The company stated that it remains committed to finding a constructive

January 2023

Mali announced a review of its mining code following a sector-wide audit conducted in 2022, which it said revealed that the country, one of Africa’s largest gold producers, was not receiving a fair share of profits stemming from mining projects. While the revised mining code was initially meant to apply only to new contracts, the government has increasingly sought to renegotiate existing agreements.

Barrick reported that it received a draft report containing preliminary findings from Mali auditors who visited LouloGounkoto in November 2022. Mali asserted that Barrick owed back taxes and should comply with the updated mining code. During the second quarter of 2023, the company responded to the report to challenge the auditors’ findings, which Barrick remarked were “legally and factually flawed.”

Aug. 8, 2023

The revised code was implemented, raising the state’s financial stake in mining projects, including LouloGounkoto. Under the new code, the local government is allowed a 10 per cent stake in mining projects, with the option to purchase a further 20 per cent stake within the first two years of commercial production.

Sept. 27, 2024

Malian authorities briefly detained four senior Barrick employees from LouloGounkoto on allegations of financial crimes.

Oct. 1, 2024

The four employees were released following the establishment of a tentative agreement between Barrick and Mali.

According to the U.S. International Trade Administration, gold is one of Mali’s most significant exports, accounting for over 80 per cent of the country’s total exports in 2023.

Nov. 25, 2024

The same four employees were later arrested and charged with unspecified offences and have been awaiting trial since then.

Dec. 5, 2024

It was reported by Reuters that Mali’s military junta issued an arrest warrant for Barrick Mining CEO Mark Bristow, accusing him of money laundering and financial violations. Reuters reportedly saw the warrant on Dec. 4, though the warrant may have been issued earlier. An arrest warrant was also issued for Cheick Abass Coulibaly, the general manager of Loulo-Gounkoto.

Dec. 16, 2024

Barrick shared that Mali’s military junta had blocked gold shipments from the complex.

Jan. 6, 2025

Barrick was restricted from shipping stockpiled gold from the complex.

Jan. 11, 2025

The local government seized around three tonnes of gold stocks, valued at around US$245 million, from the complex. The gold was then transferred to the stateowned Banque Malienne de Solidarité.

Jan. 14, 2025

Barrick decided to temporarily suspend operations at the site.

Feb. 3, 2025

Reuters reported that two former Barrick executives working in Mali were assisting the military-led government in pushing for approximately US$200 million in back taxes from Barrick.

Feb. 5, 2025

The Globe and Mail reported that Mali introduced a new mining law, which has garnered backlash from several mining companies operating in the country. The new law requires companies to divest a 35 per cent share of new projects to Malian investors, up from 20 per cent, and to increase royalty taxes from around six per cent to 10.5 per cent. Foreign-owned mining companies are concerned the move will deter investors.

April 25, 2025

Reuters reported that at least four subcontractors operating at the LouloGounkoto complex—together employing several hundred workers—were conducting layoffs.

May 8, 2025

The Malian government formally submitted a court request seeking to impose provisional administration over Loulo-Gounkoto.

May 26, 2025

Barrick shared that it was awaiting a June 2 ruling, since moved to June 12, on the Malian government’s request to place Loulo-Gounkoto under provisional administration—a move Barrick opposed as unlawful amid ongoing employee detentions and blocked gold exports— and that it continues to seek a fair resolution through dialogue and international arbitration while supporting its operations and workforce.

resolution but that it is also prepared to pursue international arbitration and legal action against the Malian government if necessary.

A Malian court was expected to rule in early June whether the Malian government could take control of the mine complex with the aim of having operations restart there. Approximately 578,000 ounces of gold were produced at LouloGounkoto in 2024.

Other companies with operations in Mali, such as B2Gold, have had more favourable dealings with the government. B2Gold was one of the first foreign mining companies to reach an agreement with Mali over the 2023 revised mining regulations. In September 2024, the company resolved an income tax dispute and agreed to adjust some of its exploration activities to comply with the new rules.

In contrast, Mali has been placing pressure on other companies to cough up more mining revenue. In November 2024, Mali detained Terry Holohan, then chief executive officer (CEO) of Resolute Mining, along with two other employees for nearly two weeks, until Resolute agreed to pay the local government US$160 million to settle a tax dispute. Holohan resigned as CEO in early February.

– Ashley Fish-Robertson

Rohitesh Dhawan, ICMM president and chief executive officer (CEO), delivered a keynote that preceded the May 5 plenary panel discussion at the 2025 CIM CONNECT Convention and Expo, which began by sharing examples from mine sites around the world that illustrate ethical leadership in the use of technology.

One such example he spoke about is the Los Bronces mine, an open-pit copper and molybdenum mine and plant located about 65 kilometres northeast of Santiago, Chile, that was first established in 1867 and has been operated by Anglo American for the last 40 years. It is one of the largest copper mines in the world, with two per cent of the world’s known copper reserves. During the mine’s technological transformation—about one third of its fleet is autonomous and it opened an integrated remote operating centre (IROC)

in Santiago in 2021—Anglo American committed to zero job losses from the shift.

