MANUFACTURING CAPABILITIES

CDL began in 1964, as S&S Electric, providing electrical services for residents and businesses around Pittsburg, Kansas. By the time we changed our name to CDL Group of Companies in 1996, we were also maintaining signals and providing electrical services for companies in the short line railroad business.

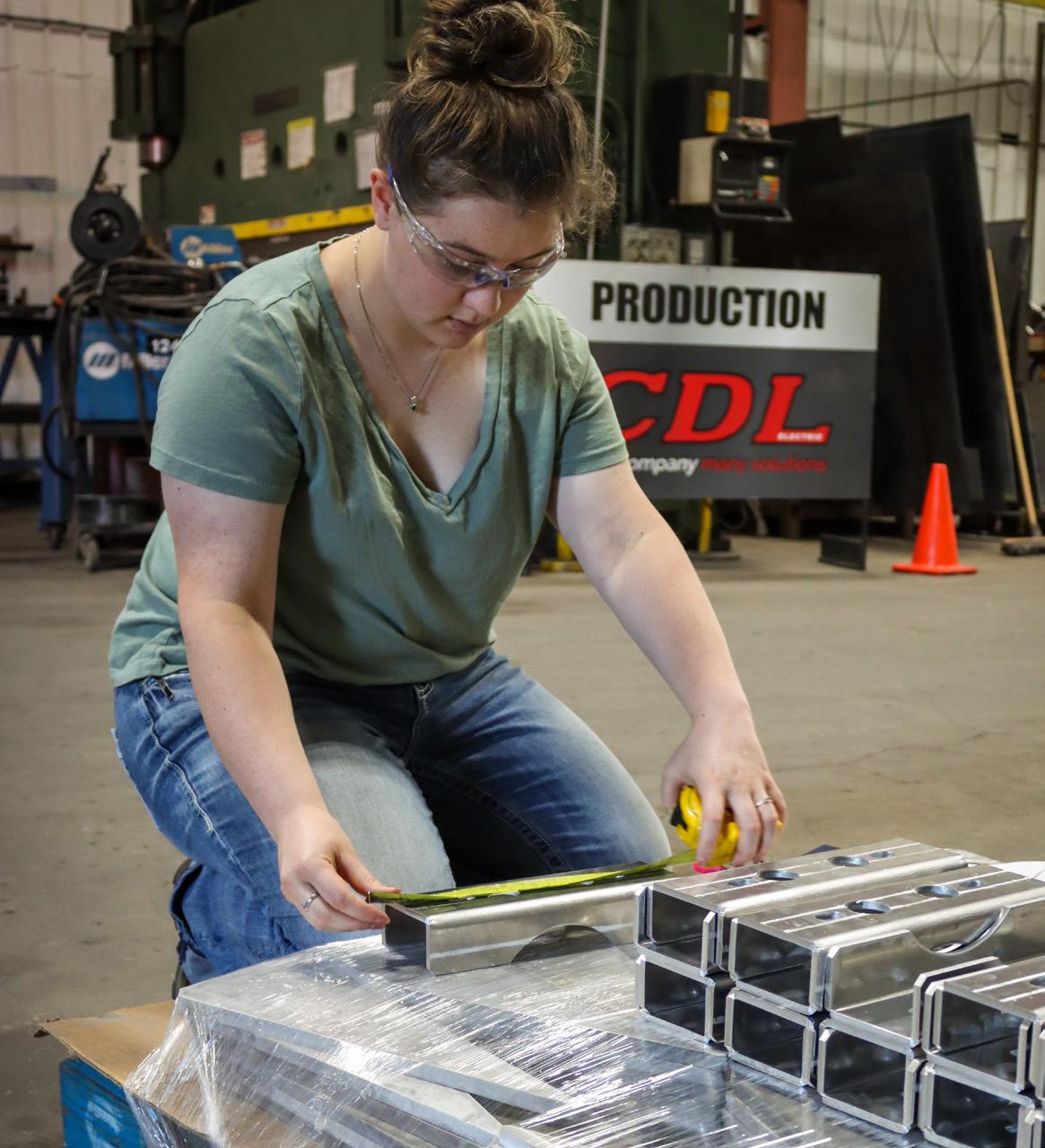

When you contact CDL Group of Companies for service, first we do a thorough evaluation of your needs. Our initial inspection will help us determine the best course of action. From engineering to shipping we handle it all in between. We currently have a 183,000 square foot manufacturing facility and use a fixture model of manufacturing to minimize handling and increase efficiency. We follow ISO standards for quality interval checking and first article inspection, and passes several audits in the transportation manufacturing industry.

We have the privilege of serving over 40,000 customers across 33 states and 2 international location. Through our strategic manufacturing partnerships we have developed relationships that provide our customers with unique solutions at affordable rates. These relationships were made possible by practicing our core values in every aspect of our company.

The FOL 3015 AJ is engineered to produce the highest quality parts at unmatched speed while reducing operating costs and environmental waste. The benefits of fiber laser technology are:

Faster cutting of thin material.

Superior speed and edge quality in material thicknesses up to 7/8” compared to other solid-state systems P.R.E. (Process Range Expansion) by providing the ability to laser cut copper, brass, titanium and other materials that were previously difficult to process.

No optics or space inside the cavity of the laser source - eliminating costs associated with mirrors and downtime for alignment of optics.

The shuttle tables externalize the material setup, eliminating interference with the cutting process.

