Thanks very much for your reading, Want to get more information, Please click here, Then get the complete manual

NOTE:

If there is no response to click on the link above, please download the PDF document first,andthen click on it.

Thanks very much for your reading, Want to get more information, Please click here, Then get the complete manual

NOTE:

If there is no response to click on the link above, please download the PDF document first,andthen click on it.

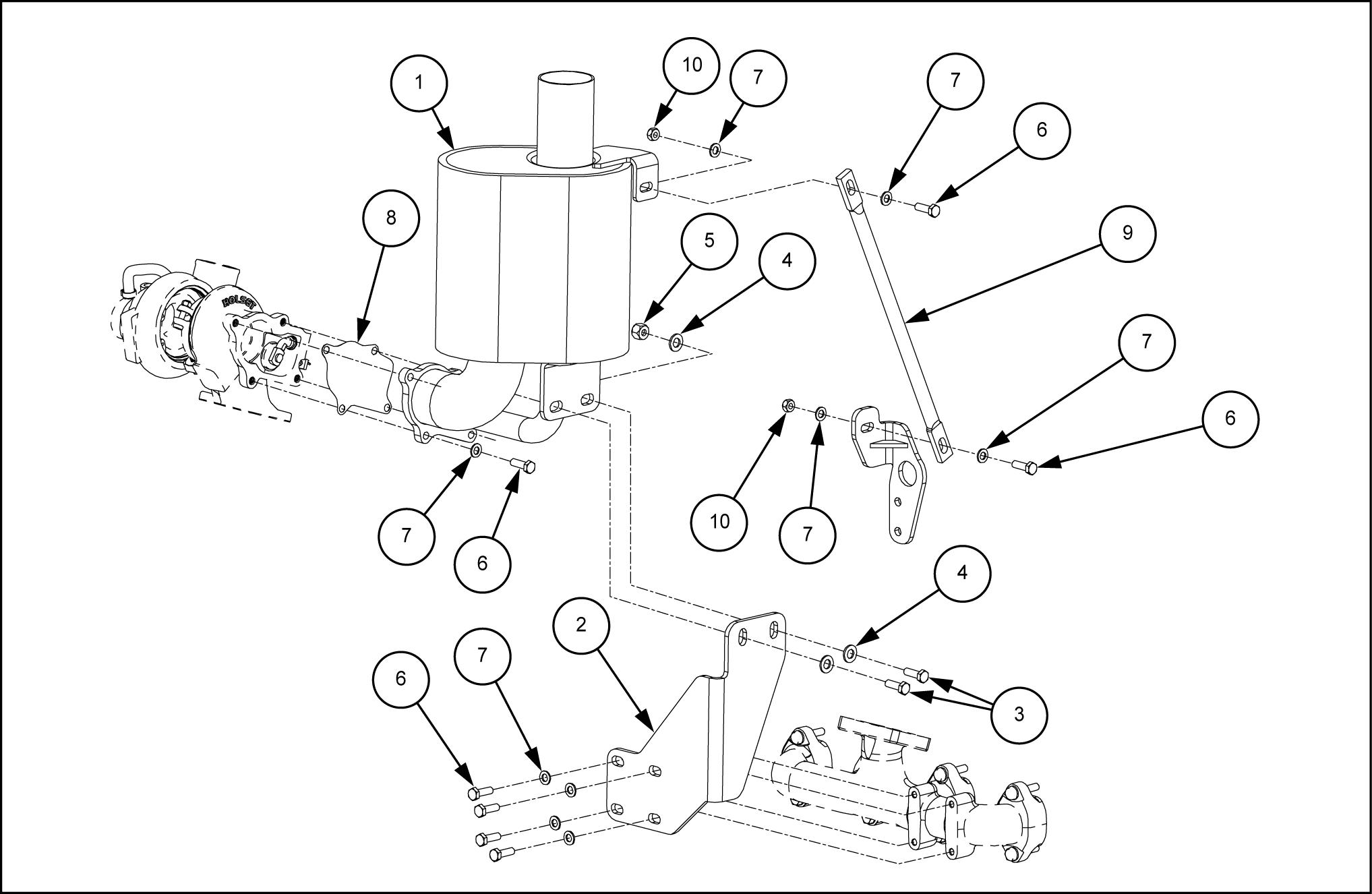

[10.254] Intake and exhaust manifolds and muf fler

cooling system

Power shuttle transmission external controls Power shuttle transmission internal components

Powered rear axle

Rear bevel gear set and dif ferential

Final drive steering and shafts

Brakes and controls

570ST ANZ - - - - - - - - - MEA

Personal safety

This the safety alert used alert you potential personal injury

Obey all safety messages that follow this symbol avoid possible death injury .

Throughout this manual you will find the signal words W and CAUTION followed special These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

CAUTION indicates a hazardous situation that, not avoided, could result minor moderate injury .

F AILURE T O FOLLOW DANGER, W ARNING, AND CAUTION MESSAGES COULD RESUL T DEA SERIOUS INJUR Y .

Machine safety

NOTICE: Notice indicates a situation not could result machine property

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property The word Notice used address practices not related personal safety

Information

NOTE: Note indicates additional information that clarifies other information this

Throughout this manual you will find the word Note followed additional information about a other information the The word Note not intended address personal safety property

570ST ANZ - - - -

MEA

Improper operation service this machine can result accident. not operate this machine perform any repair until you have read and understood the operation, lubrication, maintenance, and repair information. Failure comply will result death serious injury D0010A

Maintenance hazard!