“Automation can result in fewer workers,” Dhawan said. “Instead of seeing that as simply a cost of doing business, Anglo American thought of it differently. They committed not to make a single person involuntarily redundant as a result of the change to the integrated remote operating centre, and they stuck to that promise.”

He described how the company retrained people and reallocated them to new roles so that technology would not replace jobs. Furthermore, instead of expanding an existing centre that serves its El Soldado mine, which is 125 kilometres north of Santiago, it built a new IROC close to the mine to create local jobs.

He concluded by stating that such stories, “show us that as a sector, we have every reason to be proud and confident of our ability to mine with principles and to lead with purpose.”

Following the keynote, a panel discussion dug into the challenges and opportunities of deploying new technologies in the mining industry.

Moderated by Don Duval, CEO of NORCAT, the panel included Saskia Duyvesteyn, chief advisor of research and development at Rio Tinto; Jeff More, president and CEO of MineSense Technologies; Kimberly Keating, board director of Pan American Silver; and Eric Desaulniers, founder, president and CEO of Nouveau Monde Graphite (NMG).

Duval kicked off the session by asking the panellists: does the mining industry have an innovation problem, or an adoption and deployment problem?

Duyvesteyn said that innovation is where people, technology and processes or systems come together: “I think we have a tendency to really focus on that technology piece—how to invent it, how to develop it—but it’s that piece where it comes together with people, with systems; how do we use the technology? How are people going to interact with it? How does it change? I think that’s really where we start to see interesting things happen. Because once we have people interact with technology, we realize that it opens up so many opportunities that we didn’t know [about].”

More said that, while many mining companies are already integrating cutting-edge technologies into their operations, the industry has a history of being on the conservative side when it comes to innovation, due to the large investment required to bring in completely new or disruptive technology. “The rate of adoption is still a bit challenging in terms of how fast things can move forward,” he said.

Keating suggested that companies think about failing fast to push their company to implement new technologies. “I don’t think we have a problem with innovation in this industry; like many, I think it’s the integration and adoption of what will take us from now until the future,” she said.

“We like to say we have to treat data as an asset, and therefore you need to invest in those systems, just as much as you’re going to invest into your pumps. The best AI does not make up for poor data quality and poor data decisions.”

– Saskia Duyvesteyn, Rio Tinto

Desaulniers pointed out that it is challenging to be innovative with a greenfield project—like NMG’s flagship Matawinie mine, an open-pit graphite mine near the village of Saint-Micheldes-Saints, Quebec—as investors tend to be risk-averse.

“The word ‘new’, they don’t want to hear about it,” he said. “They want proven technology. You really need to pick your battles in terms of innovation when you develop a greenfield project. This is the reality we’re in—we want to innovate, but we first need to precisely understand in a commercial operation before changing [anything].”

The panellists also discussed the benefits and challenges that come with integrating artificial intelligence (AI) into mining operations. Duyvesteyn stated that AI should be used to help humans make decisions, creating what she called decision intelligence—which received hearty applause from the audience.

“We often think about AI making decisions, but when humans are using AI to make decisions, [that] is where you really get that shift,” she said. “Here’s a real chance for us to pivot and think about, how do we actually use [AI] going forward? Because that’s where the value comes from.”

Desaulniers agreed with Duyvesteyn, stating that, “I feel AI today is used when humans are sick of making the same decision. They want to automate a decision that they’re making so often that they get bored of doing it.”

Duyvesteyn added that while AI sounds exciting, it is important not to overlook investing into infrastructure and other critical aspects of a mine.

“It’s the shiny stuff, but we have to remember that [AI] is still built on that foundational data, the quality, the governance and the infrastructure, and that’s way less exciting,” she said. “We like to say we have to treat data as an asset, and therefore you need to invest in those systems, just as much as you’re going to invest into your pumps. The best AI does not make up for poor data quality and poor data decisions.”

The panellists also touched on how highlighting the fact that the industry, while it is an old one, is full of technological advancement and innovation could help to address mining’s labour gap. Duyvesteyn said that Rio Tinto brings its technology into schools, from K-12, to show that mining is a high-technology industry. The company also communicates how the mining industry is attempting to address its role in one of the biggest challenges of our time: climate change.

“For the upcoming generation, they want to think about these big-world problems. And we try to tell them mining is part of the solution,” she said.

Keating recommended that companies think about what skills will be needed in the workforce not just now but in the future. “What are the core skills that are going to be required to attract top talent in 2030?” she said. “They [will] look very different than what they did 15 years ago: Big data, AI, critical thinking.”

She added that while it is important to talk about the exciting things happening in the industry to attract younger talent, mining cannot lose sight of its existing workforce.

“Equally, I do think we have to be mindful of the fact that we also have a huge cohort within a lot of the companies that are from a different generation,” she said. “Trying to manage that as we introduce more technology, and making them part of the process, [is important] because we still need those people to be part of these mining operations.”

Desaulniers said that mining has “never been so sexy,” pointing to the fact that Prime Minister Mark Carney and U.S. President Donald Trump are constantly in the news talking about the importance of critical minerals, and that now is the time to seize on this heightened interest.