OMADA FOL 3015 AJ

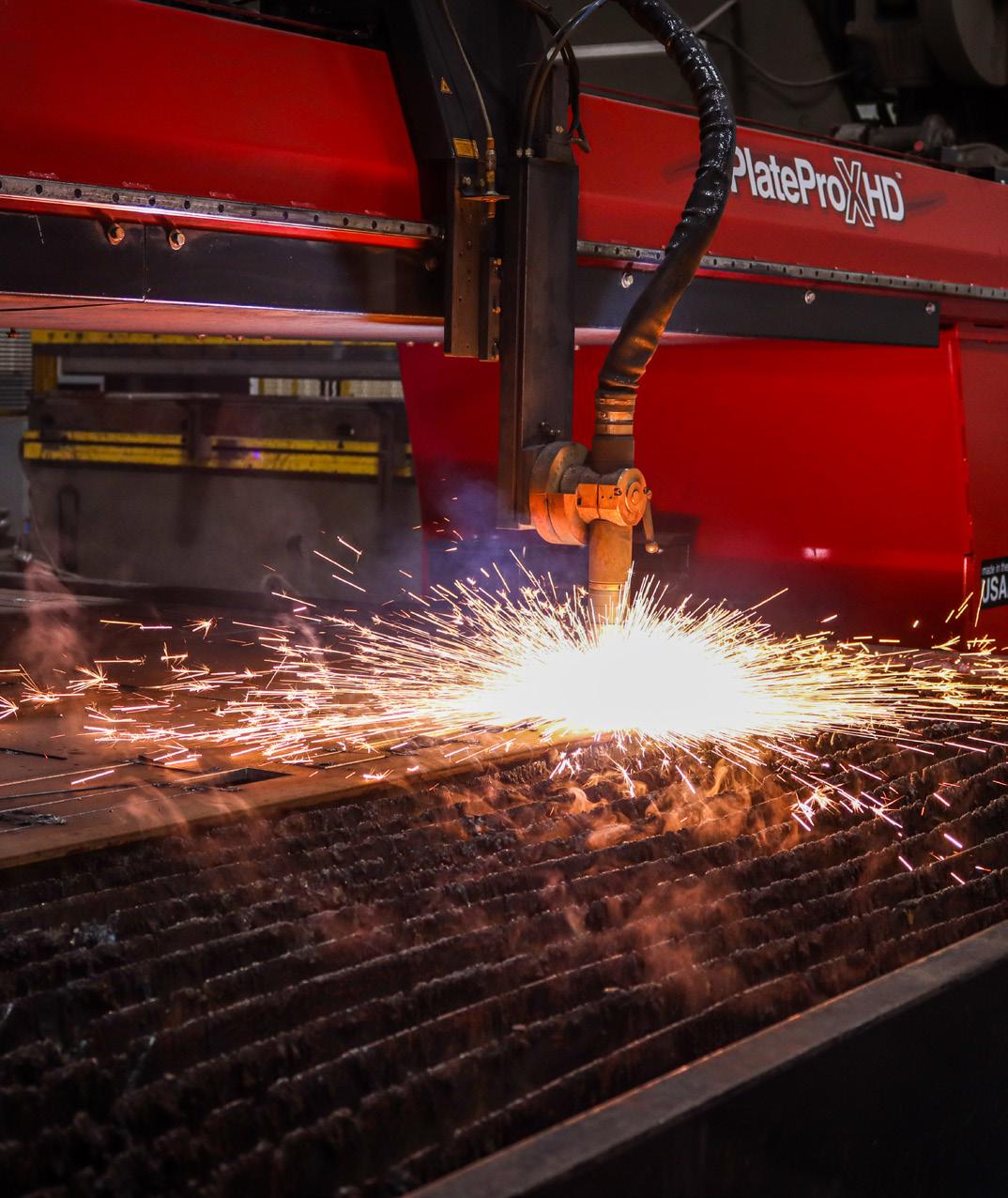

The PlateProX HD plasma table utilizes the latest technologies to provide unmatched speed, accuracy, versatility and durability in a CNC cutting system. Designed to satisfy the world’s most demanding customer requirements, the PlateProX HD has been engineered to maximize its’ performance.

Can cut up to 10’x20’ material such as: Mild Steel

Stainless Steel

Aluminum

With full contour bevel heads capable of A, V, X, Y, and K bevels.

The plus and minus 50 degree movement allows for most common angle configurations.

