SCORPION

9040 (404-03)

7045 (403-03)

7040 (402-03)

7030 (401-03)

6030 (400-01)

Repair Manual

Table of Contents

4Engine

5.26Test report for model 400/401/402 with H1 pump without auxiliary motor (0–40kph) 5-36

5.27Test report for model 403/404/402 with TMP89 pump and auxiliary motor (fixed displacement motor) (0 – 40 kph) 5-37

5.28Test report for model 403/404 diesel engine 103 kW and TMP89 pump and auxiliary motor (variable displacement motor) (0 – 40 kph) 5-38

5.29Test

5.45Variable

5.46Checking

5.50Measurement

5.54Report:

8Steering system

8.1Electrical/hydraulic

8-2

8.2Electrical/hydraulic diagrams for steering system from serial no. 400 01 0168, 401 03 0196, 402 03 0177, 403 03 0146, 404 03 0147, 8-4

8.6Steering

Table of Contents

8.7Steering circuit with variable displacement pump (LS = load sensing) ............................................................................ 8-9

8.8Hydraulic steering diagram: priority valve – variable displacement pump (LS = load sensing) 8-10

8.9Steering circuit with gear pump ..................................................................................................................................... 8-11

8.10Hydraulic steering diagram: priority valve – gear pump .................................................................................................

8.11Hydraulic

8.14Hydraulic steering diagram: diagonal steering with diagonal steering valve (crab steering) ......................................... 8-16

8.15Hydraulic steering diagram: 4 wheel steering with diagonal steering valve (crab steering) 8-17

8.16Steering

8.19Front

9Work hydraulics

9.1Work hydraulics fixed displacement pump (diagram) – raising/lowering the telescopic boom (HUSCO) ........................ 9-2

9.2Work hydraulics fixed displacement pump (diagram) – raising/lowering the telescopic boom (Bucher) ......................... 9-4

9.3Work hydraulics variable displacement pump (diagram) – raising/lowering the telescopic boom (HUSCO) ................... 9-6

9.4Work hydraulics variable displacement pump (diagram) – raising/lowering the

9.7Work hydraulics (diagram) – extending/retracting the telescopic boom, fixed displacement pump (HUSCO) .............. 9-14

9.8Work hydraulics fixed displacement pump (diagram) – extending/retracting the telescopic boom ............................... 9-16

9.9Work hydraulics variable displacement pump (diagram) – extending/retracting the telescopic boom (HUSCO) .......... 9-18

9.10Work hydraulics variable displacement pump (diagram) – extending/retracting the telescopic boom (Bucher)

9.11Work

9.12Extending/retracting the telescopic boom (electrical diagram) ...................................................................................... 9-24 9.13Retracting/extending

9.33Work

(diagram)

(HUSCO)

(diagram) – additional control circuit, Autohitch (Bucher) ...................... 9-68

9.35 Work hydraulics fixed displacement pump (diagram) – rear additional control circuit, Autohitch, tipping trailer (HUSCO) 9-70

9.36Work hydraulics fixed displacement pump (diagram) – additional control circuit, Autohitch, tipping trailer (Bucher) .... 9-72

9.37Work hydraulics variable displacement pump (diagram) – rear additional control circuit, Autohitch, tipping trailer (HUSCO)

9-74

9.38Work hydraulics variable displacement pump (diagram) – additional control circuit, Autohitch, tipping trailer (Bucher) 9-76

9.39Work

9.40Work

9.44Work

9.55Work hydraulics variable displacement pump (diagram) – additional control circuit for quick couplers on telescopic

