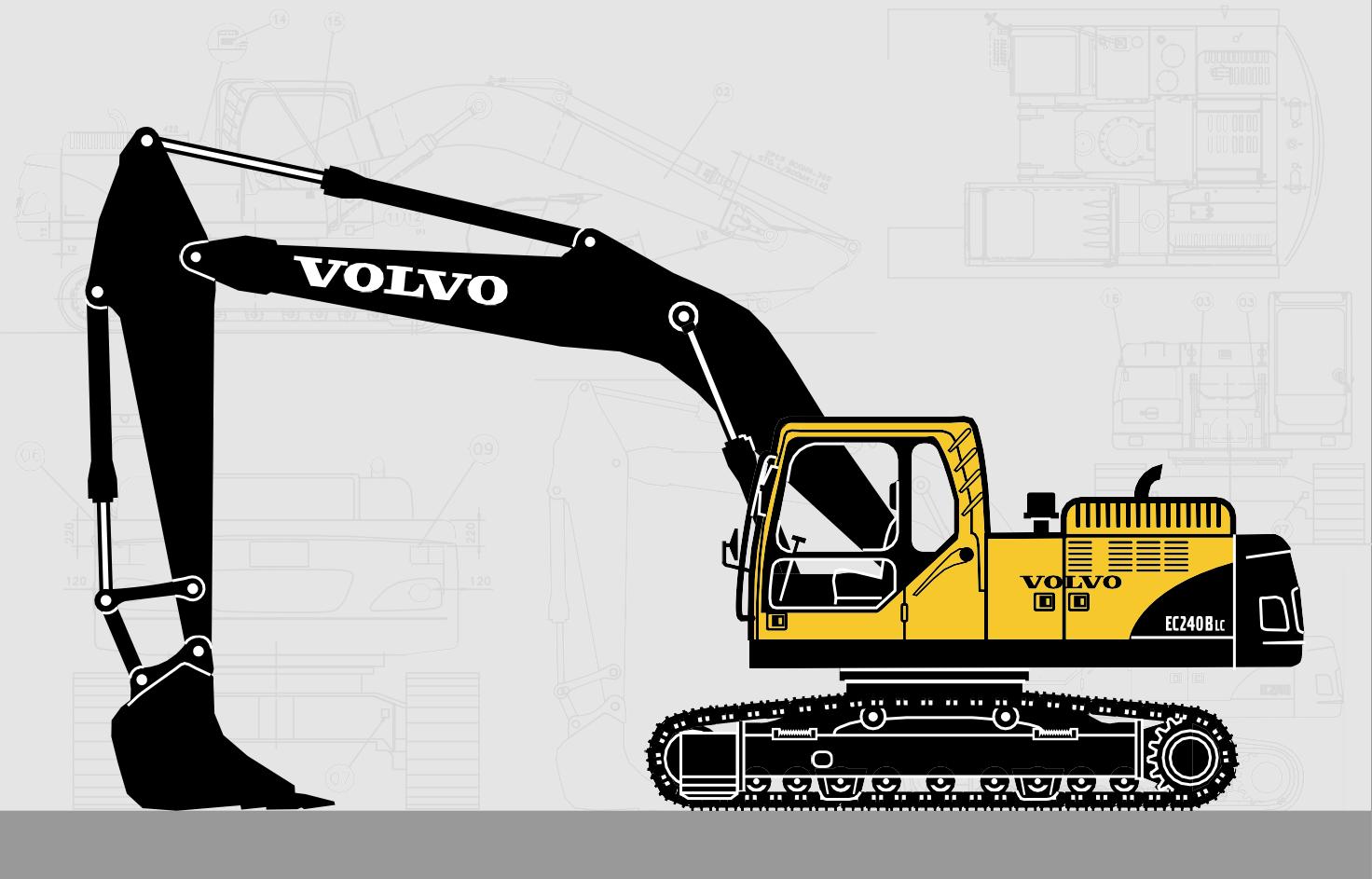

Alternative equipment (see spec. sheet for relevant machine)

Volvo excavators are extremely versatile when it comes to extra equipment which makes it possible for each dealers to customize his own machine. A wide assortment of booms, dipper arms, hydraulics and safety options are available to choose from. By choosing the right combination of boom, dipper arm and bucket you can get a machine with exactly the characteristics you want. With this system of selectable combinations, the new Volvo models offer a wide choice of optional equipment to suit most working conditions.

