SELECTED SAMPLE PORTFOLIO

1

Cristina Cazacu

Role: Part 2 Architectural Assistant

BRANDRAM ROAD YOUTH HOUSING

Lewisham, London, UK

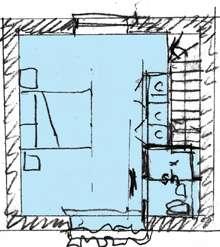

Brandram Road is located within a residential area of Lewisham. The site currently comprises three, two-storey houses with lush back gardens. We proposed a palimpsest, retaining the structure of the current 2-storey houses and plugging in new spaces in between.

Existinghouses Chosen units

2 1/PETER BARBER ARCHITECTS

1B1P (37m2) 1B1P (39m2)

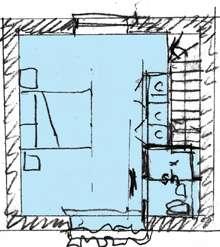

GroundFloor1:100@A3 1B1P (37m2) 1B1P (39m2) 1 bed 2 person M4(3) wheelchair adaptable unit 1 bed 1 person NTS Ground Floor

1.NWElevationofthemainbuilding

2.NWElevationofthestaffhousing

3.NEElevationofthemainbuilding

4.NWElevationofthestaffhousing

3

1 3 2 4 NTS 1st Floor

1stFloor1:100@A3

1B1P (37m2)

1B1P (39m2)

1B1P (42m2)

1 bed 2 person M4(3) wheelchair adaptable unit 1 bed 1 person

1B1P (37m2)

4

View from Church Terrace

View from Belmont Hill

ViewfromBlessingtonRoad

Role: Part 2 Architectural Assistant

WESTGATE VILLAGE

Dartford, Kent, UK

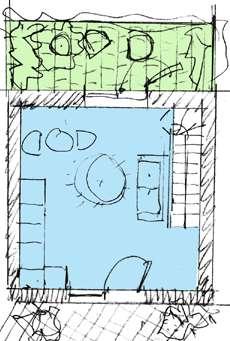

Westgate Village is a low-rise neighborhood, ranging between one and three storeys, located in the town centre of Dartford. High quality residential (~120 homes) and non residential accommodation is arranged around a network of intimately scaled mews streets, knitting together the existing Kent Road, Hythe Street and Orchard Street into a cohesive part of the town. Axonoftheproposal-bydirector

5 1/PETER BARBER ARCHITECTS

2.7 Design Proposal Options Overview Approximate No. of units: 120 homes (11,175 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 6 spaces Approximate No. of units: 100 homes (10,186 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 25 spaces Approximate No. of units: 150 homes (9750 m 2/3/4 storey cottages Approximate commercial area: for discussion Number of parking space 3 spaces Approximate No. of units: 95 homes (7715 m 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 25 spaces Approximate No. of units: 75 homes (6726 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 45 spaces Approximate No. of units: 75 homes (4875 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 40 spaces Option 1A Option 2A Option 3 Option 1B Option 2B Option 4 Option 5 Approximate No. of units: Approximate commercial area: Number of parking space

1:500 2.7 Design Proposal Options Overview Approximate No. of units: 120 homes (11,175 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 6 spaces Approximate No. of units: 100 homes (10,186 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 25 spaces Approximate No. of units: 150 homes (9750 m2 2/3/4 storey cottages Approximate commercial area: for discussion Number of parking space 3 spaces Approximate No. of units: 95 homes (7715 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 25 spaces Approximate No. of units: 75 homes (6726 m 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 45 spaces Approximate No. of units: 75 homes (4875 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 40 spaces Option 1A Option 2A Option 3 Option 1B Option 2B Option 4 Option 5 Approximate No. of Approximate commercial Number of parking 2.7 Design Options Approximate No. of units: 120 homes (11,175 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 6 spaces Approximate No. of units: 100 homes (10,186 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 25 spaces Approximate No. of units: 150 homes (9750 m 2/3/4 storey cottages Approximate commercial area: for discussion Number of parking space 3 spaces Approximate No. of units: 95 homes (7715 m 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 25 spaces Approximate No. of units: 75 homes (6726 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 45 spaces Approximate No. of units: 75 homes (4875 m2 3/4 storey apartments 2 storey cottages Approximate commercial area: for discussion Number of parking space 40 spaces Option 1A Option 2A Option 3 Option 1B Option 2B Option 4 Option 5 Approximate Approximate Number of Figuregroundplanoftheproposeddesignwithstoreynr.

AerialviewontoWestgateParking

At the heart of the scheme lies a public square, where streets converge, fostering social interaction between residents. Charming small scale shops adorn the hard edge of Hythe Street continuing and rejuvenating this commercial street . A smaller square is formed at the end of Copperfields Walk.

DINING ROOM

6 Non-res spaces Refuse Sewage Residential spaces 15000mm Exclusion 30000mm Exclusion Existing buildings

Floodingaffecting76sqmoftheproposal Ground Floor 1:100 UpperFloor1:100 Elevation 1:100 1:500 Ground Floor 1:100 First Elevation LIVING/KITCHEN/ DINING ROOM Design Typical Ground Floor 1:100 First Floor 1:100 Elevation LIVING/KITCHEN/

BEDROOM BA 01 02 03 01 02 03 Elevation 01 02 KEY

Viewontothesquare,andorielwindowinthecorner

7

Viewontothesquare

Topview

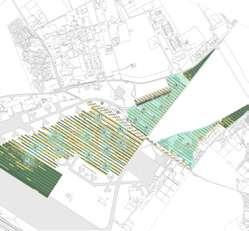

FLAXMILL SHREWSBURY

Shrewsbury, Kent, UK

Flaxmill Maltings is a delightful new urban quarter comprising , houses, flats and maisonettes laid out along pretty mews streets linking Spring Gardens to the newly refurbished Flaxmill buildings and pedestrian routes to the north of the site. Shrewsburry Flaxmill is the first iron-framed building in the world,

1/PETER BARBER ARCHITECTS

Role: Part 2 Architectural

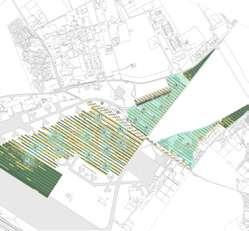

2.3 Design Proposal Proposed Figure Ground Plan

Assistant

FigureGroundPlan

University of Westminster, Year 2, DS12, Peter Barber & Ben Stringer Winner of 2nd Place Joint Shoaib Rawat Memorial Prize