Always perform all service procedures punctually the intervals stated this manual. This ensures optimum performance levels and maximum safety during machine operation. Failure comply could result death serious injury . W0132A

NOTICE: Extreme working and environmental conditions require shortened service

Use Case and filters for the best protection and performance your All and filters must disposed compliance with environmental standards and Contact your Dealer with any questions regarding the service and maintenance this machine.

Use this manual with the manual understand and perform the complete service Read the safety decals and information decals the machine. Read the Operator ’ s Manual and safety manual. Understand the operation the machine before you start any

Before you service the put a Not tag the steering wheel over the key Ensure the tag a location where everyone who might operate service the machine may see clearly

• A void using paint thinner , when cleaning plastic instrument cluster ,

• Use only water , mild and a soft cloth when you clean these

• Using can cause deformation the part being

48048556

Altering cast ductile iron can cause weaken break.

Before you weld, cut, drill holes any part this machine, make sure that the part not cast ductile Failure comply will result death serious injury .

Unauthorized modifications cast ductile iron parts can cause death serious injury . not weld, cut, drill, repair , attach items cast ductile iron parts this machine.

Altering cast ductile iron can cause weaken

Before you drill holes any part this make sure the part not cast ductile See your dealer you not know a part cast ductile

The following items are examples cast ductile iron There may also other parts made cast ductile iron that are not the list below

• two - wheel drive steering link

• dump links

• front axle

• stabilizers

• extend - a - hoe

• swing tower

• bucket linkage

• Air - Conditioning / compressor mounting bracket not make any unauthorized Consult authorized dealer before making any modifications this

Improper operation service this machine can result accident. Any unauthorized modifications made this machine can have serious consequences. Consult authorized dealer modifications that may required for this not make any unauthorized modifications.

Failure comply will result death serious injury

D0030A

Before you weld, cut, drill holes any part this machine, make sure the part not cast ductile iron. See your dealer you not know a part cast ductile The following are cast ductile iron parts:

• two wheel drive steering link

• dump links

• front axle

• stabilizers

• extendahoe

• swing

• bucket linkage

• Air Conditioning / compressor mounting bracket

Unauthorized modifications cast ductile iron parts can cause injury W drilling can cause cast ductile iron break. not weld, cut, drill repair attach items cast ductile iron parts this machine.

570ST ANZ - - - - - - - - - MEA

Unless otherwise always perform these steps before you service the machine: Park the machine a level

Place the backhoe the transport position with the swing lock pin installed for Place the loader bucket the with the bottom the loader bucket parallel the Place the direction control lever and the transmission you need open the hood perform raise the loader arms and install the support Shut down the

Place a Not tag the key switch that visible other workers remove the key

air , and water are vital factors agriculture and life When legislation does not yet rule the treatment some the substances required advanced technology , sound judgment should govern the use and disposal products a chemical and petrochemical nature.

NOTE: The following are recommendations that may assistance:

• Become acquainted with and ensure that you understand the relative legislation applicable your country

• Where legislation obtain information from suppliers cleaning with regard their fect man and nature and how safely and dispose these substances.

• A void filling tanks using cans inappropriate pressurized fuel delivery systems that may cause considerable

• avoid skin contact with all

Most them contain substances that may harmful your

• Modern oils contain not burn contaminated fuels and waste oils ordinary heating

• A void spillage when draining f used engine coolant gearbox and hydraulic brake not mix drained brake fluids fuels with Store them safely until they can disposed a proper way comply with local legislation and available resources.

• Modern coolant antifreeze and other should replaced every two They should not allowed get into the but should collected and disposed properly

• Repair any leaks defects the engine cooling hydraulic system immediately

• not increase the pressure a pressurized circuit this may lead a component

• Protect hoses during welding penetrating weld splatter may burn a hole weaken allowing the loss 48048556

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special

Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution including - without limitationlocal CASE reject any responsibility for damages caused parts and / components not approved the manufacturer , including those used for the servicing repair the product manufactured marketed the manufacturer

any case, warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer

The information this manual - - date the date the publication. the policy the manufacturer for continuous Some information could not updated due modifications a technical commercial changes the laws and regulations dif ferent

case refer your Case New Holland Construction Equipments Sales and Service

570ST ANZ

Explosive gas!

MEA

Batteries emit explosive hydrogen gas and other fumes while charging. V entilate the charging area. Keep the battery away from sparks, open flames, and other ignition sources. Never charge a frozen battery

Failure comply could result death serious injury .

Hazardous chemicals!

W0005A

Battery electrolyte contains sulfuric acid. Contact with skin and eyes could result severe irritation and burns. Always wear splash - proof goggles and protective clothing (gloves and aprons). W ash hands after

Failure comply could result death serious injury .

• not run the engine with the alternator wires

• Before using electric welder , disconnect the alternator wires, instrument cluster and batteries.

• not use a steam cleaner a cleaning solvent clean the alternator

• Keep the battery vents clean. Ensure the battery vents are not restricted.

