SERVICE MANUAL Crawler Excavator CX500C Part number 48032547 English June 2016 © 2016 CNH Industrial Italia S.p.A. All Rights Reserved.

Thanks very much for your reading, Want to get more information, Please click here, Then get the complete manual

NOTE:

If there is no response to click on the link above, please download the PDF document first,andthen click on it.

Maintenance

Engine Control System

Mechanical

Fuel Service Specifications

Emission Control

Intake Exhaust Cooling

Lube

Ignition Starting Charging

Auto Transmission Clutch

Manual Transmission Transfer Propeller Shaft

Drive Shaft

Differential

Axle Suspension

Tire & Wheel

Brake Control

SER VICE MANUAL

48032547 22/06/2016

CX500C Crawler excavator Mass excavator version (TIER - CHINA Market

Contents INTRODUCTION Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . [10.001] Engine and crankcase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.1 [10.102] Pan and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.2 [10.106] V alve drive and gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3 [10.101] Cylinder heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.4 [10.105] Connecting rods and pistons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 Crankshaft and flywheel Fuel tanks Fuel filters [10.218] Fuel injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.9 [10.250] T urbocharger and lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.10 Intake and exhaust manifolds and muf fler 1 Exhaust Gas Recirculation (EGR) exhaust treatment Engine cooling system Fan and drive Aftercooler Engine lubrication system Oil cooler and lines Hydraulic systems Hydraulic systems [35.300] Reservoir , cooler , and filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.2 Fixed displacement pump V ariable displacement pump Pump control valves Main control valve [35.357] Pilot system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.7 48032547 22/06/2016

hydraulic system

Excavator and backhoe bucket hydraulic system

Hammer and rotating bucket hydraulic system

Frames and ballasting

Ballasts and supports

T racks and track suspension

T rack frame and driving wheels

T racks

T rack tension units

T rack rollers Cab climate control

Hydraulic fan drive cooling system Hydraulic hand control [35.356] Hydraulic foot control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.10 [35.352] Hydraulic swing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.1 1 [35.353] Hydraulic travel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.12 [35.354] Hydraulic central joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.13 [35.736] Boom hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.14 [35.737] Dipper

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.15 [35.738]

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.17

[35.360]

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . [50.100] Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50.1 [50.200] Air conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50.2 Electrical systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electrical

Harnesses

Cab

Engine

Engine starting system Alternator Battery 48032547 22/06/2016

system

and connectors

engine controls

control system

Cold start aid Fuel injection system Engine intake and exhaust system Exhaust Gas Recirculation (EGR) electrical system 1 Engine cooling system Engine oil system [55.640] Electronic modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.14 [55.512] Cab controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.15 Hydraulic system control [55.051] Cab Heating, V entilation, and (HV AC) controls . . . . . . . . . . . . . . . . . 55.17 [55.050] Heating, V entilation, and Air-Conditioning (HV AC) control system . . . . . . . . . . . . . . . 55.18 [55.416] Swing control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.19 [55.417] T ravel control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.20 Camera [55.518] Wiper and washer system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.22 [55.404] External lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.23 Cab lighting W arning and instruments system F AUL T CODES Booms, dippers, and buckets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Boom Dipper arm Bucket cab, and decals [90.150] Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.1 [90.156] Cab windshield and windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.2 [90.120] operator seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90.3 48032547 22/06/2016

Engine hood and panels 48032547 22/06/2016

INTRODUCTION 48032547 22/06/2016 1

Foreword - Important notice regarding equipment servicing

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special

Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution chain, including - without limitationnational, regional, local reject any responsibility for damages caused parts and / components not approved the facturer , including those used for the servicing repair the product manufactured marketed the manufacturer any case, warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer

The manufacturer reserves the right make improvements design and changes specifications any time without notice and without incurring any obligation install them units previously and illustrative material herein are accurate known time publication but are subject change without notice.

case refer your CASE CONSTRUCTION Sales and Service 48032547

INTRODUCTION

22/06/2016 3

Safety rules

CX500C Crawler excavator Mass excavator version (TIER - CHINA Market CX500C

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury

Throughout this manual you will find the signal words W and CAUTION followed special structions. These precautions are intended for the personal safety you and those working with you.

Read and understand all the safety messages this manual before you operate service the

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

CAUTION indicates a hazardous situation not could result minor moderate injury

F AILURE T O FOLLOW DANGER, W ARNING, AND CAUTION MESSAGES COULD RESUL T DEA SERIOUS INJUR Y .

Machine safety

NOTICE: Notice indicates a situation that, not avoided, could result machine property damage.

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property The word Notice used address practices not related personal safety

Information

NOTE: Note indicates additional information that clarifies other information this

Throughout this manual you will find the word Note followed additional information about a step, procedure, other information the The word Note not intended address personal safety property

INTRODUCTION

48032547 22/06/2016 4

Safety rules - General information

Cleaning

Clean the metal parts with cleaning solution that meets the standard and steam (except for bearings)

After cleaning, dry well, and inject oil all parts.

Also inject oil into the bearings after

Inspection

When disassembling check all the there are any worn damaged replace Inspect carefully prevent initial

Bearing

Replace any loose

Air dry bearings before installing

Needle bearing

When inserting needle very careful not damage

Apply grease the section where the needle bearing will

Gear

Check that there wear and Oil seal, Oring, gasket

Always install new oil O - and

Apply grease sections where oil seals and O - rings will

Shaft

Check that there wear and

Check the bearings and check for damaged oil seals the shaft.

Service parts

Install CASE CONSTRUCTION genuine service parts.

When placing order , check the parts contains the CASE CONSTRUCTION genuine part

Any breakdowns arising from the installation non - genuine parts are not covered the warranty

Lubricants (fuel, hydraulic oil)

Use the oil from the specified company specified the manual service

Any breakdowns arising from any fuel hydraulic oil other than those specified are not covered the warranty

INTRODUCTION

48032547 22/06/2016 5

SER VICE MANUAL Engine

48032547 22/06/2016

CX500C Crawler excavator Mass excavator version (TIER - CHINA Market

Engine - Engine and crankcase

Engine - General specification

Engine main specifications

Item Engine model 6UZ1 T ype Diesel / 4 - cycle / water - inline 6 cylinder OHC Cylinder bore x stroke 120 ( ) x 145 ( ) Displacement L ( in³ ) Compression ratio Compression pressure 2746 kPa ( 398.3 psi ) / 200 RPM Combustion chamber shape Direct injection type Cylinder liner type Dry liner , tight - fit type Maximum output 270.0 ( 367.1 ) / 2000 RPM Maximum torque 1435 ( 1058.4 ) / 1500 RPM Dimensions: length x width x height 1235.0 ( 48.6 ) x 953 ( 37.520 ) x 1314 ( 51.7 ) Dry weight (Excluding air cleaner) 840 ( 1851.883 ) Fuel injection timing 0 ° BTDC Fuel injection order 4 Idling speed 900 RPM Intake 0.2 ( 0.008 ) While cool V alve clearance Exhaust 0.5 ( 0.020 ) While cool Opening / closing timing intake valve Open ° BTDC Opening / closing timing intake valve Close ° ABDC Opening / closing timing exhaust valve Open ° ABDC Opening / closing timing exhaust valve Close ° BBDC Ignition method Compression ignition Oil pump type Gear type Oil filter type Full - flow bypass integrated type x 2 Engine oil level L ( 7.93 gal ) L ( 10.8 gal ) Oil pan capacity L ( 6.60 gal ) L ( 9.51 gal ) Oil cooling type W ater - cooled multiple - disc type steps) Cooling type W ater cooling Coolant capacity engine 22.5 L ( 5.944 gal ) W ater pump type V - belt drive spiral type Thermostat type W type Injection pump type Electronic control common rail (fuel rail) type Governor type Electronic type T imer type Electronic type Injection nozzle type 8 holes T urbocharger type RHG6 (IHI) 48032547 22/06/2016 10.1 [10.001] / 3

Engine - Engine and crankcase

Cooling system main specifications Item Specifications Open valve temperature ( ) Full open temperature ( 194.0 ) / 1 1 ( 0.433 ) Lubrication system main specifications Item Specifications Lubrication device Forced circulation type 0.79 MPa ( 1 14.5895 psi ) Outlet pressure Discharge amount 2460 RPM Pump rotation speed 97.4 L / min ( 25.730 gpm ) Oil pump Open valve pressure the relief valve 0.961.16 MPa ( 139.2480168.2580 psi ) Open valve pressure the oil gallery relief valve 540 kPa ( 78.32 psi ) Oil thermostat open valve temperature 101.5104.5 ( 214.70220.10 ) Electrical system main specifications Generator Item Specification Manufacturer Mitsubishi Electric Isuzu parts number 1 - 81200 - 603 - 7 Manufacturer model A004TU6285 Nominal output V A Rated speed 5000 RPM Regulator type type Regulated voltage V V / 5000 RPM with a load 5 A measured between L and E more than A 2500 RPM Output characteristics oltage: V more than A 5000 RPM Mass ( ) Starter Item Specifications Manufacturer Mitsubishi Electric Isuzu parts number 8 - 9822 - 2203 - 2 Manufacturer code number M009T62372 Output V / 5.5 Rating s Y oke outer diameter 85.0 ( 3.35 ) Rotational direction Right Protection type Dust proof / drip proof Speed reducer Inner contact gear W eight ( ) Module Pressure angle ° Pinion Gear teeth 1 1 V oltage V Current less than 120 A load Rotational speed more than 3100 RPM 48032547 22/06/2016 10.1 [10.001] / 4

Engine - Engine and crankcase

Starter Item Specifications V current 17.8 V / 450 A less T orque more than N·m ( ) Load Rotational speed more than 1 140 RPM V oltage 8 V Current less than 1800 A Restraint T orque more than ( 56.05 ) Pinion engaged voltage 16.0 V less Glow plug Item T ype Preheat device model Glow plug QOSII Glow plug rated voltage V 48032547 22/06/2016 10.1 [10.001] / 5

