3 minute read

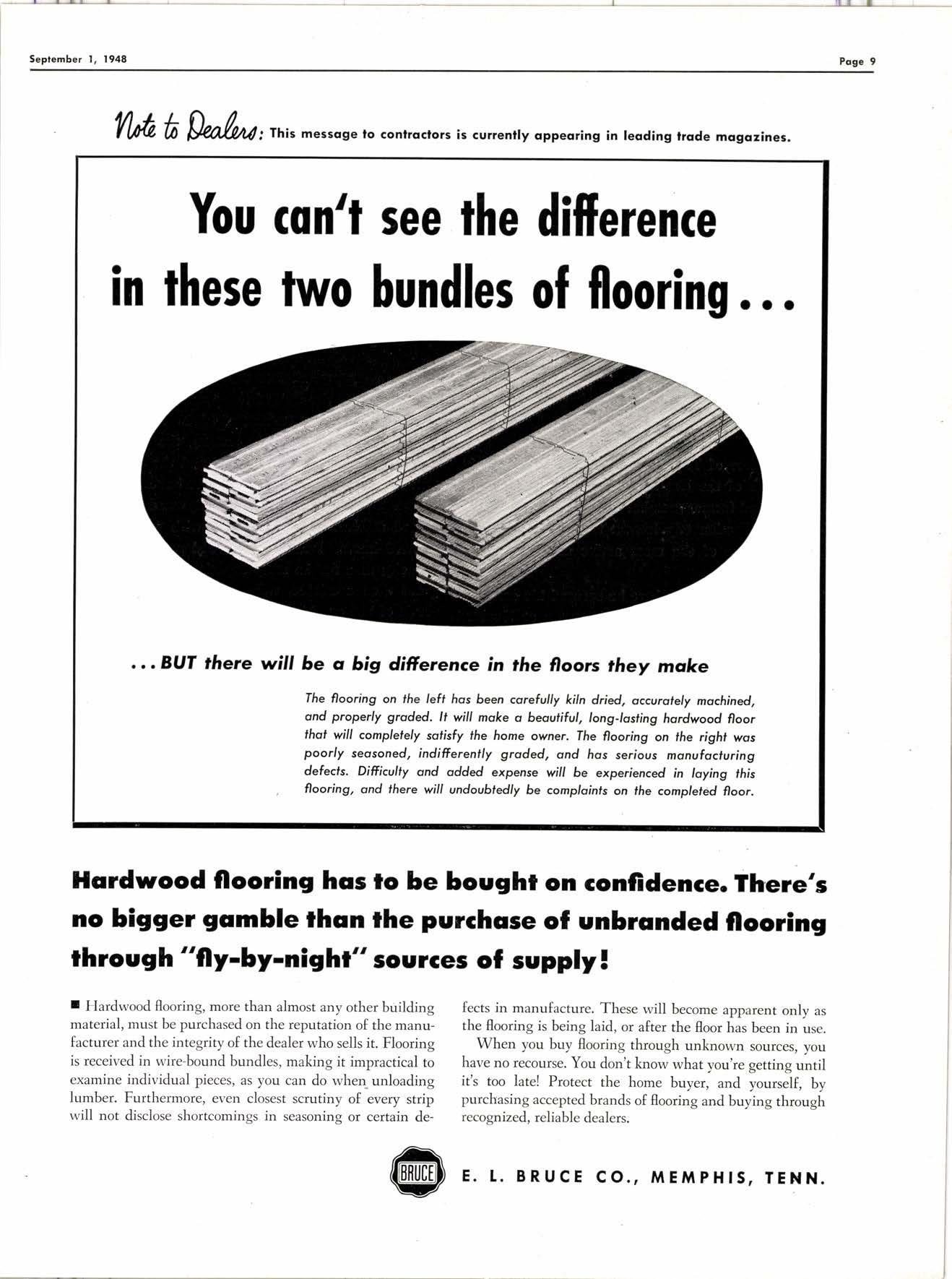

You (0n'l see the difference in these two bundles of flooring o..

.. BUI there will be a big difrerence in the floorc they mske

The flooring on the left hos been corefully kiln drid, occurotely mochind, ond properly groded. It will moke o beautiful, long-losfing hardwood floor Ihot will completely sofisfy fhe home owner. Ihe flooring on lhe righf wos poorly seosoned, indifferently groded, ond hos serious manufoctvring defecls. Difiiculty ond odded expense will be experienced in loying this flooring, and lhere will undoubtedly be comploinls on lhe completed floor.