Open the battery compartment cover the right hand side step the using the key

Disconnect the negative battery cable (1) from the negative battery

W0006A

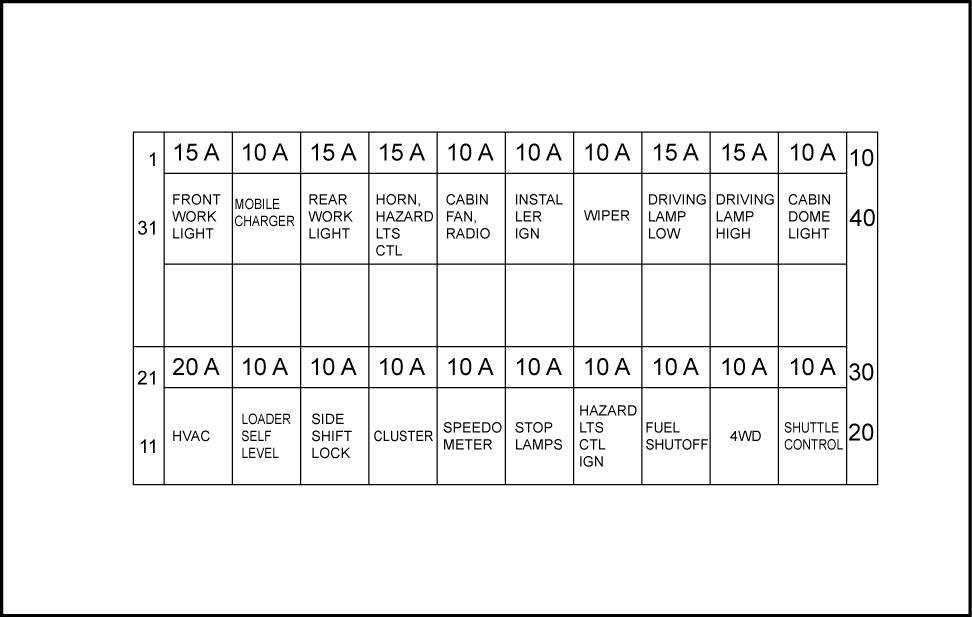

The machine equipped with a fuse located the side

T urn the thumb screws (1) loosen the panel cover (2) for the fuse Remove the panel cover

Remove the fuse box covers

Refer the decal top the panel cover for relay , and / diode

The fuses are arranged per the Fig. 2

570ST ANZ

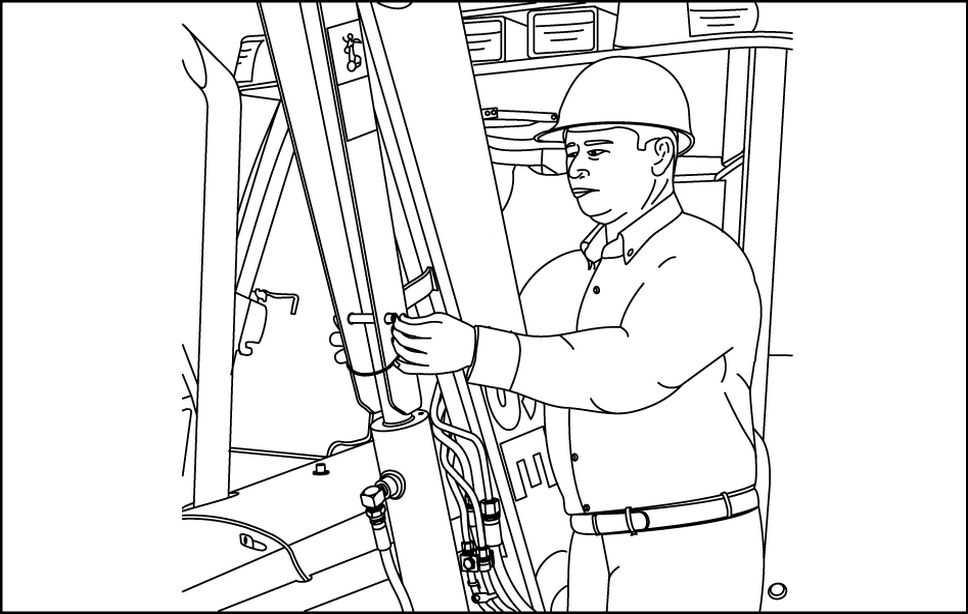

Crushing hazard!

MEA

you service the machine with the loader lift arms raised, always use the support strut. Remove the retaining pin and place the support strut onto the cylinder rod. Install the retaining pin into the support Lower the lift arms onto the support

Failure comply could result death serious injury .

Raise and support loader lift arms:

Empty the loader bucket.

Raise the loader lift arms the maximum Shut down the engine.

RCPH10TLB230AAF 1

Remove the retaining

Lower the support strut onto the cylinder

Install the retaining

RCPH10TLB221AAF 2

Start the

Slowly lower the lift arms that the end the support strut rests the cylinder

RCPH10TLB227AAF 3 48048556

W0230A

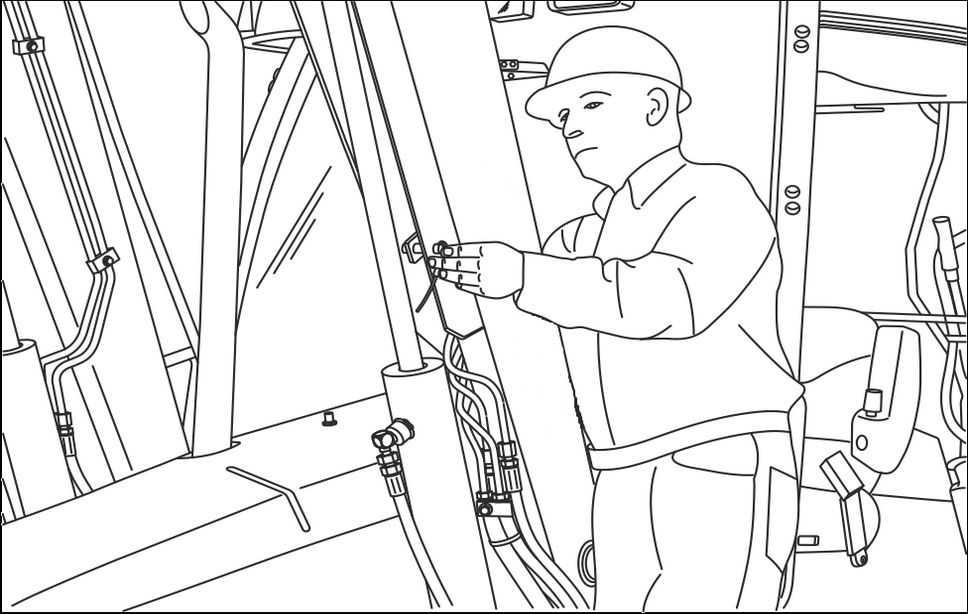

Lower supported loader lift arms:

Raise the lift arms that the end the support strut longer rests the cylinder

Shut down the engine.

