PROFESSIONAL EXPERIENCES

07—09.2024

Product Design Intern Daniel Rybakken Studio, Göteborg, Sweden

02—07.2023

Product Designer

Dotdotdot, Milan, Italy

02.2022—01.2023

Product Designer

Harry Thaler Studio, Merano, South Tyrol, Italy

09.2019

Assistant curator With Michele Galluzzo and Studio Hund for DIPLORAMA 2021 - Universal Set, Bolzano, Italy

COLLECTIVE EXHIBITIONS

08–13.04.2025

Designed in Ch, Made in Jp House of Switzerland, Milan

3.09.2024—09.02.2025

We Will Survive MUDAC Lausanne, Switzerland

16—20.04.2024

UPS – Under Pressure Solutions Via dell’Orso 16, Milano, Italy

14—21.04.2024

RoCOLLECTIBLE 2024

Via Matteo Bandello 14-16, Milano Italy

17—23.04.2023

RoPlastic Prize finalist exhibition

Palazzo Bandello, Milan, Italy

18—19.11.2022

Faucet Redesign

Beyond Surfaces

Faculty of Design and Art, Bolzano, Italy

3-6.11.2022

Biolife 2022

Fiera Bolzano/ Messe Bozen, Bolzano, Italy

26.8.2022

Farbe und Gesundheit Humboldt University, Berlin, Germany

9.07.2022

Upcycling Convention incontra REX REX, Brixen, Italy

2023—2025

Masters Degree in Product Design ECAL, (École cantonale d’art de Lausanne) Lausanne, Switzerland.

2019—2022

Bachelor Degree in Design and Art German, Italian, English Faculty of Design and Art Free University of Bozen/Bolzano, Italy

2014—2019

Upper Secondary Education Liceo Classico Europeo Marco Foscarini Venice, Italy

AWARDS

Faucet Redesign

C-idea Design Award 2023 Silver award, Student category

DIY Bamboo fibers

RoPlastic Prize 2023, 3rd prize Inspirational Learning Projects category

BRICOLA-BIN

Sea Design Contest 2023, 1st prize Industrial Design category

PRESS

RoPlastic Prize 2023 winners announced during Milan Design Week 2023, STIRworld April 27th, 2023).

Marco Ciacci Finalist for Ro PLASTIC PRIZE 2023, UNIBZ, March 27th 2023

Rubinetti e consumo idrico sostenibile: una tesi di laurea per riflettere sul tema, Ecomuseo Cusius, November 28th 2022

Einblicke in Design und Kunst an der unibz: Diplorama! is back. AUSTRIA PRESSE AGENTUR

A Bolzano ecco “Diplorama!”: la laurea diventa un’opera d’arte, Alto Adige. November 11th 2022

SELECTED WORKS 2020-2025

Hopper Chair

client - Karimoku new standard /design by Marco Ciacci & Takumi Ise / developed at ECAL / LecturersAugustin Scott de Martinville (BIG-GAME), Maxwell Ashford / Photography - Visvaldas Morkevicius

Pizza Tray developed at ECAL / Lecturers - Camille Blin, Anthony Guex , Christophe Guberan /Fotography - Brice Tempier and Marco Ciacci

Tavillion

client - Viessmann / developed at ECAL / LecturersAugustin Scott de Martinville (BIG-GAME), Maxwell Ashford / Photography - Younès Klouche

Faucet Redesign developed at UNIBZ / Lecturers - Nitzan Cohen, Aart Van Bezooijen / Prototype - Albert Kofler / Photography - Curzio Castellan /Awards: c-idea design award 2023, silver award

Diy Bamboo Fibers developed at UNIBZ / Lecturers - Van Bezooijen Aart Awards: RoPlastic Prize 2023, 3rd prize

Hut

client - Rossin / developed at UNIBZ / LecturersKlaus Hackl, Riccardo Berrone, Hans Leo Höger / Upholstery - Alberto Poch / Photography - Pietro Coda / Studio Lights - Curzio Castellan / ModelsValentina Cemin / Location - Miramonti Boutique Hotel

CONTACTS

Sestiere Dorsoduro 1018 B, 30123, (VE) Venezia marcociacci2k@gmail.com +39 3318149834 IG @marco.ciacci

Hopper Chair a wooden chair that captures the natural curves found in trees and branches with Karimoku new standard

Hopper is a multifunctional chair inspired by nature and the craftsmanship of bentwood. Drawing from the organic networks of tree branches and roots, the design highlights the beauty of bentwood while embracing efficiency and versatility. The chair features a cantilevered structure with a strong yet lightweight profile. Its straight, parallel legs allow for efficient stacking, up to five chairs, while its clean side profile ensures seamless alignment in rows, making it ideal for conference and lecture spaces. Additionally, Hopper can be easily hung on tables or flat surfaces, enhancing practicality in dynamic environments.