Heirdwood flooring hos to be bought on confiderG€o There's no bigger gqmble thonthe pulchrrse of unbranded flooring through "I)y-by-nighl" sources of supply I

I Flardwood fooring, more than almost any other building material, must be purchased on the reputation of the manufacturer and the integrity of the dealer who sells it. Flooring is received in wire-bound bundles, making it impractical to examine individual pieces, as you can do when unloading lumber. Furthermore, even closest scrutiny of every strip will not disclose shortcomings in seasoning or certain de- fects in manufacture. These r.vill become apparent only as the fooring is being laid, or after the foor has been in use.

When you buy flooring through unknown sources, you have no recourse. You don't know what you're getting until it's too late! Protect the home buyer, and yourself, by purchasing accepted brands of fooring and buying through recognized, reliable deaiers.

I. Edwcrd Martin

Discussion Ot Properties Ot Redwood Plywood

"What about the properties of Redwood plywood, and horv does that product compare with Fir Plywood ?" is a cluestion frequently asked by the trade during the past year since the manufacture of Redwood Plywood has become a matter of considerable proportions.

The M. and M. Wood Working Company, of Portland, Oregon, which operates three Fir plywood'plants and is preparing to manufacture Redwood and Fir plywood both at Eureka, California, answers that question in most intelligent fashion in a statement recently issued, as follows:

Reprinted lrom the July l, 1948 "Siqntonite"

Prominent Editor of The California Lumber Merchant, Vicegerent Snark of the Los Angeles Hoo-Hoo Club several years ago and former member of the Supreme Nine"Ed," as he is affectionately known throughout the lumber industry, is one of the most active members of the local organization.

Born in Brockton, Mass., where he secured his early education "Ed" teceived his degree in Forestry at Harvard University and spent ten years in the United States Forest Service, stationed in the west. Following his service with the government he purchased lumber throughout the Pacific Northwest for several years and when Jack Dionne started publication of the Lumber Merchant he became the first San Francisco representative. Twenty-one years ago Ed moved to Los Angeles, as managing editor of the magazine, which post he has held since that time, becoming one of the leaders in civic afiairs during the past two decades.

STANTONITES are proud of our association with all members of ou. club and it affords us particular pleasure to publish this short resume of one of the outstanding leaders of Hoo-Hoo and a swell "fellow" to every person in the lumber industry.

"The .company believes that the production of redwood plyri'ood up to the date of this prospectus has been for the most part on an experimental basis. Although there has been some commercial production, the degree of market acceptance of redwood plywood and the_ competitive position of redwood plywood with fir, have yet to be established. Production of redwood plywood in the past presented difficulties in connection with peeling as a result of hard knots. Redwood plywood requires greater dryer capacity than fir. In early experiments, the vegetable type glues then available, were not suitable adhesives. As a resrrlt of the experiments of the company and others, it is believed that commercial production of redwood plywood is feasible through improved peeling techniques, use of synthetic resin and urea resin adhesives with hot plate presses, and through installation of improved dryers of greater capacity."

Opercrting Under Own Name

Robert F. Mackie, Jr. is now conducting his wholesale lumber business undei his own name at 265 South Santa Clara Av.enue, Long Beach 2, Calif.. The telephone number is Long Beach 7-2806.

He is representing the Parelius Lumber Co., Page Lumber Co., Tom W. Rugh Lumber Co., and Hill & Morton, Inc. Bob has been in the wholesale lumber business in Long Beach Tor the past three years. He is sending a Sales Bulletin to the trade every week.

"Pee-lee"

You reap the benefits wirh Pope & Talbot Lumber

The stondord prqctice of Pope & Tolbot to produce lumber thot is properly milled, properlygrodedond properly hondled meons scrtisfied customers for you-the lumber deqler. In the West since 1849, Pope & Tcrlbot hcrs mqintqined cr reputqtion for dependobility of product ond the EXTRA mork ofquolity.

Before you ploce your lumber order check with us. Let us present our offerings qnd prices to nieet your needs. After oli, customer sqtisfoction is our greotest osset qnd we'll mCIke every effort to wqrrcrnt your potro4oge. Immediqte ovoilobility ond prompt delivery is your ossurqnce when you order from Pope & Tolbot.