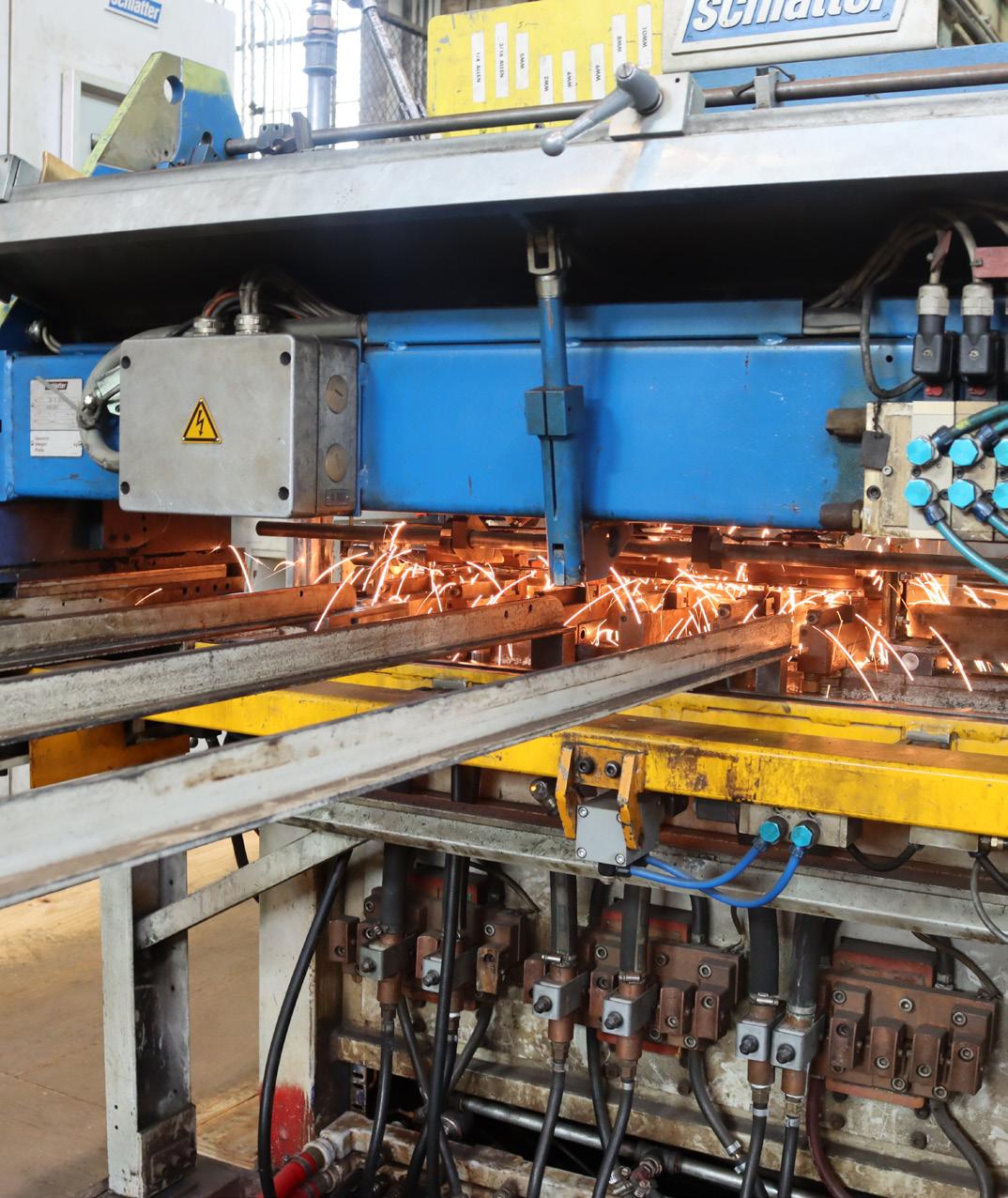

Schlatter industrial mesh systems are used for the production of dimensionally accurate mesh-work for a wide variety of applications. Industrial mesh may be used to produce shop, exhibition and warehouse equipment as well as trays for domestic appliances.

Flat meshes used as gratings, baskets or cages are typical products made out of industrial mesh.