Remove the retaining pin from the support

Raise the support strut the storage position and secure with the retaining

Start the

Lower the loader the

570ST ANZ

Open the hood: Shut down the engine.

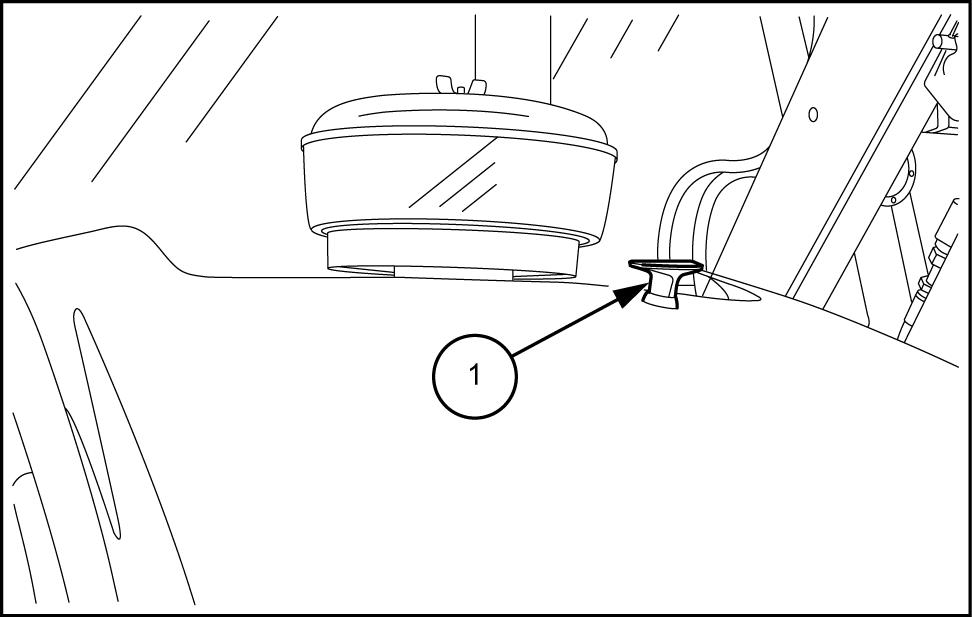

T urn the handle (1) counter - clockwise release the hood

MEA

PTIL13TLB1558AB 1

Lift the hood and rotate

PTIL12TLB0559AB 2

NOTICE: T o avoid damage the hood always close the hood before moving the loader

Close the hood:

Lower the

T urn the handle (1) clockwise lock the hood latch.

PTIL13TLB1558AB 3 48048556

570ST ANZ -

For each adjustment select adjusting shims and measure the adjusting shims individually using a eter , then add the recorded not rely measuring the entire shimming set, which may the rated value shown each

For correct rotating shaft seal proceed follows: Before assembly , allow the seal soak the oil will sealing for least thirty minutes.

Thoroughly clean the shaft and check that the working surface the shaft not Position the sealing lip facing the fluid.

NOTE: W ith hydrodynamic lips, take into consideration the shaft rotation direction and position the grooves that they will move the fluid towards the inner side the

Coat the sealing lip with a thin layer lubricant (use oil rather than grease). Fill the gap between the sealing lip and the dust lip double lip seals with

Insert the seal its seat and press down using a flat punch seal installation not tap the seal with a hammer

While you insert the check that the seal perpendicular the When the seal make sure that the seal makes contact with the thrust element, required.

T o prevent damage the seal lip the position a protective guard during installation O - ring seals

Lubricate the O - ring seals before you insert them the This will prevent the O - ring seals from overturning and twisting, which would jeopardize sealing ficiency .

Apply a sealing compound the mating surfaces when specified the procedure. Before you apply the sealing prepare the surfaces directed the product container

Spare parts

Only use CNH Original Parts CASE CONSTRUCTION Original

Only genuine spare parts guarantee the same quality , duration, and safety original parts, they are the same parts that are assembled during standard Only CNH Original Parts CASE CONSTRUCTION Original

Parts can fer this

When ordering spare always provide the following information:

• Machine model (commercial name) and Product Identification Number (PIN)

• Part number the ordered which can found the parts catalog

T o avoid damage the electronic and / electrical systems, always observe the following practices: Never make break any the charging circuit connections when the engine including the battery

Never short any the charging components

Always disconnect the ground cable from the battery before arc welding the machine any machine

• Position the welder ground clamp close the welding area

• you weld close proximity a computer then you should remove the module from the

• Never allow welding cables lie near , across any electrical wiring electronic component while you weld.

Always disconnect the negative cable from the battery when charging the battery the machine with a battery charger

NOTICE: you must weld the unit, you must disconnect the battery ground cable from the machine battery . The electronic monitoring system and charging system will damaged this not

Remove the battery ground Reconnect the cable when you complete

Special tools

Battery acid causes burns. Batteries contain sulfuric acid.

