GANGBOX GAZETTE

Don’t miss an issue! We’re going paperless. Scan to share your email and get Gangbox Gazette delivered to your inbox.

Don’t miss an issue! We’re going paperless. Scan to share your email and get Gangbox Gazette delivered to your inbox.

Across Cannistraro, teams are stepping up like never before - carefully planning their work, taking ownership of safety, and executing as one Company. The coordination between office, shop, and field is producing great outcomes and reinforcing our shared commitment for success.

It’s inspiring to see continued growth in communication, collaboration, and the pursuit of excellence across all groups. Congratulations to all!

As I reflect on the past sixty-two years in the family business, and look towards the future, I’m especially proud to see the next generation entering the industry, whether through our Heavy Metal Summer Experience, apprenticeship programs, or co-op opportunities.

Early exposure to the trades gives young people a real head start, equipping them with the skills to master their craft—wherever their career path may lead. A heartfelt thank-you to all the mentors who make these programs possible, and to the leaders across our staff and craft for fostering harmony, teamwork, and an unshakable winning spirit. Keep up the great work!

We are halfway through the year and compared to last year we have made many improvements. Now more than ever, it is crucial that we do not become complacent as the weather gets warmer. Many of us are looking forward to activities that allow us to swap out the work boots for sandals or boat shoes once off the jobsite, but while on site, it's important that we stay focused on the task at hand. Plan, Own, Commit — and we can continue to keep ourselves and each other safe. Investing in our people will remain important through training, increasing our collaboration, and planning our work.

Keep up the great work and enjoy the rest of the summer!

Robert Fuller

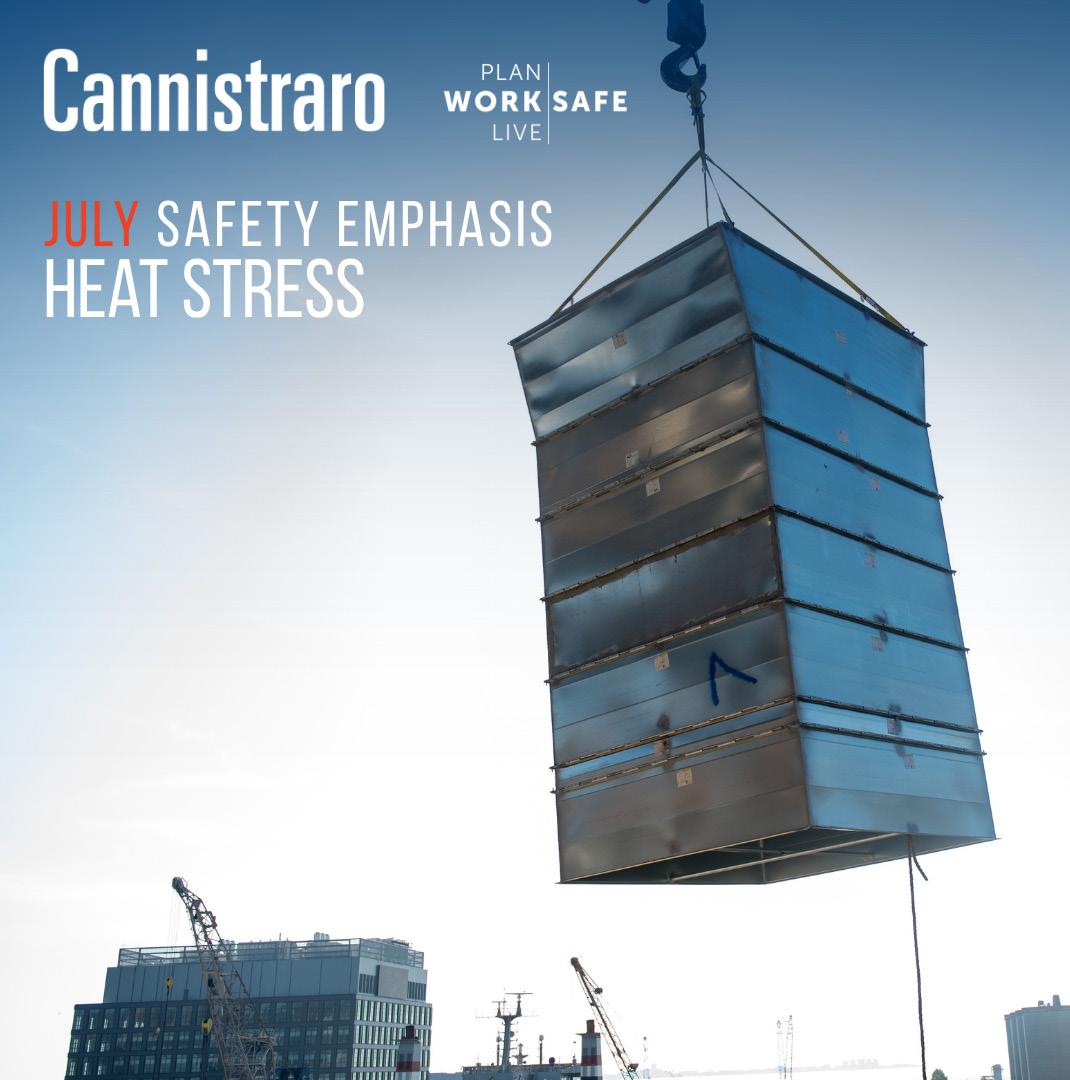

This year's Safety Week theme was "Plan, Own, Commit." This theme emphasizes the importance of proactive safety measures, personal responsibility, and strong dedication to maintaining a safe environment.

Plan: Safety starts with a solid plan.

Own: Take ownership of your safety and the safety of those around you.

Commit: Commit to continuous improvement and adherence to safety standards.

Harvard Enterprise Research Campus

- MBTA - Quincy Bus Facility Modernization

harvard university 100 south campus drive

service small projects group - the fid

University/Living & Learning Center

Innovation Square Phase III

At Cannistraro, safety isn’t just a priority—it’s a core value. That’s why we launched the “Near Miss / Good Catch” (NM/GC) program, giving our field teams the power to spot and report potential hazards before they turn into incidents. The mission? Stay ahead of risks and strengthen our culture of safety from the ground up.

A “Near Miss” refers to a close call that could have caused harm, while a “Good Catch” is the identification and correction of a hazard before an incident occurs. The program is open to all field workers with access to a company device. Submitting a report is quick and easy— the application is available on the Landing Page under “Near Miss/Good Catch” and has already been pushed to users’ devices.

Developed and tested with input from CLA cohort members and field leaders, the app underwent Alpha and Beta trials before its full rollout in March 2025. More than 180 employees have already been trained, with rollout efforts continuing this summer through on-site visits and safety meetings.

The program will evolve to include deeper data analysis and integration with systems like CMiC and ServiceTrade. With over 50 submissions already logged, Cannistraro is turning safety awareness into daily action— creating a culture where everyone plays a part in protecting one another.

Listed below are the projects awarded from April to June of 2025. In alignment with our 3-year strategy, the awarded work is both diverse and in new markets! Winning work is a team effort - thank you to everyone involved in securing these wins. Let’s keep it going!

