Basicinstructions

TechnicalInformation

Thatinformationcouldbe:

• thedescriptionofhowtoremovethecylinderhead

• atableofspecificationsforahydraulicpump

• afaultcode

• atroubleshootingtable

• aspecialtool

EachChapterisdividedintofourInformationtypes: •

ofthosecategoriestofindtherightpieceoftechnicalinformationyouneedtoresolvethatcustomersconcernonhis

INTRODUCTION

Technicalinformationiswrittentosupportthemaintenanceandserviceofthefunctionsorsystemsonacustomers isnotworkingatall,isnotworkingefficiently,orisnotrespondingcorrectlytohiscommands.Whenyourefertothe informationforthatfunctionorsystemthenyouwillfindallthemechanical,electricalorhydraulicdevices,compoByintegratingthisnewICEcodingintotechnicalinformation,youwillbeabletosearchandretrievejusttheright ThefirstcategoryistheLocation,thesecondcategoryistheInformationTypeandthethirdcategoryistheProduct: • • • PRODUCTisthemodelthatthepieceoftechnicalinformationiswrittenfor.

endofaChapter.PagenumberreferencesareincludedforeverypieceoftechnicalinformationlistedintheChapter

HowtoUsethisManual

(D)

(C) FunctionalData(howitworks)forallthemechanical,electricalorhydraulicdevices,componentsandas

(G) 8763028816/6/2007 3

•

•

(D) technicaldata(specifications), (C) functionaldata(howitworks), (F) service (G) diagnosticdata(faultcodesandtroubleshooting)thathavebeenwrittenin

INTRODUCTION

Sections tableillustrateswhichSectionscouldbeincludedinamanualforaparticularproduct. SECTION HWorkingArm PRODUCT Tractors XXXXXXXX Vehicleswithworkingarms:backhoes, XXXXXXXXX XXXXXXXXXX XXXXXXXXX XXXX Chapters CONTENTS

Contents POWERPRODUCTION TECHNICALDATA 3 FUNCTIONALDATA ENGINEDynamicdescription(B.10.AC.30.A.10) 4 SERVICE 5 DIAGNOSTIC 6 INDEX TheChapterIndexlistsinalphabeticalorderallthetypesofinformation(calledInformationUnits)thathavebeen 8763028816/6/2007 4

• (F)

TheChapterContentslistsallthe

• (1) Functionand (2) • (A) correspondstothesectionsoftherepairmanual. (B) (C)

(C) (G) Diagnosticor (F) Service.

(A) and (B)

• • Byreferringto (A) , (B) and (C)

INTRODUCTION Index ENGINE ENGINEDynamicdescription(B.10.AC.30.A.10) 4 3 5 ENGINETroubleshooting(B.10.AG.40.A.10) 6 InformationUnitsandInformationSearch informationyouarelookingfor. exampleinformationunit

C ICEcodeclassification

Stackvalve Functional

Sectionalview CRIL03J033E01

StackvalveSectionalView(A.10.A.18C.10.A.30) InformationUnitICEcode A

Distribution systems Primary hydraulic power

data

1 Navigatetothecorrectinformationunityouaresearchingforbyidentifyingthefunctionandinformationtype

(D)

8763028816/6/2007 5

Thepageheaderwillcontainthefollowingreferences:

• SectionandChapterdescription

Thepagefooterwillcontainthefollowingreferences:

INTRODUCTION

PageHeaderandFooter

Publicationdate

8763028816/6/2007 6

• • Versionreferenceforthatpublication. •

•

BOLTTORQUEINFORMATION DECIMALHARDWARE onlybetightenedtothestrengthoftheoriginal. 50% ofthedrytorque,appliedtothenut, GRADE 1or2 5 5.15.288.2 L9(Alloy) SAEMarkings forBoltsand CapScrews 2 5 8 L9(Alloy) SAEMarkings forHexNuts GRADE2* GRADE5,5.1or5.2GRADE8or8.2GRADEL9(Alloy) Lubricated Lubricated Lubricated HeadNut SIZE lb/ft lb/ft lb/ft lb/ft lb/ft lb/ft lb/ft lb/ft 1/4 UNF 7.55.55.7 1/4 UNC 5/16 UNF 1511118231718133324241826192821 5/16 UNC 1612129261919143727272027203123 3/8 UNF 27202015413031236145473541304533 3/8 UNC 31232317473534256850473547355238 7/16 UNF 433233246850473595706850 7555 8160 7/16 UNC 49363727 7555 544010880816081608865 1/2 UNF 68504735102 757555 149110108801158512995 1/2 UNC 7555 54401158588651631201229012995142105 9/16 UNF 9570 7555 14911010880203150149110163120190140 9/16 UNC 10880816016312012290231170176130183135203150 5/8 UNF 136100102 203150149110285210217160231170251185 8763028816/6/2007 7

INTRODUCTION Torque

INTRODUCTION GRADE2* GRADE5,5.1or5.2GRADE8or8.2GRADEL9(Alloy) Lubricated Lubricated Lubricated HeadNut SIZE lb/ft lb/ft lb/ft lb/ft lb/ft lb/ft lb/ft lb/ft 5/8 UNC 14911011585231170176130325240244180258190278205 3/4 UNF 237175176130353260271200515380380280359265393290 3/4 UNC 271200190140407300298220570420420310447330481355 7/8 UNF 231170170125583430434320814600610450644475685505 7/8 UNC 244180190140637470475350909670678500705520793585 1 UNF 33925025819086864065148012349109226807465501051 775 1 UNC 3802802852109767207325401383102010317609497001220900 UNF 47535036627010717908005901749129013159701390102515591150 UNC 542400407300120789090967019531440146410801559115017971325 11/4 UNF 67850051538015191120113984024681820184413601898140021701600 UNC 74655057042016811240126193027262010204815102170160023731750 UNF 1180870881650264419501980146042853160321423703932290044073250 UNC 1329980990730298322002224164048273560362126704475330049493650 IMPORTANT: DONOTusethesevaluesifadifferenttorquevalueortighteningprocedureisgivenforaspecific NOTES • 152mm ( 6in over 152mm ( 6in • **"Lubricated"meanscoatedwithalubricantsuchasengineoil,orfasterswithphosphateandoilcoatings. "Dry"meansplaindorzincplatedwithoutanylubriation. TORQUESPECIFICATIONSMETRICHARDWARE GRADE8.8Bolts,NutsandStuds GRADE10.9Bolts,NutsandStuds Dry Dry SIZE lb/inlb/ft lb/inlb/ft 3to431to35 5to644to49 5to649to55 8to971to79 10to1184to94 14to15120to136 23to26229to277 33to37293to329 M10 46to51408to460 65to74 48to54 M12 80to90 59to66114to128 85to94 M14 128to145 94to106183to205 136to153 M16 200to220 149to161285to320 208to235 M20 400to450 293to330555to620 406to460 M24 690to780 510to575955to1075 705to790 8763028816/6/2007 8

INTRODUCTION GRADE8.8Bolts,NutsandStuds GRADE10.9Bolts,NutsandStuds Dry Dry SIZE lb/inlb/ft lb/inlb/ft M30 1375to1545 1010to11401900to2140 1400to1580 M36 2400to2700 1770to19903315to3730 2445to2750 Thesevaluesapplytofastenerswithbothcoarseandfinethreadsasreceivedfromsupplier,platedorunplated, • TORQUESPECIFICATIONSSTEELHYDRAULICFITTINGS 37DegreeFlareFitting Nom.SAE DashSize TubeOD/HoseID ThreadSize Newton metres lb/inlb/ft 8to972to84 11to1296to108 14to16120to144 18to21156to192 9.5mm 27to33240to300 77to85684to756 19.0mm 107to119 79to88 127to140 94to103 131to156 97to117 31.8mm 197to223 145to165 312to338 230to250 StraightThreadwithOring DashSize TubeOD/HoseID ThreadSize Newton metres lb/inlb/ft 8to972to84 11to1296to108 20to25180to228 7.9mm 27to33240to300 43to54384to480 73to90648to804 15.9mm 100to124 74to92 138to173 102to128 173to216 128to160 25.4mm1.0inch 203to253 150to187 308to357 227to264 492to542 363to400 SplitFlangeMountingBolts Size Newtonmetres lb/in lb/ft 20to27 180to240 27to34 240to300 47to61 420to540 74to88 55to65 190to203 140to150 8763028816/6/2007 9