A void contact with skin, eyes clothing. Antidote (external): Flush with water . Antidote (eyes): flush with water for minutes and seek medical attention immediately Antidote (internal): Drink large quantities water milk. not induce vomiting. Seek medical attention immediately . Failure comply could result death serious injury

The special tools that CASE CONSTRUCTION suggests and illustrate this manual have been specifically searched and designed for use with CASE CONSTRUCTION The special tools are essential for reliable repair The special tools are accurately built and rigorously tested fer ficient and long - lasting ation.

using these repair personnel will benefit from:

• Operating optimal technical conditions

• Obtaining the best results

• Saving time and fort

• W orking safe conditions

Basic instructions - Minimum tightening torques for normal assembly

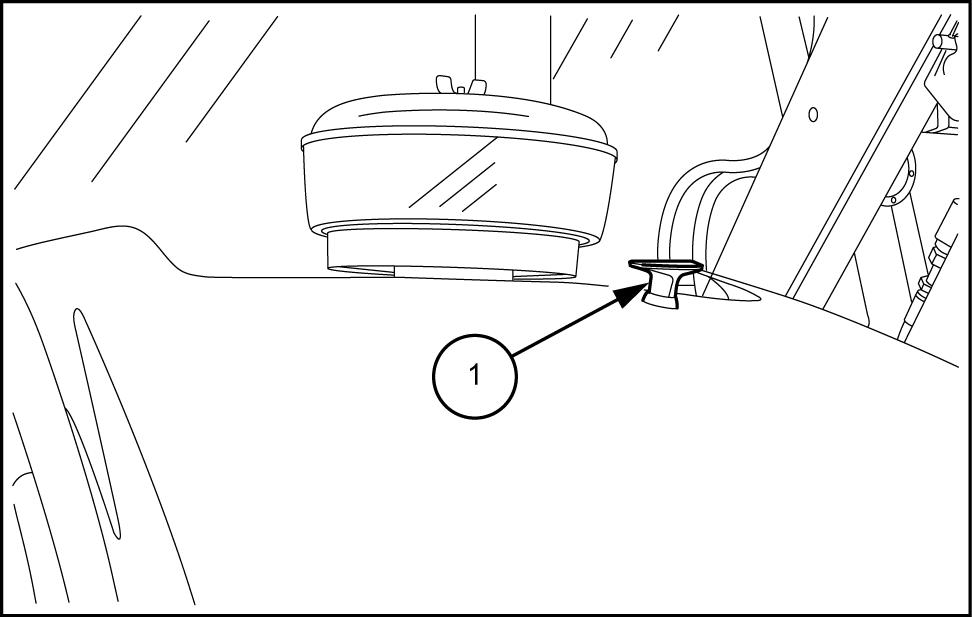

Inch Lock Nuts, All Metal (Three optional methods)

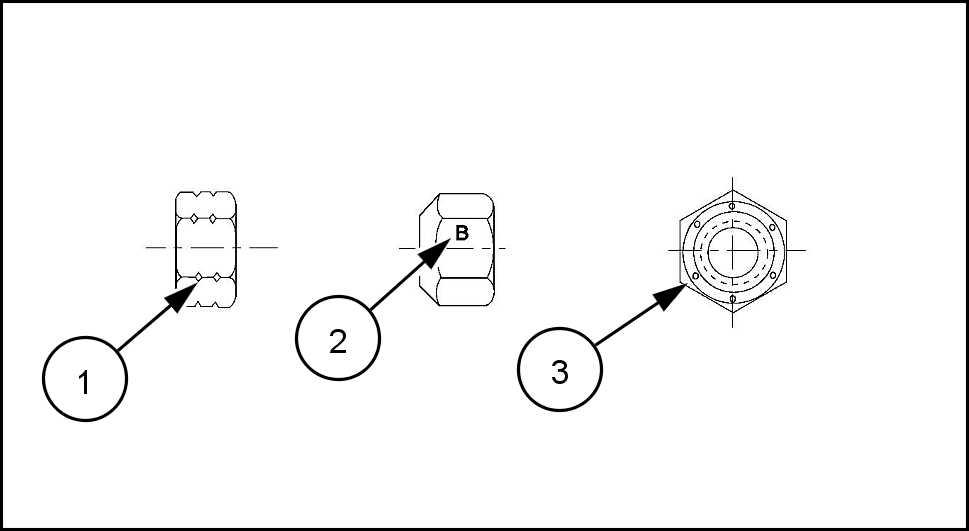

INST ALLA TION ADJUST ABLE FITTINGS STRAIGHT THREAD O RING BOSSES

Lubricate the O - ring coating with a light oil

Install the O - ring the groove adjacent the metal backup washer which assembled the extreme end the groove (4)

Install the fitting into the SAE straight thread boss until the metal backup washer contacts the face the boss (5)

NOTE: not over tighten and distort the metal backup washer

Position the fitting turning out (counterclockwise) a maximum one turn. Holding the pad the fitting with a tighten the locknut and washer against the face the boss (6)

Before installing and tightening pipe clean the threads with a clean solvent Loctite cleaner and apply sealant L OCTITE ® 567 PST P IPE S EALANT for all fittings including stainless steel L OCTITE ® 565 PST for most metal fittings. For high filtration / zero contamination tems use L OCTITE ® 545

When installing ORFS fittings thoroughly clean both flat surfaces the fittings (1) and lubricate the O - ring (2) with light Make sure both surfaces are aligned properly T orque the fitting specified torque listed throughout the repair manual.