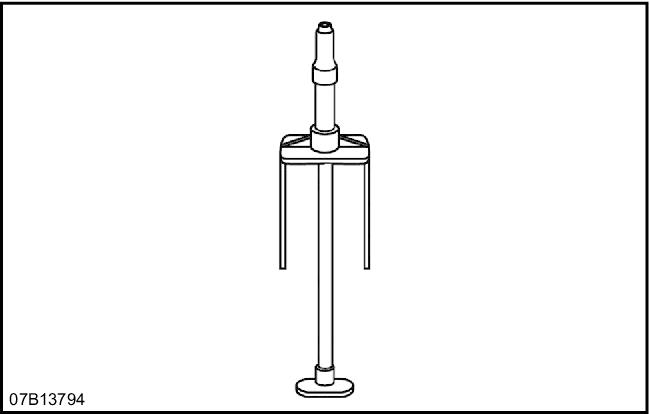

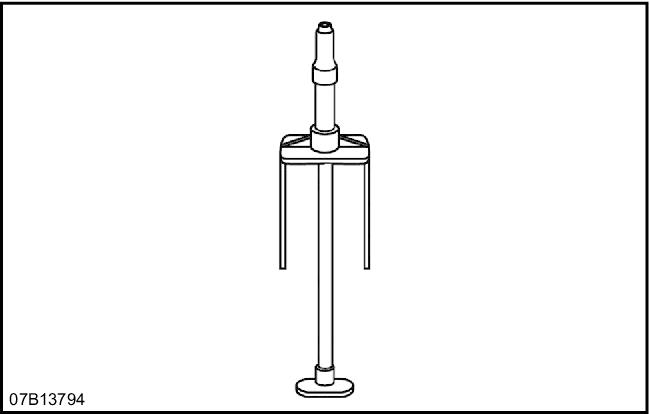

Crankcase Liner - Special tools

Isuzu reference 1 - 8523 - 1021 - 0

CASE CONSTRUCTION tool number 380300007 Description Cylinder liner remover

Isuzu reference 1 - 8522 - 1073 - 0

CASE CONSTRUCTION tool number 380300008 Description Cylinder liner installer

Engine - Engine and crankcase

07B13794 1

82D321EC 2 48032547 22/06/2016 10.1 [10.001] / 6

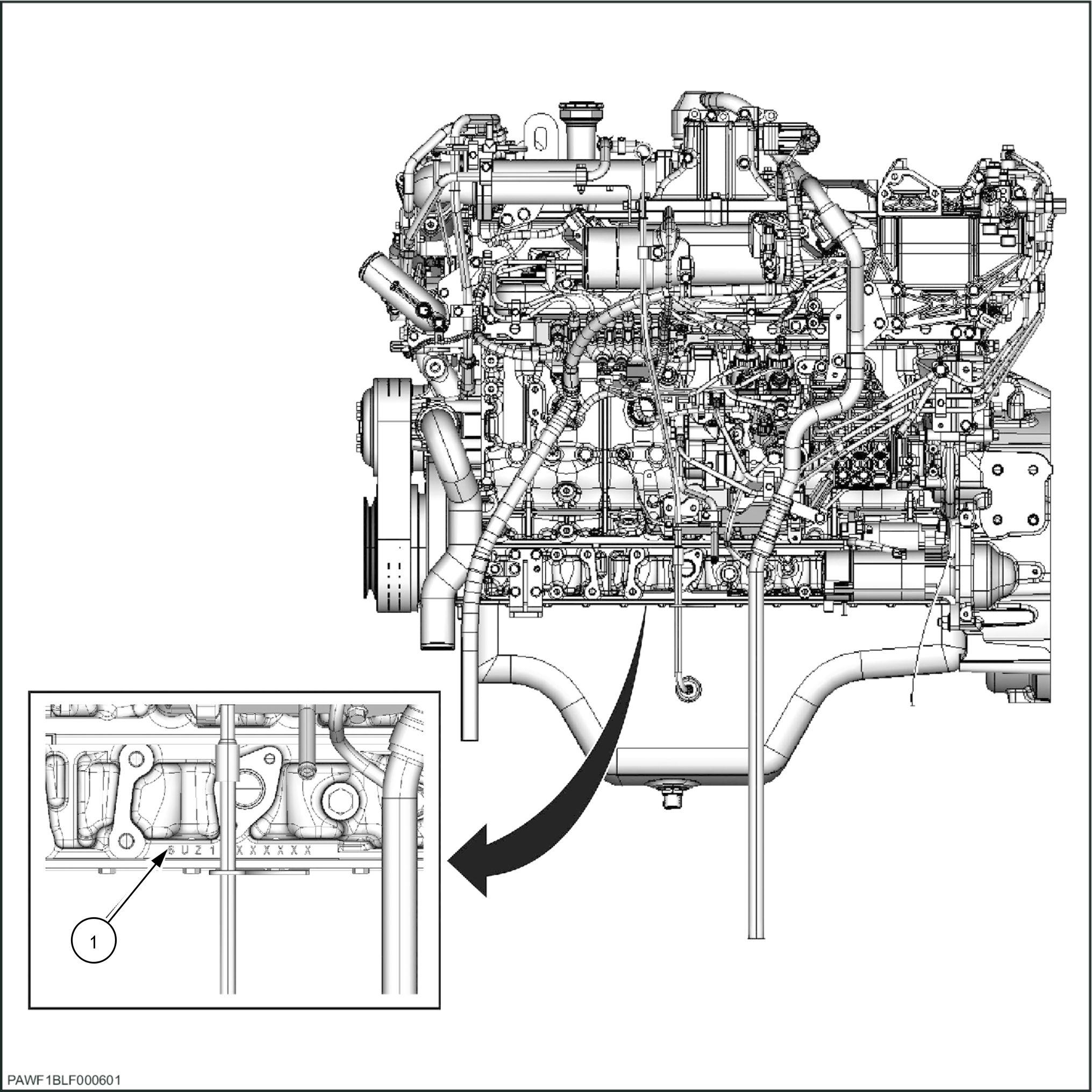

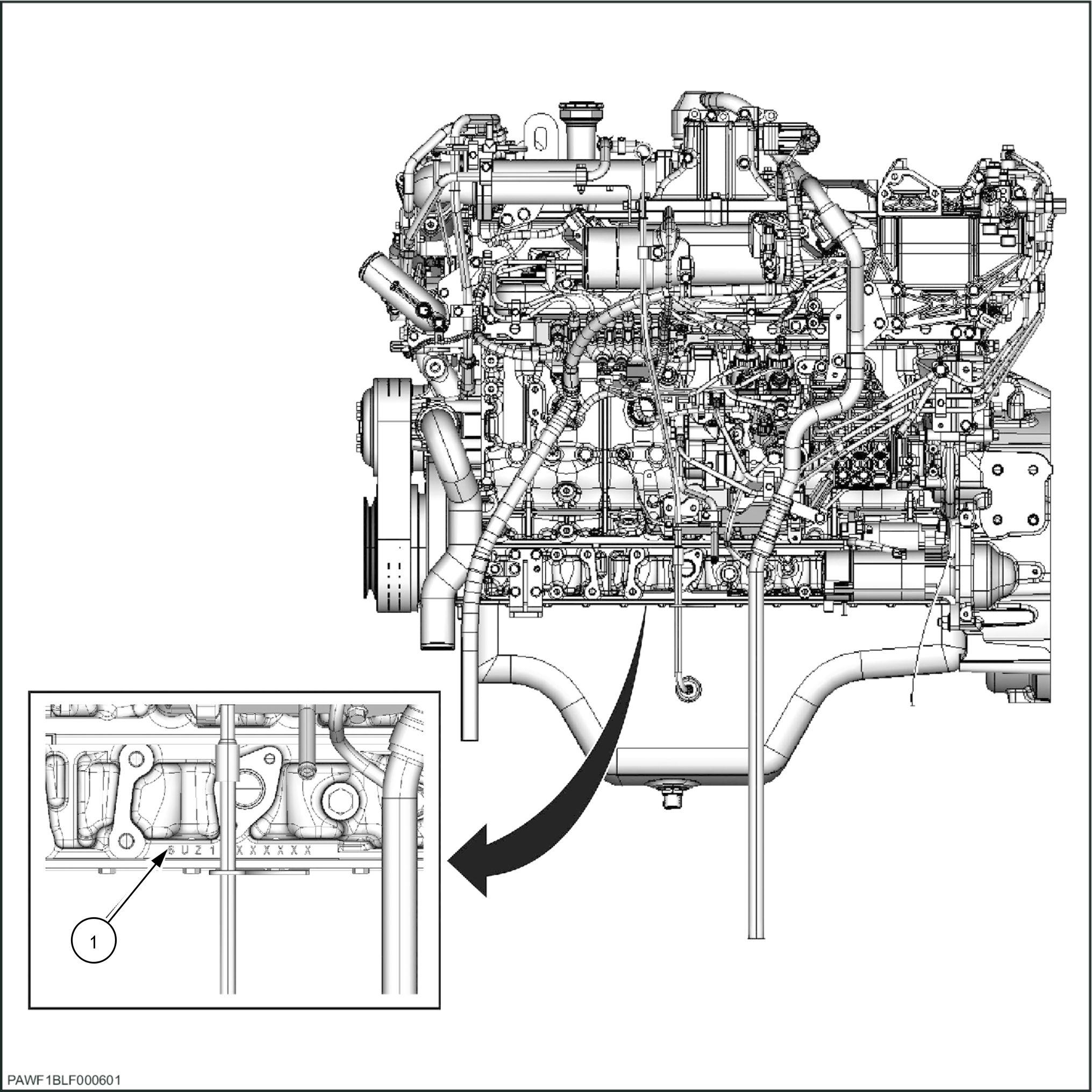

Engine - Engine and crankcase Engine - Identification P A WF1BLF000601 1 Engine number stamping 48032547 22/06/2016 10.1 [10.001] / 7