A large number of options are available to further enhance the versatility and comfort of your Volvo excavator, as well as to facilitate service and maintenance.

Some of the options in the brochure may be standard or required by law on certain markets. Please refer to the specification brochure for more information on the machine in question.

Built-in flexibility

The machines are prepared from the start for a number of options. Three extra hydraulic circuits are available. The booms and dipper arms are prepared with welded brackets for extra hydraulic piping, to eliminate the need for welding work during retrofitting.

This brochure

This brochure lists the options that can be retrofitted on Volvo excavators: EC140B, EC210B, EC240B, EC290B, EC360B, and EC460B. Several options are only available as factory installations. For your reference, these are included in the manual. Please note that some options are not available for specific markets.

Contact Volvo Construction Equipment Korea for more information.

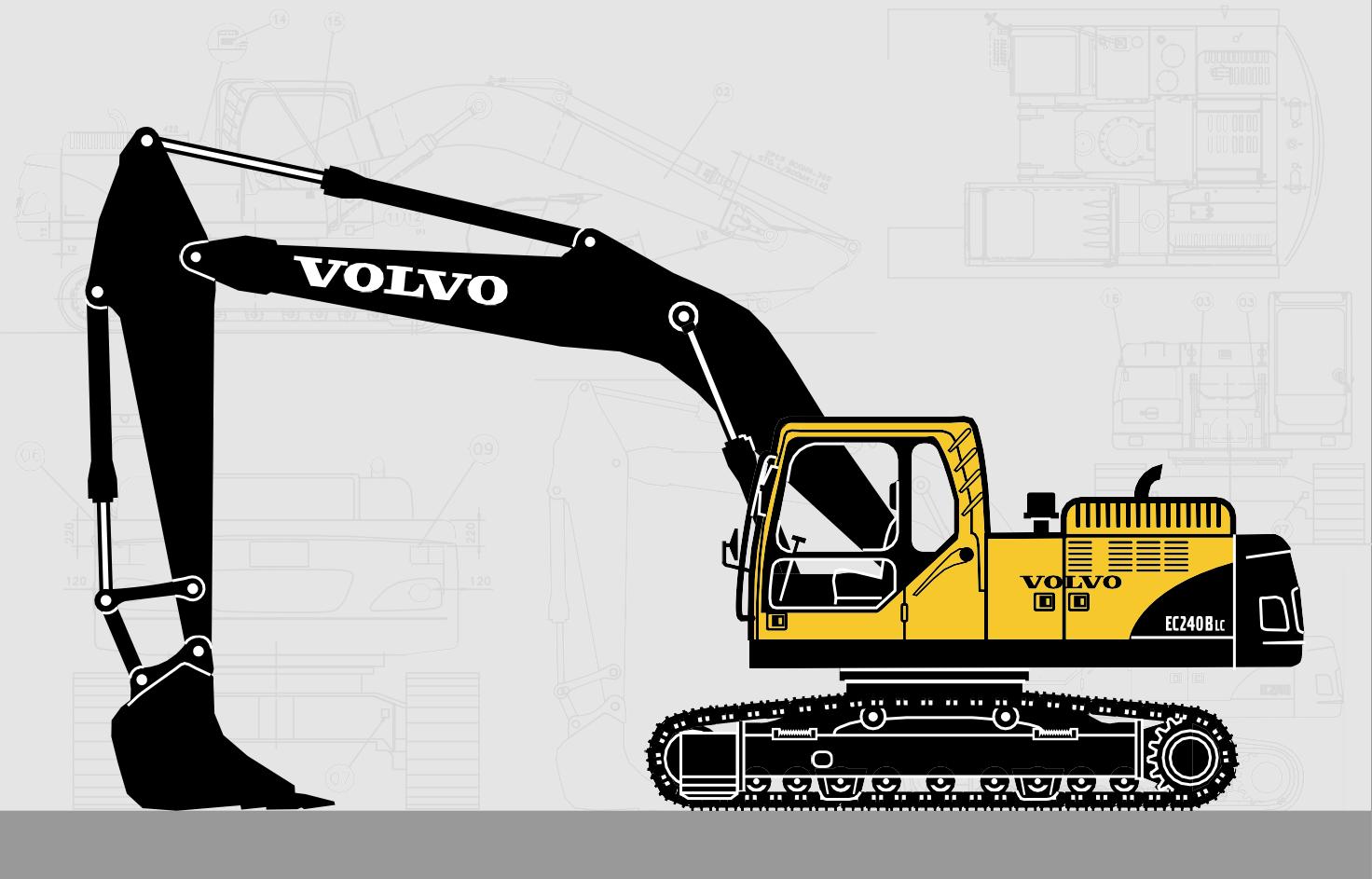

1. Superstructure engine

slew ring

slew reduction unit hydraulic tank

fuel tank

radiator and hydraulic oil cooler working hydraulics

2. Counterweight

3. Cab

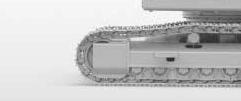

4. Undercarriage travel reduction units travel motor track frame with tracks

5. Boom

a large number of different booms are available in different versions and different lengths, for example: monoblock boom/2-piece boom/ long reach boom/ME boom

6. Boom cylinder

7. Arm

a large number of different dipper arms are available in different versions and different lengths, for example: short/standard/long arm long reach arm

8. Arm cylinder

9. Volvo quick fit

10. Bucket

11. Bucket cylinder

Alternator

A high capacity alternator is available for applications when many electrical devices have been installed, such as extra lights. Alternator 80 A does suit the electrical system load with extra work lamps for machines that work around the clock.

*: Standard for those models

Block heater

The coolant heater (engine block) are additional engine starting aids to the air heater during severe cold weather. The heaters are designed for an external power supply of 240 V AC. Recommended ambient temperature to install: below -20°C