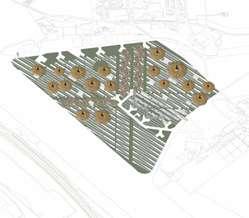

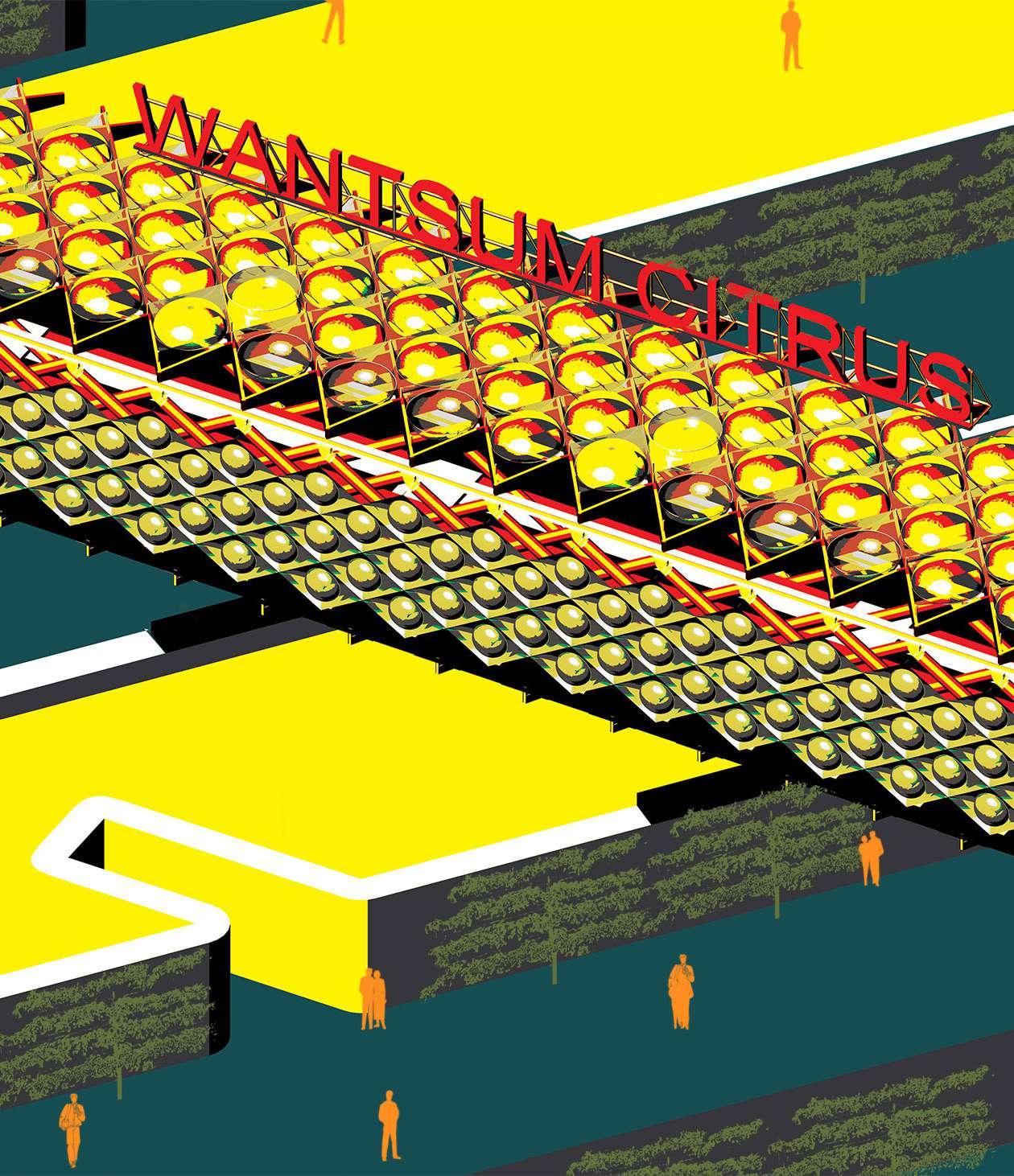

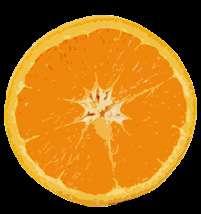

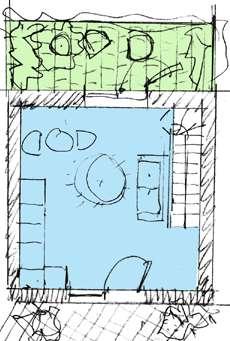

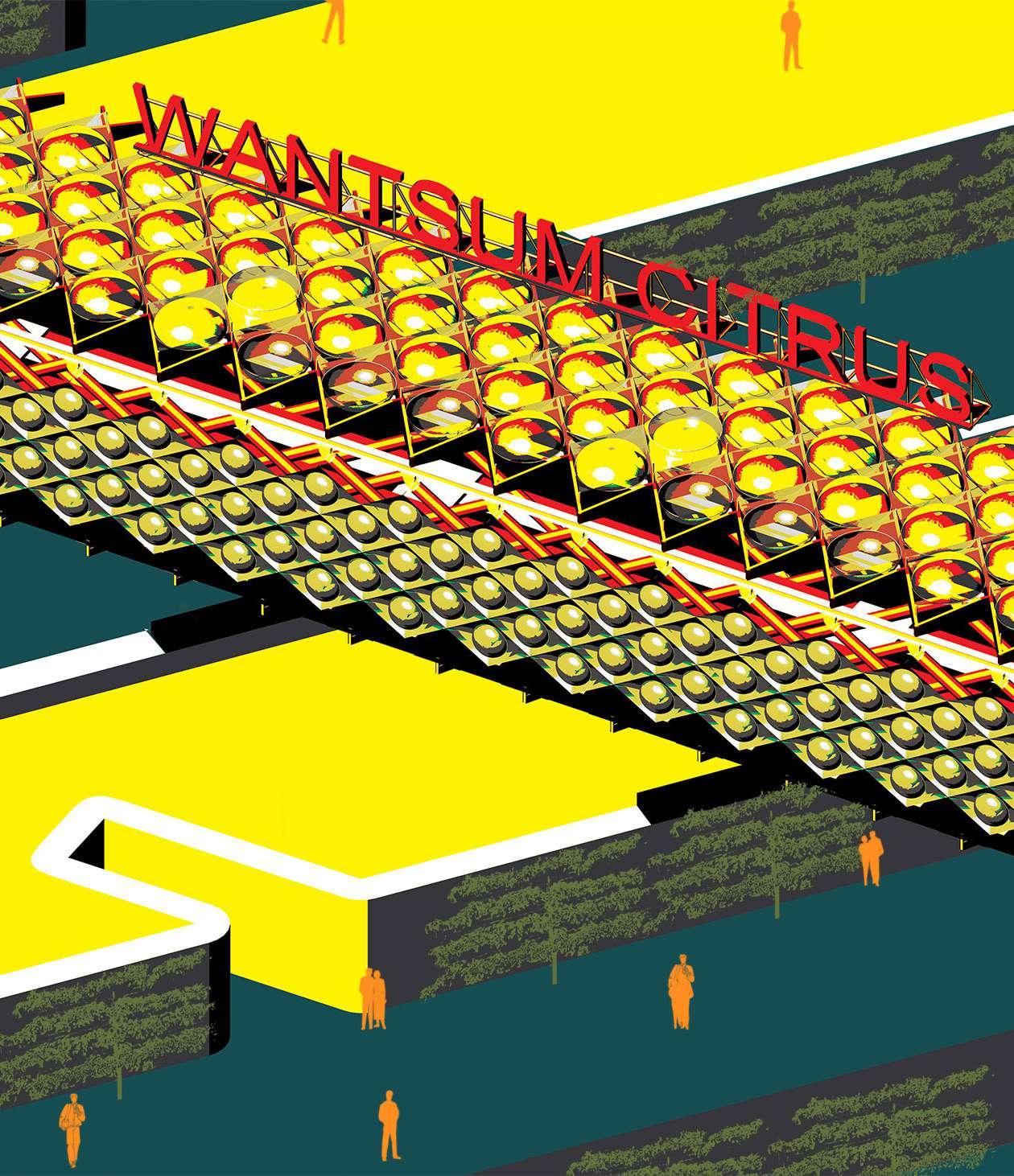

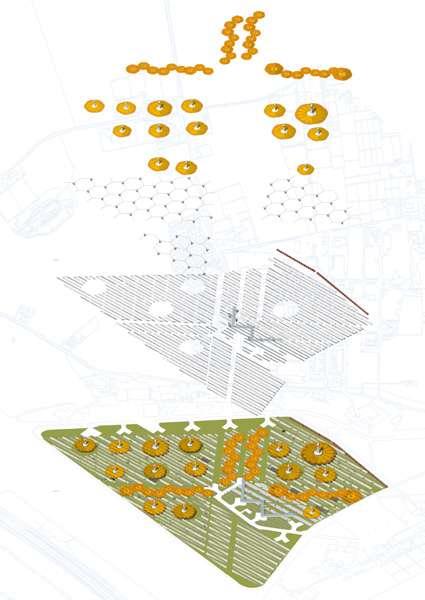

WANTSUM CITRUS

Manston Airport, Kent, UK

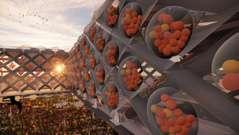

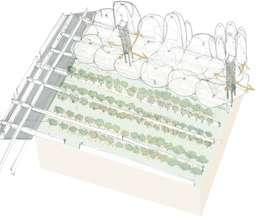

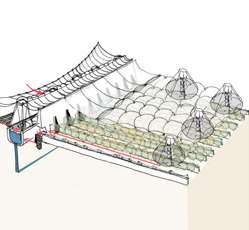

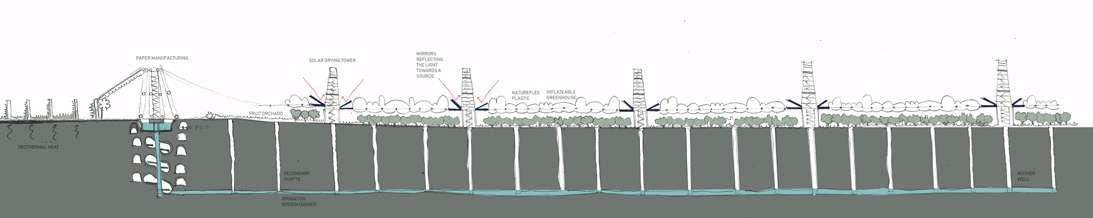

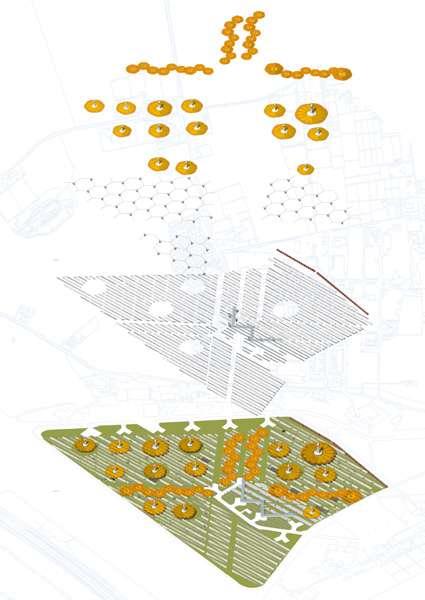

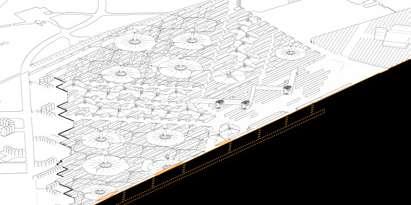

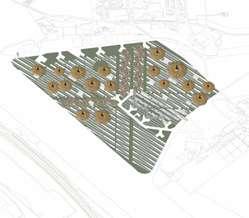

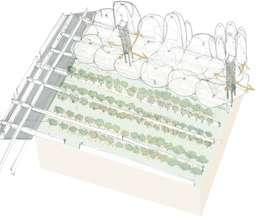

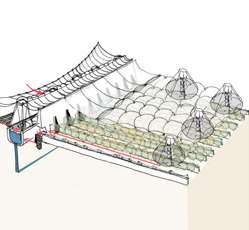

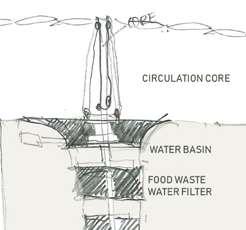

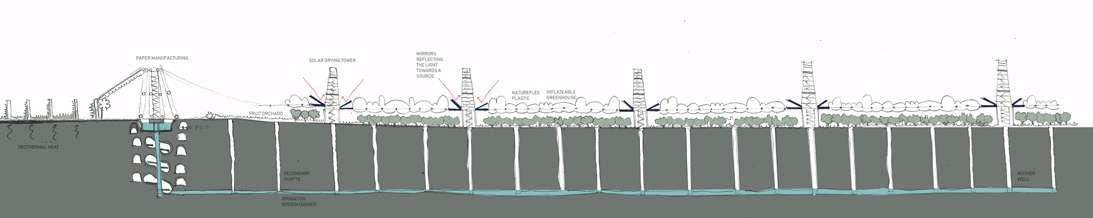

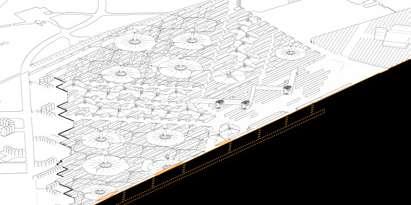

Wantsum Citrus is an experimental orange orchard in Manston, Kent, equipped with innovative inflatable greenhouse technology and optimized plant growth in times of food insecurity for consumers and farmers alike. Citrus strikes to break the dependency of food imports into the UK and build a local economy run by the people of Manston. The project rethinks food waste, in specific fruit peels, into valuable upcycled materials such as orange paper, packing material, cellulosebased bioplastic and structural kraftboard rolls made with a percentage of food waste. The orange trees grow on rammed chalk walls as south-facing espaliers, which ensures maximum sun exposure. In adverse weather conditions, an array of inflatable greenhouses is deployed across the orchard. These greenhouses use residual hot air from drying towers, where food waste is dried prior to processing it into recycled paper and building material.