Engine - Engine and crankcase

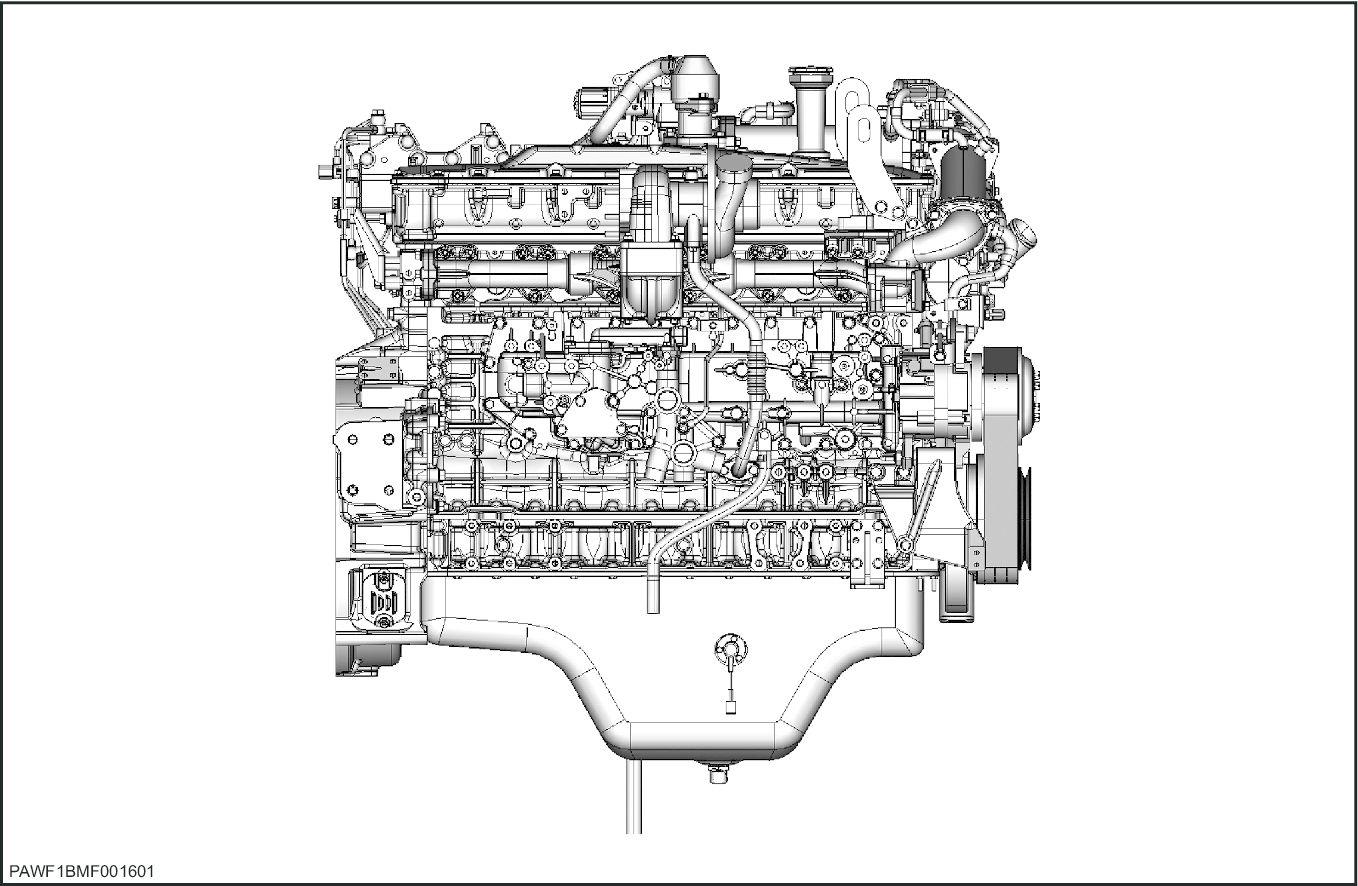

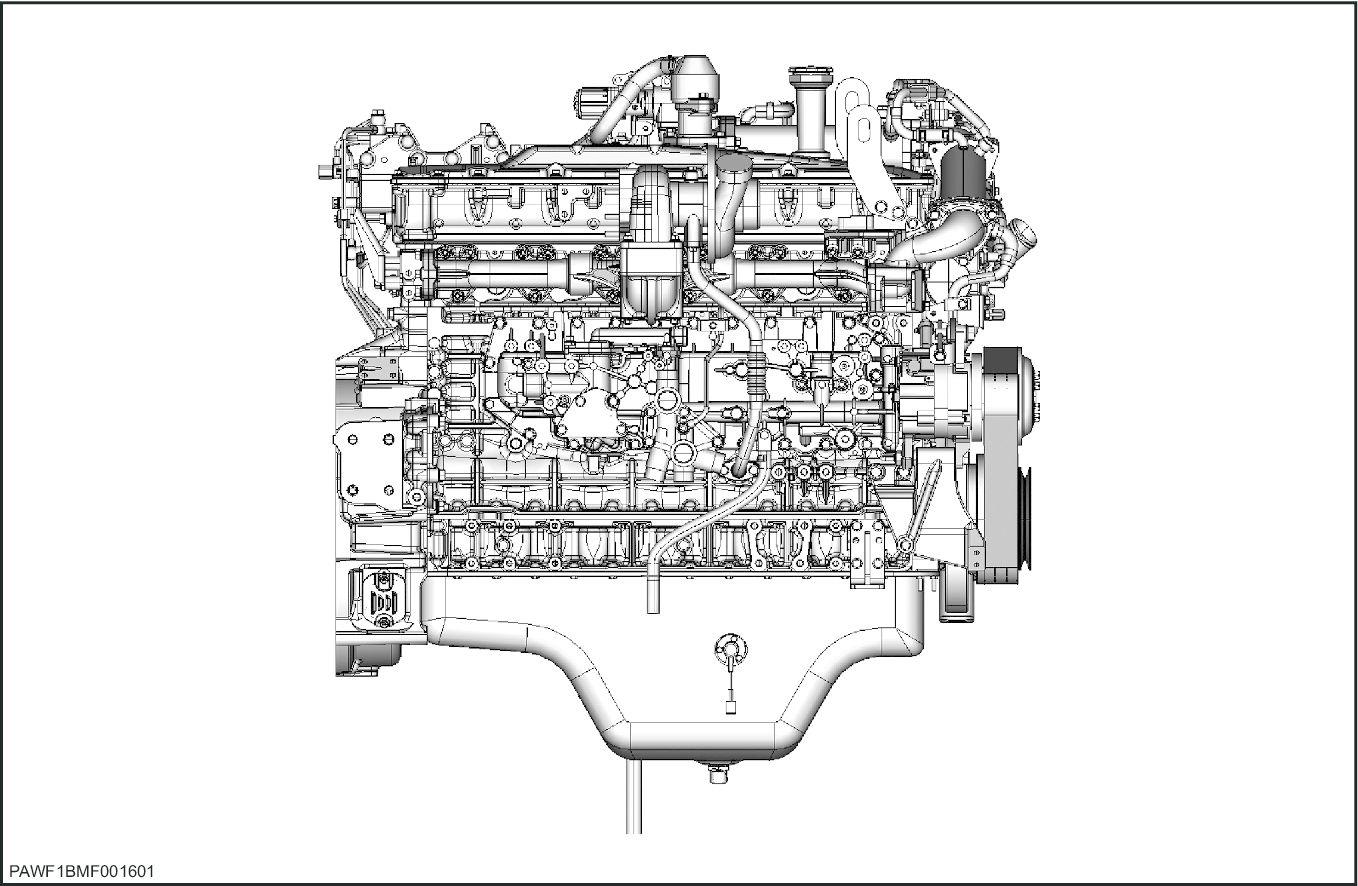

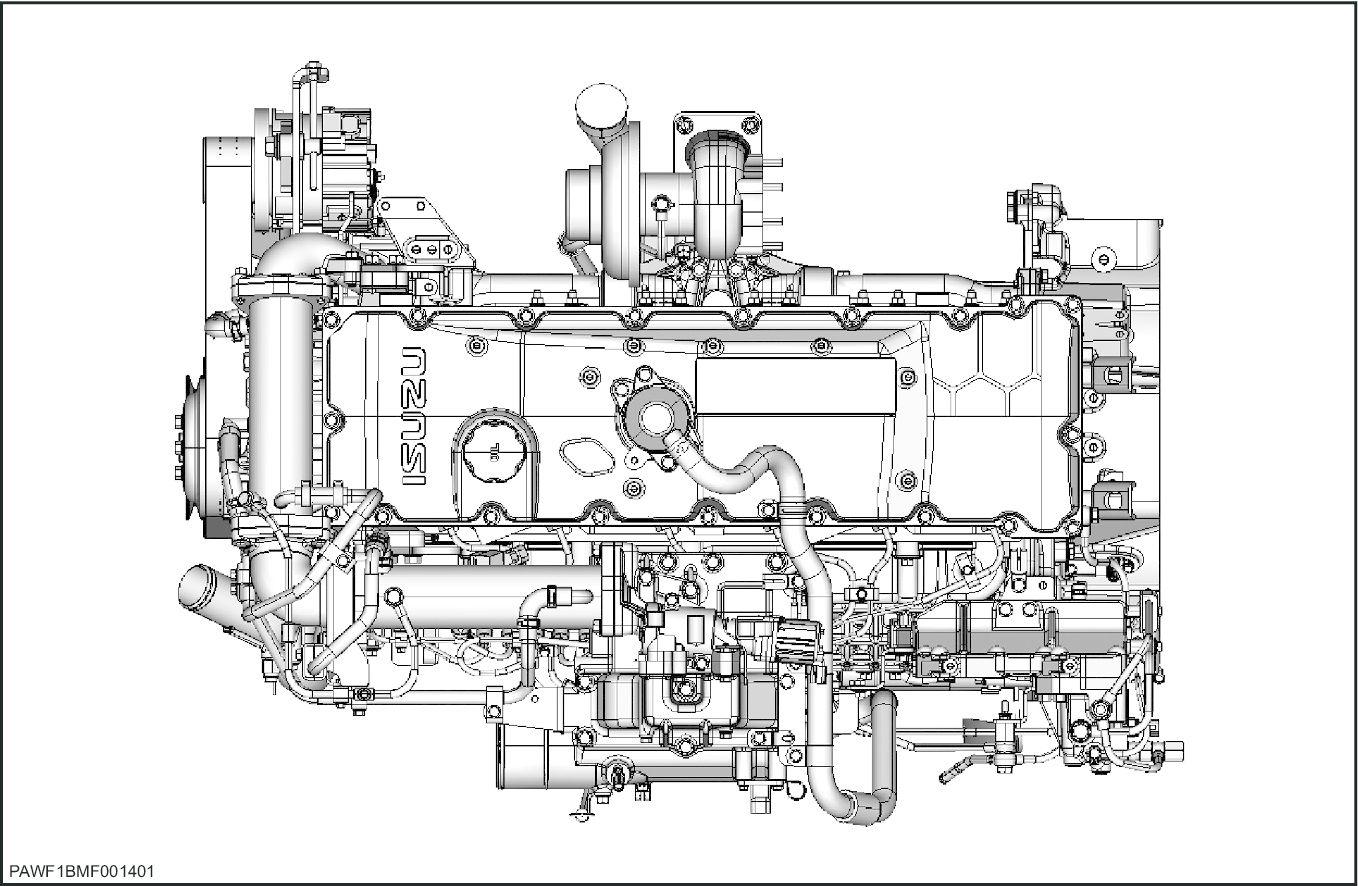

Engine structural diagram P A WF1BMF001601 1 P A WF1BMF001501 2 48032547 22/06/2016 10.1 [10.001] / 8

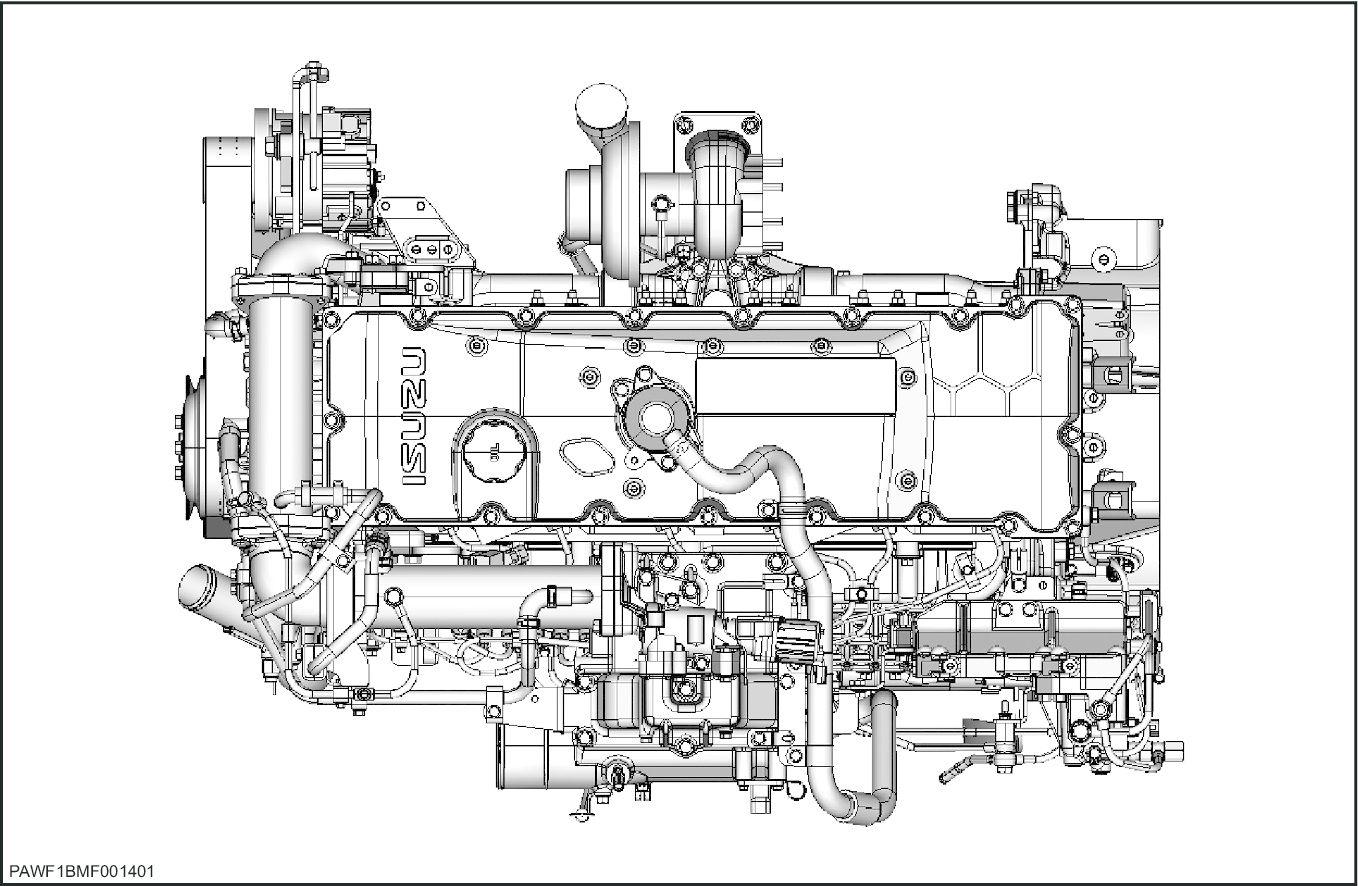

Engine - External view

Engine - Engine and crankcase P A WF1BMF001401 3 48032547 22/06/2016 10.1 [10.001] / 9

Engine - Prepare W ARNING

Escaping fluid!

Hydraulic fluid diesel fuel leaking under pressure can penetrate the skin and cause infection other injury . T o prevent personal injury: Relieve all pressure before disconnecting fluid lines forming work the hydraulic Before applying make sure all connections are tight and all components are good condition. Never use your hand check for suspected leaks under Use a piece cardboard wood for this injured leaking see your doctor immediately .

Failure comply could result death serious injury .

W ARNING

A void injury!

W0178A

Shut off the engine, remove the key , and make sure all motion stopped before servicing the machine. Failure comply could result death serious injury

128A

W ARNING

Crushing hazard!

The lifting systems must operated qualified personnel who are aware the correct procedures follow . Make sure all lifting equipment good condition, and all hooks are equipped with safety latches.

Failure comply could result death serious injury

W ARNING

Heavy objects!

W0256A

Lift and handle all heavy components using lifting equipment with adequate capacity Always support units parts with suitable slings hooks. Make sure the work area clear all bystanders.

Failure comply could result death serious injury .

W ARNING

Explosion hazard!

W0398A

Batteries emit explosive gases. Always ventilate when using enclosed area when charging. Keep the battery away from open and other ignition

Failure comply could result death serious injury .

NOTICE: Keep away from

W0369A

NOTICE: The air conditioner circuit filled with high pressure gas may spray out dangerously when loosening lines.

Engine - Engine and crankcase

48032547 22/06/2016 10.1 [10.001] /

Engine - Engine and crankcase

Items prepare:

• W renches [ 7 , 8 , , , , ]

• Box wrench [ ]

• Shackle (with the required lifting capacity) x 2

• Wire rope (with the required breaking load)

• Liftcrane (with the required lifting capacity)

• Marking pen

• Cap

• Plug

• W aste oil can

• Rag

• Cleaning fluid

• W ood

48032547 22/06/2016 10.1 [10.001] / 1 1

Engine - Engine and crankcase

Engine - Remove

Drain the engine

Drain the radiator (For see RadiatorRemove )

Remove the engine (For see HoodRemove (90.100) )

Remove the muf fler (For see Exhaust muffler - Remove )

Remove the hydraulic (For see PumpRemove (35.106) )

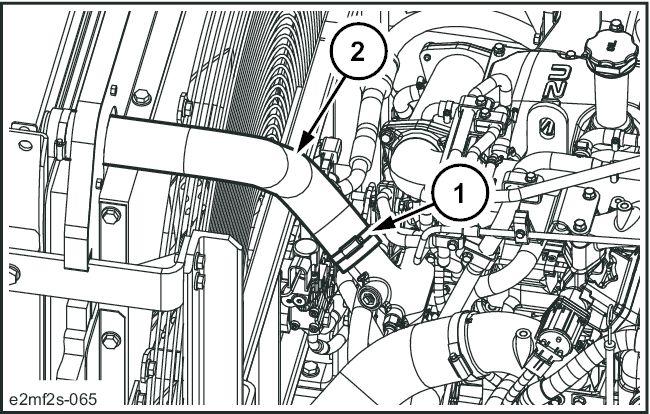

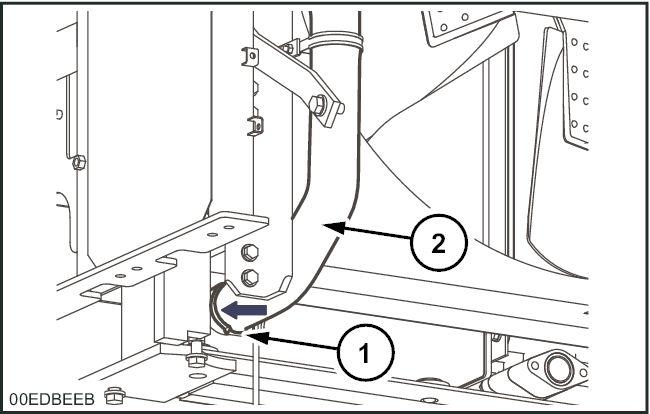

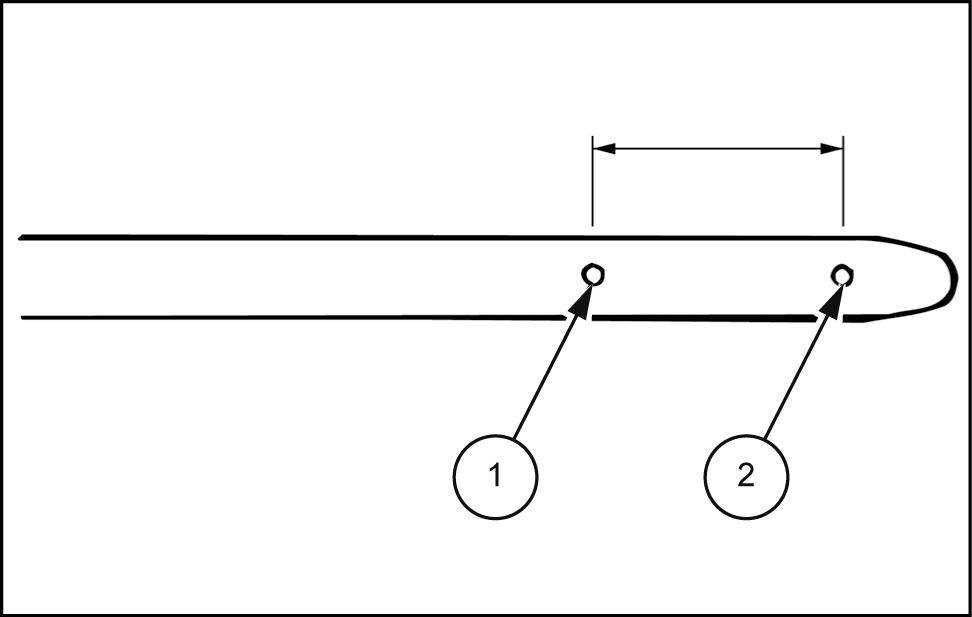

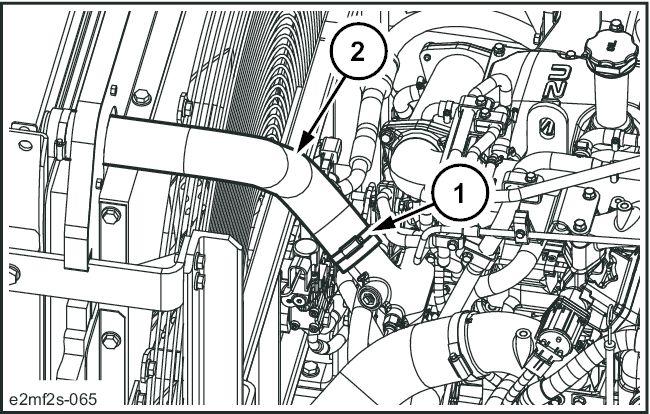

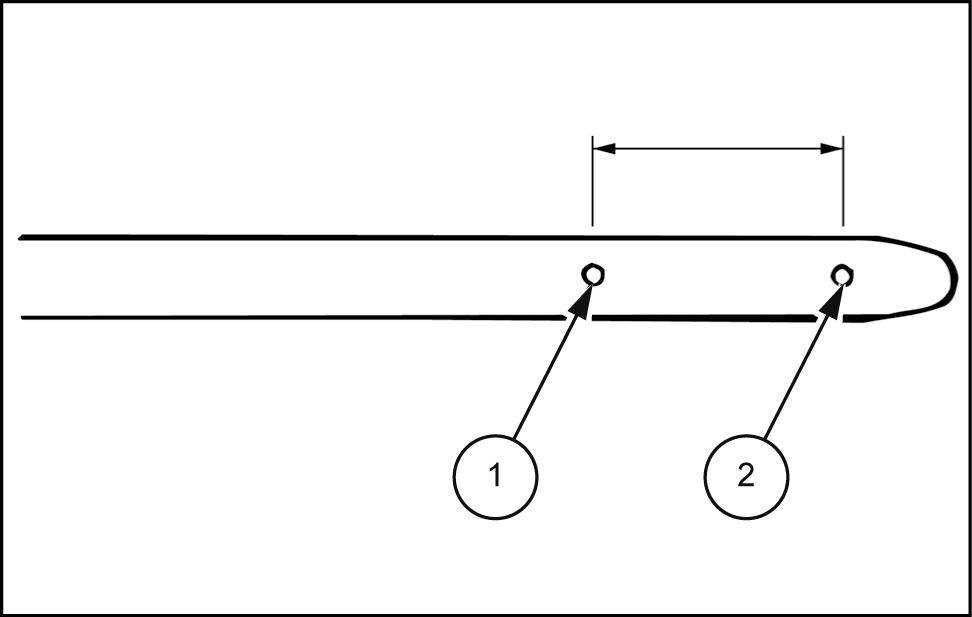

Use a wrench [ 7 ] loosen the hose band (1) the radiator , and then remove the upper hose (2)