The oil bath pre-cleaner is recommended for machines that work in dusty and humid environments. In combination with the standard air cleaner, the oil bath pre-cleaner provides extra protection against engine damage.

The diesel coolant heater facilitates starting at low temperature (and warming up the cab at the same time) where the electric source is not available. The heating time can be adjusted and the preset heating time can be seleted daily or weekly.

Extra work lamps

For the front direction, two lamps are mounted on top of the cab. For the rear direction, one lamp is mounted on

the cab and the other is mounted on the counterweight. The 80 A alternator is recommended with this option.

Travel alarm

The travel alarm is a safety device that sounds when the machine travels forward or reverse, to warn by standards of impending danger. There is a shut-off switch for long distance travel. In certain markets, a travel alarm is a legal requirement on excavators.

Rotating beacon

The rotating beacon is a safety device which is mounted on the cab roof. For transport, it can be easily tilted. There is a switch in the cab to turn the beacon on or off. In certain markets, a rotating beacon is a legal requirement on excavators.

Operator seat

For the operator’s comfort, various seat options are available.

Standard seat

Standard seat with heater

Standard seat with heater and air suspension

* The other options are available as factory installations.

Low-effort, wrist control joysticks are provided for smooth and precise control. A semi-long joystick and a five button joystick are available depending on the attachment application or operator’s preference.

* The other options are available as factory installations

An exterior front rain shield is recommended for the operator’s comfort. The front rain shield prevents rain from falling on the operator’s feet when the front window is open.

All mounting holes are already installed in the cab. Front rain shield is standard on all machines.

Lower wiper

An extra wiper for the lower front window is available to further enhance the lower visibility.

Sunlight protection (steel)

A sun shield cover on the roof reduces incoming light and heat radiation.