By refining traditional bentwood techniques, we reduced material thickness while strengthening the bond between the seat and backrest. This creates a chair with a bold visual identity that becomes integral part of its surroundings.

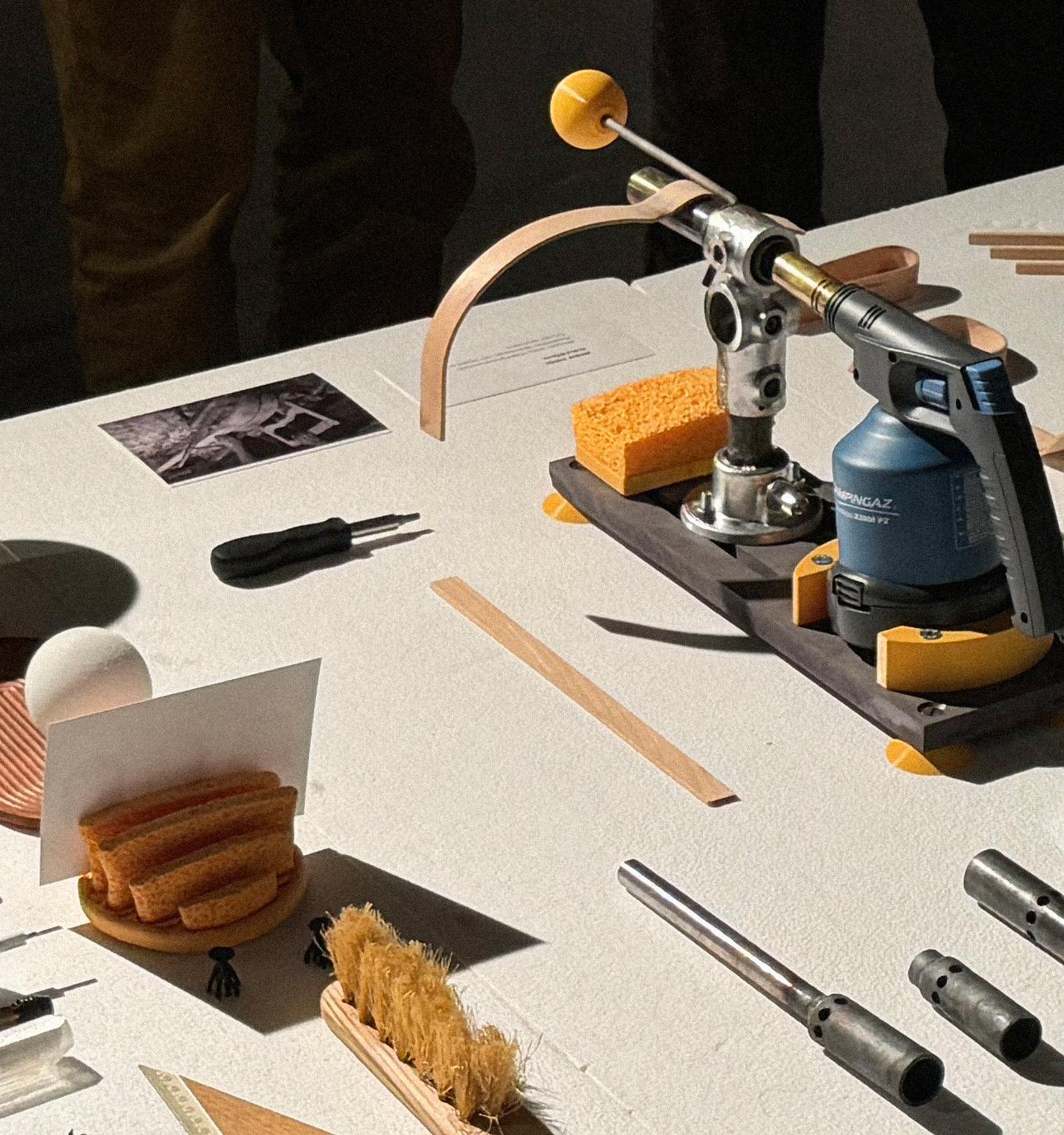

Hands-on research into the traditional method of bending wooden skis

Motivated by a deep passion for materials and their production techniques, this material exploration investigates traditional manufacturing methods that were disrupted by the plastic era, seeking possible solutions to modern circular economy requirements. Historically, skis were made of wood and bent over fire without the use of steam. Similarly, before the 20th century, factories mass-produced walking sticks from single bent branches.

In an effort to revive and industrialize this technique, a custom-designed machine was developed to bend thin strips of wood. Through this process, forms emerged that are typically associated with plastic objects, such as clothes pegs, kitchen tongs, and shoehorns. This exploration ultimately led to the design of a tray, applying the same technique to create an elegant object with surprising curves.