He added that it is crucial to engage with Indigenous communities, which could be an even greater part of the

workforce: “I think mining is closer to their heart. It’s closer to their community. We need to find a way to get all that untapped talent into mining. And if they want to be in tech in mining, there’s room. If they want to be driving a truck and mining, there’s room. If they want to do anything in the plant, there’s all sorts of skill sets. It’s our job to make it sexy.”

– Silvia Pikal

In the latest episode of The Safety Share webinar series from CIM Magazine and the CIM Health & Safety Society (HSS) on April 17, panellists explored how mobile phones and tablets are transforming connectivity, communication and safety in both open-pit and underground operations. From streamlining risk assessments to improving real-time collaboration, the discussion shed light on the benefits of implementing connected technology in mining operations.

The webinar was hosted by Jennifer Pakula, a senior engineer at Hudbay Minerals’ Lalor mine in Manitoba and an executive member of the CIM HSS. She was joined by a panel of industry experts, including Andrea Hine, product owner at Suncor; Brad Hofford, director of organizational development at Technica Mining; and Hamza Jaffri, senior mining engineer at Redpath Mining.

Hofford shared how Technica Mining’s use of Sofvie, a safe performance platform designed for mining operations, in underground operations, has improved transparency and visibility by allowing frontline workers to complete risk assessments through the platform and easily access and review digitized data. Hofford added that the platform also enables direct communication with superintendents and can proactively prompt actions from workers, such as dispatching a mechanic to a site, to address issues early on.

“We do all of our risk assessments, pre-ops, frontline risk assessments, investigations and hazard reporting on our system, and it’s easy and accessible to everyone in the organization,” he said. “I find it’s actually grown not only our capability with our safety systems, but

the quality of our safety activities has improved because of the visibility.”

For mining companies considering digital connectivity, he emphasized that while some tools work better than others, the success ultimately hinges on building a strong leadership and safety culture.

Hine also emphasized the importance of real-time connectivity for workers in surface mining. At Suncor, over 3,000 devices help frontline workers stay connected, with many field decisions now discussed through Microsoft Teams and other apps rather than over radio.

“We were pleasantly surprised with how many events we were able to get ahead of because workers had more courage and community with real-time collaboration,” said Hine.

Hine echoed Hofford’s sentiments about the importance of leadership in adopting new technology, noting that when Suncor first began rolling out digital connectivity—giving each worker their own device—she found herself coach-

in mining, removing the need for traditional radios and paper-based risk assessments, as discussed in the latest CIM Safety Share webinar.

ing the management team more than the frontline workers. She added that the workers were “hungry for change and feeling like they’re able to do more at work.”

“It’s been a massive campaign of coaching our leaders to treat our workforce with a certain level of trust and professionalism, and [our frontline workers have] risen to that challenge because they have the

BME’s AXXIS™ range – Silver, Titanium, and CEBS – delivers world-class electronic initiation trusted by mines across five continents.

Built for precision, safety, and sustainability, AXXIS™ empowers engineers and blasters to achieve consistent, high-performance blasts –even in the most demanding conditions.

• AXXIS™ Silver – Proven reliability for quarries and mid-sized mines.

• AXXIS™ Titanium – Advanced control with best-in-class safety and data capabilities.

• AXXIS™ CEBS – Centralised blasting with unmatched scale and efficiency. With AXXIS™, you don’t just initiate blasts –you initiate progress.

the full range at www.bmeexplosives.com

privilege of these connected devices,” said Hine. “Moreover, because we’ve taken this approach of trust, our workers are starting to innovate and give us feedback to make [it] more effective for them.”

Hine shared an example: some mine operators downloaded a free lightning strike app, and those crews are now more proactive in managing electrical storms instead of waiting for radio instructions to announce a pause in work.

Jaffri explained that during the tablet rollout at the Musselwhite gold mine in Ontario, where he currently works as a consultant for Redpath, much of the workforce was still using flip phones, and he admitted feeling nervous about how they would adapt.

“I was really surprised about how open and how welcoming they were to [adapt] to this change,” he said. He rein-

forced Hofford’s point that successful adoption starts at the top and requires strong support from management.

Hine explained that Suncor gave each mine manager a new digital tool and asked how it could change their operations. The feedback was telling—some managers reported improved maintenance planning through photo-enabled SAP (an enterprise resource planning software) notifications, while another noted a 20 per cent workforce reduction directly linked to the efficiencies gained from the tools.

“When you look at the impact from an enablement standpoint, we’re looking at 10-to-20-fold return on investment, so that’s how we’ve articulated our business case,” said Hine. She added that effective solutions often come from within and can be developed relatively

In case you missed it, here’s some notable news since the last issue of CIM Magazine, which is just a sample of the news you’ll find in our weekly recap emailed to our newsletter subscribers.

Arizona Lithium has received approval from Saskatchewan’s Ministry of Energy and Resources to begin phase one production at its Prairie lithium project (pictured) in southeast Saskatchewan. It is the first lithium brine project in the province, and one of the first in North America, to receive initial production approval. The project will utilize direct lithium extraction (DLE) to generate feedstock for the production of batterygrade lithium carbonate. Fabrication of the DLE unit is progressing on schedule, with completion expected by October.