2/ACADEMIC WORK

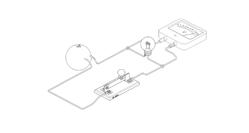

Awaitingthehelicopterride Proposal

OverviewofManstonAirportandproposedprojects

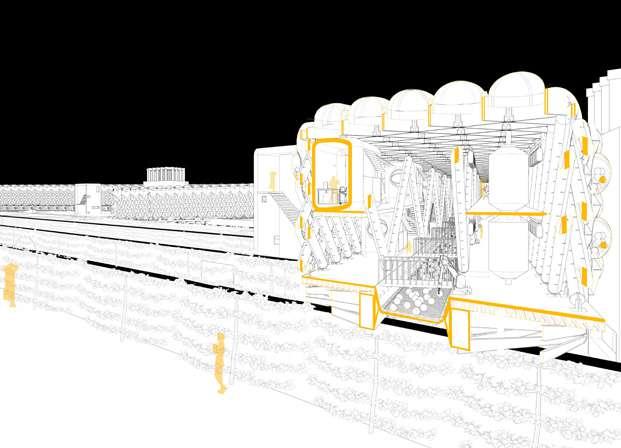

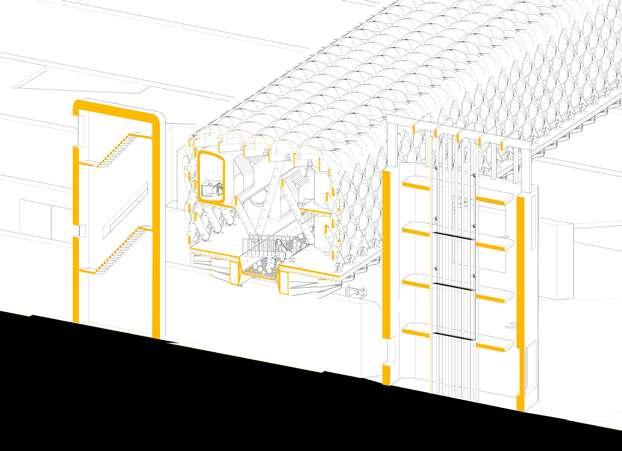

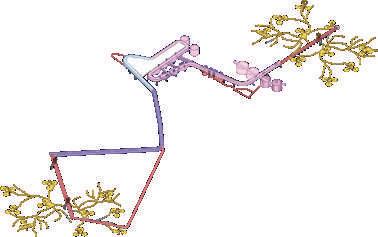

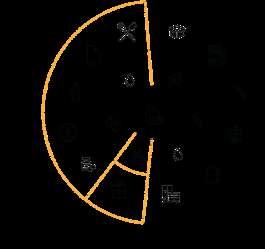

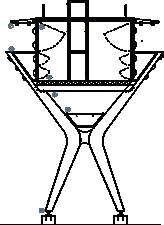

Viewthroughtheorangeorchardswithanoverlookinginflateable 1 Groundwater Well Oranges Peels Fruit Waste Purification Bioethnaol Pigment Hot Vapour Oranges Receptive bricks Habitat for mining bees Food for mining bees Soil aeration Solar Steam Distillation Sun Solar Drying Juice Pressing Fiber waste Solid residues Hot Vapor Milling Drying Mixing + Bleaching Beating Flow board Roller Forming Waste Water Paper Blossoms Srujitha’s parfume Denise’s Water Treatment Plant Sophie’s Packaging Hannah’s workforce Machinery picking Elderly plant nurturing Hanna’s Market Ian’s Medicine Fertiliser Ally’s fertiliser Tree Shipping Existing Concrete Hannah’s workforce INDUSTRY BYPRODUCTS USAGE SITE INFLUENCES WORKFORCE AGRI CULTURE Ian’s Packaging Ian’s fertiliser Ian’s leaves Denise’s wastepaper TESCO Deal Heatreg. Anthony’s Chalk Georgina’s cotton Programme:PaperoutofCitrusWaste Inflateable Greenhouses 2 Cable andpilon structure 3 Inflateable Greenhouses 4 Rammed chalk walls withupcycling facilityand papermaking facility

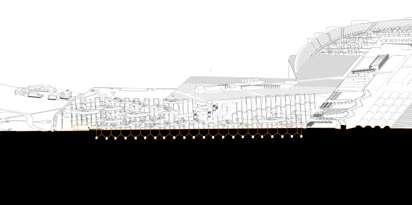

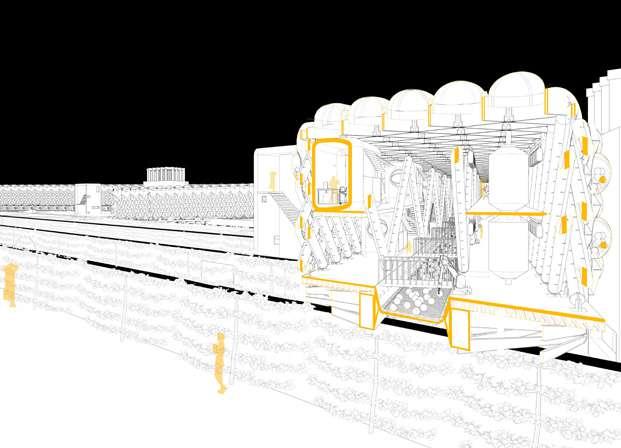

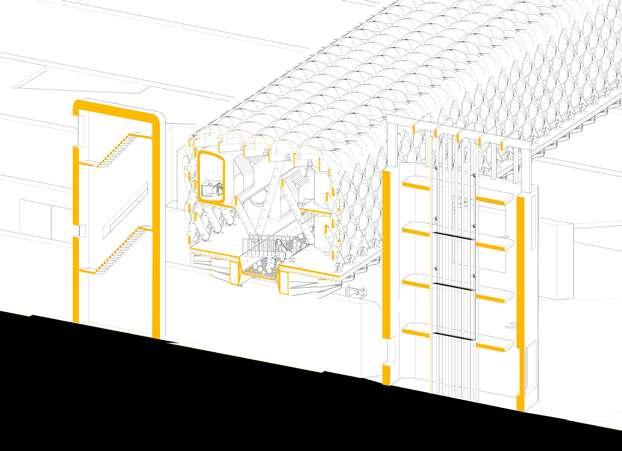

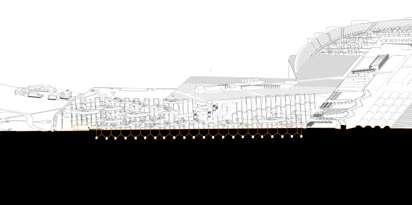

Section(North-South)throughownproject,andtheneighbouringones

Section(East-West)throughownproject,andtheneighbouringones

Anthony’sGeothermalTunnels

Anthony’sGeothermalTunnels

Sectionthroughtheorchardandneighbour’s tunnels

Pietro’sBrewery

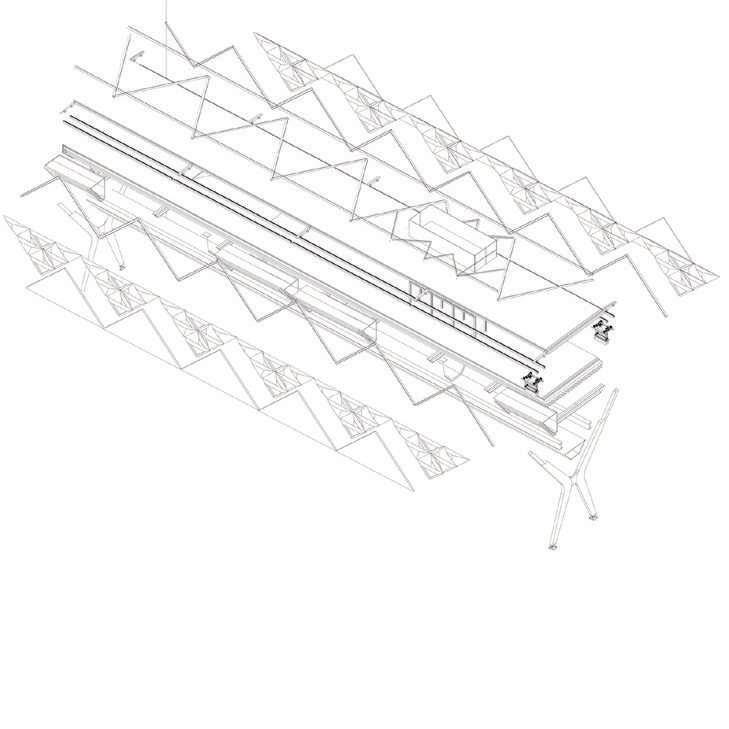

Axon of the entire scheme within the site context

Electricity from Citric Acid

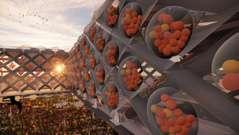

The facade holds recycled ETFE (Ralph’s Recycling Centre) pods. In them, leftover and spoilt oranges are used for their citric acid to produce enough electricity to lightup the ‘Wantsum Citrus’ Billboard on top of the facility. Once fully depleted, they are dried and used for their pulp in the paper making process

12 Viewinsideoftheorangepeelupcyclingfacility

Billboard poweredby citric acid

Citrus Circuit

Facade

Sectionthroughtheupcyclingfacility

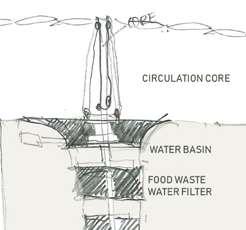

13 Circulationtower forDeliverieswithpulleysystem thethefoodwastebroughinto site MainBuildingrestingon cappingbeamsoftherammed chalkwalls Community Allotments 1 2 3 4 5 6 1 Offices 2ConveyorBeltfor WashingOranges 3 Juice Production and Rainwater Treatment 4 Rainwater Silos 5 Circulation Tower (Public) 6 Circulation Tower and Deliveries(Private)