Pizza Tray as part of UPS - Under Pressure Solutions with ECAL

In a world where consumers increasingly expect products to arrive effortlessly at their doorstep, industrial design faces new challenges. For the 2024 Milano Design Week, ECAL presented UPS, Under Pressure Solutions, an experimental research project exploring ways to reduce the environmental impact of the furniture industry through the use of shape memory materials. This approach involves creatively cutting, gluing, and stitching cellulose sponge, which expands and transforms into its final size and shape when hydrated.

As part of this research, experimentation was conducted by cutting the sponge at varying depths. Combined with stitching, this technique allowed the material to expand and fold in different ways. This exploration led to the design of a series of trays in various sizes, where stitched constraints guide the sponge’s transformation from a flat surface into a deep, curved bowl.

Current heat pump designs often do not relate to the architectural environment they are placed in, instead appearing as black, box-like structures. Historically, fireplaces and chimneys served as the primary heating systems of a house. While their shapes, sizes, and functions have evolved over time, they have remained distinctive architectural elements.

This project seeks to establish a formal language that connects heat pumps to the local architectural landscape by drawing from vernacular materials and craftsmanship. In the Swiss context, traditional building elements such as tavillon cladding and wood-shingled chimneys have been translated into the design of a heat pump. This approach allows the unit to integrate seamlessly into its surroundings and age naturally alongside the building. Additionally, the use of wood shingles, locally harvested, carbon-neutral, and sound-absorbing, ensures both functional and sustainable benefits, with a lifespan that aligns with that of the heat pump itself.

Faucet Redesign rethinking water interaction in the domestic context through a process of inversion

Summer droughts and their resulting challenges highlighted the need for more sustainable water consumption, leading to the development of this thesis. The primary point of interaction between consumers and water resources was identified as the water faucet. Extensive research has shown that the modern faucet, as commonly recognized today, originated in 1930s America, an era characterized by heightened consumption and technological progress, reflected in the streamline style. This aesthetic has largely persisted, with the design of faucets remaining relatively unchanged.

This thesis explores ways to emphasize the value and scarcity of running water in households by redefining both the interaction between users and faucets and the overall design language. The goal is to shift consumer habits from unconscious consumption to more responsible and mindful water use.

Diy Bamboo Fibers

Design research on upcycling of bamboo and its fibres

Bamboo has long been admired for its versatility and structural efficiency. This project explores its properties, beginning with an analysis of its composition to identify the fiber as the key element behind its adaptability. A study of both industrial and traditional processing methods informed the development of a more accessible, small-scale approach.

Using caustic soda, a substance commonly employed in bamboo textile production, discarded bamboo chopsticks, widely available as post-consumer waste, were dissolved and reprocessed. This easily replicable technique allows for the extraction of cellulose fibers, which can then be transformed into new objects, demonstrating an innovative and sustainable approach to material reuse.

An Outdoor Armchair with Rossin

In the context of care design, the focus of this project is on the challenge faced by some individuals, elderly or not, in coping with the cold during winter months. Inspired by Alpine traditions of wood furniture and local architectural heritage, the project resulted in a cushioned outdoor lounge chair. The chair’s padding can be easily removed and transformed into a blanket, offering warmth and protection against the cold.

The HUT armchair is composed of three main components: an iron tube frame representing the structure, a quilt filled with polyurethane foam shapes serving as the padding, and a second quilt that functions as a duvet. The quilts are transformed into upholstery through an intelligent system of folds and anchoring points. The result is a dynamic, participatory seating solution that is also circular, upgradeable, and recyclable.

all concepts and images in this presentation are property of Marco Ciacci. The reproduction or representation of all or part of this presentation or any of its contents, is therefore strictly forbidden without the prior written consent of Marco Ciacci.

updated to 06.2025

Marco Ciacci is a product designer from Venice, Italy, who completed his Master’s in Product Design at ECAL in Lausanne, Switzerland. He earned his Bachelor’s degree in Design and Art from the Free University of Bozen-Bolzano in 2022. He has worked as a product designer at Studio Harry Thaler in Merano, the Milan-based architecture firm Dotdotdot, and Daniel Rybakken’s design studio in Gothenburg, Sweden.

Grounded in contemporary discussions on the circular economy, recycling, and sustainability, Marco’s approach blends materials research and experimentation with knowledge of historical production, to develop innovative responses to the challenges of mass production. With product design his primary focus, he also includes architecture, exhibition design and material experimentation in his pursuits.

His work has been showcased at Milan Design Week and recognized internationally with the Roplastic Prize (Bamboo) and the C-IDEA Design Award (Faucet redesign).