The Ontario government will invest around $3.1 billion to boost Indigenous participation in mining, as part of the government’s broader strategy aimed at accelerating the development of a domestic critical minerals

supply chain. A majority of the funds will support loan guarantees for Indigenous business investments in Ontario mining projects, as well as grants and scholarships for Indigenous students pursuing careers in mining.

Northback Holdings’ coal exploration project at the former Grassy Mountain coal mine site in Alberta has received exploration approval from the Alberta Energy Regulator. This follows the Alberta government’s recent decision to lift its 2022 moratorium on coal exploration and development along the eastern slopes of the Rocky Mountains. The regulator emphasized that the approval is for exploration only and does not grant the company approval to begin mining.

Rio Tinto, in partnership with Indium Corporation, extracted primary gallium from bauxite processed at its Vaudreuil alumina refinery in Saguenay, Quebec. This marks a key milestone in the company’s initiative to produce commercial quantities of the critical mineral. The next step is assessing extraction techniques that will enable the company to produce larger quantities of

cheaply—provided that the company listens to its workers and builds tools alongside them, rather than relying on third parties unfamiliar with the business.

Jaffri emphasized the importance of securing both management and crew buy-in to properly implement digital connectivity. “First, you need buy-in from the management team, you need them to make sure their team is on board. That’s going to be where the biggest challenge is, getting the crews to buy-in,” he said. He also noted that, from an infrastructure perspective, it is crucial to decide early on which devices will be used.

Building on this, Hofford advised involving a mining company’s IT department

gallium at pilot-scale. If this is successful, Rio Tinto plans to build a demonstration plant in Saguenay–Lac-Saint-Jean, with a capacity to produce up to 3.5 tonnes of gallium annually. This could lead to a future commercial facility with a production capacity of 40 tonnes per year—which would account for five to 10 per cent of global gallium production.

Artemis Gold shared that it has achieved commercial production at its Blackwater gold mine in central B.C. as of May 1. In the preceding 30 days, the mill processed an average of 15,300 tonnes per day, which represents 93 per cent of design capacity. The company expects to produce between 160,000 to 200,000 ounces of gold in the final eight months of 2025 at all-in sustaining costs of US$670 to US$770 per ounce. For the 2025 financial year, total gold production is forecasted to range from 190,000 to 230,000 ounces of gold. The company is planning for a second phase expansion to boost annual output to above 500,000 equivalent gold ounces.

Ontario is introducing new legislation to accelerate permitting and streamline approvals for resource projects located in “special economic zones,” such as the Ring of Fire. The province intends to route all required paperwork through its mining ministry alone and respond within 24 months, a step it believes will shorten timelines by up to 50 per cent. Despite the legislation, significant development in the long-delayed Ring of Fire region is unlikely to occur quickly, as infrastructure gaps and public opposition remain ongoing obstacles.

early in the process to better understand the logistics of implementation, such as bandwidth requirements, charging stations and other infrastructure needs.

Hine noted that at Suncor, after implementing digital tools, workers are now spending upwards of 30 per cent more time in the field than in the office, as they can complete shift logs and communicate in real time on-site.

“There is so much more value in being able to be in the field and take a Teams call if you have to and continue with your work,” she said. She added that her team relies heavily on the features of these devices, such as real-time video feeds and connected gas detection, as safety tools.

Jaffri highlighted the benefits of autogenerated reports, explaining that instead of supervisors sifting through 20 pages of data to track drilled holes or

Export Development Canada (EDC) is looking to increase its role in financing Canada’s mining sector amid global trade uncertainty, reaching out to developers that are in later stages of mine development. Among the Canadian critical minerals companies that EDC is considering for loans is Canada Nickel Co., which is seeking US$500 million from the export agency to support its flagship Crawford nickel sulfide project near Timmins, Ontario. The project will require approximately US$2 billion to be built.

Ascot Resources has secured $61.1 million in financing to restart its Premier gold mine in B.C. Ascot halted operations at the mine last year due to delays in mine development, followed by a labour shortage that further postponed its restart. The mill is now expected to restart in early August, with full-scale operations anticipated in the first half of 2026, coinciding with the start of mining at the project’s Silver Coin deposit.

Stay up to date on the latest mining developments with our weekly news recap, where we catch you up on the most relevant and topical mining news from CIM Magazine and elsewhere you might have missed.

installed pipe, all of this information is now centralized. With reports automatically generated, supervisors spend much less time on data entry and more time focused on work on-site.

When asked about the potential of integrating artificial intelligence (AI), Hine emphasized that it is a gradual process, starting with connectivity and selecting the right devices for workers. At Suncor, a copilot program is being introduced, along with other AI tools, to provide predictive feedback to management. However, she noted that it will take at least three to five years before Suncor can fully leverage AI.

Jaffri agreed that implementing AI takes time, stating, “You have to walk before you can run. AI is pretty advanced, and we’re not at that stage yet.”

As the session concluded, Hofford reiterated that trust in workers is key. While employee devices are secure and monitored at Technica, the company has chosen a more flexible approach, trusting workers to use them responsibly rather than enforcing strict control. This trust has fostered accountability and responsible behaviour, leading to minimal issues and a more efficient work environment.