The FOG (Falling Object Guard) is recommended for tough working site applications, such as quarries and demolition. The cab mounted FOG is approved according to ISO 10262 and consists of FOPS and the front guard. The front guard is tiltable and supported by a gas strut for easy access to front window. This installation does not require welding on the superstructure.

Restrictions: Not available with FOPS, safety net, or anti-vandal kit installed on the front window.

A cab mounted FOPS, (Falling Object Protection Structure), is available for the protection of the operator. The FOPS is approved according to ISO 3449 and is easy to install.

The protection structure is bolted to the cab top. All mounting holes are already installed in the cab.

Restrictions: Not available with FOG

To prevent broken cab windows, the machine can be equipped with anti-vandal protection. The equipment consists of 7 pieces of ABS glass fiber plate, a locking key and a storage box. The storage area can be either located between the tool box and boom foot or on the cab roof (EC140B and EC210B cab roof only).

Restrictions: Not available with FOG or safety net installed on the front window. Can be installed on the anti-vandal cab only. The mounting hooks for the vandal kit are already installed on the anti-vandal cab.

For protection of the front windshield and operator during operation with a hammer or crusher, a safety screen is available. The net size is 42 mm x 42 mm. It can be tilted, and is support by a gas strut for easy access to front window. All mounting holes are already installed in the cab.

Restrictions: Not available with FOG or anti-vandal kit installed on the front window.

Service walkway

A service walkway is available for the lefthand, cab side of the EC360B and EC460B. This service walkway provides improved serviceability and maintenance access to components on that side of the machine. The service walkway consists of steel grates which are 300 mm wide and are mounted to the left side of the upper frame.

* Not available with step for cab entrance

Track shoe

Many different track shoe options are available according to the job site requirements.

* XX: The number of shoe plate

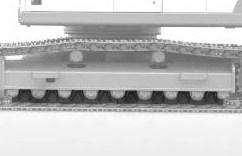

Heavy duty full track guard

Heavy duty full track guard for the undercarriage of EC210B, EC240B, EC290B, EC360B and EC460B are available for hard conditions.

Foot step for lower frame For easy access and safety, foot steps are recommended according to the shoe widths.

Skid rail

Depending on the job site conditions, the top rollers can be replaced with a skid rail. Skid rails are available on the EC140B, EC210B, EC240B and EC290B.

*Available as option kit only

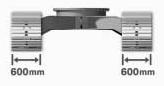

Retractable track gauge

For EC460B, the retractable track gauge is available for easy transportation. Special tool for high torque tightening and loosening the bolts is included in this kit.

Track gauge, retracted (for transportation): 2 390 mm

Track gauge, extracted (for working): 2 890 mm

* Available as factory installation.

Dozer blade (LC only)

Front dozer blade is available for EC140B LC to increase versatility in jobs such as dozing, backfilling trenches and speedy site clean-up.

Blade width: 2 590 mm

Blade height: 600 mm

* Available as factory installation.

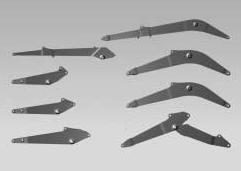

The best combination of booms and arms should be selected according to the job site requirements.

- Short boom and short arm combinations for mass excavation (ME).

- Standard boom with short arm combinations for general purpose or narrow job sites.

- Standard boom with standard arm combinations for general purpose or narrow job sites.

- Heavy duty boom with heavy duty arm combinations for severe job site conditions, such as forestry.

- Standard boom with long arm combinations for general purpose or reach work.

Long reach full kit

A long reach application kit includes a super long boom, super long arm, arm cylinder, bucket linkage, bucket cylinder and a heavier counterweight.

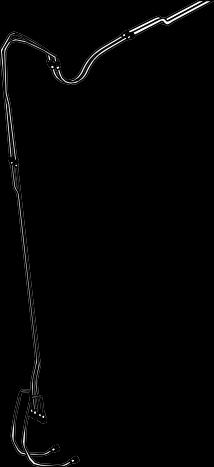

Various hydraulic equipment options can be ordered, even for different boom and arm combinations. These options can be ordered as kits. For option kit orders, selection of the option according to the boom and arm type is necessary due to their different lengths and shapes.