INTRODUCTION Nom.SAE DashSize TubeOD ThreadSize Newton metres lb/inlb/ft 23to26204to228 34to40300to348 12.7mm 52to57456to504 5/8inch 117to128 86to94 25.4mm1.0inch 152to174 112to128 179to201 132to148 157to173 Nom.SAEDash Size ThreadSize Newtonmetres lb/in lb/ft 48to54 432to480 70to78 612to684 102to114 75to84 142to160 105to117 237to254 175to187 PipeFitting Nom.SAEDashSize ThreadSize TFFT(TurnsForFingerTight) 2.03.0 1.53.0 10 2.03.0 16 1.52.5 32 NOTE: Applysealant/lubricanttomalepipethreads.Thefirsttwothreadsshouldbeleftuncoveredtoavoidsystem 8763028816/6/2007

Conversionfactors

INTRODUCTION

MULTIPLY TOOBTAIN AREA: squaremeter hectare 10.76391 squarefoot acre FORCE: newton newton ounceforce poundforce LENGTH: millimeter meter kilometer inch foot mile MASS: kilogram pound MASS/AREA: kilogram/hectare ton/acre MASS/ENERGY: 0.001644 MASS/VOLUME: kg/cubicmeter POWER: kilowatt horsepower PRESSURE: kilopascal bar 0.145038 lb/sq.inch TEMPERATURE: degreeC degreeF TORQUE: newtonmeter newtonmeter 0.737562 lb/inch lb/foot VELOCITY: VOLUME: cubiccentimeter cubicmeter cubicmeter milliliter litre litre litre litre 35.31466 cubicinch cubicfoot ounce(USfluid) quart(USliquid) quart(Imperial) gallon(USliquid) gallon(Imperial) VOLUME/TIME: MULTIPLY TOOBTAIN AREA: squarefoot acre 0.092903 squaremeter hectare FORCE: ounceforce poundforce 4.448222 newton newton LENGTH: inch foot mile 25.4* 0.3048* 1.609344* millimeter meter kilometer MASS: pound ounce 28.35 kilogram gram MASS/AREA: ton/acre 2241702 kilogram/hectare MASS/ENERGY: lb/hp/hr gr/kW/hr MASS/VOLUME: kg/cubicmeter POWER: horsepower kilowatt PRESSURE: 0.070303 kilopascal bar kg/sq.cm TEMPERATURE: degreeF 1.8F32 degreeC TORQUE: pound/inch pound/foot newtonmeter newtonmeter VELOCITY: 1.609344* 8763028816/6/2007 11

INTRODUCTION U.S.toMetric MULTIPLY TOOBTAIN VOLUME: cubicinch cubicfoot cubicyard ounce(USfluid) quart(USliquid) quart(Imperial) gallon(US) gallon(Imperial) 0.028317 0.946353 cubiccentimeter cubicmeter cubicmeter milliliter litre litre litre litre VOLUME/TIME: 8763028816/6/2007

REPAIRMANUAL DISTRIBUTIONSYSTEMS C185 C190 L180 L185 L190 8763028816/6/2007 A

Contents DISTRIBUTIONSYSTEMSA PRIMARYHYDRAULICPOWERSYSTEM A.10.A SECONDARYHYDRAULICPOWERSYSTEM A.12.A ELECTRICALPOWERSYSTEM LIGHTINGSYSTEM A.40.A 8763028816/6/2007 A