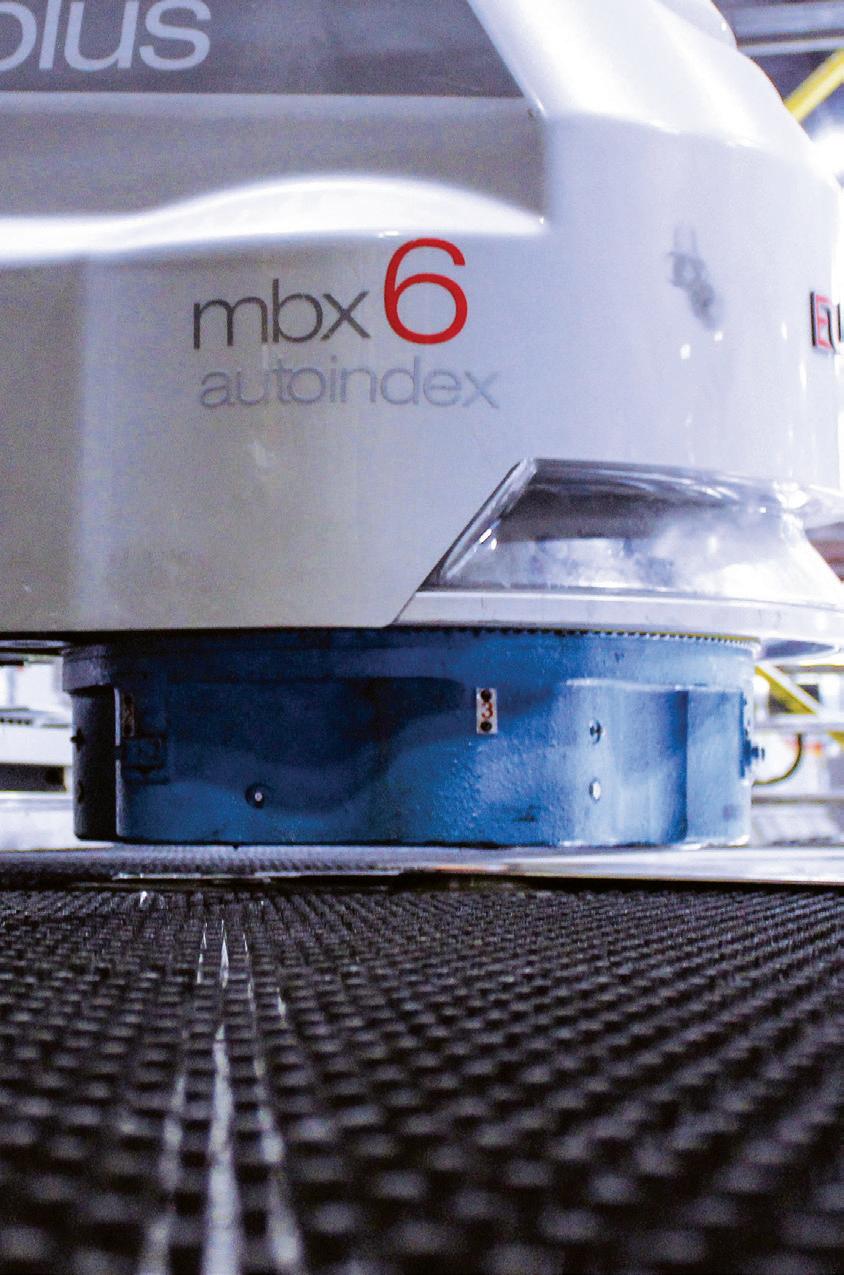

A high-performance hydraulic machine with the same high-speed axis travel as the MTX plus, achieving a hit rate of 600 per minute. These quality versatile machines punch, form, bend, thread and bead sheet metal. This machine ensures speed, stability, extreme flexibility and precision.

With a 10 HP blade motor and a 2HP hydraulic motor, the H130 is an aggressive cutting machine and ideal for many applications. The 1-1/2” wide blade enables cutting larger and harder materials and the adjustable clamping pressure allows holding solid materials securely and permits cutting materials with thinner cross-sections. All items cut on this saw are processed through manual grinding for a finished product.

The VC-Ez 20 Vertical Machining Center combines a rugged spindle and a space-saving design with unprecedented affordability to put Mazak quality and reliability in virtually any shop. With a full range of spindle, auto tool changer and chip/coolant management options, the highly configurable machine meets many production needs. Enhanced operator ergonomics and a generous work area ease the loading and unloading of workpieces and tools, while an extremely fast traverse rate of 1,654 ipm in the X, Y and Z axes enables higher throughput.

All our certified AWS welders go through bi-annual reviews to ensure they are welding to the highest quality. All of our welders are certified in MIG and TIG for both aluminum and steel. Our welders take pride in their work and built a reputation for quality and dependability.

100” - .200” 3G aluminum

.125” – 5/16” 3G aluminum

1/8” – ¾” 3G aluminum 10 – 18 gage carbon steel

From grinding, galvanization, powder coat and shipping we handle it all. Whether we do it in house our outsource we ensure that no product moves out without a finished look.

Our capabilities provide custom assemblies and components to a wide range of products, big and small. Whether its final touches or moving the project down the line our team ensures all products are handled with the utmost care so our customers receive a quality product.

We known that our customers trust us to provide a quality product that is why we manufacture to ISO standards. All products go through extensive checks to ensure that they are built to withstand the elements they are in. These quality checks happen throughout the process of manufacturing with specialized quality assurance technicians.

Whether creating new products or improving existing ones, our team of engineers focus on the development of product specifications so that our manufacturing team produces products to the highest quality.

Our expert engineering services include CAD development, BOM creation, 3D models, prototyping and testing as well as mechanical problem-solving.