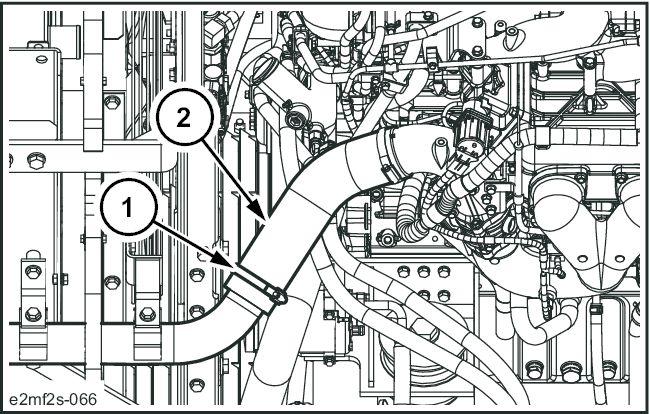

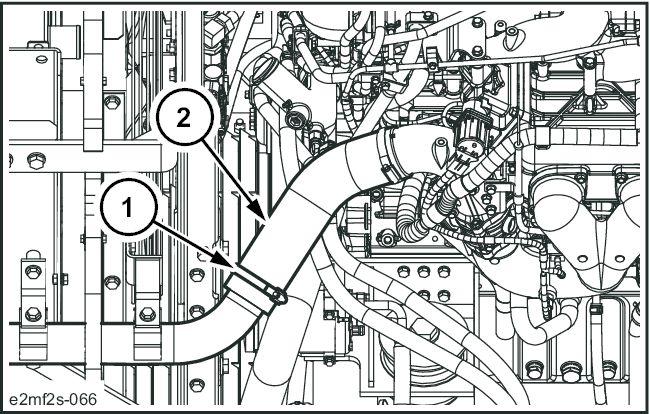

Use a wrench [ 8 ] loosen the hose band (1) the intercooler , and then remove the hose (2)

• Use caps cover the lines and hoses prevent any entry water , dust

E2MF2S - 065 1

E2MF2S - 066 2 48032547 22/06/2016 10.1 [10.001] /

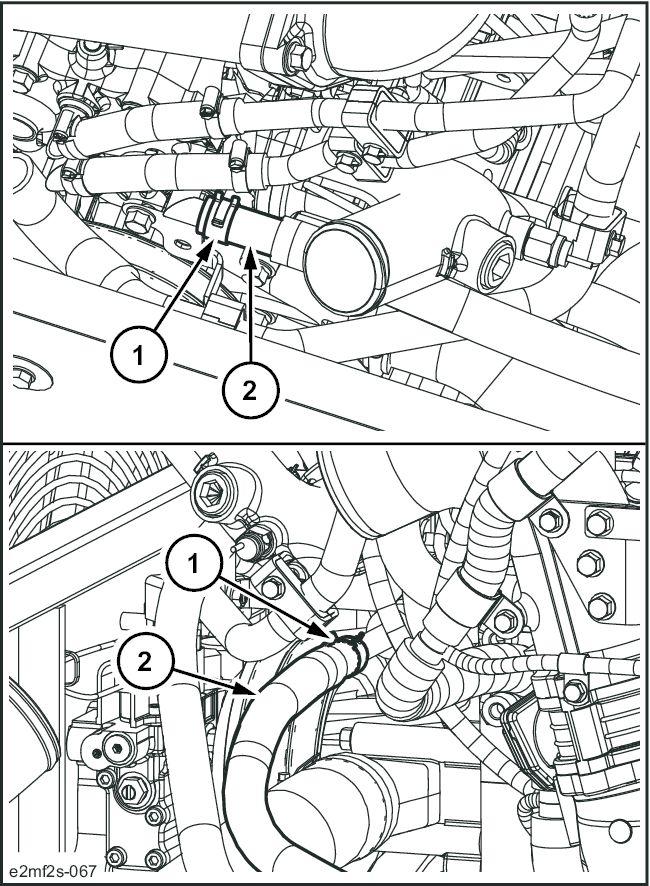

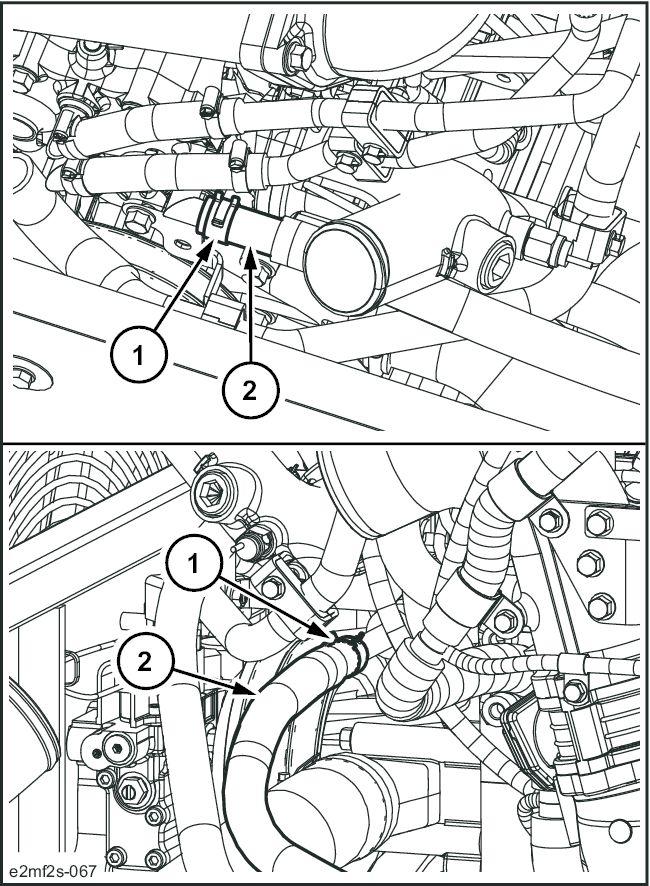

Remove the hose band (1) , and then remove the heater hose (2) Install caps plugs the engine and hoses prevent any entry water , dust

Use a wrench [ 7 ] loosen the hose band (1) the radiator , and then remove the lower hose (2)

• Use caps cover the radiator and hoses prevent any entry water , dust

• Before removing the radiator completely drain the coolant.

T ightening torque for band installation: 4.95.9 N·m ( 3.6144.352 )

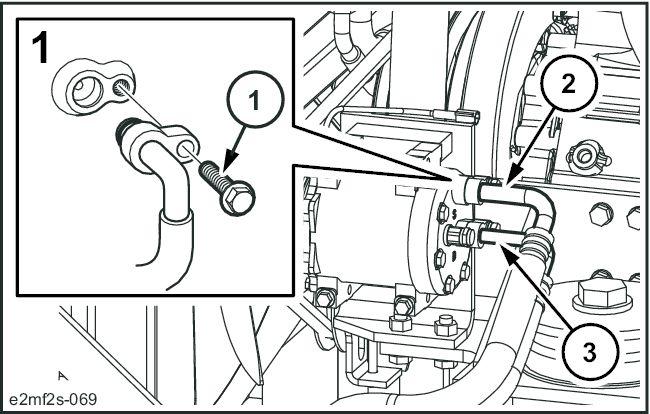

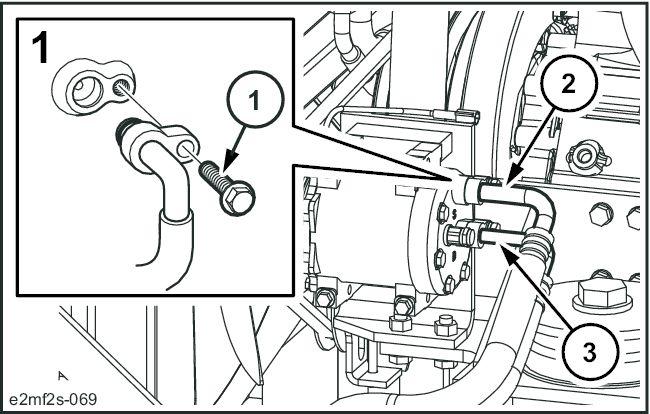

Use a wrench [ ] loosen the line bolts (1) 2 and then remove the 2 lines (2) and (3) from the compressor

• Always remove the low - pressure (suction side) line (2)

• Install caps plugs the compressor and lines prevent any entry water , dust

T ightening torque for bolt installation: 19.624.5 ( 14.518.1 )

Engine - Engine and crankcase

E2MF2S - 067 3

00EDBEEB 4

E2MF2S

069 5 48032547 22/06/2016 10.1 [10.001] /

-

Engine - Engine and crankcase

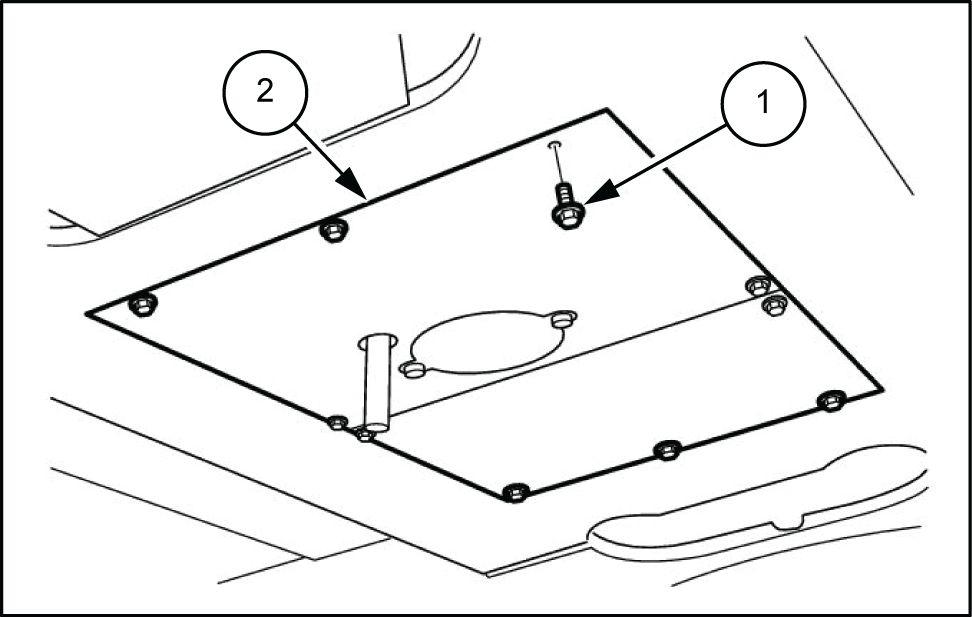

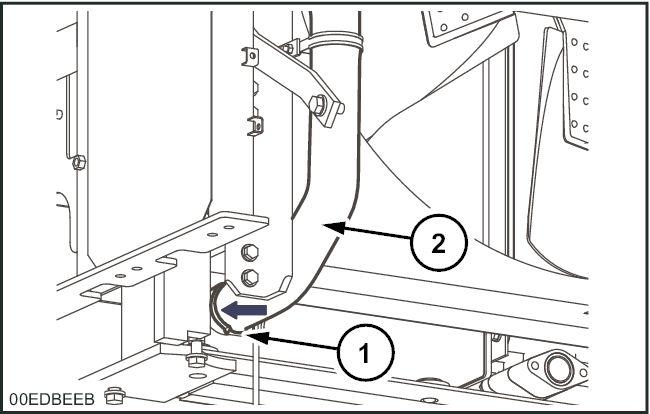

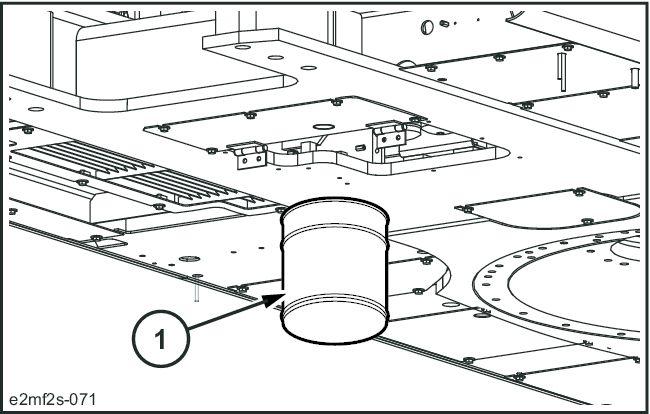

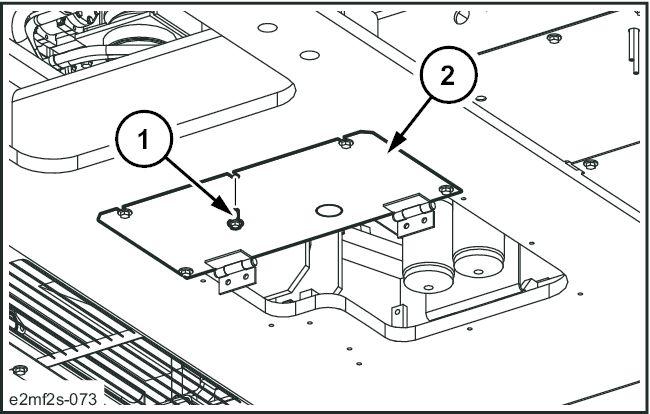

1 Use a wrench [ ] remove the 1 1 bolts (1) , then remove the under cover (2)

• Use caution when removing the parts are heavy . T ightening torque for bolt installation: -