DISTRIBUTIONSYSTEMSA C185 C190 L180 L185 L190 8763028816/6/2007

Hydraulicschematicframe07(MachinesEquippedwithPilotControls)

Hydraulicschematicframe08(MachinesEquippedwithPilotControls)

Hydraulicschematicframe09(MachinesEquippedwithPilotControls)

Hydraulicschematicframe10(MachinesEquippedwithPilotControls)

Hydraulicschematicframe11(MachinesEquippedwithPilotControls)

Hydraulicschematicframe12(MachinesEquippedwithPilotControls)

Hydraulicschematicframe13(MachinesEquippedwithPilotControls)

Hydraulicschematicframe14(MachinesEquippedwithPilotControls)

Hydraulicschematicframe15(MachinesEquippedwithPilotControls)

Contents DISTRIBUTIONSYSTEMSA TECHNICALDATA PRIMARYHYDRAULICPOWERSYSTEM Capacity 4 Specialtools 4 Generalspecification 5 Reliefvalve Generalspecification 6 Hydraulicpump Generalspecification 7 Generalspecification 8 FUNCTIONALDATA PRIMARYHYDRAULICPOWERSYSTEM Identification 9 Hydraulicschematicframe01 Hydraulicschematicframe02 Hydraulicschematicframe03 Hydraulicschematicframe04 Hydraulicschematicframe05 Hydraulicschematicframe06

Hydraulicpump Sectionalview SERVICE PRIMARYHYDRAULICPOWERSYSTEM Cleaning 8763028816/6/2007

Decontaminating

Pressuretest(MachinesEquippedwithPilotControls)

Reliefvalve Flowtest Pressuretest

Hydraulicpump Flowtest Disassemble Visualinspection Assemble Remove Install Chargepump Pressuretest

8763028816/6/2007

Reservoir Applyvacuum Filling Remove Install Visualinspection Filter Remove Install Oilcooler Remove Install DIAGNOSTIC Sensingsystem

PRIMARYHYDRAULICPOWERSYSTEMCapacity HydraulicSystem 57L ( 14.8USgal ) PRIMARYHYDRAULICPOWERSYSTEMSpecialtools CAS10280 1 CAS1808 2 CAS10090 3 8763028816/6/2007

4 CAS1804PressureTestFittingKit PRIMARYHYDRAULICPOWERSYSTEMGeneralspecification HydraulicSystemOil TypeofOil Capacity TotalSystem NEWHOLLANDAMBRAAUTO SUPREMESAE10W30 57L(14.8USgal) ChainTank (L180andL185Machines) NEWHOLLANDAMBRAAUTO SUPREMESAE10W30 EachSide 10.1L(10.7USqt) ChainTank (L190Machines) NEWHOLLANDAMBRAAUTO SUPREMESAE10W30 EachSide 12.3L(13USqt) 8763028816/6/2007

ReliefvalveGeneralspecification LoaderControlValveMainReliefPressureSettings MainReliefPressureat20gpm L180,L185andL190Machines C185andC190Machines 8763028816/6/2007

HydraulicpumpGeneralspecification HydraulicPump Type Gear Displacement(PerRevolution) 31.8cc(1.94in³)

L180L185C185Machines Displacement(PerRevolution) L190andC190Machines 36.05cc(2.20in³) FlowatEngineRatedrpmat100%VolumetricEfficiency L190andC190Machines 82.9L/min(21.9USgpm) PumptoEngineSpeed (AllModels) Ratio1:1 8763028816/6/2007

FlowatEngineRatedrpmat100%VolumetricEfficiency

FilterbypassGeneralspecification ReturnFilter BypassPressure 345kPa(50psi) 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMIdentification bs05e050 1 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame01 (MechanicalControlMachines) 1 18.Drainmanifold 6.Towvalve 14.Brakesolenoidvalve 25.Mainreliefvalve 8763028816/6/2007