NOTICE: the fitting surfaces are not properly cleaned, the O - ring will not seal properly the fitting surfaces are not properly the fittings may damaged and will not seal properly

NOTICE: Always use genuine factory replacement oils and filters ensure proper lubrication and filtration gine and hydraulic system oils.

The use proper and keeping the hydraulic system clean will extend machine and component life.

Prior operation:

Refer Basic instructions

Prior operation:

Refer Hood - Remove

Prior operation:

Refer Radiator - Remove

Prior operation:

Refer Intake and exhaust manifolds and muffler - Remove (10.254)

NOTE: Put identification tags all disconnected hoses and Close all disconnected hoses and fittings with caps and plugs immediately

NOTE: The images this procedure may different from your machine and are for reference only

A TTENTION: Allow the engine reach normal ture before performing any service maintenance

W ear safety gloves and goggles for protection from hot components and fluids severe burns could

Drain engine oil loosening the drain Collect the oil a clean container , cap and keep aside a clean place.

Disconnect the fuel return and inlet lines (1) from the mud filter (4) and cap them immediately

Loosen the mounting bolts (2) and remove the bly (3) from the machine.

Remove the exhaust pipe (1) the turbocharger and cap

Remove the muf fler support bracket bolt (2) .

Remove the bolt (1) and the muf fler assembly from the

Disconnect the throttle linkage (1) from the pump and set

Disconnect the coolant temperature (1) , alternator , oil pressure (2) and starter connectors from Remove the starter Refer Engine starter - Remove (55.201) .

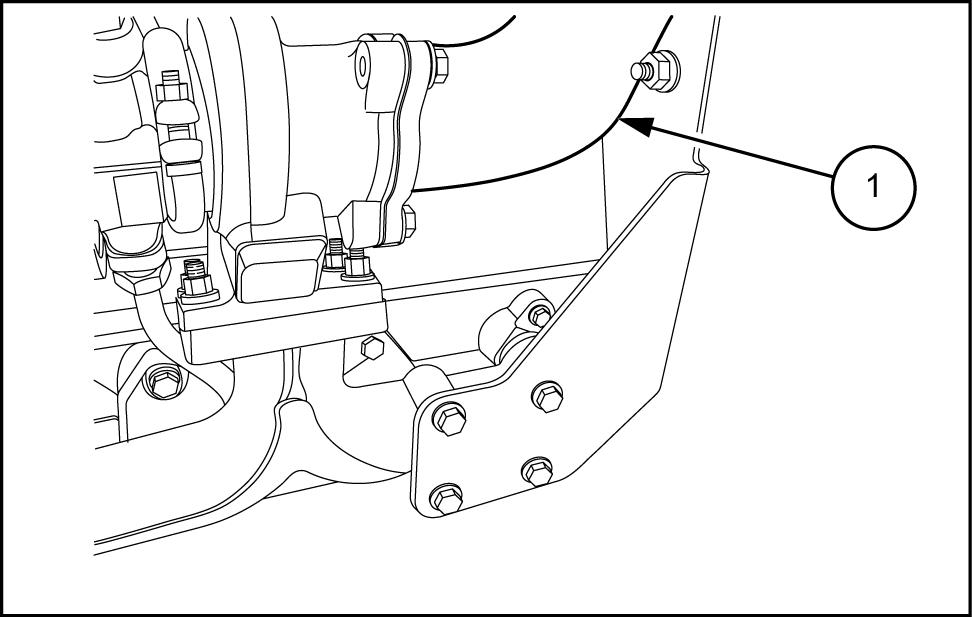

Remove the access cover from the flywheel housing (1)