73.5 N·m ( 46.954.2 )

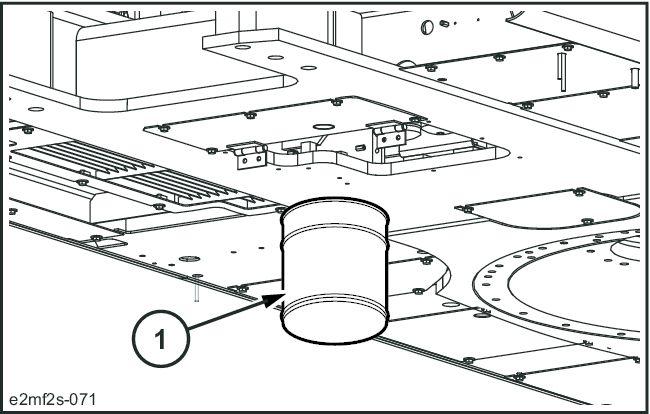

12. Prepare the waste oil can (1) .

• Drain the engine oil before removing the engine oil

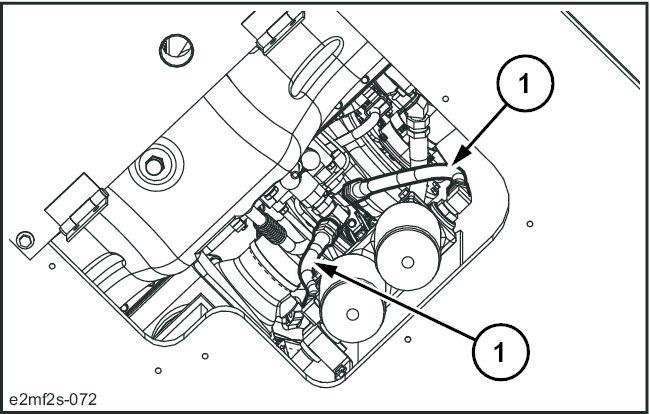

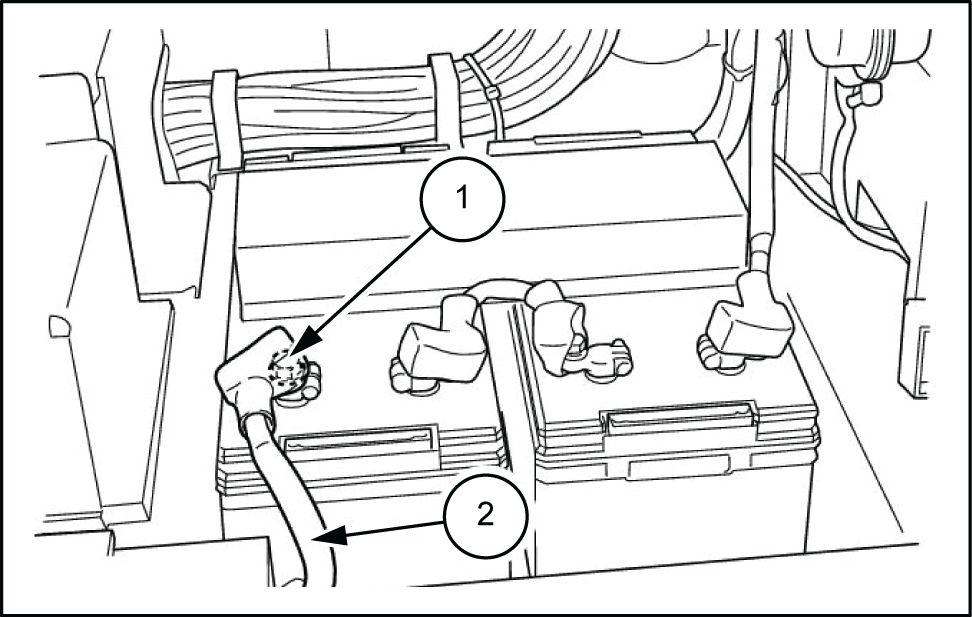

Use a wrench [ ] remove the 2 engine oil remote hoses (1)

• Mark the engine and hoses that the connectors match the time installation.

• Install caps plugs the engine and hoses prevent any entry water , dust dirt.

• Clean the engine and hoses spraying them with a parts cleaner prevent scratches and prevent dirt from accumulating the

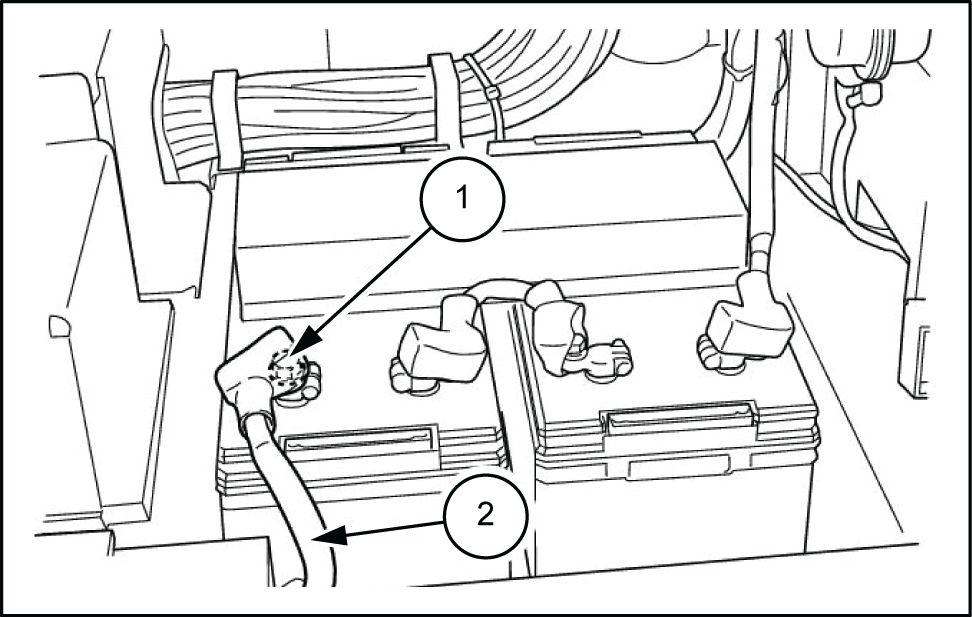

Use a wrench [ ] remove the bolt (1) , and then remove the battery cable (2) the negative

• After removing terminals fix them the frame a similar location they not fere with the

• sure protect them with a rubber cap other protective device, prevent sparks.

SMIL13CEX3134AB 6

E2MF2S - 071 7

E2MF2S - 072 8

SMIL13CEX3136AB 9 48032547 22/06/2016 10.1 [10.001] /

Engine - Engine and crankcase

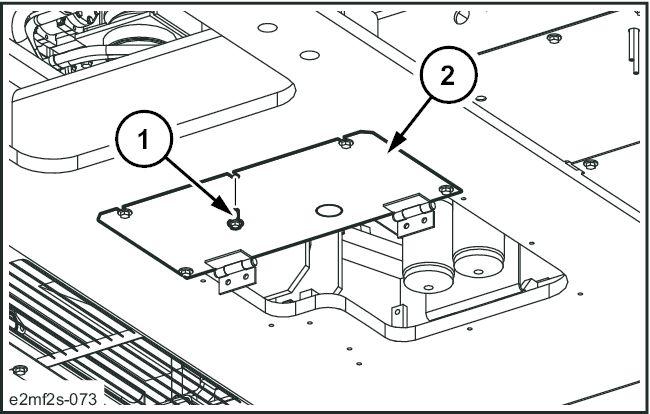

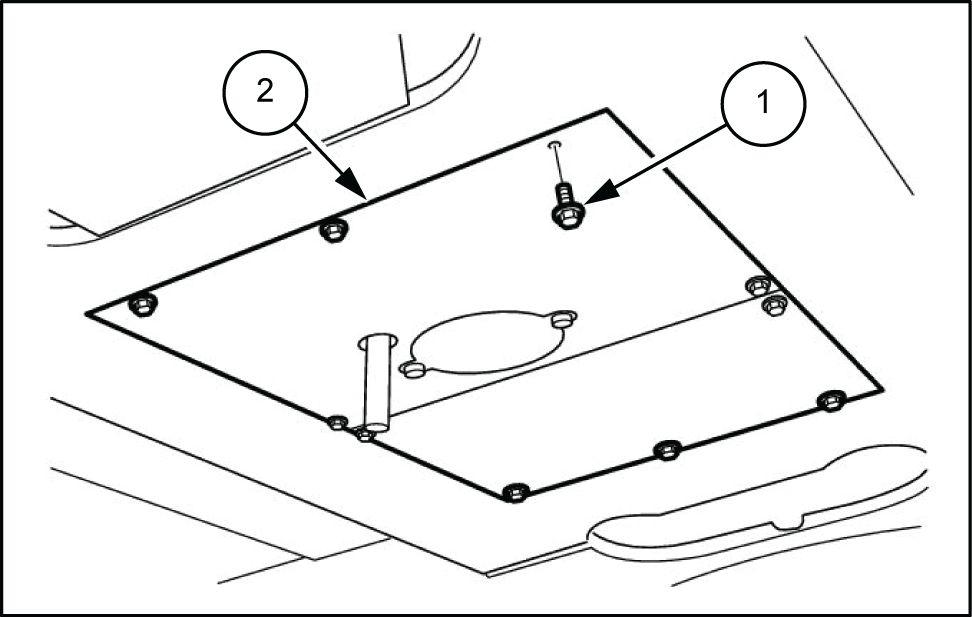

15. Use a wrench [ ] remove the 5 bolts (1) , then remove the under cover (2)

T ightening torque for bolt installation: 63.7N·m ( - )

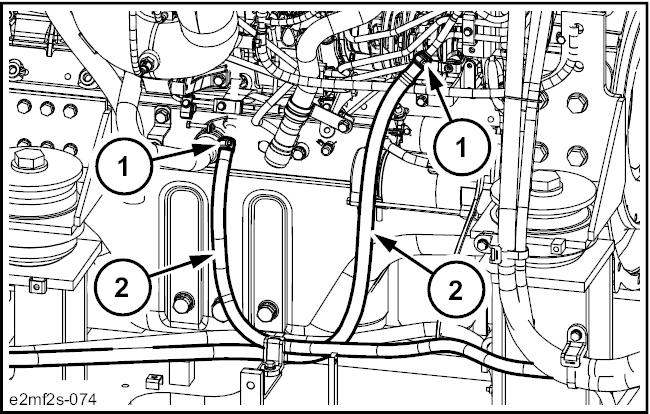

Use a wrench [ 8 ] remove the 2 nuts (1) , and then remove the wiring (2) from the starter motor

Remove the hose band (1) , and then remove the fuel hose (2) .

• Install caps plugs the engine and hoses prevent any entry water , dust dirt.

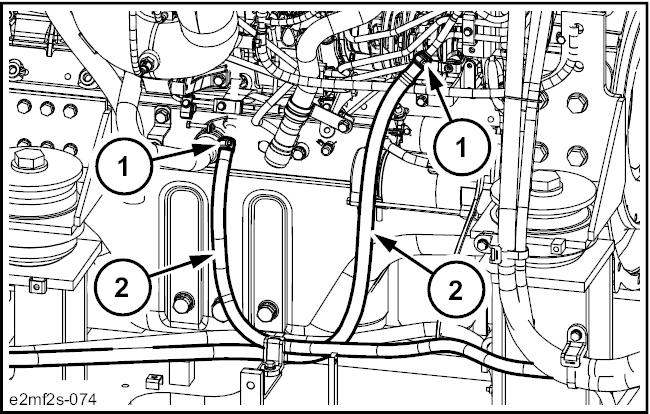

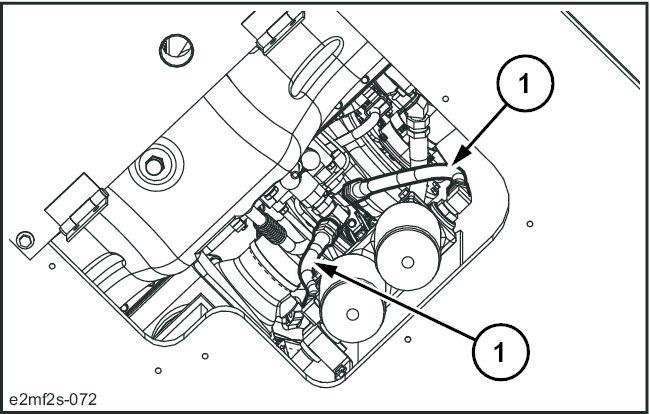

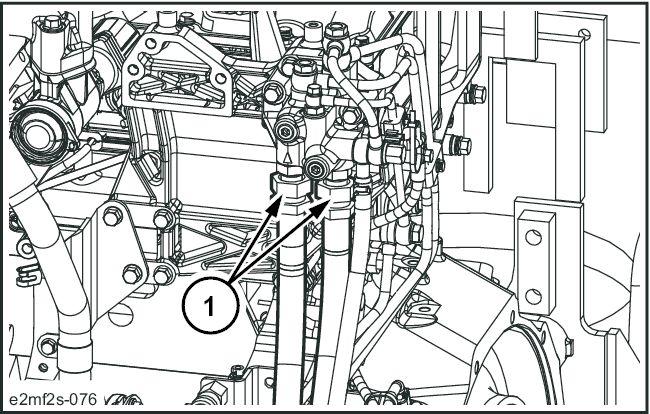

Use a wrench [ ] remove the 2 engine remote hoses (1) .