MGH - CNY 149 2nd Floor Clean Room AHU

BCHW - Security Command Center

MGH

Wise Construction

MIT - 35-408 Del Vecchio Mech Lab Biotech

Regina Pizzeria - South Station Cafco

MGH - Warren 317 Dry Lab Reno Turner

FSB - L1820-C2 North Garage DP4 Construction Trailers Skanska

BU - Chemistry Lab Reno

SC Johnson FireDos

Fire Protection & Special Hazards

Wise Construction

SC Johnson

MGH - CNY 124 2nd Floor Clean Room AHU MGH

NU - EXP Level 4 Sector 1 Fitout

BC Voute Hall Consigli HVAC

MGHW - Blue 2 Cancer Center Expansion

BU - Chemistry Lab

Suffolk

F.L. Caulfield

Wise Construction

BC Voute Hall Consigli

Eversource - Linwood Storm Drains Olsen

BU - Chemistry Lab

Wise Construction

MGH - Warren 317 Dry Lab Reno Turner

MGHW - Blue 2 Cancer Center Expansion

MGH - Simches 8 Tunnel Washer Replacement

F.L. Caulfield

F.L. Caulfield

Logan - Terminal B Startbucks Refresh Holt

BCHW - Security Command Center

Wise Construction

FSB - L1820-C2 North Garage DP4 Skanska

NU - EXP Level 4 Sector 1 Fitout

Boston Scientific - 5 Year Foam Testing

Suffolk

Corner Mall - HVAC PMA (Additional Equipment) Winsum

Vertex - AHU #5 Isolation Valve Installation Vertex

New Balance - Content Factory Modifications

Emerson College - FP PMA

39 Dalton Street - RTU Replacements

1033 Mass Ave - HHWS/R Pipe Replacement

Fall River - RTU Replacement

RM Cochrane

Emerson College

Boston Scientific Service/Direct To Owner

Sheraton Hotel

Harvard Real Estate

Executive Office of Workforce Development

Genentech - BRIC TI Level 9 Turner

OCS - State Street Executive Conference Elaine

US Food Welfare Renovations CTS Builders

MGH - Gray Bigelow Jackson Emergency Power Upgrades Turner

Chase Bank Wilmington Channel Building Company

Chase Bank Wayland Schimenti

Logan Terminal A Food Court Reno Commodore

EY Boston Elaine

Lululemon - Prudential Center Donald R Borg Construction

BCHW - Main Lobby Reno Wise Construction

Yale University - Osborn Memorial Lab Enabling Suffolk

FCB- H319-C2 Civil Air Temrinal Arch & Secuity Upgrades Commodore

Thermo Fisher Jessup, MD

Thermo Fisher Riverside, CA

&

Thermo Fisher

Thermo Fisher

Camp Edwards Fuel Maintenance Camp Edwards

DFCI Core Restrooms Reno Walsh

HBS Dillion House Suffolk

BCH Enders 12 Dry lab Wise Construction

FSB - L1774-C1 CHP Tower VFD Replacement MassPort

Logan Terminal A Food Court Reno Commodore

BCHW - Main Lobby Reno Wise Construction

Logan Terminal A Food Court Reno Commodore

Atrius Health - Kenmore MRI DPR International Place Water Feature Weston & Sampson

DFCI Core Restrooms Reno Walsh

WIT - Building 9 Steam Reffed Wentworth

Boston Scientific - Hanscom - Foam Tank Bladder Replacement Boston Scientific

Lantheus - Bldg 110 Cold Room Pre-Action

Lantheus Medical

Citizen M - Water Heater Replacement Aramark

Zinc Apartments - HVAC PMA Agreement Greystar

South Shore Hospital - AHU52 Steam Dispersion Replacement South Shore Hospital

Vertex VMC - AHU4 Coil Replacement Vertex

ARE - 3000 Minuteman Road - Boiler PMA

Alexandria Real Estate

Prudential Center - Upper EMR AC Replacement BXP

Somerville City Hall - Split System Replacement Suffolk

BMR - 301 Binney - HVAC PMA Renewal Biomed Realty

Tufts - Boiler PMA

Tufts Medical

301 Binney - AHU 2-7 Coil Replacement Kronos

136 Blackstone - Boiler Retrofit UG2

Accenture - Electrical Room Duct Extension

Misc. Under $50K

Accenture

Multiple

Beyond Yoga - Seaport

RUSSCO

BCHW - CT Trailer Wise Construction

BCHW - Waltham MRI & CT Support Wise Construction

Roccos Sports & Recreation CAFCO

Irving Pump Design

Camp Edwards

Thermo Fisher Jessup, MD

Direct To Owner

Direct To Owner

Direct To Owner

Brown University - Riser Assistance Suffolk

FSB - L1821-C1 Terminal E OPI 3 Suffolk

DFCI - 10 BP 1st Floor Demo Walsh Brothers

DFCI - Dana 7 Renovation Wise Construction

Amtrak - Southampton Yard SPS/RCC

DFCI - 10 BP 1st Floor Demo Walsh Brothers

BCHW - Waltham MRI & CT Support Wise Construction

BCHW - CT Trailer Wise Construction

Vertex - Micronizer Suffolk

DFCI - Dana 7 Renovation Wise Construction

Amtrak - Southampton Yard SPS/RCC

Suffolk University - PMA (Controls)

Suffolk University

Vertex - Additional Testing (FP) Vertex

NEBH - RTU-3 Compressor Replacement

New England Babtist Hospital

BMS - 250 Water - Steam Motorized Valve Install BMS

BMR - 11 Hurley Street - HVAC PMA

Biomed Realty

Vertex - Cold Room 6006 Compressor/ Condensor Replacement Vertex

Boston Renaissance School - DHW Replacement

Boston Renaissance School 771 Harrison - Heat Exchanger Plate Pack Replacement Brigs LLC

