2 minute read

Hydraulic equipment

Various hydraulic equipment options can be ordered, even for different boom and arm combinations. These options can be ordered as kits. For option kit orders, selection of the option according to the boom and arm type is necessary due to their different lengths and shapes.

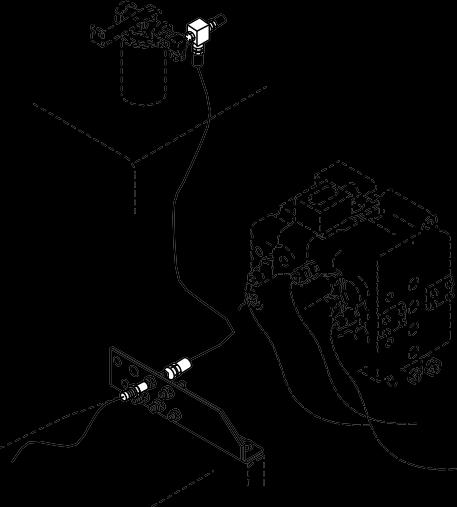

Oil leak (drain) line

Advertisement

For special functions and components that require drainage of oil, an oil leak line is available (example-case drain line on a hydraulic motor for a rotator).

*: Standard for those models

Hydraulic oil

The proper hydraulic oil is necessary to meet different climates or environmental conditions. The recommended hydraulic oil (according to climate, conditions or use of tropical kits) is:

*Biodegradable hydraulic oil (Panolin) of ISO VG 32 and 46 is also available.

* Factory installation only.

Grapple maneuver

For the application of the grapple or grab, just changing the bucket cylinder flow by the 3-way valve attached on the bucket cylinder is enough. The grapple or grab is then controlled by the right hand joystick (bucket function).

With grapple maneuver

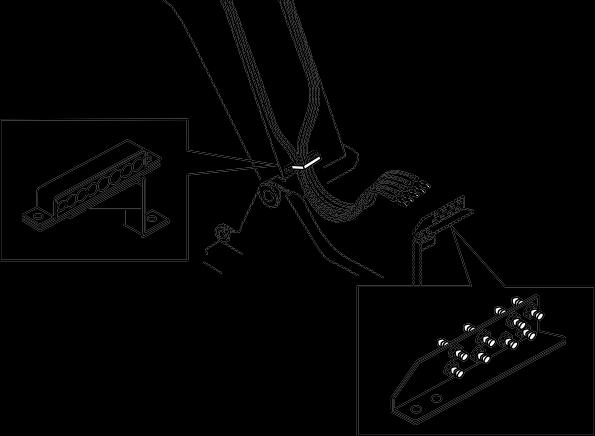

Bracket kit for hydraulic piping

When ordering some optional hydraulic equipments as a retrofit kit, the piping brackets need to be ordered at the same time to fix or clamp their hydraulic hoses.

* Available as option kit only

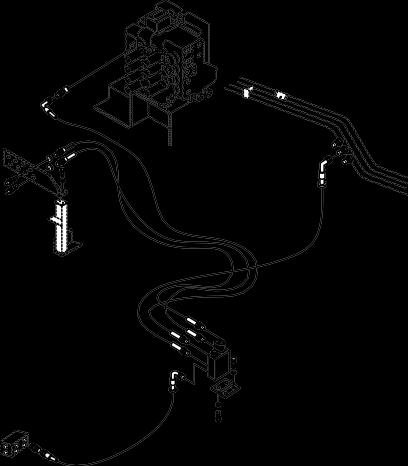

Hydraulic equipment for hammer, shear, etc.

The advantage of this option is to provide Volvo Excavators with the versatility and flexibility required on a variety of different job site conditions. With this option, called hydraulic X1 piping, one way function for Hammer and double acting function for Shear or Crusher, are available. There are many additional sub-options for the X1 piping, such as, a two pump flow option for large size attachments that require high oil flow. An additional hydraulic oil filter to reduce the oil contamination caused by hammer operation. In addition, to provide more versatility, the tilting or rotator function and a proportional pedal control can be handled by the X1 function by just installing the extra piping on the end of the X1 piping. For hammer control, both the joystick switch button and pedal can be used. The pedal, which is used for double acting movements provides the best comfort for the operator. The proper function is selected by the locking knob on the pedal. There is a kit for the simple installation of two main pumps to increase flow. Through flow control rotary switch, supplied with the X1 piping, the pump hydraulic oil flow is easily adjusted.

Rotator/tilting piping

Dimension: PT 3/8

Hydraulic equipment for rotator and slope bucket

An additionalengine driven gear pump and extra valve block are available for rotator or slope bucket. This option is called X3 piping. For the control of X3 piping, the joysticks with either 3 or 5 buttons should be selected (because this option uses electric solenoid valves).

Available pressure: 150 kg/cm2

Available oil flow: 40 l/min

Dimension: PT3/8

Hydraulic equipment for Quick fit

This equipment makes it possible to operate a quick fit easily. The hydraulic quick fit is operated by two locker switches on the panel. The equipment includes valve block with solenoid valve, switches and control lines from the base machine to the end of arm. Pilot pressure is activated continuously for the closing function. For the opening function, the pilot pressure and working pressure are activated.

Hydraulic equipment for hose rupture valves on arm Hose rupture protection valves are available for the boom and arm cylinders to prevent the attachment from falling due to hose failures. These hose rupture valves satisfy legal requirements in certain markets.

With hose rupture valve

Modification kit for hose rupture valve

Adding the hose rupture valve and piping to an existing standard piping.