Heattransport throughwater

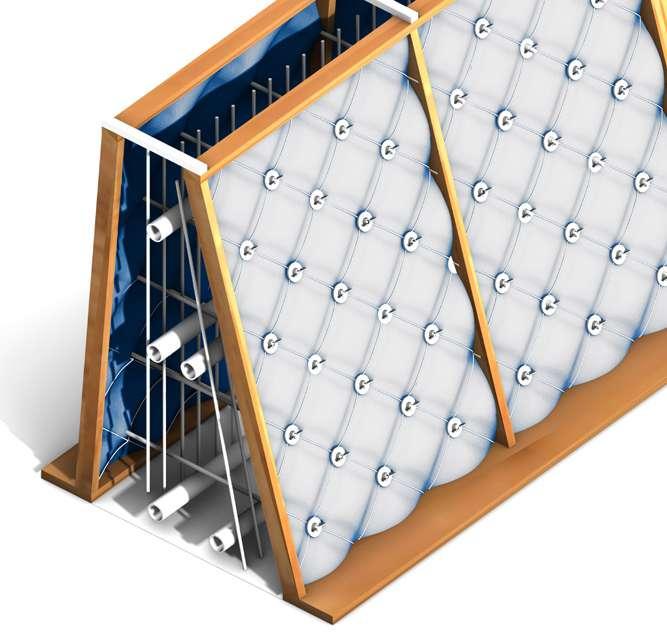

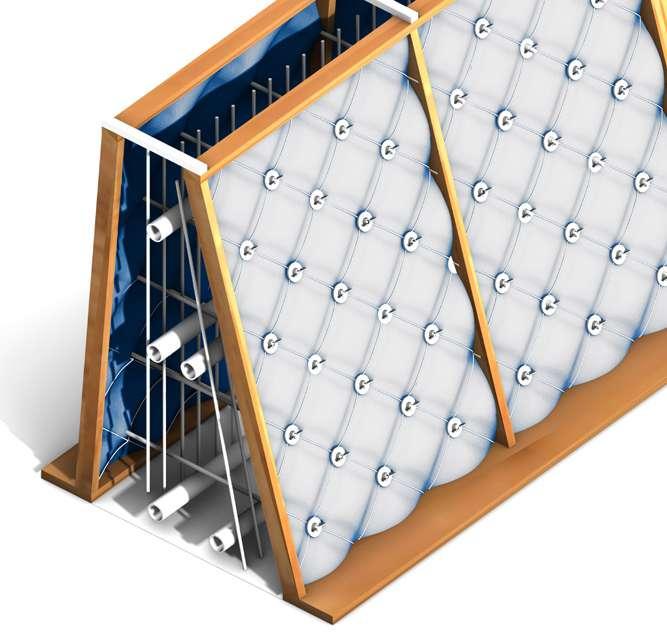

Biodegradeable plasticformwork for the chalk walls.

Pipestogeothermal plant

Theformworkisofacellulose-basedbioplasticwhich degradeswithin90days.

Closeupofthefacadewhenfullyfilled with rammed chalk

Theformworkistiedwithhempstringsgrownonthe north side of the orchard. Once filled with rammed chalk,itgetsitsondulatedshape.Then,thetimber framework is removed.

After45days:thefacadedecomposes andflakesbreakthroughweather influences off the rammed chalk wall

After90days, the rammed chalk texture is visible.

TechnologicalLayers

LayerA:HeatedWalls

LayerB:FruitHarvester

LayerC:SolarPanels(predom.North)

LayerD:Windmills(predom.South) ForestGardenLayers

Layer1:ValenciaOrange,BloodOrange

Layer2:CrabApple

Layer3:CherryTree

Layer4:Hemp

Layer5:Raspberry,Blueberry

Layer6:Blackcurrant

Layer7:Jessica’sGinger

14

15

iron

Inflatable made withasoldering

Tools:

Cedric Price’s Inflatable on the AD

Magazine1970 closed open

3.

4.Waterproof

5.

6.Blowairthroughthepipe and

the

Orange

1.Cutlayersof plastic 2. Use parchment paper to control the heat

Iron over the parchment papertomelt theedges

edges

Cut a nozzle and secure apipe/straw throughit.

secure

airflow

Paper

Grindingintoa paste Mixingwith1:4 recycledpaper BleachingwithChalk Mixingeverythinginto aliquid 47.250 ORANGE PEELS 270 ORANGE TREES PER HECTAR 94500 ORANGES IN A YEAR 1 ha 49.24% PEEL, SEED, RAG 44.81% ORANGE JUICE 2.67% PULP CELLS 2% OIL 0.92% D’LIMONENE

DriedOrange Peels

216 000 000

@90gsm

47

(project’s area)=

rolls

4.320 REAMS (

SHEETS

)

ha

2.04 billion paper

16

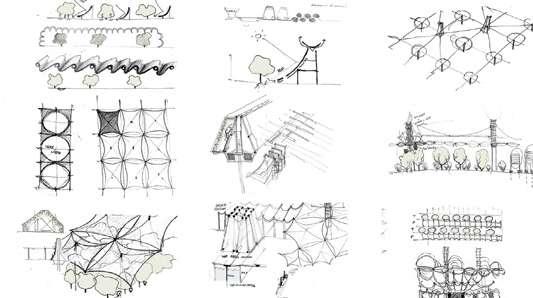

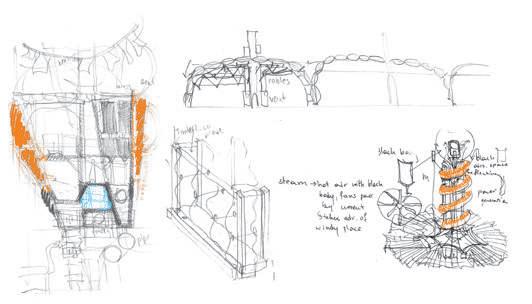

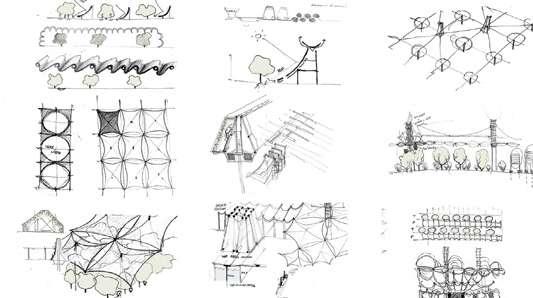

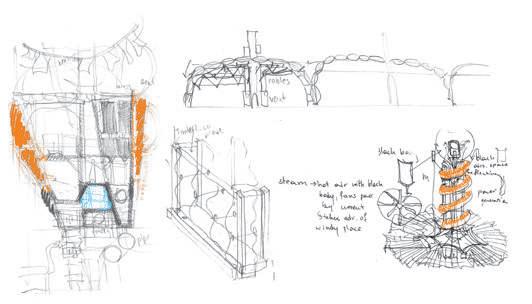

DEVELOPMENT SKETCHES PACKAGING MATERIAL PAPER AND CARDBOARD MANUFACTURING DRYING TOWERS ORANGE WALL WITH PARKING LOT FOR DELIVERIES BIOPLASTIC INFLATEABLE ROOF 5. INFLATEABLE PODS WITH CAGES GRASSLAND ORANGE PEELS; PACKAGING FOR IAN’S MEDICINE GEOTHERMAL HEAT ORANGES THE RUNWAY GREENHOUSE SITE SKETCHES GREENHOUSE UPCYCLING FACILITY DRYING TOWERS