Suffolk University - HVAC PMA

BMR - 214 1st Street - HVAC PMA

255 Main Street - Fuel Oil Pump Project

NEBH - Lahey Roof Replacement Project

Suffolk University

Biomed Realty

Boston Properties

New England Babtist Hospital

Oracle - Compressor Repalcement Oracle

Vertex - ISQ - O2/CO2 Pipe Replacement Vertex

Misc. Under $50K Multiple

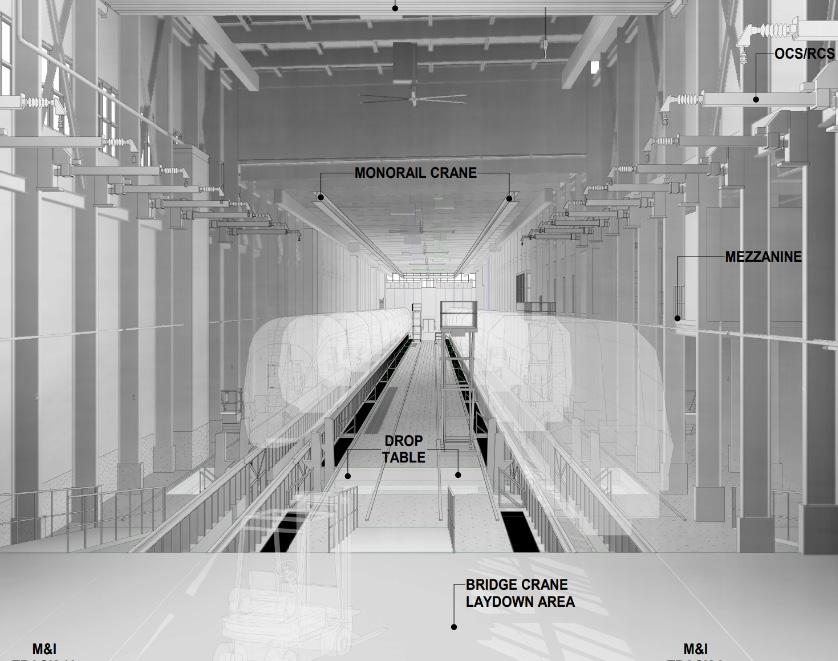

Amtrak Southampton Yard Upgrades

Trade: Plumbing, HVAC

Client: Railroad Construction & SPS New England

The Amtrak Southampton Yard Upgrades project involves the construction of a new, state-of-the-art, two-track-wide Maintenance and Inspection Facility. Over the next four years, the project will also include renovations to existing infrastructure throughout the yard. Major scope elements include:

1. Diesel Fuel Distribution System: Installation of new fuel piping extending from the storage bays to satellite fuel pumps located throughout the yard. The piping will be routed via elevated stations over existing tracks and span the full 900-foot length of the new facility.

2. Locomotive Exhaust System: Integration of a specialized ducted exhaust system designed for locomotive maintenance operations.

3. Air Curtains: Installation of (10) overhead air curtains, five at each end of the facility, to support environmental control and safety.

4. HVAC Equipment: Deployment of (1) rooftop unit (RTU), (8) heat recovery ventilators (HRVs), (30) heat pumps, and (25) supply and exhaust fans to ensure optimal indoor climate conditions.

5. Trench Drains: More than 3,000 linear feet of trench drain will be installed for effective water management.

6. Specialized Piping Systems: Installation of over 32,000 feet of piping, including:

• Vacuum Sewage for emptying train holding tanks

• Compressed Air for hose reels

• Sand Piping systems for track traction

• As well as other standard plumbing systems necessary for facility operations

7. Second Floor Amenities: Outside of the track area, a second-floor space will house administrative offices, locker rooms, and break areas for staff.

Trade: Controls

Client: Suffolk University

Cannistraro Service was awarded a preventative maintenance contract for the Building Management Systems throughout all buildings on Suffolk University's campus. It includes a weekly site visit from a Controls Technician, quarterly site visits from an Application Engineer, and 24/7 remote support. Routine maintenance includes taking backups of all controllers & servers, checking for failed devices, reviewing trends to confirm the sequence of operations are functioning properly and checking alarm logs for any recurring or nuisance alarms. Cannistraro will also work to identify potential energy savings and available rebates.

As part of our ongoing efforts to strengthen the company’s technical support across all departments and job sites, we’re implementing a few key updates to the IT department.

First, we’ve made a recent personnel change within the IT team. This adjustment is designed to better align our resources with the evolving needs of the organization and enhance the level of service we provide to both office and field employees. Additionally, beginning Monday, June 16, on-site IT support will now be available at FID three days a week (Monday through Wednesday). We’ll be monitoring this schedule closely to ensure it meets the needs of the team at FID, as well as our field operations.

As always, we ask that all IT requests—whether from the office or field—be submitted through ITsupport@cannistraro.com to ensure the most efficient handling.

We appreciate your cooperation and understanding as we roll out these changes. If you have any questions, please don’t hesitate to reach out.

Key Reminders:

New FID IT Schedule: On-site support available Monday–Wednesday. Submit Requests: ITsupport@cannistraro.com.

A special shout out of appreciation goes to the following individuals who took time out of their busy schedules to share their perspective about the role of a Cannistraro foreperson, both what is expected of the position and its day-to-day challenges. Their insight was instructive as it has affirmed what we know to be true – Cannistraro field leaders are the backbone of this company, and it is their expertise and leadership that is critically important to our success.

L&D would like to thank all of you for participating in the brainstorming sessions, held over the past few months with our consultant Al Fox, as we continue to explore opportunities for developing our field leaders. Key takeaways have been presented to senior leadership and a future Craft Council meeting agenda will include an update about these learnings and next steps.

Dave Brunet

Paul Conners

Dave Feeney Jr.

Curtis Foster

Brian Janiak

Maurice Joyce Jr.

Justin Pelletier

Mike Semler

John Sliger

John Starkey

Mike Tortomasi

Justin Troisi

Brian Belanger

Dave Dion

Glenn Dube

Chad Hickman

James Laliberty

Dave Lee

Mike Lydon

Sean Murphy

Rob O’Reilly

Matt Quigley

Eric Styles

Troy Witham

Tyler Alston

Jameson Buckley

Pete Christian

Mike Jardim

Niamh Maher

Jon Moen

Brad Sticklor

Garrett Vandette

Colin Young

We celebrate our third cohort to complete this 12-month program as they join the ranks of CLA grads who are accomplishing great success here at Cannistraro. We appreciate your commitment to the program and the work you’ve put in to develop your leadership capabilities.

Jameson Buckley

Amy Cannistraro

Steve Cook

Andrew Heiser

Tom Kosik

Emily Leopold

Wendy McGrath

Joe Mecke

Over the past three years, the Cannistraro Leadership Academy (CLA) has been an instrumental program supporting our company succession planning and the career development of our employees. The leadership coaching services provided by Samantha Shaw of Gaining Power Now and Al Fox of Fox Group Business Solutions have been an invaluable resource to our employees and their program has helped us build the future of Cannistraro leadership. Thanks to all who participated and to L&D for making this impactful program a reality!

Celebrating Growth, Craft, & Learning

Featuring:

Meet Our Co-Ops

Meet Our Apprentices

Heavy Metal Summer Experience Camp

Cannistraro's Co-Op Program provides students with valuable, hands-on experience in a real-world work environment. Through meaningful projects and mentorship, participants gain practical skills while contributing to the company's day-to-day operations. The program offers students a chance to apply academic knowledge, develop professional skills, and explore potential career paths in the construction industry.

We aim to build connections with universities and attract motivated students who are eager to learn. While the Co-Op experience is temporary, it also helps us identify potential future hires who align with our company’s needs and culture. With competitive compensation and exposure to industry professionals, the program provides a solid foundation for students preparing for their careers.

We took the opportunity to sit down with our current Co-Op cohort and learn more about their experiences working at Cannistraro, the skills they’ve gained, and how working with us has influenced their career goals.

"My favorite part of this role is being able to see behind the scenes of a company’s financials and how money flows throughout a construction company. It has given me insight into how financial operations influence different teams and departments. This has been valuable as I continue learning about accounting and financial processes."