7.Checkvalve 15.Chargepressureswitch 8763028816/6/2007

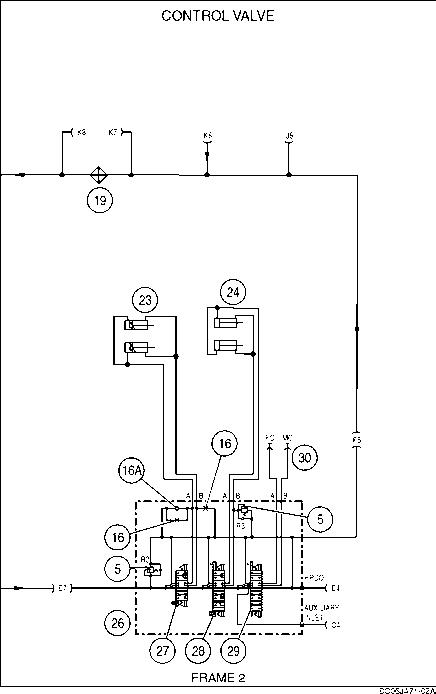

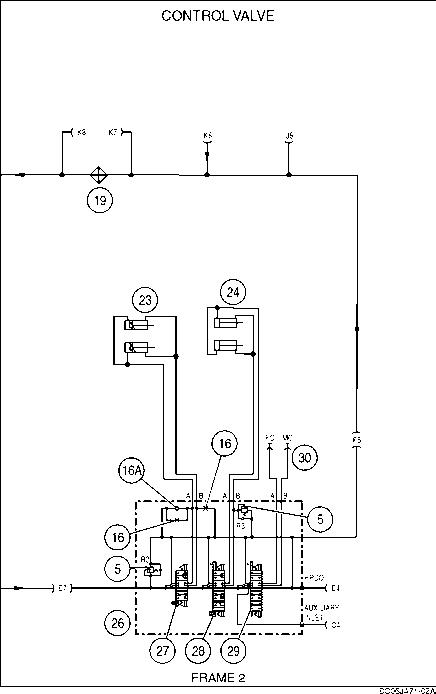

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame02 (MechanicalControlMachines) 1 (5) CircuitReliefValve (23) TiltCylinders (28) LiftSpool (16) (24) LiftCylinders (29) AuxiliarySpool (16A) (26) LoaderControlValve (30) AuxiliaryOutlets (19) OilCooler (27) TiltSpool 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame03 (MechanicalControlMachines) 1 (5) Circuitreliefvalve (15) Chargepressureswitch (33) Lefttwospeedshuttlevalve (11) Leftbrake (16) (34) Righttwospeedshuttlevalve (12) (31) Lefttwospeedmotor (35) (13) (32) Righttwospeedmotor (36) Twospeedsolenoidvalve (14) Brakesolenoidvalve 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame04 (MechanicalControlMachines) 1 (5) CircuitReliefValve (27) TiltSpool (37) HighFlowPump (5A) CircuitReliefValve(Track Models) (28) LiftSpool (38) HighFlowOilCooler (16) Orifice (29) AuxiliarySpool (39) HighFlowControlValve (26) LoaderControlValve (30) AuxiliaryOutlets 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame05 (MechanicalControlMachines) 1 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame06 (MechanicalControlMachines) 1 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame07(MachinesEquippedwithPilotControls) 1 2.RightPistonPump 10.HydraulicPump 5.CircuitReliefValve 13.LeftBrake 21.OilCooler 15.FlushingValve 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic

1 8763028816/6/2007

frame08(MachinesEquippedwithPilotControls)

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame09(MachinesEquippedwithPilotControls) 1 33.ChargePressureSwitch 18.ShutOffPlug 29.RightTwoSpeedDriveMotor 36.LeftTwoSpeedShuttleValve 30LeftBrake 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic

1 8763028816/6/2007

frame10(MachinesEquippedwithPilotControls)

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic frame11(MachinesEquippedwithPilotControls) 1 42.LoaderControlValve(WheelModels) 47.LiftCylinders ModelsOnly) 8763028816/6/2007

frame12(MachinesEquippedwithPilotControls) 1

43.TiltSpool 48.TiltCylinderswithCushions(190Models)