A recording of the webinar is available through CIM’s YouTube channel @CIM-ICM. – Ashley Fish-Robertson

Christine Healy, president and chief executive officer (CEO) of Northland Power Inc., delivered a keynote address at the 2025 CIM CONNECT Convention and Expo on May 6 on the topic “Energy Transition and the Evolving Energy Sector” that explored the future of energy and the drivers behind the energy transition.

“Today, we are living through one of the most consequential shifts in modern history,” she said. “We are transforming how the world powers itself. It’s complex and it’s urgent, and it’s happening in real time. This is a situation where no decision creates a decision, and it has impacts.”

Healy pointed out that Canada has the potential to hold a powerful position in the global energy landscape, with the fourth greenest electricity grid in the world. “More than 80 per cent of our electricity comes from non-greenhouse

gas sources,” she said. “It’s an incredible achievement, but we are in the top two per cent of the countries of the world.”

In comparison, fossil fuels account for about 80 per cent of primary global energy consumption, but investment in renewable energy is growing.

In early May, Northland Power commissioned its $700-million Oneida battery storage facility. It is the largest of its kind in Canada.

Healy also highlighted Canada’s phenomenal natural resources and other advantages. “We have engineering expertise, operational expertise [and] a strong commitment to the rule of law,” she said. “This makes Canada a reliable and necessary partner for the 98 per cent of the world who are behind Canada on their journey to green their grids.”

However, Healy acknowledged that there are several things holding Canada back, such as long approval times for large projects. “We need to build out our infrastructure at home. By most estimates, we need to double, or even triple, our electricity output by 2050,” she said. “Despite the opportunities and the resources and the talent and the urgency, progress here in Canada remains slow, and that has a lot to do with how we permit and approve large infrastructure projects. I’ll be direct—if we don’t improve our regulatory processes, we will not meet our goals, full stop.”

Fundamentally, the long permitting times are not attractive for investors or developers, Healy said. “It’s certainly not a sensible policy for a country that needs

Compiled by Ashley Fish-Robertson

Natascha Viljoen, executive vice-president (VP) and chief operating officer (COO) of Newmont Corp., has been promoted to president. She will continue in her role as COO. Prior to working for Newmont, Viljoen held the position of chief executive officer (CEO) for Anglo American Platinum.

Discovery Silver announced several appointments to its leadership team. Pierre Rocque has joined the company as COO; Jennifer Wagner has taken on the role of executive VP of corporate affairs and sustainability; Duncan King has assumed the role of VP of Canadian operations; and Eric Kallio has taken on the role of senior VP of exploration and growth. These appointments coincide with Discovery’s entry as a Canadian gold producer, following its acquisition of the Porcupine Complex in the Timmins area from Newmont Corporation.

Tim Bradburn has joined Magna Mining as senior VP, general counsel and will also serve as corporate secretary for the company. Prior to joining Magna, Bradburn held the same roles at Iamgold Corporation for over 17 years.

Paul Dunbar has joined ONGold Resources as its VP of exploration. Dunbar has held both executive and senior management roles with Canadian exploration, development and production mining companies, including as director of exploration for Argonaut Gold from 2022 to 2024, where he led a team advancing exploration and development of the Magino open-pit gold mine in Dubreuilville, Ontario. Dunbar’s new role will include leading the renewed exploration efforts at the Monument Bay gold project in Manitoba.

Liberty Gold Corp. has appointed Jon Gilligan as its new CEO. Gilligan, who currently serves as president and COO, will continue in his role as president while being promoted to CEO, succeeding Cal Everett. Everett is retiring as CEO and director after more than eight years with the company and will transition to non-executive director of Liberty Gold’s spin-out entity, Specialty American Metals Inc. He will continue to provide his expertise to Liberty Gold as a senior financial analyst. The company has not yet announced a successor for the COO role.

to double or triple its electricity output by 2050,” she said. “We need clear, apolitical processes, [and] a wholesale commitment to be efficient and effective in our permitting processes.”

Without competitive time limits and clear pathways, Healy added, capital will go elsewhere. “Projects stall and communities lose out; we lose out on jobs, on infrastructure, on our future,” she said. “The energy transition is a race against time, and right now, red tape is winning. If Canada wants to be a leader—and we should be a leader—we need fast, efficient, transparent regulatory processes.”

Healy concluded by saying that the energy transition requires a huge amount of collective effort and action from governments, companies and communities, but that the opportunity is enormous.

Following the keynote, an expert panel discussed the challenges and opportunities of the energy transition. Moderated by Sherry Iskander, senior director, centre of excellence, processing and technology at Rio Tinto, the panel included Sonia St-Arnaud, president and CEO of EVLO; Scott MacKenzie, director, corporate and external affairs at Toyota Motor Manufacturing Canada; Terry Smith, chief operating officer at Lundin Gold; and Maxime Lanctôt, general manager, energy development, Canada at Rio Tinto.