DESIGN

Heated walls

Inflateable towers over the orchard Undergroundirrigation

Dryingtower

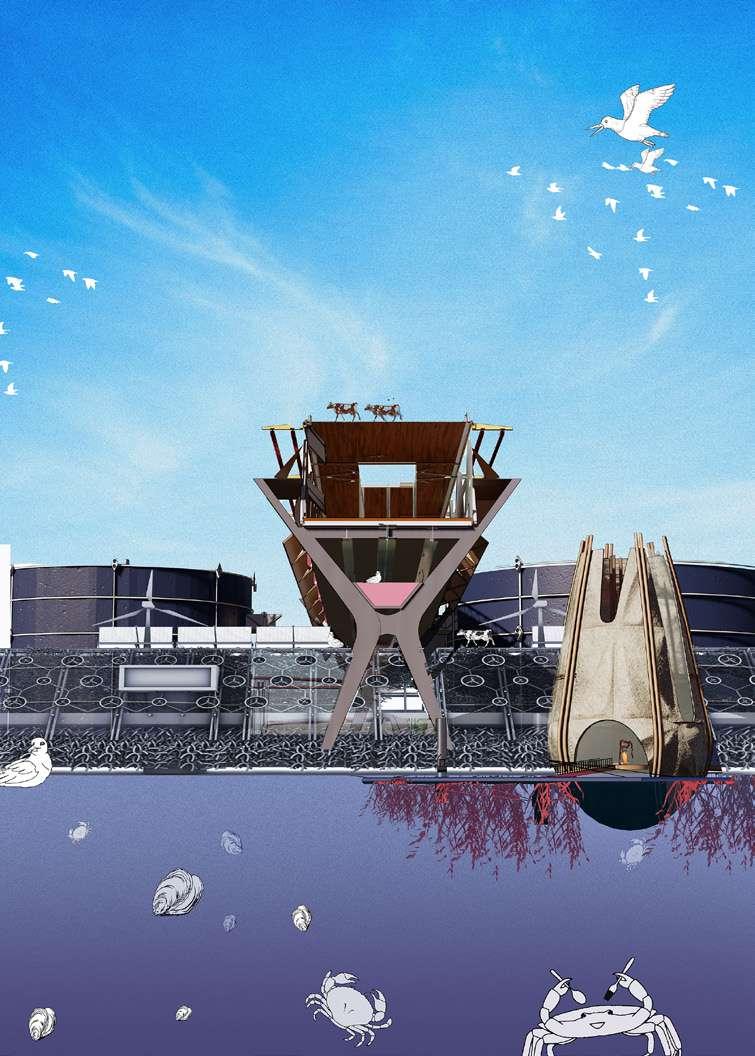

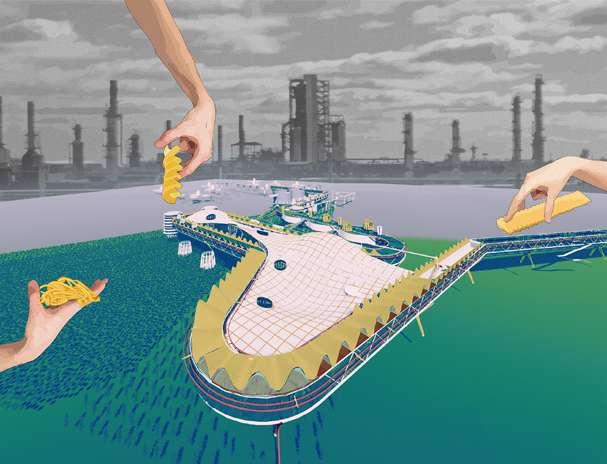

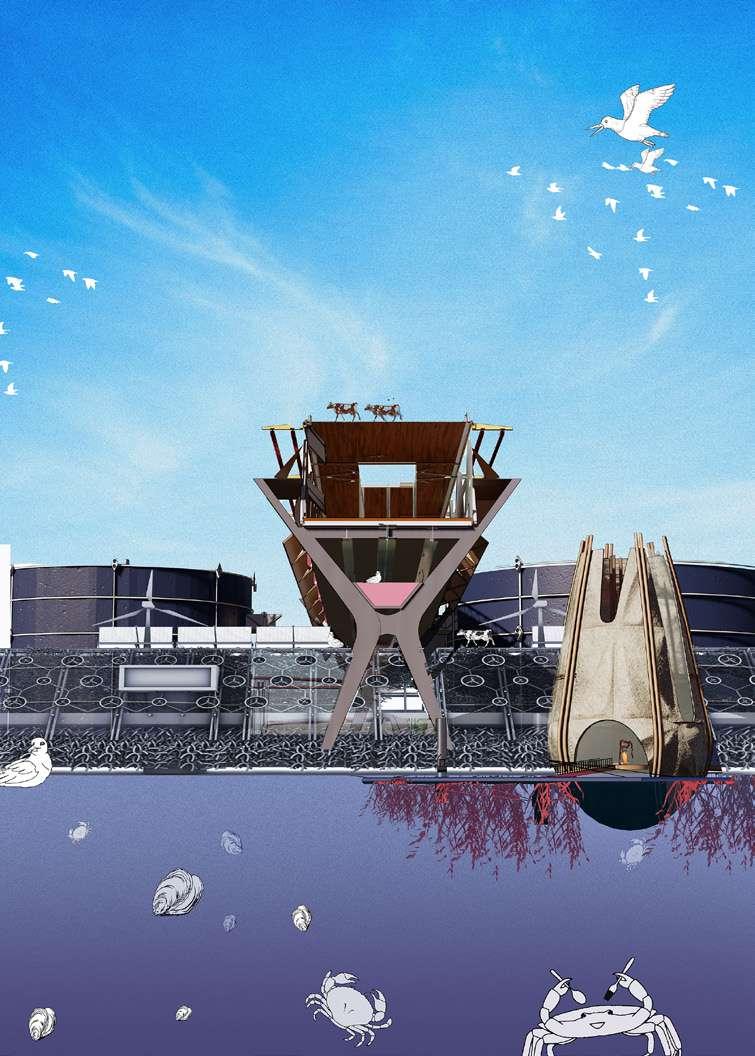

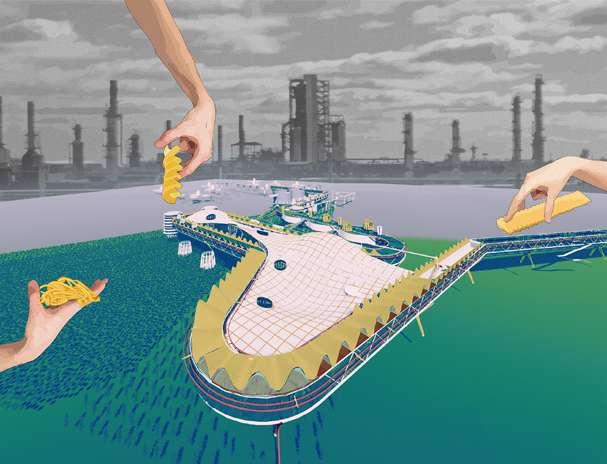

3/ACADEMIC WORK

University of Westminster, Year 1, DS12, Peter Barber & Ben Stringer

LAS SUPPER

Coryton, Stanford-le-Hope, UK

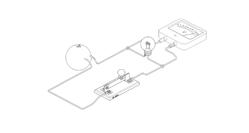

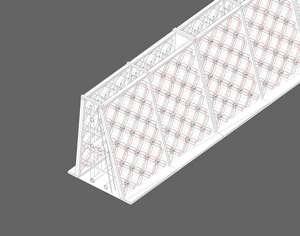

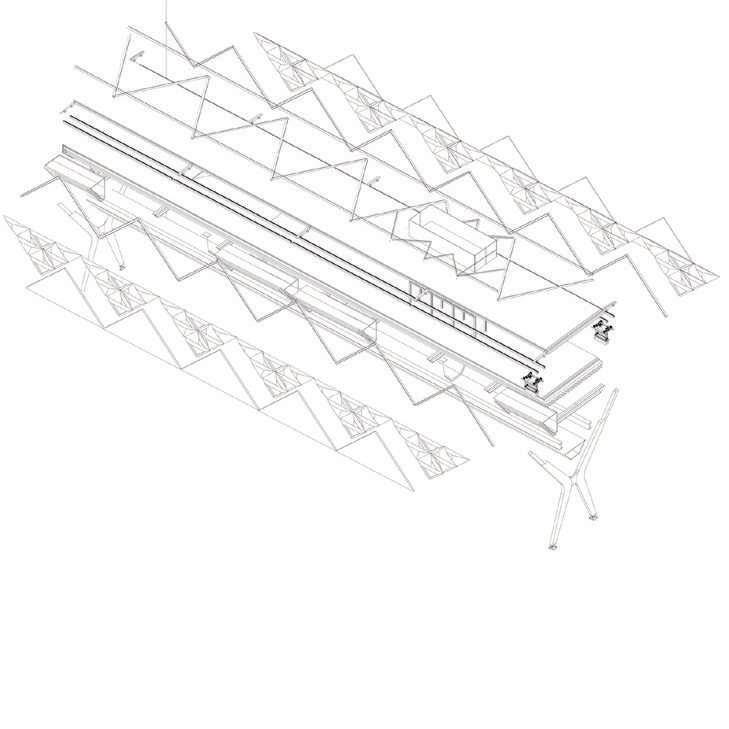

Las Supper is a linear factory, producing pasta-shaped gelatine from the red seaweed ‘Glacilaria’.

Thus the project reintroduces native food of the Thames to the local community. The factory doubles as a transportation system, with a conveyor belt running underneath. It connects neighboring projects and transports produce from one corner to the other

Viewinsideoftheorangepeelupcyclingfacility DAY IN THE LIFE OF A CORYTON FACTORY WORKER

INDUSTRY

SECONDARY

MATERIAL TRANSPORT SPORE LAB GELATINE FOOD PRODUCTION

HOUSING + FARMS OYSTER SHELL

RESTAURANT

STRUCTURE

Conceptualshot

ProjectIntersection

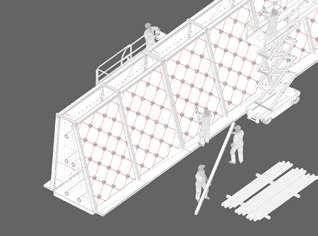

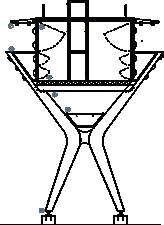

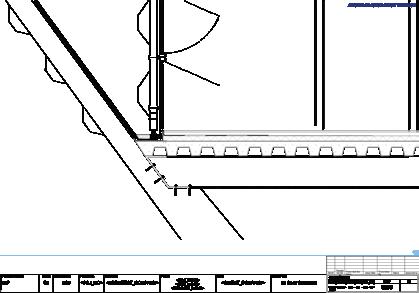

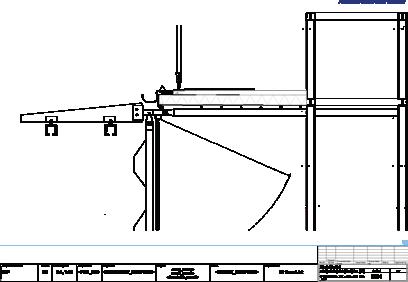

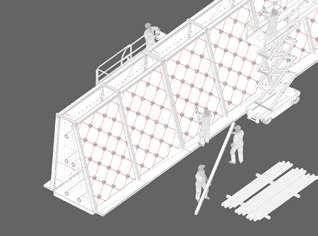

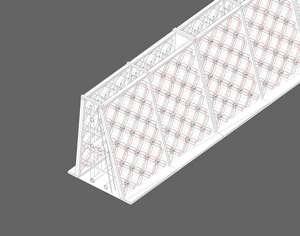

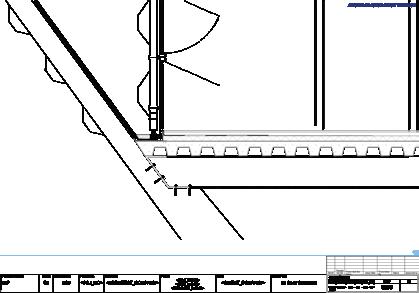

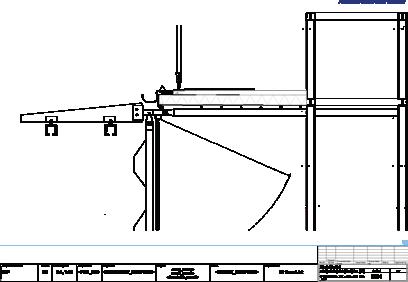

Bamboo forestry Radial cut via machine or handheld radial splitter Insect treatment by dipping bamboo into pesticide based solution Mechanical defibering (skin removal) Resin treatment of slabs Hot pressing of slabs into boards by applying from both sides Mixing the raw material :Calcium, Silicon, Iron, Aluminum: Clinker and gypsum initial crushing (2.5 cm) Clinker and gypsum initial crushing secondary crushing (fine) DOW PROCESS (Electrolysis): Solar evaporation of NaCl + H2O, inducing chemical precipitation, results in the initial separation of magnesium from brine Proportioning additive materials: sand & clay (local resource) Heating in Rotary Kiln at 1500°C Cement Mill & Storage in Silos Growth process from spore to Gametophytes in 27 days Spores are grown in the water lab for 10 days. The rest is kept