(HU SCO) 9-110

9.56Work hydraulics fixed displacement pump (diagram) –

9.103Changeover

AAppendix

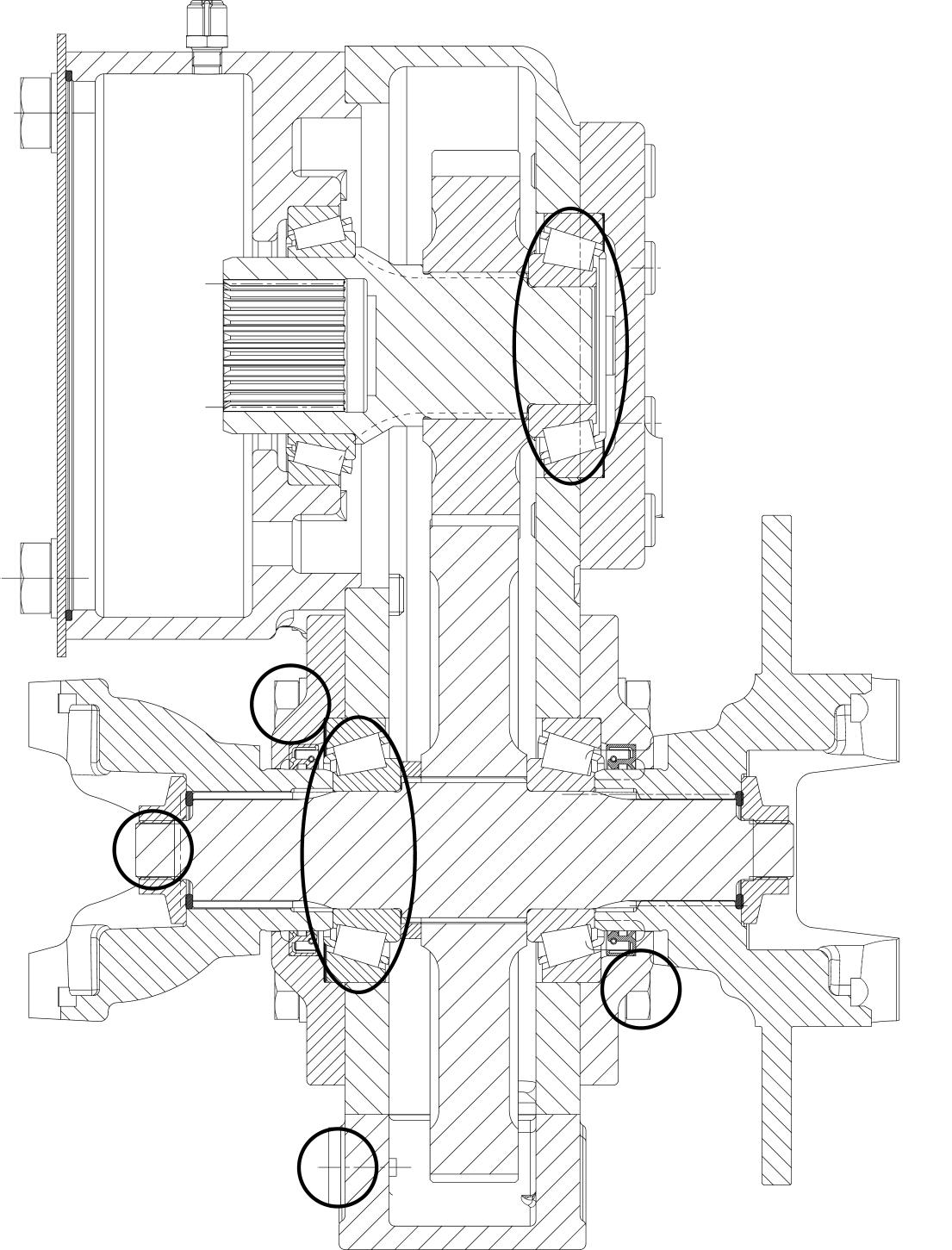

6.620 kph gearbox (overview)

Flanged hydraulic motor

6.7Removing the 20 kph gearbox

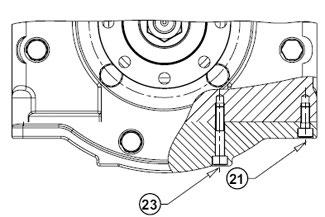

☞ Unscrew fastening screws 21 and 23 from cover 24

Caution!