MacKenzie highlighted Canada’s clean energy grid as one of the country’s advantages. “Our energy, compared to other countries where Toyota operates, is, honestly, absurdly cheap—whether that’s electricity or natural gas, we’ve got it [in Canada],” he said. “We’ve got a lot of opportunities, we’ve got a lot of technology available to us here, we’ve got a lot of innovation, [and] a highly educated workforce. We’ve got all the recipes here for success.”

The discussion touched on the role of critical minerals in the energy transition, and how the government can strengthen the domestic supply chain. MacKenzie acknowledged that the current geopolitical situation, particularly between Canada and the United States, has created a lot of unpredictability. “As a company trying to plan investments over the coming years, this is a really, really challenging time to do that,” he said. “I think what governments can do is to provide certainty.”

For example, MacKenzie suggested that governments could get involved in procuring products for manufacturers,

“Today, we are living through one of the most consequential shifts in modern history. We are transforming how the world powers itself. It’s complex and it’s urgent, and it’s happening in real time. This is a situation where no decision creates a decision, and it has impacts.”

– Christine Healy, Northland Power Inc.

or provide some cost certainty for critical minerals. “If you’re planning a battery plant, the raw materials are making up 45 to 50 per cent of that product, and the prices of those raw materials are, frankly, all over the place right now,” he said. “That creates a lot of uncertainty for the company, and it creates a lot of uncertainty for the consumer.”

Lanctôt agreed with Healy’s earlier comments about the long permitting times for large energy projects, noting that improving this process would attract more investment capital. “We need a long-term view to make those very large investments,” he said. “For me, it’s simple and actionable regulation that provides long term visibility on the investment situation.”

– Ailbhe Goodbody

Osisko Development released an updated feasibility study on April 28 for its Cariboo underground gold project in central B.C., outlining several updates from the 2023 feasibility study.

The updated study, prepared by BBA Engineering, outlines an accelerated development sequence, which involves single-phase construction and a direct ramp-up to nameplate capacity of 4,900 tonnes per day, resulting in a 16 per cent increase in the life-of-mine average gold

production to 190,000 ounces annually over a 10-year mine life, and an average of 202,000 ounces per year during the first five years.

Updated metallurgical testing led to the inclusion of a gravity circuit, which, alongside an improved flotation circuit, is expected to boost overall gold recovery

$943 million

Base case net present value

190,000

anticipated average annual gold production in ounces

10 years

Life of mine

to 92.6 per cent and enable the production of a higher-grade concentrate.

The study mentions an updated mine design with stope sizes increased by around 60 per cent, reducing the number of stopes needed to achieve average daily throughput.

Osisko also updated the price of gold from US$1,700 per ounce in 2023 to US$2,400 per ounce this year.

The company anticipates reaching a final investment decision and securing a project financing package in the coming months. Construction is expected to

begin in the second half of 2025, with completion slated for the end of 2027.

The project’s total initial capital costs are estimated at $881 million. In the company’s 2023 study, it shared that for phase one of the project, initial capital costs were estimated at around $137.4 million, and around $451.1 million for phase two.

The base case for the project delivers a net present value of $943 million (up from $502 million in 2023) at a five per cent discount rate, with an internal rate of return of 22.1 per cent and a payback of 2.8 years, based on the estimated gold price of US$2,400 per ounce.

First gold is anticipated in the second half of 2027, assuming construction proceeds as scheduled.

The updated study reflected that probable mineral reserves remain mostly unchanged, increasing slightly to 2.07 million ounces of gold (17.8 million tonnes grading 3.62 grams per tonne).

The company has already signed participation agreements with the Lhtako Dené Nation, in 2020, and the Williams Lake First Nation, in 2022. It is currently working towards an agreement with the Xatśūll First Nation.

– Ashley Fish-Robertson

Dan Apai has been promoted to VP of projects at FPX Nickel, succeeding Andrew Osterloh, who has been with FPX since 2021 and is moving on to a new role as VP of engineering and construction at Skeena Gold and Silver. Apai, who has served as engineering manager at FPX Nickel since 2023, brings over 20 years of mining industry experience, including leading study and detailed engineering projects at Fluor Canada for clients such as Teck Resources, Newmont Corp. and BHP.

Jayden Resources has appointed its current chairman and CEO, David Eaton, to step in as interim CFO following the retirement of Herrick Lau, who held this position for 17 years. Eaton will continue working as chairman and CEO while handling interim CFO duties as the company actively searches for a permanent CFO candidate.

Troubadour Resources has welcomed Zachary Kotowych as its new CEO, corporate secretary and director, as well as a member of the company’s audit committee. Prior to working at Troubadour, Kotowych previously held roles at Abitibi Metals Corp., Great Bear Resources and more. Kotowych succeeded Christopher Huggins, who resigned after working for the company since May 2024.

A new collaborative initiative is targeting invisible workplace hazards in mining, combining practical training and research to improve safety across Ontario

By Ashley Fish-Robertson

According to Workplace Safety North, exposures to caustic, noxious or allergenic substances accounted for 16 per cent of lost-time injuries and illnesses in Ontario’s mining sector in 2023.