T urn the flywheel for access the cap

Remove the cap screws disconnect the torque verter from the

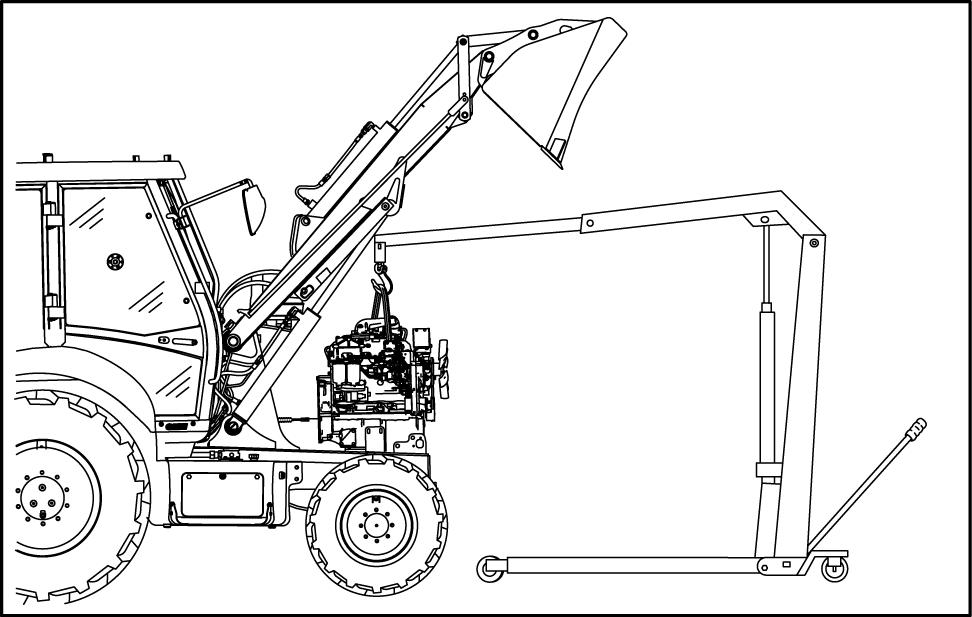

Connect lifting equipment the lifting eyes the gine hold the engine

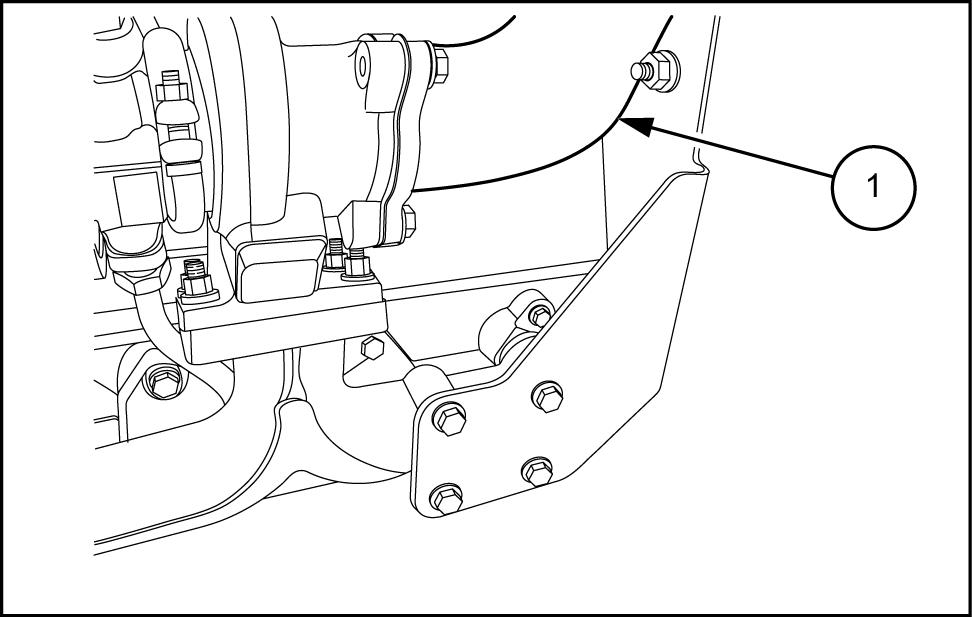

Remove the bolts (1) , flat washers, and nuts from the front engine

Loosen and remove the cap screws and flat washers that fasten the transmission the

Raise and remove the engine from the

NOTICE: Make sure that the flex plate / converter assembly stays place the the engine will separated from the transmission for extended period time fasten the flex plate / converter assembly place the

remove caps and plugs from previously disconnected hoses and fittings. Remove identification tags after making the hose and wire

NOTE: The photos this procedure may different from your machine and are for reference only

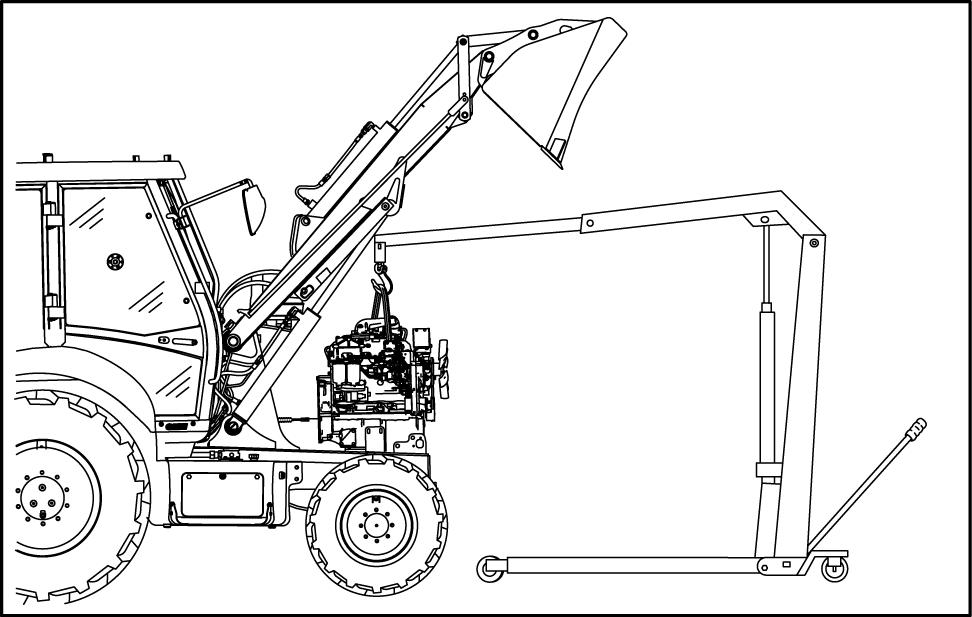

Position the engine the

NOTICE: Make sure that the flex plate / converter assembly stays place the

PTIL14TLB0126AA 1

Install and tighten the flat washers and cap screws curing the transmission the engine.