For special functions and components that require drainage of oil, an oil leak line is available (example-case drain line on a hydraulic motor for a rotator).

*: Standard for those models

Hydraulic oil

The proper hydraulic oil is necessary to meet different climates or environmental conditions. The recommended hydraulic oil (according to climate, conditions or use of tropical kits) is:

*Biodegradable hydraulic oil (Panolin) of ISO VG 32 and 46 is also available.

* Factory installation only.

Grapple maneuver

For the application of the grapple or grab, just changing the bucket cylinder flow by the 3-way valve attached on the bucket cylinder is enough. The grapple or grab is then controlled by the right hand joystick (bucket function).

With grapple maneuver

Bracket kit for hydraulic piping

When ordering some optional hydraulic equipments as a retrofit kit, the piping brackets need to be ordered at the same time to fix or clamp their hydraulic hoses.

* Available as option kit only

Hydraulic equipment for hammer, shear, etc.

The advantage of this option is to provide Volvo Excavators with the versatility and flexibility required on a variety of different job site conditions. With this option, called hydraulic X1 piping, one way function for Hammer and double acting function for Shear or Crusher, are available. There are many additional sub-options for the X1 piping, such as, a two pump flow option for large size attachments that require high oil flow. An additional hydraulic oil filter to reduce the oil contamination caused by hammer operation. In addition, to provide more versatility, the tilting or

rotator function and a proportional pedal control can be handled by the X1 function by just installing the extra piping on the end of the X1 piping. For hammer control, both the joystick switch button and pedal can be used. The pedal, which is used for double acting movements provides the best comfort for the operator. The proper function is selected by the locking knob on the pedal. There is a kit for the simple installation of two main pumps to increase flow. Through flow control rotary switch, supplied with the X1 piping, the pump hydraulic oil flow is easily adjusted.

Rotator/tilting piping

Dimension: PT 3/8

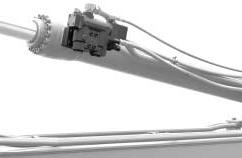

Hydraulic equipment for rotator and slope bucket

An additionalengine driven gear pump and extra valve block are available for rotator or slope bucket. This option is called X3 piping. For the control of X3 piping, the joysticks with either 3 or 5 buttons should be selected (because this option uses electric solenoid valves).

Available pressure: 150 kg/cm2

Available oil flow: 40 l/min

Dimension: PT3/8

This equipment makes it possible to operate a quick fit easily. The hydraulic quick fit is operated by two locker switches on the panel. The equipment includes valve block with solenoid valve, switches and control lines from the base machine to the end of arm. Pilot pressure is activated continuously for the closing function. For the opening function, the pilot pressure and working pressure are activated.

Hydraulic equipment for hose rupture valves on arm Hose rupture protection valves are available for the boom and arm cylinders to prevent the attachment from falling due to hose failures. These hose rupture valves satisfy legal requirements in certain markets.

With hose rupture valve

Modification kit for hose rupture valve

Adding the hose rupture valve and piping to an existing standard piping.

Removable ounterweight

For EC360B and EC460B, the removable counterweight makes it easier to remove or install the counterweight by utilizing a hydraulic cylinder and linkage system.

* Available as factory installation.

The Volvo hydraulic quick fit makes it possible to change attachments quickly and easily without the operator having to leave the cab. This increases productivity and makes the machine more versatile. To change attachments, two switches have to be activated simultaneously. This minimizes (for safety reasons) the risk of the bucket being released inadvertently during work or travel. The quick fit is equipped with a safety hook. The advantage of this is the bucket can easily be removed. This increases visibility and lifting capacity. The Volvo quick fit has a low weight and low building height which provides higher breakout forces.

The full scale toolkit includes a toolbox, end wrenches, adjustable wrenches, sockets, ratchet and hammer.

All products are not available in all markets. Under our policy of continuous improvement, we reserve the right to change specifications and designs without prior notice. The illustrations do not necessarily show the standard version of the machine.