Ontario’s Workplace Safety and Insurance Board (WSIB) has announced a $6.78 million investment to protect the province’s workers in the mining and forestry sectors. The announcement came during the 27th annual Mining Health and Safety Conference, held at Science North in Sudbury from April 30 to May 1.

The WSIB has joined forces with Workplace Safety North (WSN) and the Institute for Work and Health (IWH) to launch a campaign aimed at strengthening hygiene monitoring practices and lowering the risk of exposure to workplace hazards. Under this initiative, WSN is creating specialized training resources and will collaborate closely with employers and workers across Ontario, offering hands-on coaching and real-time support with hygiene monitoring equipment, with the aim of empowering frontline teams to better recognize and manage exposure risks.

According to WSN’s 2023 Workplace Health and Safety Snapshot for Ontario’s mining sector, 1,196 total injuries were reported among 26,391 full-time employees.

Cindy Schiewek, director of health and safety services at WSN, told CIM Magazine in an email that many of mining’s occupational hazards—such as diesel particulate matter (DPM), respirable crystalline silica, metal fumes and occupational noise—are not visible to the naked eye.

“Unlike physical hazards, workers may not immediately recognize their presence or severity, but the health consequences can be severe and long term,” she wrote. “These substances and exposures are often airborne and microscopic, accumulating in the lungs or affecting hearing over time without early warning signs.”

Schiewek added that these hazards can have irreversible effects on workers’

health, with many symptoms appearing only after years of exposure, highlighting the importance of early control and prevention measures.

Exposure to DPM and silica dust, which are classified as carcinogens, can lead to serious respiratory diseases, such as chronic obstructive pulmonary disease and silicosis. Other invisible hazards include exposure to metal fumes, which may lead to metal fume fever or more severe systemic issues. Additionally, Schiewek shared that prolonged noise exposure is a leading cause of occupational hearing loss, which can greatly impact quality of life and communication in safety-critical settings.

Schiewek explained that workers operating in underground environments, as well as mobile equipment operators, drillers, blasters and maintenance personnel, are especially vulnerable to these threats due to close and sustained exposure to fine particulate matter, toxic fumes, airborne dust and high noise levels.

Without a strong foundation in hazard identification, risk assessment, control selection and effectiveness evaluation, Schiewek noted that the mining industry risks ineffective or inconsistent protection for workers. This can lead to occupational disease cases, higher WSIB claims and potentially preventable fatalities. The new initiative aims to directly address these risks and strengthen worker protection across the mining sector.

The initiative will see WSN develop sector-specific guidance documents for Ontario’s core resource sectors, featuring virtual, in-person and eLearning training modules for workers, along with hands-on skill application supported by WSN mentorship tailored to specific hazards and work environments, such as inspections and samplings.

“This approach aims to create selfefficacy and build competent capacity in the realm of occupational health hazard identification, assessment and control,” said Schiewek. “When it comes to controls, a focus will be placed on applying the hierarchy of controls, recognizing when controls are not effective and fostering joint health and safety committee involvement in control evaluation.”

The initiative will include two key components: a competency development framework for site participants chosen

for upskilling, and a broader health and safety culture site assessment. Upskilling will involve knowledge- and skills-based training to improve workers’ abilities to manage occupational health hazards more effectively, supported by professional coaching and mentoring. There will also be a broader pre- and postproject culture assessment conducted by the IWH to determine the impact that occupational health hazards have had on the overall health and safety culture at an operation.

The development of educational materials already began in January and WSN started its first on-site portion of the initiative in May. Over the course of the five-year-long initiative, 25 mining companies are expected to participate, along with 25 companies from the forestry sector.

If this initiative proves successful, WSN will start to pilot the framework and work with IWH to determine effectiveness, practicality and required adjustments based on participant feedback and outcomes.

When asked about the biggest gaps or challenges in hygiene monitoring practices, Schiewek pointed to a mix of issues, including a lack of trained personnel and, even when staff are present, confusion about proper procedures and how to carry them out effectively.

She cited the collection of air, dust or other environmental samples from the workplace to detect hazardous substances as an example of a practice that, while seemingly straightforward, can be done incorrectly if factors like exposure times during sampling and the use of necessary equipment are not properly managed.

“It’s not that [these practices] are complicated, there’s just a lot to make sure that you do so you can get the right information to make the right decisions,” Schiewek said in a follow-up interview with CIM Magazine.

While this initiative focuses on physical safety, it also recognizes that the emotional and mental well-being of workers is equally important. “If you can picture yourself in some of these [work] environments, perhaps you’re on a 10- or 12-hour shift, and you have this noise at 100 decibels for hours, you can imagine the kind of impact that would have not just on somebody’s hearing, but also

on their mental [well-being],” said Schiewek. “If you’re operating in an area where there’s heavy equipment running, it’s loud, it’s hot, so you can see how these things can stack on one another [and have] an exponential impact.”

Once data is collected over the fiveyear period, WSN and IWH aim to uncover valuable insights and learning opportunities that will deepen the understanding of workplace hazards. IWH will use its research expertise to independently evaluate how the training programs improve worker safety and reduce hazardous exposures, informing potential expansion to other high-risk sectors.