E2MF2S - 073

SMIL13CEX3138AB 1 1

E2MF2S - 074

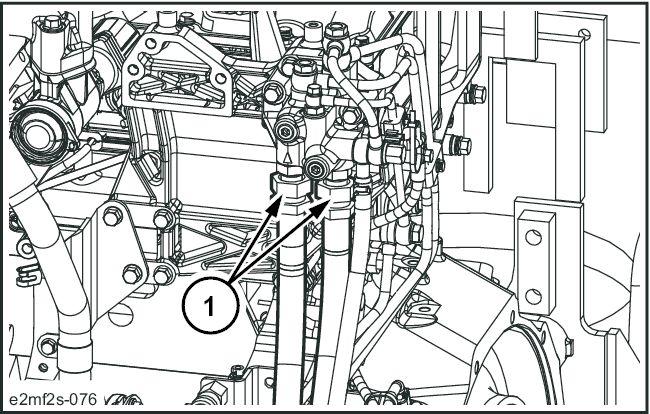

E2MF2S - 076 48032547 22/06/2016 10.1 [10.001] /

Engine - Engine and crankcase

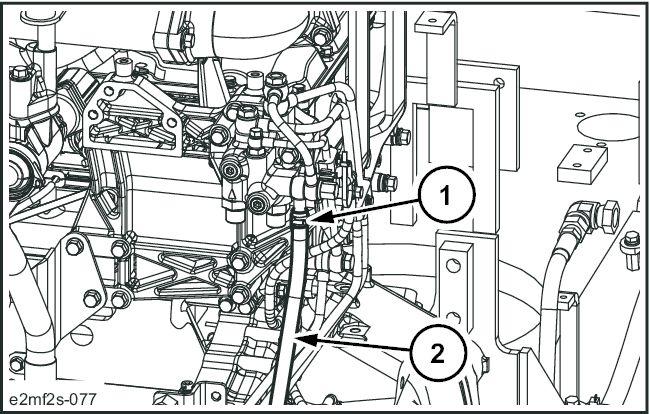

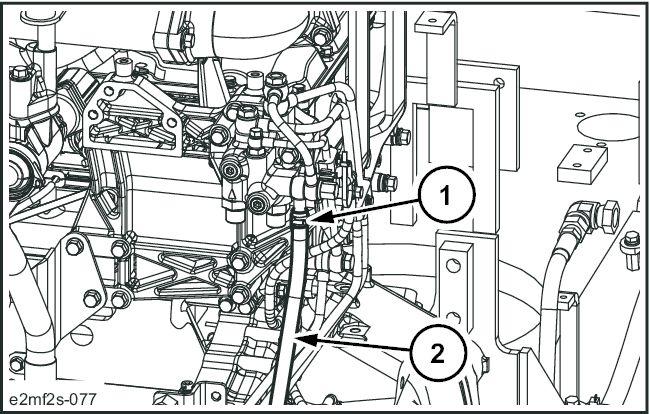

19. Remove the hose band (1) , and then remove the gine remote subhose (2) E2MF2S - 077

48032547 22/06/2016 10.1 [10.001] /

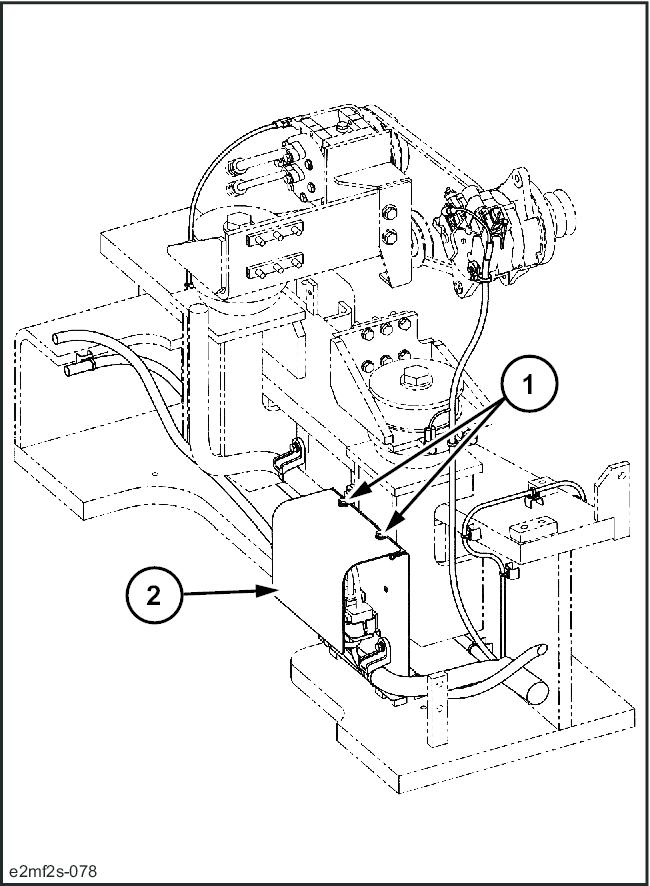

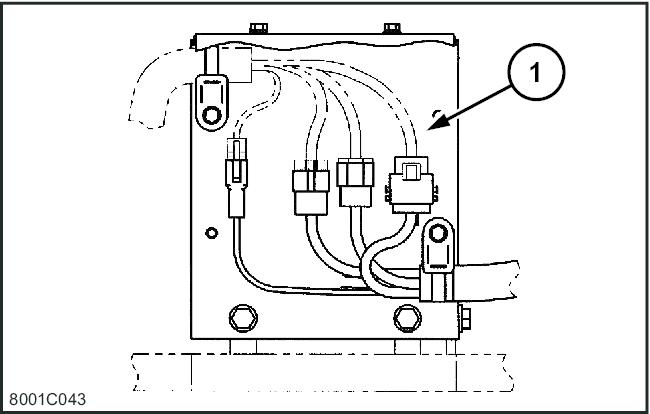

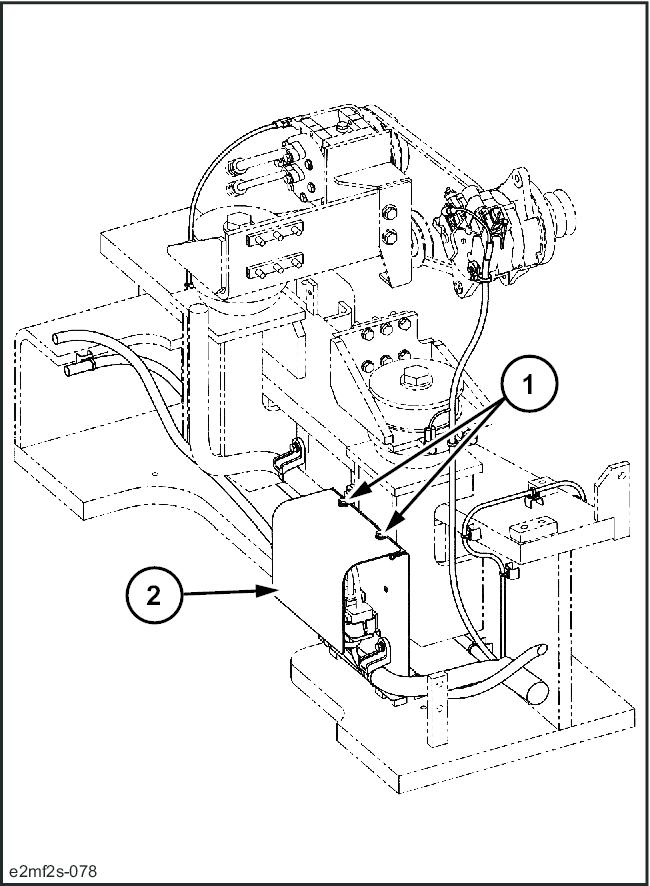

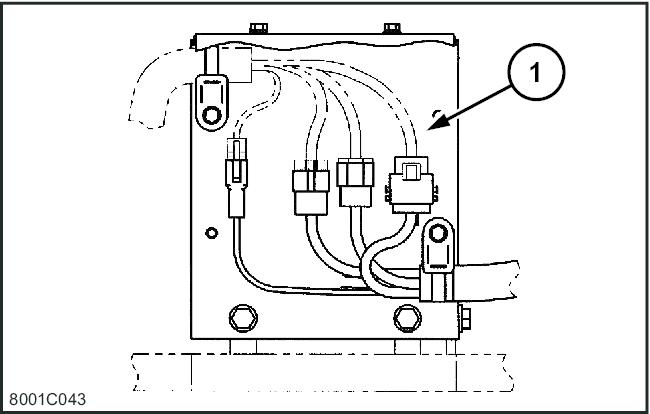

Use a wrench [ ] remove the 2 bolts (1) , and then remove the box cover (2) E2MF2S - 078 Remove the connectors (1) the • W rap the removed connectors plastic after tying them together prevent any entry water , dust dirt. 8001C043

22. Use a wrench [ 8 ] loosen the hose band (1) , and then remove the heater hose (2)

• Use caps cover the lines and hoses prevent any entry water , dust

T ightening torque for bolt installation: 8.89.8 N·m ( 6.4917.228 ) 971D17A7

Use a wrench [ 8 ] loosen the hose band (1) , and then remove the air hose (2)

• Use caps cover the lines and hoses prevent any entry water , dust dirt.

T ightening torque for bolt installation: 8.89.8 N·m ( 6.4917.228 ) C03497AE

Use a hexagon wrench [ 8 ] remove the 4 hexagon bolts (1) and 2 split flanges (2) , and then remove the hydraulic hose (3) FF472B07

Remove the connector (1) from the alternator

Engine - Engine and crankcase

VZQ8HE - 008 48032547 22/06/2016 10.1 [10.001] /

Engine - Engine and crankcase

26. Remove the cap (1) , use a wrench [ ] remove the nut (2) , and then remove the alternator wiring (3)

VZQ8HE - 009

48032547 22/06/2016 10.1 [10.001] /

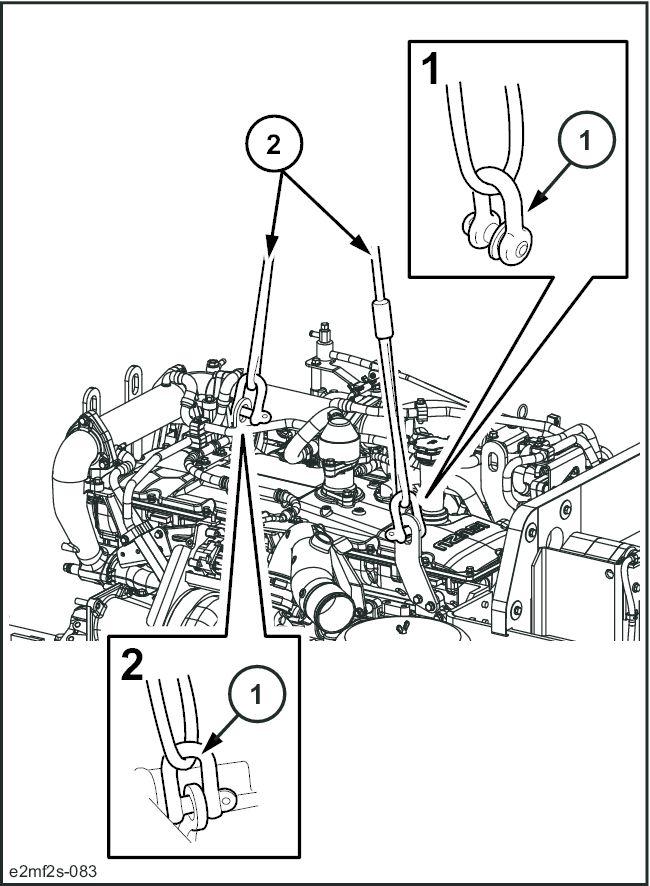

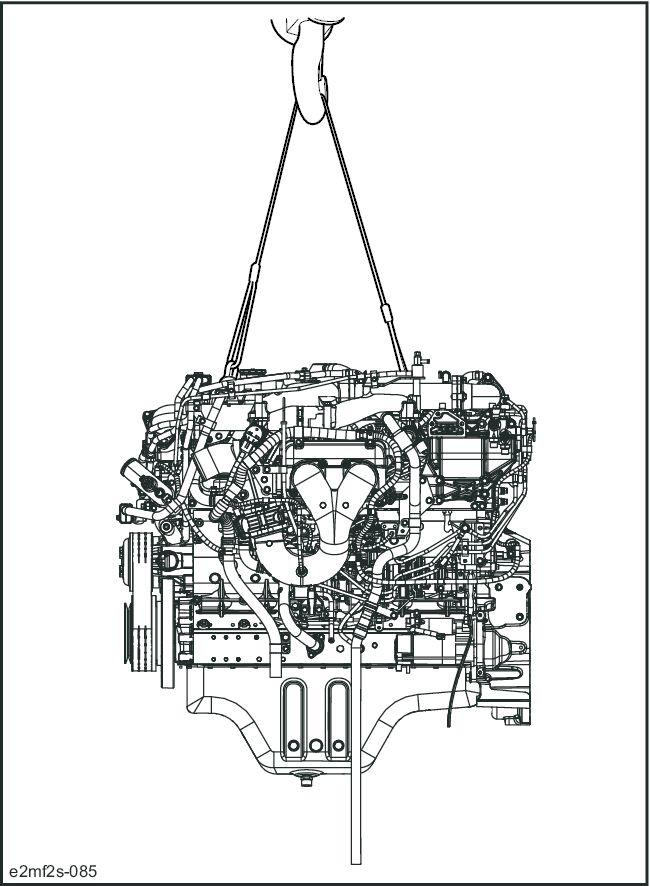

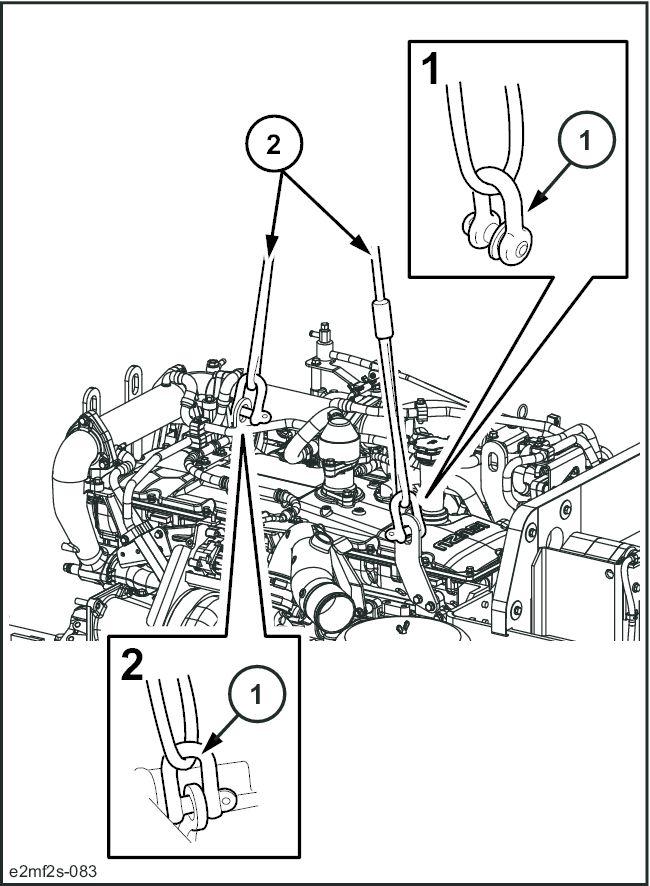

Install the 2 shackles (1) , and then use the wire rope (2) and liftcrane secure the engine main E2MF2S - 083

