RESIILIENCE, PRECISION & PARTNERSHIP

BUSINESS TIMES

SINGAPORE AERO ENGINE SERVICES

SINGAPORE ENGINE SERVICES

RESILIENCE, PRECISION AND PARTNERSHIP

INSIDE SAESL’S ROLE AS A GLOBAL AVIATION POWERHOUSE

Singapore Aero Engine Services Limited (SAESL) is a joint venture between Rolls-Royce and SIA Engineering Company, specializing in the maintenance, repair, and overhaul (MRO) of Rolls-Royce Trent engines. SAESL began operations in 2001 and has grown their capability to support the full series of Trent family engines globally within a few years. SAESL is now an integral part of the Rolls-Royce aftermarket services. Its excellent state-of-the-

Project by: Malvern Kandemwa

Words by: Michelle Duncan

art facility is designed to turn around 320 engines annually. In addition, the new engine test facility can conduct full engine tests on all Trent engines.

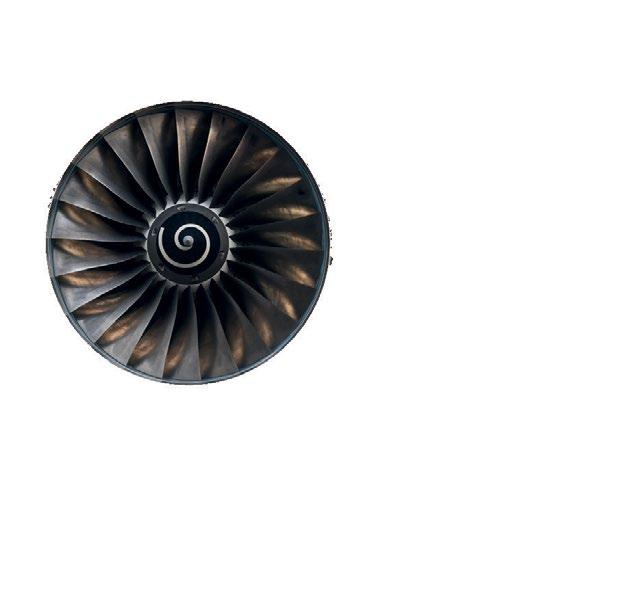

Rolls-Royce has appointed SAESL as the first Trent 900 Centre of Excellence (CoE). SAESL also has the capability to repair and overhaul the Trent 1000 engine. For the uninitiated, the Rolls-Royce Trent is a family of high-bypass turbofans that service the Airbus

A330, A340, A350 and A380, and the Boeing 777 and 787 Dreamliner. In addition, SAESL has been selected to be the lead MRO facility for the Trent XWB engine. They are a Rolls-Royce certified Gold Centre of Excellence for the repair of Rolls-Royce aero engine components, specializing in the repair and overhaul of Rolls-Royce Trent & RB211 Nozzle Guide Vanes and Compressor Stators using state-of-the-art technology.

Its current CEO is Chris Pattinson, who took over leadership in 2025 after a lengthy career at RollsRoyce. He spent over 17 years at Rolls-Royce, holding various senior leadership positions. He was the Senior Vice President - Large Engine Manufacturing Operations, Civil Aerospace, where he led a multi-year transformation of engine assembly and test activities. With his engineering background and factory/assembly experience at Rolls-Royce, Pattinson brings a strong focus on optimising manufacturing, assembly and test operations—areas critical for SAESL’s MRO business. His move to SAESL signals a strategic push for deeper operational excellence, global

engine-MRO growth, and closer alignment with the Asia-Pacific aerospace market.

Since inception, SAESL has seen significant growth and continued expansion to their facilities and capabilities. The partnership between Rolls-Royce and Singapore Airlines marked a significant turning point for both companies and for Singapore’s aerospace landscape. When Rolls-Royce secured a landmark deal to supply Trent 800 engines for Singapore Airlines’ Boeing 777 fleet, the agreement also included a commitment to set up local maintenance, repair and overhaul (MRO) capabilities.

Initially, this collaboration was focused almost entirely on supporting Singapore Airlines’ operations. However, over time, the partnership evolved and expanded far beyond its original scope—transforming into the world’s largest Rolls-Royce engine overhaul facility.