ModelsOnly) 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic

1 8763028816/6/2007

frame13(MachinesEquippedwithPilotControls)

frame14(MachinesEquippedwithPilotControls)

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic

1 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMHydraulicschematic

1 8763028816/6/2007

frame15(MachinesEquippedwithPilotControls)

HydraulicpumpSectionalview BS98F177 1 1.Gearplate 8.Washer 4.Body 10.Oilseal 16.Socketbolt 8763028816/6/2007

NOTE:

PRIMARYHYDRAULICPOWERSYSTEMCleaning

Contaminationisanyforeignmaterialinthehydraulic oil.Contaminationcanenterthehydraulicsystemin

hydraulicsystempermitsefficientoperationwitha amountofcontaminationcancauseproblemsinthe hydraulicsystem.Thefollowinglistincludessome

Quickfailureofcomponentsthathavebeen

Cycletimesareslow;machinedoesnothave PortableFiltertocleanthehydraulicsystem.

Therearetwotypesofcontamination,microscopic particlesofforeignmaterialareinsuspensioninthe scopiccontaminationcanbefoundbyidentification

Examplesoftheproblems:

(A) (B) (C) (D) (E)

tem.

(A) (B) (C) (D) (E) rapidly. (F) (G)

(H)

(A) (B) (C) 8763028816/6/2007

6.Visiblecontaminationisforeignmaterialthatcanbe cancauseasuddenfailureofcomponents.Examplesofvisiblecontamination:

Theoilhasanodorofburnedoil.

NOTE: Thehydrostaticsystemdoesnothaveanexternal replacethehydrostaticsystemfilter.

NOTE: steps: (A) Removeallthehydraulicoilfromtheinletand (B) (C) (D) Cleantheinsideofthehousingforthefilter (E)

PRIMARYHYDRAULIC

hydraulicfilter.

systembydoingthefollowingsteps:

If,inyourjudgment,thedamagetothecylinders wascausedbysevercontaminationandisnotthe hydraulicreservoir,etc.inthehydraulicsystem. Tocleanthelinesrefertothefollowingprocedure: Resermachine.Loosenandremovethedrainplugfrom

(A) (B) (C) (D)

(E)

(B) (A) (B)

(A)

(A) (B)

8763028816/6/2007

16.Usingthefittingkit CAS10508 ,installthevalveinthe 17.Stopthevacuumpump. 19.Disconnectthevacuumpump. drainplug. 22.MovetheswitchfortheportablefiltertotheONposition. theoiltooperatingtemperature: (A) (B) HoldthebucketcontrolleverintheROLLBACK (C) ReturnthebladecontrolleverintheNEUTRAL (D) eratingtemperature. portablefilterrunning,completelyextendandretract otherfor30minutes 30.Stoptheengine. 37.Installandtightenthedrainplug. reservoir. 8763028816/6/2007

40.Installnewhydraulicandhydrostaticfilterelements newhydraulicandhydrostaticfilters. 8763028816/6/2007

PRIMARYHYDRAULICPOWERSYSTEMDecontaminating

2.Completelyretracttheallattachmentcylindersonthe WARNING Ifretractingthecylinderrodscausestheattachment pressureinthehydrauliccircuits.

Haveavailableacceptableequipmenttodrainthe

Removethedrainplugfromthebottomofthe reservoir.

8.Installthedrainpluginthebottomofthereservoir.

10.DisconnectthelinefromtheOPENendand

IMPORTANT: Checktheoillevelinthehydraulicreservoir frequentlywhiledoingstep13.Haveanotherpersonhold liftcylindersinbothdirectionsuntiloilbeginstoflow untilcleanoilflowsfromtheopenline.

14.Stoptheengine. cylinder. pistonrodcomesin/outofthecylinder,oilwillbe

IMPORTANT: Anyattachmentorpartofanattachmentthat israisedmustbesupportedwithacceptableequipmentto 8763028816/6/2007

(B)

(A)