Different lengths

☞ A flange is installed on either side

☞ Remove cover 24

☞ Slacken the fastening nut on flange 13

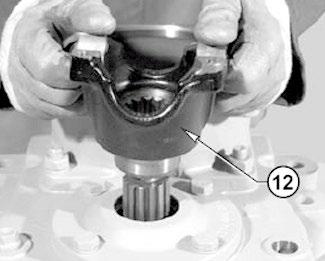

☞ Remove nut 11 and O-ring 12

Caution!

A normal flange is installed on the telehandler

☞ Remove flange 12

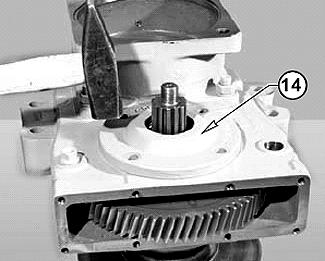

☞ Unscrew fastening screws 15 from cover 14

☞ Remove cover 14

☞ Remove spacers 18

☞ Remove sealing ring 17 from cover 14

Axles/differential lock

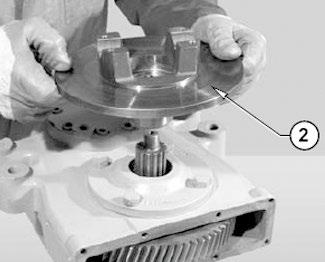

☞ Slacken the fastening nut on flange 2

Caution!