Engine - Engine and crankcase

28. Use a box wrench [ ] remove the 4 bolts (1) from the T ightening torque for bolt installation: 843.4N·m ( - )

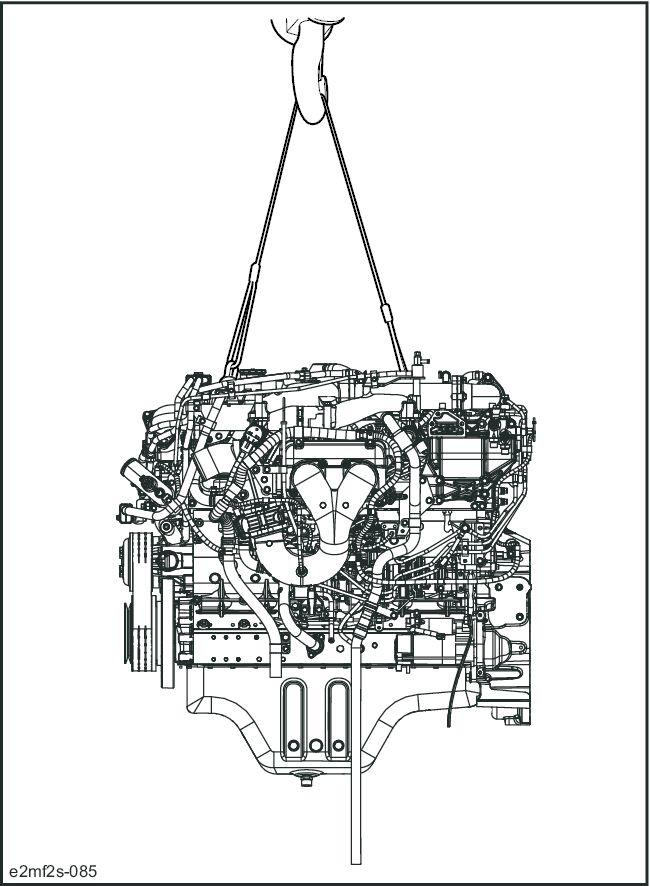

29. Use the wire rope (1) and liftcrane lift the engine main Thoroughly check that the location safe before ering the engine wood

E2MF2S - 084

48032547 22/06/2016 10.1 [10.001] /

E2MF2S - 085

Engine - Engine and crankcase

Engine - Install

T o install the perform the reverse the removal procedure.

When installing each tighten them the specified

For bolts for which the torque not see " T orque - Bolt and nut

After installing the engine, resupply coolant and engine perform fuel line air and perform filling for the air conditioner

For details, see the individual explanations for each

Run the engine - load idling and check for any ter oil

Attach the hydraulic and

For see the individual explanations for each

48032547 22/06/2016 10.1 [10.001] /

Engine - Engine and crankcase

Engine - Check - Engine oil

W ARNING

Burn hazard! not handle any service fluid (engine coolant, engine oil, hydraulic oil, etc.) temperatures that exceed (120 °F). Allow fluids cool before proceeding. Failure comply could result death serious injury

NOTICE: The engine should a horizontal position.

NOTICE: W ait least 5 min before starting the engine and after stopping the

Engine oil inspection

Remove the oil level gauge from the oil level gauge guide

NOTE: W ipe off the engine oil remaining the oil level

Install the oil level gauge the oil level gauge guide

Remove the oil level gauge from the oil level gauge guide

Inspect the engine

NOTE: Check the engine oil remaining the oil level gauge inspect the engine oil level.

Upper limit

Lower limit

NOTE: the oil level under the lower add engine Replace the engine oil engine oil dirty

W0330B

SMIL14CEX3221AB 1 48032547 22/06/2016 10.1 [10.001] /

Engine - Compression test

Engine compression pressure inspection

NOTE: W arm the engine.

Confirm that there abnormality with the battery and the starter

Disconnect the battery ground cable.

NOTICE: not disconnect the battery cable for 1 minute after turning OFF the ignition

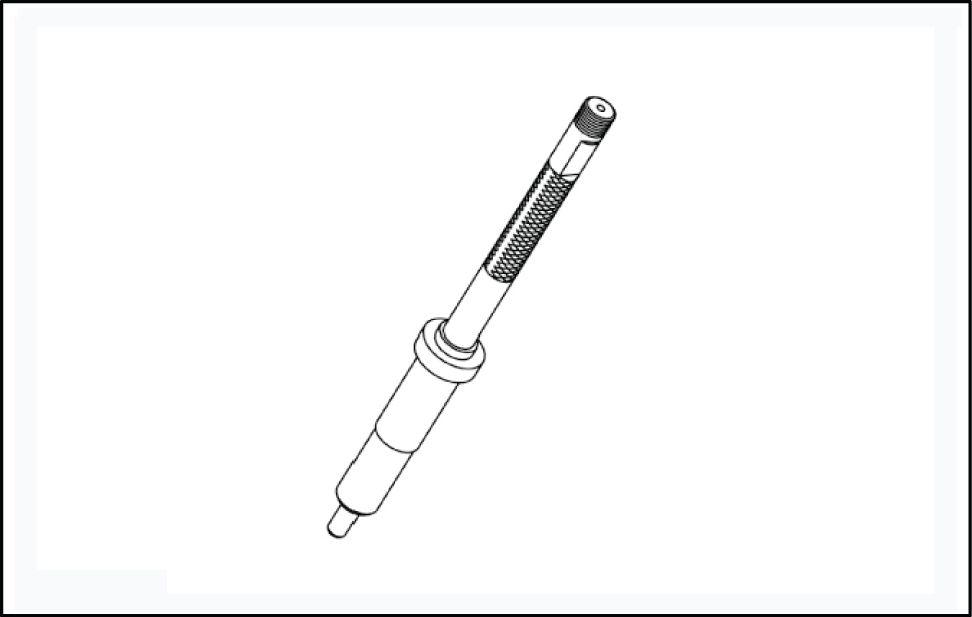

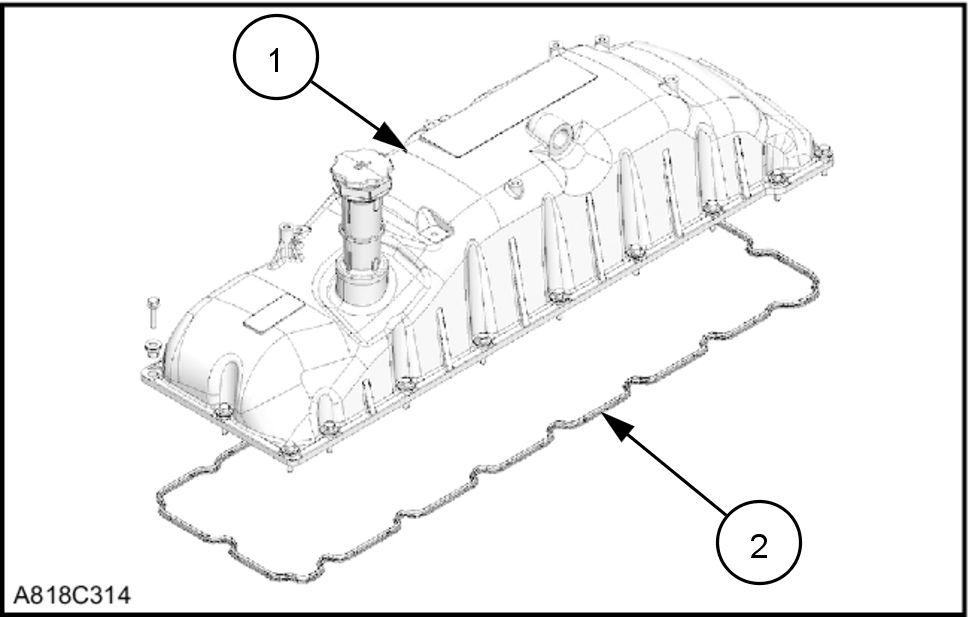

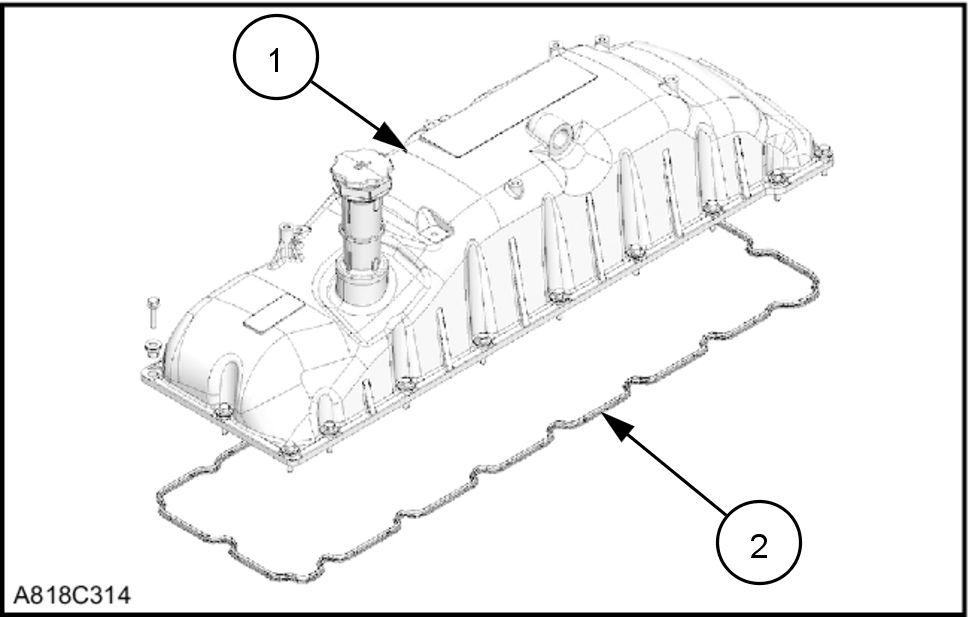

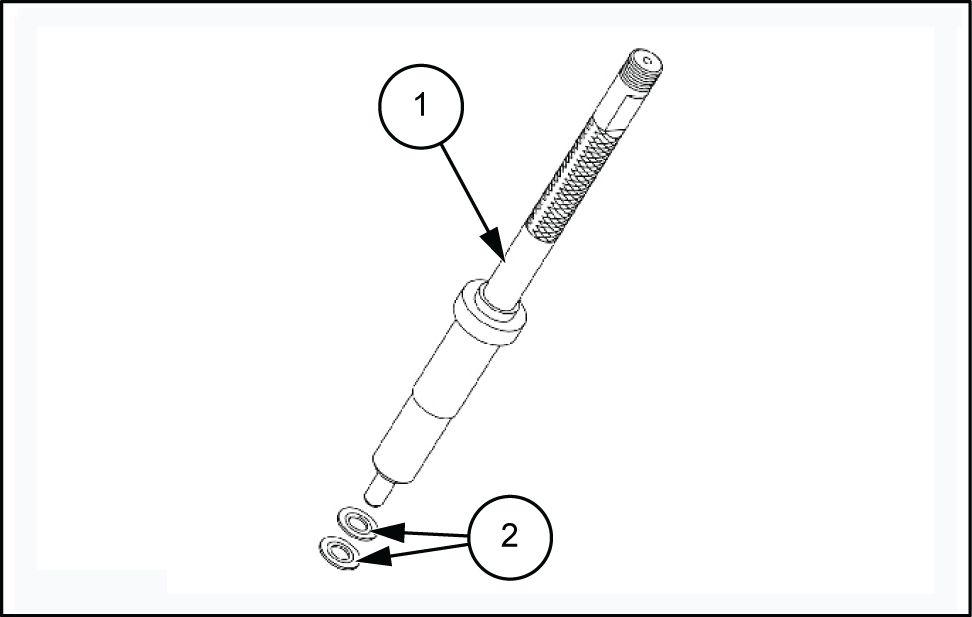

Remove the cylinder head cover (1) Gasket

Loosen the injector side sleeve nut the injection

Remove the injector

• Loosen the terminal tightening nut remove the

• Remove the harness bracket assembly

NOTICE: Removal the injector harness causes the code plate come off, avoid mix - with other injector code