Rachel McDonald Co-Op, Service

What part of your work here are you most excited to talk about when you go back to class?

"When I go back to school, one of the things I’m going to highlight about Cannistraro is how open everyone is to helping one another. I never had to worry about being judged for asking questions because everyone genuinely wanted to give me a hand."

Bobby Scott

Co-Op, Plumbing

What is your favorite part of your role and why?

"My favorite part of my role is the fast pace and constant learning that has taken place over the course of the summer. Being able to learn about HVAC and seeing how a day-to-day process is in the mechanical industry has been a great learning experience"

Ben Blanchard

Co-Op,

Multi-Trade Group 1

What skills have you developed thus far into your experience?

"This summer, I improved my communication and coordination skills by managing Windows 11 updates across the company. Scheduling around everyone’s availability was challenging, but it taught me to stay organized and flexible. One highlight was meeting and supporting so many people — it gave me a great perspective on how IT supports the whole organization."

Ethan Cox

Co-Op, IT

How has this experience shaped your career goals or interests?

“This internship opened my eyes to the mechanical side of construction—I’ve learned how vital teamwork and communication are to keeping projects on track. It’s made me excited about a future in this field.”

Alanna Felix Co-Op, HVAC

What skills have you developed thus far into your experience?

"I’ve developed the ability to communicate problems in the field and work through them."

Sean King Co-Op, Safety

What is your favorite part of your role and why?

"My favorite part here has been the variety. Getting exposure to both the design and project management sides has helped me see how a project progresses, and I’ve enjoyed seeing how my work contributes to different phases."

Yansi

Patel Co-Op, Fire Protection

What aspect of your experience has had the biggest impact on you?

"Working with both designers and project managers was my favorite part of the Co-Op. I gained insight into how different roles collaborate on complex projects and built meaningful connections that made my time at Cannistraro truly rewarding.”

Kolby Robertson Co-Op, Fire Protection

What skills have you developed that you're most proud of during your Co-Op?

“Over my time as a Co-Op, I’ve developed a strong understanding of how to estimate and price a job accurately. I’m now confident in reviewing construction drawings to assess the scope of work, estimate how long the job will take, and the approximate crew size needed to complete it efficiently, along with how much material is needed."

Tatiana Troy

Co-Op, Estimating

We are thrilled to have so many skilled apprentices working with us! Our apprenticeship programs across all trades not only ensure that the future tradespeople are trained to the highest industry standards in plumbing, HVAC, and fire protection, but also help preserve institutional knowledge and craftsmanship across generations to come. We are proud to have so many working and learning with us and know they will continue to strive in their craft!

What’s meant the most to me is how the journeymen have taken a personal interest in my growth. Their support has really helped me sharpen my skills and grow as a mechanic throughout my apprenticeship.”

Bryce McKenzie, ApprenticeLocal 12

Brandon Alves – Local 12

Joseph Barufaldi – Local 537

Kevin Belanger – Local 537

Jethro Benoit – Local 537

Dane Bertrand – Local 537

Jaquon Blackmon – Local 12

Nicholas Blaney – Local 537

Andrew Bombardier – Local 537

Dallas Burnes – Local 550

Jarrid Cardalino – Local 537

Joshua Chapman – Local 550

Christian Colantoni – Local 17

Paul Colantuoni – Local 550

Michael Costa – Local 537

Amy Costello – Local 12

Owen Cuddyer – Local 537

Yassine Dabs – Local 537

Roy Daley – Local 550

Carla DaSilva – Local 17

Cody Dias – Local 537

Aidan Donovan – Local 537

Aaron Drew – Local 17

Jake Durant – Local 537

John Eckstrom – Local 17

Joseph Fitzgibbons – Local 550

Stephen Florentine – Local 550

Brandon Furlan – Local 537

Karissa Gagnon – Local 537

Frank Girolamo – Local 12

Thomas Gomperts – Local 550

Rayon Grizzle – Local 17

Kaiden Gunning – Local 12

Joshua Haglund – Local 537

Joseph Hansen – Local 17

Victor Herrera – Local 17

Aaron Hickey – Local 550

Jenna Hickey – Local 537

Victoria Howard-Romano – Local 537

Robert Jackiewicz – Local 550

Tashyra Jamison-Rowell – Local 17

Austin Johnson-Sullivan – Local 537

Christian Joyce – Local 17

David Kenny – Local 550

Rashawn Knight – Local 12

Patrick Llewellyn – Local 17

Jordalin Lozano – Local 17

Liam Lydon – Local 12

Matthew Macedo – Local 537

Jared Malcolm – Local 537

Kyle Marobella – Local 537

Bryce Marrero – Local 537

Phillip Martin – Local 537

Kaya McGrath – Local 12

Bryce McKenzie – Local 12

Grace Miller – Local 537

Christopher Mohn – Local 17

Evanilson Monteiro – Local 17

Joseph Mullin – Local 550

Emily Napolitano – Local 537

Brendan Neff – Local 17

Brendan Nehiley – Local 550

Brendan Nicholls – Local 537

Joseph Noviello – Local 537

Dakoda Parlin – Local 537

Brianna Peck – Local 537

Christopher Perry – Local 537

Edan Pesetsky – Local 17

Diana Phan – Local 537

Victoria Phillips – Local 12

Cassandra Pierre – Local 537

Charles Polito – Local 550

Nicholas Popa – Local 537

James Richardson – Local 550

Kevin Rockwell – Local 17

Neva Romano – Local 17

Joseph Rowland – Local 550

Anthony Roy – Local 12

Jake Ryan – Local 12

Ashlee Scott – Local 550

Jason Snow – Local 537

Madison Sullivan – Local 537

Timothy Theriault – Local 537

Christopher Trask – Local 537

Lakshmikant Tripathi – Local 537

Nicholas Vick – Local 12

Joseph Villari – Local 550

Brandon Wagner – Local 17

Matthew Wilson – Local 537

Michael Yetman – Local 537

Antonio Zolt – Local 537

Year 4 of the Heavy Metal Summer Experience was a blast!

Another exciting year hosting high school students at The FID for a week full of hands-on experiences and learning about the different trades!

We wouldn't have been able to put on this program without the incredible support and national sponsors, Heavy Metal Summer Experience, SMACNA, Red Wing Shoes Store, and Milwaukee Tool as well as the support of our generous vendors F.W. Webb Company, Osprey Construction Supply, R. G. Mearn Co., Inc, Ayer Sales, Ferguson, Metropolitan Pipe & Supply Co, Independent Pipe and Supply Corp. Thank you to Local 12, Local 537, and Local 17 for your incredible hospitality. Thank you to our passionate leaders, Amy Cannistraro, Matthew Cannistraro, and Bryce McKenzie, for your dedication to the kids and for organizing the program each day. Thank you to Janelle Bassett, the Facilities team at The FID, and all of our shop, field, and office employees who stepped up to help make every activity possible

Lastly, thank you to all of the students who joined us this year. Your passion, interest, and curiosity about the trades inspire us. We can't wait to see some of you on the job very soon!