A normal flange is installed on the telehandler

☞ Remove nut 11 and O-ring 12

☞ Remove flange 2

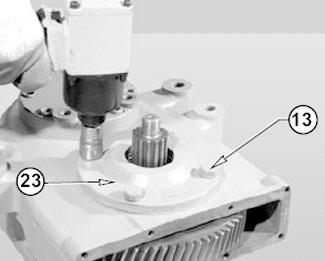

☞ Unscrew fastening screws 13 from cover 23

☞ Slacken cover 23

☞ Remove cover 23

☞ Lever out sealing ring 17

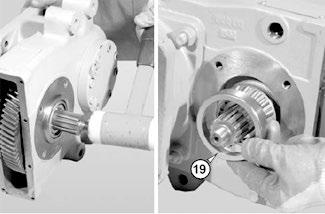

☞ Remove outer ring 19

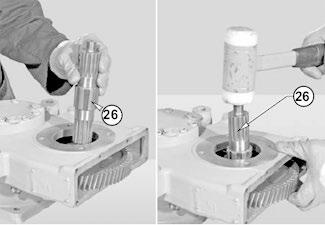

☞ Remove shaft 26

☞ Remove shaft 26

☞ Press out bearing 19

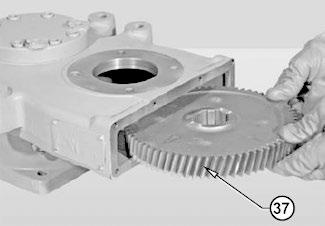

☞ Remove gear 37

☞ Remove bearing 19

☞ Expel outer ring 19

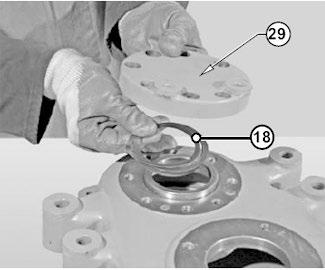

☞ Remove fastening screws 27 from cover 29

☞ Remove cover 29 and washers 18

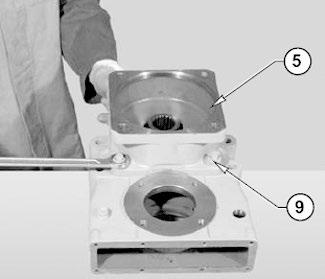

☞ Unscrew fastening screws 9 from connection housing 5

☞ Remove connection housing 5

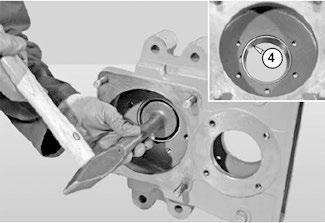

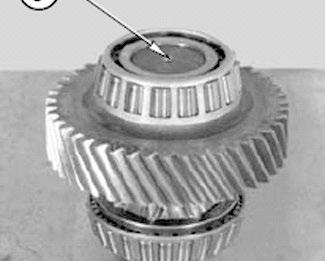

☞ Remove bearing 4 from the housing with an extractor

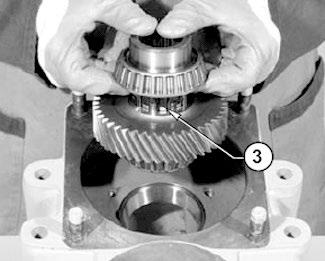

☞ Remove upper shaft 3

☞ Remove outer ring 4

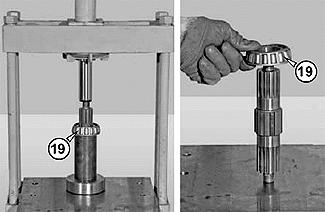

☞ Position shaft 3 under a press

☞ Press out gear 38 and bearing 19

☞ Press out bearing 4

6.8Installing the 20 kph gearbox

260 – 280 Nm

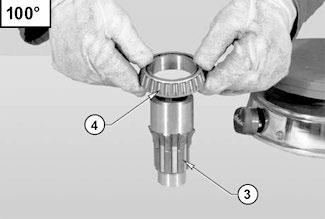

☞ Install bearing 4 on shaft 3

➥ Heat the bearing to 100 °C

☞ Install gear 13 on shaft 38

☞ Install bearing 19 on shaft 38

➥ Heat the bearing to 100 °C

☞ Install the complete shaft in the housing

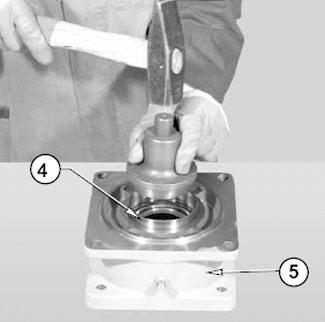

☞ Install bearing race 4 in connection housing 5

NOTE: If there is no response to click on the link above, please download the PDF document first and then clickonit.

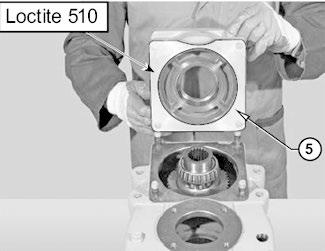

☞ Place connection housing 5 on the gearbox housing with Loctite 510

☞ Tighten fastening screws 9 to 140 Nm

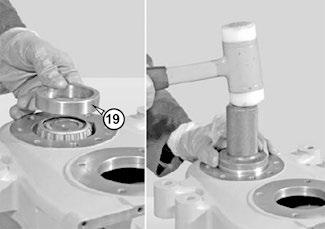

☞ Install outer ring 19

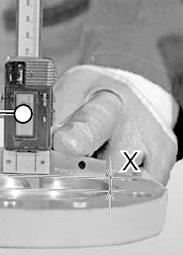

☞ Determine measure Y

➥ Outer ring to contact surface

S 1 = X – Y + 0.1 mm

Axles/differential lock

☞ Install cover 36 and fastening screws 39 with Loctite 510

☞ Tighten screws 39 to 90 Nm

☞ Check bearing for firm position

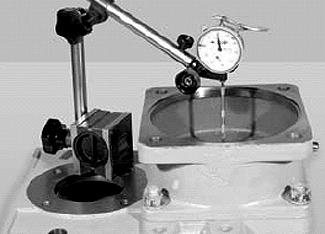

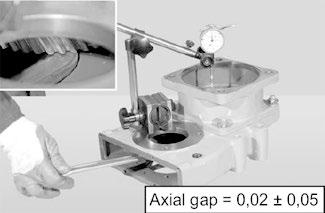

☞ Position a dial gauge

☞ Check 0.02 mm – 0.05 mm bearing play with a lever

☞ Install gear 37

☞ Install shaft 26 with a plastic hammer

☞ Heat inner ring 19 and install it onto shaft 26

☞ Install outer ring 19

☞ Turn over the gearbox

☞ Install spacer washers 17

☞ Heat the inner ring of bearing 19 to 100 °C and install it

☞ Install outer ring 19