SINCE INCEPTION,

SAESL HAS SEEN SIGNIFICANT GROWTH AND CONTINUED EXPANSION TO THEIR FACILITIES AND CAPABILITIES.

Schenck RoTec Singapore

Today, Singapore Aero Engine Services Limited (SAESL) stands as a Trent Centre of Excellence and the world’s largest Trent engine MRO provider, serving airlines across six continents. The facility has the capability to service and overhaul every member of the Trent engine family, including the Trent 700, 800, 900, 1000, XWB and 7000.

SAESL has played a critical role in supporting Rolls-Royce’s global fleet, most notably during the Trent 1000 crisis in 2016, when cracks were discovered in intermediate-pressure turbine blades powering Boeing 787 Dreamliners. At the time, as many as 44 aircraft were grounded while inspections and repairs were conducted worldwide.

To mitigate disruption and restore customer confidence, RollsRoyce ramped up capacity across its MRO network—investing heavily in new tooling, advanced equipment, and added skilled personnel. SAESL was instrumental in these recovery efforts, working around the clock to return engines to service. Thanks to that global effort, the fleet recovery was successfully completed by mid-2020, reaffirming SAESL’s reputation as a trusted cornerstone of Rolls-Royce’s global service network.

It is no surprise that Singapore Aero Engine Services Limited (SAESL) was not immune to the turbulence caused by the COVID-19 pandemic. With hundreds of aircraft grounded across the globe from early 2020, the company experienced a sharp

decline in engine overhauls and maintenance activity.

However, as an essential service provider appointed by the Singapore government, SAESL was able to maintain operations under strict health and safety measures. The company quickly adapted its workplace protocols to protect employees while keeping essential repair lines running—particularly to clear the significant backlog of Trent 1000 engines awaiting overhaul.

Under normal conditions, a Trent engine typically completes 4,000–5,000 flight cycles, or five years of service, before requiring maintenance. During the pandemic, many of these engines were grounded short of their flight limits, but as global travel has rebounded, demand for overhaul services has returned rapidly.

Today, SAESL supports 38 airlines across the Asia–Pacific region, while also serving carriers in South America and Europe. As the largest contributor to RollsRoyce’s global MRO network, SAESL plays a pivotal role in the manufacturer’s “large engine” segment. Rolls-Royce runs several other major facilities—such as its shop in Germany focused on European operations—but SAESL stays the heart of the company’s Asia–Pacific servicing capability.

With the capacity to repair and overhaul around 300 engines annually, each needing up to 9,000 man-hours and as many as 700 skilled employees, SAESL’s operations are vast and complex. Airlines typically manage fleet con-

tinuity during overhauls by using spare or leased engines from Rolls-Royce, ensuring minimal disruption to flight schedules.

A standout feature of the SAESL campus is its ultramodern test bed, a US$60 million facility integral to the company’s operations. Once an engine overhaul is complete, it’s wheeled just 30 meters to the test facility for performance verification. The test bed itself is a feat of engineering—approximately 70 meters

long, 25 meters wide, and 20 meters high, built with 1.5 meters of reinforced concrete and multiple sound-dampening layers to prevent noise pollution. Despite the enormous power generated during tests, the surrounding area stays remarkably quiet.

Singapore’s role as a global aviation and MRO hub further strengthens SAESL’s position. The city-state is home to over 130 aerospace organizations employing more than 21,000

people, with 85% of these companies involved in aircraft maintenance and repair. This dense ecosystem of expertise underpins SAESL’s operations and fuels its ongoing success.

Recognizing that long-term, local partnerships are crucial to sustaining its high standards of engineering excellence, SAESL has built strong relationships with key partners, including Professional Engineering, CK Shipping, Jebsen & Jessen, Transtherm, Ichisa

Engineering, and Dedienne Aerospace Singapore. These partnerships are deeply integrated into SAESL’s processes—companies like Professional Engineering and Dedienne, for instance, provide critical support in tooling, fixturing, and other precision stages of engine maintenance.

Through its resilience, technical mastery, and collaborative ecosystem, SAESL has not only weathered the storms of the pandemic but emerged even

stronger, reaffirming its reputation as one of the world’s premier centers of excellence in aero engine services.