Thank you to all of the students who joined us this year. Your passion, interest, and curiosity about the trades inspire us. We can't wait to see some of you on the job very soon!

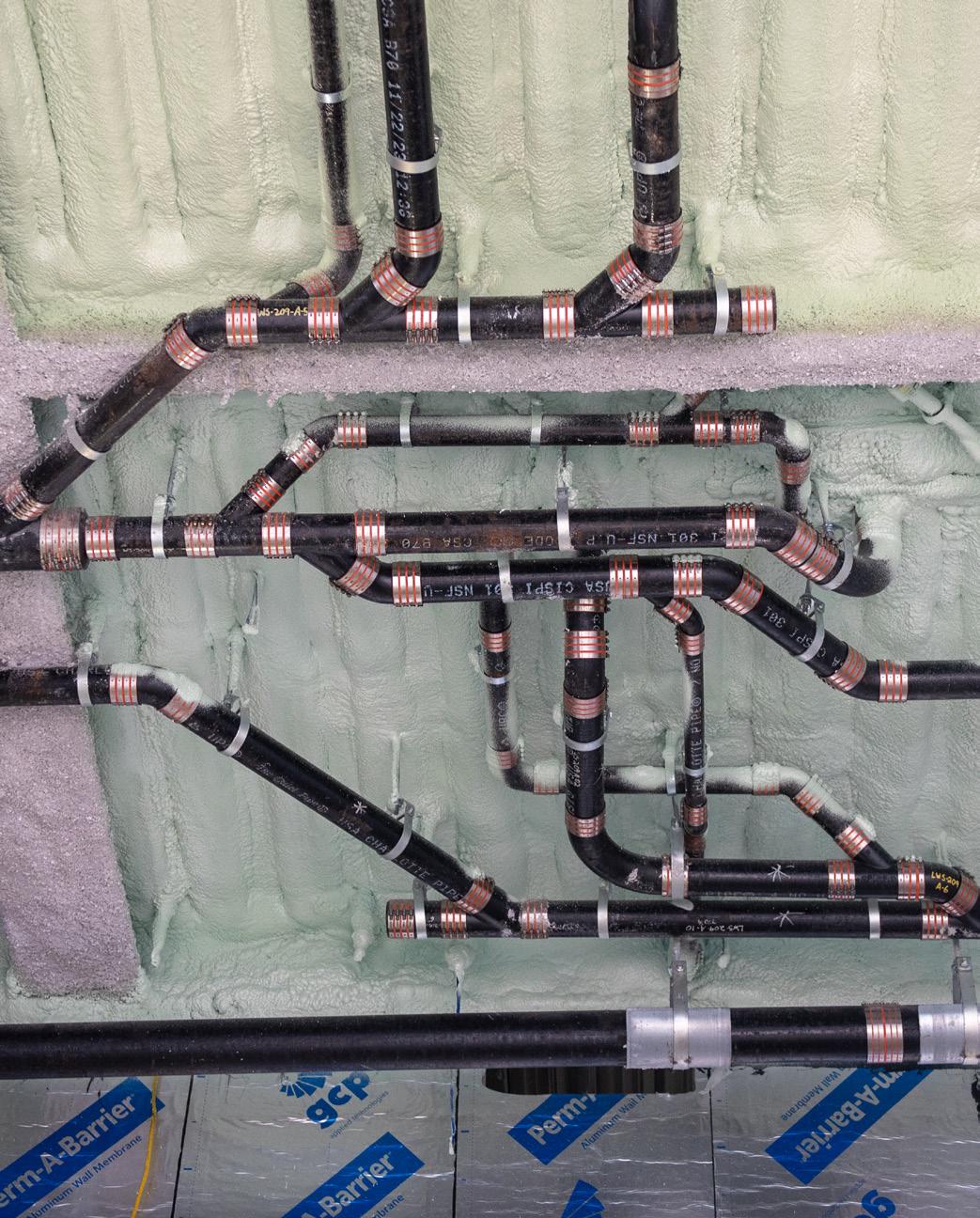

Job Type: Housing

Client: Harvard University

General Contractor: Shawmut

Project Executive: Tyler Alston

All of our shops are still hard at work on the 100 South Campus Drive (Harvard University Housing) project—a 14-story, 276-unit passive housing dormitory featuring kitchens and bathrooms in each unit. The building will feature extensive amenities, 250 sheltered bicycle spaces, and 75 automobile parking spaces, all built to meet Passive House and Living Building Challenge Petal certifications. Passive House is a rigorous energy-efficiency standard focused on reducing a building’s energy demand and improving comfort, while Living Building Challenge Petal Certification recognizes projects that achieve deep sustainability in key areas like energy, water, and materials through regenerative design. Here are the key construction milestones for the project:

• Construction is on track for scheduled completion in September 2026

• MEP rough completion is scheduled for December of 2025

• Temporary heat will be operational in October 2025

• Permanent power scheduled for mid-November 2025

• Permanent plumbing systems live and balanced by Feb 2026

• HVAC systems fully commissioned and balanced by March 2026

• Unit finish install will commence late August of 2025 completing in Jan 2026

• BFD/Life Safety Signoff scheduled for June 2026

Plumbing Contract

Project Team:

Project Manager: Jon Moen

Assistant Project Manager: Ari Troy

Plumbing Foreman: Eric Heim - Local 12

Lead Coordinator: Meghan Orisko

HVAC Contract

Project Team:

Senior Project Manager: William Bigwood

Project Manager: Niamh Maher

Sheet Metal Foreman: Mike Semler - Local 17

Mechanical Pipe Foreman: Maurice Joyce Jr. - Local 537

Lead Coordinator HVAC Pipe: Michael Wigmore

Lead Coordinator Sheet Metal: Matt Stevens

Virtual Design Manager: John Calo

Fire Protection Contract

Project Team:

Senior Project Manager: George Contis

Assistant Project Manager: Elizabeth Bradley

Fire Protection Foreman: Colin Macneil - Local 550

Lead Coordinator: George Tibbett

Designer: Kaiya Tibbett

Job Type: Laboratory/Office

Client: Vertex

General Contractor: Related Beal

Project Executive: Garrett Vandette

New 364,000 square foot eight story building with two story underground parking garage for 144 vehicles. The building contains (1) 2,800 ton chilled water plant, (6) Air Handling Units, (3) Energy Air Handling Units, (4) Cooling Towers, (4) Boilers and several Energy Recovery Systems. New automatic sprinkler system throughout to include a new Fire Pump, (10) dry systems, (3) pre-action systems and (10) Nitrogen Generators.