“We have a huge opportunity to do so much good beyond our own walls at the end of the day, and I’m definitely hopeful that we’ll be able to make an impact and work towards serving our mission of making sure everybody goes home safe and healthy,” Schiewek said. CIM

Ascot Resources has appointed Christopher Park as the company’s interim CFO, succeeding Carol Li, who has retired after eight years in the position and stepped into an adviser role with Ascot. Park previously held finance roles with Northern Vertex Mining Corp., Imperial Metals Corporation and more.

After almost 45 years of working for Caterpillar, chairman and CEO D. James Umpleby III has transitioned to executive chairman of the board. Joseph E. Creed, the current COO who has worked for Caterpillar for 28 years, succeeded Umpleby as the new CEO. A successor for the COO position has not yet been announced.

Jessie Liu-Ernsting has been promoted to chief corporate development officer at FireFly Metals, after previously serving as independent director of the company since March 2024. Liu-Ernsting brings significant experience in investor relations, corporate development and mining finance, having previously served as VP of investor relations and communications at G Mining Ventures Corp., investment manager at Resource Capital Funds, and more. She is also a director of the Management and Economics Society of CIM.

Binny Jassal has resigned from his roles as CFO and director with Lake Winn Resources, after working at the company since 2006. James Ferreira has assumed the role of interim CFO as the company searches for a permanent replacement.

By Vanessa MacLean and James Whyte Part five

f you’re reading a mining news release and see a company say something like “1.5 g/t AuEq” or “2.4 per cent CuEq,” that’s an equivalent grade. It is a way of combining multiple metals in a deposit into one simplified number. The problem, however, is that the equivalent grade calculation is often done incorrectly!

Our friend the straw man is confused: “But an equivalent grade just adds up the value of each metal using today’s prices. Everybody does it!”

And that is where the trouble begins.

Let’s think about it in terms of making a smoothie. Imagine you’re blending a smoothie with bananas, strawberries and spinach. You decide to call it a “banana-equivalent smoothie” by counting how much each ingredient costs, and then converting it into banana terms.

But here’s the thing: you don’t absorb all the nutrients equally, and not everything blends the same way. The blender (your processing plant) handles bananas better than spinach. Plus, you’re throwing some of it away (like smelter losses). So, while it sounds like all the ingredients are giving you equal banana power, they’re not!

Only considering price-weighted equivalent grade—simply adding together the grades of each metal, multiplied by their market price—suggests that all the metals are equally recoverable, equally payable and equally marketable. In the real world, they are not because:

• You never recover 100 per cent of any metal;

• You recover some metals better than others. Most mines are built to prioritize one key metal; and

• No smelter will pay you for all the metal you recover. Payables, deductions and penalties are part of mining. You’re selling concentrate under specific commercial terms, not a theoretical blend.

So, if you only use price to calculate an “equivalent” grade, you’re really just expressing a gross metal value. And that just doesn’t tell the whole story.

Wait a minute...an equivalent grade is not a gross value?

Yes, it is. When you take the total price of all the metals in a rock and divide it by the price of one main metal (like gold or copper), you’re not doing anything special. You’re just turning a dollar amount into “metal units.” It’s still the same total value, just written in ounces of gold or tonnes of copper instead of dollars. That doesn’t make it a true equivalent grade, it’s just a fancier way of showing the same number.

Gross value doesn’t consider recovery, payables or processing costs, and neither does a price-weighted “equivalent.”

So, what is the real-world equivalent grade?

Take the grades of each commodity and multiply each by that commodity’s unit price, its recovery and the payable fraction of its price. Then divide by the unit price, recovery and payable fraction that applies to the principal commodity.

Where:

Equivalent grade = (Grade1 × Price1 × Recovery1 × Payable1 + Grade2 × Price2 × Recovery2 × Payable2 + …) ÷ (Pricem × Recoverym × Payablem)

• Each “ 1,2… ” is a commodity in your resource;

• “ m ” is the main commodity, the unit you want to express your equivalent grade in (e.g., copper (CuEq), gold (AuEq));

• You apply metallurgical recoveries and commercial payables to each metal; and

• Include the formula in your disclosure! Math makes it real.

“Let's think about equivalent grades in terms of making a smoothie.”

But we’ve always done it this way.

Not really. One of us looked back through the archives of The Northern Miner and equivalent grades weren’t commonly reported until the mid-1980s, when gold-silver producers reported “gold-equivalent” production and platinum producers reported equivalent grades in concentrates. Those numbers— recovered and payable metal—made sense. Moreover, mine operators using equivalents recognized that any “equivalency” between metals had to take both price and recovery into account. But around 1988, equivalent grades started showing up in resource estimates, before anyone knew whether those resources would be economically extractable. That’s when the shortcut turned into a marketing tool.

So, it’s not traditional. But isn’t it a requirement?

Not at all. Back in 2003, the CIM Estimation of Mineral Resources & Mineral Reserves Best Practice Guidelines said this about grade equivalents:

Reporting of mineral or metal equivalence should be avoided unless appropriate correlation formulae, including assumed metal prices, metallurgical recoveries, comparative smelter charges, likely losses, payable metals, etc., are included.