in dimmed light as specimen for diversifying crop. Tank nursery of spores Brought to the factory through the conveyor transportation Attacking semi-mature seaweed to waterfronts satellite farms Byproducts: Agar cosmetics, Gelatin Pasta, Oyster Shell concocter ( Binding Agent) Oystershellconcrete Bamboo Agargelatine 1 2 3 4 5 1 2 3 4 5 6 7 1 2 3 4 5 6 1 2 3 4 5 6 6 1 2 3 4 5 6 1 2 3 4 5 6 Cantilever system with C Beam for Conveyor Operable glass container Operable facade, upper window + fire safety opening, filled with bio plastic and gelatin Material delivery via Conveyor Deck supported by I- beams girders with casted concrete 1 2 3 4 5 Glass Container for gelatine set off Footing 6 7

X&Y AXIS MOVEMENT Z AXIS MOVEMENT King’s Landing Filtering Tower Las Agna Agar Avenue Minor Penne Fussili Central Five Maccaroni Main Crossing South Walk Tower Corner West End East End Main Line Secondary Line Ferry Salt Line View from the warehouse Detail 1 Detail 3 Detail 4 Detail 2 Detail 1 Detail 2 Detail 3 Detail 4

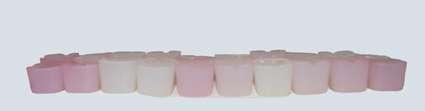

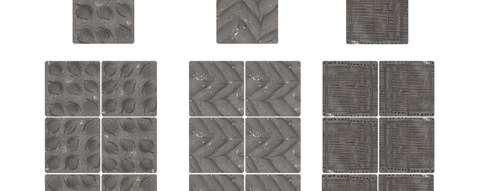

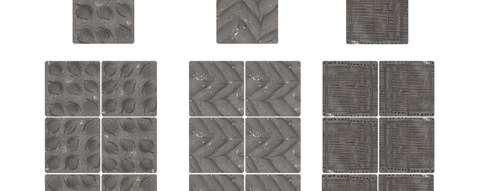

Bioplastictiles

Pastaimprintedtiles

20 20g Glycerine 5g Glycerine 20g Glycerine 20g Glycerine 5g Seaweed Gelatine Powder 150ml Water 5g Food Colouring

concrete Glacilaria gelatine

gelatine Oystershell

Bioplastic Oystershell

Glacilaria

Edible Pasta (jap.:Tokoroden)

4/ACADEMIC WORK

University of Westminster, Fablab Week, Group Work/Competition, Winner of the Technical Award

SENSORY RIBCAGE

Fablab UOW, London

Cogstructure

The preliminary research was started through the investigation of contemporary dance via Online YT videos. Here my partner and I recognize the motion pattern of CONTRACTION and RELEASE which became the defining element of the installation. The dancers seem to be pulled towards an imaginary sky, hyper extending their torso to it, in a stretching motion. After the sequence of contraction in no particular order, the dancer pulls within herself/himself, contracting their muscles. There is an interplay of contraction of muscles and of one self towards their chest . We chose to work with the chest and ribcage as it was the most expressively obvious element of the contraction and release motion.