To increase efficiency, we are prefabricating:

• Pipe risers into 30 ft. - 40 ft. modules

• Duct risers into 30 ft. - 40 ft. modules

• Double wall fuel oil containment piping

• All mechanical room piping

• Pipe racks for the floors prefabricated into 15 ft. racks

• All fire protection mains to be prefabricated as coordinated and delivered to site as needed

HVAC Contract

Project Team:

Project Manager: William Bigwood

Assistant Project Manager: Eric Lustenberger

Sheetmetal Foreman: Brian Nolan - Local 17

Pipefitter Foreman: Mike Howard - Local 537

HVAC Pipe Coordinator: Adam Mozer

HVAC Duct Coordinator: Keith LaVoie

Fire Protection Contract

Project Team:

Project Manager: George Contis

Assistant Project Manager: Elizabeth Bradley

Fire Protection Foreman: Mark Dion - Local 550

Lead Coordinators: Johnathan Andrews & Marc Ruggiero

Job Type: Higher Education

Client: Simmons University

General Contractor: Skanska

The new construction Living and Learning Center for Simmons University will consist of a 300,000 square foot dormitory with 1,110 beds, a 75,000 square foot Athletic Center with a pool and basketball court, and a 25,000 square foot full-service dining facility. We will be installing a new automatic sprinkler system consisting of a new Fire Pump, (6) Standpipes, (2) Dry Systems and (5,000) Sprinkler Heads.

To increase efficiency, all piping is fabricated in-house at the FID, with field leadership collaborating closely with the design and field teams to enhance project coordination and performance.

Fire Protection Contract

Project Team:

Project Manager: Matt Hilliger

Assistant Project Manager: Julianne Magdaleno

Fire Protection Foreman: Justin Barton - Local 550

Designer: Miguel Landestoy

Level 2 sprinkler main and branch lines with concealed sprinklers attached to flexible hose drops to be installed in the future ceiling

Job Type: Lab-Fit Out

Client: GlaxoSmithKline LLC

General Contractor: DPR

Project Hawk is fast nearing its completion as the HVAC systems are over 85% installed. All major rigging operations have been completed, all equipment has been delivered to site and final connections are in process. At the time of this writing, the majority of stainless steel exhaust duct systems, and clean steam piping systems have been installed, joined together by precision TIG welds that stand out as examples of the high-quality product our local 537 and local 17 teams are known for. We will have a busy schedule on site for the next 8 weeks, as we look to close out the remainder of our scope.

Plumbing Contract

Scope:

Renovation of six floors for lab fit-out, featuring the installation of lab gases, potable and nonpotable water systems, sanitary and lab waste systems, along with all related equipment.

Project Team:

Project Manager: Mike McCarthy

Assistant Project Manager: Anthony De La Cruz

Lab Gas Foreman: Gerry Charles - Local 537

Plumbing Foreman: Brandon Brown - Local 12

Lead Coordinator: Dy Sok

HVAC Contract

Scope: Installation of all air and water systems on all six floors, penthouse, low and high roof including Air Handling Units, steam generators, humidifiers, dehumidifiers and many more.

Project Team:

Project Executive: Garrett Vandette

Assistant Project Manager: Rijkaard Thomas

Pipe Foreman: Ron Sullivan - Local 537

Duct Foreman: Fran McDonough - Local 17

Lead Coordinators:

Pipe Coordinator - Chris Stott

Duct Coordinator - Dan Gerardi

Job Type:Medical/Hospital

Client:Mass General Brigham

General Contractor: Turner/Walsh Venture

Project Executive: Jameson Buckley

This is a new state-of-the-art hospital facility located at 275 Cambridge Street Boston, MA. This facility is the first of two new buildings planned for the site and spans an impressive 650,000 square feet across 18 above-ground levels and 6 below-grade levels. Our scope of work includes the installation of plumbing and medical gas systems across multiple mechanical room floors and two large vertical shafts. These systems support the full range of hospital operations, including domestic hot and cold water, sanitary and storm piping, and six medical gas systems serving numerous operating rooms and over 200 inpatient care rooms across seven floors.

A key feature for the facility is its ability to act as an "energy island" - it will be able to operate independently from public utilities including electricity, water, sewage, for up to 96 hours in the event of a catastrophic situation. Sustainability was prioritized throughout the design, including advanced systems to reclaim and reuse rainwater across the entire building.

To increase efficiency:

• This project was built using 90% to 95% prefabricated material

• The FID facility was used to cycle all material to the site whether it was fabricated or not to keep everything on wheels and allowed our field team to request specialty deliveries for expedited items throughout the duration of this project so far

Plumbing Contract

Project Team:

Project Manager: Bob Snipes

Assistant Project Manager: Amy Cannistraro

Plumbing Foreman: David Brunet

Lead Coordinator: Meghan Orisko

Job Type: Inspection & Testing

Client: Harvard University

The Cannistraro Special Hazards team currently inspects, tests, and services all Special Hazards suppression systems across the Harvard University campus. Working in collaboration with the Harvard University Fire Protection group, we maintain a range of systems including FM-200, FK-5-1-12 (Novec 1230), Inert Gas Clean Agents, Halon 1301, and Pre-engineered Dry Chemical systems, along with their associated detection and control components.

Sandy Cooper and Walter Lyons perform semi-annual testing and inspection at the Radcliffe Institute for Advanced Study library, which includes both Clean Agent and Pre-Action systems.

Highlights of the inspection:

• VESDA (Very Early Smoke Detection Apparatus): Air-sampling smoke detection tested to ensure proper clean agent activation

• Novec 1230 (FK-5-1-12): Clean Agent suppression system – waterless gas suppression, ideal for protecting sensitive areas like libraries, Data Centers, and other valuable assets without causing water damage. It works by absorbing heat, disrupting combustion, and penetrating tight spaces

• Photoelectric Smoke Detectors: Traditional smoke detection tested for release of the Pre-Action sprinkler system as secondary water based suppression system. Activation of two separate detection zones fills the piping with water, which is then discharged through the nearest sprinkler head once it fuses from heat

• Clean Agent / Pre-Action Releasing Panel: Tested by simulating smoke and testing activation devices such as emergency pull stations to confirm full sequence of operations—from early-warning alerts to system discharge via solenoids controlling clean agent cylinders and Pre-Action valves

Cannistraro has proudly serviced Harvard University’s Special Hazards systems since 2020 and is excited to continue growing and expanding our relationship with the university, its building managers, and the Fire Group to make sure Harvard University’s most valuable assets and commodities have the best functioning suppression systems.

Special Hazards Service Team:

Service Manager: Michael Palagi

Lead Technician: Sandy Cooper Technician: Walter Lyons

1A–1D: Walter Lyons performing a range of semi-annual inspection tasks, including re-securing a solenoid on the clean agent cylinder (1A), testing and confirming VESDA smoke detection (1B), verifying Clean Agent/Pre-Action releasing panel operation (1C), and testing photoelectric smoke detection (1D).

Job Type: Service Maintenance

Client: Boston Design Center

The Cannistraro Service Group recently completed winter maintenance at the Boston Design Center, focusing on key mechanical systems to ensure efficient performance throughout the colder season.