T ighten cap screws a torque - N·m ( - )

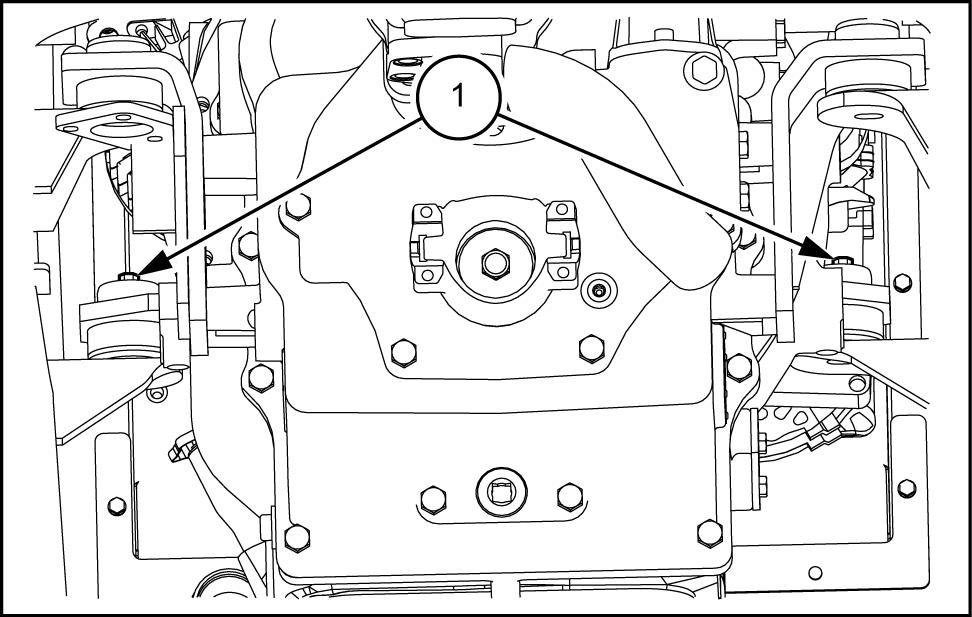

Install and tighten the front engine mounting bolts, flat and

T ighten the self - locking nuts a torque100 N·m ( - )

Disconnect the lifting equipment from the lifting eyes the

T ighten the cap screws through the access the flywheel housing (1) and fasten the flywheel the flex T ighten cap screws a torque - N·m ( - ) when fixing the torque converter

Install the access cover the bell

T ighten a torque value - N·m ()

Install the starter onto the T ighten a torque value N·m ( )

Refer Engine starter - Install (55.201)

PTIL13TLB0730AA 2

PTIL13TLB1470AA 3

Connect the coolant temperature (1) , alternator , oil pressure (2)

Connect the fuel return and inlet lines (1) and mount the fuel filter assembly (3) tightening the mounting bolts (2)

Connect the throttle rod (1)

10. Connect the throttle cable from the mounting bracket.

1 Connect the electrical connector for the oil pressure

Install the exhaust pipe (1) the turbocharger the muf fler

13. Attach the muf fler and brackets (1) the engine.

T ighten a torque value - N·m () . PTIL13TLB0958AB

14. Install the muf fler support bracket bolt (2) .

T ighten a torque value - N·m () PTIL13TLB0957AB

15. Attach the aspiration hose and the crank case lation

Install the exhaust Refer Intake and exhaust manifolds and muffler - Install (10.254)

17. Install the cooling pack. Refer Radiator - Install

Fill the engine oil and cooling system the scribed

19. See capacities Capacities for specifications.

20. Install air cleaner assembly .

Install the Refer Hood - Install

Connect the battery Refer Basic instructions

Start the engine and keep

PTIL13TLB1467AB

NOTE: The following table lists problems and their possible causes with recommended remedial

A TTENTION: When attending a repair the cause the problem must also investigated and corrected avoid repeat

Problem

Engine does not develop full power

Possible Cause Correction

Clogged air cleaner

Clean renew element

Fuel line obstructed Clean

Faulty injectors

Clean and reset

Incorrect valve clearance adjustment Clean and reset worn sticking valves

Blown head gasket

Incorrect fuel delivery

Low cylinder compression

Oil pressure warning light fails operate Bulb burnt out

Replace valves with new and / machine the valve guide bores

Check head flatness and fit new gasket

Check injectors and pump

Renew piston rings - bore / - sleeve necessary

Renew bulb

W arning Light pressure switch faulty Renew pressure switch

W arning light circuit faulty

Excessive exhaust smoke Exhaust leak exhaust manifold

Check and renew wiring

Fit new gasket

Air cleaner dirty restricted Clean

Excessive fuel delivery

Engine knocks Diluted thin oil

Overall injection pump and injectors

Check crankshaft bearings for change

Drain and refill with specified oil and renew filter Ascertain cause dilution

Insuf ficient oil supply

Check oil level and top necessary

Overhaul renew pump necessary

Check oil filter not clogged

Low oil pressure Overhaul pump relief valve necessary

Excessive crankshaft end play

Excessive connecting rod main

Bent twisted connecting rods

Replace thrust washer

Install new bearing inserts and / bearing clearance - grind crankshaft

Renew connecting rods

Crankshaft journals out round - grind crankshaft and fit undersize ing inserts

Excessive piston cylinder - bore / - sleeve block and fit i bore ance new pistons

Excessive piston ring clearance

Broken rings

Excessive piston pin clearance

Fit new pistons and rings

Fit new rings, check bore and pistons for damage

Fit new piston pin

Piston pin retainer loose missing Install new retainer , and check bore / pistons for damage

Excessive camshaft play

Imperfections timing gear teeth

Excessive timing gear backlash

Install new thrust plate

Renew timing gear

Check and adjust backlash / renew , timing gear

Engine overheats

Coolant hose connection leaking lapsed

Radiator cap defective not sealing

Radiator leakage

T ighten hose renew hose damaged

Renew radiator cap

Repair / renew radiator

Improper fan belt adjustment - adjust fan belt

Radiator fins restricted

Faulty thermostat

Internal engine leakage

W ater pump faulty

Clean with compressed air

Renew thermostat

Check for source leakage. Renew ket defective parts

Overhaul water pump