21

Manualoperation

Final Product

Cogsplacedunderthetableframe

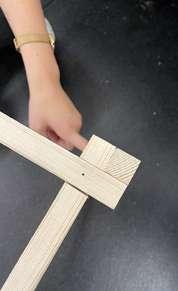

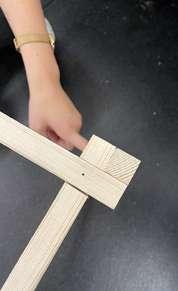

Pouringgypsumoverstockings JapaneseJoinery

Materialtestingofgypsumon stockings

22

IkeaPackagingMaterial Stockings Yellowplastickitchengloves

Layersofcardboard andplasterwith stockings

Skin like texture Undercoolwhitelight

Role: Architectural Intern

SALZWELTEN. DER SALZBERG RUFT

Salzwelten, Hallstatt, AUT

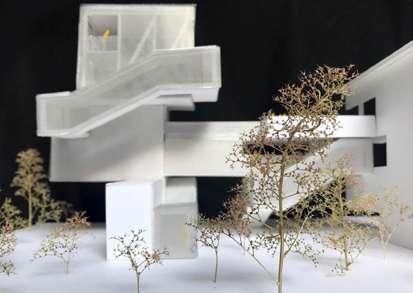

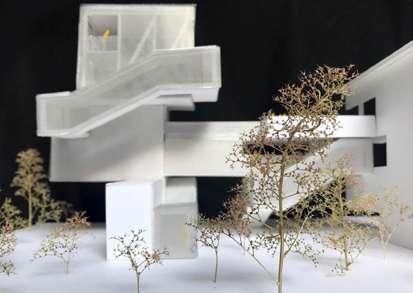

“Salzwelten” is a competition based in Hallein, Austria, for a much needed renovation of a prehistoric salt mine. It creates an interactive space in the cave itself as well as an extension of the current buildingfollowingacubistconcept. 1st

Floor

00:00 60 Ankunft Besucher-zentrum

©Heri&Salli

Ticket-check Aussicht Preview

Backview

Close-Up

Frontview

5/HERI&SALI

Role: Architectural Intern

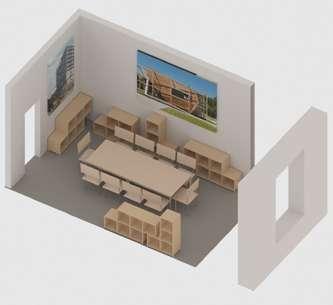

CUPBOARD MODULES

Heri&Sali, Vienna, AUT

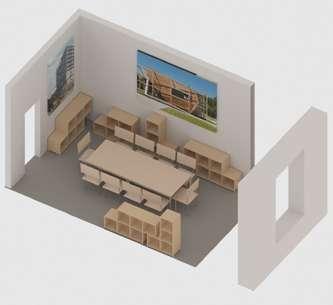

AxonometryofConferenceRoom

ObliqueViewoftheConferenceRoom

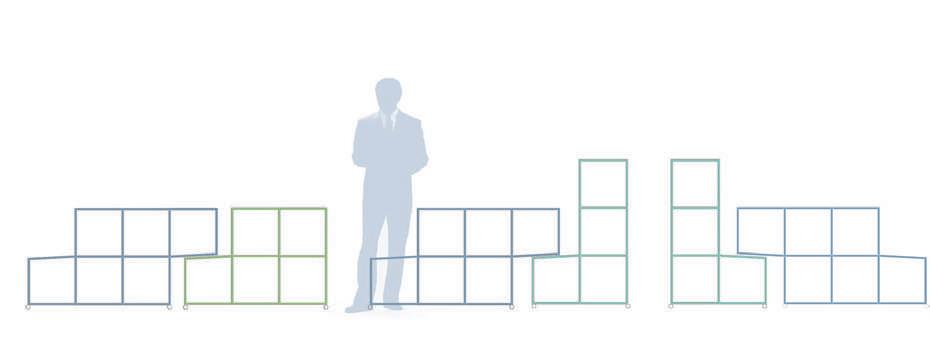

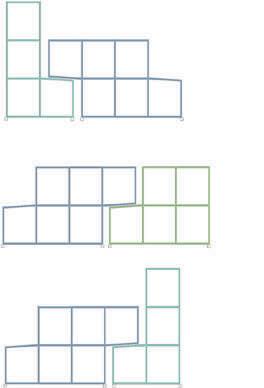

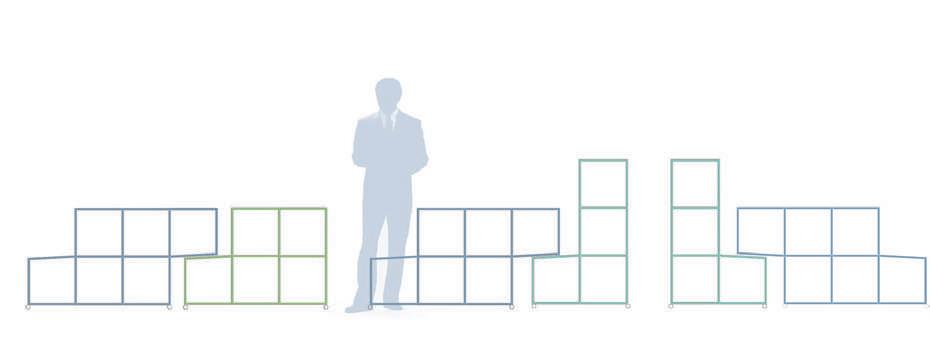

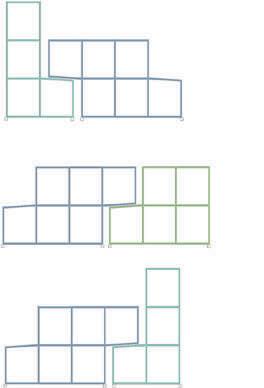

Given as a task to redecorate the Heri & Salli conference room, plywood cupboard modules were introduced. Consisting of a 330 x 330 mm per cube,aslopedplywoodboardatthefarthesthorizontalsideofthemodules allow them to be joined together, while being mobile on wheels. At only four degree of a sloping angle, this spot can be used as additional seats or as space for publications. The discussion table will also be replaced by a singularplywoodone,restingonasteelstructure,withoutanywheels.

The cupboards have a maximum of six individual boxes and a minimum of four to keep the form factor functional. The wheels allow quick and easy permutationamongstthecabinetstoachievedesirable configuration. The primary element was intended to stay as economical as possible, hence fashioned after a simple open sided even quadrilateral. The cabinet exterior is subdued to blend in with the surrounding furniture such as the mainconferencetablealongwithmultiplechairs.

24

5/HERI&SALI

Formations

Type1 + Type2

Type2 + Type3 Type2 + Type1

25

Cristina Cazacu

Anthony’sGeothermalTunnels

Anthony’sGeothermalTunnels