Winter maintenance was performed on three York centrifugal chillers. Scope of work included:

• Punching condenser tubes

• Performing frequency drive coolant flushes

• Inspecting electrical components, including drive, battery, motor, and control circuitry

• Replacing oil filters and filter driers as needed

• Conducting refrigerant leak checks

• Inspecting physical condition of chiller and pumps

• Cleaning chiller surface and work area

Heat Recovery Chiller

An annual inspection was completed on a multistack modular heat recovery chiller, which included:

• Full operational checkout in both heating and cooling modes

• Refrigerant leak testing

Marley Cooling Towers

Winter maintenance was performed on (4) Marley cooling towers. Scope of work included:

• Cleaning hot decks and sumps

• Checking condition of all tower components, including sump, fill, motor, fan and gear reducer

VRF Systems

The team also checked the condition and operation of various Daikin and Mitsubishi VRF units serving critical equipment and motor control centers.

Project Team:

Lead Technician: Michael Rodriguez

Apprentices:

Cassandra Pierre - Local 537

Jason Snow - Local 537

Timothy Theriault - Local 537

TYLER VALENTIN & JOE CIMILDORO

"You should be proud of your team they are very professional, and I am so glad that they are in the building. Joe is excellent with communication and keeping us updated. This is such a refreshing change and thank you for the quick turn around on quotes this is also wonderful that I don’t have to chase someone around for a quote."

-John Belmonte

Samual & Associates/Fenway Triangle

“Shout out to the Tools & Equipment team over at 30 FID. Over the years I’ve had more than my fair share of last minute requests for (Unique Rigging, Fall Protection, Confined Space Equipment, Smoke Eaters…. you name it) that would be “show stoppers” in the field if our team over at 30 FID wasn’t as outstanding as they are. Jimmy’s experience and knowledge has gotten me out of a ton of tough situations which ultimately limits the risk for the crews in the field without impacting schedules. They all probably cringe whenever I call, but what Jimmy, Angelo, Alex, Carl & George do on a daily basis plays a huge role in keeping our people safe and jobs finishing on time."

PROJECT BACKGROUND –MANCHESTER STREET GENERATING STATION

DAN GERARDI

"Just had a productive site walk with Dan G and wanted to give him a shout out. His diligence and speed when solving problems out on site has been invaluable, as are the connections he's made with all team members and notably the mech engineer. He's been a great (re)addition to the team. Hard to believe this is his first VDC gig, he's a software wiz. Thank you for the staffing support."

-Paul Bracchitta DPR Construction

-Bob Fuller, Director of Environmental Health & Safety

HR TEAM

“I just wanted to take a moment to express my sincere gratitude for the incredible work the HR Team –Patricia Antoine, Sewicka Bien-Aime, & Grace Arena, put into organizing this year’s Benefits Fair. Your dedication, attention to detail, and commitment to ensuring our employees had access to valuable resources did not go unnoticed. The event was informative, engaging, and well-executed, and that’s all thanks to your efforts. I appreciate the teamwork, creativity, and extra effort you put in to make it a success. It’s moments like these that make me so grateful to work with such a talented and committed group. Thank you again for everything!"

-Corrie Cummings HR Director

“The Manchester Street Generating Station is a 510 MW natural gas-fired power plant located in Providence’s Jewelry District. Defined by its (3) 321foot smoke stacks, the station includes (3) Siemens gas turbines and (3) ABB steam turbines. It serves approximately 150,000 homes annually across Rhode Island and southern New England. Cannistraro played a key role in enabling major inspections and servicing of several gas and steam turbines. This involved removing all fire protection and alarm piping and equipment to allow full access to the turbines and generator. Once the service work and generator replacement were completed, our team promptly reinstalled the fire protection systems—critical to the plant resuming operations, as the turbines cannot be restarted without those systems in place.

As echoed by plant manager AJ Gordon, this effort required exceptional dedication. Our Cannistraro team worked long hours, weekends, and holidays—often sacrificing time with their families—to ensure that every task was executed thoroughly and with care. Most importantly, we completed this work safely—a true reflection of our shared values and a responsibility we never take lightly.”

-Brian Baima General Manager Fire Protection

MANCHESTER STREET

GENERATING STATION CONT'D

"I’d like to specifically recognize our Local 669 Sprinkler Fitters—Dean Boardman, Adam Haddad, and Jim Ferrara—for their flexibility, availability, and responsiveness on-site. Special thanks also to Michael Palagi with the special hazards group for coordinating and managing this complex scope alongside site engineers and subcontractors, especially under challenging and evolving conditions. Their professionalism and tradesmanship have made a lasting impression on IHI site management and continue to serve as the foundation of our growing partnership."

-Brian Baima General Manager Fire Protection

“Last month's meeting at the Cannistraro pre-fabrication shop in Boston was truly a sight to behold. Attendees had the unique opportunity to witness firsthand the innovative prefab processes that are revolutionizing the mechanical contracting industry. The tour provided an enlightening glimpse into cutting-edge techniques such as automation, robotics, and modular construction, which are shaping the future of efficiency, quality, and sustainability in our field. The event certainly lived up to its promise of being an educational experience. Visitors left with a deeper appreciation for how prefabrication can enhance project timelines, reduce costs, and improve safety while addressing labor shortages and increasing productivity."

-ASPE, American Society of Plumbing Engineers

DAN JAWORSKI

"I wanted to reach out and give Dan Jaworski a HUGE shoutout– he has been a pleasure to work with not only on this 11th hour redesign in the Theater, but on the project overall. He’s always so quick to jump on any request that comes his way, and he’s extremely knowledgeable too. It’s not common that we get to work with coordinators who are true team players, so please know that Dan’s involvement in the project is very valued and appreciated."

-Sara Capobianco Suffolk Construction

JAMIE WELCH

“The AP Team would like to give a big KUDOS to Jamie Welch for her dedication and determination in working alongside us to significantly reduce our compliance hold/ exceed hold invoices to single digits! Jamie, your hard work over the past few weeks has truly gone above and beyond, and we are incredibly grateful for your efforts. Thank you!"

-Joann Pickard Accounting Manage

Free Friday Flicks

Dates: July 11th – August 22nd

DCR’s Hatch Memorial Shell, 47 David G Mugar Way, Boston, MA

Free Friday Flicks is a summertime tradition in Boston, attracting thousands of moviegoers to enjoy family-oriented, feature-length movies under the stars all summer long at DCR's Hatch Shell in Boston!

Bring a blanket or lawn chair, pack a picnic, and watch a movie with family and friends on Friday night for free! Movies begin at sundown, but arrive early to grab your spot on the lawn and enjoy free games and giveaways with WBZ NewsRadio 1030. The fun starts at 6pm!

Copley Square Farmer’s Market

Dates: May 16th – November 28th

11:00 AM to 6:00 PM

139 St. James Ave Boston, MA 02116

Copley Square is one of the largest farmers markets in Massachusetts. As a key Boston tourist destination, this market services Boston residents, urban professionals and visitors to New England. Shoppers can find seasonal produce, fresh flowers, baked goods, cheeses, meats, and locally made pantry items — all from regional farms and small-batch vendors.