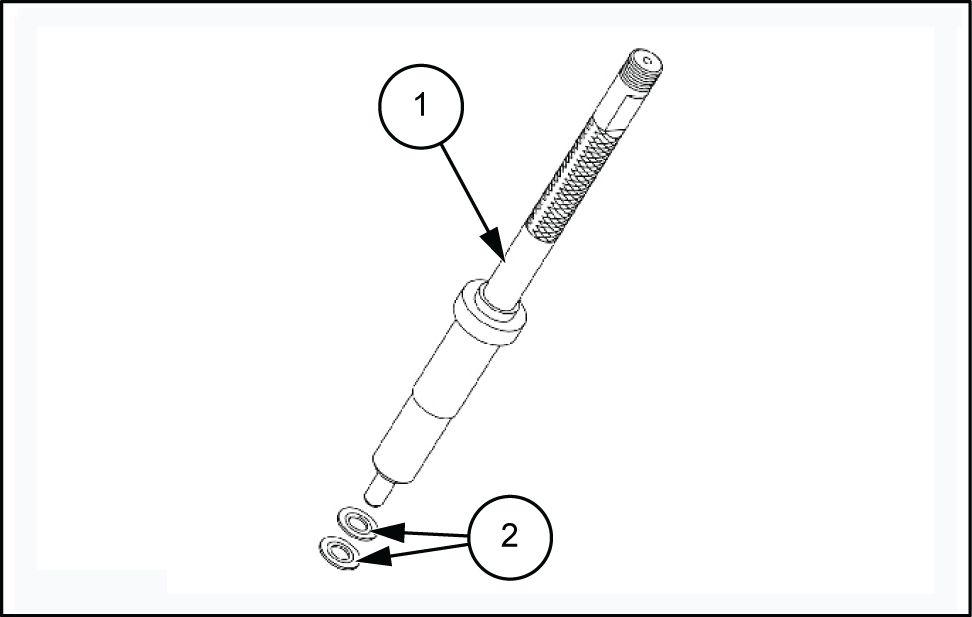

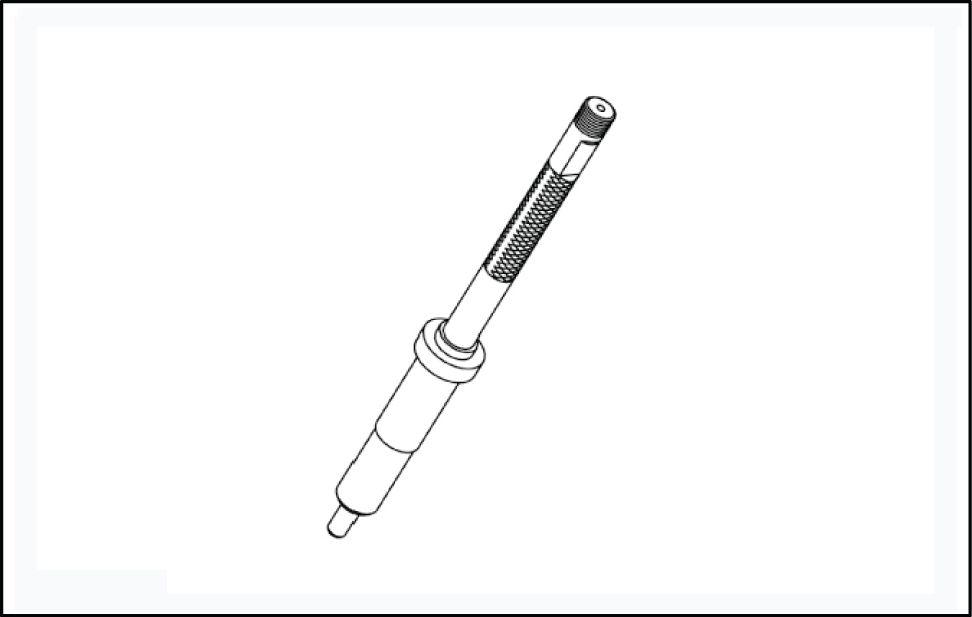

Compression gauge

Compression gauge adaptor

Remove the injector leak - f pipe.

Remove the injector from the cylinder head assembly

• Remove all

Install the special tool the cylinder head assembly

• Put 2 gaskets the compression gauge adapter and insert into the injector installation

Special tool: Compression gauge adapter (see Cylinder head - Special tools (10.101) )

Engine - Engine and crankcase

A818C314 1

SMIL13CEX6817AA 2

SMIL13CEX7147AA 3 48032547 22/06/2016 10.1 [10.001] /

Compression gauge adaptor

Gasket

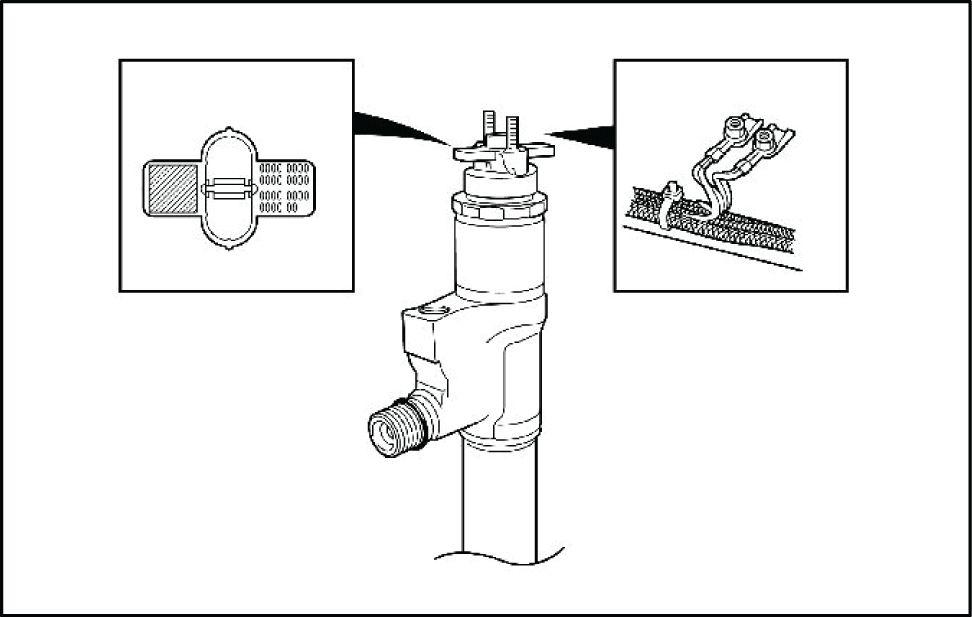

T ighten the compression gauge adapter using the jector

• Set the clamp position the center the adapter .

10. Install the compression gauge the compression gauge adaptor

• Remove all the injector gaskets other than the suring cylinder

1 Measure the compression pressure.

• Rotate the starter and read the indication the compression pressure when the compression gauge needle stabilizes with engine speed approximate 200 RPM

• Measure the compression pressure all cylinders.

NOTICE: Be aware that air bursts out through the injector hole during

NOTE: When the starter switch turned with the injector harness connector the ECM determines a malfunction and records a make sure the DTC has been cleared after the inspection completed.

Engine - Engine and crankcase

SMIL13CEX7148AB 4

SMIL13CEX7149AA 5

Standard value 2746 kPa ( 398.27 psi ) Limit value 2260 kPa ( 327.8 psi ) Dif ference between each cylinder 196 kPa ( psi )

48032547 22/06/2016 10.1 [10.001] /

Crankcase - Remove

Battery ground cable disconnect

Disengage the battery ground cable from the battery

NOTICE: not disconnect the battery cable for 1 min after turning OFF the ignition

Coolant drain

ARNING

Burn hazard!

Hot coolant can spray and scald you remove the radiator deaeration tank cap while the system hot. T o remove the cap: allow the system cool, turn the cap the first notch, and wait for all pressure release. Remove the cap only after all pressure has released.

Failure comply could result death serious injury

Drain the coolant from the radiator

NOTICE: After draining the tighten the drain

Drain the coolant from the engine assembly

NOTE: Loosen the drain plug (1) the cylinder block

Engine oil drain

Remove the drain plug from the oil pan.

NOTE: Drain engine oil into the drain pan. Install the drain plug the oil

T ightening torque: N·m ( 51.63 )

NOTICE: Be careful not forget tighten the drain

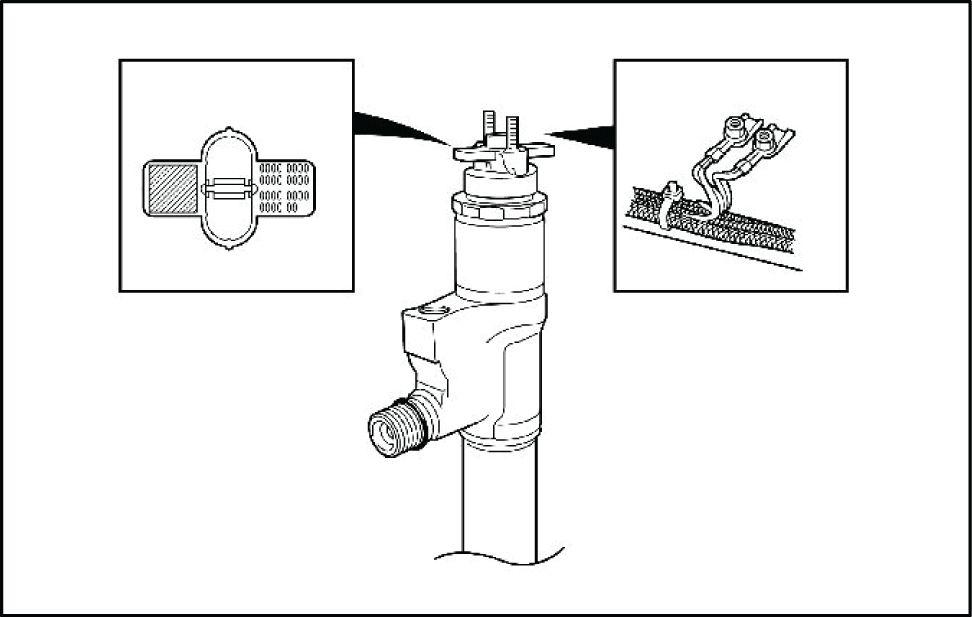

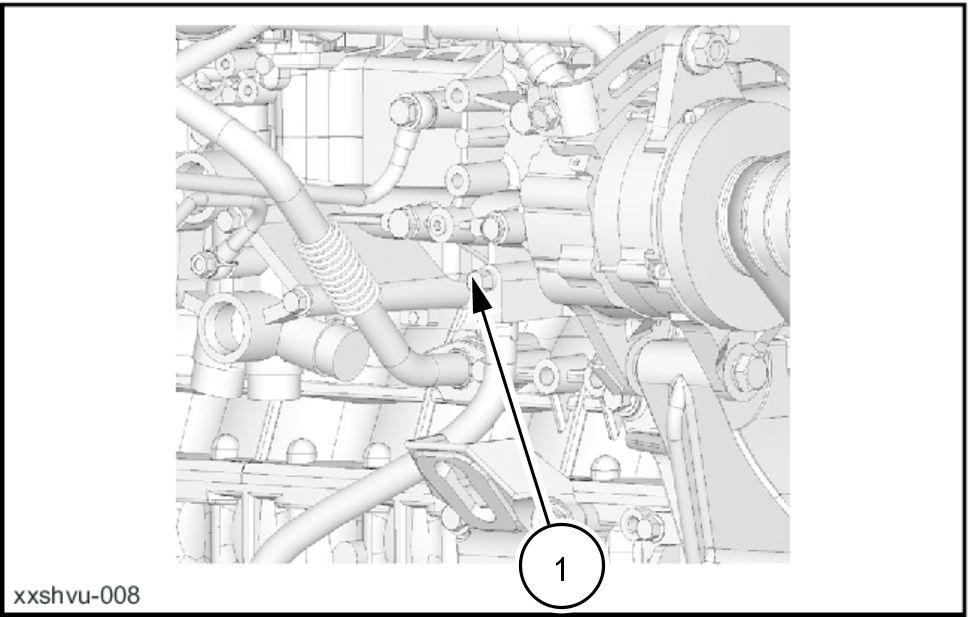

Oil level gauge guide tube removal

Remove the oil level gauge guide tube from the inlet

Disconnect the oil level gauge guide tube from the oil

NOTICE: not damage the Oring.

Engine - Engine and crankcase

W

W0367A

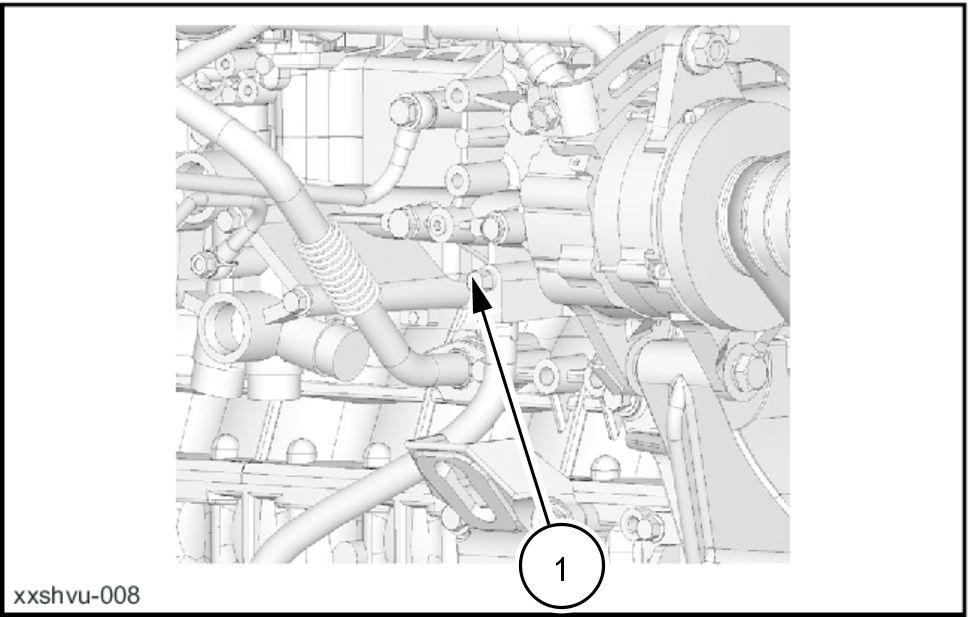

XXSHVU - 008 1

48032547 22/06/2016 10.1 [10.001] /