North End Feast Days:

115th Annual Fisherman's Feast

August 14-17th, 2025

Fleet, Lewis & North Streets, Boston’s North End

The Fisherman's Feast, Boston’s oldest continuously running Italian festival, has been held each August in the North End since 1910. Rooted in a 16th-century Sicilian tradition from Sciacca, it honors the Madonna del Soccorso, patron of fishermen. Immigrants brought the custom to Boston, and today their descendants still organize the event. The four-day celebration features a procession of the Madonna, nightly entertainment, food vendors, and a blessing of the fishing waters. It ends Sunday night with the dramatic "Flight of the Angel."

Saint Anthony’s Feast in the Boston's North End

August 28th-August 31st

Saint Anthony’s Feast is the largest Italian Religious Festival in New England.

Celebrated annually since 1919 on the weekend of the last Sunday of August Located on Endicott, Thacher, and North Margin Streets in Boston’s North End.

All entertainment is free and open to the public.

Team Cannistraro participated in one of our favorite annual events — the Boston Corporate Cup. This spirited competition brought together companies from across the region for a day of friendly athletic challenges, team spirit, and giving back.

Thanks to the incredible fundraising efforts of all the participating teams, the event raised $1 million to support important work at Boston’s leading hospital. It was a powerful reminder of what we can accomplish together.

A huge thank you to the volunteers who helped make the day so memorable. We had a blast and can’t wait to hit the field again next year!

Participating in the Corporate Cup challenge is more than just a competition for me personally as I have family and friends with kids receiving treatment at Boston Children's Hospital — but as for the competition, it really is a celebration of teamwork, determination, and pure fun! From making memories, laughing with your teammates, having a good time cheering each other on, to pushing our limits, every moment reminded me of how powerful we are when we come together as a team. I’m proud Cannistraro participates in this event every year and also of what we as a team accomplished! It is an event I look forward to doing every year!"

Joann Pickard Accounting Manager

Mark's winning dip from the Dip Contest!

Ingredients

15 oz. black beans

15 oz. black eyed peas

15 oz. chickpeas

1-1/2" cup of Shoepeg corn

1/3 cup celery

1/3 cup red peppers

1/3 cup red onions

1/3 cup olive oil

2 table spoons of apple cider vinegar

1 teaspoon of sugar

Directions

1. Add all the ingredients, toss, and keep refrigerated before serving.

Ingredients

1 1/2 lb. refrigerated, shelf-stable, or frozen gnocchi

2 broccoli crowns, cut into florets

1 pt. grape tomatoes

2 medium bell peppers, seeded and cut into 1-in. pieces

1 medium red onion, peeled and cut into 1-in. pieces

4 garlic cloves, finely chopped

1 1/2 tsp. kosher salt

1 tsp. Italian seasoning

1/2 tsp. black pepper

1/4 tsp. red pepper flakes

1/3 cup olive oil

1 (8-oz.) container small fresh mozzarella balls, drained

1/4 cup chopped fresh basil

4 oz. baby arugula, for serving

Grated Parmesan cheese, for serving

Directions

1. Preheat the oven to 450°F.

2. In a large bowl, combine the gnocchi, broccoli, tomatoes, bell peppers, red onion, garlic, salt, Italian seasoning, black pepper, and red pepper flakes. Pour the oil over the gnocchi and vegetables, tossing to coat.

3. Spoon the gnocchi onto a baking sheet. Bake until the gnocchi has begun to brown and crisp, 35 to 40 minutes, stirring halfway through. Remove the baking sheet from the oven and dot with the mozzarella balls. Bake until the mozzarella melts, 5 minutes.

4. Remove the baking sheet from the oven and sprinkle with basil. Serve hot over arugula and sprinkled with Parmesan, if you like

Tip: Add 1 pound sliced smoked sausage to the pan for added protein!

We’re proud to congratulate Ken Reagan on being elected President of the Greater Boston Plumbing Contractors Association — a well-earned recognition of his leadership and commitment to the industry!

As Ken steps into this new role, we took a moment to ask him a few questions about his journey, experiences, and advice for the next generation. Check out our short interview with him below.

Can you share a brief history of your career with Cannistraro?

I interviewed with John Cannistraro Sr. in the summer of 1984, during my junior year at Duxbury High School. My father worked as a Plumbing Foreman for Cannistraro, and from a young age, I knew I wanted to build a career in the plumbing industry.

In 1985, I began my career as a truck driver, delivering materials to job sites for a year before entering the Plumbers Local 12 apprenticeship program. After completing the apprenticeship, I continued my education at Northeastern University, where I completed the HVAC and Fire Protection Design programs through the Building Design and Management School.

I spent several years in the field as a Plumbing Foreman, heavily involved in Special Projects and Service work. In 1999, I transitioned into a new role as Outside Superintendent for the Plumbing Division. By 2002, I had moved into project management, focusing on estimating, selling, and managing multitrade special projects and service projects.

In 2018, I was promoted to Operations Manager of the Plumbing Group, a role I held until 2022, when I was named Vice President of Business Development. I currently serve on the Joint Apprenticeship Committee at Plumbers Local 12 and, as of May 2025, I am honored to serve as President of the Greater Boston Plumbing Contractors Association.

Is there a project or memory that stands out in your career?

One of my favorite projects over the years has been Logan Airport. I’ve had the opportunity to be involved in numerous projects there—both in the field and as a Project Manager—dating back to 1989. Another standout experience was working on Gillette Stadium. That project was not only exciting from a construction standpoint, but also incredibly fun, especially when it came to hosting clients at games during the Tom Brady era. It was a memorable combination of hard work and unforgettable moments.

What advice would you give to young plumbers or new employees starting out today?

The best advice I can give to the younger generation starting a career in the construction industry is this: find a role you truly love. I still love going to work every day, and I have no plans to ever retire— because when you’re passionate about what you do, it becomes a craft, a purpose, and something you were built for. Show up every day, work hard, stay committed, and you’ll be amazed at what you can accomplish in your career.

Outside of work, my favorite hobbies include playing pickleball and driving out on Duxbury Beach in my Jeep—nothing beats a day by the ocean and some friendly competition on the court.

WE’RE MAKING THE SWITCH TO A FULLY DIGITAL FORMAT—SO DON’T MISS OUT! SIGN-UP NOW TO RECEIVE FUTURE ISSUES OF THE GANGBOX GAZETTE STRAIGHT TO YOUR INBOX. SIGN-UP TO STAY CONNECTED!

We exist to empower the life-changing impact of mastering a trade.

For us, a trade is any skill, in any role, contributing to our company’s betterment and to the care of our customers. Everyone at Cannistraro works in a trade; we believe that everyone can maximize the value of their contributions and most significantly improve their own wellbeing by continuously sharpening their craft and growing in their trade.

We support this journey by advancing craftsmanship and shining a bright light on the importance of progress and professionalism in our industry. We treat all team members like family and provide the best possible training and coaching. We nurture trusting and highly valued business partnerships in order to create opportunities for everyone to thrive.

SafetyProtection from danger, risk, or injury

IntegrityHonest and strong moral principles

Continuous ImprovementThe pursuit for perfection in everything we do

CompassionCare and concern for others

CommitmentDedicated to a cause, activity, and/or people

CollaborationWorking together for a shared purpose